Ingersoll-Rand 62131 User Manual

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

SELF EVACUATING OIL DRAIN

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

OPERATING AND SAFETY PRECAUTIONS

WARNING

severe injury or death.

EXCESSIVE AIR PRESSURE. Can cause explosion resulting in

S Do not exceed the maximum inlet air pressure as stated on the model plate.

WARNING

age.

EXPLOSION HAZARD.Can causeserious injury or property dam -

S Do not use near open flame or heat source.

S This product is not designed for working in explosive environments, including

those caused by fumes and dust, or near flammable materials.

WARNING

ty damage.

HAZARDOUS MATERIALS. Can cause personal injury or proper-

S Do not use for volatile fuel and fluids.

S Obtain Material Safety Data Sheets on all materials from the supplier for proper

handling instructions.

WARNING

safety / relief valve can cause serious injury or death. Do not bypass, modify or

remove the safety / relief valve. Do not direct air stream at body.

CAUTION

safe working practices, understand it’s limitations and wear safety goggles /

equipment when required.

HIGH PRESSURE AIR. Bypassing, modifying or removing the

Be certain all operators of this equipment have been trained for

S Do not use for structural support.

S Disconnect air supply when not in use.

S Use only genuine IR replacement parts to assure longest service life.

GENERAL DESCRIPTION

Model 62131 is a waste oil container which stores up to 20 gallons (75.7 liters)in an ASME

certified steel tank and rapidly discharges using air pressure. The unit is equipped with a

safety relief valve which prevents over-pressurization and a 4-3/4” x 20-1/2” (12.0 cm x

52.0 cm) drain funnel with a filtering screen and a telescoping tube. The tank has (2) rigid

casters and (2)swivel casters for easy maneuvering. It also includes a sight gauge and an

oil shut-off valve.

OPERATION

1. To raise the funnel: Grasp the upper portion of the (5) tube, loosen the (6) thumbscrew

and raise the funnel and tube to the desired height. Tighten the (6) thumb screw and

release grasp on tube.

2. To lower the funnel:

and lower the funnel and tube to the desired position. Tighten (6) thumb screw and

release grasp on tube.

3. The reservoir includes a sight gauge. Do not overfill the reservoir.

4. To evacuate oil:

necting air supply. Connect the discharge hose to the (9) oil shut-off valve on the (18)

tank. Be sure the (9) oil shut-off valve is fully engaged. Open the (9) oil shut-off valve.

Before connecting the air supply, be sure that the inlet air line pressure is regulated at no more than 70 p.s.i. (PMAX). Connect the air supply to the (10) air man-

ifold.Never leave the unit unattended duringevacuation.Close the (12) air shut-off

valve immediately when the tank is empty. The discharge hose will begin to shake

when the (18) tank is empty. Disconnect the air supply to the (10) air manifold. Close

the (9) oil shut-off valve. Slowly open the (12) air shut-off valve to depressurizethesystem. System must be depressurized before returning to service. Disconnect the discharge hose from the (9) oil shut-off valve on the (18) tank. Periodically remove and

clean the (2) funnel screen as necessary.

5. (17) safety relief valve may discharge during evacuation.

Grasp the upper portion of (5) tube, loosen the (6) thumb screw

Lower the (1) funnel. Always connect the discharge hose before con-

DATA

Weight 105 lbs (47.6 kgs)...............................

Recommended Air Operating Pressure 20 - 70 p.s.i.g. (1.38 - 4.83 bar)......

Capacity 20 gallons (75.7 liters).............................

Height (lowered) 52 in. (132.08 cm)...... ................

Tank Diameter 16 in. (40.64 cm).........................

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

(fully extended) 73 in. (185.42 cm)...........

