Page 1

Tool Products

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

“O” SERIES “QRT” SCREWDRIVERS

SECTION

MANUAL

Released:

Revised:

M30

33

3-l-77

l-27-95

1018-2

Models:

8506-A( ), 8509-A( ),

8515-A( ) and 8521-A( ).

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

Pneumatic tools should always be installed and used in accordance with A.N.S.I. B186.1 “Safety Code For Portable Air Tools.”

Repeated prolonged operator exposure to vibrations which may

0

Operate this tool at 90 p.s.i.g. (8.2 bar) maximum air pressure

at the air inlet of the tool.

l

Disconnect air supply from tool before removing/installing bit

socket or device attached to tool or performing maintenance

procedures.

l

Keep hands, clothing and long hair away from rotating end of

tool.

0

Anticipate and be alert for sudden changes in motion during

start up and operation of any power tool.

a

Never exceed rated r.p.m. of tool.

l

Wear suitable eye and hearing protection while operating tool.

0

Tool shaft can continue to rotate briefly after throttle is released.

l

Do not lubricate tools with flammable orvolatile liquids such as

kerosene, diesel or jet fuel.

0

Do not remove any labels. Replace any damaged label.

l

Use only accessories recommended by ARO.

be generated in the use of certain hand-held tools may produce

Raynaud’s phenomenon, commonly referred to as Whitefinger

disease. The phenomenon produces numbness and burning

sensations in the hand and may cause circulation and nerve damage as well as tissue necrosis. Repetitive users of hand-held

tools who experience vibrations should closely monitor duration

of use and their physical condition.

l

The use of other than genuine ARO replacement parts may

result in safety hazards, decreased tool performance and increased maintenance and may invalidate all warranties.

l

ARO is not responsible for customer modification of tools for

applications on which ARO was not consulted.

l

Tool maintenance and repair should be performed by authorized, trained, competent personnel. Consult your nearest

ARO authorized servicenter.

l

It is the responsibility of the employer to place the information

in this manual into the hands of the operator.

Page 2

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

I

Wear hearing protection when

operating this tool.

Turn off air supply and disconnect

.

air supply hose before installing,

removing or adjusting any

accessory on this tool, or before

performing any maintenance on

this tool.

Air powered tools can vibrate in

use. Vibration, repetitive motions

or uncomfortable positions may

be harmful to your hands and

arms. Stop using any tool if

discomfort, tingling feeling or

pain occurs. Seek medical advice

before resuming use.

I

A WARNING

Do not carry the tool by the hose.

Do not use damaged, frayed or

deteriorated air hoses and

fittings.

Do not overreach when operating

this tool. Keep body stance

balanced and firm.

Operate at 90 p.s.i.g.

(6.2 bar/620 kPa)

maximum air pressure.

NOTICE

PN 48176-1 LABEL PN 49883 LABEL

(NON-EU MODELS) (-EU MODELS)

This label must appear on the tool at all times. If It is

lost or damaged, a replacement label Is available at

no cost.

WARNING = Hazards or unsafe practices which could result in severe personal injury, death or substantial

property damage.

J

CAUTION = Hazards or unsafe practices which could result in minor personal injury or product or property

damage.

NOTiCE = important installation, operation or maintenance information.

2

Page 3

ROUTINE LUBRICATION REQUIREMENTS

M30

33

Lack of or an excessive amount of lubrication will affect the performance and life of this tool. Use only recommended lubricants at

below time intervals:

EVERY 8 HOURS OF TOOL OPERATION - Fill lubricator reservoir of recommended F.R.L. with spindle oil (29665). If an in line or

air line lubricator is not used, apply several drops of spindle oil

(29665) in air inlet.

EVERY 160 HOURS OF TOOL OPERATION - Lubricate clutch

parts with molybdenum grease (400361). Lubricate gearing.

Pack bearings, coat shafts and lubricate gears with NLGI #1 “EP”

grease (33153). Gearing should contain approximately 1/8 oz.

(3.5 g) of grease per reduction.

AIR SUPPLY REQUIREMENTS

For maximum operating efficiency, the following air supply specifi-

cations should be maintained to this air tool:

l

AIR PRESSURE - 90 p.s.i.g. (6.2 bar)

l

AIR FILTRATION - 50 micron

l

LUBRICATED AIR SUPPLY

l

HOSE SIZE - 5/16” (8 mm) I.D.

An ARO model C28231-810 air line FILTER/REGULATOR/LU-

BRICATOR (F.R.L.) is recommended to maintain the above air

supply specifications.

Tool maintenance and repair shall be performed by authorized,

trained, competent personnel. Tools, hose and fittings shall be replaced if unsuitable for safe operation and responsibility should

be assigned to be sure that all tools requiring guards or other safety devices shall be kept in legible condition. Maintenance and repair records should be maintained on all tools. Frequency of

repair and the nature of the repairs can reveal unsafe application.

Scheduled maintenance by competent authorized personnel

should detect any mistreatment or abuse of the tool and worn

parts. Corrective action should be taken before returning the tool

for use.

Disassembly should be done on a clean work bench with a clean

cloth spread to prevent the loss of small parts. After disassembly

is completed, all parts should be thoroughly washed in a clean sol-

vent, blown dry with air and inspected for wear levels, abuse and

contamination. Double sealed or shielded bearings should never

be placed in solvent unless a good method of m-lubricating the

bearing is available. Open bearings may be washed but should

not be allowed to spin while being blown dry.

Upon reassembling, lubricate parts where required. Use 33153

grease, or equivalent, in bearings. Use 36460 lubricant for “O”

ring assembly. When assembling “O” rings or parts adjacent “O”

rings, care must be exercised to prevent damage to the rubber

sealing surfaces. A small amount of grease will usually hold steel

balls and other small parts in place while assembling.

When replacement parts are necessary, consult drawing contain-

ing the part for identification.

