Page 1

OPERATOR’S MANUAL

INCLUDING INSTALLATION & OPERATION

ALSO INCLUDE MANUALS 66610X-X-C (97999-100) & 67144 (97999-953)

613201-2-C Tire Fill System

Utilizing the Aro 1” Metallic Diaphragm Pump

(1:1 Ratio - Calcium Chloride Compatible)

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

613201-2-C

RELEASED: 12-13-83

REVISED: 5-13-10

(REV. D)

SERVICE KITS

Use only genuine AROR replacement parts to assure compatible

pressure rating and longest service life.

637118-C for Diaphragm Pump Air Section repair.

637119-41-C for Diaphragm Pump Fluid Section repair.

GENERAL DESCRIPTION

Operator’s Manual 66610X-X-C should be used for General Information, Installation, Operation, and Maintenance.

This pump system has been designed for the purpose of evacuating

and filling tires with calcium chloride ballast solution.

It utilizes the 67144 1” Metallic Diaphragm Pump which features an

Aluminum body and fluid manifolds, neoprene diaphragms and PTFE

balls for pumping the corrosive calcium chloride ballast solution. The

diaphragm pump has a 1:1 ratio which means the fluid outlet pressure

will be approximately equal to the available air inlet pressure. Although

the pump is capable of high volume delivery (upwards of 25 GPM at

100 PSI) filling and evacuating times will take longer due to the small

restricting diameter of the tire valve.

INSTALLATION - SET UP

The operator should make certain adequate air supply is available to

the pump, be cautious of long air lines, restrictions or other effects on

the air inlet pressure.

Assemble the hose / strainer and gun assembly to the pump (see figure

3) as shown. Be certain hoses are connected to proper sides of the siphon valve.

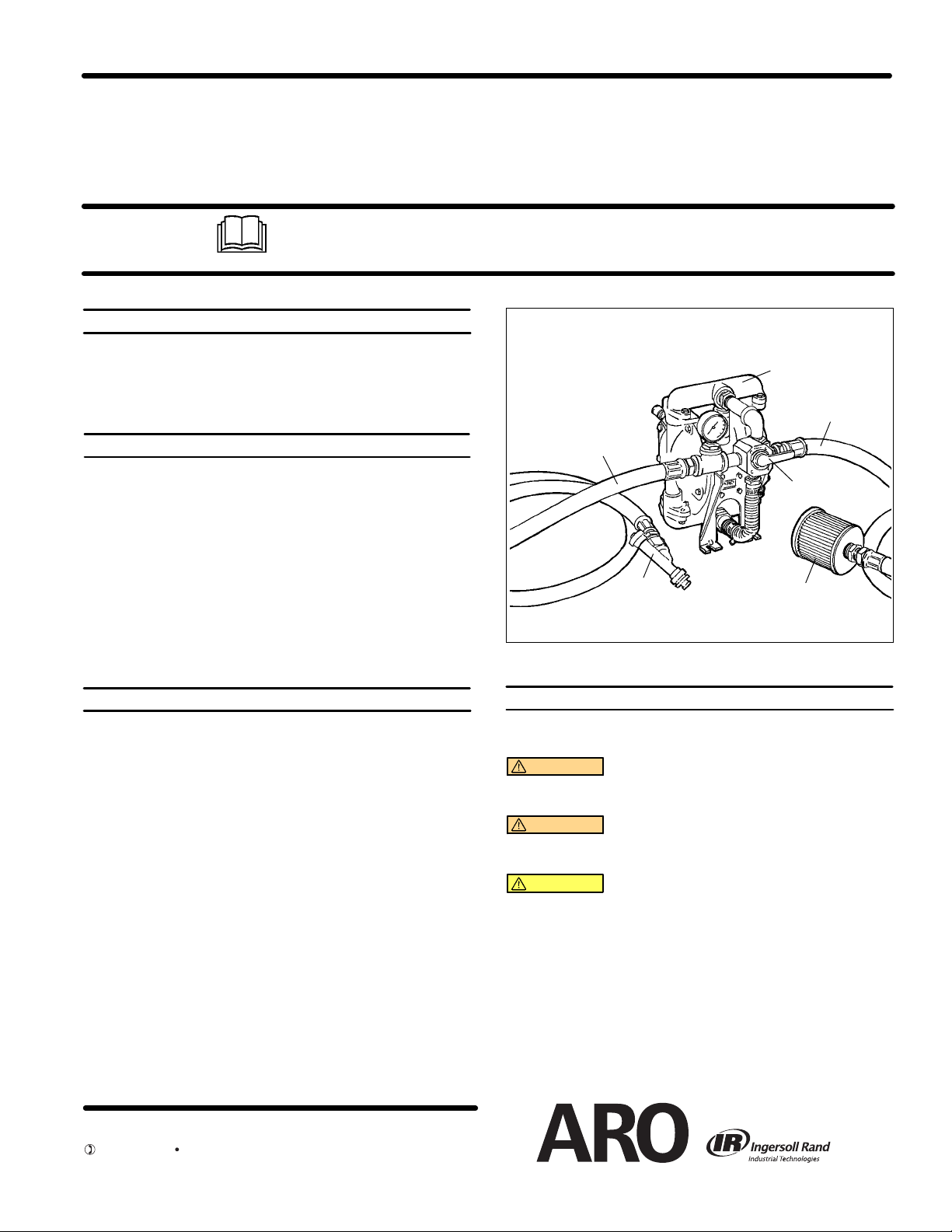

613201-2-C TIRE FILL SYSTEM

67144

Diaphragm Pump

Supply Hose

Dispensing Hose

Control Valve

Gun

FIGURE 1

Screened Inlet

SAFETY PRECAUTIONS

Z Read and heed all Warnings, Cautions, and Safety Precau-

tions before operating this pump.

