Page 1

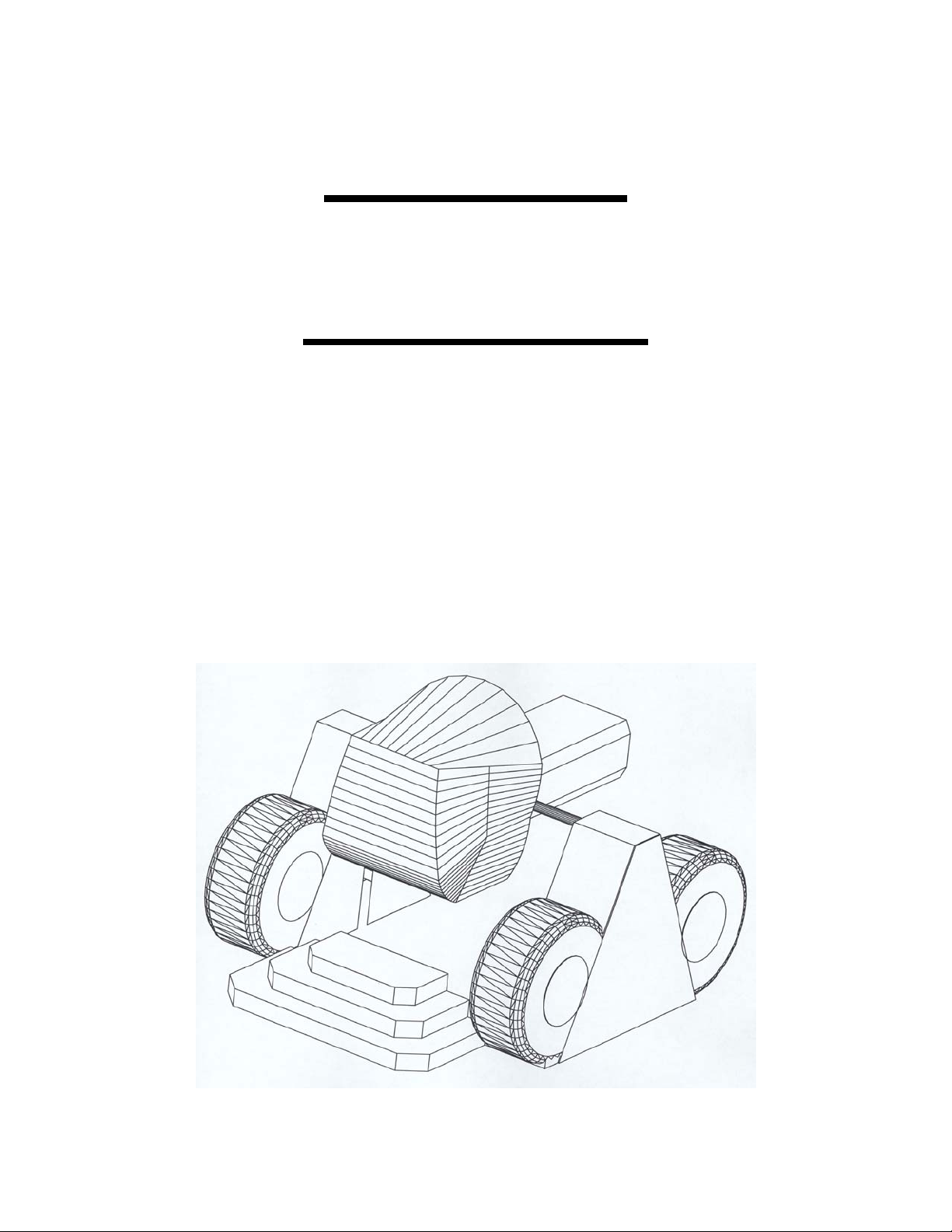

MaxFlight

MT3000(B)

“ELECTRIC”

Monster Truck Manual

Page 2

MT3000 Monster Truck Directory

Section I: Operations Page 8

CHAPTER 1: INTRODUCTION

1-1 Introduction to the electric MT3000 Page 9

1-2 Overview of the MT3000 Page 9

1-3 Overview of the Ride Selection System Page 9

1-4 Specific Ride Information Page 10

1-5 Ride Restrictions Page 10

1-6 Safety Page 10

CHAPTER 2: OPERATION

2-1 Description of Motion Page 11

2-2 System Startup Procedures Page 12

2-3 Game Start Procedures Page 12

2-4 Operation Control Icons Page 13

2-5 Game Over Page 13

2-6 Description of Customer Restraint System Page 13

2-7 Height and Weight Page 13

2-8 Game Selection Page 14

2-9 Customer Packets Page 14

2-10 Recommended Passenger Loading Procedures Page 14

2-11 System Shutdown Page 14

2-12 Emergency Stop Procedures Page 14

2-13 Power Interrupt and Re-Start Procedures Page 16

2-14 Ride and Facility Evacuation Procedure Page 16

2-15 Ride Termination Conditions Page 16

2-16 Daily Inspection Checklist Description Page 17

CHAPTER 3: SUGGESTED POSTINGS

This chapter contains notices that we suggest be placed near the unit to promote the safety of

patrons as well as operators and to ensure proper operation of the ride.

Page 3

Introduction Page 17

Emergency Procedure Page 18

Emergency Raise Procedure Page 19

Patron Notice Page 20

Daily Inspection Checklist Page 21

Site Configuration Requirements Page 22

Section II: Technical Page 24

TABLE OF CONTENTS Technical

CHAPTER 1: GENERAL THEORY OF OPERATION

1-1 Introduction Page 24

1-2 Electrical Page 24

1-3 Mechanical Page 27

1-4 Computer System Page 27

1-5 What Causes the Unit To Page 28

1-6 Operating Limitations Page 30

CHAPTER 2: ELECTRICAL

2-1 Electrical System Page 30

2-2 Motion Platform Axis Page 32

2-3 Initial Wiring Confidence Test Page 33

2-4 Manual Control of Inverter Drives Page 34

2-5 Encoder Wiring Page 35

2-6 Mitsubishi Inverter Information Page 36

2-7 Inverter Replacement Page 37

2-8 Setting Inverter Parameters Page 37

2-9 Checking Inverter Alarm Stops Page 39

2-10 Frequency Control Parameters (Accessing) Page 39

2-11 Auto Tune of Inverter Circuits Page 43

CHAPTER 3: MECHANICAL

3-1 Mechanical System Page 44

3-2 Lift Component Installation Procedures Page 45

Page 4

CHAPTER 4: COMPUTER SYSTEM/INTERFACE

4-1 Introduction Page 49

4-2 Hitachi Projector Settings Page 49

4-3 Layout Page 50

4-4 Troubleshooting Page 50

Pictures of Diagnostic Screens

Accessing Frequ. Control Part Numbers

Frequency Inverter Program Window

Auto Tune Program Window

Operator Panel

Operator Panel (RH)

Alert Window

Platform Motion Control Window

Motion Platform Window (Com)

New Player Window

Select Game Window

Select Level Window

Configuration Status Window

Devices (Config)

Devices 2 (Config)

Steering/Throttle (User Joystick 0)

Joystick Initial Setup Window

User Joystick Axes

User Joystick Sliders

Joystick Buttons

Address (Site)

EDS

Path Game Logs and Alert Logs

IO Drivers

Direct Sound

Lock

Voodoo SST Video Properties

Voodoo Properties 1

Voodoo Properties 2

New Program/Platform motion Window

New Test Client and Switch Test window

Page 5

Current Software window

Regedit32 windows

Software HKEY Local Machine (MF Motion Area)

Lift motion Editor

Counterweight motion Editor

Pitch motion Editor

Pitch filter 1

Pitch filter 2 &3

Roll motion Editor

Roll filter 1 &2

Roll filter 3

CHAPTER 5: MAINTENANCE AND TROUBLESHOOTING

5-1 Required Daily Inspections Page 71

5-2 Weekly Maintenance Page 72

5-3 Inverter Maintenance Page 73

5-4 Extended Periods of non Use Page 74

5-5 Harsh Environmental Conditions Page 74

5-6 Cleaning of Cockpit and Consoles Page 75

5-7 Troubleshooting Page 75

5-7A Power Problems Page 75

5-7B No Computer Power Page 75

5-7C Cockpit Power Page 76

5-8 Video Problems Page 76

5-9 Audio Problems Page 77

5-10 If Unit Does Not Raise Page 77

5-11 Unit Does Not Counterbalance Page 78

5-12 Platform Lowered Sensor Page 78

5-13 Fails to raise level in pitch or roll Page 79

5-14 Occupant Safety Switch Page 79

5-15 Unit Stops Motion Page 79

5-16 No Roll or Pitch Movement when at the Top Page 79

5-17 Up Sensor Faults Page 79

5-18 Maintenance Warnings and Cautions Page 79

5-19 Maintenance and testing of Motors Page 80

5-20 Setup and Calibration of Joystick/CIB-1000 Page 80

Page 6

5-21 Creating and configuring the Artificial Intel. (AI)

Joystick Devices Page 81

CHAPTER 6: Time Replacement Items

6-1 Introduction Page 82

6-2 Relays Page 84

6-3 Projector Bulbs Page 84

6-4 Non Destructive Testing Procedures Page 84

Attachment. 1Weekly Inspection Checklist Page 87

2 Cable Numbering and Routing Page 88

3 Electrical Circuits List Page 91

4 Hitachi Projector Settings Page 92

Part of Document Package

I: Mitsubishi Transistorized Inverter Manual

II: Hitachi Projector Manual

III: Sumitomo Motor and Gear Box Manual

IV: Warranty Cards for all Items

Section III: Installation Page 94

TABLE OF CONTENTS INSTALL

CHAPTER 1: SET UP

1-1 Field Torque Procedure (Turn-of-the-Nut) Page 95

1-2 Assembly Instructions Page 95

ASSEMBLY DRAWINGS (SEE ”DRAWINGS FILE” )