RECOMMENDED LUBRICANTS

After disassembly is complete, all parts, except sealed or shielded

bearings, should be washed with solvent. To relubricate parts, or

for routine lubrication, use the following recommended lubricants:

Where ARO Description

Air Motor 29665

“O” Rings & Lip Seals 36460

Gears and Bearings 33153

Clutches 40036-1

1 qt Spindle Oil

4 oz. Stringy Lubricant

5 lb. “EP” - NLGI #1 Grease

1 lb. “EP” Molybdenum Disulfide

INSPECTION, MAINTENANCE AND INSTALLATION

Disconnect air supply from the tool or shut off air supply and exhaust (drain) line of compressed air before performing maintenance or service to the tool.

It is important that the tools be serviced and inspected at regular

intervals for maintaining safe, trouble-free operation of the tool.

Be sure the tool is receiving adequate lubrication, as failure to lu-

bricate can create hazardous operating conditions resulting from

excessive wear.

Be sure that the air supply lines and connectors are of proper size

to provide a sufficient quantity of air to the tool.

.

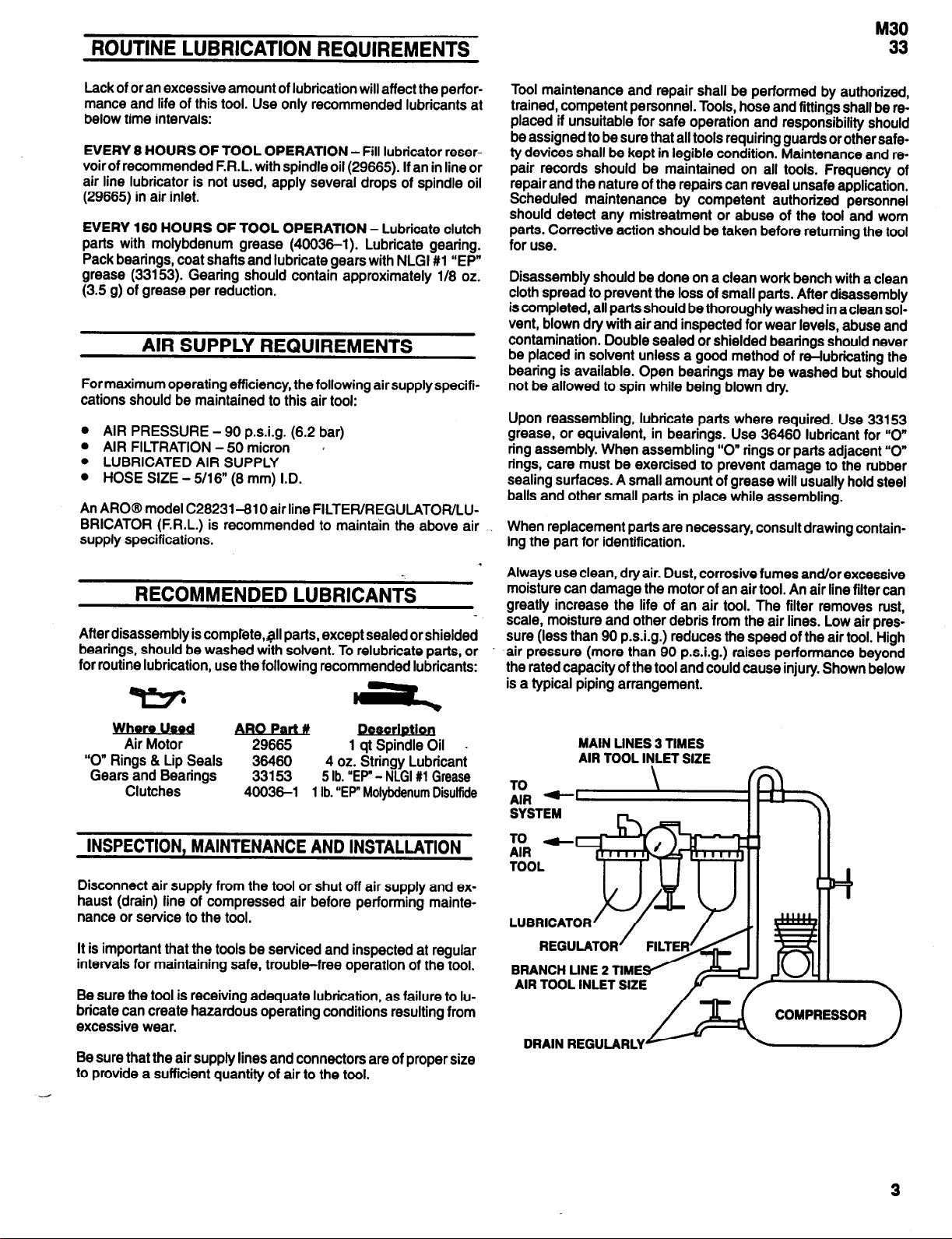

Always use clean, dry air. Dust, corrosive fumes and/or excessive

moisture can damage the motor of an air tool. An air line filter can

greatly increase the life of an air tool. The filter removes rust,

scale, moisture and other debris from the air lines. Low air pressure (less than 90 p.s.i.g.) reduces the speed of the air tool. High

air pressure (more than 90 p.s.i.g.) raises performance beyond

the rated capacity of the tool and could cause injury. Shown below

is a typical piping arrangement.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