WARNING DO NOT EXCEED MAXIMUM INLET AIR PRES-

SURE OF 120 PSI (8 BAR). Operating pump at higher pressure

can cause pump damage.

WARNING HAZARDOUS PRESSURE. Can result in serious

injury or property damage. Do not service or clean pump,

hoses or dispensing valve while the system is pressurized.

CAUTION Be certain all operators of this equipment have

been trained for safe working practices, understand it’s limita-

tions, and wear safety goggles / equipment when required.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX (800) 892-6276

www.ingersollrandproducts.com

© 2010

CCN 81380057

Page 2

OPERATION

WARNING DO NOT EXCEED MAXIMUM INLET AIR PRES-

SURE OF 120 PSI (8.2 Bar). OPERATING PUMP AT HIGHER

PRESSURE CAN CAUSE PUMP DAMAGE.

CONTROL VALVE OPERATION

TO FILL - TURN CONTROL VALVE LEVER CLOCKWISE

TO EVACUATE - TURN CONTROL VALVE LEVER

COUNTER-CLOCK WISE (BACK 90_)

To purge the system of air:

1. Place the hose / screen assembly into barrel or drum of material.

2. Supply air to pump and adjust the air regulator to a few pounds and

cycle pump slowly to prime system while holding gun in the fluid

container.

3. Allow the pump to continue cycling until the pump primes and the

air has been eliminated from the system.

SYSTEM OPERATION - FILLI NG TIRE

Jack up the vehicle and rotate the tire until the valve stem is located at

top of the wheel. NOTE: Adapter (D) and core remover (2) are used

only for 1-piece valves.

CAUTION: Disconnect air supply to the pump while making connection to valve stem.

CONNECTING TO VALVE STEM

To connect to 2-piece valve stem:

1. Remove the (B) adapter from the gun assembly.

2. Thread the (B) adapter onto the valve stem, finger tight.

3. Thread the swivel nut on the (B) adapter onto the gun. The (A)handle should be pulled back from the (B) adapter.

(Make sure the gasket in the (B) adapter is in place.)

REMOVING THE VALVE CORE & FILLING TIRE

1. Push the (A) handle in until it makes contact with valve core.

2. Hold the gun ass’y. with one hand and hit the (A) handle with the

other, driving the core remover onto the valve core.

3. Turn the (A) handle counter-clockwise and completely un-thread

the core from valve stem.

4. Pull the (4) handle all the way back from valve stem. Move the handle of the siphon valve to FILL position, fill tire.

Periodically check pressure in tube. The tube will be about 2/3 full

when pressure reaches 30 lbs.

5. Move the handle of the siphon valve to EVACUA TE position

(counter-clockwise) until air bubbles stop coming up in liquid container. Continue filling the tire until recommended volume or

weight is reached.

DISCONNECTING AFTER FILLING TIRE

1. Shut pump of f. Place valve core into valve stem with (4) handle.

2. Turn(4) handle of gun to the right or clockwise threading valve core

into valve stem tightly.

3. Pull the (4) handle back from valve stem. Then turn handle of siphon valve to EVACUATE position. Remove gun ass’y and (B)

adapter from valve stem.

PROPER TIRE PRESSURE

Inflate tire to 8 - 10 psi above recommended tire pressure.

With valve stem at top bleed until it is 1 or 2 psi above recommended

tire pressure.

Let vehicle off jack, with valve stem located at bottom of the wheel

check pressure with an air-water gauge.

REMOVING FLUID FROM TIRE

1. Jack up the vehicle, rotate the tire so that the valve stem is at the

bottom of the wheel.

2. Connect the gun to the valve stem (see Connecting to ValveStem).

3. After connection has been made remove the valve core (see Filling

Tire Instructions).

4. Start pump, turn handle of siphon valve to EVACUA TE position.

Continue to run pump until fluid level in container no longer increases, then shut pump off.

5. Place valve core into valve stem and remove the gun (see Disconnecting Instructions).

MAINTENANCE

The air line should be disconnected from the air motor if the pump

sets idle for long periods of time.

Periodically clean and inspect the material screen asm.

