Page 1

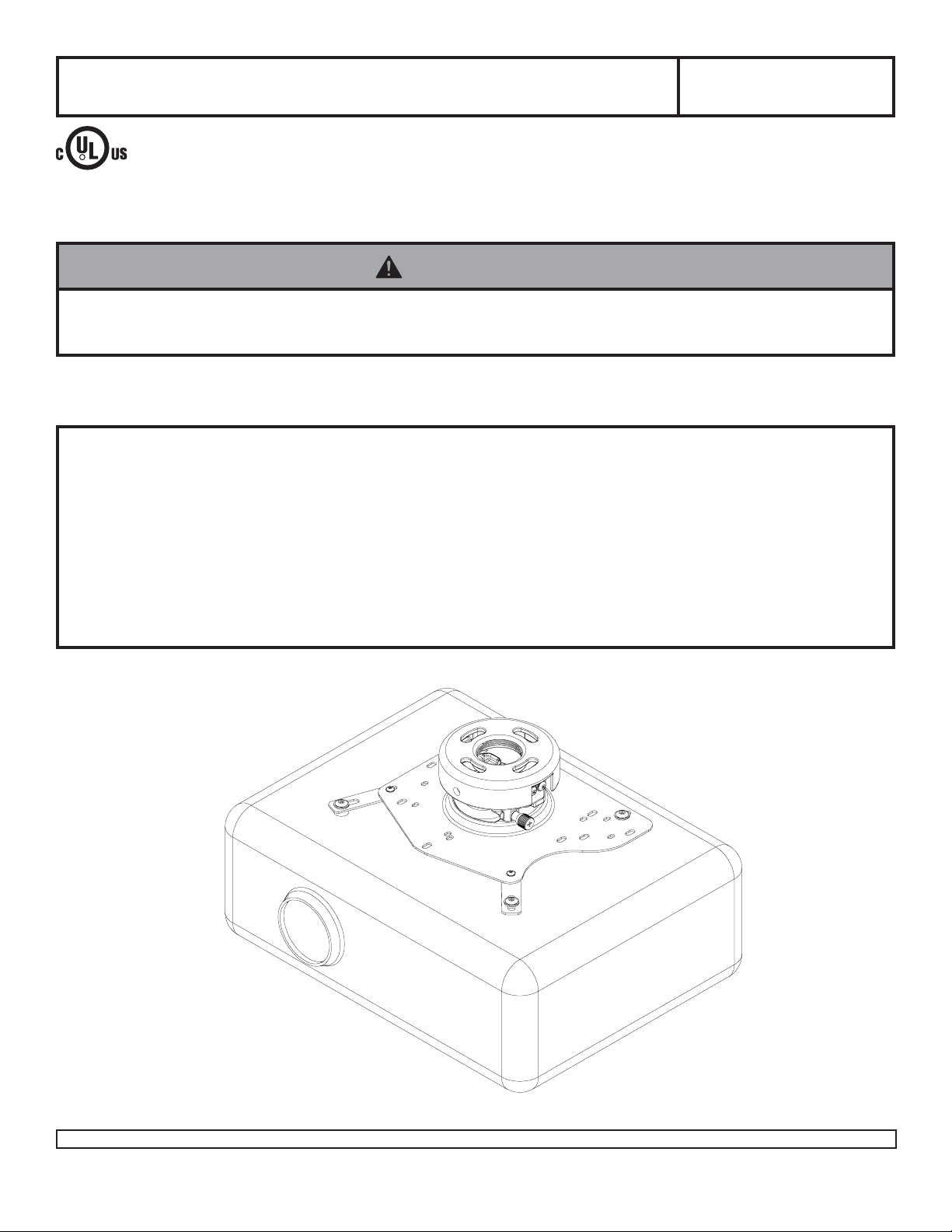

Installation and Assembly - All-in-one Projector Adapter Plate for

InFocus® Projectors

Model: SP-CEIL-UNIV

This product is intended for use with UL

R

Listed products and must be installed

by a qualified professional installer.

Maximum Load Capacity: 25 lb (11 kg)

Read instruction sheet before you start inst allation and assembly.

