Page 1

Screw Driver

日立牌電動起子機

W 6VM • W 6V4 • W 6VA4 • W 6VB3 • W 8VB2

HANDLING INSTRUCTION

使用說明書

W6VM • W6V4 • W6VA4

W6VB3 • W8VB2

Read through carefully and understand these instructions before use.

使用前務請詳加閱讀

Page 2

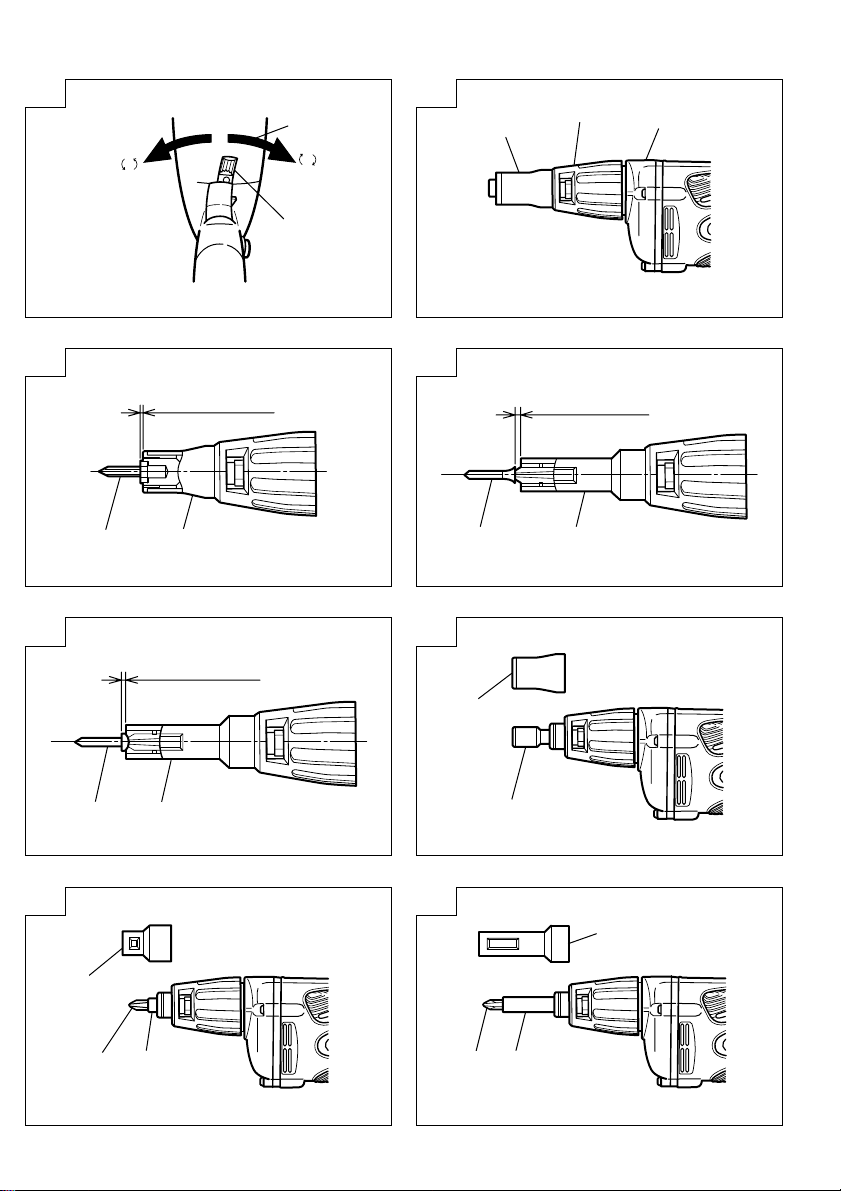

12

2

L

R

3

4

5

1

3

5

7

6 9

1 - 1.5 mm

8 D

1 - 1.5 mm

4

1.5 - 2 mm

7 D

6

9

:

8

D

A

B C

1

B E

Page 3

Lever

1

R side

2

Sub-Stopper (B)

3

Locator

4

Gear cover

5

Hex. head screw

6

Drywall screw

7

Self-drilling screw

8

Sub-Stopper (B)

9

Magnetic hex. socket

@

Sub-Stopper (G)

A

Bit

B

Bit holder (Short type)

C

Sub-Stopper (F)

D

Bit holder

E

拉杆

R 側

副制動器 (B)

定位器

齒輪罩

六腳頭螺絲

清水牆螺絲

自鑽螺絲

副制動器 (B)

磁性六腳座

副制動器 (G)

鑽頭

鑽頭座(短型)

副制動器 (F)

鑽頭座

2

Page 4

English

GENERAL SAFETY RULES

WARNING!

Read all instructions

Failure to follow all instructions listed below may result

in electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed below

refers to your mains operated (corded) power tool or

battery operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

Power tools create sparks which may ignite the

dust of fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk

of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

b) Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal

injuries.

c) Avoid accidental starting. Ensure the switch is in

the off position before plugging in.

Carrying power tools with your finger on the

switch or plugging in power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear looses clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

Use of these devices can reduce dust related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off.

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source before

making any adjustments, changing accessories,

or storing power tools.

Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation.

If damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc., in accordance with these instructions and in

the manner intended for the particular type of

power tool, taking into account the working

conditions and the work to be performed.

Use of the power tool for operations different from

intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool

is maintained.

PRECAUTION

Keep children and infirm persons away.

When not in use, tools should be stored out of reach of

children and infirm persons.