DET-01 Power Box Page 100

DET-02A Right side Electrical Page 100

DET-02B Left Side Electrical Page 101

DET-04 Encoder Placement Page 101

DET-05 Platform Front Support Page 102

DET-06 Floor Plan\Accessories Page 102

DET-07 TV and Cabinetry Page 103

DET-08 Squaring the Ride Page 103

DET-09 Cabinetry Page 104

DET-010 Tail Cover and Stand Page 104

Page 7

DET-011 Tail Closure/Pitch Motor Page 105

DET-013 Platform/Front Stand Page 105

DET-014 A frame Assy. Page 106

DET-015 Side A frame ABS Page 106

DET-016 Pitch shaft placement Page 107

DET-017 Pitch shaft Installation Page 107

DET-018 Safety Wiring Page 108

DET-022 Power Box Serial Interface Page 108

DET-035 CPU Card Layout Page 109

DET-036 CPU Card Layout MT,FS Page 109

DET-037 Mother Board Layout Page 110

DET-038 Lube Requirements Page 110

DET-039 MT Layout and spacing Page 111

DET-040 Lower Cockpit Fiberglass Page 111

DET-041 Lower ear ABS Page 112

DET-042 Upper rear ABS Page 112

DET-043A Lift Jack Clutch/Tower Page 113

DET-044 Pitch Rings Installation Page 113

DET-045 Roll Hub and Gear Box Page 114

DET-046 Cockpit Power Strip Page 114

DET-048 Lift cross drive system Page 115

DET-049 Cable routing to center Page 115

DET-050 Motion Control Card Jumpers settings Page 116

DET-051 MT,FS Command Console Layout Page 116

APPENDIX B: INSTALLATION & PERFORMANCE TESTING CHECKLIST

Page 117

Section IV: Drawings Start at Page 122

A. Electrical

B. Mechanical

Page 8

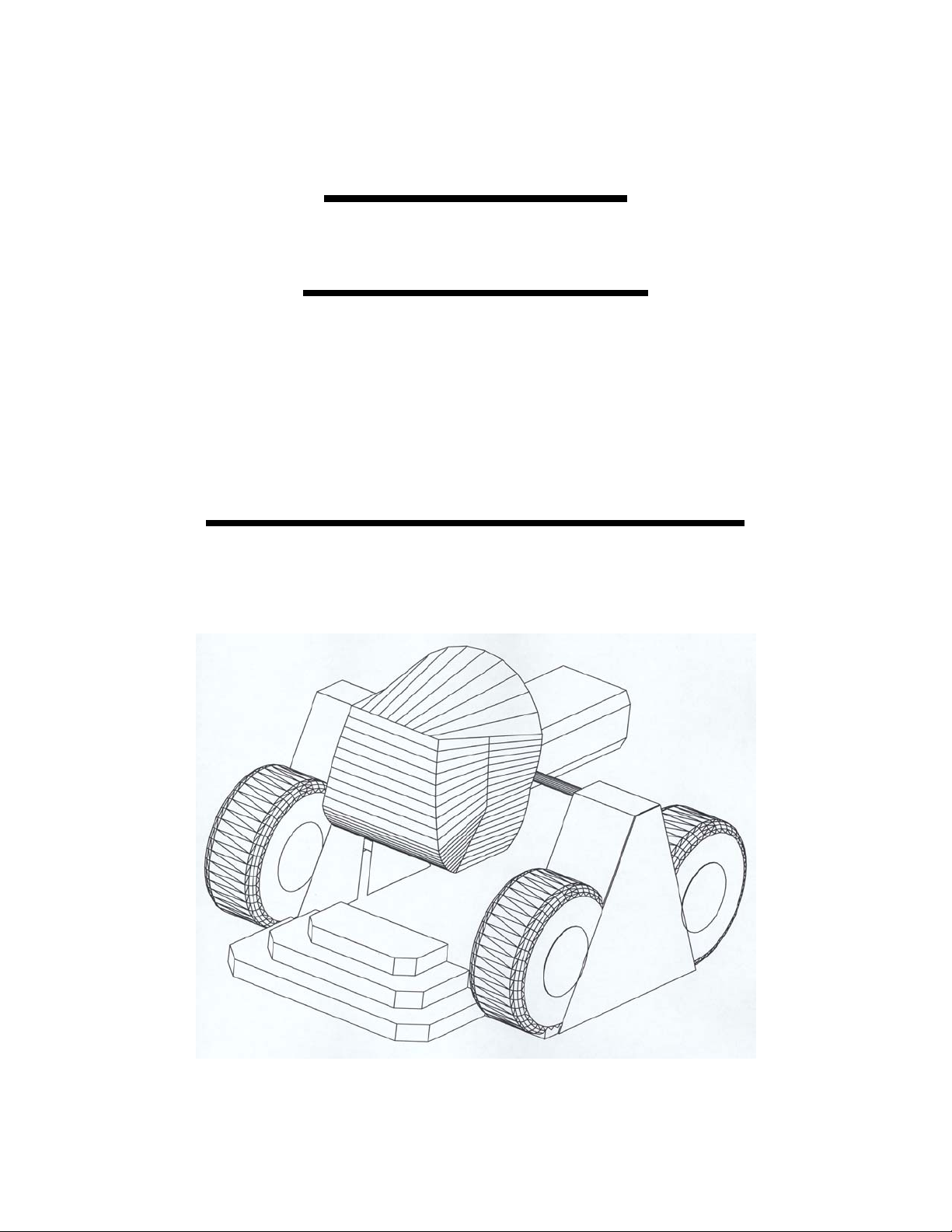

MaxFlight

MT3000(B)

“ELECTRIC”

Operators Manual

Page 9

CHAPTER 1 – INTRODUCTION

1-1 Introduction to the MT3000

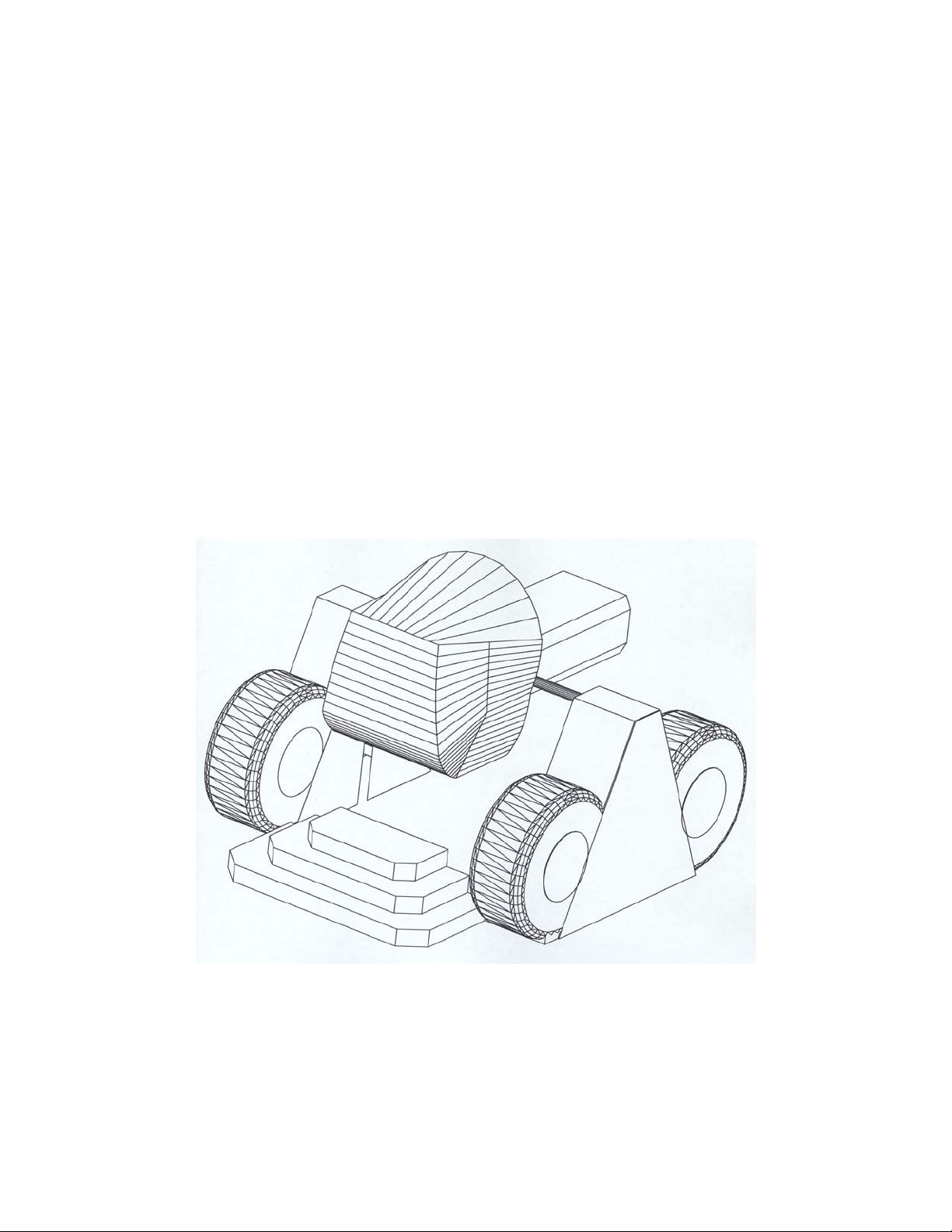

Welcome!! And thank you on your purchase of the MT3000 Monster Truck Simulator. The MT3000 is

the only full motion interactive networked experience of it’s kind. This is a dual seat monster truck

simulator based on a virtual reality environment with a full 360 degree, 2 axis motion platform. The

experience time can be varied according to patron demand while the standard time set is 6 minutes. You

can select from two track layouts thus making your ride as unique as possible.

1-2 Overview of the MT3000

The MT3000 is a computer driven monster truck simulator that provides a realistic monster truck driving

track.

1-3 Overview of the Ride Selection System

The customer can select their own track layout. There are two specific tracks that the simulator

can run on and they are: Monster truck arena, a series of jumps and bumps in a confined space

and the island road race, a open space environment with all the pitfalls of real cross country

driving. Whenever the terrain warrants a motion of the monster truck it will emulate it to a

degree of two motion flips. The (2) passenger cockpit is equipped with a huge 58” projection

screen and a pulse pounding surround sound system. Once the cockpit is closed and locked, the

passengers embark on a six minute (variable by operator) default driving experience without the

hassle of city traffic. A ride they will never forget.

1-4 Specific Ride Information

This section has been included in your manual to give you specific and detailed information about the

MT3000 Monster Truck Simulator. This information complies with the ASTM 698-94 standard (American

Society for Testing and Materials) which governs Physical Information to be provided for Amusement

Rides and Devices.

Ride Speed: Pitch Axis - 90 Degrees per second (15RPM)

Roll Axis - 90 Degrees per second (15 RPM)

Direction of Travel: Pitch – 360 Degrees

Roll – 360 Degrees

Vertical axis (Y-axis)

Maximum passenger capacity by weight per passenger position: 250 lbs.

Maximum passenger capacity by weight per the total device: 500 lbs.

Maximum passenger capacity by number per the total device: 2

Duration of passenger exposure: Up to six minutes

Passenger weight distribution: Maximum Unbalance – 100 lbs.

