Page 1

Impact Drill

Schlagbohrmaschine

Perceuse à percussion

Trapano battente

Slagboormachine

Taladro de impacto

FDV 16VB • FDV 16T • FDV 16

FDV 16VB

Read through carefully and understand these instructions before use.

Diese Anleitung vor Benutzung des Werkzeugs sorgfältig durchlesen und verstehen.

Lire soigneusement et bien assimiler ces instructions avant usage.

Prima dell’uso leggere attentamente e comprendere queste istruzioni.

Deze gebruiksaanwijzing s.v.p. voor gebruik zorgvuldig doorlezen.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

Handling instructions

Bedienungsanleitung

Mode d’emploi

Istruzioni per l’uso

Gebruiksaanwijzing

Instrucciones de manejo

Page 2

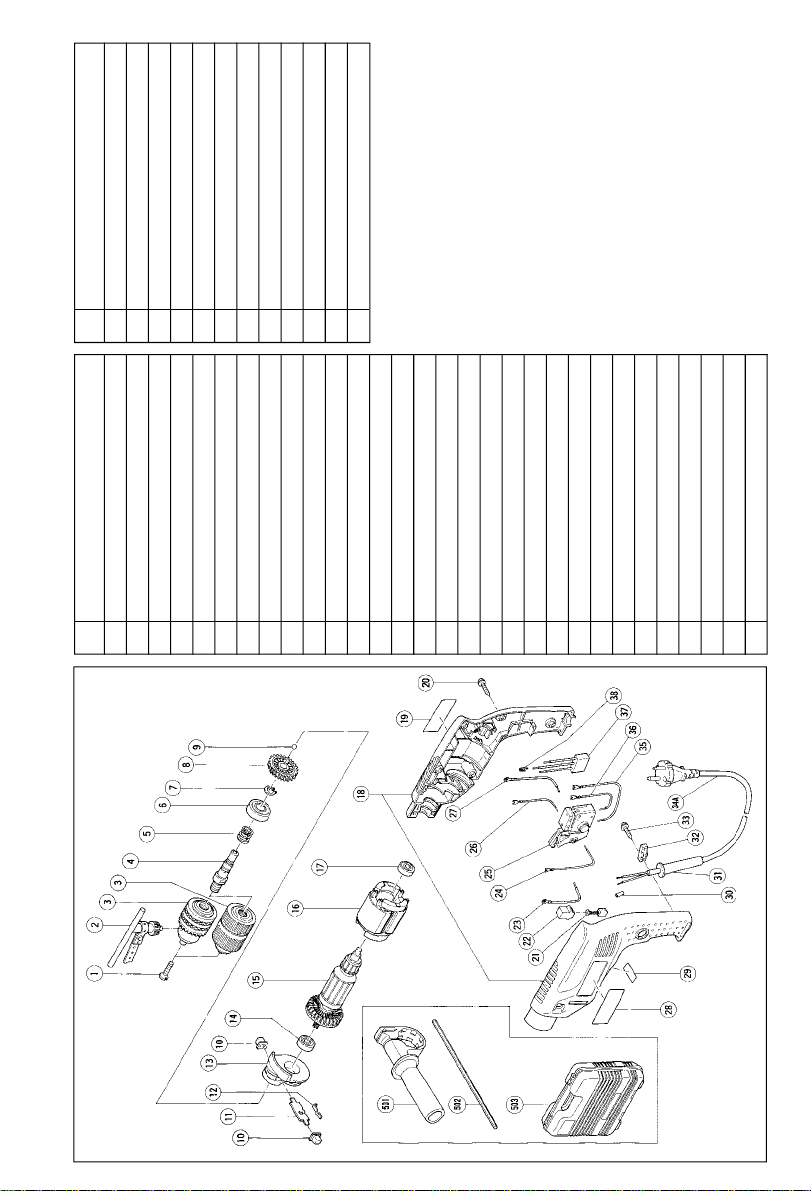

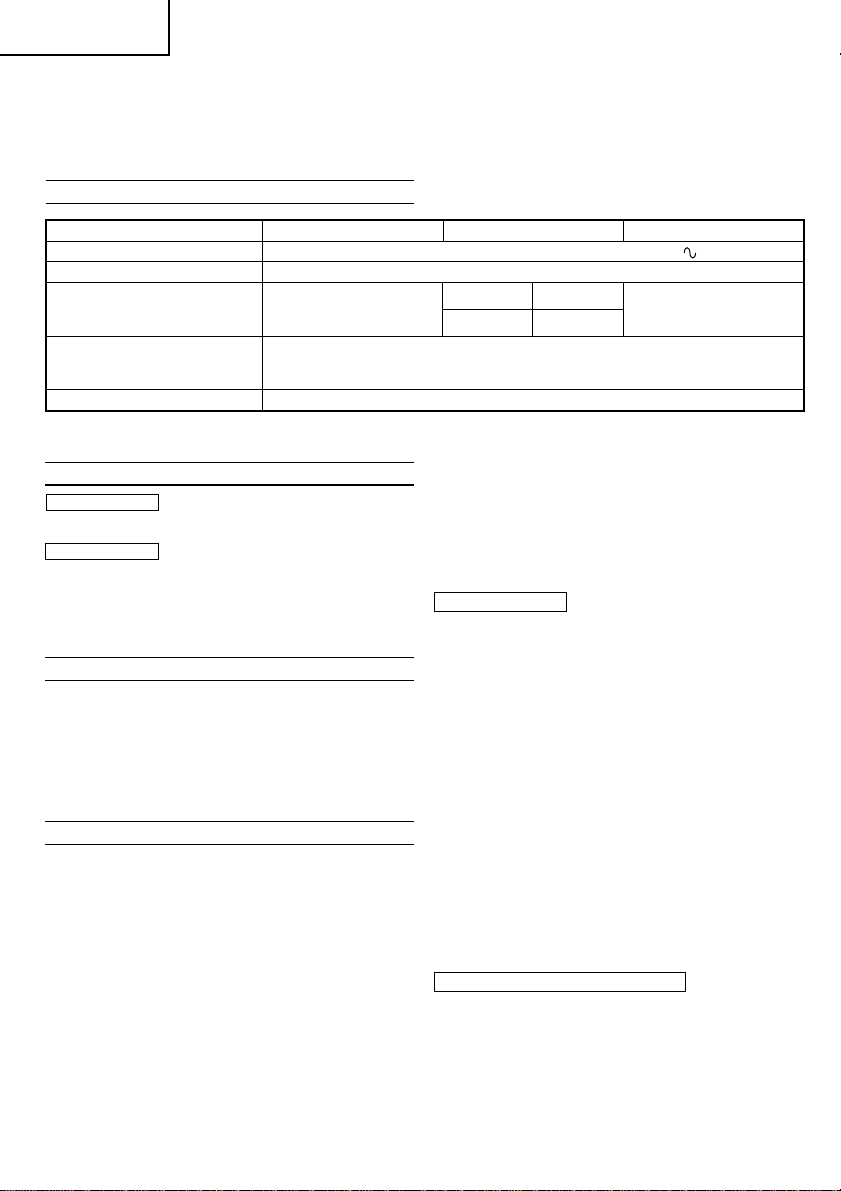

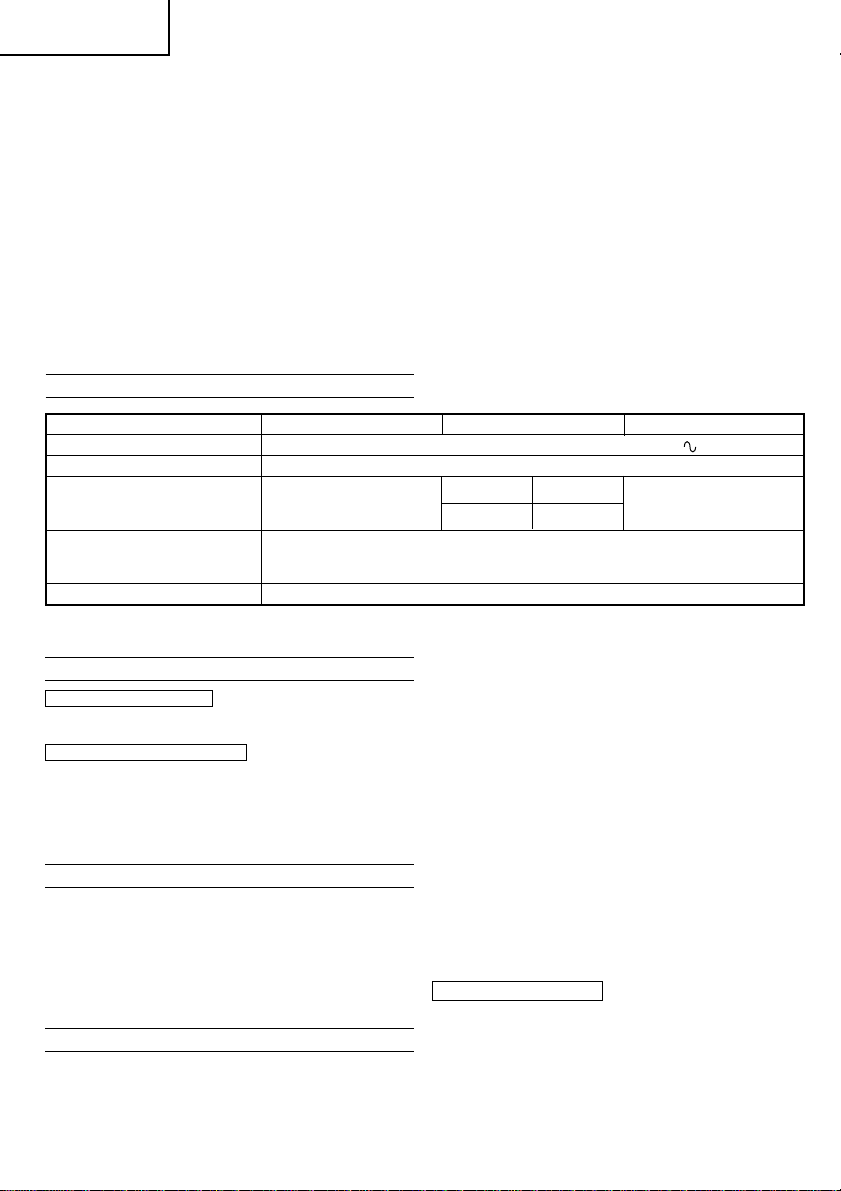

Part Name

No.

Item

Part Name

No.

Item

FDV16VB

31 Cord Armor

32 Cord Clip

33 Tapping Screw (W/Flange) D4 × 16

35 Internal Wire (B)

30 Tube (D)

36 Internal Wire (A)

34A Cord

Drill Chuck 13VLRC-N (W/O Chuck Wrench)

1 Flat Hd. Screw (A) (Left Hand) M6 × 25

2 Chuck Wrench For 13VLB-D, 13VLR-D

3 Drill Chuck 13VLRB-D

3

4 Spindle

5 Spring

6 Ball Bearing (6201VVCMPS2S)

37 Noise Suppressor

38 Earth Terminal

501 Side Handle

502 Depth Gauge

503 Case

Parts are subject to possible modification

without notice due to improvements.

The drawing and the list are parts structural

drawing and parts list of model FDV16VB.

7 Retaining Ring For D12 Shaft

8 Gear

9 Steel Ball D4.76

10 Change Knob

11 Change Plate

12 Spring (A)

13 Holder

14 Ball Bearing (608VVMC2EPS2L)

For other models refer to the drawing and

the list.

15 Armature

16 Stator

17 Ball Bearing (626VVMC2ERPS2S)

18 Housing (A) • (B) Set

19 Nameplate

20 Tapping SCrew (W/Flange) D4 × 20

21 Carbon Brush

22 Brush Holder

23 Choke Coil

24 Internal Wire (D)

25 Switch (M)

26 Internal Wire (C)

27 Choke Coil

28 HITACHI Label

29 Label

The exploded assembly drawing should be used only for authorized service center.