3

Page 5

English

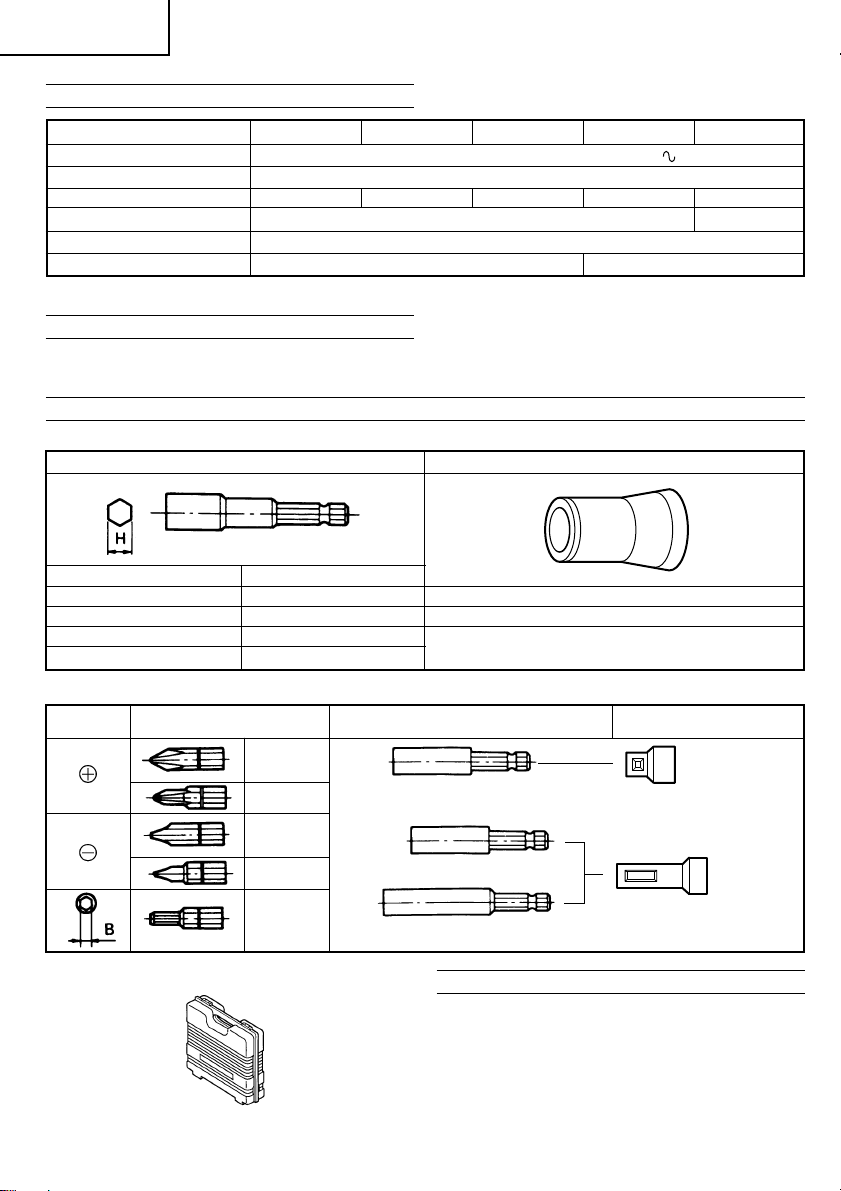

SPECIFICATIONS

Model W6VM W6V4 W6VA4 W6VB3 W8VB2

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power input 620 W

No-load speed 0 – 6000/min 0 – 4500/min 0 – 3000/min 0 – 2600/min 0 – 1700/min

Capacities 6 mm 8 mm

Bit shank size 6.35 mm Hex.

Weight (without cord) 1.4 kg 1.5 kg

* Be sure to check the nameplate on product as it is subject to change by areas.

