Ingersoll-Rand 8315 User Manual

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

Tool & Hoist Products MARKING PEN

Model 8315

IMPORTANT: READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

Released:

Revised:

Form:

8/77

8-2-93

1035-2

OPERATING AND SAFETY PRECAUTIONS

Pneumatic tools should always be installed and used in accordance with A.N.S.I. R186.1 “Safety Code For Portable Air Tools.”

CAUTION:

l

Keep hands and clothing away from working end of tool.

l

Wear suitable eye protection while operating tool.

l

Use tool only for purposes for which it was intended.

l

SHUT OFF and DISCONNECT AlR SUPPLY from tool BEFORE performing maintenance, service or disassembly of

tool.

WARNING: Repeated prolonged operator exposure to vibrations

which may be generated in the use of certain hand-held tools

may produce Raynaud’s phenomenon, commonly referred to as

Whitefinger disease. The phenomenon produces numbness and

burning sensations in the hand and may cause circulation and

nerve damage as well as tissue necrosis. Repetitive users of

hand-held tools who experience vibrations should closely monitor duration of use and their physical condition.

ROUTINE LUBRICATION REQUIREMENTS

Lack of or an excessive amount of lubrication will affect the performance and life of this tool. Use only recommended lubricants at

below time intervals:

EVERY 8 HOURS OF TOOL OPERATION - Fill lubricator reser-

voir of recommended F.R.L. with spindle oil (29665). If an in line or

air line lubricator is not used, apply several drops of spindle oil

(29665) in air inlet.

EVERY 40 HOURS OF TOOL OPERATION - Flush tool with a

solution of three (3) parts cleaning solvent to one (1) part spindle

oil. After flushing, apply a small amount of spindle oil in air inlet and

run free for one minute.

AIR SUPPLY REQUIREMENTS

For maximum operating efficiency, the following air supply specifications should be maintained to this air tool:

l

AIR PRESSURE - 90 PSIG (6 bar)

l

AIR FILTRATION - 50 micron

. LUBRICATED AIR SUPPLY

l

HOSE SIZE - 1/8” (3 mm) I.D.

An AR0® model 128121-300 air line FILTER/REGULATOR/LUBRICATOR (F.R.L.) is recommended to maintain the above air

supply specifications.

NOTE: Marking pen operates effectively at 50 - 70 p.s.i.g.

RECOMMENDED LUBRICANTS

Afterdisassembly is complete, all parts, except sealed or shielded

bearings, should be washed with solvent. To relubricate parts, or

for routine lubrication, use the following recommended lubricants:

Where Used

Air Motor

“0” Rings & Lip Seals 36460 4 oz. Stringy Lubricant

ARO Part # Description

29665

1 qt. Spindle Oil

For parts and service information, contact your local ARO distributor, or the Customer Service Dept. of the Ingersoll-Rand Distribution Center, White House, TN at PH: (615) 672-0321, FAX: (615) 672-0601.

ARO Tool & Hoist Products

Ingersoll-Rand Company

1725 U.S. No. 1 North P.O. Box 8000 l Southern Pines, NC 28388-8000

© 1993 THE ARO CORPORATION. PRINTED IN U.S.A.

INGERSOLL-RAND®

PROFESSIONALTOOLS

GENERAL DESCRIPTION AND OPERATION

The ARO model 8315 air operated marking pen is a high frequency tool (approximately 36,000 c.p.m.) used for marking various

hardened tool steels, other metals, plastics, glass, etc. It can be

used as you would a pen or pencil.

The model 8315 features a turn type throttle, which should be

turned to full on position (approximately one full turn -360”) when

starting. The valve can then be rotated towards the off position to

reduce the impact force on the needle when working in softer materials or if very fine marks are to be made. If the tool does not start,

which may occur if the turn throttle is opened too slowly, lightly tap

the needle with a soft face hammer or against a suitable surface.

For maximum accuracy, hold the marking pen near its point and at

a steep angle to the work piece.

MAINTENANCE

Air tools are made of precision parts and should be handled with

reasonable care when servicing. Excessive pressure exerted by

a holding device may cause distortion of a part. Apply pressure

evenly when disassembling (or assembling) parts which have a

press fit. It is important that the correct tools and fixtures are used

when servicing this air tool.

Disassembly should be done on a clean work bench with a clean

cloth spread to prevent the loss of small parts. After disassembly

is completed, all parts should be thoroughly washed in a clean solvent, blown dry with air and inspected for wear levels, abuse and

contamination.

Before reassembling, lubricate pads where required. Use “0” ring

lube 36460 for “0” ring assembly. When assembling “0” rings or

parts adjacent “0” rings, care must be exercised to prevent dam-

age to the rubber sealing surfaces.

When ordering pans, be sure to list part number, description,

tool model number and serial number.