Environmental restrictions: Stable Environment – Temperatures less than 80°F,

Humidity less than 60%

Recommended passenger restrictions: Minimum Height – 48”

Page 10

Mechanical power requirements: The pitch movement is powered by a 5 HP electric

motor.

The roll movement is powered by a 3.0 HP electric

motor.

The lift movement is powered by a 3 HP electric

motor.

Static information: Height:7’ 9” (approx.)

Width: 12’ 8” (approx.)

Length: 15’ (approx.)

Weight: 4800 lbs.

Dynamic information: Height:12’ 10” (approx.)

Width: 12’ 8” (approx.)

Length: 15’ (approx.)

Weight: 5300 lbs. maximum

Fastener schedule: Refer to the MaxFlight MT3000 Installation Manual

Maximum static load distribution per footing: NS – based on static weight distributed by

(4) 8” x 16” feet and

(2) 4” x 14” feet

INA = Information Not Available N/A = Not Applicable UNK = Unknown NS =

Not Specified

1-5 Ride Restrictions

There are certain conditions that the machines should not be operated under. These conditions are

described below.

1-5A Intoxication

If a patron is under the influence of any drugs or alcohol they should not be allowed to utilize the

equipment. If a question arises have a manager speak to the patron.

1-5B Heart Conditions

Any heart or other similar condition would preclude a passenger from riding the simulator.

1-5C Pregnancy

It is not recommended that women who are pregnant ride the simulator.

1-5D Weight and Height Restrictions

The patrons must be at least 48” (1.22 m) tall and total weight is not to exceed 500 lb. (226.8 kg) with no

more than a 100 lb. (45.36 kg) difference between the passengers. All patrons must be capable of sitting

normally in the seat and be capable of using all the restraint devices available and mandatory. If this

is not possible the patron cannot ride.

1-5E Impairments

We recommend that patrons with the following impairments/conditions do not ride the VR2002

Cyber Coaster:

♦ Head, neck, heart or back problems

Page 11

♦ Recent operations

♦ High blood pressure

♦ Motion sickness

♦ Women who are pregnant

♦ Epileptic patrons; due to the special strobe and lighting effects that are known

to trigger seizures

♦ Intoxicated patrons

♦ Claustrophobia

1-6 Safety

Due to the nature of the MT3000 there are several safety precautions that must be observed in

order to ensure the safety of both the patrons and the operators during operation of the

experience.

1-6A Ensure that the cockpit has completed movement prior to continuing with any other

procedures.

1-6B NOTE: Ensure that during the time of operation, all persons must stay clear of the

simulator in order to prevent injuries.

1-6C Ensure that the operating personnel do not operate the simulator with any of the cover

plates removed.

1-6D Ensure that only authorized personnel open the power distribution box for any reason.

1-6E Ensure that patrons pass the height and weight requirements to ride the simulator.

1-6F Queue Line Safety

The queue line must be kept orderly. The patrons must remain behind the established barriers

while waiting their turn to ride. The queue line should also be used to familiarize patrons with

the operation of the Occupant Panic Switch (OPS) Button.

1-6G Loading/Unloading Safety

During the loading and unloading of patrons, the operator must ensure that the simulator has

come to a complete stop prior to opening the cockpit. The operator is required to assist the

patrons to negotiate the steps and cockpit.

1-6H During the operation of the simulator, the operator must stay within the proximity of their

assigned units. Operators must watch for such things as equipment failure, abuse of the simulator

and customers who wish to terminate game play.

1-6I During the operation of the ride, the operator(s) should be posted at the control console

where the computer screen, mouse and unit will be in his/her direct line of sight

Page 12

CHAPTER 2 – OPERATION

2-1 Description of Motion During Operation

There are three basic axes of motion that the simulator travels on, Pitch, Roll and vertical lift into the game

position.

2-1A The Pitch Axis

The pitch motor is a 5 HP 208 VAC drive motor. Controlled by the frequency drive inverters. The pitch

axis will rotate the cockpit in either a clockwise or counterclockwise direction. The maximum velocity the

pitch axis will produce is 90 degrees per second.

2-1B The Roll Axis

The roll motor is a 3.0 HP 208 VAC drive motor. Controlled by the frequency drive

inverters. The roll axis will rotate the cockpit in either a clockwise or counterclockwise

direction. The maximum velocity the roll axis will produce is 90 degrees per second.

2-1C The Vertical Lift System

The Lift motor is a 3.0 HP 208 VAC drive motor. Controlled by the frequency drive inverter. The vertical

lift system raises and lowers the main assembly into the load and ride positions.

2-2 System Startup Procedures

The procedures listed below must be followed to ensure the simulator operates in a safe

condition.

1. On the left A frame, turn the power switch on the power strip to “ON”. This will

power up the following;

a. Projector power

b. Wireless receiver power.

c. Network switch power.

d. Television power.

e. On-board computer.

f. On-board amplifier.

g. On-board TV elite video signal splitter.

h. All cooling fans in the cockpit and drive motors.

2. In the command console, turn power strip on bottom to “ON”.

3. Power up the Battery Backup unit, press switch in on right top side. Green light

comes “ON”. The monitor will come on automatically.

4. Press the power on button on front of computer and allow unit to come up to desktop.

5. Power up any stand ups if needed or applicable.

6. Turn projector bulb on by aiming remote towards mirror and pressing green “ON”

button once. Bulb comes on and gets brighter over next few seconds.

7. Pull out the red E-Stop button on side of command console to power up Inverters.

NOTE: The bird and an alert window will open while the inverters are powering up and the

communication path between the CPU and power box is established. If all is well, the bird and

window will close. If there is a problem, another alert window will come up stating the problem.

Correct all faults before running/starting any other program.

Page 13

2-2A Description of Control Windows and Icons

A. Desktop Displays

• “Remote GSM” icon- shortcut to the actual program, double clicking it

will initiate the program.

• “Mitsubishi Inverter Test” icon- shortcut to the manual test of the

inverters in all axes. This is the icon used for the emergency raise procedure.

• “Mitsubishi Test Client” icon- shortcut to the semi-automatic maintenance

test program of the platform.

• ‘Game Log” icon- shortcut to the recorded game log.

• “Start” icon- lower left, initiates system shutdown or other internal CPU

functions.

• “VNC” icon- shortcut to the remote on-board computer.

B. Game Program Windows and Icons

1. Maxzilla Program Window

a. “New Game” opens game setup window

(1) Game Setup Window

(a). Single Player- select if no remote viewer is used

(b). Multiplayer Host- select if remote viewer is used

© “OK” select and go to next window

b. Track Setup Window

(1) Island Data Base – open country and mountain trails

(2) “OK” goes to next window

c. Loading Play Area Window – loads selected scenario into CPU

RAM for play

d. New Player” icon – opens truck type and time selection window

(1) Select Track if change takes @ 2 minutes to load

(2) Select Time - default is 6 minutes, can be changed as

desired

(3) “OK” goes to next window

e. Top Row Indicators

(1) GAME

STOP – stops selected program

QUIT – shuts selected program down completely, clears

memory

2. “Maxflight Base Lift Control” window

a. Raise icon – allows the platform to raise, balance normal and go

to the top.

b. Stop icon – stops motion of the platform at any point.

c. Lower icon – allows the platform to lower to the steps level

normal.

Page 14

2-3 Description of Passenger Restraint System

There are two restraint systems employed for passenger comfort and safety, a primary

and a secondary.

2-3A Primary Restraint

The primary restraint system is similar to an Airline safety belt. It simply pulls around

the passenger and plugs into the receptacle. It is then tightened with the pulling of the

strap.

2-3B Secondary Restraint

The secondary restraint system consists of a molded structural steel bar shaped to fit the

passenger. The bars are covered with padding and vinyl covers for passenger comfort.

Once lowered into place, the passengers cannot release themselves, preventing

inadvertent discharge. To operate, lower the harness to the patrons comfort, then check it

for security and that it is locked.

2-4 Height and Weight

Maximum total weight for the ride is 500 lbs. (226.8 kg) with no more than a 100 lb. (45.4 kg)

difference between the passengers.

Minimum height requirement for the ride is 48 in. (1.22 m)

2-5 Game Selection

Patrons should be encouraged to make their game selections while waiting in the queue line.

2-6 Customer Pockets

The attendant must ask each patron if they have any objects in their pockets that could

come out during the ride. If so, remove and place the items in a secure container for the

duration of the ride. Be sure to remind patrons at the end of their ride to retrieve their

possessions.

2-7 Recommended Passenger Loading Procedures

Assist the passenger into the cockpit and tell them to put on the primary restraint (the

seatbelt). Lower the restraint harness until it is snug against the waist and chest. Render

any assistance or instructions required. This is a good time to give the patrons

instructions on how to use the Occupant Panic Switch and the controls/operations of the

Steering Wheel, Gas pedal, Brake pedal, and Fwd/Rev Shifter. After it has been

explained, they should be asked if they understand how to use these items. Close the

canopy and secure it with the locking devise.

2-8 Game Start Procedures

2-8A Initial Game Startup

1. Double click on “Remote GSM” icon and the program will initiate and open

program window.

2. Click on “NEW GAME” another selection window opens up.

3. Click on SINGLE PLAYER – if remote viewer is not used.

Page 15

Game Setup window opens, select ISLAND DATA BASE.

Highlight by clicking on selection the click “OK”

4. CPU loads the game data and opens the “MAXFLIGHT BASE LIFT

CONTROL AND PROGRAM ” window.

5. Select “NEW PLAYER”, select truck type and time. Time default is 6

minutes but can be changed.

6. Select “OK”

7. Raise the platform to the run position. Click RAISE lower right window.

2-8B Raising the Unit

Ensure that power is applied and normal program is loaded. Go to the LIFT CONTROL, click on the

“RAISE” icon. The unit will come up about two( 3) inches and stop to balance. Upon completion of

balancing, the unit will continue raising up to the upper limit switches. If the unit does not balance within

one (1) minute, lower the unit and retry.

NOTE: The weight limit is 500 pounds.

2-8C Game Start

Game will start when normally raised to the top after a game is selected. When the platform reaches the

upper limit switches the CPU will enable the program and full motion is enabled. Game will continue until

pre set timer runs down, stopped by rider, or stopped by operator.

2-9 Game Over

When the time runs out, stopped by rider pressing the cockpit e-stop or operator clicks

STOP icon. The “LOWER PLATFORM” icon will highlight. During this time the unit

will return to “HOME POSITION”. Click on the “LOWER” icon and after the unit

has lowered onto the stairway, and movement has stopped, discharge the patrons.

