Page 1

InfoPrint 6500-V Line Matrix Printers

User’s Manual Cabinet and Pedestal Models

S550-1002-01

Page 2

Page 3

InfoPrint 6500-V Line Matrix Printers

User’s Manual Cabinet and Pedestal Models

S550-1002-01

Page 4

Note:

Before using this information and the product it supports, read the information in “Notices” on

page 289.

Second edition (January 2010)

This edition applies to the InfoPrint 6500-V Line Matrix Printers and to all subsequent releases of these products

until otherwise indicated in new releases or technical newsletters, and replaces the following publication: InfoPrint

6500-V Line Matrix Printers: User's Manual Cabinet and Pedestal Models , S550-1002-00.

Internet

Visit our home page: http://www.infoprint.com

You can send comments by e-mail to printpub@us.ibm.com or by mail to:

InfoPrint Solutions Company

6300 Diagonal Hwy 002J

Boulder, CO 80301-9270

U.S.A.

This product is or contains commercial computer software and commercial computer software documentation

developed exclusively at private expense. As specified in Federal Acquisition Regulation 12.212 in the case of

civilian agencies and Defense Federal Acquisition Regulation Supplement 227.7202 in the case of military agencies,

use, duplication and disclosure by agencies of the U.S. Government shall solely be in accordance with the

accompanying International Program License Agreement in case of software products and in accordance with the

licensing terms specified in the product’s documentation in the case of hardware products.

© Copyright InfoPrint Solutions Company 2005, 2010.

