Page 1

SECTION

Tool Products

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

BANT-A-MATIC® SELF-FEED DRILLS

MANUAL

Released: 3-l 1-88

Revised: 1 l-l 7-95

Form:

Models

8245-B(

)-( ) and

8345-B( )-( )

IMPORTANT: READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

M102

12

3261-2

OPERATING PRECAUTIONS

Keep hands and clothing away from rotating end of tool.

l

Wear suitable eye protection while operating tool.

l

Disconnect air supply from tool before removing/installing bit

l

or performing other maintenance procedures.

ROUTINE LUBRICATION REQUIREMENTS

Lack of or an excessive amount of lubrication will affect the performance and life of this tool. Use only recommended lubricants at

below time intervals:

EVERY 8 HOURS OF TOOL OPERATION

- Fill lubricator reser-

voir of recommended F.R.L. with spindle oil (29665).

EVERY 160 HOURS OF TOOL OPERATION

- Inject NLGI #1

“EP” grease (33153) 1 to 2 strokes, thru grease fitting in gear

housing. NOTE: Spindle must be extended from outer sleeve suf-

ficiently to expose grease fitting in gear housing. Gearing should

contain approximately 1/8 oz. (3.5 g) of grease.

AIR SUPPLY REQUIREMENTS

For maximum operating efficiency, the following air supply specifi-

cations should be maintained to this air tool:

l

AIR PRESSURE - 90 PSIG (6 bar)

l

AIR FILTRATION - 50 micron

l

LUBRICATED AIR SUPPLY

l

HOSE SIZE - 5/16” (8 mm) I.D.

An ARO@ model C28231-810 air line FILTER/REGULATOR/LUBRICATOR (F.R.L.) is recommended to maintain the above air

supply specifications.

MOUNTING

The nose end of the outer sleeve (41) is provided with 1-7/16” -

18 L.H. threads [remove thread guard (47) for use] and a 1-7/1 6” x

1/2” long pilot diameter for fixture mounting. Foot and flange type

mounting brackets are available for tool mounting.

RECOMMENDED LUBRICANTS

After disassembly is complete, all parts, except sealed or shielded

bearings, should be washed with solvent. To relubricate parts, or

for routine lubrication, use the following recommended lubricants:

Where Used ARO Part #

Air Motor

“O” Rings & Lip Seals

Gears and Bearings

29665

36460

33153 5

Prescription

1 qt. Spindle Oil

4

oz. Stringy Lubricant

lb. “EP” - NLGI #1 Grease

SET-UP PROCEDURE

WARNING: Keep clear of rotating end of unit with hands and/or

clothing. Keep fingers/hands from being pinched between housing or valves and adjustment screws and/or trip bracket.

l

Loosen two screws (29) and remove cover (1).

0

Allow a minimum distance of 1/4” between the drill point of the

unit and the workpiece. This is necessary for the air motor to

start and reach free speed before the drill point touches the

workpiece.

a

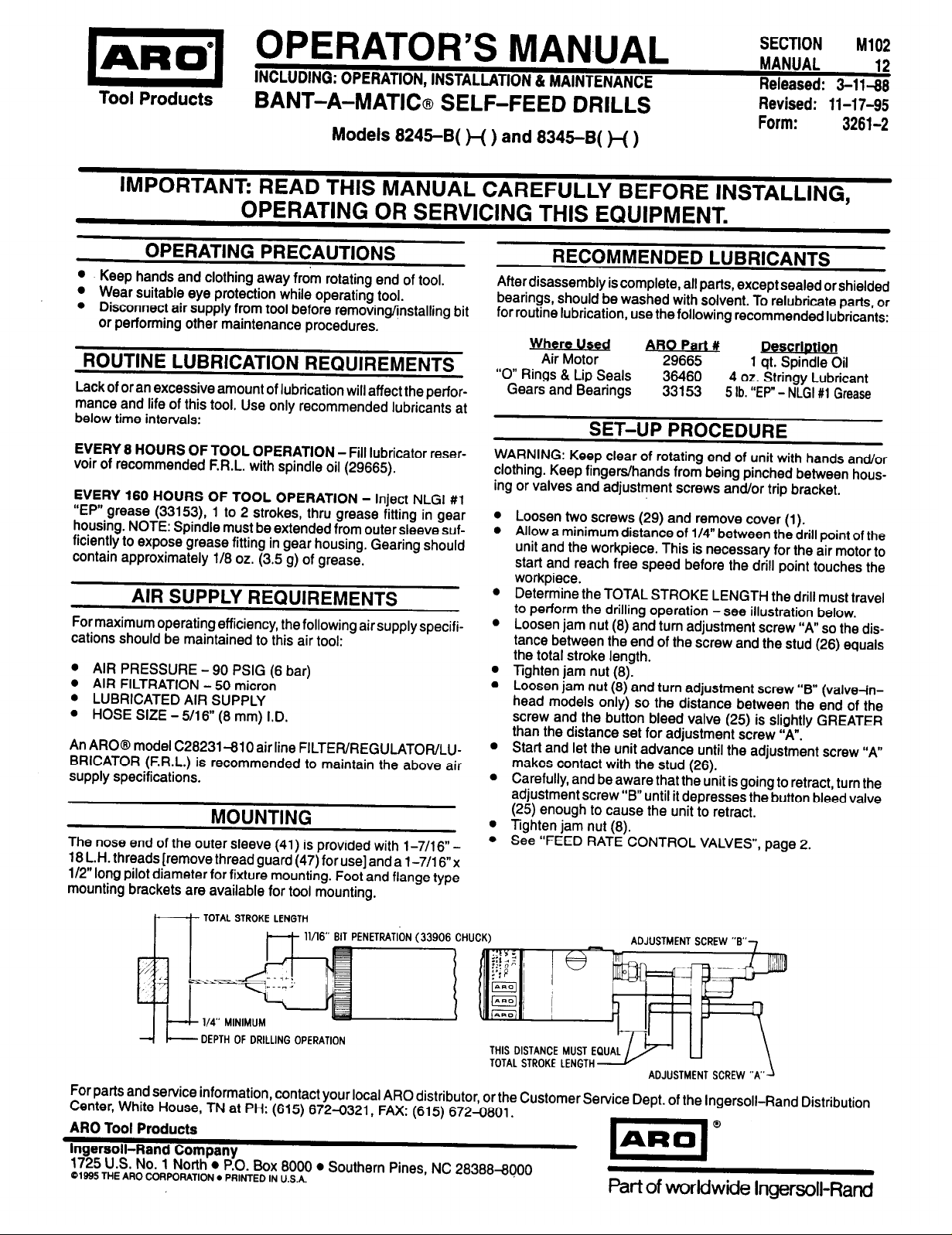

Determine the TOTAL STROKE LENGTH the drill must travel

to perform the drilling operation -see illustration below.