WARNING

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached hardware and components.

IMPORT ANT! T urn to the appropriate page for your ceiling inst allation.

Applications:

Flush Mount................................................................................................................................................. page 5

Extension Column............................................................................................................... ......................... page 6

Lightweight Suspended Ceiling Plate ....................................................................................................... page 7

Installations:

To Wood Joist Finished Ceilings,

Exposed Wood Joists, or Wood Beam Ceilings........................................................................................page 3

T o Concrete Ceilings.................................................................................................................................... page 4

Visit the InFocus Web Site at www.infocus.com

1 of 11

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

Page 2

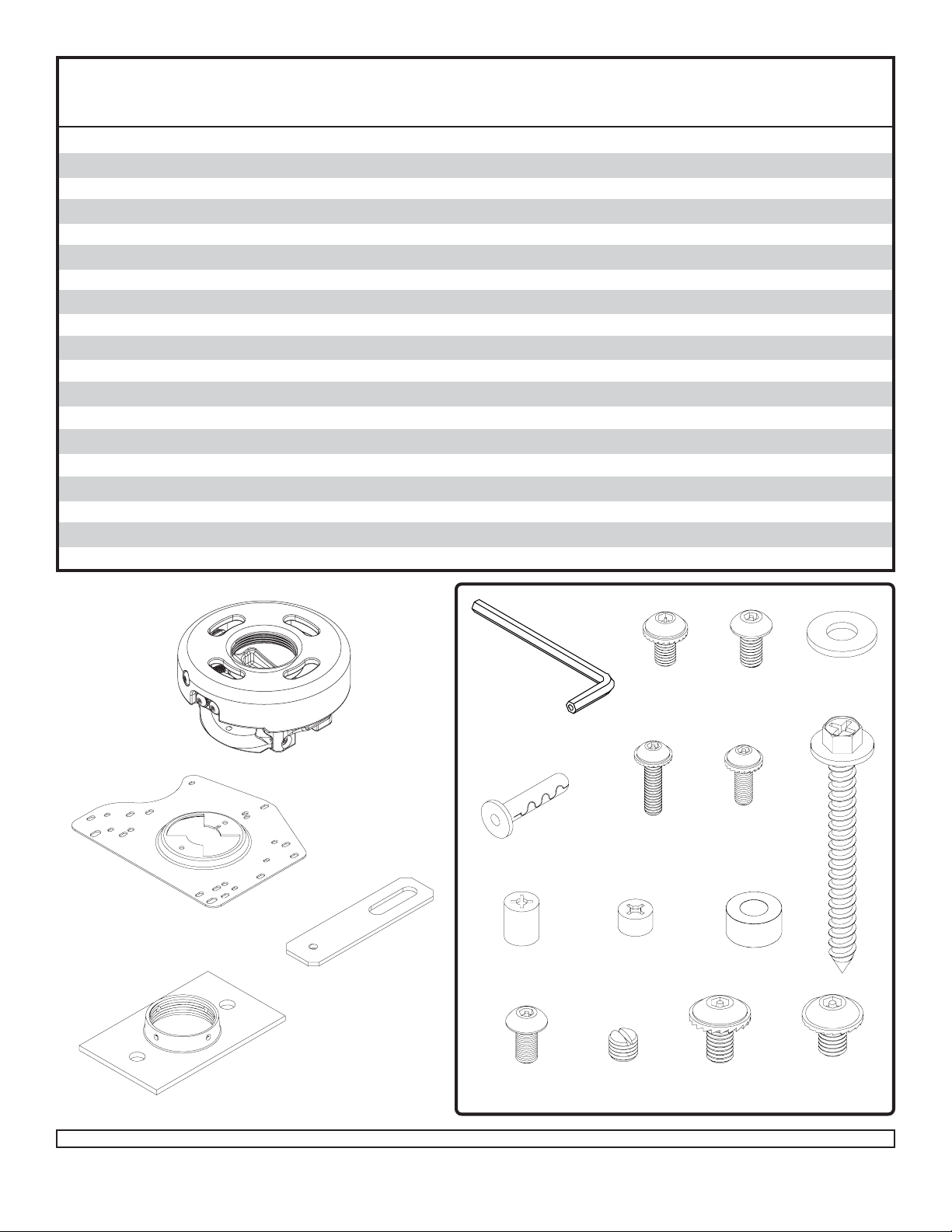

Before you start check the parts list to insure all of the parts shown are included.