Page 5

Contents

Figures ..............vii

Tables ...............ix

Safety and environmental notices . . . xi

About This User’s Manual ......xiii

Notes And Notices ...........xiii

Conventions In This User’s Manual ......xiv

Related Documents ...........xiv

Chapter 1. Printer Overview ......1

The InfoPrint 6500 Printer Family .......1

How To Identify The Printer ........2

RibbonMinder .............3

Standard Capabilities ..........4

Optional Features ............7

Protocols and Emulations .........9

Graphics Enhancements .........9

Taking Care of Your Printer ........10

Chapter 2. Installation, Attachment, and

Configuration Overview .......11

Before You Begin ............13

Power Requirements ...........13

Select a Site ..............13

Printer Dimensions ............14

Printer Component Locations ........16

Chapter 3. Configuring the Printer . . . 19

Overview ...............19

The Configurations ...........19

Active Versus Saved Configurations .....20

The Configuration Main Menu ........20

Using the Operator Panel..........23

Program Mode .............27

Unlocking The Program Mode .......27

Locking The Program Mode ........28

Entering Program Mode .........28

Printing the Current Configuration ......28

Changing Parameters ...........30

Saving Your Configuration in a Custom Set....32

Loading Custom Sets or Factory Default Values . . 35

Changing the Power On Configuration .....37

Chapter 4. The Configuration Menus . . 39

Configuration Overview ..........39

Main Menu ..............40

Quick Setup Menu ............42

Printer Control Menu ...........45

Interface Selection ...........47

Display Language ...........47

Print Direction ............47

Hex Print Mode ............48

Power On State ............48

Paper Jam Detection ..........48

Forms Speed .............48

Set Platen at BOF ...........49

Shuttle Timeout ............49

Energy Saver Timer...........49

OCR Font Density ...........50

Eject/Restore .............50

PTR Setup Option ...........51

File System .............51

Power Stacker ............52

Auto Elevator ............52

Printer Management Port .........52

Top Exit Tear Distance ..........52

Ribbon End Point ...........53

Ribbon Action ............53

Configuration Management Menu .......54

Recall Custom Set ...........55

Save Current Values ..........56

Delete Custom Set ...........56

Change Power On Set ..........56

Protect Custom Sets ..........56

Print Custom Set Values .........56

Config Key Default ...........57

Name Custom Sets ...........57

Reset Custom Set Names .........57

Twinax Interface Menu ..........58

Print Language ............60

Print Character Table ..........60

Active Print Language ..........60

Twinax Printer Emulation ........60

Printer Address ............60

World Trade .............61

Cancel Buffers ............61

Early Print Complete ..........61

Hex Transparent Control .........62

Undefined Char Report .........63

Undefined Char Sub ..........63

Load Alt Char Option ..........63

LAC Approximation ..........63

Print Text Direction ...........64

Override Host ............64

Format Control

Maximum Printable Width ........65

Hex Print Mode ............65

C/T Hotport .............65

Coax Interface Menu ...........67

Print Language ............69

Print Character Table ..........69

Active Print Language ..........69

PA1................69

PA2................70

Buffer Reprint ............70

Early Print Complete ..........70

SCS Buffer Control ...........71

............64

© Copyright InfoPrint Solutions Company 2005, 2010 iii

Page 6

Cancel Buffers ............71

Hex Transparent Control .........71

Mono/Dual Case ...........72

Undefined Char Sub ..........72

Print Text Direction ...........72

Image Buffer Size ...........73

Intervention Required ..........73

Compatibility Options ..........73

Translate Table ............73

Override Host ............73

Format Control ............74

C/T Hotport .............74

Maximum Printable Width ........75

Hex Print Mode ............75

Compatibility Options Menu .......76

5250 Interface Menu ...........80

Print Language ............82

Print Character Table ..........82

Active Print Language ..........82

Hex Transparent Control .........82

Undefined Char Reporting ........83

Undefined Char Sub ..........84

Print Text Direction ...........84

Override Host ............84

Format Control ............85

Maximum Printable Width ........85

C/T Hotport .............85

3270 Interface Menu ...........87

Print Language ............89

Print Character Table ..........89

Active Print Language ..........89

Early Print Complete ..........89

Hex Transparent Control .........89

Mono/Dual Case ...........90

Undefined Char Substitution .......91

Print Text Direction ...........91

Intervention Required ..........91

Override Host ............92

Format Control ............92

C/T Hotport .............92

Maximum Printable Width ........93

Compatibility Options Menu .......94

Network Setup Menu ...........98

Adapter Address Submenu ........99

Adapter Parameters Submenu .......100

Ethernet Address Submenu........104

Ethernet Parameters Submenu .......105

Wireless Address Menu .........108

Wireless Parameters Menu .........109

Signal Strength ............110

SSID Name

Reset SSID Name ...........110

Operation Mode ...........110

Minimum Transfer Rate .........110

Channel ..............110

Antenna Diversity ...........111

Preamble ..............111

Power Management ..........111

Transmit Power............111

International Mode ..........111

Authentication Method .........111

.............110

Default WEP Key ...........112

WEP Key Format ...........112

WEP Key Width ...........112

WEP Key BYTE1 through BYTE13 .....112

Reset WEP Keys ...........112

Wireless Kerberos ............113

Kerberos Enable ...........113

Kerberos Password ..........114

Reset Kerberos Password ........114

KDC Port Number ..........114

Clock Skew .............114

Ticket Lifetime ............114

Renew Lifetime ............114

Wireless LEAP .............115

Authentication Method .........115

LEAP Username ...........116

Reset LEAP User ...........116

LEAP Password ...........116

Reset LEAP Password .........116

Parallel Interface Menu ..........117

Interface Type ............117

PC Parallel .............117

Dataproducts ............117

IEEE 1284 .............117

Parallel Hotport ...........118

PC Parallel Menu ...........119

Dataproducts Menu ..........122

IEEE 1284 .............125

Serial Interface Menu ...........127

Interface Type ............128

Data Protocol ............128

Baud Rate .............128

Data Bits ..............128

Stop Bits ..............128

Parity ...............129

Data Terminal Ready ..........129

Request to Send ...........130

Buffer Size in Kbytes ..........130

Poll Character ............130

One Char Enquiry ...........130

Serial Hotport ............131

Framing Errors ............132

Emulation Configuration Menu .......133

Active Emulation ...........134

ASCII Printer Emulation.........134

Printer Emulation Configuration ......134

Print Format.............134

IPDS Feature .............134

Configuration ............134

IPDS Parameters ...........135

IPDS Configuration Menu ........135

ANSI ................142

CPI/LPI Select ............144

Font Attributes ............144

Page Format .............146

IGP Feature (PGL)............150

Configuration ............150

IGP Parameters ............150

IGP Emulation Menu ..........151

Code V Feature (VGL) ..........156

Configuration ............156

iv InfoPrint 6500-V User’s Manual

Page 7

Code V Parameters ..........156

Code V Emulation Menu ........157

Printer Emul Config Menu .........166

Proprinter III XL Emulation Menu .....167

Epson Emulation Menu .........169

pSeries Emulation Menu ........171

pSeries XQ Emulation Menu .......175

Serial Matrix Emulation Menu.......178

Print Format Menu ..........181

Operator Print Tests Menu .........189

Printer Demonstration .........189

Print Error Log ............189

Print Ribbon Log ...........189

Ripple Print .............190

AllE’s...............190

AllH’s ..............190

AllE’s+FF.............190

Underlines .............190

Adapter Test Page ...........190

Ethernet Test Page ...........190

Clear Error Log............190

Printer Information Menu .........191

Installed Memory ...........191

Power On Time ...........191

Printing Time ............191

Print Strokes ............192

11 Inch Pages ............192

Interior Cleaning ...........212

Printer Self–Tests ............215

Running the Printer Self-Tests ........216

Hex Code Printout ...........217

Fault Messages .............221

Fault Correction Procedure ........221

Appendix A. Printer Specifications 251

Ribbon Specifications ...........251

Ordering Ribbons ............251

6500-vxx Models ...........251

Paper Specifications ...........254

Paper ...............254

Labels ...............255

Printer Dimensions and Weight .......255

Cabinet Models............255

Pedestal Models ...........255

Environmental Characteristics ........256

Temperature.............256

Relative Humidity ...........256

Acoustic Noise Level ..........256

Electrical Characteristics ..........257

Input Voltage ............257

Power Consumption ..........257

Interfaces...............260

Cables ................260

Printing Rates .............261

Chapter 5. Printer Interfaces .....193

Overview...............193

RS-232 and RS-422 Serial Interfaces ......194

RS-232...............194

RS-422...............195

RS-232 Serial Interface Protocols ......195

RS-232 and RS-422 Serial Interface Protocols . . 196

RS-232 and RS-422 Serial Interface Error

Handling ..............196

RS-232 and RS-422 Serial Interface

Configuration ............197

PC Parallel Interface ...........198

PC Parallel Interface Signals .......199

PC Parallel Interface Configuration .....199

Dataproducts Parallel Interface .......200

Dataproducts Parallel Interface Signals ....201

Dataproducts Parallel Interface Configuration 201

IEEE 1284 Parallel Interface.........202

Operating Modes ...........202

The Negotiation Phase .........203

Signals ..............203

Terminating Resistor Configurations .....206

Chapter 6. Reprogramming The

Security Key ............209

How To Reprogram The Security Key .....209

Chapter 7. Routine Service and

Diagnostics ............211

Overview...............211

Cleaning Requirements ..........211

Exterior Cleaning ...........211

Appendix B. A Quick Look at Line

Matrix Printing ...........263

Character Formation ...........263

Printing Speed .............265

Appendix C. Host Attachment ....267

Compatibility and Limitations ........268

Compatibility ............268

Limitations .............270

Appendix D. Attaching Host Systems

to a Coax/Twinax Printer ......273

Attaching Printer to an IBM System i or zSeries

Host System ..............273

Attaching Printer to an IBM System i Host System 273

Attaching Printer to an IBM System i with

Twinax Interface ...........273

Changing Your IBM System i Printer

Configuration ............274

Attaching Printer to Remote Control Unit with

Twinax Interface ...........276

Attaching Printer to zSeries Systems......277

Types of Installation covered for MVS/JES2 . . 277

6500-LU1-SCS-Local SNA 3174 Control Unit . . 277

6500-LU1-SCS-Remote SNA 3174 Control Unit 279

6500-LU3-DSE-Local SNA 3174 Control Unit . . 281

6500-LU3-DSE-Remote SNA 3174 Control Unit 282

6500-LU0-DSC-Local Non-SNA 3174 Control

Unit ...............284

Attaching Printer to VM Host System .....285

SNA Attachment ...........285

Non-SNA Attachment .........286

Contents v

Page 8

Physical and Logical Unit Types .......286

Physical Unit (PU) types and examples ....286

Summary of LU Types and Representative IBM

Products ..............287

Notices ..............289

Product recycling and disposal .......291

Trademarks ..............291

Communication statements .........293

Software License Agreement.....297

Limited Software Product Warranty ......298

Remedy ..............299

Disclaimer of Warranties and Limitation of

Remedies..............299

Termination of License Agreement .....299

U.S. Government Restricted Rights .....299

Acknowledgement of Terms and Conditions . . 299

Glossary .............301

References ..............301

Terms ...............301

Index ...............307

vi

InfoPrint 6500-V User’s Manual

Page 9

Figures

1. Printer Model Number Interpretation ....2

2. Exploded View of Cabinet Model Printer

Dimensions ............14

3. Exploded View of Cabinet Model with Power

Paper Stacker Printer Dimensions .....15

4. Exploded View of Pedestal Model Printer

Dimensions ............16

5. 6500 Printer Component Locations with the

Ribbon Spools Exploded Above ......17

6. Pedestal Model Printer Component Locations

with Open Access Cover and Ribbon Spools

Exploded Above ...........18

7. Configuration Main Menu .......21

8. Configuration Main Menu (continued) . . . 22

9. The Operator Panel ..........23

10. Configuration Management Menu - Print

Custom Set Values ..........29

11. Printer Control Menu - Print Direction . . . 30

12. Configuration Management Menu - Save

Current Values ...........32

13. Configuration Management Menu - Recall

Custom Sets ............35

14. Configuration Management Menu - Change

Power On Set ............37

15. 6500 Series Main Menu Configuration....40

16. 6500 Series Main Menu Configuration

(continued).............41

17. Quick Setup Menu ..........42

18. Quick Setup Menu (continued) ......43

19. Printer Control Menu .........45

20. Printer Control Menu (continued) .....46

21. Configuration Management Menu .....54

22. Twinax Interface Menu.........58

23. Twinax Interface Menu - Print Language 59

24. Coax Interface Menu .........67

25. Coax Interface Menu - Print Language . . . 68

26. Compatibility Options Menu .......76

27. 5250 Interface Menu .........80

28. 5250 Interface Menu - Print Language ....81

29. 3270 Interface Menu .........87

30. 3270 Interface Menu - Print Language ....88

31. Compatibility Options Menu .......94

32. Network Setup Menu .........98

33. Adapter Address Submenu .......99

34. Adapter Parameters Submenu ......100

35. Ethernet Address Submenu .......104

36. Ethernet Parameters Submenu ......105

37. Wireless Address Menu ........108

38. Wireless Parameters Menu .......109

39. Wireless Kerberos Menu ........113

40. Wireless LEAP Menu .........115

41. Parallel Interface Menu ........117

42. PC Parallel Menu ..........119

43. Dataproducts Menu .........122

44. IEEE 1284 Menu ..........125

45. Serial Interface Menu .........127

46. Emulation Configuration Menu .....133

47. IPDS Configuration Menu .......135

48. IPDS Configuration Menu - Print Language 136

49. ANSI Emulation Menu ........142

50. ANSI Emulation Menu - Font Attributes,

Character Set, and Page Format Menus . . . 143

51. IGP Emulation Menu

52. Code V Emulation Menu........157

53. Code V Emulation Menu - Graphic Options 158

54. Printer Emulation Configuration Menu 166

55. Proprinter III XL Emulation Menu ....167

56. Epson Emulation Menu ........169

57. pSeries Emulation Menu ........171

58. pSeries Emulation Menu - Print Language 172

59. pSeries XQ Emulation Menu ......175

60. Serial Matrix Emulation Menu ......178

61. Print Format Menu .........181

62. Top of Line and Bottom of Line Text Positions 187

63. Operator Print Tests Menu .......189

64. Printer Information Menu .......191

65. Resistor Locations ..........206

66. Inserting the SPX into the Debug Port 209

67. Interior Components of the Cabinet Models 213

68. Interior Components of the Pedestal Models

with Ribbon Spool Above .......214

69. Sample ASCII Hex Code Printout .....219

70. Sample Coax Hex Code Printout .....220

71. Sample Twinax Hex Code Printout ....221

72. Typical Character Formation ......263

73. Line Matrix Printing .........264

.........151

© Copyright InfoPrint Solutions Company 2005, 2010 vii

Page 10

viii InfoPrint 6500-V User’s Manual

Page 11

Tables

1. The InfoPrint 6500 Printer Family .....2

2. Maximum Interface Connection Cable Length 14

3. Form Width ............147

4. CPI Settings ............184

5. 6500-v20 RS-232 Serial Interface Connector

Pin Assignments ..........194

6. RS-422 Serial Interface Connector Pin

Assignments ............195

7. Printer PC Parallel Interface Connector Pin

Assignments ............198

8. Dataproducts Parallel Interface Connector Pin

Assignments (with a 50-pin AMP HDH-20

Data Cable Connector) ........200

9. 1284 Signals ............203

10. Terminating Resistor Configurations ....206

11. Fault Messages ...........222

12. 6500 Nominal Print Rates (1 of 2) .....261

13. 6500 Nominal Print Rates (2 of 2) .....261

14. Operating System Report .......268

© Copyright InfoPrint Solutions Company 2005, 2010 ix

Page 12

x InfoPrint 6500-V User’s Manual

Page 13

Safety and environmental notices

<1> Before powering on the printer ensure the printer is plugged into an

appropriate power source. Refer to Chapter 2, “Installation, Attachment, and

Configuration Overview,” on page 11 for information on the proper source.