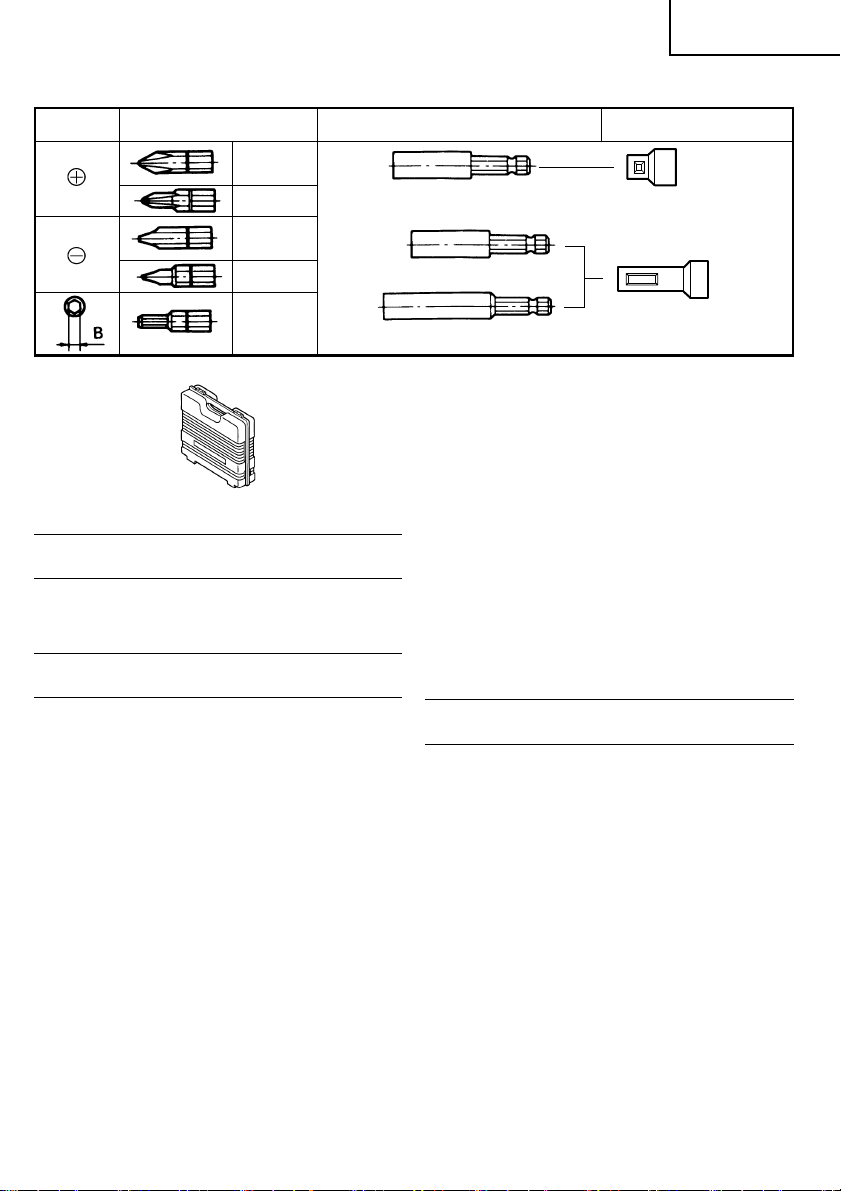

STANDARD ACCESSORIES

(1)

No. 2 Plus bit .............................. 1(W6VM, W6V4, W6VA4)

(2)

Magnetic hex socket (H = 10 mm) ....... 1 (W6VB3, W8VB2)

OPTIONAL ACCESSORIES (sold separately)

1. For hex-head screws

Hex-socket Sub-Stopper (B)

Standard accessories are subject to change without

notice.

Magnetic type

H = 6.35 mm

H = 7.94 mm

H = 9.53 mm

H = 10 mm

2. For other screws

Screw

head

3. Plastic case

Optional accessories are subject to change without

notice.

4

Bit type Sub-Stopper

Non magnetic type

H = 6.35 mm

H = 7.94 mm

H = 9.53 mm

H = 10 mm

No.1

No.2

No.3

No.1

No.2

No.1

No.2

No.3

No.1

No.2

B Size

4 mm

5 mm

Magnetic bit holder

(Short type)

Magnetic bit holder

Non-magnetic bit bolder

H 1/4

H 5/16

H 3/8

Bit holder

Sub-Stopper (G)

Sub-Stopper (F)

APPLICATIONS

䡬 Tightening hex-head screws.

䡬 Tightening drywall screws, wood screws and self-

drilling screws.

Page 6

English

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If

the plug is connected to a power receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause a

serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

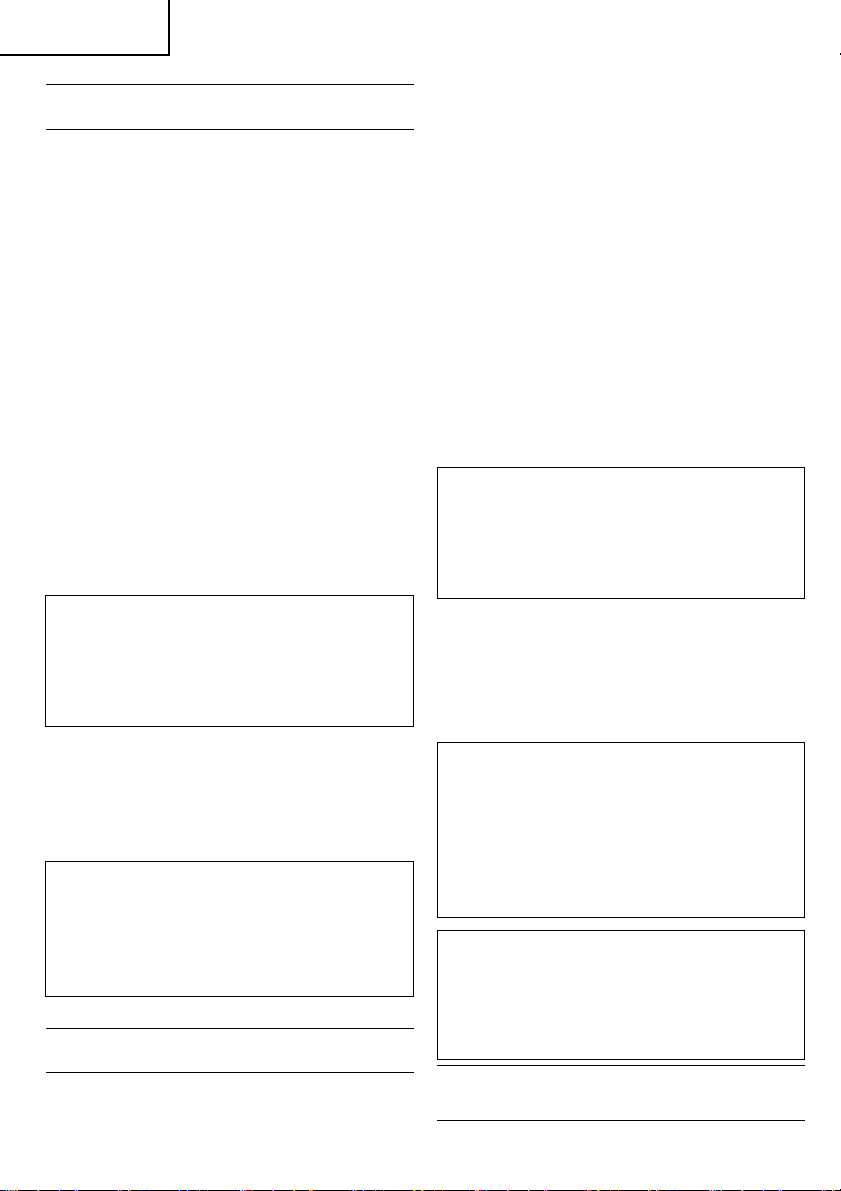

4. Confirm the direction of bit rotation (Fig. 1)

The bit rotates clockwise (viewed from the rear side)

when the reversing switch lever is set to the “R” side

position. When the lever is set to the “L” side position,

the bit rotates counterclockwise and can be used to

loosen and remove screws.