SYSTEM

REGULATOR

BRANCH LINE 2 TIME/

AIR TOOL INLET SIZE

DRAIN REGULARLY

n

3

Page 4

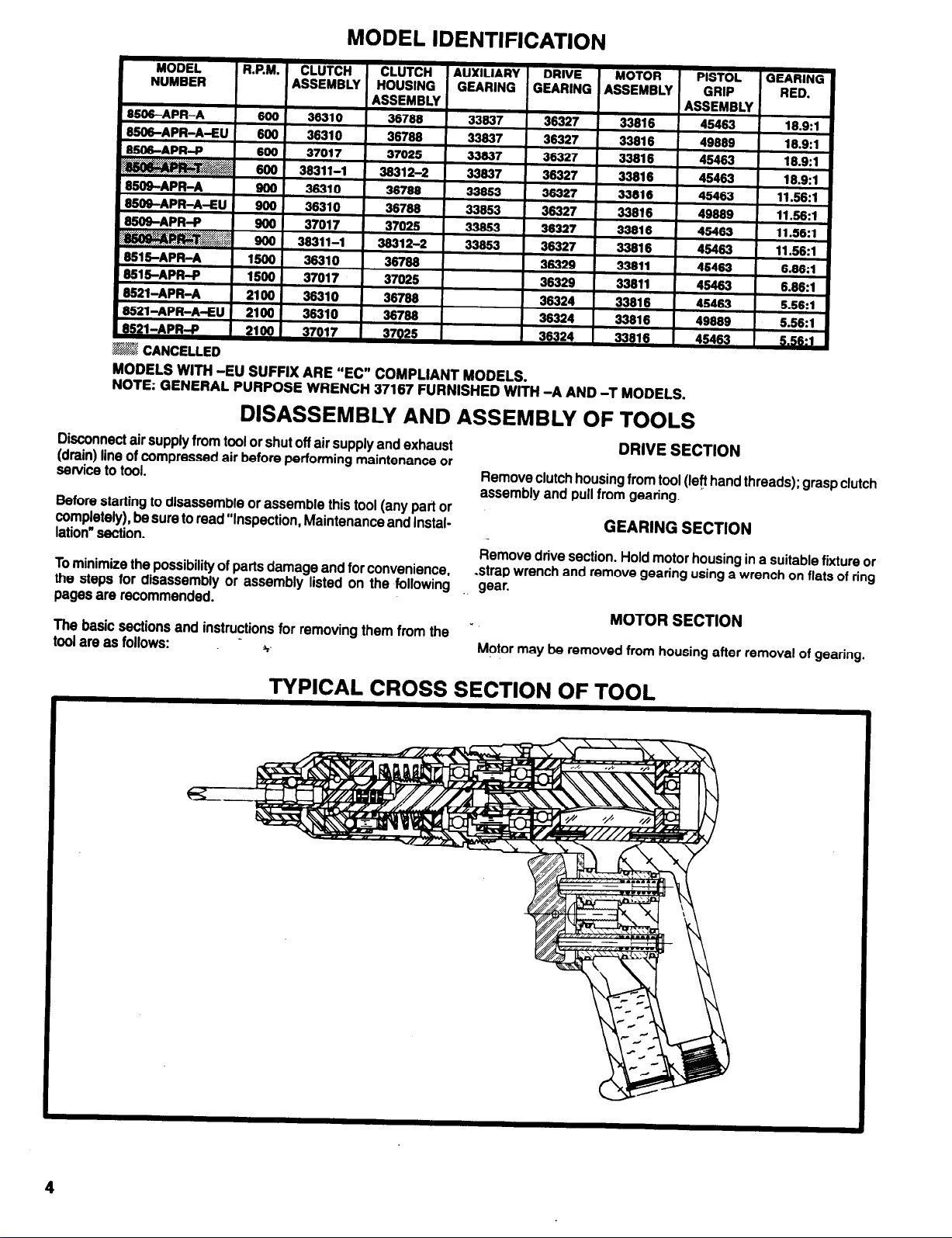

MODEL IDENTIFICATION

MODELS WITH -EU SUFFIX ARE “EC” COMPLIANT MODELS.

NOTE: GENERAL PURPOSE WRENCH 37167 FURNISHED WITH -A AND -T MODELS.

DISASSEMBLY AND ASSEMBLY OF TOOLS

Disconnect air supply from tool or shut off air supply and exhaust

(drain) line of compressed air before performing maintenance or

service to tool.

Before starting to disassemble or assemble this tool (any part or

completely), be sure to read “Inspection, Maintenance and Installation” section.

To minimize the possibility of parts damage and for convenience

the steps for disassembly or assembly listed on the following gear.

pages are recommended.

The basic sections and instructions for removing them from the

tool are as follows:

Remove clutch housing from tool (left hand threads); grasp clutch

assembly and pull from gearing.

Remove drive section. Hold motor housing in a suitable fixture or

strap wrench and remove gearing using a wrench on flats of ring

Motor may be removed from housing after removal of gearing.

