Page 1

InfoPrint 6700 Series Thermal Printer

TGLTM Programmer’s Reference Manual

G550-0979-03

Page 2

Page 3

InfoPrint 6700 Series Thermal Printer

TGLTM Programmer’s Reference Manual

G550-0979-03

Page 4

Note!

Before using this information and the product it supports, read the information in “Notices” on

page 33.

Fourth Edition (January 2010)

This edition applies to the InfoPrint 6700 Series Thermal Printer and replaces the following

publication:

G550-0979-02.

Visit our home page at: http://www.infoprint.com

You can send comments by e-mail to printpub@infoprint.com or by mail to:

InfoPrint Solutions Company, LLC

6300 Diagonal Hwy 002J

Boulder, CO 80301-9270

U.S.A.

This product is or contains commercial computer software and commercial computer software

documentation developed exclusively at private expense. As specified in Federal Acquisition

Regulation 12.212 in the case of civilian agencies and Defense Federal Acquisition Regulation

Supplement 227.7202 in the case of military agencies, use, duplication and disclosure by agencies

of the U.S. Government shall solely be in accordance with the accompanying International

Program License Agreement in case of software products and in accordance with the licensing

terms specified in the product’s documentation in the case of hardware products.

© Copyright InfoPrint Solutions Company 2007, 2010. All rights reserved.

InfoPrint 6700 Series Thermal Printer: TGLTM Programmer’s Reference Manual,

Internet

Page 5

Table of Contents

1 Introduction ........................................................... 7

About This Manual................................................................................. 7

TGL SETUP Menu................................................................................. 8

TGL SETUP Submenus .................................................................. 9

Active ........................................................................................ 9

Character Set............................................................................ 9

Slash Zero ................................................................................ 9

Image Scale .............................................................................. 9

SFCC Select ............................................................................. 9

SFCC ........................................................................................ 9

SFCC Separator ..................................................................... 10

SFCC Terminator.................................................................... 10

EURO Symbol ........................................................................ 10

Speed CMDs .......................................................................... 10

AY Intensity CMD ................................................................... 10

U1/U2 Move CMDs ................................................................. 10

XS Sensor Param ................................................................... 11

XS Media ‘C’ Act ..................................................................... 11

XS Media ‘D’ Act ..................................................................... 11

AR Pre-Feed CMD.................................................................. 11

AX Fine Adj. CMD................................................................... 11

Page Alignment ...................................................................... 12

Vert. DPI Adjust ...................................................................... 12

Status Response .................................................................... 12

2 Fully Supported Commands ............................... 13

AR – Pre-Feed ........................................................................ 13

AX – Position Fine Adjustment ............................................... 13

AY – Print Density Fine Adjustment........................................ 13

C – Image Buffer Clear ........................................................... 13

D – Label Size Set .................................................................. 13

D..E – Label Length Set.......................................................... 13

IB – Eject ................................................................................ 13

J1 – Flash Format ................................................................... 13

LC – Line Format .................................................................... 14

PC – Bitmap Font Format ....................................................... 14

Page 6

Table of Contents

PV – Outline Font Format ....................................................... 15

RB / rB – Barcode Data .......................................................... 15

RC / rC – Bitmap Font Data .................................................... 16

RV / rV – Outline Font Data .................................................... 16

SG – Graphic .......................................................................... 16

SG0 / SG1 – Graphic .............................................................. 16

T – Feed ................................................................................. 16

U1 / U2 – Forward/Reverse Feed ........................................... 16

WS – Status Request Command............................................ 17

XB – Barcode Format ............................................................. 17

XD – Bitmap Writable Character............................................. 18

XJ – Message Display ............................................................ 18

XO – Save Start ...................................................................... 19

XP – Save Terminate.............................................................. 19

XQ – Saved Data Call............................................................. 19

XR – Clear Area...................................................................... 19

XS – Issue .............................................................................. 19

i / iN – Issue ............................................................................ 19

3 Ignored Commands............................................. 21

HD – Head Broken Dots Check .............................................. 21

RM – Ribbon Motor Drive Voltage Adjust ............................... 21

WR – Reset ............................................................................ 21

WS – Status Request ............................................................. 21

4 Command Enhancements And Differences........ 23

J1 – Flash Format................................................................... 23

~LI – Listen Mode ................................................................... 23

T – Feed ................................................................................. 23

XB – Barcode.......................................................................... 23

XS – Issue .............................................................................. 23

~QU – Quiet Mode.................................................................. 23

A TGL Menu Conversions ...................................... 25

B Status Response................................................. 29

Serial And Ethernet Interface............................................................... 29

Notices ................................................................ 33

Page 7

1 Introduction

About This Manual

This manual explains the differences between the Printer Protocol Interpreter

®

TEC

Graphic Language (TGL) Utility and the TEC printer language. If you

have a 6700 printer use this manual with your

for complete printer-protocol operation. If you have a 6700-M40 printer use

this manual with your

Subtle enhancements to the 6700 printer (models 5504-Rxx) were made in

late 2009. Printers manufactured prior to this date are referred to as "older

6700 printers" throughout this manual. Older 6700 printers do not have the

letter "J" as the third character in the printer's serial number.

NOTE: When substituting a TEC B-470/870 model printer with a 6700 or

6700-M40 printer, refer to TGL Menu Conversions on page

InfoPrint 6700 User’s Manual

InfoPrint 6700-M40 User’s Manual

.

25.