2-10 System Shutdown

At the end of the operating day, follow these procedures to ensure that the simulator is

safely secured for the day.

1. Turn projector bulb OFF by using the remote. Double click the green button

while pointing at the mirror. Projector goes to standby and will cool itself.

2. Lower the passenger restraint harness to the down position.

3. Lock the seat belts together.

4. Press the E-Stop on side of console IN. Removes all motor power and locks

the brakes.

5. Click on the CLOSE icon lower left, program window will close, on-board

program will close down the Truck program.

6. VNC to the on-board computer and

a. Select START lower left

b. Select SHUTDOWN

c. Select OK

7. After on-board computer has shut down shut down command console

computer.

a. Select START lower left

b. Select SHUTDOWN

c. Select OK

Page 16

8. Turn the UPS power switch to OFF green light out

9. Turn Cockpit power OFF on A frame power strip.

The system is now secured.

2-11 Emergency Stop Procedures

In the event of an emergency follow the procedures described below for the type of emergency.

2-11A Occupant Panic Switch

During the ride the patrons have the ability to initiate a ride abort by depressing the

Occupant Panic Switch (Labeled “Safety Stop” in the cockpit). When this switch is

depressed the ride will return to the “home” position, the video projector will freeze and

the sound will stop. Once the unit is level, lower the unit by clicking the “lower” icon on

the computer screen. When the unit is completely lowered onto the stairway, open the

cockpit door and ask the riders if they would like to continue. If they do not which to

continue, discharge the passengers following the Passenger Unloading Procedure. If they

wish to continue, close the canopy and secure it with the locking device. Click on the

“raise” icon and once the unit is completely balanced it will raise to top and continue.

2-11B Emergency Termination Procedures

In the event of an emergency not involving the simulator directly, click on the ‘STOP” icon on the screen.

Wait for the unit to level, and then lower the platform as normal. In the event that the unit is not

responding to the commands, use the Red EMERGENCY STOP BUTTON on the side of the Command

Consol to terminate power to the electric motors. The unit will then have to be leveled and lowered

manually as described in section 2-11C. Assist the patrons out of the simulator and direct them to the exit.

2-11C Emergency Stop without Electrical Power

The Red EMERGENCY STOP BUTTON on the side of the Command Consol must be depressed

IMMEDIATELY; this will disable the Electric Motors and set the manual brakes. Level the unit on both

the pitch and roll axis manually as described in section 2-11C. Using the manual BRAKE RELEASE on

the back of the lift motor, slowly lower the unit to the base. Open the canopy and release the restraint

harness and assist patrons from the cockpit.

Fig. 1 Fig. 2

2-11D Emergency Leveling and

Lowering

To level the machine in the pitch axis pull on the

PITCH BREAK RELEASE (Fig. 1) and level the

machine manually. There is a level mounted on

the Roll Motor (Fig. 2) to aid in getting the ride

into the home position. A Second person should

be used when performing this procedure.

Fig. 3 Fig. 4

To level the machine in the roll axis

move the manual BREAK RELEASE

LEVER (Fig. 3) towards the Tail

Boom Cover. There is another level

mounted on the back of the seat frame

Page 17

(Fig. 4) to help find home level in the Roll axis.

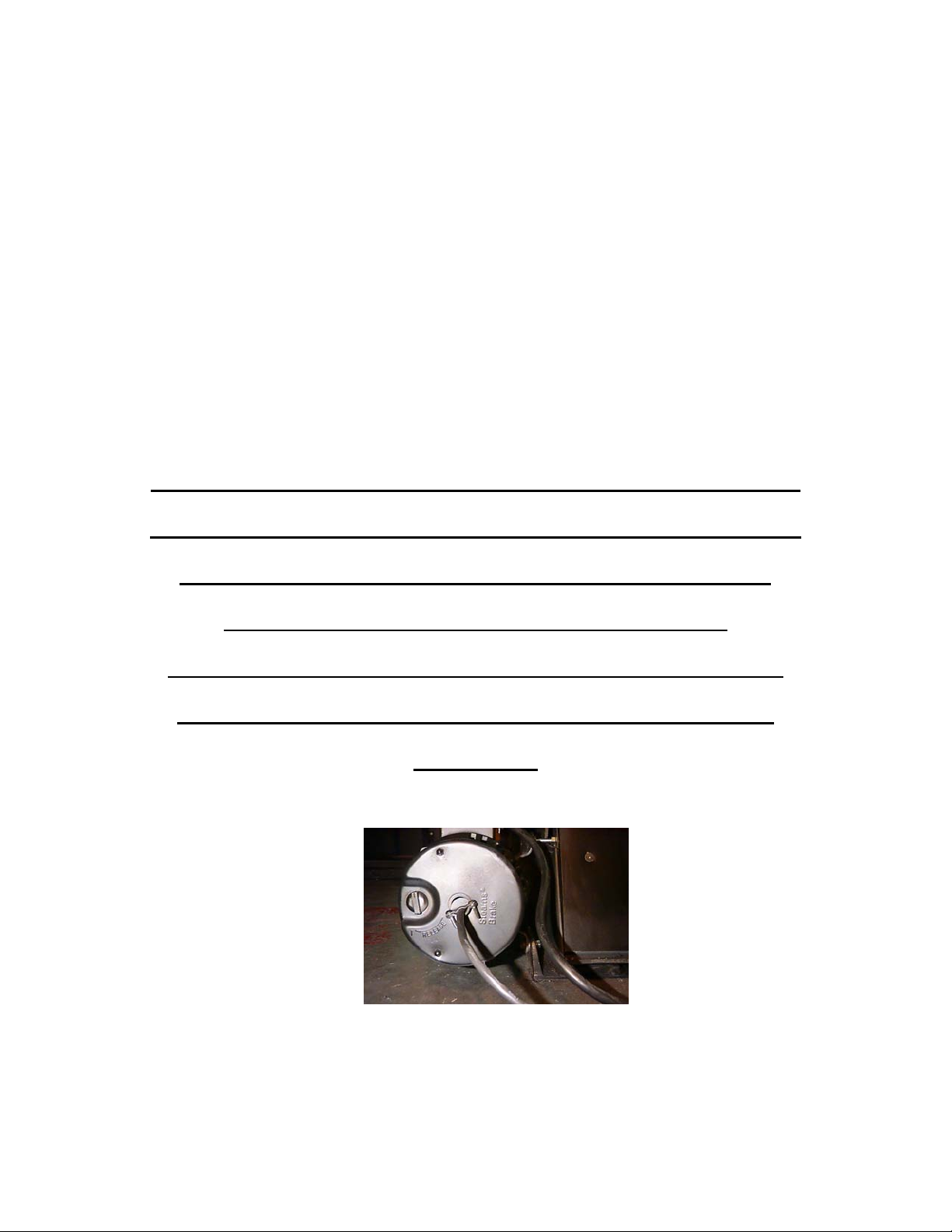

Fig. 5

Once the machine is in the HOME position (level on both pitch and roll

axis) it can be lowered. Using the manual BREAK RELEASE KNOB on

the back of the Lift Motor (Fig. 5), Slowly turn the knob clockwise until

the platform lowers from the elevated position. Adjust lowering speed by

the amount you turn the knob. Releasing of the knob will stop the

lowering.

CAUTION: WHEN LOWERING UNIT MANUALLY, ALLOW UNIT

TO COME TO A SLOW, SMOOTH STOP.

2-12 Power Interruptions and Restart Procedures

Should the power be interrupted, the following procedures should be followed.

2-12A Facility Emergency Lighting

Facility emergency lighting must be configured to allow attendants and patrons enough lighting to safely

exit the ride and area.

2-12B Restart Procedures

Even if the power comes back on, lower the platform to its full down position, using the manual lowering

procedure para. 2-11C. If the power is normal, you can follow the normal Start-up procedures para 2-

2.

2-13 Ride and Facility Evacuation Procedure

Terminate the ride from the PC. Quietly and calmly, have the queue line begin exiting the facility. Lower

the unit(s) open and unbuckle all patrons and assist with the evacuation of the facility. Follow the system

shut down procedure if time permits or at least press the “E-Stop” this removes power to the electric

motors. NOTE: It is most important that the power to the motors is disabled.

2-14 Ride Termination Conditions

1. Any abnormal vibration or abrupt motion changes that would not be considered part of the normal

operation.

2. Any undue movement of either the fiberglass, covering panels, A-frames or any hinges or fabricated

metal that would indicate fatigue, fracture or loose bolts.

3. Any type of electrical problem that would effect continuation of the game and could include electrical

problems within the building that could inadvertently affect the operation of the simulator.

4. Any computer malfunction that would include system lock-up, program termination or any other

condition that would affect game play.

5. Any condition with the movement that is abnormal (i.e. the TV set showing a roll where the simulator

remains stationary).

6. Any loose objects that roll around inside the cockpit as these items would damage the patron as well as

the components inside the cockpit.

7. Any signs that the concrete anchors may be loose by allowing the unit to walk or move.

Page 18

8. Any signs of smoke or sparks which would indicate the potential for fire.

9. Any condition where the passenger was tampering with the system such as pounding on the fiberglass

or undue pressure on the cockpit.

2-15 Operational Restrictions

There are certain conditions that the machines should not be operated under. These conditions are

described below.

2-15A Intoxication

If a patron is under the influence of any drugs or alcohol they should not be allowed to utilize the

equipment.

2-15B Heart Conditions

Any heart or other similar condition would preclude a passenger from riding the simulator.

2-15C Pregnancy

It is not recommended that women who are pregnant ride the simulator.

2-15D Weight and Height Restrictions

The patrons must be at least 48” (1.22 m) tall and total weight is not to exceed 500 lb. (226.8 kg) with no

more than a 100 lb. (45.36 kg) difference between the passengers.

2-15E Electrical Storms

It is up to the discretion of the owner operator to operate during an electrical storm. However, it is NOT

recommended to rely on the internal facility safe guards to protect the equipment. When in doubt, shut

down the system to ensure safety of not only the passengers but also the safety of the system.

2-16 Daily Inspection Checklist Description

The Daily Checklist is to be completed by the first shift attendant operating the MT3000 as well as the

second shift attendant (if applicable) at the beginning of his/her shift. These sheets must be filled out on a

daily basis. DO NOT check off the items in the checklist unless you have performed the required

inspection. This maintenance is required to maintain optimum performance of the MT3000. The master

copy of this checklist can be found at the end of the Operator’s Manual.