DRIVE SECTION

GEARING SECTION

MOTOR SECTION

TYPICAL CROSS SECTION OF TOOL

4

Page 5

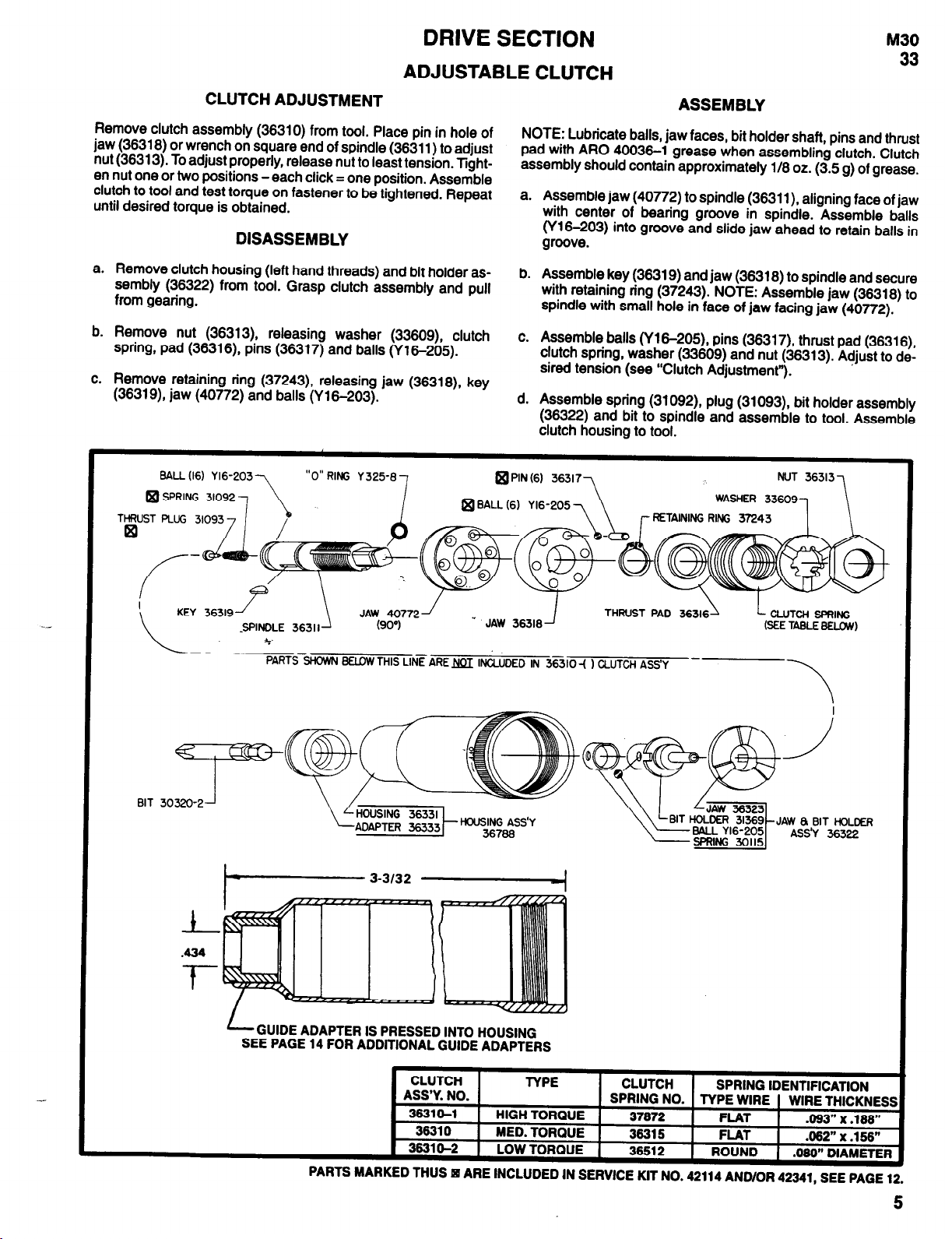

DRIVE SECTION

ADJUSTABLE CLUTCH

M30

33

CLUTCH ADJUSTMENT

Remove clutch assembly (36310) from tool. Place pin in hole of

jaw (36318) or wrench on square end of spindle (36311) to adjust

nut (36313). To adjust properly, release nut to least tension. Tighten nut one or two positions -each click = one position. Assemble

clutch to tool and test torque on fastener to be tightened. Repeat

until desired torque is obtained.

DISASSEMBLY

a. Remove clutch housing (left hand threads) and bit holder as-

sembly (36322) from tool. Grasp clutch assembly and pull

from gearing.

b. Remove nut (36313) releasing washer (33609) clutch

spring, pad (36316) pins (36317) and balls (Y16-205).

c. Remove retaining ring (37243) releasing jaw (36318) key

(36319) jaw (40772) and balls (Y 16-203).

BALL (16) Y 16-203

31092,

SPRING

THRUST PLUG 310933

“O” RING Y 325-8

7

BALL Yl6-205

q

ASSEMBLY

NOTE: Lubricate balls, jaw faces, bit holder shaft, pins and thrust

pad with ARO 40036-1 grease when assembling clutch. Clutch

assembly should contain approximately 1/8 oz. (3.5 g) of grease.

a. Assemble jaw (40772) to spindle (36311) aligning face of jaw

with center of bearing groove in spindle. Assemble balls

(Y16-203) into groove and slide jaw ahead to retain balls in

groove.

b.

Assemble key (36319) and jaw (36318) to spindle and secure

with retaining ring (37243). NOTE: Assemble jaw (36318) to

spindle with small hole in face of jaw facing jaw (40772).

c. Assemble balls (Y16-205), pins (36317) thrust pad (36316)

clutch spring, washer (33609) and nut (36313). Adjust to desired tension (see “Clutch Adjustment”).

d. Assemble spring (31092) plug (31093) bit holder assembly

(36322) and bit to spindle and assemble to tool. Assemble

clutch housing to tool.

@PIN (6) 36317

(6) 7

\

RETAINING RING 37243

WASHER

NUT 36313

336091

BIT 30320-2

/

GUIDE ADAPTER IS PRESSED

SEE PAGE 14 FOR ADDlTlONAL GUIDE ADAPTERS

PARTS

MARKED

INTO HOUSING

CLUTCH

ASS’Y. NO.

38310-l

38310

3831 o-2

THUS

q

HIGH TORQUE

MED. TORQUE

LOW TORQUE

ARE

INCLUDED

TYPE

IN SERVICE KIT NO. 42114 AND/OR

CLUTCH

SPRING NO. TYPE WIRE WIRE THICKNESS

37872

36315

38512 ROUND

JAW 8 BIT HOLDER

ASS’Y 36322

SPRING IDENTIFICATION

FLAT

FLAT

.093” x .188”

.062” x .156”

.080” DIAMETER

42341, SEE PAGE 12.

