InfoPrint 4247 Z03 Maintenance Information

InfoPrint 4247 Serial Matrix Printers

InfoPrint 4247 Model Z03 Printer:

Maintenance Information

Document Number: G550-1021-00

Note:

Before using this information and the product it supports, read the information in “Safety and environmental notices” on page 10

and “Notices” on page 296.

First edition (May 2008)

Internet

Visit our home page: http://www.infoprint.com

You can send comments by e-mail to printpub@us.ibm.com or by mail to:

InfoPrint Solutions Company

6300 Diagonal Hwy 002J

Boulder, CO 80301-9270

U.S.A.

This

product is or contains commercial computer software and commercial computer software documentation developed exclusively

at private expense. As specified in Federal Acquisition Regulation 12.212 in the case of civilian agencies and Defense Federal

Acquisition Regulation Supplement 227.7202 in the case of military agencies, use, duplication and disclosure by agencies of the U.S.

Government shall solely be in accordance with the accompanying International Program License Agreement in case of software

products and in accordance with the licensing terms specified in the product’s documentation in the case of hardware products.

© Copyright InfoPrint Solutions Company 2008. All rights reserved.

Contents

Safety and environmental notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Safety notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Danger hazard level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Caution hazard level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Attention notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Electrostatic discharge (ESD) procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Approved power cord and receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Electrical safety and portable power strip receptacles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Connecting or disconnecting a communication port, a teleport, or an attachment connector . . . . . . . . . .14

Servicing during an electrical storm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Safety inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Reference items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Safety inspection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Performing a power-receptacle safety-check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Ground connectors check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Environmental notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Product recycling and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

||

The 4247 Model Z03 Serial Matrix Impact Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Print speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Paper paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Paper path nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Print qualities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Fast draft print quality selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4247 Model Z03 differences and commonality with other models . . . . . . . . . . . . . . . . . . . . . . . . .24

© Copyright InfoPrint Solutions Company 2008 3

Controller boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Flash memory download and printer microcode file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

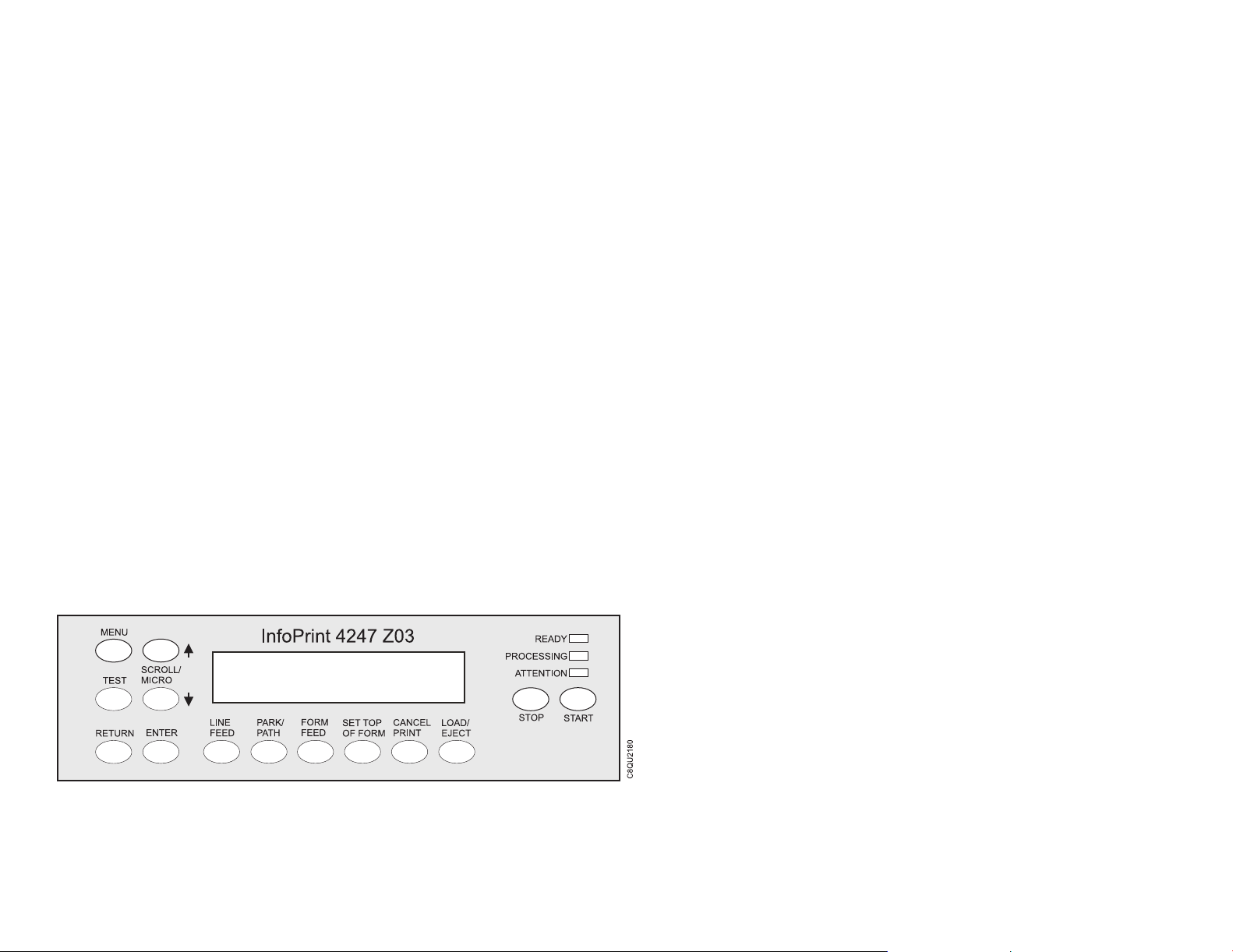

Operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Paper paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Printhead mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

