Ingersoll-Rand 7RALC1, 7RALC3, 7RLLC1, 7 Series, 7RAMC1 Product Information

...

Air Screwdriver

7 Series

Product Information

EN

Product Information

ES

Especicaciones del producto

FR

Spécications du produit

PT

Especicações do Produto

ZH

产品信息

80167299

Edition 2

Janaury 2014

Save These Instructions

4

7

5

3

2

1

9

6

48h

100h

PMAX

24h

8

10

100h

11

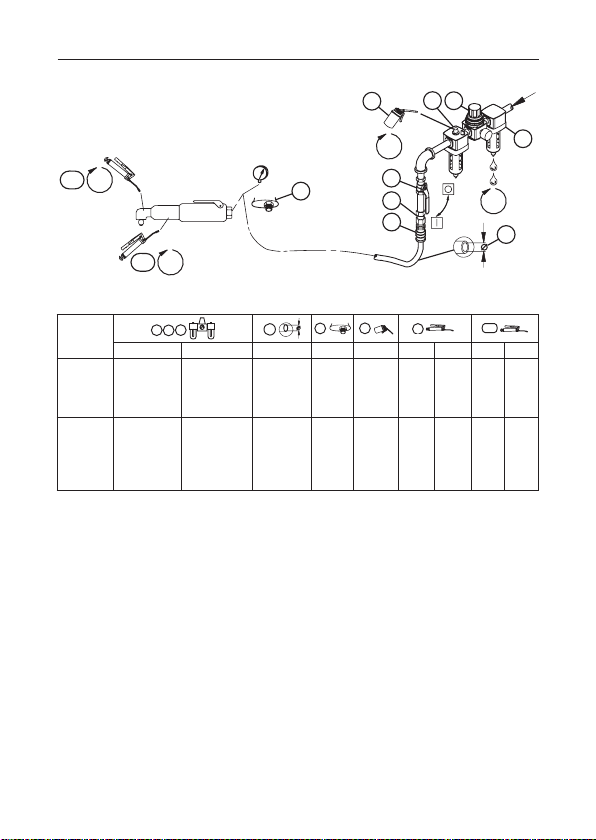

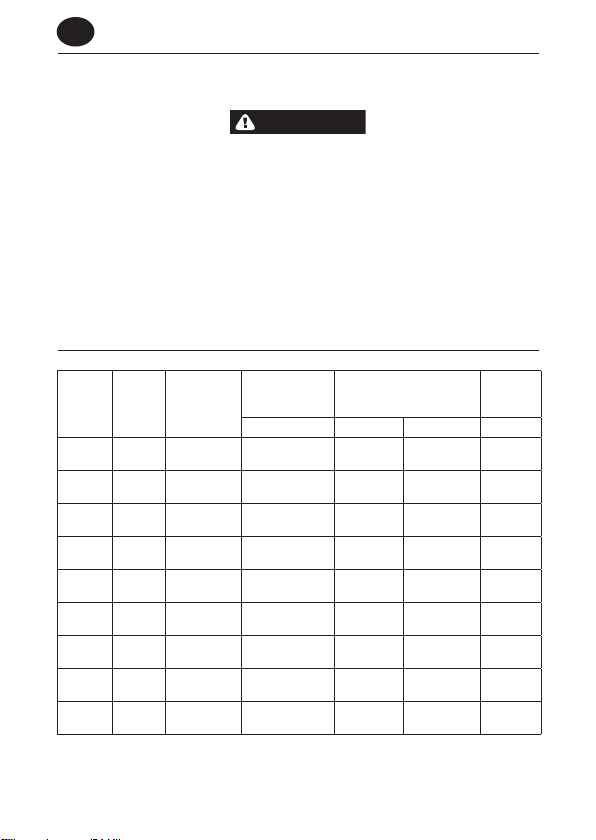

(Dwg. 16585762)

1

3

2

5

6

8

9

10

Model(s)

2 80167299_ed2

IR # - NPT IR # - BS inch (mm) NPT IR # IR # cm3IR # cm

7RALC1

7RALC3

C38121-800 C383D1-810 5/16 (8) 1/4 10 28 2 67 ---

7RLLC1

7RALD1

7RAMC1

7RAMC3

7RLMC1

C38121-800 C383D1-810 5/16 (8) 1/4 10 28 4 67 --7RAMP1

7RANP1

3

Product Safety Information

WARNING

WARNING

Intended Use:

These tools are designed to install or remove threaded fasteners.

Failure to observe the following warnings, and to avoid these potentially hazardous

●

situations, could result in death or serious injury.

Always turn o the air supply, bleed the air pressure and disconnect the air supply hose

●

when not in use, before installing, removing or adjusting any accessory on this tool, or

before performing any maintenance on this tool or any accessory.