5

Page 6

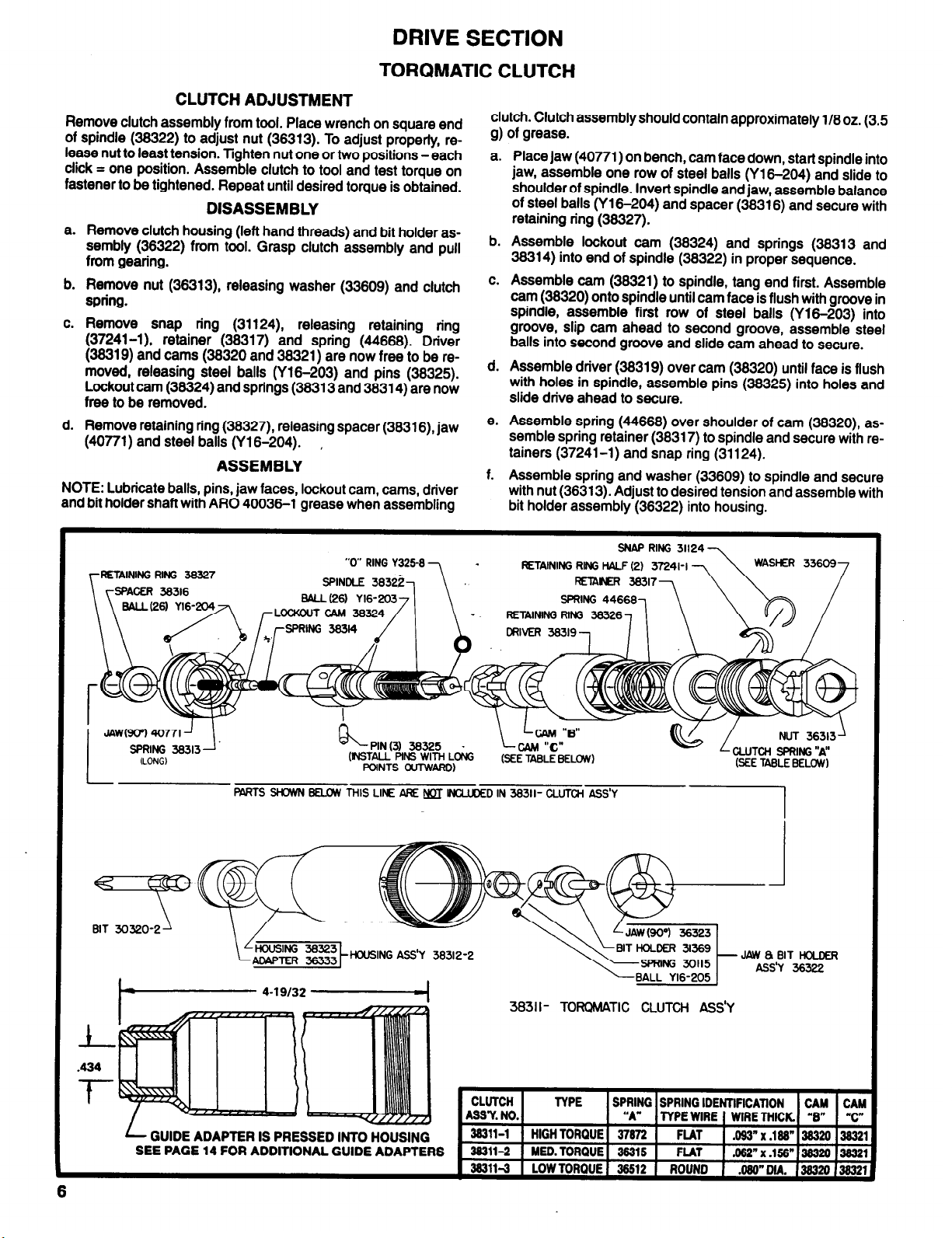

DRIVE SECTION

TORQMATIC CLUTCH

CLUTCH ADJUSTMENT

Remove clutch assembly from tool. Place wrench on square end

of spindle (38322) to adjust nut (38313). To adjust properly, release nut to least tension. Tighten nut one or two positions -each

click = one position. Assemble clutch to tool and test torque on

fastener to be tightened. Repeat until desired torque is obtained.

DISASSEMBLY

a. Remove clutch housing (left hand threads) and bit holder as-

sembly (38322) from tool. Grasp clutch assembly and pull

from gearing.

b. Remove nut (36313) releasing washer (33809) and clutch

spring.

c. Remove snap ring (31124) releasing retaining ring

(37241-l), retainer (38317) and spring (44888). Driver

(36319) and cams (38320 and 38321) are now free to be removed, releasing steel balls (Y16-203) and pins (38325).

Lockout cam (38324) and springs (38313 and 38314) are now

free to be removed.

d. Remove retaining ring (38327) releasing spacer (38316) jaw

(40771) and steel balls (Y16-204).

,

ASSEMBLY

NOTE: Lubricate balls, pins, jaw faces, lockout cam, cams, driver

and bit holder shaft with ARO 40036-l grease when assembling

RETAINING RING 36327

clutch. Clutch assembly should contain approximately 1/8 oz. (3.5

g) of grease.

a.

Place jaw (40771) on bench, cam face down, start spindle into

jaw, assemble one row of steel balls (Y16-204) and slide to

shoulder of spindle. Invert spindle and jaw, assemble balance

of steel balls (Y16-204) and spacer (38318) and secure with

retaining ring (38327).

b. Assemble lockout cam (38324) and springs (38313 and

36314) into end of spindle (38322) in proper sequence.

c. Assemble cam (38321) to spindle, tang end first. Assemble

cam (36320) onto spindle until cam face is flush with groove in

spindle, assemble first row of steel balls (Y16-203) into

groove, slip cam ahead to second groove, assemble steel

balls into second groove and slide cam ahead to secure.

d. Assemble driver (38319) over cam (38320) until face is flush

with holes in spindle, assemble pins (38325) into holes and

slide drive ahead to secure.

e. Assemble spring (44868) over shoulder of cam (38320) as-

semble spring retainer (38317) to spindle and secure with retainers (37241-l) and snap ring (31124).

f.

Assemble spring and washer (33609) to spindle and secure

with nut (36313). Adjust to desired tension and assemble with

bit holder assembly (36322) into housing.

SNAP RING

RETAINING RING HALF (2)

RETAINER 38317

31124

BIT 30320-2

RETAINING RING 36326

PIN (3) 36325

PARTS SHOWN BELOW THIS LINE ARE NOT lNCLUDED IN 38311- CLUTCH ASS’Y

HOUSING ASS'Y 38312-2

.

3831 I- TORQMATIC CLUTCH ASS’Y

6

GUIDE ADAPTER IS PRESSED INTO HOUSING

SEE PAGE 14 FOR ADDITIONAL GUIDE ADAPTERS

Page 7

Page 8

GEARING SECTION

DRIVE GEARING

DISASSEMBLY

a.

Remove spindle and components from ring gear.

b.

To remove gears from spindle, remove bearing, spacer and

shafts.

ASSEMBLY

NOTE: Pack bearings and lubricate gears liberally with ARO

33153 grease upon assembly. Gearing assembly should contain

BEARING

32325

RING GEAR

39325

approximately 1/8 oz. (3.5 g) of grease.

a. Assemble spacer (33691 or 33693) and gears to spindle and

secure with shafts, aligning notch in shafts with spacer.

NOTE: Shafts (33686) contain fifteen (15) loose needle bearings (33458) per shaft.

b. Assemble spacer (37676), where applicable, and bearings to

spindle and assemble to ring gear.