PAG E 2 OF 4

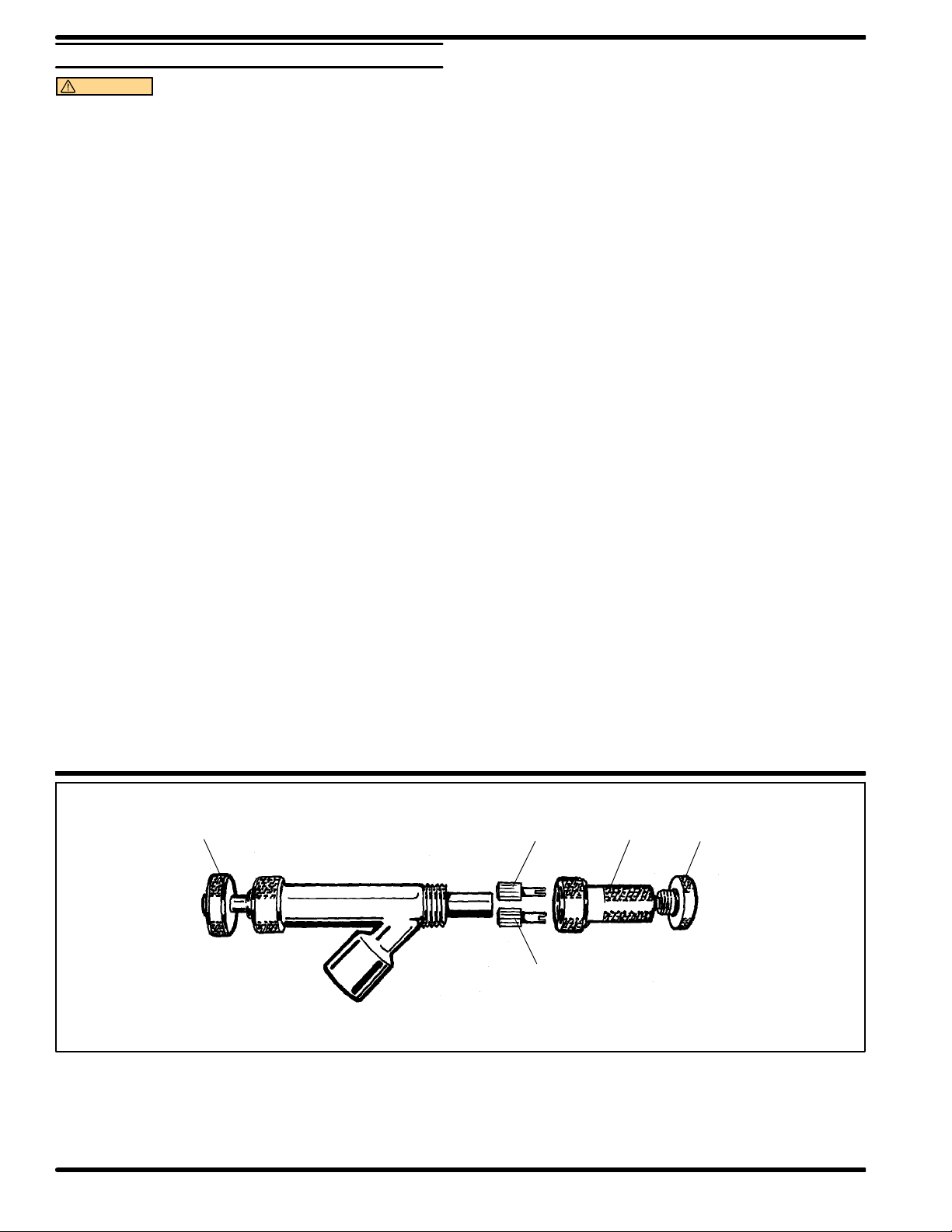

FIGURE 2

66239 GUN ASM.

A

B*

B*

* Choose the proper core remover to fit the valve core.

C

D

613201-2-C

Page 3

GROUND LUG

613201-2-C TIRE FILL SYSTEM

FIGURE 4

12

13

14

11

10

66239 GUN

SEE FIG. 2

1

2

3

POSITION

LEVER

4

FILL - EVACUATE

5

6

7

8

17

9

15

16

2

FIGURE 3

613201-2-C PARTS LIST

ITEM DESCRIPTION (Size in inches) (QTY) PART NO.

1 Gauge (1) 73338 10 Fitting (3/4) (1) Y43-135

2 Reducing Bushing (1 x 3/4) (3) Y45-213 11 Bushing (3/4 x 1/4) (1) Y45-207

3 Nipple (3/4 x 4) (1) Y44-345 12 Nipple (1) 1950

4 Elbow (3/4) (1) Y43-105 13 Union (1) 75364

5 Control Valve Assembly (1) 60155 14 Check Valve (Regulator) (1) 104104-NS2

6 Nipple (3/4) (1) Y27-25 15 Connector (3/4 x 1/2) (1) Y167-14

7 Insert (2) 76958 16 Material Strainer (1) 79198

8 Clamp (2) 61204-1 17 Hose Assembly (10 Ft) (2) 622651-10

9 Tubing (1) 72255-8-H Gun Assembly (See Fig 2) (1) 66239

613201-2-C

ITEM DESCRIPTION (Size in inches) (QTY) PART NO.

PAG E 3 OF 4

Page 4

PAG E 4 OF 4

PN 97999-441

613201-2-C

Loading...

Loading...