FDV16VB

Page 3

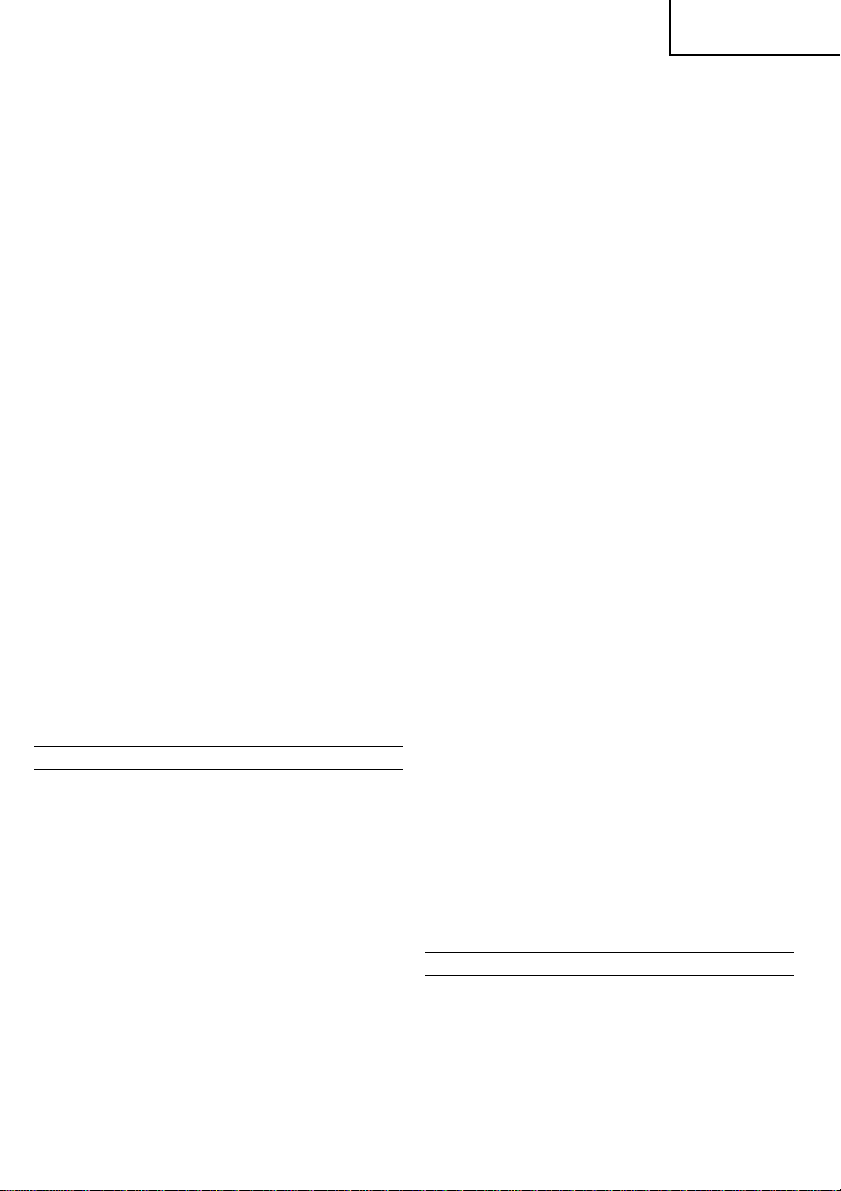

1

3

2

2

1

4

4

2

1

3

6

5

3

4

0

9

4

87

6

A

C

5

(FDV 16VB)

B

D

7

E

(FDV 16T)