7

Page 8

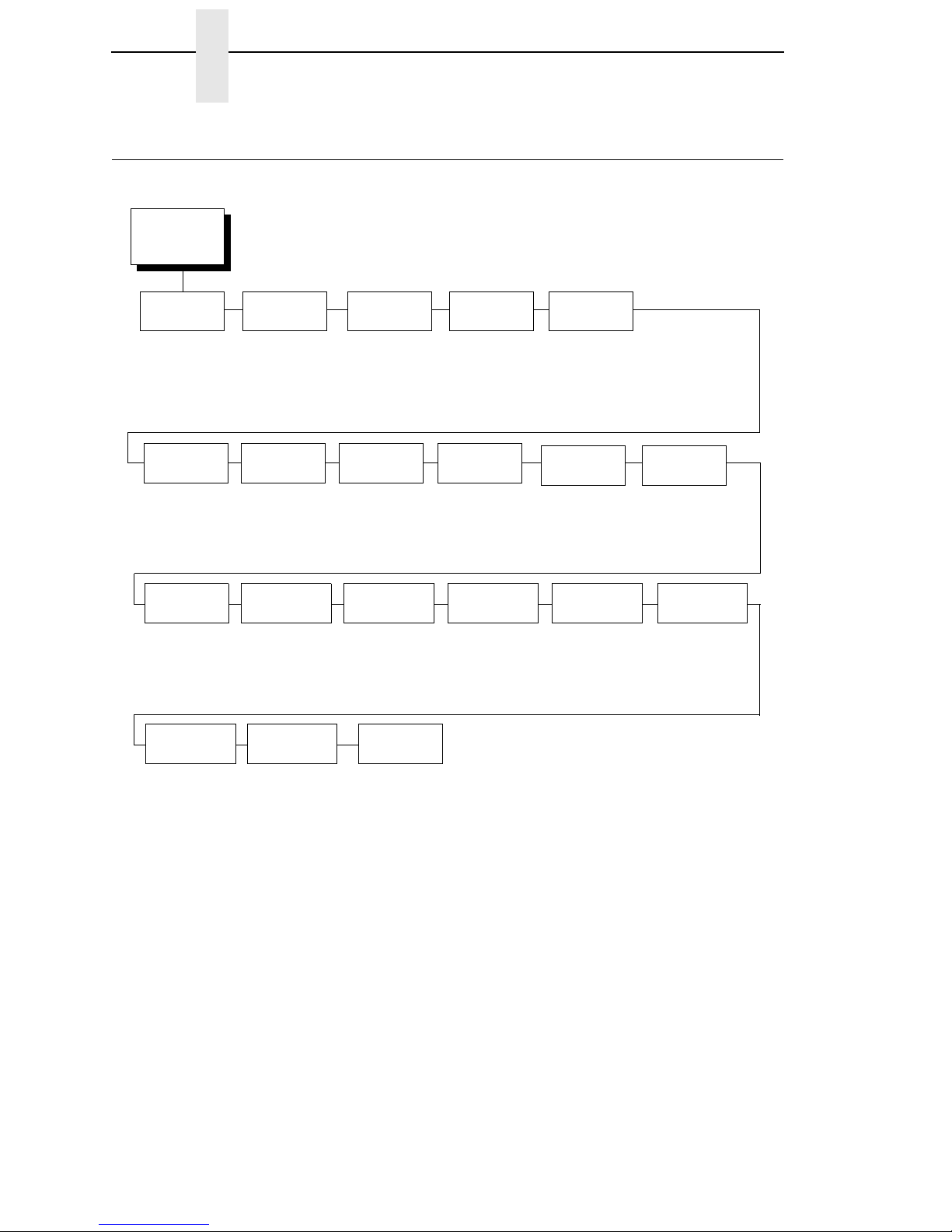

Chapter 1 TGL SETUP Menu

TGL SETUP Menu

TGL SETUP

Yes*

No

0x7B*

0x0 - 0xFF

U1/U2 Move

Process*

Ignore

1

Active Character

PC-850*

PC-8

8859-2 Latin 2

2

SFCC

0x7C*

0x0 - 0xFF

CMDs

Process*

Ignore

Set

SFCC

Separator

XS Sensor

Param

2

Slash Zero

Disable*

Enable

SFCC

Terminator

0x7D*

0x0 - 0xFF

XS Media

‘C’ Act

Continuous*

Tear-Off Strip

Tear Off

Peel Off

4

Ignore

2

Disable*

Enable

0xB0*

0x20 - 0xFF

Tear Off*

Peel Off

Ignore

Continuous

Tear-Off Strip

Image

Scale

Euro

Symbol

XS Media

‘D’ Act

SFCC

Select

Auto Select*

<ESC><LF><NULL>

{|}

User Defined

Speed

CMDs

Process*

Ignore

AR Pre-Feed

CMD

4, 5

Ignore

6

Process*

AY Intensity

CMD

Process*

Ignore

AX Fine Adj.

Process*

Ignore

CMD

8

Alignment

Center*

Left

Right

Page

Vert. DPI

Adjust

0*

-100 to 100

5

Status

Response

Disable*

On Request Only

On Request+Auto

Notes:

* = Default

For 6700 printers, italicized items are available only when you

enable Admin User in the PRINTER CONTROL menu.

For 6700-M40 printers, the TGL Setup Menu is available only

when you enable Admin User in the PRINTER SETUP menu.

1

When substituting a TEC B-470/870 model printer with a

6700 printer, refer to the menu conversion in Appendix F.

2

These menus are available only when you select User

Defined in the SFCC Select menu.

3

Available for 6700-M40 printers only.

4

Available for 6700 printers only.

5

Default option on 6700 printers.

6

Default option on 6700-M40 printers.

Page 9

TGL SETUP Submenus

TGL SETUP Submenus

Active

• Yes (default). When enabled, all data is parsed by the TGL emulation.

Non-TGL data is absorbed.

• No. When disabled, non-TGL text data prints.

Character Set

Selects the character set: either PC-850, PC-8, or 8859-2 Latin 2. The factory

default is PC-850.

Slash Zero

• Enable. When enabled, the zero character is overlaid with a slash

character.

• Disable (default). If disabled, the zero character does not have a slash

character.

Image Scale

• Enable. When enabled, images are scaled from TEC printer resolution

(306 dpi) to the resolution of the TGL printer (300 dpi).

• Disable (default). If disabled, scaling will not take place, resulting in

images that are 2% larger than images printed on the TEC printer.

Printing is faster though, and the image keeps the right proportions.

SFCC Select

Use this menu to select the SFCC, SFCC-Separator, and SFCC-Terminator

sets.

• Auto Select (default). The printer selects the SFCC set based upon the

received host data.

• <ESC><LF><NULL> is a predefined set. The ESC character is the

SFCC, the LF is the SFCC-Separator, and the NULL character is the

SFCC-Terminator.

• { I } is a predefined set. The { character is the SFCC, the I is the SFCC-

Separator, and the } character is the SFCC-Terminator.

• User Defined. When you select User Defined, three additional menus

appear in the tree. These menus allow the SFCC, SFCC-Separator, and

SFCC-Terminator to be configured individually.