CHAPTER 3 – SUGGESTED POSTINGS and

Manufacturer’s Specifications

3-1 Manufacturer’s Specifications

Reference Standard:

ASTM-F24 Standards on Amusement Rides and Devices

1. F583 Maintenance Procedures for Amusement Rides and Devices

2. F893 Inspection of Amusement Rides and Devices

3. F1159 Design and Manufacture of Amusement Rides and devices

MaxFlight, Corp., at the time of the initial design and prototype manufacture, determines by calculations

and testing the appropriateness of the functional design criteria. The visual esthetics of the ride are also

evaluated and together with the functional design criteria make up the manufacturer’s design specifications.

These design specifications are adhered to on all subsequently produced rides of the same style.

Occasionally, through field experience, it becomes necessary to specify a modification to the original

design specifications. Actual modification to meet the change in design specifications can only be

Page 19

performed by qualified personnel, following the directives of a MaxFlight, Corp. Service Bulletin, Service

Kit, or a MaxFlight, Corp. representative, where applicable.

Any modification performed on a MaxFlight, Corp. product outside the recommended directives

established by MaxFlight, Corp. as referenced above, constitutes an unauthorized modification. MaxFlight,

Corp. specifically disclaims any liability for loss associated with any unauthorized alteration and/or

modification to any of its products. MaxFlight,Corp. will not issue letters for the operation of rides which

do not meet the manufacturing specifications; this includes cases where the non-conforming modifications

of an aesthetic nature only.

It is the responsibility of the individual inspector to thoroughly inspect the ride as deemed necessary, based

on his knowledge and field experience to determine that the ride meets the manufacturers and/or is safe for

operation.

3-2 Suggested Postings

This chapter also contains notices that we suggest be placed near the unit to promote the safety of patrons

as well as operators and to ensure proper operation of the ride.

Page 20

EMERGENCY PROCEDURE

POSTINGS

Emergency Stop Procedure

The Red Emergency Stop Button, located on the side of the command consol, MUST be depressed

IMMEDIATELY. This will deactivate the Electric Motors. The unit will need to be leveled manually on

both the Pitch and Roll axes. Located on the back of the Lift Motor is the manual brake release knob.

SLOWLY turn the knob clockwise until the unit lowers from the elevated position. Adjust the lowering

speed by the amount you turn the knob. After the ride has lowered, open the canopy, raise the harness

restraints and aide the patrons in exiting if necessary.

Ride and Facility Evacuation Procedure

Terminate Game Play from the host PC.

Quietly and calmly, have the Queue line

begin exiting the facility. Lower the

unit, open the canopy, raise the

harness(s) and unbuckle the patron(s),

then assist with the evacuation of the

facility.

Page 21

NEW EMERGENCY RAISE

PROCEDURES

FOR

ELECTRIC MACHINES

This Emergency Procedure to be used anytime if/when the Motion Platform lowers in a

abnormal way, ie: Contacts the stands, floor or is stuck half way between all the way UP

or DWN.

1. Anytime an abnormal action occurs on the motion platform the operator

MUST immediately depress the E-Stop on the side of the command console.

2. Verify that the E-Stop is depressed.

3. On the Lower Right corner of the Task Bar right click with the mouse on the

icon that contains a checkmark in a green circle. This opens a Properties

window.

4. Click on Emergency Raise, another control window will open up showing a

STOP and RAISE icon.

5. Pull out the E-Stop on side of command console. Verify immediately that

there is no motion on the platform. If there is push E-Stop back in

immediately and then back out, this will reset the brakes on all drive motors.

6. Click on RAISE icon, the unit platform will rise approximately ½ to ¾ of an

inch at a time. It will do so until it contacts the upper limit sensors and stop.

7. When motion platform is all the way UP, DEPRESS E-STOP.

8. Manually level the platform in Pitch and Roll.

9. Lower the platform using the manual lowering procedure, by turning the brake

lever on rear of lift motor clockwise slowly until the platform lowers.

10. Lower all the way. When down on the stands open the cockpit and help

patrons out.

11. Call Maintenance for repair and/or unit testing to certify that this unit is safe

to operate.

Page 22

PATRON NOTICE

Maximum Passengers Per Ride: 2

Maximum Combined Weight: 500 lbs. / 226.8 kg

Minimum Height Per Passenger: 48 in. / 1.22 m

This ride is NOT RECOMMENDED for persons who:

Are under the influence of alcohol or any type of drugs.

Are pregnant.

Suffer from Motion Sickness or Claustrophobia.

Anyone having Heart Conditions, Back or Neck Ailments

or any Serious Disabilities.

Epileptic patrons; due to the special strobe and lighting

effects that are known to trigger seizures

All loose articles such as pens, loose change, etc. that may

come off during flight should be removed.

Patrons have a responsibility to exercise good judgment

and act in a responsible manner while riding the MT3000.

Patrons have a responsibility to become familiar with and

obey all oral and written warnings and instructions prior to

and during their use of the MT3000 simulator.

The MaxFlight MT3000 is intended for the enjoyment of patrons and the above information is for your

safety and well being.

Page 23

MaxFlight Corporation

750 Airport Road ◦ Lakewood, NJ 08701

Phone: (732) 942-9898 Fax: (732) 942-1114

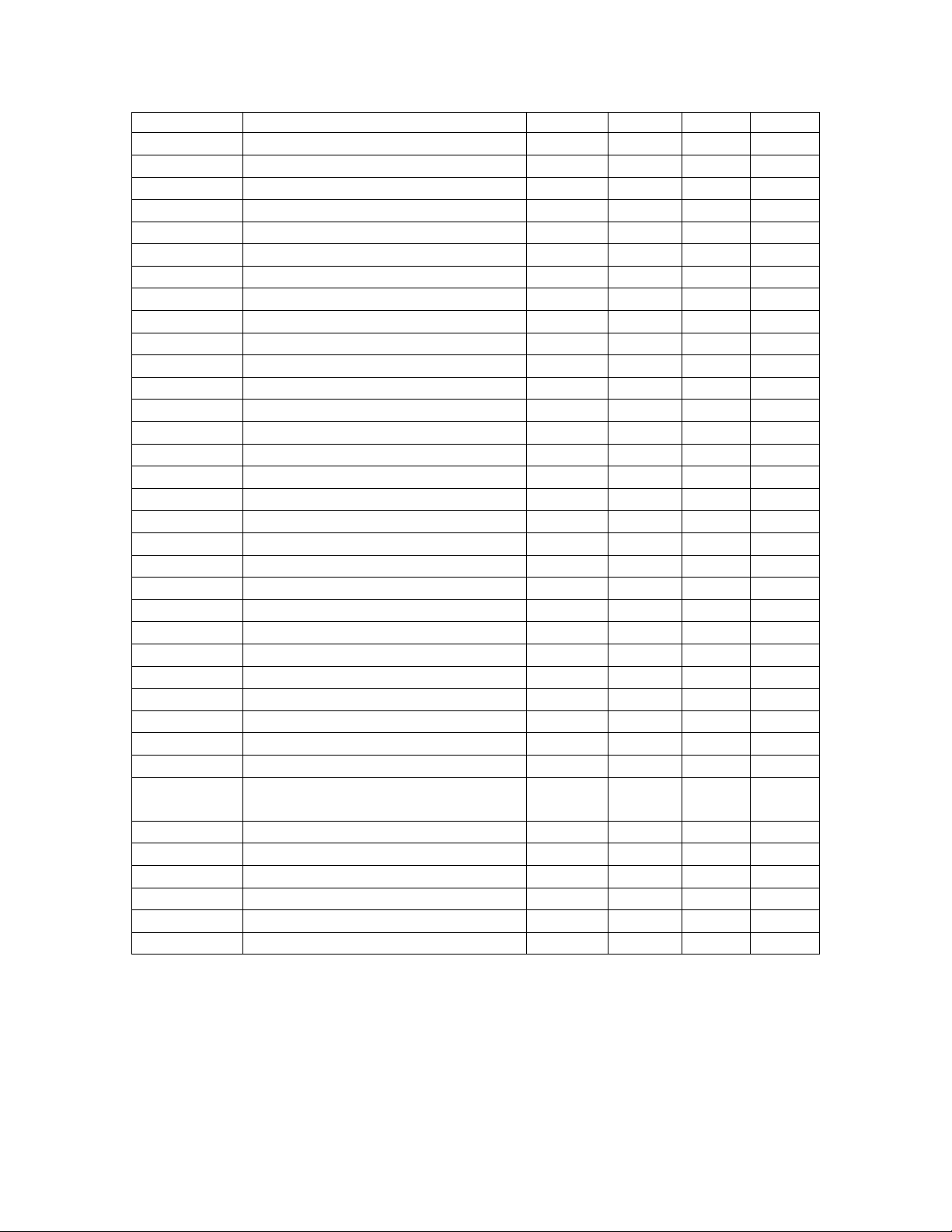

Electric MT3000 Daily Inspection Checklist

Date of Inspection: AM Inspected By:

PM Inspected By:

* These sheets must be filled out completely and kept in your records.

AM Check PM Check

Inspect projector for proper operation and cleanliness

Make sure that the ductwork is secure and functioning properly

Make sure the screen assembly and padding are secure and in good condition

_____ _____ Ensure the Emergency Stop Button is functioning properly

Check to see canopy sensor works properly

Make sure the sound system and speakers are secure and operational

Make sure the cockpit Occupant Panic Switch is functioning properly

Inspect harnesses for proper operation and condition

Inspect seat belts for proper operation and condition

Make sure gas spring safety clips are secured properly

Make sure canopy alignment pins are tight

Inspect the Cockpit latch for proper operation and condition

Check stairway for any movement

Make sure the tail boom stand is in good condition and its proper

location

Make sure the concealment panel on the tail cover is secure

Make sure all pine tree fasteners are in place and panels are secure

Ensure that the molding on the cockpit and tail boom cover is intact and secure

Make sure tail cover bolts are snug

Inspect all fiberglass for any visible damage

Check for general ride cleanliness

at the center weldment to ensure that there are no cracks, also inspect the safety

properly

NOTE: When inspection is completed, run one full ride cycle to ensure all system components function

properly

Inspect any entrances, exits, stairways, ramps, fencing, guarding and barricades

Inspect the flange welds of the Right/Left Pitch Shafts and Counterweight shaft

wire and bolts for security

Ensure the Manual Leveling and Lowering Brake release Levers are functioning

Page 24

APPENDIX A – SITE CONFIGURATION REQUIREMENTS

To determine the site configuration, there are several factors that need careful attention.

1 - Available Floor Space

Each unit has a footprint of 12’ 8” (3.9 m) wide by 17’ 3”’ (5.26 m) deep, including the loading platform.