<2> Switch off the printer power and unplug the printer power cord before

cleaning the printer.

<3> Do not connect or disconnect any communication port, teleport, attachment

connector, or power cord during an electrical storm.

<5> Power off the printer and disconnect the power cord before connecting or

disconnecting any communication port, teleport, or attachment cable

connector.

CAUTION:

This product is equipped with a 3-wire power cord and plug for the user’s

safety. Use this power cord in conjunction with a properly grounded electrical

outlet to avoid electrical shock.

© Copyright InfoPrint Solutions Company 2005, 2010 xi

Page 14

xii InfoPrint 6500-V User’s Manual

Page 15

About This User’s Manual

This User’s Manual is designed so that you can quickly install and configure your

InfoPrint®6500 printer.

Notes And Notices

For your safety and to protect valuable equipment, it is very important that you

read and comply with all information noted in the following section:

DANGER:

<#> The word Danger next to the lightning slash indicates the presence of a

hazard that could cause death or serious personal injury. Danger and Caution

notices are numbered to help you find the translated versions in the InfoPrint

6500 Line Matrix Printer: Safety Information .

!

<#> The word Caution next to the exclamation point (!) indicates the presence of a

<#> The word Caution next to this symbol indicates a part or assembly that is hot

Attention: The word Attention indicates the possibility of damage to a program,

device, system, or data.

IMPORTANT: The word Important indicates information vital to proper operation

Note: A note gives you helpful information and tips about printer operation and

maintenance.

CAUTION:

hazard that could cause moderate or minor personal injury.

CAUTION:

enough to burn you.

of the printer.

© Copyright InfoPrint Solutions Company 2005, 2010 xiii

Page 16

Conventions In This User’s Manual

Operator panel keys and LCD messages are set off from regular text in this

manual:

v Operator panel keys and indicators are printed boldface and UPPERCASE.

Example: Press the CANCEL key, then press the START key.

v Liquid Crystal Dislay (LCD) messages are printed in capital letters inside

quotation marks (" ").

Example: Press the STOP key. "NOT READY" appears on the LCD.

v Key combinations are denoted by the + (plus) symbol.

Example: Press ↑SCROLL/MICRO + ↓SCROLL/MICRO means press the

↑SCROLL/MICRO key and the ↓SCROLL/MICRO key at the same

time.

Related Documents

v InfoPrint 6500 Coax/Twinax Programmer’s Reference Manual – Covers the host

control codes and character sets for the Coax and Twinax emulations.

v InfoPrint 6500 ASCII Programmer’s Reference Manual – Covers the host control

codes for the LinePrinter Plus emulation.

v InfoPrint 6500 IGP Programmer’s Reference Manual – Provides information used

with the optional IGP emulation enhancement feature.

v InfoPrint 6500 Code V Programmer’s Reference Manual – Provides information used

with the optional Code V emulation enhancement feature.

v InfoPrint 6500 ANSI Programmer’s Reference Manual – Provides host control codes

and character sets for the ANSI emulation.

v IPDS Emulation Programmer’s Reference Manual – Provides an overview of

Intelligent Printer Data Stream

v Ethernet Interface User’s Manual – Information about network protocols,

configuration, and operation.

v InfoPrint 6500 Line Matrix Printers: Safety Information – This manual contains

English and translated versions of the InfoPrint 6500 Printer Safety Notices.

Warning, Caution, and Danger notices are included.

v InfoPrint 6500 Line Matrix Printers: Quick Start Guide - Explains how to unpack

and set up the printer.

™

(IPDS™) features, commands, and diagnostics.

xiv InfoPrint 6500-V User’s Manual

Page 17

Chapter 1. Printer Overview

This section provides a general overview of your printer and the conventions used

within this manual.

The InfoPrint 6500 Printer Family

The InfoPrint Solutions Company's InfoPrint 6500 series consist of 500, 1000, 1500,

and 2000 lines per minute (lpm) models and are packaged in various

configurations. All of the models offer software versatility and the latest

refinements in line matrix printing technology. The print mechanisms are housed

in sound-insulated cabinets which make the printer family among the quietest

printers in the world. Additionally, your printer has a flexible architecture that

allows you to add new features and emulations as they become available.

ASCII is the standard emulation. ASCII includes the Epson FX-1050, Printronix

pSeries, pSeries XQ, Serial Matrix and Proprinter III XL emulations. Coax/Twinax,

IPDS , ANSI and the IGP/PGL and IGP/VGL graphics enhancement emulations

are available as optional upgrades. No matter what emulation is installed, your

printer is easy to use. The message display and lights on the control panel

communicate with you directly and clearly. You can select every function on your

printer at the control panel, or you can send commands from the host computer.

The printer combines the use of Flash, RAM, and nonvolatile RAM for program

execution. The Flash is used for all program, font, and emulation storage. New

fonts, emulations, or program updates can be downloaded to Flash memory via

the parallel or serial interface, or through the Ethernet interface. The RAM is used

for buffers, print image storage, and execution variables. The nonvolatile RAM

stores configuration, statistics, and internal parameters.

© Copyright InfoPrint Solutions Company 2005, 2010 1

Page 18

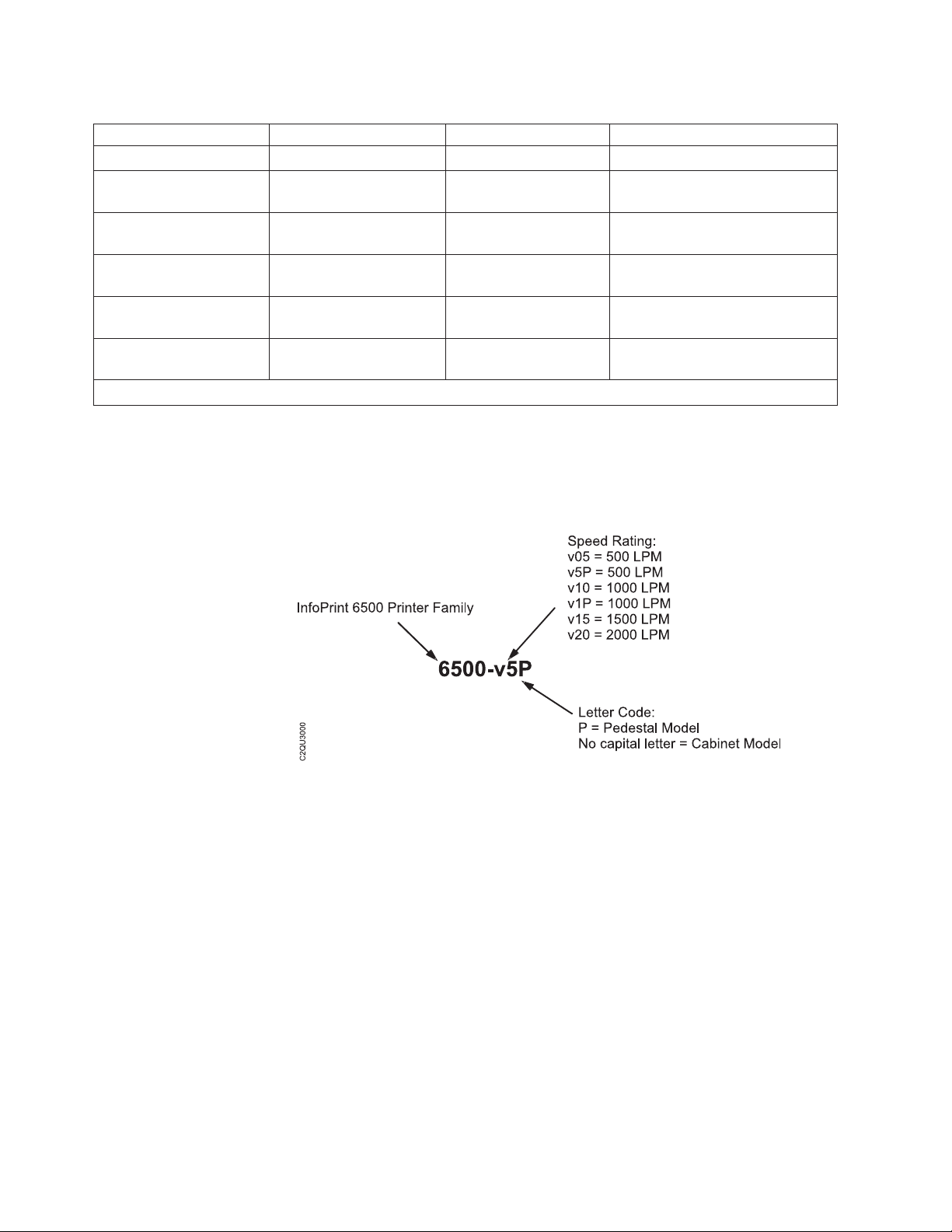

Table 1. The InfoPrint 6500 Printer Family

Model Number Print Speed Enclosure Hammer Bank

6500-v05 500 LPM* Floor Cabinet 28 Hammers

6500-v5P 500 LPM Pedestal,

Quick Access

6500-v10 1000 LPM Floor Cabinet,

Power Stacker optional

6500-v1P 1000 LPM Pedestal,

Quick Access

6500-v15 1500 LPM Floor Cabinet,

Power Stacker optional

6500-v20 2000 LPM Floor Cabinet,

Power Stacker optional

* Lines Per Minute

28 Hammers

60 Hammers

60 Hammers

102 Hammers

156 Hammers

How To Identify The Printer

The model number of the printer indicates the printer family, rated maximum print

speed, and type of enclosure. (See Figure 1.)