SFCC

This menu is only present when “User Defined” is selected in the SFCC

menu. Using this menu, the SFCC can be set to any value between 0x0 and

0xFF. The factory default is 0x7B.

9

Page 10

Chapter 1 TGL SETUP Menu

SFCC Separator

This menu is only present when “User Defined” is selected in the SFCC

menu. SFCC-Separator can be set to any value between 0x0 and 0xFF. The

factory default is 0x7C.

SFCC Terminator

This menu is only present when “User Defined” is selected in the SFCC

menu. SFCC-Terminator can be set to any value between 0x0 and 0xFF.

The factory default is 0x7D.

EURO Symbol

This menu allows you to configure the position of the EURO symbol in the

code pages. EURO Symbol can be set to any value between 0x20 and 0xFF.

The factory default is 0xB0.

Speed CMDs

This option allows you to choose whether the engine commands that affect

the print/feed speed should be processed or ignored. To adjust the print/feed

speed through the front panel, use this menu to prevent the host commands

from overriding these settings. When you select “Ignore,” TGL ignores the

following commands or command parameters:

• The print speed parameter in the XS command. The parameter will have

no effect; the “Print Speed” value as configured in the “MEDIA

CONTROL” menu will be used.

• The feed speed parameter in the T command. The parameter will have no

effect; the “Slew Speed” value as configured in the “MEDIA CONTROL”

menu will be used.

The factory default is Process.

AY Intensity CMD

This option allows you to choose whether the engine command to set the print

intensity (AY) should be processed or ignored. If you want to adjust the print

intensity through the front panel, use this menu to prevent the host commands

from overriding these settings. When you select “Ignore,” the AY command

will be ignored and “Print Intensity” as configured in the “MEDIA CONTROL”

menu will be used.

The factory default is Process.

U1/U2 Move CMDs

This option allows you to choose whether the engine command to move

paper forward (U1) or backward (U2) will be processed or ignored. When you

select “Ignore,” the paper will not be moved when either command is

received.

The factory default is Process.

10

Page 11

TGL SETUP Submenus

XS Sensor Param

This option allows you to choose whether the sensor type parameter in the XS

command will be processed or ignored. When you select “Ignore” TGL will

use the sensor type as configured through “Gap/Mark Sensor” under the

“CALIBRATE CTRL” menu.

The factory default is Process.

XS Media ‘C’ Act

This option defines which media mode TGL will operate on receipt of a ‘C’

(strip mode) for the issue mode parameter in the XS command. Any of the

supported media modes can be selected. When you select “Ignore,” TGL will

use the issue mode as configured through “Media Handling” under the

“MEDIA CONTROL” menu.

The factory default is Continuous.

XS Media ‘D’ Act

This option defines which media mode TGL will operate on receipt of a ‘D’

(strip mode) for the issue mode parameter in the XS command. Any of the

supported media modes can be selected. When you select “Ignore,” TGL will

use the issue mode as configured through “Media Handling” under the

“MEDIA CONTROL” menu.

Tear-Off is the default for 6700 printers. Tear-Off Strip is the default for

6700-M40 printers.

AR Pre-Feed CMD

This option allows you to choose whether the engine command for a paper

pre-feed (AR) should be processed or ignored. When you select “Ignore,” the

paper will not pre-feed.

The factory default is Process.

AX Fine Adj. CMD

This option allows you to choose whether the engine command for a position

fine adjust (AX) should be processed or ignored. When you select “Ignore,”

the paper will not fine-adjust.

The factory default is Process.

11

Page 12

Chapter 1 TGL SETUP Menu

Page Alignment

This menu is used to define the alignment of the image on the page. If set to

Center, the image will be centered on the page, using the page width set in

the configuration. For example, if the image is 4 inches wide, and the label

width is 6 inches, a 1 inch margin is applied to the left and right sides of the

image.

If set to Left the image will align to the left side. When the label is printed in

portrait mode (top of label comes out first), the left side is the right side of the

label when standing in front of the printer. If the label is printed in inverted

portrait mode (bottom of label comes out first), left is also the left side of the

label when standing in front of the printer.

If set to Right the image will align to the right side. When the label is printed in

portrait mode (top of label comes out first), the right side is the left side of the

label when standing in front of the printer. If the label is printed in inverted

portrait mode (bottom of label comes out first), right is also the right side of the

label when standing in front of the printer.

The factory default is Center.

Vert. DPI Adjust

NOTE: Applies to 6700-M40 and older 6700 printers only.

This option fine adjusts the resolution used to convert the coordinates of page

elements (barcodes, font fields, graphic images, lines and boxes). The

coordinates received from the host are in 1/10 mm and are converted to

engine resolution (203 or 300 dpi). In cases where the printed image length is

incorrect, the vertical resolution value TGL uses for calculations can be fine

adjusted between –100 and +100. Negative values result in a lower DPI value

and thus a longer image. Positive values result in a higher DPI value and thus

a shorter image. Note that this adjustment does not affect the size of fonts

and barcodes, only the coordinates.

The factory default is 0.

Status Response

This option selects when a status response is sent back to the host. This

menu contains the following options:

• Disable. No status response will be sent to the host.

• On Request Only. A status response is sent to the host only after

receiving the WS command.

• On Request+Auto. A status response is sent to the host after receiving

the WS command, or automatically when specific conditions are met.

See Appendix B on page 29 for details.

The factory default is Disable.

When this menu item is enabled (Set to 'On Request Only' or

'On Request+Auto'), IGP Windows Drivers cannot be utilized.

For 6700 printers, the TN Protocol cannot be utilized.

12

Page 13

2 Fully Supported

Commands

AR – Pre-Feed

This legacy command sets the feed length in successive mode.

AX – Position Fine Adjustment

This command configures the feed, cut/strip, and back feed distances.

AY – Print Density Fine Adjustment

This command adjusts the print density.

C – Image Buffer Clear

This command clears the image buffer.

D – Label Size Set

This command defines the pitch, effective print width, and effective print

length of a label in 1/10 mm units. Any label printed on continuous media will

move the pitch length of media.

D..E – Label Length Set

This legacy command defines the pitch and gap length of a label in 1/10 mm

units. It does not define the label width. Any label printed on continuous media

will move the pitch length of media.

IB – Eject

This command ejects the current label.

J1 – Flash Format

This command formats the sections in flash memory where the host data

(through XO, XP commands) or bitmap graphic characters (through XD

command) are stored.