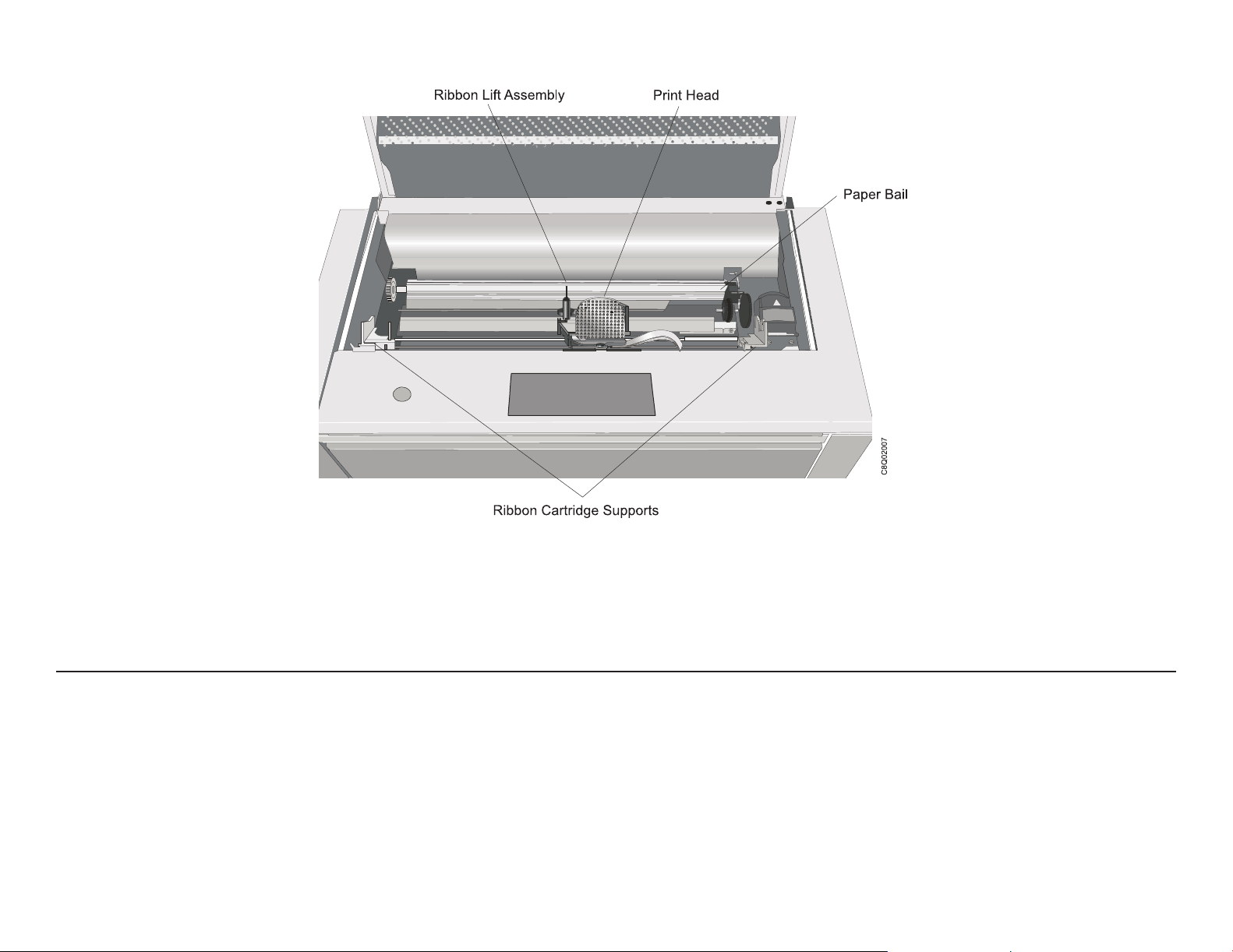

Ribbon cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Test & Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Related information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Softcopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Hardcopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Chapter 1. Diagnosing problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Maintenance analysis procedures (MAPs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Defining the problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

MAP 0100: START of call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

MAP 0120: Parallel, serial or USB interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

MAP 0122: LAN Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

MAP 0130: No paper movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

MAP 0131: Paper path sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

MAP 0140: Printhead drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

MAP 0150: Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

MAP 0160: Ribbon feed and ribbon lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

MAP 0180: To p cover interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

MAP 0190: Form feed problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

MAP 0200: 055 AFTA errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

MAP 0210: Intermittent failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

MAPs reference tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Reference table 1, error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Contents 4

Reference table 2, no printed characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Reference table 3, print quality failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Reference table 4, operator panel and miscellaneous problems . . . . . . . . . . . . . . . . . . . . . . . .79

Reference table 5, power supply connector pins and voltages . . . . . . . . . . . . . . . . . . . . . . . . .81

Reference table 6, ribbon lift and 26-pin cable connectors . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Chapter 2. Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Test and diagnostic information—Model Z03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Printing the printer demonstration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Printing the firmware part number and version levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Printing the printer configuration and the custom sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Printing and clearing the error log, and printing the usage metrics . . . . . . . . . . . . . . . . . . . . . . .86

Running the test and diagnostic (T&D) programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

T&D procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

T&D error messages and actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Chapter 3. Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

18-Wire printhead resistance checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Printhead cable wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

AFTA motor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Attachment Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Carriage motor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Operator panel cable wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Paper feed motor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Ribbon feed motor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Ribbon lift motor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Sensor cable assembly wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Tractor assembly cable wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Chapter 4. Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Contents 5

Chapter 5. Removals, service checks and adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Service position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Paper path nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Service checks and adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Automatic Forms Thickness Adjustment (AFTA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Print Head Gap Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Bidirectional Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Carriage drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Carriage support shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

First line printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Paper feed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Paper path service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Print quality service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Printhead drive service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Ribbon feed and ribbon lift service check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Sensor service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Tear-off line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Tractor asm. service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Removals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Slot assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Attention light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Automatic forms thickness adjust (AFTA) assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Carriage assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Carriage drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Carriage drive motor assembly and fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Carriage support shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Encoder board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Engine board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Contents 6

Lower plastic shield/lower mylar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

Paper bail assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Paper feed motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Paper feed motor drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Platen assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Printer mechanical assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Printhead Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Ribbon drive motor and drive assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Ribbon lift motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Upper feed roller shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Sensor cable assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Tractor asms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Chapter 6. Parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