Parts List

Description Qty. Part Number

A projector mount assembly 1 055-0420

B 4 mm security allen wrench 1 560-9646

C #10-32 x 3/8" serrated socket pin screw 2 520-1 151

D #10-32 x 1/4" socket pin screw 1 520-1 196

E 1/4" flat washer 2 540-9440

F #14 x 2.5 phillips hex head wood screw 2 5S1-015-C03

G concrete anchor 2 590-0097

H M4 x 16 mm serrated socket pin screw 3 510-1087

I M4 x 12 mm serrated socket pin screw 1 510-1079

J .198 x .313 x .375 retaining spacer 3 590-2020

K .198 x .313 x .187 retaining spacer 1 590-1030

L .25" ID x .56" OD x .26" spacer 6 590-1050

M M5 x 10 mm socket pin screw 1 520-1 164

N #10-32 x 3/16" slotted set screw 1 520-1 187

O M6 x 12 mm serrated socket pin screw 4 510-1050

P M4 x 6 mm serrated socket pin screw 2 510-1059

Q ceiling plate 1 580-1042

R adapter plate 1 055-1539

S extension bracket 2 055-1540

A

R

S

Q

Note: Actual parts may appear slightly different than illustrated.

B

G

H

J K

M

FASTENERS

N

C

D

E

I

F

L

OP

Visit the InFocus Web Site at www.infocus.com

2 of 11

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