13

Page 14

Chapter 2

LC – Line Format

Using this command, lines or squares can be drawn in the drawing space.

Coordinates are specified in 1/10 mm units. Squares can have rounded

corners. If the radius is set higher than the square width and height, circles

can be drawn.

PC – Bitmap Font Format

This command formats bitmap font fields. The location coordinates are

specified in 1/10 mm units. The font type can be set to any of the types listed

in

Table 1. Attributes like expansion and reverse can be applied. Data to be

printed can be included in this command or supplied separately through the

RC command.

Table 1.

Parameter Font Attributes Size

A Times Roman medium 8 point

B Times Roman medium 10 point

C Times Roman bold 10 point

D Times Roman bold 12 point

E Times Roman bold 14 point

F Times Roman italic 12 point

G Helvetica medium 6 point

H Helvetica medium 10 point

I Helvetica medium 12 point

J Helvetica bold 12 point

K Helvetica bold 14 point

L Helvetica italic 12 point

M Presentation bold 18 point

N Letter Gothic medium 9.5 point

O Prestige Elite medium 7 point

P Prestige Elite medium 10 point

Q Courier medium 10 point

R Courier bold 12 point

S OCR-A 12 point

T OCR-B 12 point

14

Page 15

Table 1. (continued)

Parameter Font Attributes Size

01 ... 40 Writable char. 1 …

Writable char. 40

1 x 1 dot to 720 x 720

dots

PV – Outline Font Format

This command formats outline (scalable) font fields. The location coordinates

are specified in 1/10 mm units. The font type can be set to either a fixed pitch

or a proportional font. The fonts are printed at the configured size in 1/10 mm

units. Data to be printed can be included in this command or supplied

separately through the RV command.

If a scalable font with Font-ID H, I, or J (as supported on newer TEC printers)

is required, the font must be downloaded to the printer first. To ensure that the

size and pitch matches the output of TEC printers, the font must be bought at

www.myfonts.com, and converted to a download file using the cnvt2fls utility.

Use following table to select the correct font(s) and printer file name.

FontID Font Name www.myfonts.com Flash File

H Dutch 801 BT (OpenTtype TTF) Dutch801.ttf

I Brush 738 (OpenTtype TTF) Brush 738.ttf

J Gothic 725 Black (OpenTtype TTF) Gothic725.ttf

Usage of cnvt2fls utility: cnvt2fls file_name1 file_name2 file_name3 A FONT

<return>

file_name1: Input file name to be converted from

(the filename used by myfonts.com, e.g. tt0013m_.ttf )

file_name2: Output file name for file download

(download filename e.g. Dutch.dnl )

file_name3: Flash file name (as shown in table above, e.g. Dutch801.ttf )

hw_type: Specify A.

FONT: Optional, specify FONT.

Place the printer in download mode and send the converted file

(e.g. Dutch.dnl). The font will appear in the flash file system with the printer

name (e.g. Dutch801.ttf), and can be used through the PV command.

RB / rB – Barcode Data

This command supplies data for a barcode field configured by the XB

command. The data will replace the data supplied with the XB command or

with a preceding RB command.

15

Page 16

Chapter 2

RC / rC – Bitmap Font Data

This command supplies data for a bitmap font field configured by the PC

command. The data will replace the data supplied with the PC command or

with a preceding RC command.

RV / rV – Outline Font Data

This command supplies data for an outline font field configured by the PV

command. The data will replace the data supplied with the PV command or

with a preceding RV command.

SG – Graphic

This command is used to draw graphics. The location and size of the image

are specified in 1/10 mm units. Six modes are supported: Nibble mode

(Overwrite), Hex mode (Overwrite), Bitmap (.BMP) mode, Topix Compression

mode, Nibble mode (OR), and Hex mode (OR).

NOTE: A configuration setting (Scale Image) is provided to scale the images

drawn with this command in order to exactly match the size of images

on TEC printers (Scaling 306 > 300 dpi).

SG0 / SG1 – Graphic

These are two legacy commands that were supported on older TEC models.

The commands are used to draw graphics. The location of the image is

specified in 1/10 mm units. The size is specified in multiples of 8 dots. For

example, a width of 3 and a height of 2 will draw an image of 24 x 16 dots.

T – Feed

This command feeds one label of the size set by the D command. Parameters

specify the feed speed, sensor to be used, etc.

U1 / U2 – Forward/Reverse Feed

This command moves the media forward (U1) or reverse (U2) over the

specified distance in 1/10 mm units.

NOTE: For 6700-M40 printers, the Backward Feed is limited to a maximum of

1 inch. The valid range for this parameter on the 6700-M40 is

0030 to 0254 (in 0.1 mm units).

16

Page 17

WS – Status Request Command

This command tells the printer to send its own status to the host computer.

The transmitted status is the current printer status, and indicates the latest

status only. The remaining count indicates the remaining batch count

currently being printed.

NOTE: The remaining batch count waiting to be printed is NOT transmitted.

Syntax: ESC WS LF NULL

Parameters:none

Response Format: See “Status Response” on page 12.

NOTE: The status request command is effective on serial (RS-232C) and

Ethernet interfaces only. Since the status cannot be sent via the

parallel interface (Centronics), this command is ignored.

After the code of the writable character command (XD) or the graphic

command (SG) is received, the status request command is not

processed until the printer receives the data type.

XB – Barcode Format

This command formats barcode fields. The location coordinates are specified

in 1/10 mm units. Many parameters of the barcode can be configured, like bar

and space widths, if and how the PDF must be printed, etc. The barcode

types listed in

this command or supplied separately through the RB command.

Table 2 can be printed. Data to be printed can be included in

Table 2.

Parameter Type of Barcode

0 JAN8, EAN8

1 MSI

2 Interleaved 2 of 5

3 CODE39 (standard)

4 NW7 (coda bar)

5 JAN13, EAN13

6 UPC-E

7 EAN13 + 2 digits

8 EAN13 + 5 digits

9 CODE128 (with auto code selection)

A CODE128 (without auto code selection)

B CODE39 (full ASCII)

C CODE93

17

Page 18

Chapter 2

Table 2. (continued)

Parameter Type of Barcode

G UPC-E + 2 digits

H UPC-E + 5 digits

I EAN8 + 2 digits

J EAN8 + 5 digits

K UPC-A

L UPC-A+ 2 digits

M UPC-A + 5 digits

N UCC/EAN128

O Industrial 2 of 5

P PDF417

Q Data Matrix

T QR

U POSTNET (for US)

V RM4SCC (for UK)

W KIX CODE

X MicroPDF417

Z Maxicode

b RSS

XD – Bitmap Writable Character

This command downloads bitmap characters or logos into the flash memory

of the printer. User-defined character sets 01 to 40 have been reserved for

this. After downloading, the characters or logos can be printed through the

PC/RC commands.