5. Adjusting the tightening depth (Fig. 2)

The tightening depth can be adjusted by turning

locator right and left click feeling.

(1) For hex-head screws:

Mount a hex-head screw on the hex-socket and set

the distance between the sub-stopper end and the

screw head neck to 1–1.5 mm, as shown in Fig. 3.

(2) For drywall screws:

Mount a drywall screw on the bit, and set the distance

between the sub-stopper end and the screw head to

1.5–2 mm, as shown in Fig. 4.

(3) For cross-recessed self-drilling screws:

Mount a self-drilling screw on the bit, and set the

distance between the sub-stopper end and the screw

head bottom to 1–1.5 mm, as shown in Fig. 5.

6. Mounting the bit

For details, refer to the item “Mounting and

dismounting the bit”.

MOUNTING AND DISMOUNTING THE HEXSOCKET OR THE BIT

1. Dismounting the hex-socket (Fig. 6)

(1) While rotating the Sub-Stopper pull it out from the

locator.

(2) Remove the hex-socket, hold it with the opposite

side of bit by hand or vise and pull out the bit with

pliers.

2. Dismounting the bit (Fig. 7)

Remove sub-stopper (G) as the same manner of hexhead socket and remove the bit holder, then pull out

the bit with pliers.

3. Dismounting the bit (Fig. 8)

Remove the sub-stopper (F) as the same manner of

hex-head socket and remove the bit holder, then pull

out the bit with pliers.

4. Mounting the hex-socket or the bit

Install the bit in the reverse order to removal.

HOW TO USE THE SCREW DRIVER

1. Switch operation and rotational speed adjustment

Bit rotational speed can be adjusted between 0 –

6000/min (W6VM) or 0 – 4500/min (W6V4) or

0 – 3000/min (W6VA4) or 0 – 2600/min (W6VB3) or 0 –

1700/min (W8VB2) varying the degree by which the

trigger switch is pulled. Rotational speed increases

as the trigger switch is pulled, and reaches a

maximum speed of 6000/min (W6VM) or 4500

/min (W6V4) or 3000/min (W6VA4) or 2600

/min (W6VB3) or 1700/min (W8VB2) when the trigger

switch is pulled fully.

To facilitate continuous operation, pull the trigger

switch and depress the switch stopper. The switch

will then remain ON even when the finger is released.

By pulling the trigger switch again, the switch stopper

disengages and the switch is turned OFF when the

trigger switch is released.

2. Screw Driver operation

When the switch is turned ON, the motor starts to run

but the hex-socket (or the bit) does not rotate. Attach

the hex-socket to the screw head groove, and push

the Screw Driver against the screw. The hex-socket

then rotates and tightens the screw.

CAUTION

Ensure that the Screw Driver is held truly

perpendicular to the head of the screw.

If held at an angle, the driving force will not be fully

transferred to the screw, and the screw head and/or

hex-socket will be damaged. Hex-socket rotation stops

when pushing force is released.

3. Direction of hex-socket rotation

The hex-socket rotates clockwise (viewed from the

rear side) when the reversing switch lever is set to

the “R” side position. When the lever is set to the “L”

side position, the hex-socket rotates counterclockwise, and can be used to loosen and remove

screws.

CAUTION

Never change the direction of hex-socket (or bit

holder) rotation while the motor is running. To do so

would seriously damage the motor. Turn the power

switch OFF before changing the direction of hexsocket (or bit holder) rotation.

MAINTENANCE AND INSPECTION

1. Inspecting the hex-socket (or bit)

Since continued use of a worn hex-socket (bit) will

damage screw heads, replace the hexsocket (bit) with

a new one as soon as excessive wear is noticed.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very ”heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

5

Page 7

English

4. Inspecting the carbon brushes

For your continued safety and electrical shock

protection, carbon brush inspection and replacement

on this tool should ONLY be performed by a Hitachi

Authorized Service Center.

5. Service and repairs

All quality power tools will eventually require

servicing or replacement of parts because of wear

from normal use. To assure that only authorized

replacement parts will be used, all service and repairs

must be performed by a Hitachi Authorized Service

Center, ONLY.

CAUTION

䡬 Be sure to follow the above assembly procedures

exactly. Should be internal wiring contact the

armature or become pinched between the handle

cover and housing, a serious risk of electric shock

to the operator would be created.

䡬 Do not tamper with parts other than those necessary

to effect carbon brush replacement.