a

Loosen jam nut (8) and turn adjustment screw “A” so the dis-

tance between the end of the screw and the stud (26) equals

the total stroke length.

l

Tighten jam nut (8).

l

Loosen jam nut (8) and turn adjustment screw “B” (valve in-

head models only) so the distance between the end of the

screw and the button bleed valve (25) is slightly GREATER

than the distance set for adjustment screw “A”.

0

Start and let the unit advance until the adjustment screw “A”

makes contact with the stud (26).

a

Carefully, and be aware that the unit is going to retract, turn the

adjustment screw “B” until it depresses the button bleed valve

(25) enough to cause the unit to retract.

l

Tighten jam nut (8).

l

See “FEED RATE CONTROL VALVES”, page 2.

DEPTH OF DRILLING OPERATION

THIS DISTANCE MUST E

TOTAL STROKE LENGTH

For parts and service information, contact your local ARO distributor, or the Customer Service Dept. of the Ingersoll-Rand Distribution

Center, White House, TN at PH: (615) 672-0321, FAX: (615) 672-0801.

ARO Tool Products

Ingersoll-Rand Company

1725 U.S. No. 1 North l P.O. Box 8000 l Southern Pines, NC 28388-8000

01995

THE ARO CORPORATION PRINTED

IN

U.S.A.

Page 2

FEED RATE CONTROL VALVES

Turn valve (23), marked “R” on top of housing, approximately 1-1/2

l

turns counterclockwise (open).

l Turn the other valve (23), marked “F” on top of housing, clock-

wise until closed (do not tighten too snugly).

Start unit and slowly turn valve (23) marked “F” counterclockwise

l

(open) until the desired forward rote of feed

A final adjustment of the rate of return (retract) con be made with

l

IS

reached.

the valve (23) marked “R” on housing.

MANUAL OPERATION

Install button bleed valve (25) in either the “F” port located at top

l

of valve housing or the “F” port located at the rear of valve housing

NOTE: Unused port must be plugged with pipe plug (24).

l Depress button bleed valve (25) marked “F” on valve housing.

The unit will start in the forward (advancing) mode and continue

to feed forward until the adjusting screw “B” has depressed bleed

valve (25) marked “R” to retract the unit See set-up procedure.

l A manual emergency retract button bleed valve (25) con be In-

stalled in “R” port at top of valve housing if desired This valve

con be used to immediately retract the unit in case of misaligned

port or other emergency. Valve not furnished.