XJ – Message Display

This command displays a message on the LCD of the printer’s front panel.

Since TEC printers have a 20-character display, and TGL printers have two

lines of 16 characters each, any text exceeding 16 characters is word

wrapped to the second line on the LCD. The message disappears when the

ONLINE key is pressed.

18

Page 19

XO – Save Start

After this command is received, all subsequent commands will be stored in a

file in flash memory until the save terminate command (XP) is received. The

ID in this command specifies the file name. The files can later be loaded from

flash and executed as host data using the XQ command.

XP – Save Terminate

This command terminates the saving of data into a file in flash memory.

Saving into a file is started through the XO command.

XQ – Saved Data Call

This command loads a saved file from flash memory and executes it as host

data. Files are saved in flash memory using the XO and XP commands.

XR – Clear Area

This command clears or inverts a specified area in the drawing space. The

area coordinates are specified in 1/10 mm units.

XS – Issue

This command prints the label. Several parameters are provided which

configure the print settings: speed, sensor type, and copy-count.

i / iN – Issue

This legacy command prints the label. If N is provided, a copy count can be

specified.

19

Page 20

Chapter 2

20

Page 21

3 Ignored Commands

HD – Head Broken Dots Check

This command is used to check the print head for broken dots. This command

is accepted but ignored, because TGL printers do not have the hardware

facilities for checking the thermal head. On TEC printers, data processing is

continued when no broken dots are found. The TGL emulation will always

behave as if no broken dots were found.

RM – Ribbon Motor Drive Voltage Adjust

This command is used to adjust the ribbon motor voltages. It is accepted but

ignored, because TGL printers have a closed loop to control the motor

voltages. Adjustment through host control is therefore not necessary.

WR – Reset

This command resets the printer to its power-on state.

WS – Status Request

This command sends the printer status to the host.

21

Page 22

Chapter 3

22

Page 23

4 Command Enhancements

And Differences

J1 – Flash Format

Similiar to TEC printers, the flash files are removed, but the flash memory is

not formatted. To reuse the flash memory, an optimize and reboot action is

required.

~LI – Listen Mode

This command is not supported on TEC printers. It allows the TGL emulation

to become active again after it has been put in quiet mode through the ~QU

command.

T – Feed

The ribbon-saving function supported on TEC printers is not supported on

TGL printers. Enabling ribbon-saving on TGL printers will therefore have no

effect.

XB – Barcode

The Japanese barcode types (parameter values R and S) are not supported

in TGL.

XS – Issue

The ribbon-saving function supported on TEC printers is not supported on

TGL printers. Enabling ribbon-saving on TGL printers will therefore have no

effect.

~QU – Quiet Mode

This command puts the TGL emulation in quiet mode, which allows for the

printing of pure text until the listen command is received (~LI). In Quiet Mode

TGL commands are ignored.

23

Page 24

Chapter 4

24

Page 25

A TGL Menu Conversions

When substituting a TEC B-470/870 model printer with a 6700 or 6700-M40

printer, refer to the TGL conversion table below.

Table 3: TGL Menu

TEC B-470/870 Series 6700 or 6700-M40

with TGL Emulation

PARAMETER SET MODE,

Feed Adjust - (-50.0 to +50.0 MM) +0.0 MM*

- Feed length, fine adjustment. Adjusts

vertical print position on label. (- ) value

moves the image down from the leading edge

of the label. (+ ) value moves the image up

toward the leading edge of the label.

PARAMETER SET MODE,

Cut Adjust - (-50.0 to +50.0 MM)+0.0 MM -

Cut or tear off strip position, fine adjustment.

(- ) value sets leading edge of label behind

the tear bar. (+) value sets the leading edge of

the label past the tear bar.

PARAMETER SET MODE,

Back Feed - (-9.5 to +9.5 MM)

+0.0 MM - Adjusts vertical print position on

label. (+) value moves the image down from

the leading edge of the label. (-) value moves

the image up toward the leading edge of the

label.

6700: QUICK SETUP Menu

6700-M40: MEDIA SETUP Menu

Ver Im age Shift - (-1 to+12.8”) 0.0*”.

Adjusts vertical print position on label.

(- ) value moves the image up toward the leading edge of

the label. (+ ) value moves the image down from the

leading edge of the label.

6700: QUICK SETUP Menu

Tear Off Adjust- (-0.50 to+0.2) 0.00 Inch*

6700-M40: MEDIA SETUP Menu

Paper Feed Shift - (-0.50 to+12.8) 0.00 Inch*

Adjusts Tear Off, Tear-Off Strip, Peel-Off & Cut position in

Inches or MM. (-) value sets leading edge of label behind

tear bar. (+) value sets the leading edge of the label past

the tear bar.

6700: QUICK SETUP Menu

6700-M40: MEDIA SETUP Menu

Ver Im age Shift - (-1 to+12.8”) 0.0*”.

Adjusts vertical print position on label.

(+) value moves the image down from the leading edge of

the label. (-) value moves the image up toward the

leading edge of the label.

PARAMETER SET MODE,

X Adjust - (-99.0 to +99.0 MM)

+0.0 MM - X axis (horizontal) print position,

fine adjustment. (+) value shifts image left. (-)

value shifts image right.

6700: QUICK SETUP Menu

6700-M40: MEDIA SETUP Menu

Hor Image Shift - (-1.0 to +1.0) 0.0”*.

Adjusts image horizontally from left edge of label in

inches. (+) value shifts image left. (-) value shifts image

right.

25

Page 26

Appendix A

TEC B-470/870 Series 6700 or 6700-M40

Table 3: TGL Menu (continued)

with TGL Emulation

PARAMETER SET MODE,

Tone Adjust <T> - (-10 to +10) +0*.

Darkness of image on label for Thermal

Transfer printing (use of ribbon).