If a tool stalls the full torque capacity of the tool will be applied to the operator’s hands,

●

unless a suspension arm or reaction bar is used. This force may cause serious personal

injury from crushing, pinching, loss of balance or loss of control of the tool.

For additional information refer to Product Safety Information Manual Form 04585006.

Manuals can be downloaded from ingersollrandproducts.com

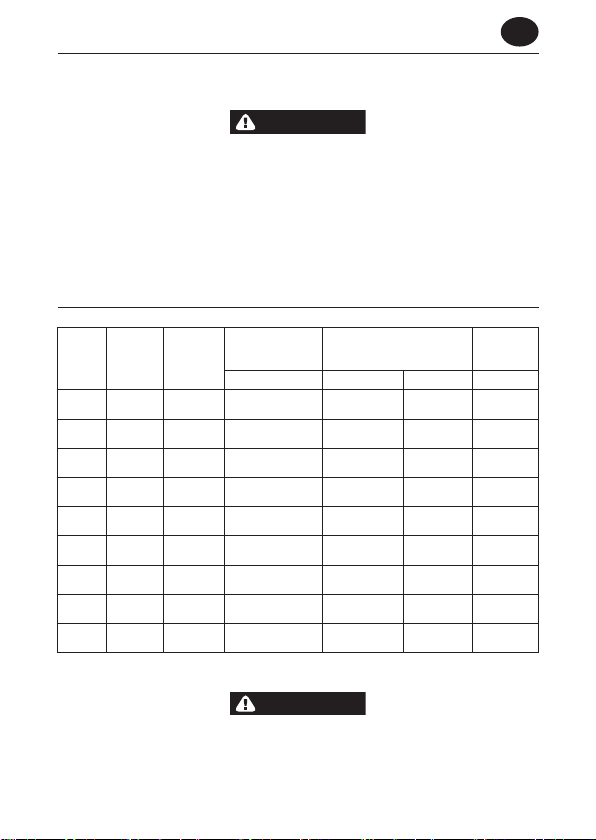

Product Specications

Model Style Clutch

Reversible

pistol

Reversible

pistol

Reversible

pistol

Reversible

pistol

Reversible

lever

Reversible

lever

Reversible

pistol

Reversible

pistol

Reversible

pistol

Adjustable

cushion

Adjustable

cushion

Adjustable

cushion

Adjustable

cushion

Adjustable

cushion

Adjustable

cushion

Positive

jaw

Positive

jaw

Direct

drive

7RALC

7RALC3

7RAMC1

7RAMC3

7RLLC1

7RLMC1

7RAMP1

7RANP1

7RALD1

† KpA = 3dB measurement uncertainty

‡ KwA = 3dB measurement uncertainty

Recommended

Torque Range

(soft draw)

in-lbs (Nm)

15-75 (1.7-8.5) 80.9 91.9 < 2.5

15-75 (1.7-8.5) 80.9 91.9 < 2.5

20-110 (2.3-12.5) 80.9 91.9 < 2.5

20-110 (2.3-12.5) 80.9 91.9 < 2.5

15-75 (1.7-7.4) 80.9 91.9 < 2.5

20-110 (2.3-12.5) 80.9 91.9 < 2.5

63 (7.2) @ 50 psi

115 (13.1) @ 90 psi

91 (10.3) @ 50 psi

165 (18.8) @ 90 psi

39 (4.4) @ 50 psi

70 (8.0) @ 90 psi

Sound Level dB(A)

(ISO15744)

† Pressure (Lp) ‡ Power (Lw) m/s

80.9 91.9 < 2.5

80.9 91.9 < 2.5

80.9 91.9 < 2.5

Vibration

Level

(ISO28927)

EN

2

Sound and vibration values were measured in compliance with internationally recognized

test standards. The exposure to the user in a specic tool application may vary from these

results. Therefore, on site measurements should be used to determine the hazard level in

that specic application.

80167299_ed2 EN-1

EN-2 80167299_ed2

EN

WARNING

NOTICE

WARNING

Installation and Lubrication

Size air supply line to ensure tool’s maximum operating pressure (PMAX) at tool inlet. Drain

condensate from valve(s) at low point(s) of piping, air lter and compressor tank daily. Install

a properly sized Safety Air Fuse upstream of hose and use an anti-whip device across any

hose coupling without internal shut-o, to prevent hose whipping if a hose fails or coupling

disconnects. See drawing 16585762 and table on page 2. Maintenance frequency is shown in a

circular arrow and dened as h=hours, d=days, and m=months of actual use. Items identied as:

1. Air lter 7. Coupling

2. Regulator 8. Safety Air Fuse

3. Lubricator 9. Oil

4. Emergency shut-o valve 10. Grease - through tting

5. Hose diameter 11. Grease - disassembly required

6. Thread size

Clutch Adjustment

Models ending in C1 incorporate an adjustable clutch that can be externally adjusted

within a certain range to ratchet when a predetermined torque has been delivered.