Page 3

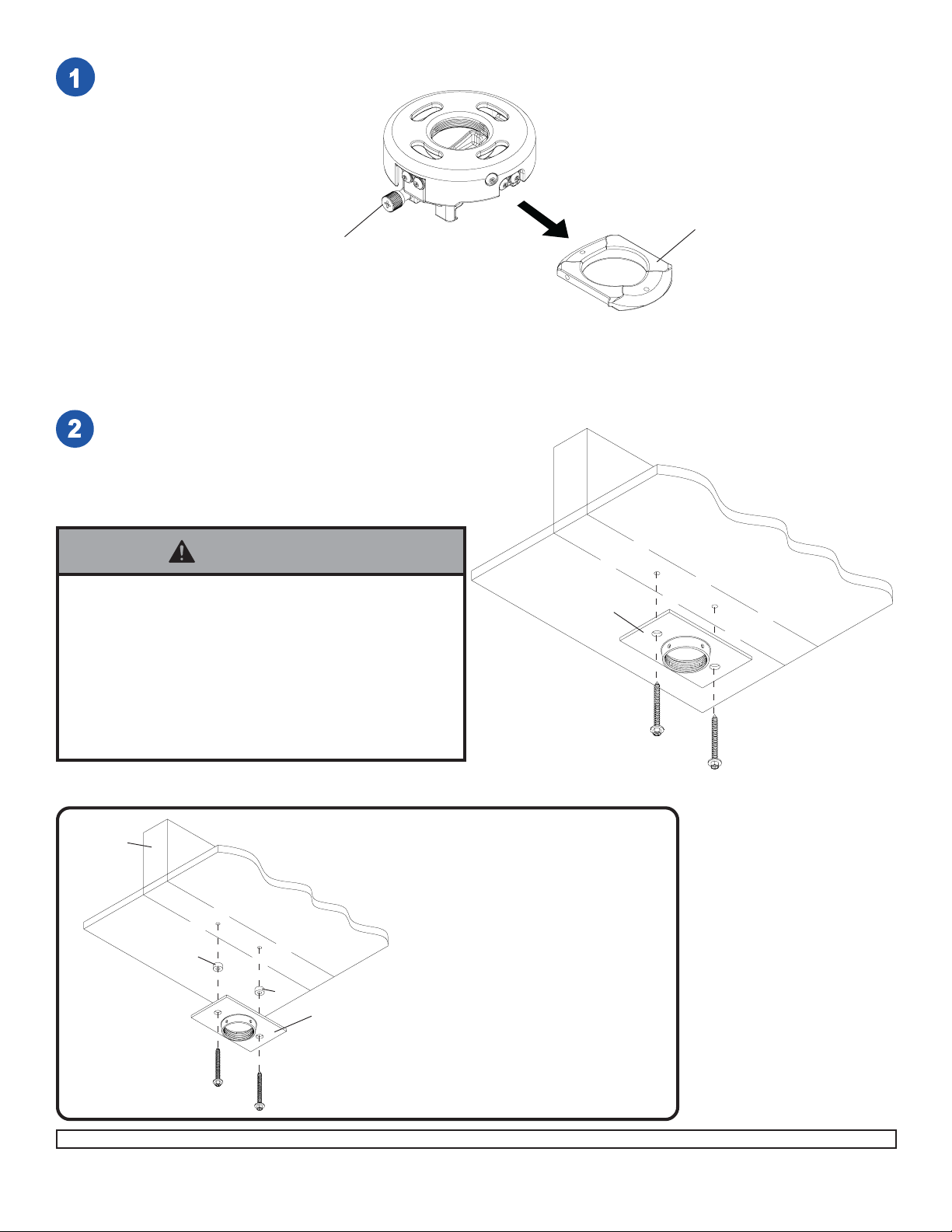

Disengage connection block from projector mount assembly (A) by unscrewing captive screw and sliding out

connection block as shown.

A

CONNECTION BLOCK

CAPTIVE SCREW

Installation To Wood Joist Finished Ceilings, Exposed

Wood Joists, or Wood Beam Ceilings

Drill two 5/32" (4 mm) dia. holes to a minimum depth

of 2.5" (64 mm). Attach ceiling plate (Q) with two

#14 x 2.5" (6 mm x 65 mm) wood screws (F) as

shown using 3/8" (10 mm) socket wrench. Tighten

wood screws (F) so ceiling plate (Q) is firmly

attached.

WOOD

JOIST

CEILING

WARNING

• Tighten wood screws so that ceiling plate is firmly

attached, but do not overtighten. Overtightening can

damage the screws, greatly reducing their holding

power.

• Never tighten in excess of 80 in • lb (9 N.M.).

• Make sure that mounting screws are anchored into the

center of the joist. The use of an "edge to edge" stud

finder is highly recommended.

Skip to step 7.

WOOD

JOIST

CEILING

L

L

Q

For optional Cord Management,

install two spacers (L) between ceiling

plate (Q) and ceiling.