How to use this parts catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Assembly 1: Cover assembly, main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Assembly 2: Cover assembly, front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Assembly 3: Cover assembly, left- and right- side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Assembly 4: Cover assembly, rear and controller board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Assembly 5: Cover assembly, top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Assembly 6: Board (front), encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Assembly 7: Boards and fans (rear) engine, power supply, and fans . . . . . . . . . . . . . . . . . . . . . . 247

Assembly 8: Carriage assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Assembly 9: Mechanical assembly I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Assembly 10: Mechanical assembly II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Assembly 11: Mechanical assembly III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Assembly 12: Mechanical assembly and base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Contents 7

Assembly 13: Cover Assembly, Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Assembly 14: Parts kits, tools, and line cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Assembly 15: Printhead and cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Assembly 16: Tractor assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Chapter 7. Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Appendix A. Printer configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Unlocking and locking printer configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Printing the printer configuration and the custom sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Factory defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Changing a value in the printer configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

IPDS configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

ASCII configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

LAN attachment configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Appendix B. Supplies, forms, paths, & environmental considerations . . . . . . . . . . . . . . . . . . . 281

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Choosing a forms path for your needs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Choosing a forms path for special forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Other considerations for forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Forms and paper specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Forms stacking recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Forms stack input and output locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Shipping Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Storage Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Appendix C. Firmware Downloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Loading code though the Parallel Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Loading code though the Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Contents 8

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Product recycling and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Communication statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Part number index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Contents 9

Safety and environmental notices

Safety notices

There are two levels of safety notices: Danger and Cautions.

Danger hazard level

The word Danger indicates the presence of a hazard that has the potential of causing death or serious personal

injury.

DANGER notices are numbered <1-1>, <1-2>, and so forth where they appear in the text of this manual. Use the

notice number to locate the national language translation of that notice in InfoPrint 4247 Printers: Safety

Information, (S550-1020).

Example of a Danger notice:

DANGER

<1-10>

Hazardous voltages are present. Do not touch the pins or sockets of the power receptacle.

Caution hazard level

The word Caution indicates the presence of a hazard that has the potential of causing moderate or minor

personal injury.

CAUTION notices are numbered <2-1>, <2-2>, and so forth where they appear in the text of this manual. Use the

notice number to locate the national language translation of that notice in InfoPrint 4247 Printers: Safety

Information, (S550-1020).

Example of a Caution notice:

© Copyright InfoPrint Solutions Company 2008 10

CAUTION:

!

<2-22> Carefully follow all cleaning instructions, using only the materials and solutions recommended by InfoPrint

Solutions Company.

Attention notices

The word Attention calls attention to the possibility of damage to a program, device, system, or data.

Attention notices are not numbered.

Examples of an Attention notices:

Attention: This is an ESD sensitive device.

Safety precautions

Electrical safety

This printer is inspected and listed by recognized national testing laboratories, such as Underwriters Laboratories,

Inc. (UL) in the U.S.A. and Canadian Standards Association (CSA) in Canada. Listing of a product by a national

testing laboratory indicates that the product is designed and manufactured in accordance with national

requirements intended to minimize safety hazards. InfoPrint Solutions Company equipment meets a very high

standard of safety in design and manufacture. Remember, however, that this product operates under conditions of

high electrical potentials and heat generation, both of which are functionally necessary.

®

Because the paper used in the printer can burn, you should take normal precautions to prevent fire. These

precautions include common sense measures, such as keeping potentially combustible materials (for example,

curtains and chemicals) away from the printer, providing adequate ventilation and cooling, limiting unattended

operation, and having trained personnel available and assigned to the printer.

Safety and environmental notices 11

Electrostatic discharge (ESD) procedures

Read the following electrostatic discharge (ESD) information because, if discharged into the circuitry of an

integrated circuit, static electricity can damage the circuit. The following Attention notice in the text of this book

warns of possible damage caused by ESD.

Attention: This is an ESD sensitive area. See “Electrostatic discharge (ESD) procedures” before working with

parts that are sensitive to ESD.

Follow these guidelines to prevent damage to ESD-sensitive components:

v Keep an ESD-sensitive part in its original shipping container, usually a protective bag, until you are ready to

install it.

v Make the fewest possible movements to minimize static electricity.

v Touch the metal frame of the printer or the assembly to discharge static electricity in your body just before

touching the ESD-sensitive part.

v Hold the ESD-sensitive part by its edges. Do not touch any components, pins, or connectors. If possible, keep

one hand on the frame while you are installing or removing an ESD-sensitive part.

v Do not place an ESD-sensitive part on anything that can provide a discharge path from your body through the

ESD-sensitive part. If you need to put down the ESD-sensitive part, first put it into the ESD protective wrapper

in which it was shipped.

v Prevent ESD-sensitive parts from being touched by other persons.

v Cables may connect to engine cards or boards that are ESD-sensitive. Be careful when working with

connectors.

v Be careful when working with ESD-sensitive parts when the humidity is low. Low humidity increases static

electricity.

Using the ESD kit

To safely discharge all static electricity, use the ESD kit following the guidelines under “Electrostatic discharge

(ESD) procedures.”

v Turn off the printer before you put on the ESD wrist band.

v Connect the wrist band to an unpainted, frame-ground point of the printer.

Safety and environmental notices 12

v Remove the ESD wrist band when working on any part of the printer that has power turned on.

v Do not put the ESD mat near any electrical circuit that has power turned on. The internal resistance

(1 megohm) in the ESD cable limits the current if it touches a high voltage.

v Do not put the ESD mat near a grounded surface. Ground the ESD mat only through the ESD cable. The ESD

cable supplies a high resistance to ground for your safety. If the ESD mat touches a grounded surface, the high

resistance in the ESD cable is bypassed, which causes the ESD mat not to work as expected.

Approved power cord and receptacle

DANGER

<1-11>

Your country may require an approved power cord and plug. Ensure that you have the correct power cord

and plug. Use this cord and plug only with an approved, correctly-installed power receptacle.

Electrical safety and portable power strip receptacles

Extension cords

The customer must supply the correct electrical outlet which must meet the requirements stated under “Approved

power cord and receptacle.”

DANGER

<1-12>

Do not use an extension power-cord.

Safety and environmental notices 13

Portable power strip receptacles (temporary power taps)

Portable power strip receptacles (referred to as “temporary power taps” by the National Electrical Code®) may be

used if they are fully approved in the customer’s geographic location. It is the customer’s responsibility to supply a

fully approved “temporary power tap”, if one is to be used.

