Ingersoll-Rand 612729 User Manual

OPERATOR’S MANUAL

INCLUDING: SERVICE KITS, GENERAL DESCRIPTION & TROUBLESHOOTING

ALSO INCLUDE MANUALS: 662420-B BASIC PUMP MANUAL (PN 97999-108)

& S-632 GENERAL INFORMATION (PN 97999-624).

612729

RELEASED: 12-1-64

REVISED: 1-18-11

(REV. F)

4-1/4” AIR MOTOR

OIL SUPPLY PUMP

9:1 RATIO

4” STROKE

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

• 61268 for repair of Air Motor section.

• 61053 for repair of entire pump.

• 65823 for repair of Base Packing.

• Use only genuine AROR replacement parts to assure compatible

pressure rating and longest service life.

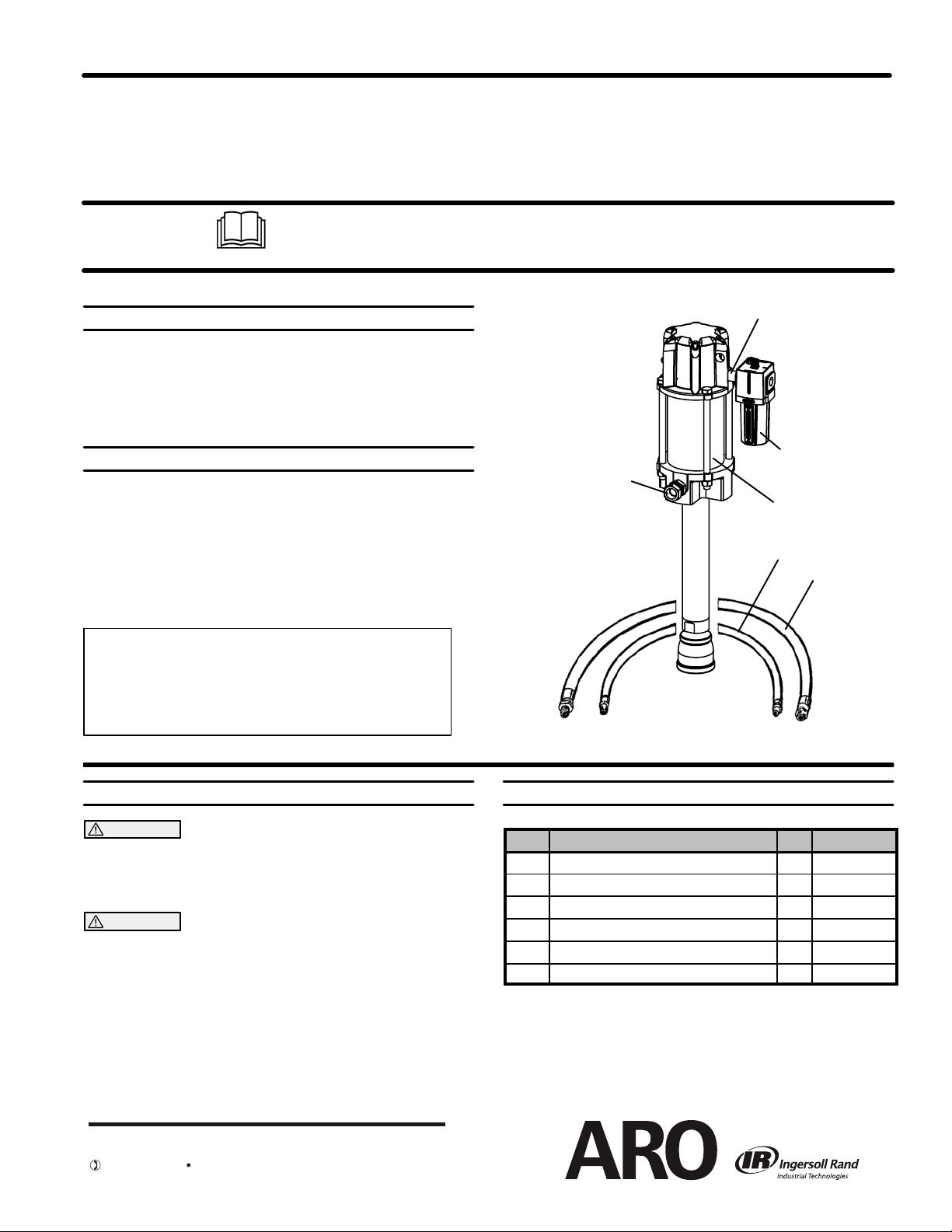

GENERAL DESCRIPTION

This model is designed for high volume delivery of low viscosity fluids

from standard containers. The model covered by this manual includes

an outlet swivel, material supply hoses and airline lubricator. Material

dispensing accessories and supply lines and fittings must be capable of

withstanding pressures developed by the pump.

• The AROR 9:1 ratio basic pump assembly consists of4-1/4” air mo-

tor and two ball lower pump end.

STUB

1

4

8

5

7

6

INLET PRESSURE TO PUMP MOTOR

PUMP RATIO X

Pump ratio is an expression of the relationship between the pump motor area and

the lower pump end area. EXAMPLE: When 150 p.s.i. (10 bar) inlet pressure is

supplied to the motor of a 9:1 ratio pump it will develop a maximum of 1350 p.s.i.

(93 bar) fluid pressure (at no flow) -- as the fluid control is opened, the flow rate will

increase as the motor cycle rate increases to keep up with the demand.

MAXIMUM PUMP

=

FLUID PRESSURE

AIR AND LUBE REQUIREMENTS

WARNING

mum inlet air pressure of 150 psi (10 bar). Operating pump at

higher pressure may cause pump damage and/or personal injury and/or property damage.

WARNING

safety precautions and important information.

HAZARDOUS PRESSURE. Do not exceed maxi-

Refer to general information sheet for additional

• Excessive air pressure will shorten the life of the pump.

• Formaximum operating efficiency,the followingair supply specifica-

tions should be maintained to this pump.

• AIR PRESSURE - Up to 150 P.S.I. (10 Bar)