© 2010

CCN 15231640

1

5

30

10

31

32

29

19

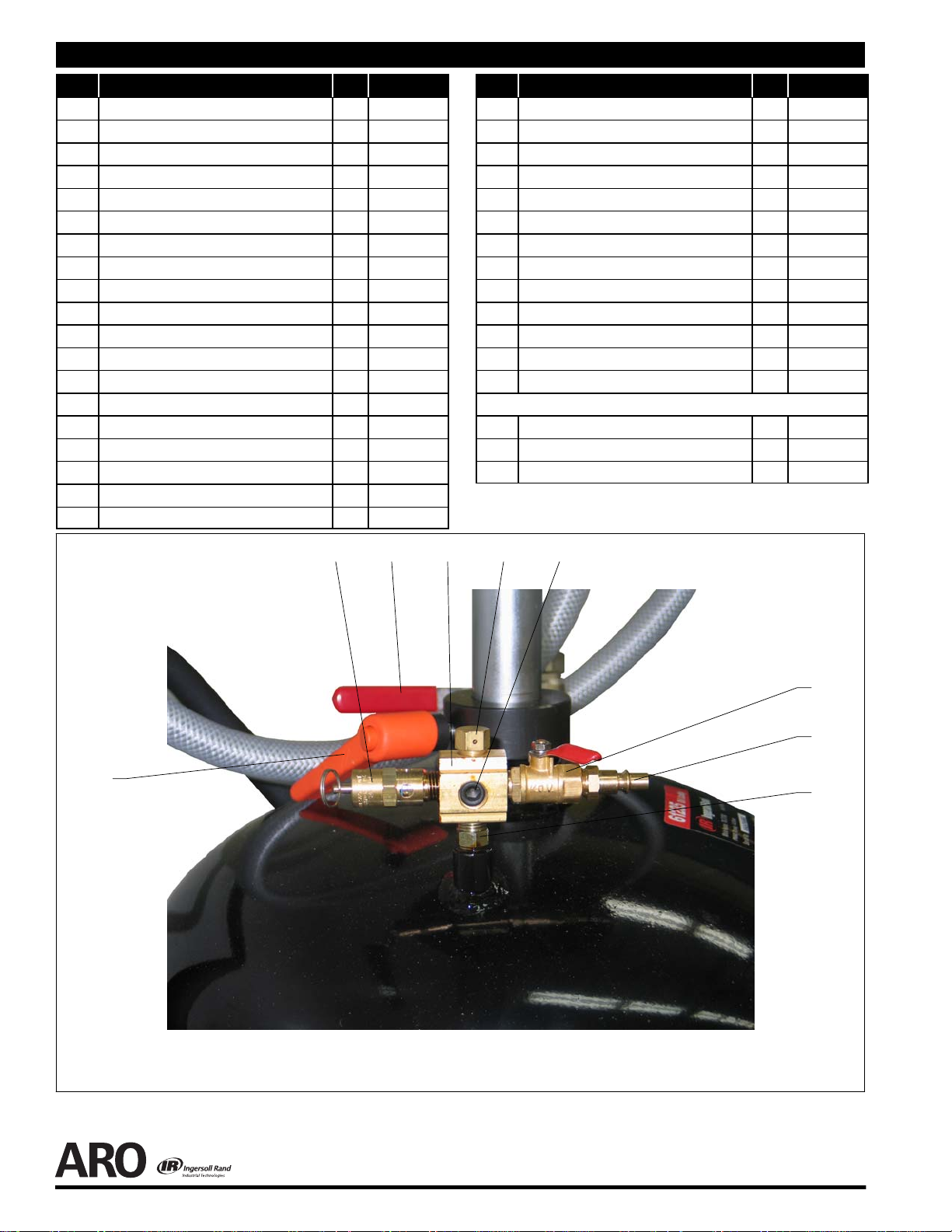

Figure 1

FLOAT VALVE SERVICE PROCEDURES

1. Depressurize system before and during servicing.

2. Wear appropriate safety equipment during servicing.

3. Remove (1) funnel from (5) tube.

4. Remove (6) thumbscrew from (7) collar.

5. Unbolt (30) handle and remove from the (18) tank.

6. Loosen the (7) collar and remove the (5) tube from the (18) tank.

7. To loosen the (7) collar, it may require the use of an industrial heat gun to soften the

pipe thread sealant on the (7) collar thread.

a. WARNING -- Do not use an open flame.

b. WARNING -- Be sure the tank vents are open during service.

c. WARNING -- Keep heat away from product labels.

8. Use a large spanner wrench or 12” pipe wrench to remove the (7) collar.

9. Secure tank when removing the collar.

10. Remove the (27) roll pin and the (25) ball from the (26) seat.

11. Remove the (26) seat by unscrewing the seat from the (5) tube.

12. Remove debrisand particulates from the(27) roll pin, (25) balland (26) seat using mild

detergent and water.

a. WARNING -- Do not use solvent, as this may damage the ball.

13. Before reassembly, apply PTFE tape to the (26) seat threads.

14. Assemble in reverse order. Apply Loctite PST or equivalent pipe thread sealant to the

(7) collar threads prior to assembly. Tighten securely.

15. Test all joints for air leakage prior to putting drain back into service.

62131

RELEASED: 10-13-04

REVISED: 5- 24-10

(REV. 05)

3

8

7

18

20

62131 PARTS LIST

Item Description (size) Qty Part No. Item Description (size) Qty Part No.

1 Funnel (includes item 4) (1) 96546

9 2 Funnel Screen (1) 96547

3 Set Screw (M6x1-6gx5mm) (1)

9 4 Wing Nut (3/8” - 18) (1)

5 Tube (includes items 3, 6, 7 and 25 - 28) (1) 96281

6 Thumbscrew (1)

7 Collar (1)

8 Hose Assembly (3/4 - 14 N.P.T. male) (1) 628094

9 Oil Shut-Off Valve (3/4 - 14 N.P .T.) (1) 10559433

10 Air Manifold Ass’y (includes items 11 - 16) (1) 10559482

11 Air Line Connector (1/4 - 18 P.T.F. male) (1)

12 Air Shut-Off Valve (1)

13 Manifold Block (1)

14 Vent (1)

15 Nipple (1/4 - 18 N.P.T.) (1)

16 Pipe Plug (1/4 - 18 N.P.T.) (1)

17 Safety Relief Valve (80 p.s.i.) (1) 72062185

18 Tank (1) 10559649

19 Rigid Caster (2) 10559466

20 Swivel Caster (2) 10559474

9 21 Cap Screw (5/16” - 18 x 1”) (16)

9 22 Washer (5/16” i.d.) (32)

9 23 Nut (5/16” - 18 NC2B) (16)

9 24 Float Valve Kit (includes items 25 and 27) (1) 67351

9 25 Ball (1” diameter) (1)

9 26 Seat (1)

9 27 Roll Pin (1)

9 28 “O” Ring (1/16” x 1-5/8” o.d.) (1)

9 29 Oil Site Glass (1 - 11-1/2 N.P.T. male) (1) 97330245

30 Handle (1) 10559458

31 Screw (1/4” - 20 x 1/2”) (4) Y6-41-C

32 Warning Label (1) 96261

ACCESSORIES

Transmission Tray 96268

Tool Tray 96269

Oil Drain Accessory Kit 621603-6

9 Items not shown.

17 169

13 14

12

11

6

15

Figure 2

PN 97999-1130

62131 (en)Page 2 of 2

Loading...

Loading...