Connecting or disconnecting a communication port, a teleport, or an attachment connector

DANGER

<1-14>

Switch off printer power and unplug the printer power cord before connecting or disconnecting a

communication port, a teleport, or other attachment connector.

Servicing during an electrical storm

DANGER

<1-13>

Do not connect or disconnect a communication port, a teleport, or any other connector during an

electrical storm.

Safety and environmental notices 14

Safety inspection

Instructions

Perform this safety inspection before performing any of the following tasks:

v Accept a machine for service agreement

v Provide per-call service

v Relocate a machine

v Review changes or attachments on any InfoPrint Solutions Company machine that is leased, on service

agreement, or on per-call service

Ensure

that you correct unsafe conditions before you continue.

Possible safety hazards are:

v Electrical—An electrically charged frame, or exposed wires or connections, can cause serious electrical shock.

v Mechanical—A missing safety cover or shield is hazardous. Moving parts, such as gears, shaft, and pulleys

are hazardous.

v Chemical—Use only approved cleaning agents. Do not use other solvents or chemicals.

Reference items

You will need the following items:

v A copy of the machine EC history

v A list of current safety ECs

© Copyright InfoPrint Solutions Company 2008 15

Safety inspection procedure

1. Check that the printer is installed near the socket-outlet and that the socket-outlet is easily accessible.

2. Turn off and unplug the printer.

3. Check exterior covers for damage (loose, broken, or sharp edges).

4. Check top main cover interlock operation (see T&D17—Top cover interlock test).

5. Check the power cord for:

a. A third-wire ground connector in good condition. Use a meter to measure the third-wire ground continuity

for 0.1 ohm or less between the external ground pin and frame ground.

b. A power connector ground wire fastened with a screw and star washer near the power supply. Repair as

needed.

c. A second star washer between the frame ground and the wire lug.

d. A power cord of the appropriate type, shipped for the 4247 printer.

e. Insulation in good condition (not frayed nor worn).

6. Remove the covers (see Covers).

7. Check that the power supply cover has not been removed nor tampered with.

8. Check for any obvious non-InfoPrint Solutions Company alterations.

9. Check inside the unit for any obvious unsafe conditions, such as metal-filing contamination, water or other

liquids, or signs of fire or smoke damage.

10. Check for worn, frayed, or pinched cables.

Performing a power-receptacle safety-check

A trained service representative or a qualified electrician should perform all checks necessary to ensure safe

operation. These should include the following checks and any other required by local regulations.

v Check the ac voltage at all associated power receptacles (see “4247 Model Z03 nominal ac input power

requirements” on page 17).

v Check that all associated power receptacles are properly grounded.

Safety inspection 16

Check safety documentation for the correct test equipment and procedures before performing any of the following

|

tasks:

|

v Checking ac voltage at all associated power receptacles

|

v Checking that all associated power receptacles are properly grounded

|

DANGER

<1-10>

Use only the applicable high-voltage probes. 4247 Model Z03 nominal ac input power requirements gives the

|

appropriate voltage ranges.

|

Hazardous voltages are present. Do not touch the pins or sockets of the power receptacle.

The printer electrical outlet and any temporary power tap, must meet the requirements as stated in 4247 Model

Z03 nominal ac input power requirements.

Attention: If the voltages are not within the correct operating range, allow correction before the equipment is

plugged in and operated.

For pluggable equipment, the socket-outlet shall be installed near the equipment and shall be easily accessible.