PARAMETER SET MODE,

Toner Adjust <D> - (-10 to +10) +0*.

Darkness of image on label for Direct

Thermal printing (no ribbon).

PARAMETER SET MODE,

Font Code - (PC-850* or PC-8)

PARAMETER SET MODE,

Zero Font - (0* or Ø) Selects 0 or slashed Ø.

PARAMETER SET MODE,

Code - (Auto*, ESC, LF, NUL or { | } )

Selects the command code.

PARAMETER SET MODE,

Ribbon - (Trans. or Non-Trans*) -

Non-Transmissive - With ribbon

Transmissive - Ribbon out

6700: QUICK SETUP Menu

6700-M40: MEDIA SETUP Menu

Print Intensity - (-15 to +15) -3*

Print Mode - (Transfer, Direct)

6700: QUICK SETUP Menu

6700-M40: MEDIA SETUP Menu

Print Intensity - (-15 to +15) 0*

Print Mode - (Transfer, Direct)

TGL SETUP Menu,

Character Set - (PC-850* or PC-8)

TGL SETUP Menu,

Slash Zero - (0* or Ø).

TGL SETUP Menu,

SFCC Select - (Auto Select*, ESC, LF, NUL, User

Defined or { | })

6700: QUICK SETUP Menu

6700-M40: MEDIA SETUP Menu

Print Mode - (Transfer* or Direct)

Auto Ribbon Save Function - (Without*,

With) – (Opt) Dip SW 1 (1)

Language - Sets the display language.

English*, Spanish, French, German, Dutch,

Japanese. Dip SW 1 (2-4)

Rewinder Use- (Without*, With)

Dip SW 1 (6)

Baud Rate - (9600*, 2400 - 19200)

Dip SW 2 (1-2)

Stop Bits – (1 bit* or 2 bits)

Dip SW 2 (3)

Word Length – (7-bits* or 8-bits)

Dip SW 2 (4)

Parity Check - (With* or Without)

Dip SW 2 (5)

Parity - (Even* or Odd)

Dip SW 2 (6)

N/A

6700: PRINTER CONTROL Menu

6700-M40: PRINTER SETUP Menu

Display Language - English*, Spanish, French,

German, Italian, Portuguese.

Factory installed Option - No menu selection required.

SERIAL PORT,

Baud Rate - (9600*, 600 - 115200)

SERIAL PORT,

Stop Bits - 1* or 2

SERIAL PORT,

Word Length 7 or 8*

SERIAL PORT,

Parity - (None*, Even, Odd)

SERIAL PORT,

Parity - (None*, Even, Odd)

26

Page 27

Table 3: TGL Menu (continued)

TEC B-470/870 Series 6700 or 6700-M40

with TGL Emulation

Data Protocol - XON/XOFF*, Ready Busy

(DTR), XON/XOFF +Ready Busy(DTR).

DIP SW 2 ( 7-8)

N/A TGL SETUP Menu,

N/A TGL SETUP Menu,

N/A TGL SETUP Menu,

SERIAL PORT,

Data Protocol (XON/XOFF*, ETX/ACK, ACK/NAK, Series 1 Char,

Series 2 Char or DTR)

Active - (Yes*, No)

Yes - All data is parsed by the TGL emulation.

Non-TGL data is absorbed.

No – All non-TGL data prints.

Image Scale - (Disable*, Enable)

Enable - For 6700, images are scaled from TEC printer

resolution (306 dpi) to TGL resolution

(300 dpi). For 6700-M40 printers, images are scaled from

TEC printer resolution (306 dpi) to TGL resolution

(305 dpi).

Disable - No scaling, resulting in 2% larger images on

TGL printers vs TEC printers.

EURO Symbol - (0x0 - 0xFF) 0XB0*

Allows configuration position of _ symbol in the code

pages.

N/A TGL SETUP Menu,

Speed CMDs - (Process*, Ignore)

Process - Print speed in the XS command & slew speed

in the T command will be used and override the Media

Control menu settings.

Ignore - Print speed in the XS command & slew speed in

the T command will have no effect. The Media Control

menu settings will be used instead.

N/A TGL SETUP Menu,

AY Intensity CMD - (Process*, Ignore)

Process - Print Intensity via the AY command is used &

overrides the Quick Setup menu value (6700) or Media

Setup menu value (6700-M40).

Ignore - Print Intensity via the AY command is ignored.

Quick Setup menu value used instead.

27

Page 28

Appendix A

Table 3: TGL Menu (continued)

TEC B-470/870 Series 6700 or 6700-M40

N/A TGL SETUP Menu,

U1/U2 Move CMDs - (Process*, Ignore)

Process - U1 move media forward & U2 move media

backward cmds are used & override the Quick Setup

menu (6700) or Media Setup menu

(6700-M40) Ver Image Shift value.

Ignore - U1 and U2 commands are ignored and Quick

Setup menu

(6700-M40) Ver Image Shift value is used.

N/A TGL SETUP Menu,

XS Media ‘D’ Act - (Tear-Off*, Peel-Off, Ignore,

Continuous, Tear-Off Strip)

Note: Tear-Off is available for 6700 printers only and is

the default value. Tear-Off is not available for 6700-M40

printers. Tear-Off Strip is the default for 6700-M40.

Uses the XS media ‘D’ command to select any of the

Media Handling modes listed above.

Ignore - The printer only uses the Media Handing mode

selected in the Quick Setup menu (6700) or Media Setup

menu (6700-M40).

(6700) or Media Setup menu

with TGL Emulation

N/A TGL SETUP Menu,

AR Pre-feed CMD - (Process*, Ignore)

Process - Printer uses the media pre-feed AR command.

Ignore - Printer ignores the pre-feed AR command.

Media is not pre-fed.

N/A TGL SETUP Menu,

AX Fine Adj. CMD - (Process*, Ignore)

Process - Position fine adjust AX command is acted on if

received.

Ignore - Position fine adjust AX cmd is ignored if

received. Media will not be fine adjusted.

28

Page 29

B Status Response

Serial And Ethernet Interface

1. Auto Status Response

The Auto Status Response feature is enabled or disabled by the status

response parameter in the XS command.

Once an XS command enables the Auto Status Response feature, it will stay

enabled until another XS command disables it. The status response menu

defines whether the Auto Status Response after power up must be enabled or

disabled. If set to 'On Request+Auto', Auto Status Response is enabled until

disabled by an XS command.