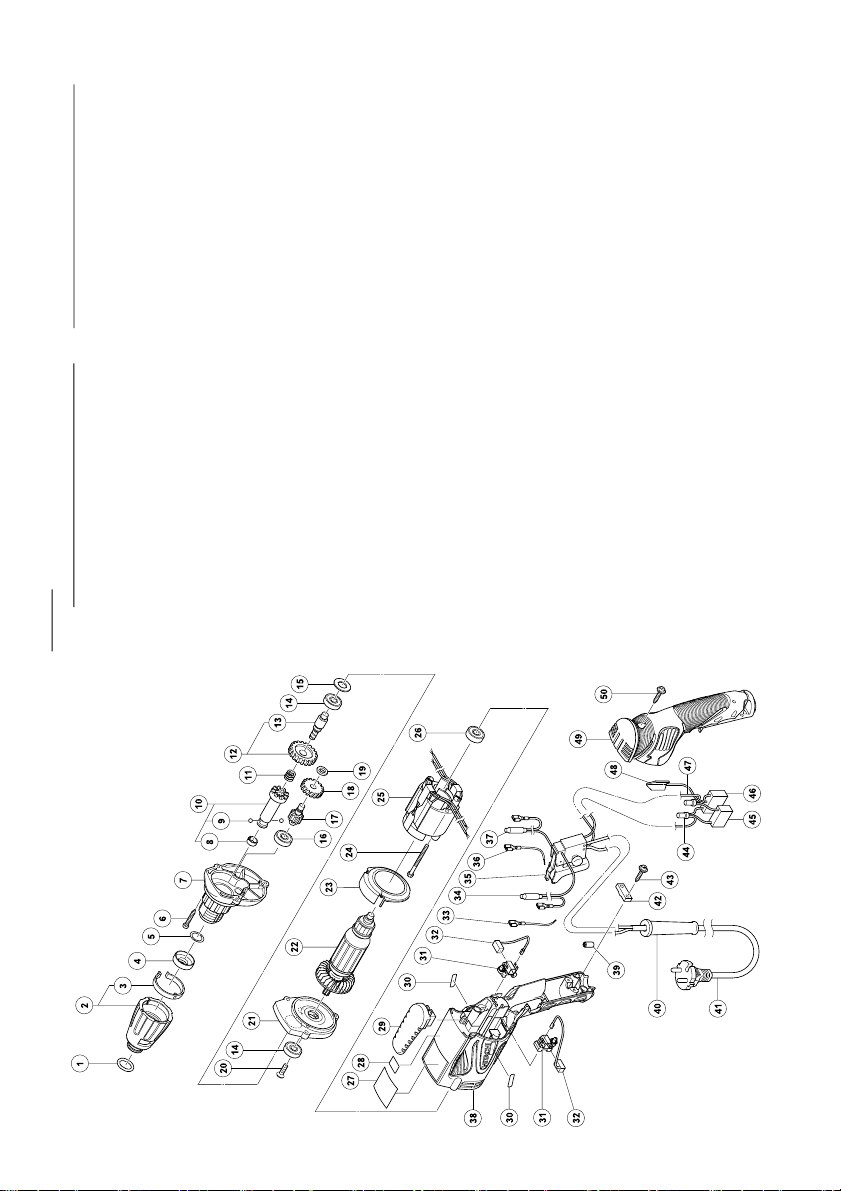

6. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by a Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATION

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

NOTE:

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

6

Page 8

中國語

一般安全規則

警告!