4247 Model Z03 nominal ac input power requirements

Nominal Voltage Voltage Range Amps Phase / Hz

100–230 V ac 90–264 V ac 2.9–1.3 A Single phase / 50–60 Hz

Ground connectors check

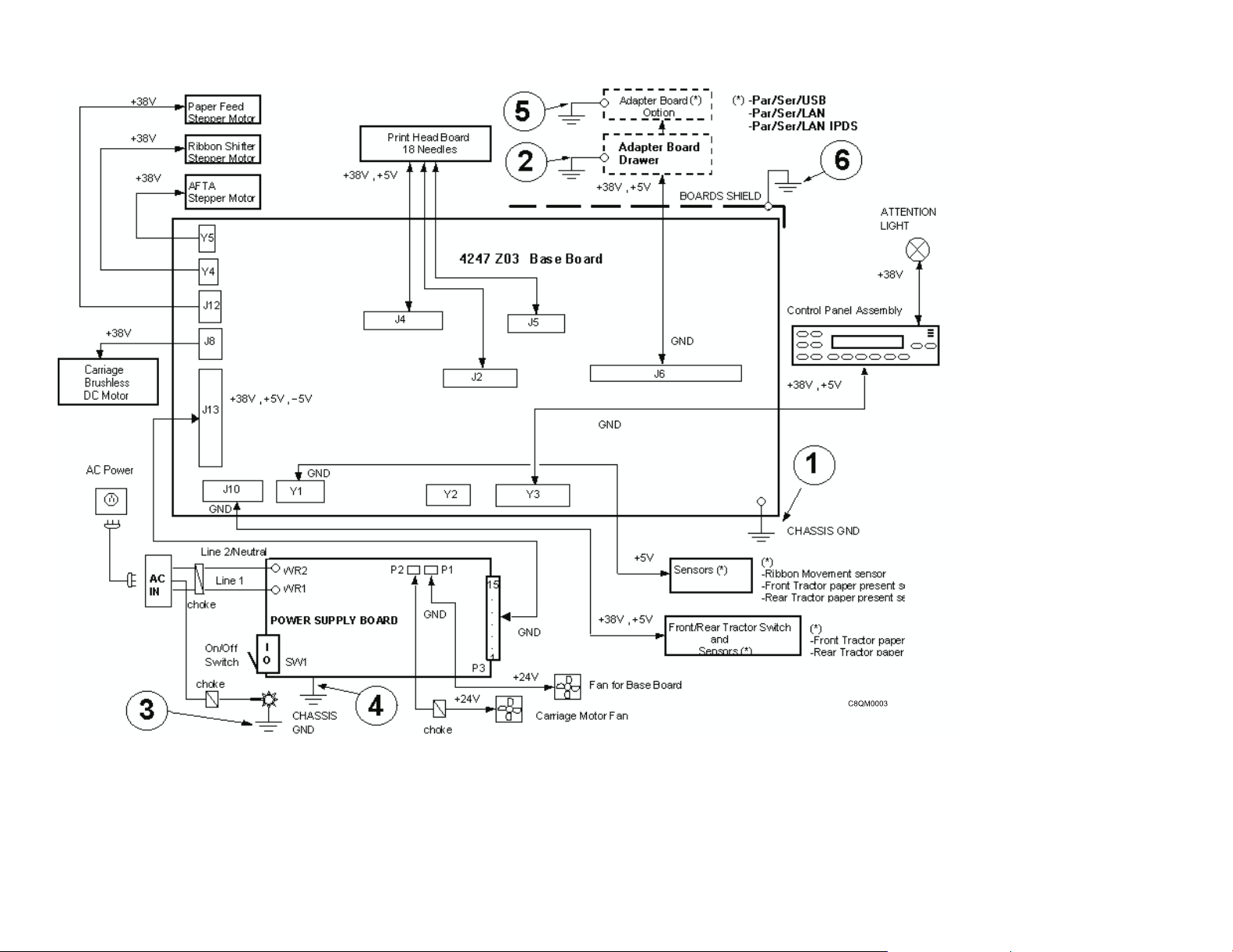

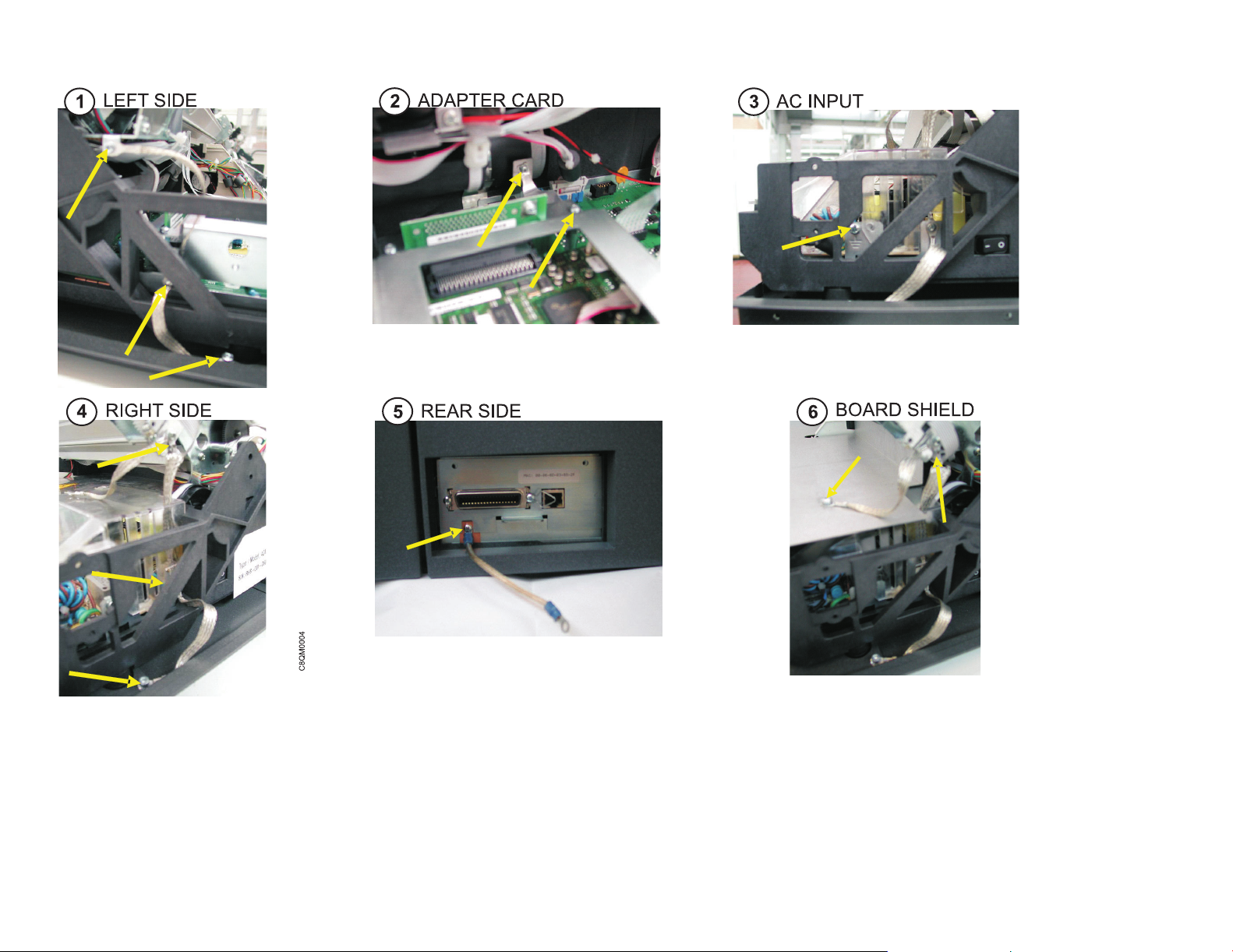

Using Figure 1 on page 18 and Figure 2 on page 19, ensure that all safety grounds are correctly installed.

Safety inspection 17

Figure 1. Ground path diagram

Safety inspection 18

Figure 2. Ground path illustrations

Safety inspection 19

Environmental notices

Product recycling and disposal

|

InfoPrint Solutions Company encourages owners of information technology (IT) equipment to responsibly recycle

|

their equipment when it is no longer needed.

|

Information on recycling programs offered by InfoPrint Solutions Company can be found at http://

|

|

www.infoprint.com.