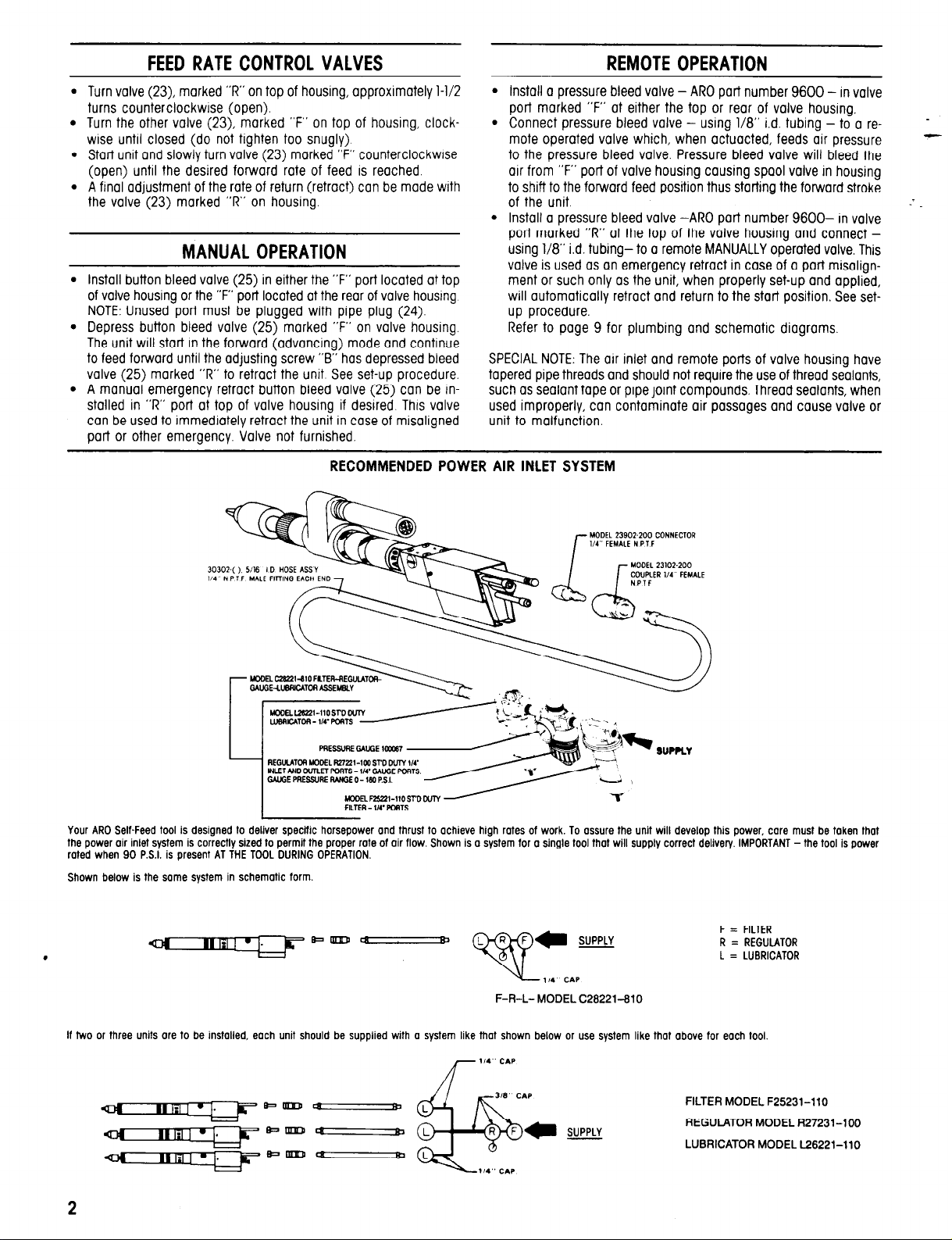

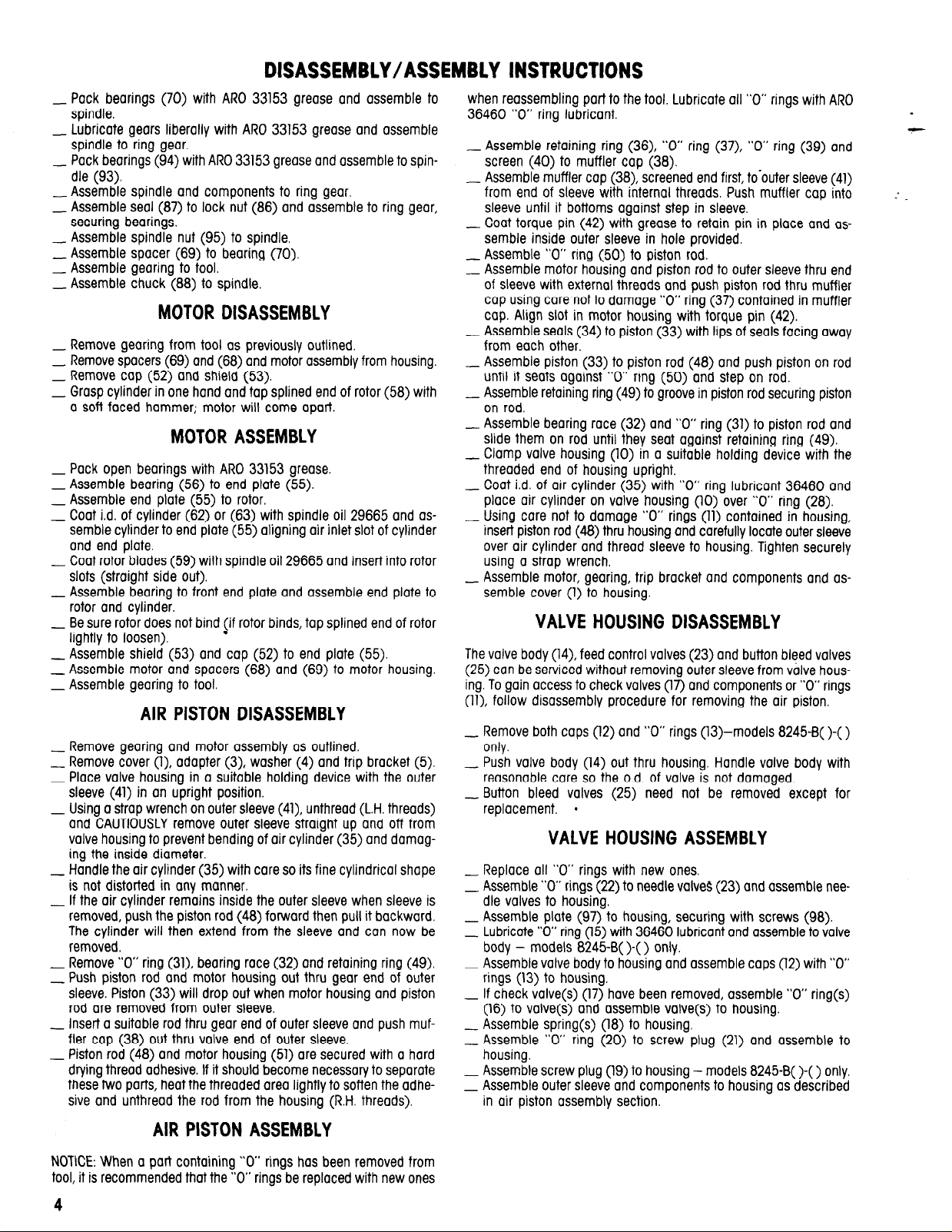

RECOMMENDED POWER AIR INLET SYSTEM

REMOTE OPERATION

Install a pressure bleed valve - ARO port number 9600 - In valve

port marked “F” at either the top or rear of valve housing.

Connect pressure bleed valve - using 1/8” i.d. tubing - to a re-

mote operated valve which, when actuacted, feeds oil pressure

to the pressure bleed valve. Pressure bleed valve will bleed the

air from “F” port of valve housing causing spool valve in housing

to shift to the forward feed position thus starting the forward stroke

of the unit

Install a pressure bleed valve -ARO part number 9600- in valve

port marked “R” at the top of the valve housing and connect using 1/8” i.d. tubing- to o remote MANUALLY operated valve. This

valve is used OS an emergency retract in case of a part misalignment or such only OS the unit, when properly set-up and applied,

will automatically retract and return to the start position. See setup procedure.

Refer to page 9 for plumbing and schematic diagrams.

SPECIAL NOTE: The air inlet and remote ports of valve housing hove

tapered pipe threads and should not require the use of thread sealants,

such OS sealant tape or pipe joint compounds. Thread sealants, when

used improperly, can contaminate air passages and cause valve or

unit to malfunction.

Your ARO Self-Feed tool is designed to deliver specific horsepower and thrust to achieve high rates of work. To assure the unit will develop this power, care

the power air inlet system is correctly sized to permit the proper rate of air flow. Shown is a system for a single tool that will supply correct delivery. IMPORTANT

rated when 90 P.S.I. is present AT THE TOOL DURING OPERATION.

Shown below is the same system in schematic form. Shown below is the same system in schematic form.