請通讀本說明書

若不遵守下列注意事項,可能會導致電擊、火災及/或

嚴重傷害。

下述警告中的術語「電動工具」,指插電 (有線) 電

動工具或電池 (無線) 電動工具。

請妥善保管本說明書

1) 工作場所

a) 工作場所應打掃乾淨,並保持充分的亮度。

雜亂無章及光線昏暗容易導致事故。

b) 請勿在易爆炸的環境中操作電動工具,如存在

易燃液體、氣體或粉塵的環境中。

電動工具產生的火花可能會點燃煙塵。

c) 操作電動工具時,孩童與旁觀者勿靠近工作場

所。

工作時分神可能會造成工具失控。

2) 電氣安全

a) 電動工具插頭必須與插座相配。

不得以任何形式改裝插頭。

不得對接地的電動工具使用任何轉接插頭。

原裝插頭及相配插座將會減少電擊的危險。

b) 應避免身體與大地或接地表面,如管道、散熱

器、爐灶、冰箱等的接觸。

若身體接觸大地或接地表面,更會增加電擊的

危險。

c) 電動工具不可任其風吹雨打,或置於潮濕的環

境中。

水進入電動工具也會增加電擊的危險。

d) 要小心使用電線。不要用電線提拉電動工具,

或拉扯電線來拆除工具的插頭。

電線應遠離熱源、油液,並避免接觸到銳利邊

緣或轉動部分。

電線損壞或攪纏在一起會增加電擊的危險。

e) 在室外操作電動工具時,請使用專用延伸線。

使用專用延伸線可降低電擊的危險。

3) 人身安全

a) 保持高度警覺,充分掌握情況,以正常的判斷

力從事作業。

疲勞狀態或服藥、飲酒後,請勿使用電動工

具。

操作電動工具時,一時的疏忽都可能造成嚴重

的人身傷害。

b) 使用安全設備。始終配戴安全眼鏡。

在適用條件下,使用防塵面罩、防滑膠鞋、安

全帽或聽覺保護裝置等安全設備,都會減少人

身傷害。

c) 謹防誤開動。插接電源前,請先確認開關是否

已切斷。

搬移電動工具時指頭接觸開關,或接通開關狀

態下插上電源插座,都容易導致事故。

d) 開動前務必把調整用鍵和扳手類拆除下來。

扳手或鍵留在轉動部分上,可能會造成人身傷

害。

e) 要在力所能及的範圍內進行作業。作業時腳步

要站穩,身體姿勢要保持平衡。

這樣在意外情況下可以更好地控制工具。

f) 工作時衣服穿戴要合適。不要穿著過於寬鬆的

衣服或佩帶首飾。頭髮、衣角和手套等應遠離

轉動部分。

鬆散的衣角、首飾或長髮都可能會捲入轉動部

分。

g) 如果提供連接除塵和集塵的設備,請確認是否

已經連接好並且使用正常。

使用這些設備可降低粉塵引起的危險。

4) 電動工具的使用和維護

a) 不要使勁用力推壓。應正確使用電動工具。

正確使用才能讓工具按設計條件有效而安全地

工作。

b) 如果電動工具不能正常開關,切勿使用。

無法控制開關的電動工具非常危險,必須進行

修理。

c) 進行調整、更換附件或存放工具前,請拆除電

源插頭。

此類預防安全措施可減少誤開動工具的危險。

d) 閒置不用的工具,應存放在孩童夠不到的地

方;不熟悉電動工具或本說明書的人員,不允

許操作本工具。

未經培訓的人員使用電動工具非常危險。

e) 妥善維護工具。檢查轉動部分的對準、連接,

各零件有無異常,及其他足以給工作帶來不良

影響的情況。

如有損壞,必須修理後才能使用。

許多事故都是因工具維護不良引起的。

7

Page 9

中國語

f) 保持工具鋒利、清潔。

正確維護工具,使其保持鋒利,作業順暢,便

於控制。

g) 請根據本說明書,按照特殊類型電動工具的方

式,使用本工具、附件及鑽頭,並考慮作業條

件及具體的作業情況。

電動工具用於規定外的作業,可能會導致危險

狀況。

5) 維修

a) 本電動工具的維修必須由專業人員使用純正配

件進行。

這樣才能確保電動工具的安全性。

注意事項:

不可讓孩童和體弱人士靠近工作場所。

應將不使用的工具存放在孩童和體弱人士伸手不及的

地方。

規 格

型 式 W6VM W6V4 W6VA4 W6VB3 W8VB2

電 壓(按地區)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

輸入功率 620 W

額定輸出功率 270 W

空載轉速 0 – 6000轉/分 0 – 4500轉/分 0 – 3000轉/分 0 – 2600轉/分 0 – 1700轉/分

螺絲旋緊能力 6 mm 8 mm

鑽頭杆的尺寸 6.35 mm 六角形

重 量(不含線纜) 1.4 kg 1.5 kg

*當須改變地區時應檢查產品上的銘牌。

標 準 附 件

(1) 2 號十字形鑽頭..... 1 (W6VM, W6V4, W6VA4)

(2) 磁性六腳座

(H = 10 mm) .............. 1 (W6VB3, W8VB2)

標準附件可能不預先通告而徑予更改。

選購附件(分開銷售)

1. 用于六腳頭螺絲

六腳座

磁性型

H = 6.35 mm

H = 7.94 mm

H = 9.53 mm

H = 10 mm

8

無磁性型

H = 6.35 mm

H = 7.94 mm

H = 9.53 mm

H = 10 mm

副制動器 (B )

H 1/4

H 5/16

H 3/8

Page 10

2. 用于其他螺絲

螺絲頭

1號

2號

3號

1號

2號

1號

2號

3號

1號

2號

B 尺寸

4 mm

5 mm

磁性鑽頭座

(短型)

磁性鑽頭座

無磁性鑽頭座

中國語

副制動器鑽頭座

副制動器 ( G)

副制動器 ( F)

3. 塑料套

選購附件可能不預先通告而徑予更改。

用 途

○ 旋緊六腳頭螺絲。

○ 清水牆螺絲、木螺絲和自鑽螺絲的旋緊。

作 業 之 前

1. 電源

確認所使用的電源與工具銘牌上標示的規格是否相

符。

2. 電源開關

確認電源開關已經切斷。若電源開關接通,則插頭

插入電源插座時電動工具將出其不意地立刻轉動,

從而招致嚴重事故。

3. 延伸線纜

若作業場所移到離開電源的地點,應使用容量足

夠、鎧裝合適的延伸線纜,並且要盡可能地短些。

4. 確認鑽頭的旋轉方向(圖 1)

將換向開關杆設為“R”側位置時,鑽頭按順時針

方向旋轉(從后面看時)。將換向開關杆設為

“L”側位置時,鑽頭按逆時針方向旋轉並可以旋

鬆螺絲。

5. 調節旋緊深度(圖 2)

左右旋轉定位器來調節上緊的深度,直至有卡嗒的

感覺。

(1)用于六腳頭螺絲︰

按圖 3 所示方法,將六腳頭螺絲裝配在六腳座上,

並將從副製動器末端至螺絲頭底部的距離設為

1 – 1.5 mm。

(2)使用清水牆螺絲時:

按圖 4 所示方法,將清水牆螺絲裝配在鑽頭上,並

將從副制動器末端至螺絲頭底部的距離設定為

1.5 – 2 mm。

(3)使用十字形頭自鑽螺絲時:

按圖 5 所示方法,將自鑽螺絲裝配在鑽頭上,並將

從副制動器末端至螺絲頭底部的距離設定為

1 – 1.5 mm。

6. 安裝鑽頭

詳細請參考“安裝與拆卸鑽頭”。

安裝與拆卸六腳座或鑽頭

1. 拆卸六腳座(圖 6)

(1)一邊旋轉副制動器一邊將其拔出。

(2)拆下六腳座后,用手或鉗子夾住鑽頭的反面,用另

一鉗子拉出鑽頭。

2. 拆卸鑽頭(圖 7)

與六腳座相似,拆下副制動器(G)並拆下鑽頭

座,然后用鉗子拉出鑽頭。

3. 拆卸鑽頭(圖 8)