Figure 1. Printer Model Number Interpretation

2 InfoPrint 6500-V User’s Manual

Page 19

RibbonMinder

The InfoPrint 6500 has a new feature that automatically monitors and

communicates ribbon life. Using a specially barcoded spool, the printer can

automatically detect when a new or used ribbon is loaded, and all ribbon

properties. With a sophisticated algorithm, the system monitors all jobs printed

and automatically updates the remaining ribbon life on the front panel display.

This allows the system administrator to have precise control over print quality and

consumable costs. The accurate presentation of available ribbon life allows for

efficient planning of print jobs. For example, you can install a new ribbon before

printing large print jobs.

When the ribbon life gets near the end point, the printer displays a ribbon low

message and flashes the indicator light. Printing will continue without

interruption. Once the ribbon reaches 0% remaining, the alarm sounds, the

indicator light flashes, the display updates, and printing pauses. If a new ribbon is

loaded, the system automatically detects the change, clears the condition, and

restarts the life at 100%. If it is not convenient to change the ribbon immediately,

cycle the printer on and offline and it will resume printing for a few minutes. This

should be enough to complete the job. If not, repeat the same procedure

indefinitely to extend printing on the same ribbon.

Output Darkness

By default the system is configured to meet most user requirements. However,

some applications require that the output remains darker than the nominal set

point while some applications are less critical and could tolerate a lighter final

image. The system can easily adjust to this variability. A setting under Printer

Control, Ribbon End Point is available that allows the user to adjust the final

output. The range is as follows:

Lighter −4 (Default)

Darker +1 through +6

Normal

Lighter −1 through −10

The ribbon life indicator always cycles between 100% and 0%, but if a darker

setting is selected, zero will be reached more quickly. If a lighter setting is selected,

the system will extend the amount of printing it takes to reach zero.

Ribbon Flipping

In some cases, the application’s print pattern is narrow enough where only half of

the ribbon is used when printing. In these cases, you can flip the ribbon and use

the other half. The RibbonMinder detects the flip and resets the ribbon life to

100%.

Note: It is the user’s responsibility to ensure the print pattern is sufficiently

narrow to support flipping. If not, the ribbon life may falsely indicate 100%

for the flipped ribbon.

Chapter 1. Printer Overview 3

Page 20

Loading a Used Ribbon

You can take ribbons off the printer and reload it at a later time. The ribbon life

gauge automatically updates to reflect the correct remaining capacity.

Note: The ribbon must be reloaded back onto the same printer, and in the same

orientation as it was removed. If the used ribbon is loaded onto a different

printer, or if it is flipped over, it will incorrectly indicate the ribbon as new.

Ribbon Log

The RibbonMinder tracks all used ribbons. This data allows you to monitor how

many ribbons and ribbon types have been used on the printer. This data is

contained in the ribbon log. To print the ribbon log, see “Print Ribbon Log” on

page 189.

Consumable Monitoring With The Printer Management Utility

The RibbonMinder works with the Printer Management Utility (PMU). The PMU

allows a system administrator to remotely view the current consumable status of

all printers. The PMU can be configured to deliver alerts on all consumable

warnings. When a ribbon reaches the low state, the PMU notifies the system

administrator remotely via an automated e-mail alert of the low condition. This

allows corrective action to be taken before the ribbon reaches its end of life. If the

ribbon is not changed, an alert will again be initiated once the ribbon reaches the

0% end point. Refer to your Printer Management Utility User's Manual for details.

Standard Capabilities

The InfoPrint 6500 printer family has the following general characteristics:

v A broad range of print speeds in both cabinet and pedestal models

v Support of similar features across the entire product line to allow maximum

flexibility in matching the printer to the requirements

v Energy Star compliant

The following sections summarize the standard capabilities of the InfoPrint 6500

printers.

Host Computer Interfaces

v RS 232 Serial

v RS 422 Serial

v PC Parallel

v Dataproducts Parallel

v Ethernet Interface

v IEEE 1284

Coax/Twinax features are available with this printer:

v Coax/Twinax

4 InfoPrint 6500-V User’s Manual

Page 21

Printer Emulations

Each emulation provides a different set of configuration menus, control codes, and

character sets. The following printer emulations (or protocols) are standard, and

selectable at the operator panel:

v Proprinter III XL Emulation

v Epson FX Emulation

v pSeries Printer Emulation

v pSeries XQ Variant Printer Emulation

v Serial Matrix Printer Emulation

Proprinter III XL and Epson FX Emulations: The Proprinter III XL and Epson FX

emulations are industry standard printer emulations.

pSeries Printer Emulation: This code system was developed especially for line

matrix printers. As line matrix printers became more sophisticated, this code

system kept pace by adding codes that fully utilized line matrix printer

capabilities.

IMPORTANT: This emulation appears as “pSeries” on the operator panel.

pSeries XQ Variant Printer Emulation: This code system was devised for a series

of printers manufactured between 1974 and 1991, that are no longer available.

IMPORTANT: This emulation appears as “pSeries XQ” on the operator panel.

Serial Matrix Printer Emulation: This printer emulation is very similar to the

code systems used by an InfoPrint Graphics Printer, but incorporates several

systems into one emulation. This emulation enables a line matrix printer to print

files coded for a serial matrix printer, and is sometimes referred to as the Serial

Matrix collection.

Chapter 1. Printer Overview 5

Page 22

IMPORTANT: This emulation appears as “Serial Matrix” on the operator panel.

Note: Serial matrix refers to the way printer characters are formed. A moving

printhead uses pins to form whole characters one at a time and one after the

other. The pins print dots according to programmed matrix patterns. Data is

sent to the printer through either a serial or parallel interface, but the

printhead must receive the data serially to form each character.

An InfoPrint line matrix printer also forms characters with dots in matrix

patterns, but it feeds print data in parallel to many hammers mounted on a

rapidly oscillating shuttle. The hammers fire simultaneously to print entire

lines at a time.

Output Control

The printers have the following output control features:

v Six modes for printing text:

– Near-Letter Quality (NLQ)

– Near-Letter Quality San Serif

– Data Processing (DP)

– Draft

– Optical Character Recognition Font A (OCR A)

– Optical Character Recognition Font B (OCR B)

OCR A and OCR B support 120 and 180 PEL, with 120 PEL the default value.

v Selectable forms length and width

v Character attribute specification:

– Selectable pitch: normal, expanded, and compressed

– Emphasized (shadow) printing

– Automatic underlining and overscoring

– Superscript and subscript printing

– Double high and wide printing

v Resident multinational character sets

6 InfoPrint 6500-V User’s Manual

Page 23

Graphics and Vertical Formatting

Several graphics and vertical formatting features are available:

v Three built-in graphics generators:

– Proprinter III XL bit-image graphics

– Epson FX dot graphics mode

– pSeries Plot

v Programmable electronic vertical formatting provides rapid vertical paper

movement to specified lines for printing repetitive and continuous forms. You

can use the following methods:

– Vertical tabbing in Serial Matrix, Proprinter III XL, and Epson FX emulation

modes

– Electronic Vertical Format Unit (EVFU) in pSeries emulation mode

Built-in Diagnostic Tools

The following diagnostic tools are provided with the printer:

v Comprehensive diagnostic self-tests permanently stored in the printer

v Configuration printout

v Data stream hex code printout

Optional Features

The following features can be ordered and installed on this printer. If you ordered

a feature at the time of purchase, the feature may already be installed on your

printer. Refer to the documentation shipped with the feature for more details.

For detailed information about these features or for information on ordering a

feature, contact your sales representative.

v Coax/Twinax Attachment:

®

Enables you to attach this printer to IBM

zSeries

®

Host System. This feature also helps you to replace Coax/Twinax

host systems, such as an iSeries®or

printers such as the IBM 3262 Models 3 and 13, IBM 4234 Models 1, 2, and 9,

and IBM 5224 Models 1 and 2. This feature can be used with the Intelligent

Printer Data Stream (IPDS) feature which is described below.

v InfoPrint Solutions Company Intelligent Printer Data Stream:

Provides the ability to create forms, overlays, and graphics. IPDS also provides

compatibility when replacing printers such as the IBM 4234 Models 12 and 11.

This feature also supports many versions of the Print Services Facility

™

(PSF).