F = FILTER

R = REGULATOR

L = LUBRICATOR

It two or three units ore to be instolled, each unit should be supplied with a system like that shown below or use system like that above for each tool

FILTER MODEL F25231-110

REGULATOR MODEL R27231-100

LUBRICATOR MODEL L26221-110

must be token that

- the tool is power

Page 3

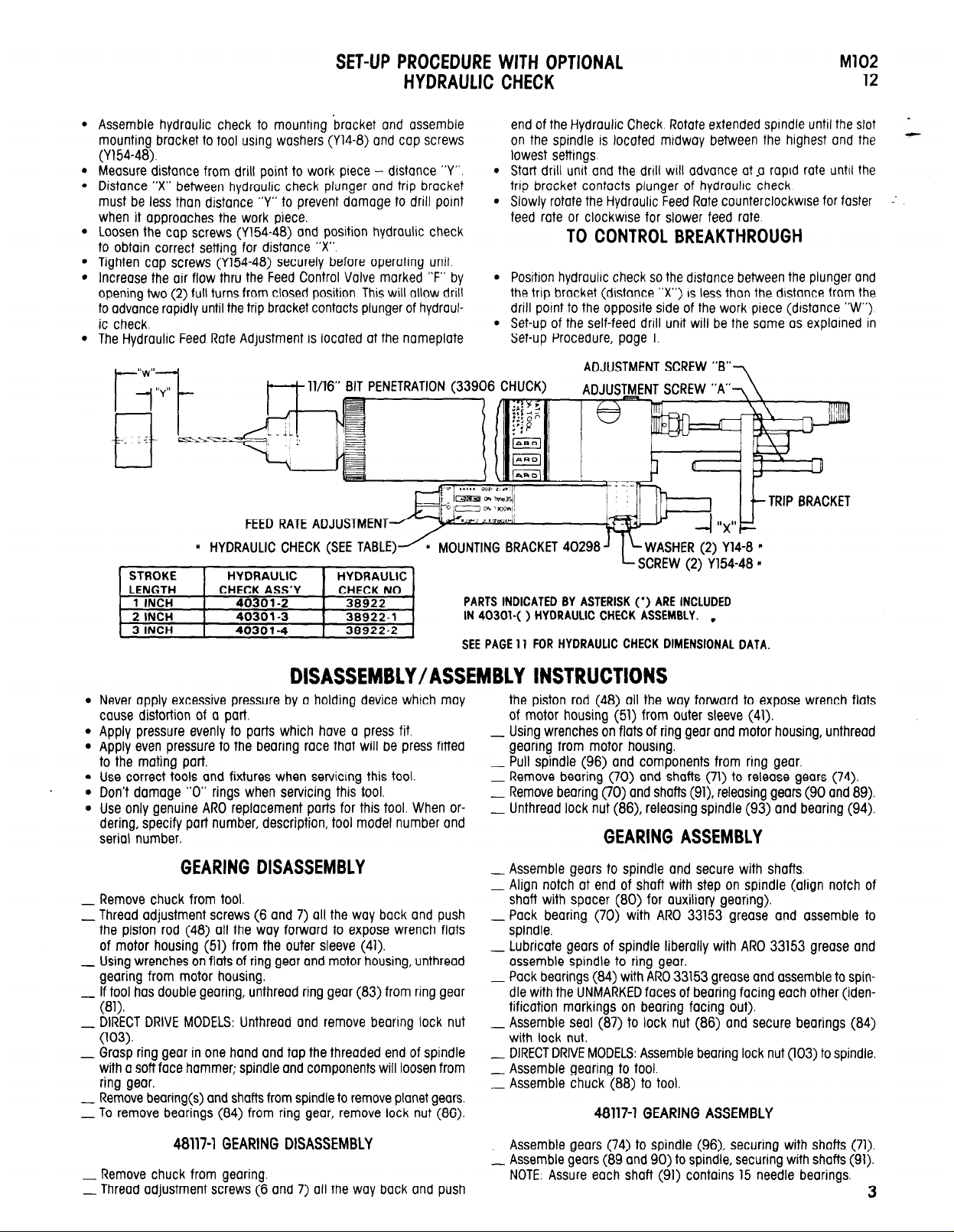

SET-UP PROCEDURE WITH OPTIONAL

HYDRAULIC CHECK

M102

12

Assemble hydraulic check to mounting bracket and assemble

mounting bracket to tool using washers (Y14-8) and cap screws

(Y154-48).

Measure distance from drill point to work piece - distance “Y”.

Distance “X” between hydraulic check plunger and trip bracket

must be less than distance “Y” to prevent damage to drill point

when it approaches the work piece.

Loosen the cap screws (Y154-48) and position hydraulic check

to obtain correct setting for distance “X”.

Tighten cap screws (Y154-48) securely before operating unit.

Increase the air flow thru the Feed Control Valve marked “F” by

opening two (2) full turns from closed position. This will allow drill

to advance rapidly until the trip bracket contacts plunger of hydraul-

ic check.

The Hydraulic Feed Rate Adjustment is located at the nameplate

11/16” BIT PENETRATION (33906 CHUCK)

FEED RATE ADJUSTMENT

l

HYDRAULIC CHECK (SEE TABLE)

MOUNTING BRACKET 40298

end of the Hydraulic Check Rotate extended spindle until the slot

on the spindle is located midway between the highest and the

lowest settings

l

Start drill unit and the drill wiII advance at a rapid rate until the

trip bracket contacts plunger of hydraulic check

l

Slowly rotate the Hydraulic Feed Rate counterclockwise for faster

feed rate or clockwise for slower feed rote

TO CONTROL BREAKTHROUGH

l

Positron hydraulic check so the distance between the plunger and

the trip bracket (distance “X”) IS less thon the distance from the

drill point to the opposite side of the work piece (distance “W”)

l

Set-up of the self-feed drill unit will be the some as explained in

Set-up Procedure, page 1.

ADJUSTMENT SCREW “B”

7

.

ADJUSTMENT SCREW

i

“A”-,

-

-

.

Never apply excessive pressure by a holding device which may

cause distortion of a part

.