Safety inspection 20

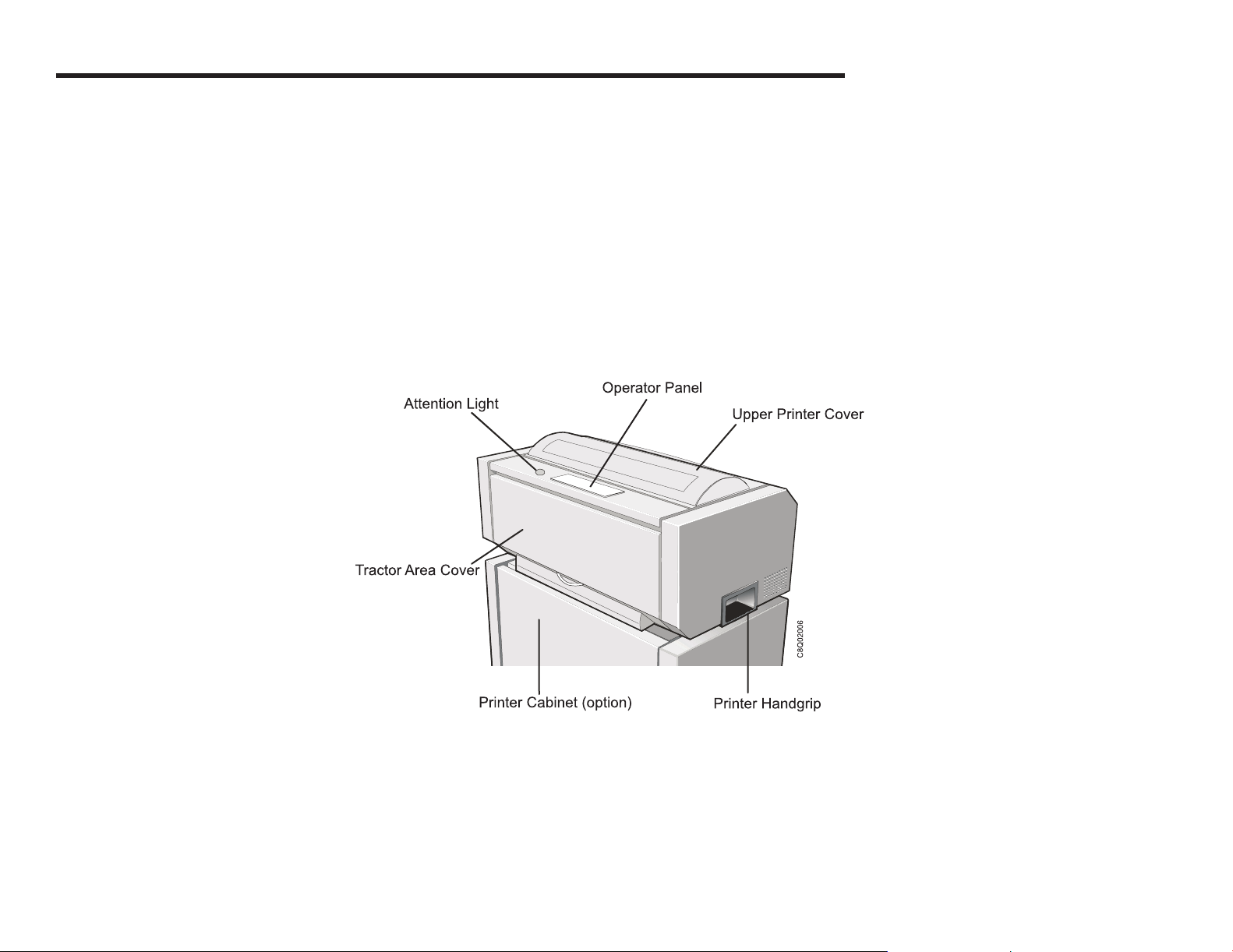

The 4247 Model Z03 Serial Matrix Impact Printer

The 4247 Model Z03 is a professional, industrial impact-matrix printer capable of printing at speeds of up to 1100

characters per second (cps) at 10 cpi in Fast Draft mode. The 4247 Model Z03 is a rugged printer, and is

designed for harsh environments and demanding applications. It is complementary with previous IBM® 4247

models and offers interface cards that can be installed by the user.

The 4247 Model Z03 can have either one or two straight continuous-forms paper paths. One paper path is

standard, and the second path is an optional feature. The printer operator panel is common with the Model X03

and includes the same full-function, full-size, 2 line by 24 character display, making messages and menus easy to

understand.

© Copyright InfoPrint Solutions Company 2008 21

Print quality choices are Fast Draft mode, DP mode (DP), DP Text mode (DP Text), and Near Letter Quality mode

(NLQ). Versatile paper handling capability provides printing on up to 8-part forms. Typical applications include

transaction processing for invoices, office or internal business documents, as well as barcodes, labels, and

multipart forms.

Print speeds

The InfoPrint 4247 Model Z03 print speeds (in characters per second) are up to:

v 1100 cps at 10 characters per inch (cpi) in Fast Draft mode

v 800 cps in DP mode

v 480 cps in DP Text mode

The 4247 Model Z03 Serial Matrix Impact Printer 22

v 240 cps in NLQ

Paper paths

The InfoPrint 4247 Model Z03 printer provides exceptional forms handling flexibility. The base printer includes one

continuous-form tractor paper-path, a second tractor paper path is optional. Both continuous form paper paths are

front loading.

Paper path nomenclature

Base tractor (rear tractor when a second tractor is installed)

This tractor is installed at the factory on all machines. In a single tractor machine the base tractor is the front

tractor. The base tractor becomes the rear tractor when a second (optional) tractor is installed.

Second tractor (optional, becomes front tractor)

This tractor can be installed in front of the base tractor as an option. In a two tractor machine the second

(optional) tractor is the front tractor and the base tractor becomes the rear tractor.

Print qualities

Fast Draft is a print quality for the InfoPrint 4247 Model Z03 that is available only on the 4247 Model Z03 (and on

the previous 4247 model V03). The Data Processing (DP), Data Processing Text (DP Text), Near 2 Letter Quality

(NLQ), OCR-A, and OCR-B print qualities on the 4247 Model Z03 are equivalent in character size, shape, and

resolution to the print qualities available on the 4247 Model X03 printer.

Fast draft print quality selection

Print quality can be selected via program control or through the printer operator panel. Program control

datastream commands take precedence over operator panel settings and can not be overridden.

Available printer operator panel settings are:

Print Quality = Fast Draft (default setting)

Print Quality = DP

The 4247 Model Z03 Serial Matrix Impact Printer 23

Print Quality = DP TEXT

Print Quality = NLQ

Print Quality = OCR-A

Print Quality = OCR-B

A 4247 Model Z03 operator panel feature, Host Fast Draft, is a setting that allows application programs written

for earlier printers in DP mode to print in Fast Draft mode without changes to application program. If Host Fast

Draft is enabled (default setting) then DP mode applications print in Fast Draft mode. If Host Fast Draft is

disabled then DP mode applications print in DP mode.