This feature requires a Coax/Twinax attachment or Ethernet card attachment.

Chapter 1. Printer Overview 7

Page 24

v Code V:

This is an implementation of the Intelligent Graphics Processor architecture and

is used commonly to create graphics for optical character recognition and bar

codes. This feature is also designed for those applications which use the Quality

Micro Systems, Inc. graphics language, which is often referred to as the QMS

Code V Magnum emulation and those applications that use the Code V

Graphics Language. The Code V Graphics Language is often referred to as VGL.

v IGP:

This is an implementation of Intelligent Graphics Processor architecture and is

used commonly to create graphics for optical character recognition and bar

codes. This feature is also designed for those applications which use the

Graphics Language, which is often referred to as PGL.

This feature can coexist with the Intelligent Printer Data Stream feature, and/or

with either Coax/Twinax feature or can be used on the ASCII models.

v TN5250/TN3270 Emulations:

The TN5250/TN3270 feature enables your printer to communicate with a host

system through a Network Interface Card (NIC) using the 5250/3270 datastream.

This feature allows you to use an application generated for the Twinax/Coax

emulation to be printed through the NIC.

Users who are converting from Twinax to TN5250 may see some differences.

Please refer to “Compatibility and Limitations” on page 268 for details.

v ANSI Emulation:

The ANSI option allows you to print files coded for the ANSI (American

National Standards Institute) printer control language.

v Network Print Server:

Enables you to attach your printer to Local Area Networks using token-ring or

Ethernet protocols. The Network Print Server functions as a workstation server

on your network, enabling your users to submit print jobs to your printer.

The Network Print Server provides multiple network protocol support that

allows you to submit print jobs from Novell Netware, LAN Server, AIX

®

*, and

other TCP/IP networks.

v Dataproducts Adapter:

Supplies a 50 pin AMP Amplimite HDH-20 data cable connector. This feature is

necessary if you are using the Dataproducts parallel protocol.

v Ethernet Interface:

Enables you to attach your printer to Local Area Networks using Ethernet

protocols. The Ethernet Interface functions as a workstation server on your

network, enabling your users to submit print jobs to your printer.

8 InfoPrint 6500-V User’s Manual

Page 25

v Power Paper Stacker:

Mechanically directs the paper from the printer to the paper stacking area. This

feature provides consistent paper handling with fewer paper jam errors.

v Input Paper Shelf:

Pedestal model only. Provides a shelf to hold a box of paper or forms. This is a

convenient feature if you need to move the printer often.

v Pull Out Tray:

Cabinet model only. A tent tray to hold printed papers or forms that you can

pull out for accessibility.

v Wireless:

An embedded wireless Ethernet Interface card that allows you to attach printers

on a local area network (LAN) rather than attaching them directly to a host

system.

Protocols and Emulations

A protocol is a set of rules governing the exchange of information between the

printer and its host computer. These rules consist of codes that manipulate and

print data and allow for machine-to-machine communication. A printer and its

host computer must use the same protocol. As used in this manual, protocol and

emulation mean the same thing.

Most impact printers are single ASCII character codes to print text, numbers, and

punctuation marks. Some characters, both singularly and in groups are defined as

control codes. Control codes instruct the printer to perform specific functions, such

as underlining text, print subscripts, setting page margins, etc. The main difference

between most printer protocols is in the characters used to create control codes and

the ways in which these characters are formatted.

When the printer executes the character and control codes of a particular printer

protocol, it is “emulating” that printer. If the printer uses the Proprinter III XL

protocol, for example, it is emulating an IBM Proprinter III XL printer. If the

printer is using the Epson FX printer protocol, for example, we can also say it is in

Epson FX emulation mode.

There are additional emulations that are provided as optional features, such the

Code V and IGP emulations. For additional information, refer to “Code V Feature

(VGL)” on page 156 and “IGP Feature (PGL)” on page 150.

Graphics Enhancements

The PGL and Code V emulations allow you to create and store forms, generate

logos, bar codes, expanded characters, and create other graphics. Alphanumeric

and bar code data are added as the form is printed.

These emulations are available as factory-installed or field-installed options. For

more information, contact your authorized service representative.

Chapter 1. Printer Overview 9

Page 26

Taking Care of Your Printer

Your printer will produce high print quality jobs if it is well taken care of. Periodic

cleaning, handling the printer properly, and using the correct printer supplies such

as paper and ink transport media ensures optimum performance. Chapter 7,

“Routine Service and Diagnostics” explains how to clean the printer, and printer

supplies are listed in Appendix A, “Printer Specifications,” on page 251.

Whenever it is necessary to service the printer, remember this important

maintenance concept.

v Incorrect closure of the forms thickness lever can lead to smearing, degraded

print quality, paper jams, and damage to the platen and shuttle assembly. Never

close the forms thickness lever too tightly.

10 InfoPrint 6500-V User’s Manual

Page 27

Chapter 2. Installation, Attachment, and Configuration Overview

Note!

Before using this information and the product it supports, read the

information and Communication Statements in “Notices” on page 289.

DANGER

<4> Do not connect or disconnect any communication port, teleport, attachment

connector, or power cord during an electrical storm.

<5> Power off the printer and disconnect the power cord before connecting or

disconnecting communication port, teleport, or attachment cable connector.

The following is an overview of the steps you need to complete to successfully

install, attach, and configure your printer:

1. Unpack the printer from the shipping package. Follow the instructions

provided on the shipping package.

2. Set up the printer, which includes; removing shipping materials, installing the

ink transport assembly, ink transport media, ink cartridge, and loading paper.

Follow the instructions in InfoPrint 6500 Line Matrix Printers: Quick Start Guide.

3. Perform an initial print test by printing the current configuration page as

described on page 28.

4. Review the information contained in the README.1ST file on the

Configuration Utility section on the User’s CD.

Note: The Configuration Utility section contains a README.1ST file that

describes the contents of the CD, AIX print drivers, and configuration

information for replacing existing InfoPrint Solutions Company printers.

In addition, there might be another file, called README.TXT that

contains information that was added after the printer documentation was

printed.

© Copyright InfoPrint Solutions Company 2005, 2010 11

Page 28

5. Attach the printer to the host system and configure the host system to work

with the printer.

a. For ASCII attachments, follow the instructions in the InfoPrint 6500 ASCII

Programmer’s Reference Manual.

b. For Coax/Twinax attachments, follow the instructions in theInfoPrint 6500

Coax/Twinax Programmer’s Reference Manual.

c. If you have ordered the Ethernet Interface, follow the instructions in the

Ethernet Interface User’s Manual.

Note: If you are attaching this printer to an AIX host system, refer to the

Configuration Utility section on the User’s CD.

6. If you have not already ordered a communications cable, see page 260.

7. Configure the printer to work with host systems and to match your emulation,

such as IBM Proprinter III XL. Follow the instructions provided in Chapter 3,

“Configuring the Printer,” on page 19 and review the information provided in

Appendix C, “Host Attachment,” on page 267

Note: If you are replacing another printer with this printer, make sure you

review the information on the Configuration Utility diskette. The

Configuration Utility diskette contains information that will help you

configure this printer to match the configuration of the printer you are

replacing.

8. Install and/or configure optional features by following instructions provided in

the appropriate feature manual. For a brief description of the following

optional features, refer to: “IPDS Feature” on page 134, “Code V Feature

(VGL)” on page 156, and “IGP Feature (PGL)” on page 150.

Note: For more detailed information about any optional feature, refer to the

manual that was shipped with the feature. If you want to order a manual to

learn more about these features, see the “Related Documents” on page xiv.

12 InfoPrint 6500-V User’s Manual

Page 29

Before You Begin

Read this section carefully before installing and operating the printer. The printer is

easy to install. However, for your safety and to protect valuable equipment,

perform all the procedures in this section in the order presented.

IMPORTANT: Make sure you have a way to move the printer and shipping

<1> Two people are required to unload the printer from the shipping pallet.

pallet. You will need a jack.

Make sure you have adequate room to maneuver the shipping

pallet and printer to the location where you plan to install the

printer.

CAUTION

The shipping weight of the cabinet model is 129.3 kilograms (285 pounds)

or 139 kilograms (306 pounds) if the Power Paper Stacker is installed. The

shipping weight of the pedestal model printer is 72.6 kilograms (160

pounds.)

Power Requirements

The printer must be connected to a power outlet that supplies 88 to 135 Volts AC

or 178 to 271 Volts AC at 50 to 60 Hz. The printer automatically senses and adjusts

itself to conform to the correct voltage range.

Primary circuit protection is provided by the power switch, which is also a circuit

breaker. Consult an electrician if printer operation affects local electrical lines. See

“Electrical Characteristics” on page 257 for additional power specifications.

IMPORTANT: Printer power should be supplied from a separate AC circuit

Select a Site

Select a printer site that meets all of the following requirements:

v Cabinet models: Permits complete opening of the printer cover and both doors

of the floor cabinet. Allows at least three feet of clearance behind the printer.