Apply pressure evenly to parts which have a press fit.

.

Apply even pressure to the bearing race that will be press fitted

to the mating part.

.

. .

Use correct tools and fixtures when servicing this tool.

Don’t damage “0” rings when servicing this tool.

.

Use only genuine ARO replacement parts for this tool. When ordering, specify pat-t number, description, tool model number and

serial number.

GEARING DISASSEMBLY

_ Remove chuck from tool.

_ Thread adjustment screws (6 and 7) all the way back and push

the piston rod (48) all the way forward to expose wrench flats

of motor housing (51) from the outer sleeve (41).

Using wrenches on flats of ring gear and motor housing, unthread

- gearing from motor housing.

If tool has double gearing, unthread ring gear (83) from ring gear

- (81).

DIRECT DRIVE MODELS: Unthread and remove bearing lock nut

- (103).

_ Grasp ring gear in one hand and tap the threaded end of spindle

with a soft face hammer; spindle and components will loosen from

ring gear.

Remove bearing(s) and shafts from spindle to remove planet gears.

- To remove bearings (84) from ring gear, remove lock nut (86).

PARTS INDICATED BY ASTERISK (*) ARE INCLUDED

IN 40301-( ) HYDRAULIC CHECK ASSEMBLY. ,

SEE PAGE 11 FOR HYDRAULIC CHECK DIMENSIONAL DATA.

the piston rod (48) all the way forward to expose wrench flats

of motor housing (51) from outer sleeve (41).

Using wrenches on flats of ring gear and motor housing, unthread

- gearing from motor housing.

Pull spindle (96) and components from ring gear.

- Remove bearing (70) and shafts (71) to release gears (74).

Remove bearing (70) and shafts (91), releasing gears (90 and 89).

- Unthread lock nut (86), releasing spindle (93) and bearing (94).

GEARING ASSEMBLY

_ Assemble gears to spindle and secure with shafts

Align notch at end of shaft with step on spindle (align notch of

- shaft with spacer (80) for auxiliary gearing).

Pack bearing (70) with ARO 33153 grease and assemble to

-

spindle.

Lubricate gears of spindle liberally with ARO 33153 grease and

assemble spindle to ring gear.

Pack bearings (84) with ARO 33153 grease and assemble to spin-

- dle with the UNMARKED faces of bearing facing each other (iden-

tification markings on bearing facing out).

_ Assemble seal (87) to lock nut (86) and secure bearings (84)

with lock nut.

DIRECT DRIVE MODELS: Assemble bearing lock nut (103) to spindle.

- Assemble gearing to tool.

_ Assemble chuck (88) to tool.

48117-1 GEARING ASSEMBLY

48117-1 GEARING DISASSEMBLY

Remove chuck from gearing.

- Thread adjustment screws (6 and 7) all the way back and push

_ Assemble gears (74) to spindle (96), securing with shafts (71).

_ Assemble gears (89 and 90) to spindle, securing with shafts (91).

NOTE: Assure each shaft (91) contains 15 needle bearings.

3

Page 4

DISASSEMBLY/ASSEMBLY INSTRUCTIONS

Pack bearings (70) with ARO 33153 grease and assemble to when reassembling part to the tool. Lubricate all “O” rings with ARO

spindle. 36460 “0” ring lubricant.

Lubricate gears liberally with ARO 33153 grease and assemble

spindle to ring gear.

Pack bearings (94) with ARO 33153 grease and assemble to spin-

- dle (93).

_ Assemble spindle and components to ring gear.

_ Assemble seal (87) to lock nut (86) and assemble to ring gear,

securing bearings.

Assemble spindle nut (95) to spindle.

1 Assemble spacer (69) to bearing (70).

_ Assemble gearing to tool.

_ Assemble chuck (88) to spindle.

MOTOR DISASSEMBLY

_ Remove gearing from tool as previously outlined,

Remove spacers (69) and (68) and

1 Remove cap (52) and shield (53).

_ Grasp cylinder in one hand and tap splined end of rotor (58) with

a soft faced hammer; motor will come apart.

motor assembly from housing.

MOTOR ASSEMBLY

Pack open bearings with ARO 33153 grease.

1 Assemble bearing (56) to end plate (55).

_ Assemble end plate (55) to rotor.

_ Coat i.d. of cylinder (62) or (63) with spindle oil 29665 and as-

semble cylinder to end plate (55) aligning air inlet slot of cylinder

and end plate.

_ Coat rotor blades (59) with spindle oil 29665 and insert into rotor

slots (straight side out).

_ Assemble bearing to front end plate and assemble end plate to

rotor and cylinder.

Be sure rotor does not bind Jif rotor binds, tap splined end of rotor

- lightly to loosen).

_ Assemble shield (53) and cap (52) to end plate (55).

_ Assemble motor and spacers (68) and (69) to motor housing.

_ Assemble gearing to tool.

AIR PISTON DISASSEMBLY

Remove gearing and motor assembly as outlined.

1 Remove cover (1). adapter (3), washer (4) and trip bracket (5).

Place valve housing in a suitable holding device with the outer

- sleeve (41) in an upright position.

Using a strap wrench on outer sleeve (41), unthread (L.H. threads)

and CAUTIOUSLY remove outer sleeve straight up and off from

valve housing to prevent bending of air cylinder (35) and damaging the inside diameter.

Handle the air cylinder (35) with care so its fine cylindrical shape

is not distorted in any manner.

If the air cylinder remains inside the outer sleeve when sleeve is

removed, push the piston rod (48) forward then pull it backward.

The cylinder will then extend from the sleeve and can now be

removed.

_ Remove “0” ring (31), bearing race (32) and retaining ring (49).

Push piston rod and motor housing out thru gear end of outer

sleeve. Piston (33) will drop out when motor housing and piston

rod ore removed from outer sleeve.

Insert a suitable rod thru gear end of outer sleeve and push muf-

- fler cop (38) out thru valve end of outer sleeve.

Piston rod (48) and motor housing (51) are secured with a hard

- drying thread adhesive. If it should become necessary to separate

these two parts, heat the threaded area lightly to soften the adhe-

sive and unthread the rod from the housing (R.H. threads).