與六腳座相似,拆下副制動器(F)並拆下鑽頭

座,然后用鉗子拉出鑽頭。

4. 安裝六腳座或鑽頭

請按與拆卸時的相反順序來安裝鑽頭。

9

Page 11

中國語

電動起子機的使用方法

1. 開關操作法和轉速的調節法

鑽頭的轉速的可變範圍為 0-6000 轉∕分

(W6VM),0 - 4500 轉∕分(W6V4),0 3000 轉∕分(W6VA4),0-2600 轉∕分

(W6VB3),0 - 1700 轉∕分(W8VB2)鑽

頭的轉速是由扳機開關的扣動程度而決定的。扳機

開關完全被拉起時,鑽頭便達到最大轉速 6000

轉∕分(W6VM),4500 轉∕分(W6V4),

3000 轉∕分(W6VA4),2600 轉∕分

(W6VB3),1700 轉∕分(W8VB2)。

若想連續進行操作,請扣動扳機開關后再按下開關

停止銷。這樣,即使鬆開手指,扳機開關也會停在

ON (開)的位置。再一次扣動扳機時,開關停止

銷便會自動鬆開。這時,鬆開手指的話,扳機開關

便回到 OFF(關)的位置。

2. 電動起子機的操作法

將開關設在 ON(開)的位置時,馬達開始轉動,

但六腳座(或鑽頭)仍靜止不動。請將六腳座插進

螺絲頭部的槽中,並將螺絲起子機壓在螺絲上。此

時,六腳座便開始轉動,並將螺絲旋緊。

注意:

操作時,螺絲起子機必須與螺絲頭保持完全垂

直。若不垂直的話,因驅動力沒被全部傳遞給螺

絲,螺絲頭和/或六腳座會受損。將螺絲起子機

從螺絲上鬆開時,六腳座便會自動停止轉動。

3. 六腳座的旋轉方向

將換向開關杆設于 R 側時,六腳座按順時針方向

旋轉(從后側看時)。而將換向開關杆設于 L 側

時,六腳座按逆時針方向旋轉,這時,便可旋鬆或

收回螺絲。

注意︰

在馬達旋轉時,切勿更改六腳座(或鑽頭座)的

旋轉方向。這樣做會嚴重損壞馬達。在更改六腳

座(或鑽頭座)的旋轉方向之前,請將電源開關

設于 OFF(關)處。

維 護 和 檢 查

1. 檢查六腳座(或鑽頭)

如繼續使用已破損了的六腳座(或鑽頭),會損傷

螺絲頭。因此,一旦注意到六腳座(或鑽頭)過度

破損,請立即用新六腳座(或鑽頭)更換之。

2. 檢查安裝螺釘

要經常檢查安裝螺釘是否緊固妥善。若發現螺釘鬆

了,應立即重新扭緊,否則會導致嚴重的事故。

3. 電動機的維護

電動機繞線是電動工具的心臟部。應仔細檢查有無

損傷,是否被油液或水沾濕。

4. 檢查碳刷

為了長期的安全及觸電保護,本工具上碳刷的檢查

與更換必須由日立授權的服務中心承擔。

5. 保養與修理

所有高質量的電動工具最終都需要對由於正常使用

而磨損的零件進行保養或更換。為了確保使用合格

的備件,所有保養及修理必須由日立授權的服務中

心承擔。

注意︰

○ 務必請遵循如上所述的組裝順序。如內部導

線碰到了轉子,或夾在了手柄罩與外殼之

間,會導致操作者嚴重觸電的危險。

○ 切勿亂碰拿那些與更換碳刷不相關的零件。

6. 維修部件目錄

A:項目號碼

B:代碼號碼

C:所使用號碼

D:備註

注意:

日立電動工具的修理、維護和檢查必須由日立所認

可的維修中心進行。

當尋求修理或其他維護時,將本部件目錄與工具一

起提交給日立所認可的維修中心會對您有所幫助。

在操作和維護電動工具中,必須遵守各國的安全規

則和標准規定。

改進:

日立電動工具隨時都在進行改進以適應最新的技術

進步。

因此,有些部件(如,代碼號碼和/或設計)可能

未預先通知而進行改進。

注︰為求改進,本手冊所載規格可能不預先通告而徑

予更改。

10

Page 12

ABCD

36 981-373 2

1 876-031 1 S-16

ABCD

W6VM

37 953-327 1 D8.8

2 323-487 1 “3”

1

————

39 937-631 1

40 984-750 2 D4×16

38

41 959-140 2

42 930-039 1

43 994-273 1

44 343-478 2

45 992-635 1

46 323-484 1

47 301-653 3 D4×20

THA, TPE, KOR”

1

1

1

————

————

————

3 323-488 1

4 971-468 1

5 317-662 1

6 321-057 3 D4×25

7 323-486 1 “5”

8 872-573 1

9 959-148 2 D3.175

11 323-476 1

12 306-024 1

13 323-504 1

14 608-VVM 1 608VVMC2PS2L

15 933-545 2

16 301-936 2 M4×10

17 690-0VV 1 6900VVCMPS2L

10 1 323-491 1 “8, 9”

10 2 323-492 1 “8, 9” “HKG,

18 323-503 1 “14-17”

20 323-472 1

19 1 360-676 1 110V-120V

19 2 360-677U 1 120V “14, 23”

19 3 360-677E 1 220V-230V

19 4 360-677F 1 240V

21 961-672 2 D4×50

22 1 340-599C 1 110V-120V

22 2 340-599E 1 220V-230V

23 608-VVM 1 608VVC2PS2L

24

25

26 323-471 1

22 3 340-599F 1 240V

27

28 323-512 2

29 999-091 2

30 323-489 1

31 323-480 1

32 323-479 1

33 323-490 1

34 323-481 1

35 323-483 1

11

Page 13

ABCD

ABCD

W6V4

36 953-327 1 D8.8

1 876-031 1 S-16

1

————

37

2 323-487 1 “3”

38 937-631 1

39 984-750 2 D4×16

40 959-140 2

41 930-039 1

42 994-273 1

43 323-478 2

44 992-635 1

45 323-484 1

46 301-653 3 D4×20

THA, HKG, KOR”