(This permits air to circulate freely around the printer and provides access to the

paper stacking area.)

v Pedestal models: Permits complete opening of the printer cover and good access

to the paper areas at the front and rear of the printer.

v Has a standard power outlet that supplies 88-135 Volts AC or 178-270 Volts AC

power, at 47 to 63 Hz. The printer automatically senses and adjusts itself to

conform to the correct voltage range.

v Is relatively dust-free.

v Has a temperature range of 10 C to 40 C (50 F to 104 F) and a relative humidity

from 15% to 90% non-condensing.

protected at 10 amperes for 100 - 120 volts or 5 amperes for 200 240 volts at 50 or 60 Hertz.

Chapter 2. Installation, Attachment, and Configuration Overview 13

Page 30

v Is located within the maximum allowable cable length to the host computer. This

distance depends on the type of interface you plan to use, as shown in Table 2.

Table 2. Maximum Interface Connection Cable Length

PC Parallel 5 meters (15 feet)

IEEE 1284 Parallel 10 meters (32 feet)

Dataproducts Parallel 12 meters (40 feet)

Serial RS 232 15 meters (50 feet)

Serial RS 422 1220 meters (4000 feet)

Twinax (shielded cable) 1500 meters (4920 feet)

Twisted Pair / Type 3 300 meters (492 feet)

Dataproducts Long Line 150 meters (492 feet)

Coax 1500 meters (4920 feet)

Twisted Pair / Type 3 300 meters (985 feet)

Ethernet 10/100Base-T 100 meters (328 feet)

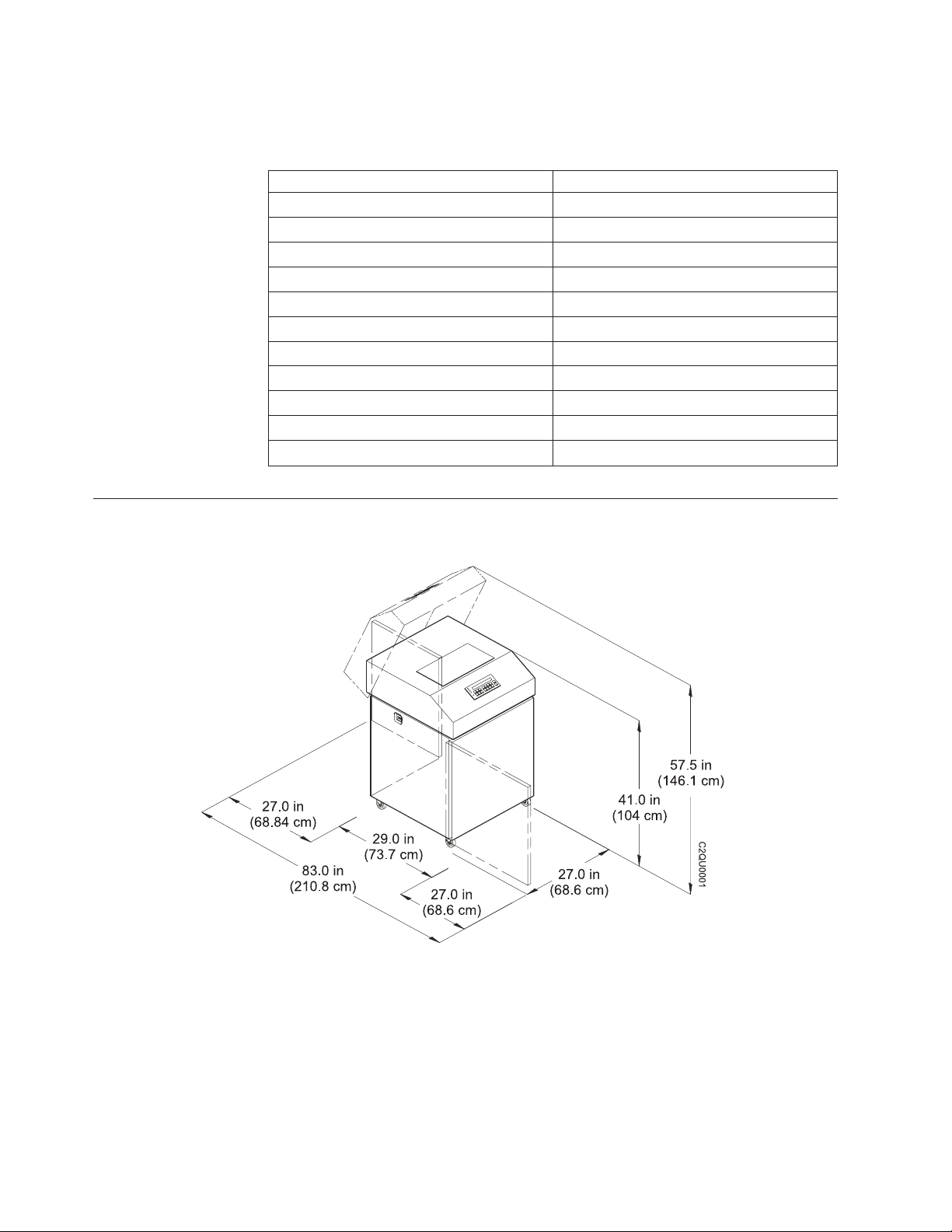

Printer Dimensions

Interface Type Maximum Cable Length

Figure 2. Exploded View of Cabinet Model Printer Dimensions

14 InfoPrint 6500-V User’s Manual

Page 31

Figure 3. Exploded View of Cabinet Model with Power Paper Stacker Printer Dimensions

Chapter 2. Installation, Attachment, and Configuration Overview 15

Page 32

Figure 4. Exploded View of Pedestal Model Printer Dimensions

Printer Component Locations

Familiarize yourself with the names and locations of the printer components,

shown in Figure 5 and Figure 6 before continuing with the rest of the installation

procedures.

16 InfoPrint 6500-V User’s Manual

Page 33

Ribbon Spool

Barcode

Ribbon

Date Code Label

Splined

Shaft

Paper Support (2)

Tractor (2)

Hub Latch

Blue Tractor

Lock (2)

Platen Stop

Barcode Sensor

Ribbon Guide (2)

Figure 5. 6500 Printer Component Locations with the Ribbon Spools Exploded Above

Hammer Bank

Cover and

Ribbon Mask

Vertical

Position Knob

C2QQ2001

Platen Lever

Chapter 2. Installation, Attachment, and Configuration Overview 17

Page 34

Ribbon Spool

Hub Latch (2)

Barcode

Ribbon

Date Code Label

Printer Cover

Blue Tractor

Door (2)

Blue Tractor

Lock (2)

C2QQ2002

Splined Shaft

Platen Lever

Platen Stop

Ribbon Guide (2)

Figure 6. Pedestal Model Printer Component Locations with Open Access Cover and Ribbon Spools Exploded Above

18 InfoPrint 6500-V User’s Manual

Page 35

Chapter 3. Configuring the Printer

IMPORTANT: Configuration directly affects printer operation. Do not try to

change the configuration of your printer until you are thoroughly

familiar with the procedures in this section.

Overview

To print data, the printer must respond correctly to signals and commands

received from the host computer. Configuration is the process of matching the

printer operating characteristics to those of the host computer and to specific tasks,

such as printing labels, or printing on different sizes of paper. The characteristics

that define the printer response to signals and commands received from the host

computer are called configuration parameters.

You can configure the printer by pressing operator panel keys or by sending

control codes from the host computer. This chapter explains how to use the

operator panel to change individual parameters and save them as a custom

configuration.

Your programmers reference manuals provide information about control codes.

The Configurations

A configuration consists of a group of parameters, such as line spacing and forms

length. Your printer contains the following configurations:

v Four preloaded configurations that have been customized for printer setup.

v The factory default configuration. It can be loaded, but it cannot be altered.

v Four configurations that you can customize for unique print job requirements.

The process of creating customized configurations is explained in “Changing

Parameters” on page 30.

© Copyright InfoPrint Solutions Company 2005, 2010 19

Page 36

Active Versus Saved Configurations

When you change a parameter value, it is active as long as the printer is on or

until it is changed again. This is true whether you use the operator panel or send a

control code from the host. Parameter values defined by control codes override the

active operator panel parameters when the printer is using any of the parallel or

serial interfaces. For example, if you set the line spacing to 6 lpi with the operator

panel, and application software later changes this to 8 lpi with a control code, the

control code setting overrides the operator panel setting.

Using the operator panel, you can save the parameters as a customized

configuration that is stored in nonvolatile random access memory (NVRAM). A

saved configuration is not lost when you power off the printer.

Note: Saved configurations are also referred to as “custom sets”.

There are no control codes that allow you to save a parameter in NVRAM.

However, you can save a configuration defined partially by control codes and store

it in NVRAM using the operator panel. You can also save configuration values

using PTR_SETUP (see “PTR Setup Option” on page 51.)