_ Assemble retaining ring (36), “0” ring (37), “0” ring (39) and

screen (40) to muffler cap (38).

_ Assemble muffler cap (38), screened end first, to-outer sleeve (41)

from end of sleeve with internal threads. Push muffler cap into

sleeve until it bottoms against step in sleeve.

Coat torque pin (42) with grease to retain pin in place and as-

semble inside outer sleeve in hole provided.

_ Assemble “0” ring (50) to piston rod.

Assemble motor housing and piston rod to outer sleeve thru end

of sleeve with external threads and push piston rod thru muffler

cap using care not to damage “0” ring (37) contained in muffler

cap. Align slot in motor housing with torque pin (42).

Assemble seals (34) to piston (33) with lips of seals facing away

- from each other.

Assemble piston (33) to piston rod (48) and push piston on rod

until it seats against “O” ring (50) and step on rod.

_ Assemble retaining ring (49) to groove in piston rod securing piston

on rod.

_ Assemble bearing race (32) and “0” ring (31) to piston rod and

slide them on rod until they seat against retaining ring (49).

Clamp valve housing (10) in a suitable holding device with the

-threaded end of housing upright.

_ Coat i.d. of air cylinder (35) with “0” ring lubricant 36460 ond

place air cylinder on valve housing (10) over “O” ring (28).

Using core not to damage “O” rings (11) contained in housing,

insert piston rod (48) thru housing and carefully locate outer sleeve

over air cylinder and thread sleeve to housing. Tighten securely

using a strap wrench.

Assemble motor, gearing, trip bracket and components and as-

-

semble cover (1) to housing.

VALVE HOUSING DISASSEMBLY

The valve body (14), feed control valves (23) and button bleed valves

(25) can be serviced without removing outer sleeve from valve housing. To gain access to check valves (17) and components or “0” rings

(11), follow disassembly procedure for removing the air piston.

_ Remove both caps (12) and “0” rings (13)-models 8245-B( )-( )

Push valve body (14) out thru housing. Handle valve body with

-

reasonable care so the o.d. of valve is not damaged.

_ Button bleed valves (25) need not be removed except for

replacement.

l

VALVE HOUSING ASSEMBLY

Replace all “O” rings with new ones.

1 Assemble “0” rings (22) to needle valves (23) and assemble nee-

dle valves to housing.

_ Assemble plate (97) to housing, securing with screws (98).

Lubricate “O” ring (15) with 36460 lubricant and assemble to valve

-

body - models 8245-B( )-() only.

_ Assemble valve body to housing and assemble caps (12) with “0”

rings (13) to housing.

If check valve(s) (17) have been removed, assemble “0” ring(s)

- (16) to valve(s) and assemble valve(s) to housing.

Assemble spring(s) (18) to housing.

-

Assemble “O” ring (20) to screw plug (21) and assemble to

- housing.

_ Assemble screw plug (19) to housing - models 8245-B( )-( ) only.

_ Assemble outer sleeve and components to housing as described

in air piston assembly section.

AIR PISTON ASSEMBLY

NOTICE: When a part containing “O” rings has been removed from

tool, it is recommended that the “0” rings be replaced with new ones

4

Page 5

77

I

70

4.83:1 RED.

M102

12

4.83:1 RED.

I

I

74

n

n

72

n

70

1:1 RED.

5

Page 6

88

90

91

92

94

95

96

6

PART NUMBER FOR ORDERING

Drive Gearing Ass’y (8:1) includes items 70,

71 (2 req’d), 73, 74 (2 req’d) and 83 thru 87

Chuck

Sun Gear (7 interior - 15 exterior teeth)

Gear (2 req’d) 16 teeth

Shaft (2 req’d) (includes 15 needle bearings

per shaft).

Ring Gear (includes grease fitting 35967)

Spindle

Bearing (2 req’d)

Spindle Nut

Spindle.

,.

.

PANT NUMBER FOR ORDERING

Drive Gearing Ass’y (1.88:1) includes items

69, 70 (2 req’d), 71 (2 req’d), 74 (2 req’d),

86, 87, 89, 90 (2 req’d), 91 (2 req’d), 92,

93, 94 (2 req’d), 95 and 96

97

Plate

98

Screw (2 req’d)

99

Spindle

100

Ring Gear

101

Lock Ring

102

Seal

103

Bearing Lock Nut

104

Collet

Collet Nut : : : : : : : : : : : : : : :

105

48117-1

48440-1

Y211-1

38723

38248-1

38719

38720

38718

31812-8

38721

Page 7

\

28

27

I

M102

12

-

P

* ASSEMBLE WITH THREAD ADHESIVE SUCH AS LOCTITE 242

25

Page 8

PART NUMBER FOR ORDERING

I

1

Cover

models 8245-B( )-1 and 8345-B( )-1

models 8245-B( )-2 and 8345-B( )-2

models 8245-80-3 and 8345-80-3

Pipe Plug

Adapter

Lock Washer

Trip Bracket

models 8245-B( )-()

models 8345-B( )-( )

6

Adjustment Screw “A”

models 8245-B( )-1,-2 and 8345-B( )-1,-2

models 8245-B( )-3 and 8345-B()-3

7

Adjustment Screw “B”

model 8245-80-l

models 8245-B( )-2 and 8245-B()-3

8

Nut [2 req’d on models 8245-B( )-( )]

9

Pipe Nipple

models 8245-B( )-1 and 8345-B( )-1

models 8245-B( )-2,-3 and 8345-B( )-2,-3

10

Valve Housing

models 8245-B( )-1 and 8245-B( )-2

models 8245-B( )-3

models 8345-B( )-1 and 8345-B( )-2

models 8345-B( )-3

11

“0” Ring (3 req’d)

12

Cap (2 req’d)(models 8245-B( )-() only)

“0” Ring (2 req’d)(models 8245-B( )-( )

13

only)

14

Valve Body (models 8245-B( )-( ) only)

“O” Ring (5 req’d)(models 8245-B( )-( )

15

only)

16

“O” Ring (2 req’d on models 8245-B( )-( ))

17

Check Valve (2 req’d on models

8245-B( )-( ))

18

Spring [2 req’d on models 8245-B( )-( )]

19

Screw Plug (models 8245-B()-() only)

20

“0” Ring

Screw Plug

22:

“O” Ring [2 req’d on’ models 8245-B( )-( )]

23

Needle Valve (2 req’d on models

8245-B( )-( )]

24

Pipe Plug (2 req’d)

Button Bleed Valve (2 req’d on models

25

8245-B( )-( ) only]

26

Stud.........