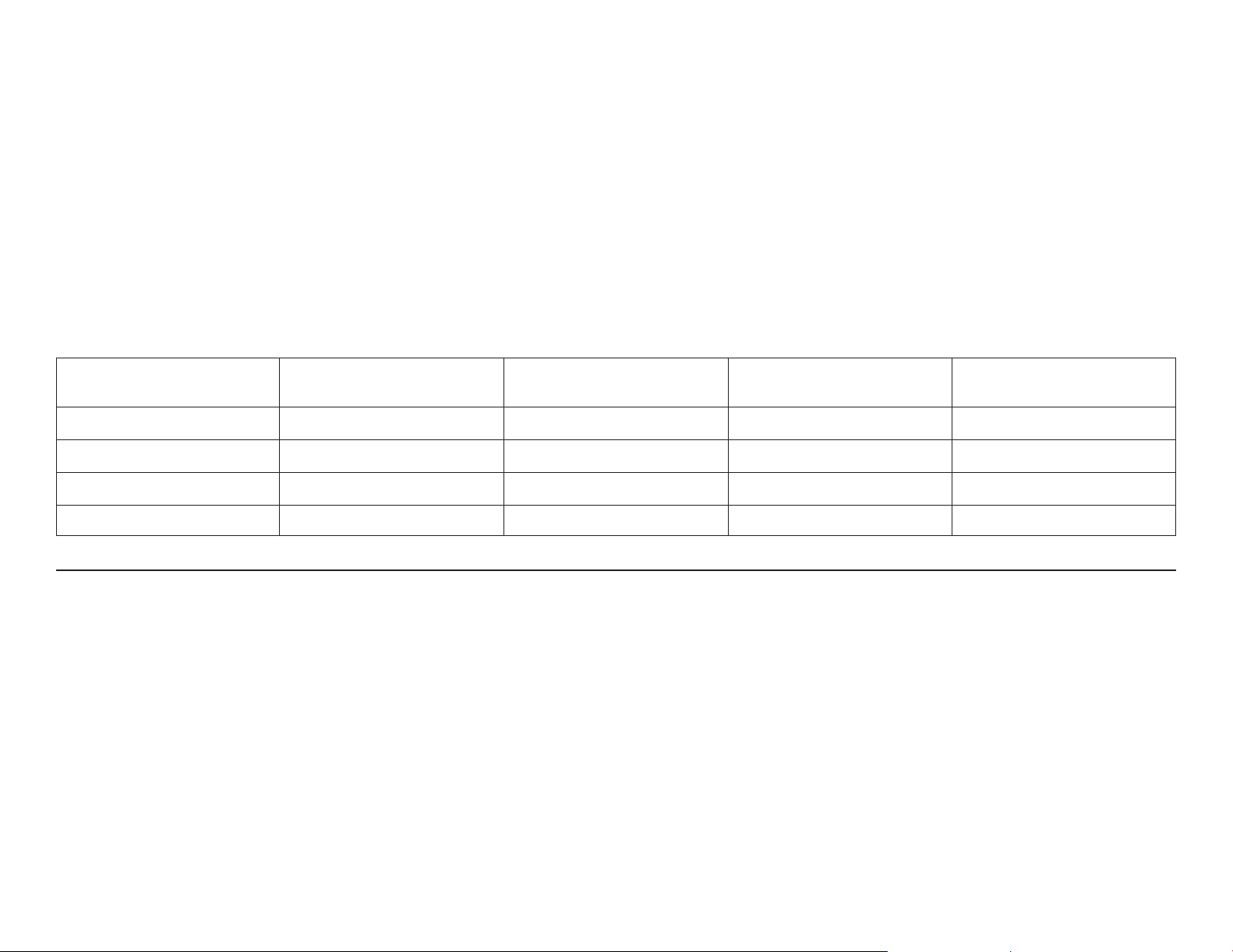

The following table summarizes the print quality for Fast Draft, DP, DP Text, and NLQ:

Print quality Horizontal DPI Vertical DPI

Horizontal character

cell size (dots)

Vertical character cell

size (dots)

Fast Draft 45 72 9 9

DP 60 72 12 9

DP Text 100 72 20 9

NLQ 100 144 20 18

4247 Model Z03 differences and commonality with other models

Controller boards

Controller board part numbers are not common (that is, Controller Boards are not interchangeable) between the

models Z03 and X03 printers. However, the controller board types for the X03 and Z03 are:

v Parallel, serial, and USB 2.0 interfaces

v Parallel and ASCII Ethernet 10/100 LAN interfaces

v Parallel and ASCII/IPDS Ethernet 10/100 LAN interfaces

The 4247 Model Z03 Serial Matrix Impact Printer 24

Carriage

The 4247 Model Z03 carriage is driven by a dc servo motor. An optical sensor mounted to the print head carriage

travels along a linear grid encoder strip. The sensor detects marks along the encoder strip, and returns pulses to

the engine board that are used to control the speed and position of the print head. The 4247 Model Z03 carriage

belt is the same as the V03 model but is changed from earlier models, and the belt tension adjustment procedure

is set to a higher tension.

Covers

The 4247 Model Z03 covers are metal and plastic which are heavy duty and extremely durable.

Flash memory download and printer microcode file

The 4247 Model Z03 flash download code is a single file that supports all printer attachment configurations. The

download program, which can be executed from a DOS command window from any computer, sends code to the

printer through the parallel or Ethernet ports.

Operator panel

The 4247 Model Z03 operator panel is new and common with the model X03 printer, and includes drive circuits

for the Attention Light, which resides on the top cover. The new operator panel features three status indicators

(READY, PROCESSING, and ATTENTION), 14 printer function keys, 2 line by 24 character display panel, and an

audible alarm.

The 4247 Model Z03 Serial Matrix Impact Printer 25

Paper paths

The 4247 Model Z03 has 2 front-loading push tractor paper paths.