The Configuration Main Menu

Figure 7 on page 21 shows an overview of the printer configuration menus. The

pages that follow describe how to enter program mode, print the current

configuration, change configuration parameters, and save and load custom sets.

For specific configuration menu options and their descriptions, refer to Chapter 4,

“The Configuration Menus,” on page 39.

Note: The menus that are displayed from the operator panel are determined by

the installed features.

Each feature is shipped with a document that describes the feature in detail.

For more information about these documents, see the “Related Documents”

section on page xiv.

20 InfoPrint 6500-V User’s Manual

Page 37

Figure 7. Configuration Main Menu

Notes:

1. The Twinax and Coax interface menus only appear in the menus if the

Coax/Twinax feature is installed.

2. The Early Print Complete option appears in the Twinax menu only if the IPDS

feature is installed.

3. IPDS, Code V Emulation, and IGP Emulation options appear in the menus

only if these features are installed.

4. Ethernet information only appears when the Ethernet feature is installed.

5. Ether the Ethernet Interface menu or the Parallel Interface menu will display.

They cannot display at the same time.

6. If installed.

7. Not if 4234-12 is running IPDS code.

8. Only if Autoswitching is enabled.

9. Only if Coax Emulation is enabled.

10. The 5250 and 3270 Interface menu only appear in the menus if the

TN5250/3270 feature is installed.

11. Only if ANSI is installed.

Chapter 3. Configuring the Printer 21

Page 38

Figure 8. Configuration Main Menu (continued)

22 InfoPrint 6500-V User’s Manual

Page 39

Using the Operator Panel

This section provides numerous examples of how to use the operator panel keys

and indicator message display to configure the printer.

Figure 9. The Operator Panel

The operator panel is shown above. A physically common (but electrically

different) operator control panel is used for both cabinet and pedestal models.

During the configuration process, you will use the

SCROLL/MICRO , ENTER, and RETURN keys on the operator panel to access

configuration settings and diagnostic tests via the configuration menus. As you

access menus and options, menu names and option values appear on the operator

panel message display (sometimes referred to as LCD, or Liquid Crystal Display).

Message Display

An alphanumeric LCD display consists of a minimum of two rows of

twenty-four characters each used to display printer status, fault messages,

and menus to permit the operator to set various configurations. The

display can be set to any one of the following languages: English, French,

German, Italian, Spanish, Dutch, Brazilian-Portuguese, and Polish.

Status Indicator

A high visibility light for indicating general printer status. The light is on

when the printer is READY (on-line to the host), off when the printer is

NOT READY (off-line), or flashes if a fault condition exists.

Control Panel Overlay

An adhesive-backed overlay is provided that adheres to the face of the

control panel. Overlays are provided in the following languages: English,

French, German, Italian, Spanish, Dutch, Brazilian-Portuguese, and Polish.

The overlay legends can be translated into additional languages as

required.

Switch Functionality

Fourteen keys are provided for selecting and controlling printer features

and options.

SCROLL/MICRO,

START

Use the START key to place the printer in the READY (on-line)

state if it is off-line. Pressing Start in the Program mode exits the

menus and places the printer in the READY state. After pressing

View or Eject to move the print position to the tractor area,

pressing the START key moves the paper back to its original print

position, and places the printer in the READY state.

Chapter 3. Configuring the Printer 23

Page 40

STOP Use the STOP key to place the printer in the NOT READY

(off-line) state if it is on-line. When a fault condition exists,

pressing STOP clears the fault and places the printer in the NOT

READY state. After pressing VIEW or EJECT to move the print

position to the tractor area, pressing Stop moves the paper back to

its original print position and places the printer in the NOT

READY state.

MENU

The MENU key operates only in the NOT READY state and is

used to display the printers control menu. Press MENU repeatedly

to view the menus without changing any settings. No

configuration changes can be made when the Program state is

locked. To change the configuration settings, press the RETURN

and ENTER keys at the same time to unlock the Program state,

then press MENU. The menu is then viewed using the

SCROLL/MICRO, SCROLL/MICRO, and the RETURN and

ENTER keys. When the Program state is unlocked, new values

may be selected from the menus using the ENTER key.

CONFIG

(Printer configuration) The CONFIG key operates only in the NOT

READY state. Pressing CONFIG prints the currently selected

configuration. Pressing the STOP key stops printing and returns to

NOT READY.

RETURN

The RETURN key operates only in the NOT READY state. In the

Program state, it causes the display to move to a higher level in

the menu structure.

Pressing the RETURN and ENTER keys at the same time unlocks

the ENTER key when in the Program state.

SCROLL/MICRO

Pressing the SCROLL/MICRO key in the READY state has no

effect and returns the message “INVALID KEY PRESS”. In the

NOT READY state, this key micro–steps the paper upward in 1/72

inch increments. Press and hold the key to move paper at 10

increments per second. In the MENU state, pressing

SCROLL/MICRO navigates the menu and does not move the

paper.

SCROLL/MICRO

Pressing the

effect and returns the message “INVALID KEY PRESS”. In the

NOT READY state, this key micro–steps the paper downward in

1/72 inch increments. Press and hold the key to move paper at 10

increments per second. When in the MENU state, pressing this key

navigates the menu and does not move the paper.

ENTER

The ENTER key operates only in the NOT READY state.

v In the Program state it moves the display to a lower level in the

menu structure.

v In the unlocked Program state it selects a configuration option

value.

v In the Program state it starts and stops a Print Test selected from

the Operator Print Tests menu.

SCROLL/MICRO key in the READY state has no

24 InfoPrint 6500-V User’s Manual

Page 41

v In the NOT READY state pressing STOP and ENTER performs a

soft reset of the printer which resets the printer to the Power On

configuration.

Pressing the ENTER and STOP keys at the same time while the

printer is in the NOT READY state causes a soft reset.

Pressing the RETURN and ENTER keys at the same time unlocks

the ENTER key when in the Program state.

LINE FEED

Pressing the LINE FEED key when in the NOT READY state,

prints any data in the buffer and then moves the paper. Data not in

the buffer is not affected. The initial paper motion is one line at the

currently defined line spacing. LINE FEED repeats if the key is

continually held down.

VIEW Pressing the VIEW key in the NOT READY state moves the paper

from the current print position up to the tractor area for viewing. If

there is any data left in the print buffer, it is printed and then the

paper moves up for viewing. Pressing VIEW a second time or

pressing START or STOP returns the paper to its original print

position.

FORM FEED

Pressing and releasing the FORM FEED key in the NOT READY

state moves the paper to the top–of–form on the next page. If there

is any data in the print buffer, it prints first and then the paper

moves to the next top–of–form. Data not in the print buffer is not

affected. Press the FORM FEED key in the Fault state to silence the

alarm and cause the paper to move. The top–of–form setting is

lost.

SET TOP OF FORM

Pressing the SET TOP OF FORM key in the NOT READY state,

unless there is data in the buffer, moves the paper downward

relative from the TOF alignment index to the print station and sets

this position to be the top of form. Positions the TOF correctly,

independent of the form length. If there is data in the buffers, this

data is printed and then the printer slews to the place on the page

where the printing left off.

CANCEL

Pressing the CANCEL key clears all of the data in the print buffer.

This key can be disabled in the menus. The CANCEL key is not

active during VIEW and EJECT operations. The CANCEL key

does the following:

1. Stops printer tests in progress.

2. Cancels a print job. This operation depends on the printer

interface.

Coax Interface (non-SCS mode)

Coax Interface (SCS mode)

The CANCEL key is not effective and the “009

INVALID KEY” error message displays.

Note: With a Coax Interface, press the CANCEL key a

second time to stop the previous cancel.

Effective in the NOT READY state, but the action

Chapter 3. Configuring the Printer 25

Page 42

occurs only in the READY state. When pressed, the

“059 CANCEL PRINT ACTIVE” message is displayed.

Twinax Interface

Effective in the READY and NOT READY states. When

pressed, the “059 CANCEL PRINT ACTIVE” message is

displayed.

IPDS Interface

Ethernet (IPDS mode): Effective in the NOT READY

state. The two forms of cancel are:

a. Full Cancel: A CANCEL command is sent to the

host requesting that the print job be cancelled and

the next job in the queue be submitted for printing.

This is done by pressing the CANCEL key twice.

When pressed, the “059 CANCEL PRINT ACTIVE”

message is displayed.

b. Clear Buffers: A Clear Buffers command is sent to

the host informing the host that the printer has

cleared its buffers. At this point, the job can be

restarted from any page based on the instruction

from the host. This is done by pressing the

CANCEL key once, then pressing the STOP key.

When pressed, the “069 DATA CLEARED” message

is displayed.

Serial/Parallel/Ethernet Interface

We recommend that you stop the print job from the

host system before you press CANCEL. Effective in the

NOT READY state. When pressed, the “069 DATA

CLEARED” message is displayed.