1

1

1

————

————

————

3 323-488 1

4 971-468 1

5 317-662 1

6 321-057 3 D4×25

7 323-486 1 “5”

8 872-573 1

9 959-148 2

11 323-476 1

12 306-024 1

13 323-485 1

14 608-VVM 2 608VVC2PS2L

15 933-545 1

16 301-936 2 M4×10

10 1 323-491 1 “8, 9”

10 2 323-482 1 “8, 9” “TPE,

17 323-473 1

18 1 360-672 1 110V

18 2 360-673U 1 120V

19 323-472 1

20 961-672 2 D4×50

18 3 360-673E 1 220V-230V

18 4 360-673F 1 240V

22 608-VVM 1 608VVC2P2L

21 1 340-599C 1 110V-120V

21 2 340-599E 1 220V-230V

21 3 340-599F 1 240V

23

24

25 323-471 1

26

27 323-512 2

28 999-091 2

29 323-489 1

30 323-480 1

31 323-479 1

32 323-490 1

33 323-481 1

34 323-483 1

35 981-373 2

12

Page 14

ABCD

ABCD

A4

W6V

1

————

37

1 876-031 1 S-16

38 937-631 1

2 323-487 1 “3”

39 984-750 2 D4×16

40 959-140 2

41 930-039 1

42 994-273 1

43 323-478 2

44 992-635 1

45 323-484 1

46 301-653 3 D4×20

HKG”

1

1

1

————

————

————

3 323-488 1

4 971-468 1

5 317-662 1

6 321-057 3 D4×25

7 323-486 1 “5”

8 872-573 1

9 959-148 2 D3.175

11 323-476 1

12 306-024 1

13 323-474 1

14 608-VVM 2 608VVC2PS2L

15 933-545 1

16 301-936 2 M4×10

10 1 323-491 1 “8, 9”

10 2 323-482 1 “8, 9” “TPE, SIN,

17 323-473 1

19 323-472 1

18 1 360-670 1 100V-110V

18 2 360-671U 1 120V “14, 22”

18 3 360-671 1 220V-230V

18 4 360-671F 1 240V

20 961-672 2 D4×50

21 1 340-599C 1 110V-120V

21 2 340-599E 1 220V-230V

22 608-VVM 1 608VVC2PS2L

23

24

21 3 340-599F 1 240V

25 323-471 1

26

27 323-512 2

28 999-091 2

29 323-489 1

30 323-480 1

31 323-479 1

32 323-490 1

33 323-481 1

34 323-483 1

35 981-373 2

36 953-327 1 D8.8

13

Page 15

ABCD

38 323-483 1

1 876-031 1 S-16

ABCD

W6VB3

39 981-373 2

2 323-487 1 “3”

40 953-327 1 D8.8

3 323-488 1

1

————

42 937-631 1

43 984-750 2 D4×16

41

44 959-140 2

45 930-039 1

46 994-273 1

47 323-478 2

48 992-635 1

49 323-484 1

50 301-653 3 D4×20

1

1

1

————

————

————

4 971-468 1

5 317-662 1

6 321-057 3 D4×25

7 323-498 1 “5, 16”

8 872-573 1

9 959-148 2 D3.175

11 306-024 1

12 323-494 1 “13”

13 323-495 1

14 608-VVM 2 608VVMC2PS2L

15 933-545 1

16 608-VVM 1 608VVC2PS2L

17 323-496 1 “18”

18 307-337 1

19 323-497 1

20 301-936 2 M4×10

10 1 317-664 1

10 2 323-507 1 “USA, CAN”

21 323-493 1 “14, 15, 20”

23 323-472 1

22 1 360-674 1 110V

22 2 360-675U 1 120V “14, 26“

22 3 360-675E 1 220V-230V

22 4 360-675F 1 240V

24 961-672 2 D4×50

25 1 340-599C 1 110V-120V

25 2 340-599U 1 220V-230V

26 608-VVM 1 608VVMC2PS2L

28

27

25 3 340-599F 1 240V

29 323-471 1

30

31 323-512 2

32 999-091 2

33 323-489 1

34 323-480 1

35 323-479 1

36 323-490 1

37 323-481 1

14

Page 16

ABCD

ABCD

W8VB2

1

————

40 937-631 1

41 984-755 2 D4×16

42 959-140 2

39

1 876-031 1

2 323-487 1 “3”

43 930-039 1

44 994-273 1

45 323-478 2

46 992-635 1

47 323-484 1

48 301-653 3 D4×20

1

1

1

————

————

————

3 323-488 1

4 971-468 1

5 317-662 1

6 321-057 3 D4×25

7 323-498 1 “5, 16”

8 872-573 1

9 959-148 2

10 317-664 1 “8, 9”

11 306-024 1

12 323-505 1 “13”

13 323-495 1

14 608-VVM 2 608VVC2PS2L

15 933-545 1

16 608-VVM 1 608VVC2PS2L

17 307-338 1 “18”

18 307-337 1

19 323-497 1

20 301-936 2 M4×10

21 323-473 1 “14, 15, 20”

23 323-472 1

22 1 360-674 1 110V

22 2 360-675E 1 220V-230V

22 3 360-675F 1 240V

24 961-672 2 D4×50

26 608-VVM 1 608VVC2PS2L

25 1 340-599C 1 110V-120V

25 2 340-599E 1 220V-230V

25 3 340-599F 1 240V

28

27

29 323-471 1

30

31 323-512 2

32 999-091 2

33 323-480 1

34 323-479 1

35 323-481 1

36 323-483 1

37 981-373 2

38 953-327 1 D8.8

15

Page 17

Hitachi Koki Co., Ltd.

Code No. C99129931

Printed in Malaysia

407

Loading...

Loading...