Q

F

F

F

F

Visit the InFocus Web Site at www.infocus.com

3 of 11

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

Page 4

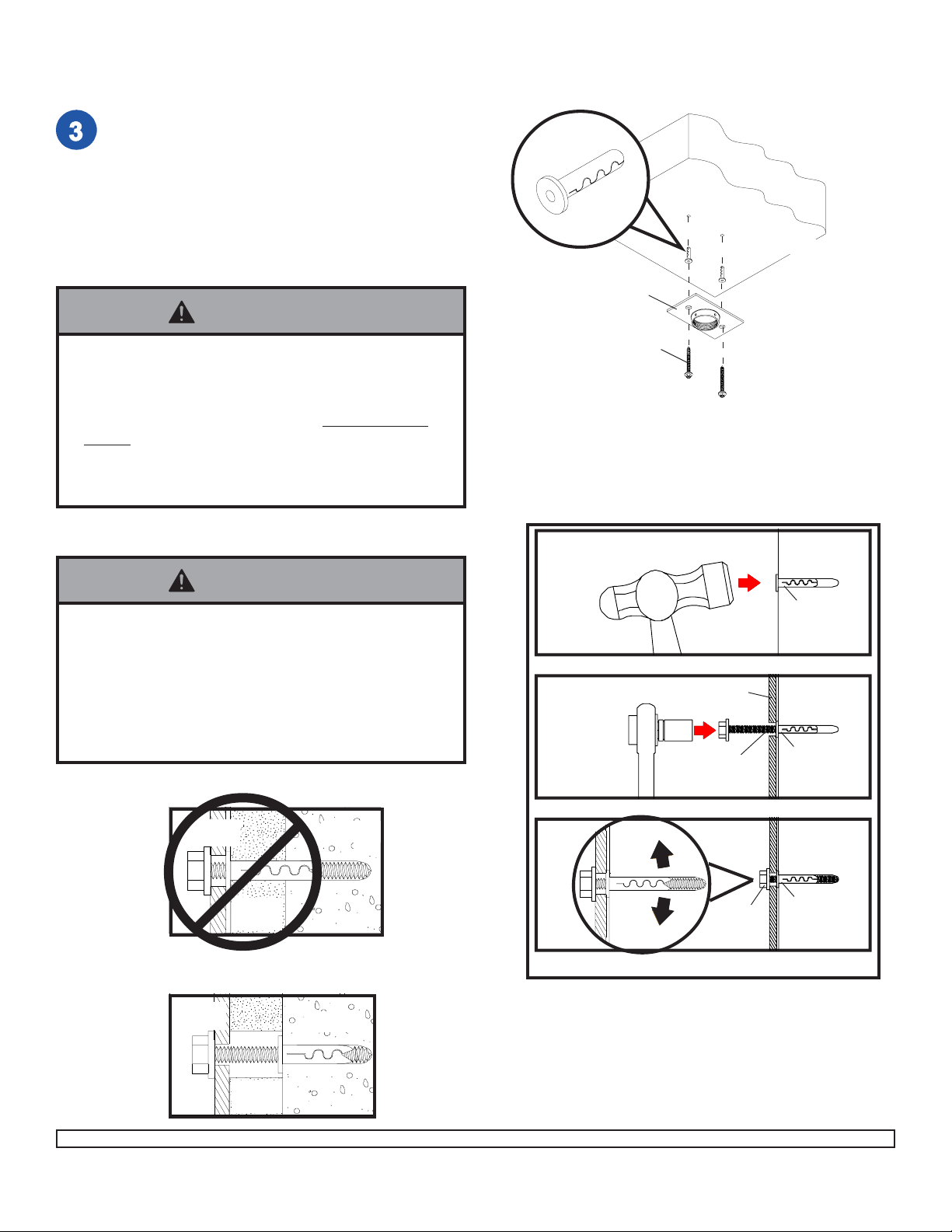

Installation to Concrete Ceilings

Alligator® concrete anchors are recommended.

Drill two 1/4" (6 mm) dia. holes to a minimum depth of

2.5" (64 mm). Attach ceiling plate (Q) using two

concrete anchors (G) and #14 x 2.5" wood screws (F)

as shown in Illustration A and 1, 2, and 3. Tighten all

fasteners.

Skip to step 7.

WARNING

G

CONCRETE CEILING

Q

• Make sure that the supporting surface will safely

support the combined load of the equipment and all

attached hardware and components.

• Tighten concrete anchor bolt firmly , but do not overtighten. Overtightening can damage the bolt, greatly

reducing its holding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

WARNING

• Concrete anchors are not intended for attachment to

concrete wall covered with a layer of plaster, drywall,

or other finishing material. If mounting to concrete wall

covered with plaster/drywall is unavoidable, plaster/

drywall (up to 5/8" thick) must be counterbored as

shown below. If plaster/drywall is thicker than 5/8",

custom fasteners must be supplied by installer .

INCORRECT

F

Illustration A

1

Drill hole and insert anchor.

2

Q

F

concrete

ceiling

G

G

metal

bracket

plaster/

dry wall

CORRECT

CUT AW A Y VIEW

metal

bracket

plaster/

dry wall

Visit the InFocus Web Site at www.infocus.com

concrete

concrete

4 of 11

Place ceiling plate over anchor and secure with screw.

3

F

After repeating step one tighten all fasteners.