32325 BEARING

36325 RING GEAR

(9 INTERIOR - 17 EXTERIOR TEETH)

32325

BEARING

SPINDLE 32325

36326

33691 SPACER

BEARING

36324

37676 SPACER

36327 GEARING ASSEMBLY

GEARING ASSEMBLY

5.5:1

3.4:1

6

36325

RING GEAR

-

SPINDLE 32325

36330

BEARING

36329

GEARING ASSEMBLY

6.8:1

Page 9

DISASSEMBLY

GEARING SECTION

AUXILIARY GEARING

M30

33

a. Grasp adapter (ring gear) in one hand and tap splined end of

spindle with a soft face hammer; spindle and components will

loosen from adapter.

b. To remove gears from spindle, remove bearing, spacer and

shafts.

ASSEMBLY

NOTE: Pack bearings and lubricate gears liberally with ARO

Y147-7 RETAINING RING

32326 ADAPTER

32326 BEARING

(9 INTERIOR - 17 EXTERIOR TEETH)

37667 SPINDLE

32314 SPACER

30901 DPIVE GEAR

33153 grease upon assembly. Gearing should contain approxi-

mately 118 oz. (3.5 g) of grease.

a.

Assemble spacer (32314 or 32312) and gears to spindle and

secure with shafts, aligning notch in shafts with spacer.

NOTE: Shafts (33686) contain fifteen (15) loose needle bear-.

ings (33458) per shaft.

b.

Assemble spacer (37676), where applicable, and bearings to

spindle and assemble to adapter (32326).

16

ASS’Y

32325

BEARING

3666 SHAFT (2) (INCLUDES

37676 SPACER

33853 GEARING

3.4:1

32326 ADAPTER

32325 BEARING

32312 SPACER

33425 SPINDLE

32325

BEARING

33837 GEARING

5.56:1

ASS’Y

9

Page 10

MOTOR SECTION

DISASSEMBLY

Remove motor from housing. Grasp cylinder in one hand and

a.

tap splined end of rotor with a soft face hammer; motor will

come apart.

ASSEMBLY

Pack bearings with ARO 33153 grease and assemble bearing

a.

(Y65-7) into end plate (31601), pressing on outer race of

bearing.

Assemble end plate (31601) to rotor, pressing on inner race of

b.

bearing.

Coat i.d. of cylinder (37684) with ARO 29665 spindle oil and

c.

assemble over rotor, aligning air inlet holes of cylinder with air

inlet slots of end plate.

d. Coat blades (31363) with ARO 29665 spindle oil and as-

semble to rotor slots - straight side out.

Assemble bearing (Y65-15) to end plate (31602) pressing on

e.

outer race of bearing.

Assemble end plate (31602) to cylinder, aligning roll pin in cyl-

f.

inder with hole in end plate.

Be sure rotordoes not bind (if rotor binds, tap splined end light-

g.

ly with a soft face hammer to loosen) and assemble motor to

housing with locating pin (32814) and porting block (45471).

h.

Assemble spacers (32310 and 32305) and gearing to tool.

* 32614 LOCATING PIN

31662 END PLATE

Y65-15 BEARING

32310 SPACER *

2366 SPACER *

* NOT INCLUDED IN MOTOR ASSEMBLY

t INCLUDED WlTH 37664 CYLINDER

31662 END PLATE

Y65-15 BEARING

Y178-24 ROLL PIN

37664 CYLINDER

Y176-26 ROLL PIN t

31661 END PLATE

31633 ROTOR

31601 END PLATE

Y65-7 BEARING

33811

Y65-7 BEARING

MOTOR ASSEMBLY

10

32310 SPACER $

32365 SPACER

37664 CYLINDER

0 31363 BLADE

PARTS MARKED THUS 0 ARE INCLUDED IN SERVICE KIT NO. 42114 AND/OR 42341, SEE PAGE 12.

(5)

33816 MOTOR ASSEMBLY

Page 11

DISASSEMBLY

HEAD SECTION

M30

33

a. Remove roll pin (Y178-25), releasing trigger (45469).

b. Remove screw (Y222-156-C) releasing shroud (45468).

c. Grasp end of valve assembly (47880) and pull to remove

valve assembly and bushing (45465).

d. Remove retaining ring (Y147-68), releasing screens (42911)

and muffler (45474).

ASSEMBLY

NOTE: Whenever a part containing “O” rings has been removed

from the tool, it is recommended the “O” rings be replaced.

Grease all “O” rings before assembly.

a. Assemble “O” rings (Y325-13, Y325-12 and Y325-11) to

45471 PORTING BLOCK

47990 VALVE ASSEMBLY (2)

47979 PLUNGER (2)

Y325-12 “O” RING (2)

q Y225-13 “O” RING (2)

Y222-156-C SCREW

Y179-25 ROLL PIN

bushings (45465).

b.

Assemble “O” ring (Y325-7) to valve assembly (47680).

c.

Lubricate plunger (47879) and valve assembly (47860) with

ARO 29665 spindle oil.

d.

Assemble springs (48806-l) to valve assembly (47880).

e.

Assemble plungers (47879) and valve assemblies (47880) to

bushings (45465) and assemble bushings to housing, aligning flats of bushings with flats of shroud.

f.

Assemble shroud (45468) to housing, securing with screw

(Y222-156-C).

g.

Assemble trigger to shroud, securing with roll pin (Y178-25).

h. Assemble muffler (45474) and screens (42911) to housing,

securing with retaining ring (Y147-68).

n HOUSING ASSEMBLY

STANDARD MODELS - 49492

“-EU” MODELS - 49910

45469 TRIGGER

45465 BUSHING (2)

Y225-11 “O” RING (2)

49906-1 SPRING (2)

Y325-7 “O” RING (2)

REVERSIBLE HOUSING AND VALVE ASSEMBLY

STANDARD MODELS - 45463

“-EU” MODELS - 49889

* NOT INCLUDED IN HOUSING AND VALVE ASSEMBLY

PARTS MARKED THUS ARE INCLUDED IN SERVICE KIT NO. 42114 AND/OR 42341, SEE PAGE 12.