Depending on the site topography, the actual configuration will vary.

2 - Ceiling Clearances

The ceiling height requirement is 12’ 10” (3.9 m) with a pathway of approximately 4’ (1.2 m) wide at the

top, 2’ (0.61m) either side of center.

3 - Floor Loading Capabilities

Floors must be able to support the weight of the units. To obtain this information, consult an engineer or an

architect.

Approximate Unit Weight – 4200 lbs (1909 kg)

Load Distribution per Square Foot – 25.26 lbs (11.4 kg)

4 - Aisle Clearance

Consult local building codes. A minimum of 6’ (1.83 m) is recommended, but should not supersede the

local building codes.

5 - Entrances & Exits

Egress routs must be clear and unobstructed. Local building codes will dictate.

6 - Environment

Keep facility operating temperature reasonably stable. Temperatures less than 80 degrees Fahrenheit with

humidity levels less than 60% would keep patrons comfortable and keep equipment functioning well. Also,

for the best visual effect, facility lighting should be kept low.

Warning – If the environment is not stable it will cause damage to the electronic

equipment.

7 - Floor Finishes

A carpeted floor is the preferred floor finish. Tiled floors and bare concrete floors are okay but may require

placing the machine on an anti-slip pad.

8 - Truck Routes

Depending on the size of the purchase, there could be a need to have access to the facility capable of

accommodating large freight trucks, which require maneuvering room.

9 - Docking

Obtain and forward dock heights before shipping arrangements are made so that accommodations can be

made for the ease of unloading.

10 - Freight Elevators

When installing units that are above the ground or dock level of your facility, examination of freight

elevators for capacities, size and operability is necessary. Schedule time and operators for the day of

delivery where applicable.

Page 25

11 - Electrical Configurations

U.S. CONFIGURATION

Facilities with available three-phase service need:

A. 2 circuit single-phase, 110 volts, 20 amp, 60 Hz

B. 1 circuit three-phase, 208 volts, 30 amp, 60 Hz

EUROPEAN CONFIGURATION

Facility requirements are:

A. 2 circuit single-phase, 220 volts, 10 amp, 50 Hz

B. 1 circuit three-phase, 230 volts, 20 amp, 50 Hz

HONG KONG CONFIGURATION

Facility requirements are:

A. 2 circuit single-phase, 110 volts, 15 amp, 50 Hz

B. 1 circuit three-phase, 230 volts, 20 amp, 50 Hz

12 - Public Barrier System

Barriers may need to be set up to restrict patrons from coming within reach of the machine while in

operation. It is not the responsibility of MaxFlight to provide or install the public barrier system.

Page 26

MaxFlight

MT3000(B)

”ELECTRIC”

Technical Manual

Page 27

CHAPTER 1 – THEORY OF OPERATION

1-1 Introduction

To understand why certain steps have to be performed while running this motion

simulator you should know how the unit does what it does. You also need to know how

each part plays its part so when something should go wrong, it can be corrected with

minimum down time.

NOTE: The Inverters must be matched at the factory to the power available in the field

installation. The motors can be rewired for various inputs but the inverters

cannot.

1-2 ELECTRICAL

1-2A Input Power: 115/20 VAC one phase 60hz for computer, blowers, projector, audio amplifiers.

208/440/477 VAC three phase, for drive motors.

.

1-2B Power Box: Contains the following;

1. Three frequency drive invertors that are the same

a. Pitch

b. Roll

c. Lift

2. Frequency drive for the counterweight motor

3. Three brake control relays

4. CPU interface distribution box, serial control bus

5. Main power relay contactor and thermal overload protect

6. Receptacles for all connections

7. Cooling fan

8. Brake resistors for the big drive motors (three)

1-2C Electro Magnetic Interference (EMI)

EMI is a problem when you have high current wires laying parallel with low current/voltage wires. When

the magnetic field about a wire changes, that change induces voltage spikes or signal interference into

associated wires. If this becomes a problem there are ways to correct this. One, is limiting induction on

other wires by using shielded cables and connections. The other method is to space wires apart or run them

ninety degrees to each other. In this system we use both methods to limit power interference into video,

audio and control signal cabling.

1-2D Roll Axis

Roll Motor: Three phase AC motor. Mounted in the center weldment with four bolts and shims for

spacing. Roll shaft and hub assembly gets mounted through the center of the gearbox. Gearbox pre-filled

at factory. A key transmits torque to roll shaft.

Roll Brake:

receives 220 VAC to the rectifier inside the enclosure. The coil is a 220 VDC unit. It has a manual release

lever.

Roll Encoder:

computer via the interface board and motion control board.

Mounted on the end of drive motor. Stops motor rotation and holds the axis where last left. It

Mounted on the end of the roll motor shaft. Sends roll position of the platform back to the

Page 28

1-2E Pitch Axis

Pitch Motor: A motor gearbox combination mounted to the left pitch shaft. Physically moves unit in pitch

axis. A key mechanically transmits torque from motor to the shaft. Filled with gear lube at the buildup of

the unit.

Pitch Brake:

rectifier inside the enclosure. The coil is a 220 VDC unit. It has a manual release lever.

Pitch Encoder:

computer via the interface board and motion control board.

Mounted on the end of pitch drive motor integral to the unit. . It receives 220 VAC to the

Is a 400 or 120 line encoder mounted to the motor shaft. Sends pitch position to the

1-2F Lift Axis

Lift Motor: Motor brake combination. Mounted at the right rear inner side of the A frame. Connected to a

90-degree gearbox via couplings and drive shaft. Drives, through couplings, the lift jack gearboxes at each

side of the base.

Lift Brake:

Lift Encoder:

that gives height feedback to the computer via the interface and motion control boards.

Mounted at end of the motor. Controlled by a 220 VAC coil.

Mounted to the drive axle from motor to the ninety degree gear box. A 400 or 120 line unit

1-2G Counterweight Drive System

Drive Motor/Brake/Gear box mounted on top of center weldment, attached to a horizontal drive

screw that moves the counterweight in either direction as commanded by the CPU.

Brake

attached to end of motor, this is a 115 VAC controlled coil.

1-2H Pitch Slip Rings

These units are sealed no maintenance required or allowed.

1. Power Side: Located above the power cabinet right side on the end of the pitch

shaft. Feeds wires to the center weldment to the roll motor/brake and counterweight

motor/brake.

2. Signal Side: Located at the end of the pitch shaft left side right before the pitch

motor. Feeds all the signals to the center weldment. Projector video, roll encoder

power and signal, HAPP box joystick signal on M/T3000, power to the cockpit area,

canopy sensor and occupant E-Stop.

1-2I Blowers

1. 4.5” blower mounted on pitch motor.

2. 3.5” blower for the projector.

3. 2- 4.5” blowers mounted at rear of cockpit for ventilation.

1-2J Power Strips

One left inner rear side of A-frame and one located under seats of the cockpit and one in base of command

console.

1-2K Sensors

One left upper limit sensor, one right upper limit sensor, one lower limit sensor, one canopy sensor and one

demo switch sensor.

1-2L Switches

There is one Occupant Safety Switch between the seats in the cockpit and one E-Stop switch on the side of

the command console.

Page 29

1-2M Encoders

All encoders (three) are the same. A 400 line, metal disc type. Power to them is from the computer, a 5

VDC signal powers the light diode that shines through the disc to a receiver diode.

1-2N Interface

Interface Control Boards are by Omnitech and located behind left front cabinetry.

1-2O Roll Slip Rings

Located between the weldment and the cockpit. Mounted over the roll shaft it passes the signal to the

cockpit. These units are sealed and no maintenance allowed.

1-2P Steering Wheels/Throttle/Brake and HAAP Box (CIB1000) or( USB

UGCI) Interface

There are two steering wheels and two sets of Gas/Brake pedal units mounted on the

floor boards. These units interface to the HAAP (USB UGCI) controller installed beneath the

seat area. The HAAP box is powered by a DC eliminator transformer that is plugged into the AC

power strip. The USB interface is powered by the computer directly. The signals are transferred

to the CPU via a DH9 connector by way of the roll and pitch signal slip rings to the CPU Com#2

input to the mother board (Older Style Units). On later style units the signal is routed directly to

the computer along the USB bus cable. The controllers are calibrated within the window program

and Monster Truck program configuration windows. See setup instructions in Technical Section

starting at paragraph 5-20.

1-3 Mechanical

1. A-frame - two each, right and left.

2. Center weldment.

3. Pitch arms two

4. Tail shaft

5. H frame assembly, attached to the tail shaft

6. Counterweight gear and gear box

7. Counterweight @300 pounds

8. Chair assembly

9. Seat back assembly

10. Lift drive network

11. Roll motor mounting

12. Pitch motor mounting

13. Roll hub assembly

14. Fiberglass cockpit shells

15. Front stand

16. Rear stand

17. Entry stair assembly

18. Cabinetry

1-4 COMPUTER SYSTEM

Computer System/Control Console

1. CPU- audio card, video card, mother board, Voodoo 3dfx card, motion control board,

network card, modem board, power supply, hard disk drives, CD drive, and software to

control it all.

2. Monitor

3. UPS (Uninterrupted Power Supply)

4. Power audio amp

5. Audio pre-amp

6. Cabling

Page 30

1-5 What Causes the Unit to:

1-5A Raising

NOTE: In the following brake “OFF means brake solenoid is powered, allowing motor rotation. Motor

brake “ON” is brake solenoid de-energized and brake is applied preventing rotation.

When you click on the “RAISE” icon on the program window, this signals the CPU that you want to start

the raise sequence.

1. LIFT BRAKE “ON” CPU signals the motor drive invertors of pitch/roll to set the brakes to

“OFF”

2. Pitch, roll and lift encoders are set to zero and monitored for count by CPU. Roll axes is

locked at this time brake ON.

3. Lift brake “OFF”, platform raises @2.5” and stops the raise command to allow platform to

level, Lift brake back “ON”.

4. Monitoring the pitch encoder, the counterweight moves opposite the heavy end, stops,

reverses direction, stops. The CPU counts the encoder value takes the average and takes ½

the signal to drive the counterweight to null or balanced position. Pitch motor brake is turned

“ON” thereby locking the axes to zero before the remainder of lift occurs. Also, the CPU is

now monitoring for a Roll or Pitch movement. Should either occur and move greater than 15

degrees, motion is stopped immediately and all brakes applied. Emergency lowering must be

done.

5. Lift brake to “OFF” , CPU monitors lift encoder for the rest of the raise command. Platform

raises a max. of 29.75”, calculated by counting lines per revolution per inch of raise.