EJECT The EJECT key has two modes of operation. Standard mode is the

only mode available on the cabinet models. For pedestal models

(without zero tear option), the Standard mode can be selected from

the menu and should be selected when using the rear paper exit.

In Standard mode, the EJECT key moves the paper forward to

facilitate tearing off the paper at the perforation then restores the

original paper position. Once the paper is torn at the perforation,

pressing either the EJECT, START,orStop keys retracts the paper

to its previous position, as described below:

EJECT Moves the paper to its previous position. The printer

returns to the mode it was in before EJECT was used.

START

Moves the paper to its previous position and places the

printer in the READY state.

STOP Moves the paper to its previous position and places the

printer in the NOT READY state.

If the paper is to be torn off, the FORM FEED key must be pressed

before pressing the EJECT, START,orSTOP keys. This feeds an

additional page first and prevents the paper from unloading when

it is restored to its original position after the form is torn off.

26 InfoPrint 6500-V User’s Manual

For pedestal models (without zero tear option), in the Top Exit Tear

mode (selectable at the operator panel), this key moves the paper

to the top of the next form. In the NOT READY state, pressing the

Page 43

Program Mode

Unlocking The Program Mode

EJECT key moves the paper forward to the tear–off position. In the

NOT READY state, pressing the EJECT key moves the paper

forward to the tear–off position. Pressing one of the following keys

has the function described below:

EJECT Moves the paper to its next available position. The printer

returns to the mode it was in before EJECT was pressed.

START

Moves the paper to its next available position and places

the printer in the READY state.

STOP Moves the paper to its previous position and places the

printer in the NOT READY state.

The printer is in Program mode whenever the configuration menus and option

values are displayed on the operator panel message display. Program mode is

either locked or unlocked. In order to select new configuration values, you must

unlock Program mode. In order to prevent accidental changing of the configuration

settings, you may lock Program mode.

To use the operator panel to change the configuration settings, Program mode

must be unlocked. When Program mode is unlocked, pressing the Enter key selects

configuration values as the active values, that is, places them into printer DRAM.

An asterisk (*) after a displayed setting shows it is entered into memory.

Press the Return + Enter keys at the same time to unlock Program mode. The

following message will appear briefly:

OPERATOR MENU

UNLOCKED

Chapter 3. Configuring the Printer 27

Page 44

Locking The Program Mode

When Program mode is locked, you cannot use the operator panel to change the

configuration settings. However, you can still select the configuration menus and

view the current configuration settings.

Press the Return + Enter keys at the same time to lock Program mode. The

following message will appear briefly:

OPERATOR MENU

LOCKED

Entering Program Mode

To place the printer in Program mode, press the MENU key.

Printing the Current Configuration

Step Key LCD Result Notes

1. Make sure the printer is on

2. Press

3.

4.

5.

STOP

CONFIG

START

START

NOT READY The printer must be in NOT READY

mode to print the configuration.

PRESS START TO PRINT

PRESS STOP TO EXIT

NOT READY Indicates that the configuration has

READY The printer is READY for normal

You are prompted to press the START

key before the configuration prints.

printed. Date and store the printout in a

safe place. You may also want to label

the printout (for example,

“Configuration for 2-up Labels”).

operation.

28 InfoPrint 6500-V User’s Manual

Page 45

The second method for printing the current configuration, as well as several other

configurations, is to use the Print Custom Set Values menu option, shown on the

following page.

Figure 10. Configuration Management Menu - Print Custom Set Values

The Print Custom Set Values selection on the Configuration Management menu

allows you to print any or all of the configurations shown above. The default

setting, “Current Custom Set”, will print the same information as pressing the

Printer Configuration key. The Current Custom Set is the Power On configuration

until you begin modifying the printer configuration.

Custom sets 1 through 4 do not exist until you save configuration parameters to

them. You must define and save a custom set before you can print it.

Custom/Preload Sets 5 through 8 contain configuration sets that assist with the

installation and configuration of this printer.

The other options will only be useful once you have modified and saved the

printer configuration parameter settings.

The Power On Custom Set is defined by the “Change Power On Set” option.

Custom Sets 1 through 8 are defined by the “Save Current Values” option.

These options are described in detail under the Configuration Management Menu

description starting on page 54.

Chapter 3. Configuring the Printer 29

Page 46

Changing Parameters

Figure 11. Printer Control Menu - Print Direction

The following procedure shows you how to change a configuration setting.

Changing the Print Direction from the factory default setting BIDIRECTIONAL to

the setting UNIDIRECTIONAL is provided as an example. Print Direction is one of

the Printer Control menu options. The procedure is similar for other configuration

changes. Use these basic guidelines to navigate the configuration menus and

change other parameters.

Note: Press START at any time to exit the configuration menu.

Step Key LCD Results Notes

1. Determine which parameters you want to change and what the new values will be. In

this example, the value for the PRINT DIRECTION parameter will be changed from

“BIDIRECTIONAL” to “UNIDIRECTIONAL”.

2. Press

3.

4.

5.

6.

STOP

MENU

ENTER

UNTIL

NOT READY Places the printer in NOT

READY mode before entering

the operator menus.

OPERATOR MENU

UNLOCKED

OPERATOR MENU

PRINTER CONTROL

PRINTER CONTROL

INTERFACE SELECTION

PRINTER CONTROL

PRINT DIRECTION

Unlocks the Operator Menu,

which allows you to make

configuration changes.

Displays the first Configuration

Main Menu option, PRINTER

CONTROL.

Moves into the PRINTER

CONTROL menu.

Moves to the PRINT

DIRECTION parameter.

7.

30 InfoPrint 6500-V User’s Manual

ENTER

PRINT DIRECTION

BIDIRECTIONAL*

Move into the PRINT

DIRECTION menu. The

asterisk (*) shows that this is

the active value.

Page 47

Step Key LCD Results Notes

8.

PRINT DIRECTION

UNIDIRECTIONAL

Moves to the next available

option, the UNIDIRECTIONAL

option.

9.

ENTER

PRINT DIRECTION

UNIDIRECTIONAL*

Selects the displayed value. An

asterisk (*) appears indicating

that this choice is now the

active value.

10. Continue this pattern to make all of the changes, using the information in this chapter.

11. To save changes so that they will remain when the printer is reset or powered back

on, see “Saving Your Configuration in a Custom Set” on page 32. If you want to use

these values without saving, continue to the next step.

12.

13.

14.

STOP

STOP

NOT READY Returns the printer to the NOT

READY mode.

OPERATOR MENU

LOCKED

Locks Program mode and the

Operator Menu.

READY Places the printer in READY

mode, prepared for normal

operation.

Chapter 3. Configuring the Printer 31

Page 48

Saving Your Configuration in a Custom Set

Figure 12. Configuration Management Menu - Save Current Values

Once you have changed all of the necessary parameters, it is recommended you

save them as a configuration that can be stored and loaded later for future use.

You can save your configurations to meet different print job requirements.

The saved configurations (called custom sets) are stored in NVRAM—they will not

be lost if you power off the printer.

Later, you can load one of the configurations for a specific print job. This

eliminates the need to change settings, such as CPI and LPI, for each new job. See

“Loading Custom Sets or Factory Default Values” on page 35 for details on loading

configurations.

You may want to print records of your configurations (see “Printing the Current

Configuration” on page 28) and store them in a safe place, such as inside the

printer cabinet.

32 InfoPrint 6500-V User’s Manual

Page 49

If you do not save your configuration before you power off the printer, all of the

new parameter values that have not been saved to NVRAM will be erased. When

you power the printer on again, the power-on configuration will load. If no

configuration has been designated as the power-on configuration, the factory

configuration will load.

Note: To avoid overwriting an existing custom set, the Protect Custom Sets

parameter must be set to ENABLE. See “Protect Custom Sets” on page 56

for details.

Step Key LCD Results Notes

1. Press

STOP

NOT READY Places the printer in NOT READY mode.

2.

3.

4.

5.

6.

7.

MENU

UNTIL

ENTER

UNTIL

ENTER

OPERATOR MENU

UNLOCKED

OPERATOR MENU

PRINTER CONTROL

OPERATOR MENU

CONFIGURATION

MANAGEMENT

CONFIGURATION

MANAGEMENT

RECALL CUSTOM SET

CONFIGURATION

MANAGEMENT

SAVE CURRENT

VALUES

SAVE CURRENT

VALUES

1*

Unlocks the Operator Menu, which

allows you to make configuration

changes.

Displays the first Configuration Main

Menu option, PRINTER CONTROL.

Moves to the Configuration

Management menu option.

Selects the CONFIGURATION

MANAGEMENT menu. The RECALL

CUSTOM SET option appears.

Moves to the SAVE CURRENT VALUES

option.

Selects the SAVE CURRENT VALUES

menu.

8.

9.

10.

UNTIL

ENTER

STOP

SAVE CURRENT

VALUES

2

SAVING

CONFIGURATION