Printhead

The 4247 Model Z03 print head is a 18-wire moving ruby print head capable of printing at speeds of up to

1100 characters per second in Fast Draft mode. The 4247 Model Z03 print head includes two connectors not

found on some earlier model print heads. One connector drives the carriage encoder optical sensor. The second

connector, that may be present, might also have a 12-pin ribbon cable plugged into it. This connector and cable

are not used by the 4247 Model Z03 18-wire print head. AFTA service check and adjustment procedures for the

Z03 are similar with earlier models.

Printhead mask

The 4247 Model Z03 print head mask is an easy-change metal spring attached to the carriage by two

easy-access screws.

Ribbon cartridge

The 4247 Model Z03 ribbon is specifically designed for the faster print speeds of the 4247 Model Z03 printer. The

ribbon cartridge and ribbon support brackets are keyed to prevent earlier model ribbons from being used on this

printer. The ribbon cartridge is common for 4247 model X03 and Z03 printers. Use part number 57P1743 when

ordering a replacement ribbon cartridge.

Test & Diagnostics

The 4247 Model Z03 T&Ds are similar to T&Ds found on earlier models. The T&D numbering scheme has

changed on this model, as have the test names displayed on the operator panel (due to the 2 line by 24 character

display) and the T&Ds instructions (due to new button designations).

The 4247 Model Z03 Serial Matrix Impact Printer 26

Related information

Softcopy

v InfoPrint 4247 Model Z03 Printer: Customer Information CD, GK4T-3959.

Contents of CD-ROM (This CD-ROM is packaged with the printer.)

– InfoPrint 4247 Model Z03 Printers: Quick Setup Guide, S550-1017.

– InfoPrint 4247 Model Z03 Printers: User’s Guide, S550-1018.

– InfoPrint 4247 Printers: Safety Information, S550-1020.

– InfoPrint 4247 Model X03/Z03 Printers: Programming Reference, S550-1019.

Hardcopy

v InfoPrint 4247 Printers: Safety Information, S550-1020.

v InfoPrint 4247 Model Z03 Printer: Quick Setup Guide, S550-1017.

The 4247 Model Z03 Serial Matrix Impact Printer 27

Chapter 1. Diagnosing problems

Maintenance analysis procedures (MAPs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Defining the problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

MAP 0100: START of call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

MAP 0120: Parallel, serial or USB interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

MAP 0122: LAN Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

MAP 0130: No paper movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

MAP 0131: Paper path sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

MAP 0140: Printhead drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

MAP 0150: Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

MAP 0160: Ribbon feed and ribbon lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

MAP 0180: To p cover interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

MAP 0190: Form feed problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

MAP 0200: 055 AFTA errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

MAP 0210: Intermittent failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

MAPs reference tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Reference table 1, error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Reference table 2, no printed characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Reference table 3, print quality failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Reference table 4, operator panel and miscellaneous problems . . . . . . . . . . . . . . . . . . . . . . . .79

Reference table 5, power supply connector pins and voltages . . . . . . . . . . . . . . . . . . . . . . . . .81

Reference table 6, ribbon lift and 26-pin cable connectors . . . . . . . . . . . . . . . . . . . . . . . . . . .82

© Copyright InfoPrint Solutions Company 2008 28

Maintenance analysis procedures (MAPs)

Defining the problem

These Maintenance Analysis Procedures (MAPs) are designed to aid in diagnosing printer problems. The MAPs

use a sequential plan for isolating the possible causes of printer problems and point you to the part needing

adjustment, repair, or exchange.

Suggestions for Using the MAPs

v Discuss the printer symptoms with the operator.

v Verify that the current configuration is correct. See Appendix A, Printer Configuration (Appendix A, “Printer

configuration”).

v Verify that the environment, the paper and the forms used are within specifications. See Appendix B, Supplies,

Forms, Paths and Environmental Considerations (Appendix B, “Supplies, forms, paths, & environmental

considerations”).

v Make a quick visual inspection for problems — loose or broken parts, disconnected connectors, or forms jams.

This check may quickly identify problem areas.

v The normal place to start a service call in these MAPs is at “MAP 0100: START OF CALL” (MAP 0100: START

OF CALL). This MAP sends you to a Field Replaceable Unit (FRU) or to another MAP that is indicated by the

symptoms. If you bypass “MAP 0100: START OF CALL,” and start the service with another MAP, you may be

using the wrong MAP. The questions in that MAP may not refer to your symptom and may send you to the

wrong resolution.

v These MAPs are an aid in solving most problems. If you misunderstand instructions or questions, a MAP may

lead you to an incorrect resolution. Start again in the MAPs and read each step carefully. If, after going through

the MAPs a second time you still have no solution to the problem, the printer may have two interrelated

problems or an intermittent problem. Use other diagnostic techniques or call InfoPrint Solutions Company

Support for aid.

v Read carefully! The MAPs will aid you in resolving the situation only if you follow every instruction and answer

each question accurately.

Chapter 1. Diagnosing problems 29

v Follow the sequence! Always do one question at a time. When a procedure precedes the question, do all of

the steps in the procedure before answering the question. Some steps have additional information that pertains

to that step. This information is in the map flow and is an aid in describing why questions or actions are needed

to find the correct failing FRU.

v Follow instructions! Instructions must be followed exactly in the order given. Questions rely on the instructions

immediately before the questions. Do not change the conditions prepared by the instructions before answering

the question. Do not turn off the printer or disconnect any cable unless you are instructed to do so. Whenever

possible, the MAPs are written so that No is the error path answer.

v Verify repair or exchange FRU! When a card or a cable is identified as the failing FRU, reseat it and verify

that the same problem remains. If the problem continues, exchange the FRU. Start again at MAP 0100: START

OF CALL (see MAP 0100: START of call), to ensure the correct operation of the printer before returning it to

the customer.

Intermittent strategy: For intermittent symptoms, see “MAP 0210: Intermittent Failures” (see MAP 0210:

Intermittent failures).

Voltage/continuity readings: When taking voltage or continuity readings, do exactly as the MAP instructs.

Abbreviations used in this book

AFTA automatic forms thickness adjustment

CPI characters per inch

CPU central processing unit

EMI electromagnetic interference

EPA environmental protection agency

MAP maintenance analysis procedure

NLQ near letter quality

Chapter 1. Diagnosing problems 30

Loading...

Loading...