6. Platform reaches the top, stops, lift brake turned “ON” when upper limit switches are reached.

Upper limit switches do not stop raise power of lift motor. They are only a signal to the CPU that

the platform has reached the upper limit and it is safe to allow full motion.

1-5B Lowering

At the completion of a programmed ride or anytime normal lowering is desired the following occurs:

1. CPU commands pitch/roll brake “ON”.

2. CPU while monitoring the lift encoder during decent, counts the lines per inch. Lift brake “OFF”

lowering initiated. CPU also monitors for 15 degree safety movement in Pitch/Roll axes.

3. CPU measures @27” of decent and slows the lowering speed.

4. CPU measures @29” of decent and slows motor again.

5. At @29” the CPU commands pitch/roll brakes “OFF”, these stay off for remainder of action.

6. Platform comes to rest at @29.75”, hits lower stop bar, CPU stops lift motor drive and turns lift

brake to “ON”

7. Lowered or down sensor is enabled, this signals the CPU to zero all the encoders, motion com

and Maxzilla program are reset to default start ready for the next cycle.

1-5C Stop

STOP is a command given by:

1. Computer during a normal cycle of operation that is semi-automatic in nature.

2. Manual directed via the CPU by the operator. Stops all motion if in a running program.

Stops motion when testing an axes in manual test.

3. E-Stop manually removes all power to the motor drives and applies all the brakes on all the

motors instantly. This halts all motion instantly.

Page 31

1-5D Pitch and Roll

Roll/Pitch

CPU program commands motion via motherboard (COM 1), cabled to power box, to the

respective frequency drive unit. The program commands the direction and rate of movement.

The respective encoder sends a counter signal back to the CPU via the Interface card, cable to the

Motion Control card to the program. When the encoder signal cancels out the original drive

signal, all motion stops.

1-5E Balance

See paragraph 7-4A, it includes complete detail.

1-5F Interface with Relays

1. Brake relays in the power box are activated by the CPU via COM 1, to the serial

interface box in power box , to the inverter and finally the OPTO 22 relay. This relay

allows the second leg of 220 VAC power to get to the brake solenoid on the motors.

2. The Power Contactor relay is activated by pulling out the red E-Stop button. The

same button turns all power off to the power box by removing control from the

contactor.

1-5G Interface with Motion Control Board

1. CPU provides +5 and +12 to the interface board from the computer power supply through

motion control card and ribbon cable to the interface board. This power (+5VDC) is used by

the encoders and all sensors except canopy and patron E-stop which use the +12 VDC. Using

dead end resistor network the (+12/5VDC) is used by the sensors powered from this panel.

2. All encoder return signals pass through the interface board to the CPU motion control card

and on to the program running.

3. All sensor switch indications run through the interface board. The signal that the CPU reads

is either a +5VDC signal or a high switch open or 0 VDC switch closed.

1-5H Interface with Unit Sensors

There are five sensors that are monitored by the CPU. Signals flow from the sensors to

the interface board on to the motion control board in the CPU. These are:

1. LH upper limit

2. RH upper limit

3. Down sensor

4. Patron E-stop sensor

5. Canopy sensor

5-1I Interface with Projector/TV and Monitor

CPU mother board processes the signal and passes it on to:

1. Monitor, connected to video output in rear of CPU, allows the operator

to see control windows etc.

2. VOODOO 3DFX card used on MT3000, units, these signals are

processed passed on through TV magic box, one consolidated signal

goes to the TV the other VGA signal goes to the INFOCUS projector.

1-5J Interface with Inverters and the power box

CPU program through the motion control board activates the inverters movement by sending a proportional

+ or – 10 VDC by way of the analog cable to the power box. This voltage gives direction and rate to the

Page 32

respective axis. The software command signals are transmitted through the serial interface cable to each

inverter. This signals when to apply or release the motor brakes and internal parameter functions of each

inverter.

1-6 – OPERATING LIMITATIONS

1-6A Computer

When starting up the computer system, the operator should observe any error indications or signs that the

computer is not functioning correctly. Provided there are no error messages and the game can be

initialized, the system should be cycled at least once to ensure that the computer is functioning properly.

1-6B Restraint System

By raising and lowering the restraint harness you will be able to establish that they are operating properly.

If any part should fail, the unit should be shut down until the repair is made.

1-6C Electrical Control Box and Mitsubishi Inverters

The Electrical Control Box should allow adequate amount of airflow so the inverters inside can stay cool

during operation. Avoid locations where the control box is subjected to direct sunlight, high temperature

and high humidity. The emergency stop button must be used to remove power supplied to the motion

system before servicing the control box. NOTE: make sure that the main power is also disconnected at the

wall outlet or circuit breaker panel, and wait at least five (10) minutes before entering the Electrical Control

Box. This is to ensure that the power capacitors are fully discharged.

1-6D Frame and Structure

A daily inspection of bolts and welds should be accomplished to ensure that there is no metal fatigue or

loose bolts. Loose bolts should be tightened in accordance with MaxFlight specifications, however, if there

is any question as to why there are loose bolts, the unit should be shut down and examined to determine any

causes that are not obvious. It is up to the operator to report these conditions to qualified, on-sight

technical personnel only. If there are any stress cracks or cracks in a solid member, the system should be

shut down and examined immediately.

1-6E Motion Platform

If at any time there is a question with the stability of the motion platform, passengers should not be allowed

to enter

the ride until an adequate means of entry or exit is available.

Page 33

CHAPTER 2 – ELECTRICAL SYSTEM

2-1 Electrical System

The electrical system provides the force for the motion of the unit during operation. The motion

base is a two-axis system with a lifting system for raising the unit to the operation position, and a

counterweight system for balancing the cockpit. Each of the axes has an electric motor that

drives in two directions. 208-volt 3-phase powered, variable frequency inverters control these

motors. Sending a DC analog signal from a remote computer to the inverters can set the direction,

position and speed of the motors precisely. The RS-485 connection is a serial communication

path between the inverters and the computer, which allows the computer to monitor and send

commands to the inverters.

Located inside the right A-Frame, the electrical panel incorporates all the electronics mentioned

above. The panel contains fourteen (14) connectors, namely the main power, pitch motor power,

pitch motor brake power, lift motor power, lift motor brake power, fan power, roll motor power,

roll motor brake power, counterweight motor power, counterweight motor brake power, two RS485 communication ports (one spare), inverter speed analog signal, and emergency stop button

connector. Four Mitsubishi inverters are mounted inside the panel. Pitch, roll, and lift run on

bigger units; the counterweight runs on a smaller unit. See panel drawings at the end of this

manual for more information about where they are mounted in the Electrical Control Box.

10Base-T networking receptacles are used for the RS-485 communication ports. Hubbell twist

lock connectors are used for the main, pitch motor, roll motor, and lift motor power. All other

connectors are military style connectors.

Motor power connections provide 208-volt 3-phase power to the Pitch, Roll and Lift motors, and

brake power connections provide power to the motor brakes. The counter-weight motor brake is

powered by 110-volt single-phase system the rest are 220. The frequency inverters ensure that the

brakes are not applied during motion.

The computer program knows the position of the unit by reading the encoders on the pitch, roll,

and lift axis. The encoders are electrical devices powered by a 5-volt supply on the motion

control interface card, movement can be measured by sending a light beam through a metal disc

that has 400 holes/slits on it. Each light or dark sends a pulse to the Computer Motion Control

Board, which “reads” the pulses and determines where in the pitch, roll and lift axis the motion

platform is at any given time. The encoders know the position of each axis to within .006”. There

is a safety backup to the encoders and that is software driven. It monitors the Roll and Pitch

platform position. If the computer requests movement and does not get an encoder return signal

it will default and shut down motion to the platform. Also should there be a motion on the

platform greater than 15 degrees, that was not requested by the computer the computer will stop

motion of the platform.

The counterweight is used to balance the cockpit and tail section at their vortex, referred to as the

center weldment. The balance is obtained by powering a drive motor, located on top of the

weldment, which moves the counterweight back and forth on a shaft as required to balance the

machine. When the cockpit is balanced, the unit will rise to its maximum up position.

Page 34

The emergency stop switch, located in the center of the cockpit, activates the emergency stop

condition, returning the machine to its original horizontal (Home) position. The motion platform

can then be lowered to the stairway by using the raise/lower switch.

The upper and lower sensor switches, which are mounted on the center sections of the A-Frames

directly in line with the bearing blocks, signal the computer when the machine is in the proper

position to begin the game (raised) or load and unload passengers prior to or at the end of the

game sequence (lowered).

The electrical swivels allow current and data signals to flow into the cockpit and associated

devices via a series of rotating rings with brushes that make contact and allow pitch and roll

motion through a range of 360 degrees in either direction.

The pitch input connections consist of cockpit power feed (120VAC), grounding wire, left/right

phono jacks, counterweight motor feed, video feed, emergency stop and a data line to the roll

encoder. These signals are then transferred to the center weldment where the power, phono,

video and emergency stop and canopy sensor are transferred to the roll electrical swivel and on to

the cockpit.

Thus, the unit can be described, from an electrical perspective, as being controlled from the

computer and the electrical panel. RS-485 serial communication allows the Mitsubishi inverters

inside the panel to communicate with the computer, thus giving direction to the inverters, and an

analog feedback signal to the CPU, telling the CPU what each inverter is doing. The encoders

also give feedback to the CPU, which is the heart of the system to null out motion and direction.

2-2 Motion Platform Axis Movements

In order to insure that the three (3) axis motors (pitch, roll and lift) are moving in the proper

direction, the following observations should be made. Clockwise and counter-clockwise

observations are to be made from the position of the respective motor, facing the cockpit of the

motion platform. For the ROLL axis, the observation point is from the center weldment facing

forward. For the PITCH axis the observation point is from the pitch motor facing the motion

platform. For the LIFT axis the observation point is from behind the motor facing towards the

front of the motion platform.

2-2A Installing the MaxFlight Motion Com Objects (MF Motion)Package Version

1.2.5

Although, the following procedure is normally performed at the factory, there may come

a time when the computer may have to be reloaded from the beginning due to a

malfunction of the drives or other internal components.

1. Prior to installing the MF Motion package, your system must be updated with the

latest version of Internet Explorer and the latest version of Microsoft Management

Console 1.2.

2. If you are installing on a Windows NT 4.0 system, install Internet Explorer 5.01 and

Microsoft Management Console 1.2. If these versions are already installed, you do

not have to perform these steps. If Windows 2000 system is loaded, the above are

loaded by default.

a. Install Internet Explorer 5.01 or later.

b. Reboot the computer when instructed.