27

“O” Ring

“O” Ring.

28

19

Screw (2 req’d)

Washer (2 req’d) : :

30

: : : : : : : :

Housing and Valve Assembly

(includes items 10 thru 30, 97 and 98

models 8245-B( )-1 and 8245-B( )-2

model 8245-B( )-3

includes items 10, 11, 16, 17, 18, 20 thru 24,

26 thru 30, 97 and 98

models 8345-B( )-1 and 8345-B( )-2

model 8345-B( )-3

“O” Ring. : : : : :

31

32

Bearing Race.

Piston

33

34

Seal (2 req”d) I :

35

Air Cylinder

models 8245-80-l and 8345-80-l

models 8245-B( )-2 and 8345-B( )-2

models 8245-B( )-3 and 8345-B( )-3

36

Retaining Ring

“O” Ring

Muffler Cap

“O” Ring

Screen

: :

t

40294-l

40294

40294-2

Y227-2-L

44883

Y14-616

41713-2

41713-1

40292-2

40292-3

40292-l

40292-2

Y11-4-C

40857-5-l

40857-7-l

40285

40799

41298-1

41298-2

34276

46696

Y325-12

40287

41082

Y325-2

39587

35733

39652

Y325-3

38863

Y325-7

48441-1

Y227-2-L

24130

46558

Y325-26

Y325-24

Y154-19

Y14-4

40813-l

40813-2

41301-3

41301-4

41534

42364

39459-1

35922

39458-1

39458

39458-2

39471

Y325-16

39456

Y325-24

39461

PART NUMBER FOR ORDERING

41

Outer Sleeve

models 8245-B( )-1 and 8345-B( )-1

models 8245B( )-2 and 8345-B( )-2

models 8245-B()-3 and 8345-B()-3

42

Torque Pin

43

Muffler

Manifold (includes items 45 and 46)

45

Set Screw

46

“0” Ring (2 req’d)

47

Thread Guard : :

48

Piston Rod

models 8245-B( )-1 and 8345-B( )-1

models 8245-B()-2 and 8345-B()-2

models 8245-B( )-3 and 8345-B( )-3

Retaining Ring

49

50

“O” Ring (2 req’d) : : : : : : :

51

Motor Housing

models 8245-B( )-1,-2 and 8345-B( )-1,-2

models 8245-B( )-3 and 8345-B()-3

52

Cap

53

Shield.

55

Rear End Plate : : : : : : :

56

Bearing.

58

Rotor

7 teeth, used with motor ass’y 33654-2

12 teeth, used with motor ass’y 34746-2

59

Blade (5 req’d)

Roll Pin. : : : : : : : :

60

61

Roll Pin.

62

Cylinder (includes items 60 and 61) : :

63

Cylinder (includes item 60)

64

Front End Plate, used with motor 33654-2

65

Bearing.

66

Front End Plate, used with motor ‘347462

67

Bearing.

Motor Assembly

for 2700 r.p.m. models

for 900, 4400 and 19000 r.p.m. models

68

Spacer

Spacer

69

Bearing . : ::.....:.,

70

71

Shaft (2 req’d)

72

Spline Driver

73

Spindle

74

Gear (2 req’d) 20 teeth : : : :

75

Shaft (2 req’d)

Spindle

76

77

Gear (2 req’d) 17 teeth’ : : : : :

78

Shaft (2 req’d)

Spindle. : :

79

Spacer

81

Ring Gear : : : :

84

Retaining Ring

83

Ring Gear (includes grease fitting’ 35967)

used with 4.83:1 and 23.3:1 gearing (46

teeth)

used with 1:1 and 8:1 gearing (49 teeth)

84

Bearing (2 req’d)

used with 4.83:1 and 8:1 gearing

used with 1:1 gearing

Spindle Nut

86

Lock Nut,

87

Seal

Auxiliary Gearing Ass’y (4.83:1) includes

items 70 (2 req’d), 77 (2 req’d), 78 (2 req’d),

79,80, 81 and 82

Drive Gearing Ass’y (1:1) includes items 70,

71 (2 req’d), 72, 84 (2 req’d) and 99 thru 105

Drive Gearing Ass’y (4.83:1) includes items

70, 75 (2 req’d), 76, 77 (2 req’d) and 83 thru

87..........................

40750

40295

40800

40297-1

43551-2

41204

Y29-82 .

Y325-29

35912

10751-1

40293-1

40801-1

Y145-20

Y325-13

40296

40802

39466

39465

33096

38232

33026-l

34734-l

32860

33416

1178-l

33397

34747

33024

32851

34742

Y65-8

33654-2

34746-2

34737

33018

32850

38251

38108

39467

: : :

33048

38722

39468

34745

34735

: :

:

: :

35915

34736

35914

35900

39481

39482

18305-l

34682

38893-l

38250

:

38895

36017

38724-2

39478

Page 9

BASIC REMOTE CONTROL FOR START

AND EMERGENCY RETRACT FUNCTIONS

M102

12

‘OUT’ PORT

3-WAY PALM BUTTON VALVE (MODEL 461-2).

RED BUTTON WITHOUT GUARD lNSTANT TUBE

CONNECTIONS AND SPRING RETURN

‘PACKAGED 10 TO A BOX

REMOTE OPERATION

Remote operation of the unit may be achieved by Connecting a 3-way valve to the remote start and/or remote retract ports, as shown above.

TO START - depress the remote button momentarily. The unit will advance the drill to a preset depth and automatically retract to the initial position whereupon me unit will stop.

EMERGENCY RETRACT - depress the emergency button momentarily. This signal to the unit will shift the built-in pressure operated valve, commanding the unit to retract immediately

to the initial position whereupon the unit will stop.