45474 MUFFLER

q

42911 SCREEN (2)

Y147-68 RETAINING RING

11

Page 12

SERVICE KIT NO. 42114

FOR SERVICING ADJUSTABLE CLUTCH MODELS

QTY

1

1

5

6

1

1

1

2

1

PART

NUMBER

31092

31093

31363

36317

41795

41799

41954

42911

45474

DESCRIPTION

SPRING

THRUST PIN

BLADE

PIN

MOTOR OIL

GEAR LUBE

“O” RING LUBE

SCREEN

MUFFLER

QTY

6 Y16-205

1

Y147-68

1 Y178-25

2 Y180-13

2

Y325-7

2 Y325-11

2 Y325-12

2 Y325-13

SERVICE KIT NO. 42341

FOR SERVICING DIRECT DRIVE AND POSITIVE CLUTCH MODELS

PART PART

NUMBER

31092 SPRING

31093 THRUST PIN

31363 BLADE

41795

41799

41954 “O” RING LUBE

42911 SCREEN

45474

DESCRIPTION

MOTOR OIL

GEAR LUBE

MUFFLER

QTY

1 Y147-68 RETAINER RING

1 Y178-25 ROLL PIN

2

2 Y325-7 “O” RING

2 Y325-11 “0” RING

2 Y325-12 “0” RING

2

Y180-13

Y325-13 “0” RING

PART

NUMBER

DESCRIPTION

BALL

RETAINING RING

ROLL PIN

“E” RETAINING RING

“O” RING

“0” RING

“0” RING

“0” RING

NUMBER DESCRIPTION

“E” RING

TROUBLE SHOOTING

LlSTED BELOW ARE SOME OF THE MOST COMMON CAUSES FOR THE SCREWDRIVER TO MALFUNCTION. MALFUNCTlONS BEYOND THE SCOPE OF THIS

MANUAL SHOULD BE BROUGHTTO THE ATTENTlON OF YOUR ARO REPRESENTATlVE OR RETURN THE TOOL TO THE FACTORY FOR REPAIR.

CONDITION

LOW SPEED OR

FAILURE TO OPER-

ATE.

CLUTCH DISENGAGES TOO SOON

OR FAILURE OF

CLUTCH TO DISENGAGE.

POSSIBLE CAUSE

I. INADEQUATE AIR SUPPLY.

2. CLOGGED AIR INLET, BADLY WORN

OR DAMAGED THROTTLE COM-

PONENTS OR CLOGGED MUFFLER.

3. IMPROPER LUBRICATION OF UNIT

(MOTOR AND/OR GEARING), DIRTY

MOTOR (ROTOR BLADES STICKING,

ETC.), OR BROKEN OR BADLY WORN

ROTOR BLADES OR BEARINGS IN

MOTOR.

4. BADLY WORN OR DAMAGED

CLUTCH COMPONENTS.

1. IMPROPER CLUTCH ADJUSTMENT.

2. BADLY WORN OR DAMAGED 2.

CLUTCH COMPONENTS.

I.

2.

3.

4.

1.

CHECK AIR SUPPLY FOR CORRECT REGULATOR ADJUST-

MENT (90 P.S.I.G. MAX. WHEN TOOL IS OPERATING).

DISASSEMBLE, CLEAN, INSPECT THROTTLE COMPONENTS,

REPLACE WORN OR DAMAGED PARTS. REFER TO PAGE 11.

BE SURE LUBRICATOR IS FULL OF OIL AND GEARING IS LUBRICATED REGULARLY, REFER TO PAGE 3. DISASSEMBLE,

CLEAN, INSPECT, REPLACE WORN OR DAMAGED PARTS, LUBRICATE.

DISASSEMBLE CLUTCH. CLEAN, INSPECT, REPLACE WORN

OR DAMAGED PARTS, LUBRICATE.

REFER TO CLUTCH ADJUSTMENT, PAGES 5 AND 6.

DISASSEMBLE CLUTCH, CLEAN, INSPECT, REPLACE WORN

OR DAMAGED PARTS, LUBRICATE. REFER TO PAGES 6 AND 6.

CORRECTIVE ACTION

12

Page 13

ACCESSORIES

44361-(

30302-( ) INLET HOSE - 5/16” I.D.

) PIPED EXHAUST SYSTEM ASSEMBLY

M30

33

1/4” P.T.F. THREAD

46672-l ADAPTER ASSEMBLY

PIPED EXHAUST ASSEMBLY CONSISTS OF 5/16” I.D. AIR INLET HOSE WlTH IN” MALE FlTTlNG AT EACH END, 1/2”

I.D. EXHAUST HOSE, 45672-l ADAPTER ASSEMBLY AND 2622 BARBED INSERT WlTH 3/8” MALE THREAD.

TO ORDER PIPED EXHAUSTSYSTEM ASSEMBLY: ADD DASH NUMBER TO PART NUMBER TO INDICATE DESIRED

LENGTH OF HOSE IN FEET. EXAMPLE: 44361-20, THE -20 INDICATES 20 FEET OF HOSE. ORDER LENGTH DESIRED UP TO 30 FEET MAXIMUM.

TO ASSEMBLE ADAPTER TO TOOL: REMOVE RETAINING RING (Y147-68), 2 SCREENS (42611) AND MUFFLER (45474) FROM TOOL. INSERT ADAPTER

(46572-l) INTO HOUSING UNTIL lT BOTTOMS IN HOUSING AND SECURE WITH RETAINING RING (Y147-68). THREAD INLET HOSE TO TOOL AND TlGHTEN

SO EXHAUST HOSE ALIGNS WlTH ADAPTER (45572) AND SUP EXHAUST HOSE OVER ADAPTER. NO CLAMP IS NEEDED TO SECURE HOSE TO ADAPTER

SINCE EXHAUST PRESSURE IS VERY LOW.

CAN BE USED ON THE “QRT” SCREWDRIVER AS AN IN-LlNE REGULATOR. HAS 1/4” MALE N.P.T.F. AND 1/4” FEMALE N.P.T.F. INLET FOR

AIR HOSE.