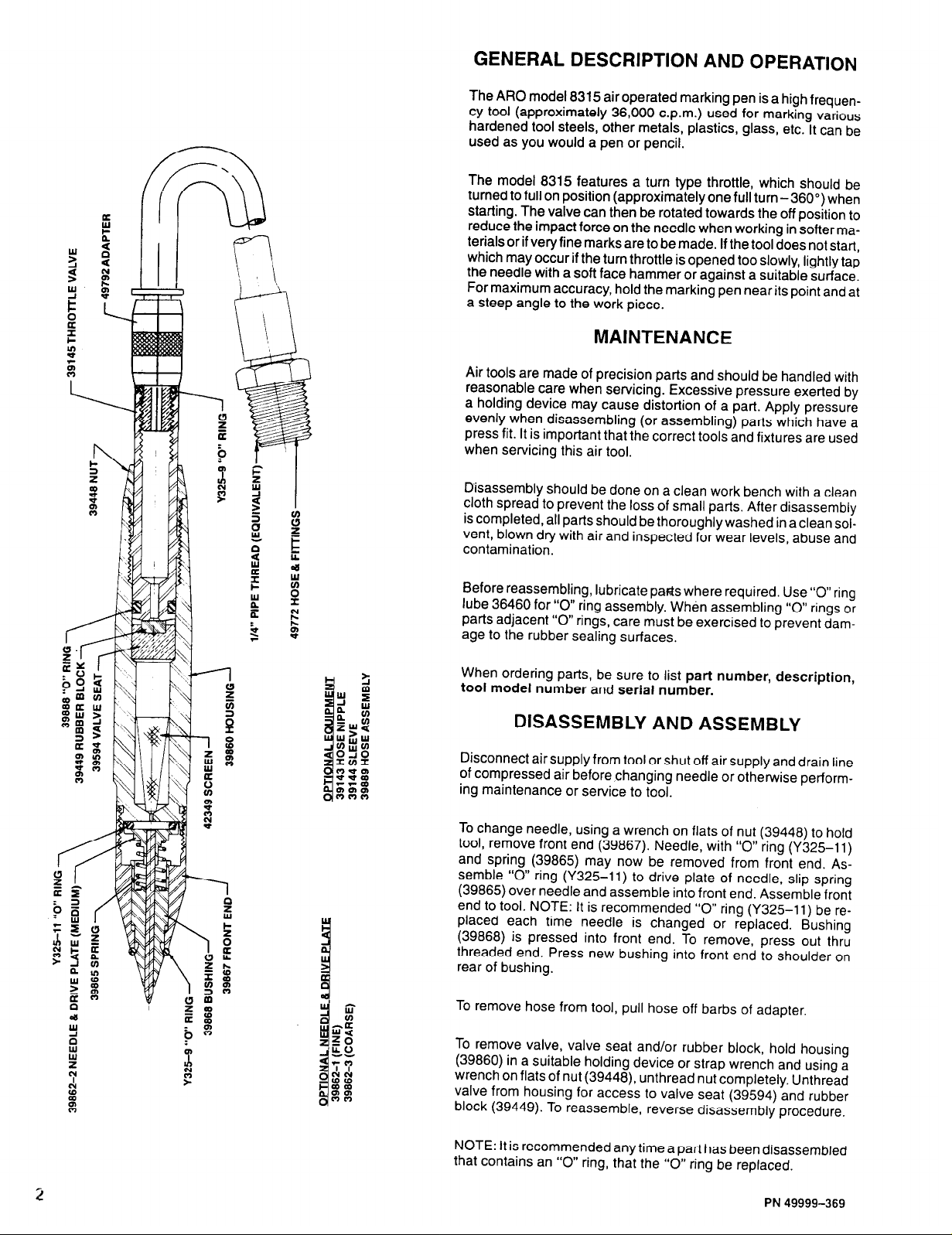

DISASSEMBLY AND ASSEMBLY

Disconnect air supply from tool or shut off air supply and drain line

of compressed air before changing needle or otherwise performing maintenance or service to tool.

To change needle, using a wrench on flats of nut (39448) to hold

tool, remove front end (39867). Needle, with “0” ring (Y325-11)

and spring (39865) may now be removed from front end. Assemble “0” ring (Y325-11) to drive plate of needle, slip spring

(39865) over needle and assemble into front end. Assemble front

end to tool. NOTE: It is recommended “0” ring (Y325-11) be replaced each time needle is changed or replaced. Bushing

(39868) is pressed into front end. To remove, press out thru

threaded end. Press new bushing into front end to shoulder on

rear of bushing.

To remove hose from tool, pull hose off barbs of adapter.

To remove valve, valve seat and/or rubber block, hold housing

(39860) in a suitable holding device or strap wrench and using a

wrench on flats of nut (39448), unthread nut completely. Unthread

valve from housing for access to valve seat (39594) and rubber

block (39449). To reassemble, reverse disassembly procedure.

NOTE: It is recommended any time a part has been disassembled

that contains an “0” ring, that the “0” ring be replaced.

PN 49999-369

Loading...

Loading...