• AIR FILTRATION - 50 micron

• LUBRICATED AIR SUPPLY

• AIR INLET SIZE - 1/2” NPTF

ACCESSORIES LIST

ITEM Description Qty Part No.

1 Nipple(1/2x1-1/8) 1 Y27-154-C

4 Lubricator + 1 L36341-110

5 Basic Pump + 1 662420-B

6 Material Hose 1 624601-4

7 Air Hose 1 621501-3

8 Swivel 1 75367

+ SEE OPERATOR’S MANUAL

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276

www.ingersollrandproducts.com

FAX(800) 892-6276

© 2011

AIR AND LUBE REQUIREMENTS (cont)

TROUBLE-SHOOTING

• Filtered and oiled air will allow the pump to operate more efficiently

and yield a longer life to operating parts and mechanisms.

• Lack of or an excessive amount of lubrication will affect the perfor-

mance and life of this pump. Use only recommended lubricants.

• DAILY Fill air line lubricator with a good grade of S.A.E. NO. 90W

non-detergent gear oil, adjust to 1 to 2 drops per minute.

• If pump is to be inoperative for more than a few hours at a time, dis-

connect air supply and relieve all pressure from the system.

It is recommended that an oiler be installed inthe air line asclose as possible to the pump. This increases the service lifeof the pump by reducing

wear of the air motor’s internal parts.

Should pump operate, but dispense little or no material, check for:

• Inadequate supply of material or possible malfunctioning of 77006

Foot Valve which would prevent material from feeding into suction

tube.

• Dirt or foreign matter in 77006 Foot Valve or other cause which may

be preventing it from closing on downstroke of piston.

If unit should fail to operate, the following procedure will be helpful in determining the cause:

• Check air pressure at pump to insure air line is notobstructed and air

is being supplied to pump.

• If insufficientair is not the trouble, disconnect air supply to pump and

then detach Hose andGun at75367 Swivel.REMOVE SLOWLYAS

PRESSURE MAYBE BUILTUP IN PUMP.Hold rag at this point and

apply air to pump. If pump now operates, there is obstruction in material line,reel, or control handle.If, however,pump will still not operate, consult local dealer,

PN 97999-420

6127292OF2

Loading...

Loading...