Page 35

c. Install Microsoft Management Console 1.2 (run iMMC.exe from the

MFMotion distribution CD).

d. Reboot the computer.

3. Install the MFMotion package (run Setup.exe from the distribution CD). The default

choices are appropriate for most systems. However, electric machines select

CUSTOM, deselect Hydraulic system by “X” out drive type. Certain third party

software packages are installed as part of this installation; if any ask for the computer

to be rebooted, answer NO and allow the full MFMotion installation to complete.

4. Reboot the computer (this is generally advisable because the MFMotion installation

also installs third-party packages that if updating your system may require a reboot).

5. The MFMotion installation installs default registry settings that are valid only for

testing. They do not actively allow the motion platform to be driven. You must

install the default registry settings for the particular type of motion platform and

product you are installing this for. To install the default registry settings:

a. Open a Command Prompt window. (DOS window)

b. Type “CD\Program Files\Common Files\MaxFlight “enter”

c. Type “MFMotion<configuration><product>-RegUpdate”

“<configuration>” is one of the following

(1) -ME MC3628 / Electric

(2) -MH MC3628 / Hydraulic

(3) -GE Galil /Electric

(4) -TC Test Configuration

“<product >” is:

(1) -MT3000

(2) –MT3000

(3) –MT3000

(4) –CR2502

(5) –MT3000

and press Enter.

EXAMPLE; If you would type and enter “MFMOTION -ME -MT3000 -RegUpdate” this

would be for an Electric MT3000 with an MC3628 adapter. (Coaster)

MFMotion –ME -MT3000 -RegUpdate “enter”

6. A message will appear on the screen confirming the registry update.

7. You can reload the default registry setting using this method any time. Do not load

them while the Motion system software is running because they will be overwritten

with the old values when the software ends.

8. The MaxFlight Motion COM objects are now installed and configured.

Page 36

2-3 Initial Wiring Confidence Check

2-3A Input 3-phase Wiring

The wiring of the individual phases of input power to the controllers does not make any

difference in the behavior of the drive motors. Guarantee that 208/440 or 470 three phase 60 Hz

power is available.

2-3B Output 3-phase Wiring

The wiring of phases between the controller and the motor affects the direction of motor

movement Reverse any two (2) phases of the controllers output to the motor, in order to reverse

the motor direction. Perform paragraph 2-4

To test and set correct drive rotation of all motors. Output power is digital DC to the drive

motors.

2-4 MANUAL CONTROL OF INVERTER DRIVES

This line legend must be

highlighted

Current reading

WARNING!!

or equipment damage may occur. Make sure, “E-Stop” is pressed in, power off before proceeding.

If the machine moves in the wrong direction, make corrections as in paragraph 2-3B above.

NOTE: Prior to performing this test, if the inverter/s are run for the first time, Paragraph 2-8 through 2-11

must be complied with or the respective inverter/s will not talk to the computer nor answer commands by

the operator.

WARNING! This test procedure allows the maintenance person direct control of the inverter drive circuits.

There are ”NO SAFEGUARDS” available when these tests are performed. In other words if you

accidentally activate pitch or roll while in the complete down position, you will drive the cockpit and/or

platform into the ground or leveling stands. No one is allowed inside the rotation plane of the platform as

long as this test window is active.

To perform manual inverter drive tests in the following axis these steps must be followed exactly:

1.) Ensure that the “E-Stop” is pressed in, power off to inverters.

2.) Double click on “Mitsubishi Inverter Test” icon on the desktop or go to program icon. This

In the following steps all procedures must be followed exactly or grave bodily injury

opens the test window for all the axes.

Page 37

NOTE: When you apply power to the inverters by pulling out the “E-Stop” if there is any motion on

the platform, immediately press “E-Stop” back in. Wait several seconds and try again if “OK” go

to next step.

3.) Pull out “E-Stop” all the legends n the window should highlight and all axes must have the

“START” icons highlighted. If not immediately press on the respective “STOP” icon to

close that axes. Also ensure that the OFF brake icon is highlighted under each axes except

counterweight.

NOTE: All axes movement of the motion platform is monitored by you sitting inside the

machine/cockpit facing forwards.

2-4A Lift Axis

1. To raise the platform, click on the left RAISE icon, the machine will slowly raise to the top.

2. Monitor the current value. As soon as it starts to rise sharply press “STOP” icon.

3.

To lower the platform, click on right LOWER icon and the platform will slowly descend.

4. Monitor the current value. As soon as it starts to rise sharply, press “STOP” icon.

NOTE: The platform can be stopped at any point along the lift axis. However, you must not command any

other axes motion unless the platform is all the way at the top.

WARNING: THE PLATFORM MUST BE ALL THE WAY AT THE TOP BEFORE RUNNING

EITHER ROLL OR PITCH MOTION.

2-4B Roll Axis

NOTE!!!! Motion as seen sitting in the machine facing forward.

1. Click on RIGHT icon, the machine will roll clockwise (+) direction, it will continue to roll until you

command “STOP”

2. Hit “STOP” before commanding rotation in opposite direction

3. Click LEFT icon, the machine will roll counter-clockwise (-) until you hit stop.

4. Hit “STOP” before commanding rotation in opposite direction.

2-4C Pitch Axis

1. Click on left DOWN icon, the machine will PITCH DWN (-) direction, it will continue until you

command “STOP”

2. Click on “STOP”

3. Click on right UP icon, the machine Pitch UP (+) direction.

Hit “STOP” before commanding rotation in opposite direction

2-4D Counterweight Motor

1. Click on DECREASE icon, weight will move towards the center. Hit “STOP” before

going the other way.

2. Click on INCREASE icon, weight will move away from the center.

2-4E Confirm Direction of Motor Movement

The correct direction of motion on the motion platform using the Mitsubishi Inverter control

program buttons is as follows: Direction of rotation is referenced you sitting in cockpit seat.

1. PITCH: DOWN unit moves (nose-down), UP unit moves (nose-up)

2. ROLL: RIGHT unit moves clockwise, LEFT unit moves counter-clockwise.

3. LIFT: RAISE unit moves upwards, LOWER unit moves down .

4. Counterweight DECREASE moves weight toward weldment, INCREASE moves weight

away from center.

Page 38

If the direction of movement is incorrect for any axis, reverse any two (2) phases as described in

paragraph 3-3B above.

2-5 Encoder wiring

The encoders are wired so that the labeled terminals for A and A-not, B and B-not on the encoder are

matched with corresponding terminals on the motion control interface board All cables return and start at

the interface board.

2-5A Encoder Positioning

The pitch and roll encoders are mounted directly to the motor shaft from the rear of the motor so that the

encoder is facing the motor from behind The lift encoder is mounted on the drive shaft connecting the

motor to the ninety degree gear box. Located right inside rear of ride lower level.

2-5B Encoder Behavior Confirmation

For each axis, the encoder forms a closed loop with the motion control adapter to generate an analog signal

that commands the drive motor to move in a specific direction. In the formula EP=DP-AP, (DP is the

desired position, AP is the actual position and EP is the error position) a positive EP results in a positive

analog signal to move the motor in the direction which will decrease the error.

PITCH: As the unit moves clockwise (up) the encoder reading should return increasing

values (positive). The clockwise Positive registry entry for the axis is set to 1 for true.

ROLL: As the unit moves clockwise the encoder reading should return increasing values

(positive). The clockwise Positive registry entry for the axis is set to 1 for true.

LIFT: As the unit moves up, the encoder reading should return decreasing values to the

registry, where in the software we reverse the appearance of the encoder reading using the

Clockwise Positive registry entry for the axis (set to 0 for false) so that in

the application we

will see increasing values when the unit is going up in inches not degrees..

If the value moves in the opposite direction, check the clockwise positive registry entry

for that axis. If it is set correctly, check the encoder wiring.

2-6 Mitsubishi Inverter Information

2-6A Appearance and Structure

Page 39

2-6B Removal of the Front Cover

The inverters are designed to work without the front cover in your MaxFlight simulator, and they should

already be removed and shipped in a separate package. Remove the front cover from new inverter as follow

when replacement is needed.

1) Hold both sides of the front cover top and gently push the front cover down.

2) Hold down the front cover and pull it toward you to remove. (The front cover

maybe removed with the PU (FR-DU04) on.)

2-7 Inverter Replacement

The inverter can be changed with the control circuit wiring kept connected.

1. Remove the mounting screws in both ends of the control circuit terminal block.

2. With both hands, pull down the terminal block from the back of the control circuit terminals.

3. When installing the terminal block to a new inverter, exercise care not to bend the pins of the

control circuit terminal block connector.

4. Disconnect all main circuit terminal wirings.

5. Unscrew the 4 mounting screws at the corners and remove the inverter unit.

6. Mount the new inverter.

7. Rewire the main circuit. See wiring diagram for jumper removal directions.

8. Reconnect the control circuit terminal block and tighten the screws.

After physical replacement of the inverter, it has to be configured to work for your simulator. The

operation panel (FR-DU04) is necessary to initialize this process, so make sure you familiarize

yourself with the panel with the attached information at the back of this manual. Also see

paragraph 3-8.

Page 40

2-8 Setting Parameters with the Operation Panel (FR-DU04)

When you replace an old inverter with a new unit, the inverter needs to be configured property

with the right parameter settings. These settings are saved in the inverter memory. Since there are

approximately 300 parameters, ask for technical support if you feel uncomfortable with the

inverter operation panel or using a personal computer. For operation panel (FR-DU04) operating

instruction, check attachment at the end of this manual.

The operation panel can access and configure any settings stored in the inverter memory, extra

hardware is not necessary to reconfigure your new unit to the same condition as your old drive.

However, changing 300 parameters with the panel is a time consuming process. To get around

this, a computer software program can be used to upload the settings. See paragraph 3-10,

Accessing Frequency Control Settings. However, a few parameter settings with the operation

panel are required to initialize the communication with the new inverter. Once all the parameter

settings are loaded for the new inverter, you must perform an Auto Tune procedure, of the new

inverter/motor combination. See paragraph 3-11, Auto Tune of Drive. The following

instruction shows how to initialize the unit:

2-8A Initial Configuration of Mitsubishi Inverters

The Mitsubishi Inverters must be manually configured before they can communicate over the RS485 connection to the computer. This configuration is performed using the FRU-DU04 Control

Panel. The Control Panel is connected to the inverter using an 8- pin straight through RJ-45

cable, or by directly mounting the Control Panel on the inverter using the straight through RJ-45

plug included with each inverter. It can only be connected to a single inverter at a time.

There are four (4) parameters that must be manually configured before the computer will talk to

any respective inverter. Following the steps outlined below manually configure the four initial

parameters.