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

G

Page 5

Flush Mount Installation

Drill two 5/32" (4 mm) dia. holes to a minimum depth of 2.5" (64 mm). Attach projector mount assembly (A) with two

#14 x 2.5" (6 mm x 65 mm) wood screws (F) and two flat washers (E) as shown in figure 1 or figure 2 depending

on joist orientation. Tighten wood screws (F) using 3/8" (10 mm) socket wrench until projector mount assembly (A)

is firmly attached.

WARNING

• Tighten wood screws so that projector mount assembly is firmly attached, but do not overtighten. Overtightening can damage the screws, greatly reducing their

holding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

• Make sure that mounting screws are anchored into the

center of the joist. The use of an "edge to edge" stud

finder is highly recommended.

Skip to step 7.

WOOD JOIST

A

figure 1

E

F

FRONT OF

MOUNT

A

WOOD JOIST

FRONT OF

MOUNT

E

F

figure 2

Visit the InFocus Web Site at www.infocus.com

5 of 11

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

Page 6

Installation to Extension Column (SP-EXTARM-01, SPEXTARM-02, SP-EXTARM-03, SP-EXTARM-04)

Screw extension column (sold separately) to

ceiling plate (Q). Align the notch with one of the

four holes in the ceiling plate (Q) and secure

extension column with a M5 x 10 mm socket pin

screw (M) using security allen wrench (B). See

detail 3.

Screw projector mount assembly (A) onto the

extension column as shown in detail 4.

Note: For 3/4" extension columns, reducer

ACC 913 will be required as shown in detail 5.

Tighten swivel stop screw against extension

column or reducer using security allen wrench (B).

Note: Swivel stop screw is used to jam against

threads of extension column or reducer to prevent

any excess movement of projector mount

assembly (A). Do not overtighten screw;

overtightening screw will damage threads making

it difficult to separate products.

Note: Slotted set screws (N) are used to jam

against the threads of each connecting joint to

prevent any excess movement. Do not overtighten

screws; overtightening screws will damage

threads making it difficult to separate the

products.

M

EXTENSION

COLUMN

DETAIL 3

N

Q

A

Q

EXTENSION COLUMN

(SOLD SEPARA TEL Y)

(UL LISTED)

Skip to step 7.

A

SWIVEL STOP SCREW

DETAIL 5

3/4" EXTENSION COLUMN

ACC 913

(NOT UL LISTED)

BACK OF

MOUNT

SWIVEL STOP SCREW

BACK OF

MOUNT

DETAIL 4

Visit the InFocus Web Site at www.infocus.com

6 of 11

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

Page 7

Installation to

Lightweight Suspended

Ceiling Plate

(EXT-L TMT-PLTB)

Refer to instruction sheet for lightweight

suspended ceiling plate (sold

separately) for attachment of ceiling

plate to ceiling.

Screw extension column (sold

separately) to

tray. Align the notch with one of the

four holes in retaining collar and secure

extension column with a M5 x 10 mm

socket pin screw (M) using security

allen wrench (B). See detail 6.

Screw projector mount assembly (A)

onto the extension column as shown in

detail 7.

Note: For 3/4" extension columns,

reducer ACC 913 will be required as

shown in detail 8.

retaining collar in ceiling

LIGHTWEIGHT

SUSPENDED CEILING

PLATE (SOLD

SEPARATEL Y )

RETAINING COLLAR

M

N

DETAIL 6

EXTENSION

COLUMN

(UL LISTED)

Tighten swivel stop screw against

extension column or reducer using

security allen wrench (B).

Note: Swivel stop screw is used to jam

against threads of extension column or

reducer to prevent any excess

movement of projector mount assembly

(A). Do not overtighten screw;

overtightening screw will damage

threads making it difficult to separate

products.

Note: Slotted set screws (N) are used

to jam against the threads of each

connecting joint to prevent any excess

movement. Do not overtighten screws;

overtightening screws will damage

threads making it difficult to separate

the products.

Skip to step 7.

A

SWIVEL STOP SCREW

DETAIL 7

DETAIL 8

3/4" EXTENSION

COLUMN

PLTB

ACC 913

(NOT UL

LISTED)

Visit the InFocus Web Site at www.infocus.com

A

SWIVEL STOP SCREW

7 of 11

BACK OF

MOUNT

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

Page 8

Note: The projector adapter plate and projector you are installing may differ in appearance from the sample illustrated

below.