If the Auto Status Response is enabled, a response will be sent to the host

• after processing the Issue (XS) command when

• the Issue Mode parameter is set to Batch Mode, after printing the

designated number of labels.

• the Issue Mode parameter is set to Strip Mode, after printing one

label.

• at the end of the Feed (T) command.

• if one of the errors listed in the table below occurs.

2. On Status Request command ( WS-command )

The Status Request command is enabled by selecting either the On Request

Only or the On Request + Auto option in the TGL SETUP > Status Response

menu. The printer sends its current status to the host, regardless of the option

“status response” in the label issue command (XS). The remaining count

indicates the remaining number of labels in the current batch.

29

Page 30

Appendix B Serial And Ethernet Interface

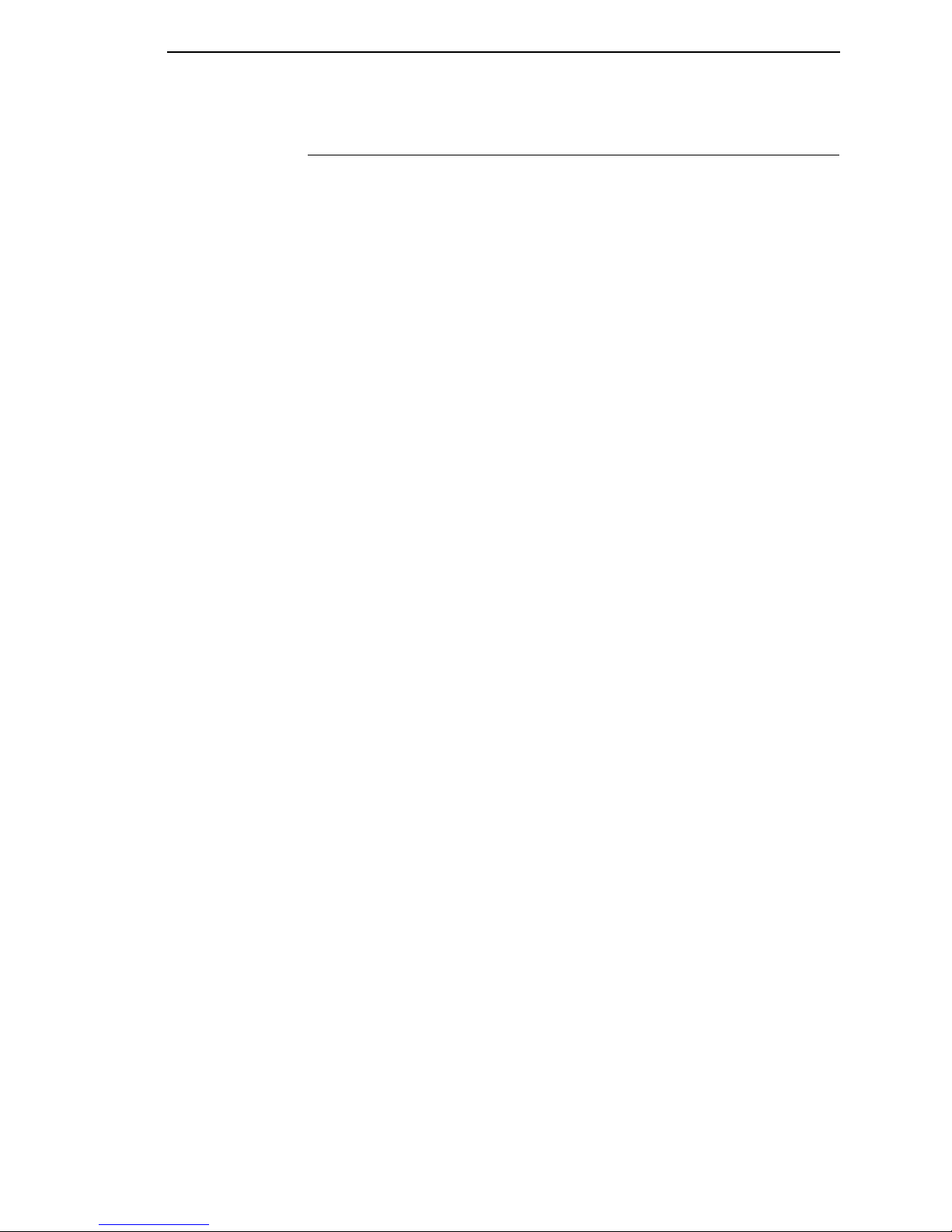

01H 02H 3XH 3XH 3XH 3XH 3XH 3XH 3XH 03H 04H 0DH 0AH

Remaining counts 0000 to 9999

Type of status:

1. (31H) = Status Request Command

2. (32H) = Auto Status Command

Detailed status, see table next page

LF CR EOT ETX SOH STX Status Remaining counts

Figure 1. Format Status Response

Tabl e 4. Status Response (not saving writable characters to flash)

LCD Message Printer Status

Auto Status

Transmission

Command

On line Idle X 00

Head open The head was opened in online mode 01 01.

See Note on

page 31.

On line In operation (analyzing, drawing,

X 02

printing, feeding)

Pause In pause X 04.

See Note on

page 31.

On line Waiting for stripping X 05

On line Command error found during analyzing 06 06.

See Note on

page 31.

Status

Request

30

Page 31

Table 4. Status Response (not saving writable characters to flash)

LCD Message Printer Status

Communication

error

Parity, overrun, framing error occurred

during serial comm.

Auto Status

Transmission

Command

07 07.

See Note on

page 31.

Paper jam Paper jam occurred during paper feed 11 11 .

See Note on

page 31.

Cutter error Fault condition in the cutter 12 12.

See Note on

page 31.

No paper The label has run out 13 13.

See Note on

page 31.

No ribbon The ribbon has run out 14 14.

See Note on

page 31.

Head open An attempt was made to feed or issue

with the head open

15 15.

See Note on

page 31.

Status

Request

Excessive head

temperature

The thermal head temperature has

become excessively high.

18 18.

See Note on

page 31.

Ribbon error Fault condition in ribbon transport 21 21.

See Note on

page 31.

Rewind full Overflow in the rewinder 22 22

See Note on

page 31.