P.T.F. THREAD

TO AIR SUPPLY

1/2” I.D.

2622 HOSE ADAPTER

3/8” MALE N.P.T.F.

43551-6 MUFFLER

3/8” FEMALE N.RT.F.

37526 AIR REGULATOR

13

Page 14

ACCESSORIES

HOUSING AND ADAPTER ASSEMBLIES

FINDER ADAPTER 39332

FlNDER ADAPTER IS

HOUSlNG AND FINDER ADAPTER -USE WITH FlNDERS 36106-(), 36105-(), 41292-() AND 41292-(). ALSO USE WITH GUIDES 30334-(), 40261 AND 41767. ALSO

FOR USE WITH BALL LOCK ADAPTER ASSEMBLY 44699 WITHOUT USE OF GUIDE BUSHING.

NEEDLE BEARING ADAPTER IS PRESSED INTO HOUSING.

PRESSED

FOR USE WITH 37792-4 BALL LOCK ASSEMBLY AND 38815-2 AND 39616-4 SQUARE DRIVE ASSEMBLIES. PAGE 17.

INTO HOUSING.

.

ASSEMBLY NUMBER HOUSING DIMENSION “A” CLUTCH USED ON

36796

39312-1

37023

37023

ASSEMBLY NUMBER HOUSING DIMENSION “A” CLUTCH USED ON

36769-l

39312-3

37929-l 37931 2-1/4”

370251 37631 2-1/4”

36331 3”

39323

37631 2-1/4”

37031

36331

39323 4-1/2”

4-1/2”

2-1/4”

3” ADJUSTABLE

HOUSING ASSEMBLY

ADJUSTABLE

TORQMATIC

POSITlVE

DIRECT DRIVE

HOUSING ASSEMBLY

TORQMATIC

POSITlVE

DIRECT DRIVE

FINDERS

STANDARD LENGTH FOR 1/4” HEX BITS

NOTE: SPRING 39111 AND LOCK SPRING 31574 REQUIRED FOR USE

WITH FINDERS (ORDER SEPARATELY). USE WITH FINDER ADAPTER

36332.

Page 15

ACCESSORIES

FINDERS

EXTENSION FINDER FOR 1/4” HEX BITS

NOTE: SPRING 30111 AND LOCK SPRING 31574 REQUIRED FOR USE

WITH FINDERS (ORDER SEPARATELY). USE WITH FINDER ADAPTER

36332.

BELL MOUTH FINDER FOR 1/4” HEX BITS

Similar to standard finders except that each finder will accept mm sizes and types of screw heads.

NOTE: SPRING 36111 AND LOCK SPRING 31574 REQUIRED FOR USE

WITH FINDERS (ORDER SEPARATELY). USE WITH FINDER ADAPTER

36332.

M30

33

BELL MOUTH EXTENSION FINDER FOR 1/4” HEX BITS

Similar to standard finders. except that each finder will accept more sizes and types of screw heads.

STANDARD LENGTH

BLADED BITS FOR

SLOTTED SCREWS.

NOTE: SPRING

WITH FINDERS

36332.

36111 AND LOCK SPRING 31574 REQUIRED FOR USE

(ORDER SEPARATELY). USE WITH FINDER ADAPTER

BITS AND BIT HOLDERS

1/4” HEX DRIVE BITS

15

Page 16

EXTENSION BLADED BITS

FOR SLOTTED SCREWS.

ACCESSORIES

BITS AND BIT HOLDERS

1/4” HEX DRIVE BITS

PHILLIPS BITS

REED & PRINCE BITS

POSl-DRIVE BITS

EXTENDED BIT WITH INTEGRAL

FINDER FOR SLOTTED SCREWS.

PART NO.

30320-l

30320-2 1-15/16”

30320-3 1-15/16”

31531-1 2-3/4”

31531-2 2-3/4”

315313 2-3/4”

.

PART NO.

30776-l 1-15/16” 1/4

30776-2

30351-10 3-29/32”

30382-5 I 6-23/32” 5F-6R .193”

30382-6 1 6-23/32” 1 6F-8R

30382-8 6-23/32” 1 8F-10R

LENGTH

1-15/16” 1

LENGTH

2-3/4” 1/4

POINT SIZE

POINT SIZE

10F-12R .350”

SHAFT DIA.

2 .246”

3

1 .182”

2 .246”

3 .310”

SHAFT DIA.

1 .241”

1 290”

.182”

.310”

.250”

.250”

16

INSERT BITS

INSERT BIT HOLDER

Page 17

ACCESSORIES

BITS AND BIT HOLDERS

M30

33

SOCKET HEAD DRIVERS

MAGNETIC BIT HOLDER

USE WITH GUIDE BUSHING 46261.

SQUARE DRIVE ADAPTERS

USE WITH GUIDE BUSHING 30334-( ).

HEX BALL LOCK ADAPTER

PART

30370-2

30370-3

30370-4

30370-5 1-15/16” 3/16”

30370-6

30370-7

39379-8

30370-9

LENGTH HEX SETSCREW CAP SCREW SHAFT DIA.

NO.

SIZE

3/32”

1/8”

5/32”

7/32”

1/4”

7/64”

9/64”

PART NO.

40259

SIZE

#10-#12

1/4

5/16

3/8

7/16

1/2

1 LENGTH

1 2-31/32”

SIZE

#4-#5

#10

114

5/16

#6

#8

1 BIT SIZE

Hex 1 7/16”

1 1/4”

.187”

.187”

.187”

.250”

.250”

--

.312”

.187”

.187”

1 SHAFT DIA.

NOTE: 41764 - PULL SLEEVE TO RELEASE BIT.

41765 -PUSH SLEEVE TO RELEASE BIT.

44599 - PULL SLEEVE TO RELEASE BIT USE WITH HOUSING ASSEMBLY 36786 WITHOUT GUIDE BUSHING.

GUIDE BUSHlNGS

USE WITH FINDER ADAPTER 36332 AND LOCK SPRING 31574.

GUIDE BUSHING 49261 (BRONZE)

GUIDE BUSHING 41767 (BRONZE)

17

Page 18

PN 49999-032

Loading...

Loading...