Align shoulder on connection block opposite of front of projector. Attach adapter plate (R) to connection block from

projector mount assembly (A) using two #10-32 x 3/8" serrated socket pin screws (C) as shown.

CONNECTION BLOCK

SHOULDER

ADAPTER PLATE

R

FRONT OF

PROJECTOR

P

S

Visit the InFocus Web Site at www.infocus.com

R

C

8 of 11

Attach extension brackets (S) to adapter plate (R)

using two M4 x 6 mm serrated socket pin screws (P).

For specific models, see step 8H.

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

Page 9

Flip projector upside down. Find your projector from the models listed below . Using the holes indicated on the corresponding hole pattern diagram, attach adapter plate (R) to projector using three M4 x 16 mm serrated socket pin

screws (H) and three .198 x .313 x .375 retaining spacers (J).

Notes:

Retaining spacers go between adapter plate and projector .

* Front of projector.

** Projectors using hole pattern G use one M4 x 12 mm screw (I) and one .198 x .313 x .187 retaining spacer (K)

where indicated.

*** Using holes indicated in hole pattern H, attach adapter plate (R) to projector using four M6 x 12 mm serrated

socket pin screws (O) and four spacers (L)

A. C200, DP6500X, LP650, SP5700,

SP7200, SP7205, SP7210

*

R

D. C100, C105, DP6150, DP6155,

LP690

*

B. C40, C50, DP2000S, DP2000X,

LP240, LP250

*

RR

E. C109, C1 10, DP8000, LP790,

SP4800, SP4805, X1, X1a, X2, X3

*

C. LP340, LP350, LP500, LP530,

SP1 10

*

F. C170, LP600

*

R

G. C160, C180, LP540, LP640,

SP5000

*

**

R

Visit the InFocus Web Site at www.infocus.com

R

H. C440, C450, C460, DP8400X,

DP8500X, LP840, LP850, LP860

***

S

*

R

9 of 11

***

S

***

R

I. C410, C420, LP815, LP820,

DP8200X

***

*

R

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

Page 10

J. IN72, IN74, IN76

K. IN24, IN26

*

R

*

R

WARNING

• Always use an assistant or mechanical lifting equipment to safely lift and position the projector .

Slide connection block with projector into projector mount

assembly (A) as shown. Tighten captive screw to secure

projector to projector mount assembly (A).

FRONT OF MOUNT

CAPTIVE SCREW

IMPORTANT: For security installations, insert

one #10-32 x 1/4" socket pin screw (D) through

projector mount assembly (A) and into connection

block as shown.

CONNECTION BLOCK

A

CONNECTION BLOCK

A

D

Visit the InFocus Web Site at www.infocus.com

10 of 11

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

Page 11

Projector AlignmentProjector Alignment

Projector Alignment

Projector AlignmentProjector Alignment

To adjust yaw (swivel) for wood stud, concrete ceiling, and threaded rod mounting applications: Loosen

wood screws (F), or locknuts for threaded rods, until projector mount can be rotated. Rotate mount to desired

position and retighten screws or locknuts.

T o adjust yaw (swivel) for extension column applications: Loosen screw on projector mount assembly (A)

indicated below until projector mount can be rotated. Rotate mount to desired position and retighten screw .

T o adjust pitch (forward and backward tilt): Loosen two screws on projector mount assembly (A) indicated

below. Tilt mount to desired position and retighten screws.

T o adjust roll (side to side tilt): Loosen two screws on projector mount assembly (A) indicated below . T ilt mount

to desired position and retighten screws.

SCREWS FOR PITCH

ADJUSTMENT

A

SCREW FOR SWIVEL STOP

SCREWS FOR ROLL

ADJUSTMENT

BACK OF MOUNT

Visit the InFocus Web Site at www.infocus.com

11 of 11

ISSUED: 10-22-04 SHEET #: 055-9236-5 01-10-06

Loading...

Loading...