To increase the adjustable torque range, three Clutch Springs are oered.

Turn o the air supply and disconnect the air supply hose from the Tool before proceeding.

To adjust the Clutch, proceed as follows.

1. Rotate the Adjusting Hole Cover on the Clutch Housing to expose the adjusting hole.

2. Insert a 1/4” hexagon steel (Allen Key) into the clutch hexagon recess in the Bit Holder. Rotate

the clutch mechanism until one of the radial holes in the Clutch Adjusting Nut is visible

through the adjusting hole. Insert the end of the No. 5C1-416 Adjusting Key (a hardened

steel pin or rod 3/32” [2 mm] diameter is also suitable) into the hole in the Adjusting Nut to

sprag the Nut against rotation.

3. Grasp the Tool rmly in one hand and rotate the Bit Holder to shift the Nut along the Bit

Holder. This is a left-hand thread; rotating the Bit Holder clockwise when facing the front

increases the compression on the Clutch Spring and raises the torque at which the clutch will

ratchet.

The most satisfactory adjustment is usually obtained by use of the Tool on the actual

application, and increasing or decreasing the delivered torque until the desired setting

is reached. In any event it is recommended that nal adjustment be made by gradual

progression.

The clutch, when equipped with the Heavy Spring, can be set beyond the torque capacity

of the tool, in which case the tool will stall before the Clutch ratchets. Do not adjust the

Clutch beyond the torque capacity of the tool.

EN

4. Insert the Clutch Adjusting Key into the hole in the Clutch Adjusting Nut and, while holding

the Nut against rotation, rotate the Bit Holder counterclockwise until there is no compression

on the Clutch Spring.

Parts and Maintenance

When the life of the tool has expired, it is recommended that the tool be disassembled,

degreased and parts be separated by material so that they can be recycled.

Original instructions are in English. Other languages are a translation of the original instructions.

Tool repair and maintenance should only be carried out by an authorized Service Center.

Refer all communications to the nearest Ingersoll Rand Oce or Distributor.

80167299_ed2 EN-3

ES-1 80167299_ed2

ES

ADVERTENCIA

Información de seguridad sobre el producto

Uso indicado:

Estas herramientas están diseñadas para extraer y montar elementos de sujeción roscados.

No observar las siguientes advertencias y no evitar estas situaciones potencialmente

●

peligrosas podría causar lesiones graves o incluso la muerte.

Corte siempre el suministro de aire, purgue la presión de aire y desconecte la manguera

●

de suministro de aire antes de instalar, desmontar o ajustar cualquier accesorio de

esta herramienta, o antes de realizar cualquier operación de mantenimiento en la

herramienta o en cualquier accesorio.

Si una herramienta se atasca, la capacidad total de torsión de la herramienta se aplicará

●

a las manos del operador, a menos que se utilice un brazo de suspensión o una barra de

reacción. Esta fuerza puede causar lesiones físicas graves por aplastamiento, enganche,

pérdida de equilibrio o pérdida de control de la herramienta.

Para más información, consulte el formulario 04585006 del Manual de información de

seguridad del producto.

Los manuales pueden descargarse desde ingersollrandproducts.com.com.

Especicaciones del producto

Modelo(s) Tipo

Pistola

7RALC

reversible

Pistola

7RALC3

reversible

Pistola

7RAMC1

reversible

Pistola

7RAMC3

reversible

Palanca

7RLLC1

reversible

Palanca

7RLMC1

reversible

Pistola

7RAMP1

reversible

Pistola

7RANP1

reversible

Pistola

7RALD1

reversible

† KpA = 3dB de error

‡ KwA = 3dB de error

Tipo de

embrague

ajustable

ajustable

ajustable

ajustable

ajustable

ajustable

Mordaza

positiva

Mordaza

positiva

Accionamiento

directo

Intervalo de par

recomendado

(torsión suave)

Cojín

Cojín

Cojín

Cojín

Cojín

Cojín

in-lbs (Nm) † Presión (Lp) ‡ Potencia (Lw) m/s

15-75 (1.7-8.5) 80.9 91.9 < 2.5

15-75 (1.7-8.5) 80.9 91.9 < 2.5

20-110 (2.3-12.5) 80.9 91.9 < 2.5

20-110 (2.3-12.5) 80.9 91.9 < 2.5

15-75 (1.7-7.4) 80.9 91.9 < 2.5

20-110 (2.3-12.5) 80.9 91.9 < 2.5

63 (7.2) @ 50 psi

115 (13.1) @ 90 psi

91 (10.3) @ 50 psi

165 (18.8) @ 90 psi

39 (4.4) @ 50 psi

70 (8.0) @ 90 psi

Nivel Sonoro dB(A)

(ISO15744)

80.9 91.9 < 2.5

80.9 91.9 < 2.5

80.9 91.9 < 2.5

Nivel de

Vibración

(ISO28927)

2

Loading...

Loading...