NOTE: MANUAL START and EMERGENCY RETRACT buttons on the tool ore fully operational even when remote control is used. The manually operated buttons can be used when

set-up is required.

Shown below is the same system in schematic farm.

MODEL 8345-B( )-( )

CONNECTED 70 “IN” PORT

l

PACKAGED 10 TO A BOX

TH MALE CONNECTOR S9474-004

I-WAY VALVE (MODEL 5040-10 SHOWN)

2-POSITlON, MANUAL RETURN

1/8” N. P. T. F. PORTS

TUBING 59690( ). SEE TABLE

l

REMOTE OPERATION

Remote operation is achieved by connecting a 4-way valve to the remote start and retract ports as shown above. This valve supplies power directly to the feed piston in the tool.

TO START - move lever forward. The unit will advance to o preset depth (adjustment screw contacts stud on valve housing)

TO RETRACT - move lever rearward (back), The unit will retract to the initial position.

EMERGENCY RETRACT - the unit will retract at any time the lever is moved to the rearward (bock) position. The motor runs continuously as long as air pressure is present at the

air inlet to the tool. A shut-off valve should be installed in the air inlet Line to completely shut the tool off in case of an emergency.

Shown below is the some system in schematic form.

9

Page 10

SERVICE KIT NO. 41205-l

FOR SERVICING ONE MODEL 8245-B( )-( ) or 8345-B( )-( ) EXCEPT

8245-B30-( ), 8345-B30-( ) or 8245-101-( )

QTY PART NO. DESCRIPTION

1

38232 Bear

5

32860 Blade

3 34276 “O” Ring

2

35733 Spring

2 35922 Seal

1

39461

1

39466

5 41082

1

41534

1

41795 Motor Oil

Screen

Cap

“O” Ring

“O” Ring

QTY PART NO. DESCRIPTION

1 41799 Gear Lube

41954

1

Y325-2

2

Y325-3

1

Y325-7

2

Y325-12

2

Y325-13

2

Y325-16

1

2 Y325-24

Y325-26

1

“O” Ring Lube

Bearing

“O” Ring

“O” Ring

“O” Ring

“O” Ring

“O” Ring

“O” Ring

“O” Ring

“O” Ring

SERVICE KIT NO. 41310-1

FOR SERVICING ONE MODEL 8245-B30-( ), 8345-B30-( ) or 8245-101-( )

QTY PART NO. DESCRIPTION

1 38232 Bearing 1 41795

1 32851

5 32860

3 34276

2 35733

2 35922

1 39461

1 39466

5 41082

Bearing

Blade

“O” Ring 2

Spring

Seal 2

Screen

Cap

“O” Ring

“O” Ring 1

QTY PART NO. DESCRIPTION

Motor Oil

1 41799

1 41954

Y325-2

1 Y325-3

Y325-7 “O” Ring

2 Y325-12

2 Y325-13

1

Y325-16

2 Y325-24

Y325-26 “O” Ring

Gear Lube

“O” Ring Lube

“O” Ring

“O” Ring

“O” Ring

“O” Ring

“O” Ring

“O” Ring

1

I

MODEL

NUMBER

8245-B8-( ) 8345-B8-( )

8245-B30-(

8245-B45-(

) 8345-B30-(

) 8345-B45-(

8245-101-() I

8245-203-(

8345-203-()

)

R.P.M.

900

) 2700

) 4400

110,000 1 33654-2 1

19.000

MOTOR

AUXILIARY

34746-2 36017

33654-2

34746-2

I

34746-2

MODELS WITH -EU SUFFIX ARE “EC” COMPLIANT MODELS.

39478

39479

39478 4.83:1

1 48117-1

-----

23.3:1

8:l

PISTON

SECTION

,

I

GEARING

SECTION

10

Page 11

TROUBLE SHOOTING

LISTED BELOW ARE SOME OF THE MOST COMMON CAUSES FOR THE SELF-FEED DRILL TO MALFUNCTION. MALFUNCTIONS BEYOND THE SCOPE

OF THIS MANUAL SHOULD BE BROUGHT TO THE ATTENTlON OF YOUR ARO REPRESENTATIVE OR RETURN THE TOOL TO FACTORY FOR REPAIR.

M102

12

CONDITION

Failure to feed or

irregular or erratic feed.

Low speed or motor

fails to operate.

Motor continues to

run after retraction.

Failure to retract.

POSSIBLE CAUSE

1. Inadequate air supply

2. Feed control valves improperly adjusted.

3. Air leak around cap (12).

4. Dirt or damaged “O” rings on

spool valve (14).

5. Clogged air passage in valve

housing.

1. Inadequate air supply.

2. Clogged air passage in valve

housing.

1. Piston not fully retracted.

2. Damaged “O” ring (11) inside

valve housing.

1. Improper adjustment or align-

ment between adjustment screw

and button bleed valve.

CORRECTIVE ACTION

1 Check air supply for correct regulator adjustment (90 p.s.i.g.

max. when tool is operating).

2. Refer to set-up procedure, page 1

3. Check for damage to “O” ring. Check and insure caps are properly

tightened.

4. Refer to valve section, page 4, and remove spool valve

Inspect, clean and replace “O” rings

5. Remove valve housing from tool. Disassemble and blow all air

passages clear of debris.

1. Check air supply for correct regulator adjustment

2. Remove valve housing from tool. Disassemble and blow all air

passages clear of debris.

1. Insure piston is not obstructed and is returned all the way back

2. Remove valve housing from tool. Replace “O” rings.

Refer to set-up procedure, page 1.

2. Feed control valves (23) improp

erly adjusted or dirty

3. Air leak around cap (12).

4. Damaged “O” rings in muffler cap,

valve housing or spool valve or

seals on piston.

5. Clogged air passage in valve

housing.

ACCESSORIES

2. Check adjustment, refer to page 2. Remove, inspect and

clean.

3. Check for damage to “O” ring. Check and insure caps are properly

tightened.

4. Disassemble, inspect and replace “O” rings and/or seals.

5. Remove valve housing from tool. Disassemble and blow air

passages clear of debris.

Page 12

12

DIMENSIONAL DATA

PN 49999-030

Loading...

Loading...