On line No error in label issue 40 X

On line No error in feed 41 X

NOTE: This status will not be sent out if the serial interface is used. Other than on TEC printers,

InfoPrint printers will go offline when an error occurs, and therefore prevent the host

computer from sending status request commands.

31

Page 32

Appendix B Serial And Ethernet Interface

Tabl e 5. Status Response in Save Mode (saving writable characters to flash)

LCD Message Printer Status

Save mode Saving downloadable characters or

labels

Flash write

error

Format error Error in erasing flash 51 51

Flash memory

full

On line Command error found during analyzing 06 06

Communication

error

Error in writing to flash 50 50

Insufficient capacity of the flash memory 54 54

Parity, overrun, framing error occurred

during serial comm.

Auto Status

Transmission

X 55

See Note on

page 32.

See Note on

page 32.

See Note on

page 32.

See Note on

page 32.

07 07

See Note on

page 32.

Status

Request

Command

NOTE: This status will not be sent out if the serial interface is used. Other than on TEC printers,

InfoPrint printers will go offline when an error occurs, and therefore prevent the host

computer from sending status request commands.

32

Page 33

Notices

This information was developed for products and services offered in the

U.S.A.

InfoPrint Solutions Company may not offer the products, services, or features

discussed in this document in other countries. Consult your local InfoPrint

Solutions Company representative for information on the products and

services currently available in your area. Any reference to an InfoPrint

Solutions Company product, program, or service is not intended to state or

imply that only that InfoPrint Solutions Company product, program, or service

may be used. Any functionally equivalent product, program, or service that

does not infringe any InfoPrint Solutions Company intellectual property rights

may be used instead. However, it is the user’s responsibility to evaluate and

verify the operation of any non-InfoPrint Solutions Company product,

program, or service.

References in this document to InfoPrint Solutions Company products,

product features, programs or services do not imply that InfoPrint Solutions

Company intends to make such products, product features, programs or

services available in all countries in which InfoPrint Solutions Company

operates or does business.

InfoPrint Solutions Company may have patents or pending patent applications

covering subject matter described in this document. The furnishing of this

document does not give you any license to these patents. You can send

license inquiries, in writing, to:

InfoPrint Solutions Company, LLC

6300 Diagonal Hwy 002J

Boulder, CO 80301-9270

U.S.A.

For license inquiries regarding double-byte (DBCS) information, contact the

InfoPrint Solutions Company Intellectual Property Department in your country

or send inquiries, in writing, to:

InfoPrint Solutions Company, LLC

6300 Diagonal Hwy 002J

Boulder, CO 80301-9270

U.S.A.

33

Page 34

The following paragraph does not apply to the United Kingdom or any

other country where such provisions are inconsistent with local law:

INFOPRINT SOLUTIONS COMPANY PROVIDES THIS PUBLICATION “AS

IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

implied warranties in certain transactions, therefore, this statement may not

apply to you.

This information could include technical inaccuracies or typographical errors.

Changes are periodically made to the information herein; these changes will

be incorporated in new editions of the publication. InfoPrint Solutions

Company may make improvements and/or changes in the product(s)

described in this publication at any time without notice.

Any references in this information to non-InfoPrint Solutions Company Web

sites are provided for convenience only and do not in any manner serve as an

endorsement of those Web sites. The materials at those Web sites are not

part of the materials for this InfoPrint Solutions Company product and use of

those Web sites is at your own risk.

InfoPrint Solutions Company may use or distribute any of the information you

supply in any way it believes appropriate without incurring any obligation to

you.

Licensees of this program who wish to have information about it for the

purpose of enabling: (i) the exchange of information between independently

created programs and other programs (including this one) and (ii) the mutual

use of the information which has been exchanged, should contact:

InfoPrint Solutions Company, LLC

6300 Diagonal Hwy 002J

Boulder, CO 80301-9270

U.S.A.

Such information may be available, subject to appropriate terms and

conditions, including in some cases, payment of a fee.

The licensed program described in this document and all licensed material

available for it are provided by InfoPrint Solutions Company under terms of

the InfoPrint Solutions Company Customer Agreement, InfoPrint Solutions

Company International Program License Agreement or any equivalent

agreement between us.

Any performance data contained herein was determined in a controlled

environment. Therefore, the results obtained in other operating environments

may vary significantly. Some measurements may have been made on

development-level systems and there is no guarantee that these

measurements will be the same on generally available systems. Furthermore,

some measurement may have been estimated through extrapolation. Actual

results may vary. Users of this document should verify the applicable data for

their specific environment.

34

Page 35

Trademarks

Information concerning non-InfoPrint Solutions Company products was

obtained from the suppliers of those products, their published announcements

or other publicly available sources. InfoPrint Solutions Company has not

tested those products and cannot confirm the accuracy of performance,

compatibility or any other claims related to non-InfoPrint Solutions Company

products. Questions on the capabilities of non-InfoPrint Solutions Company

products should be addressed to the suppliers of those products.

COPYRIGHT LICENSE:

This information contains sample application programs in source language,

which illustrates programming techniques on various operating platforms. You

may copy, modify, and distribute these sample programs in any form without

payment to InfoPrint Solutions Company, for the purposes of developing,

using, marketing or distributing application programs conforming to the

application programming interface for the operating platform for which the

sample programs are written. These examples have not been thoroughly

tested under all conditions. InfoPrint Solutions Company, therefore, cannot

guarantee or imply reliability, serviceability, or function of these programs.

If you are viewing this information softcopy, the photographs and color

illustrations may not appear.

These terms are trademarks or registered trademarks of Ricoh Co., Ltd., in

the United States, other countries, or both:

• InfoPrint

• Infoprint

• Ricoh

IBM, the IBM logo, and ibm.com are trademarks or registered trademarks of

International Business Machines Corporation in the United States, other

countries, or both. If these and other IBM trademarked terms are marked on

their first occurrence in this information with a trademark symbol (® or ™),

these symbols indicate U.S. registered or common law trademarks owned by

IBM at the time this information was published. Such trademarks may also be

registered or common law trademarks in other countries. A current list of IBM

trademarks is available on the Web at "Copyright and trademark information"

at www.ibm.com/legal/copytrade.shtml

Other company, product, or service names may be trademarks or service

marks of others.

35

Page 36

36

Page 37

Page 38

Printed in U.S.A

G550-0979-03

*07G550097903*

Loading...

Loading...