1

Page 4

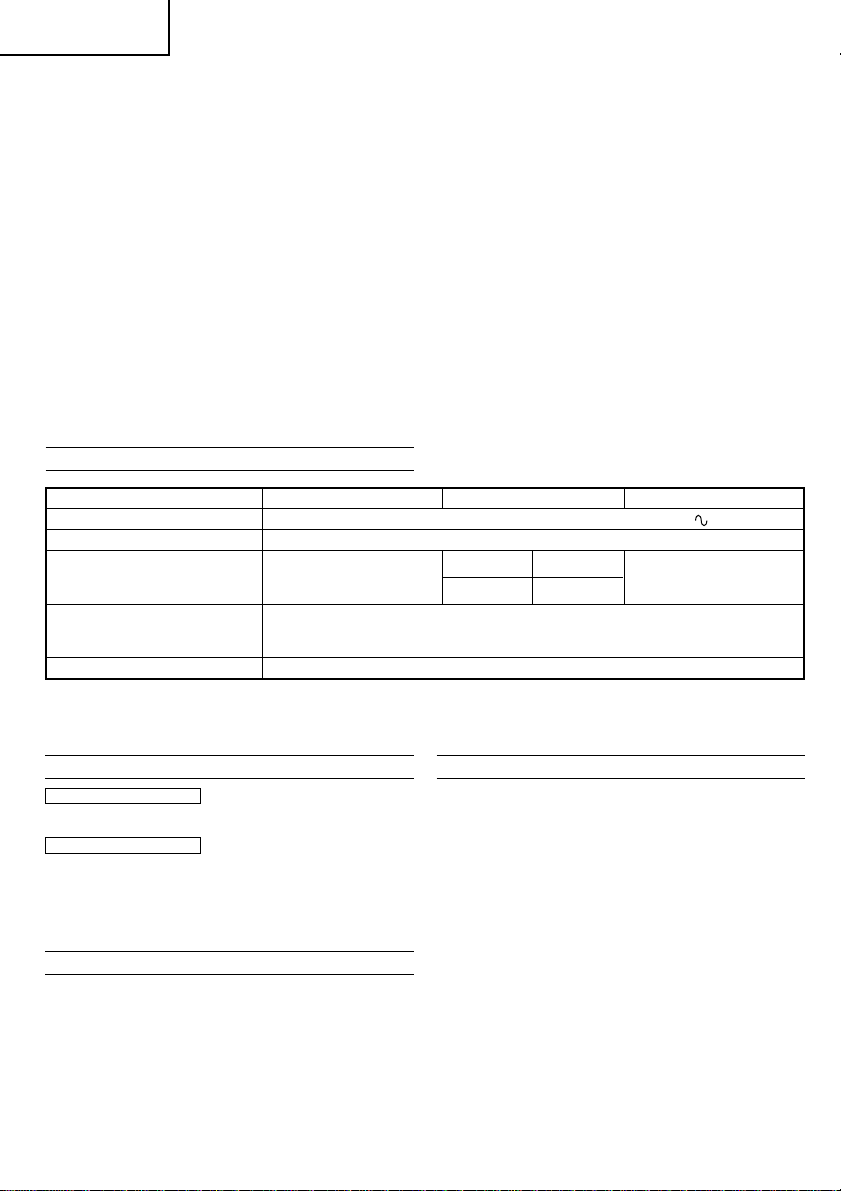

English Deutsch Français

Ring Ring Anneau

1

Sleeve Manschette Manchon

2

Tighten Anziehen Serrer

3

Loosen Lösen Desserrer

4

Side handle Seitengriff Poignée latérale

5

Chuck wrench Bohrfutterschlüssel Clef pour mendrin

6

Clockwise Im Uhrzeigersinn Sens horaire

7

Counterclockwise Gegen den Uhrzeigersinn Sens antihoraire

8

Rotation + Impact Schlagbohrfunktion Rotation + Percussion

9

Rotation Reine Bohrfunktion Rotation

;

Adjust knob Einstellknopf Bouton de réglage

A

High speed Hohe Geschwindigkeit Grande vitesse

B

Low speed Niedrige Geschwindigkeit Petite vitesse

C

Stopper Stopper Butée

D

Shift knob Umschaltknopf Sélecteur

E

Italiano Nederlands Español

Anello Ring Anillo

1

Collare Klembus Manguito

2

Stringere Aandraaien Apretar

3

Allentare Losdraaen Aflojar

4

Impugnatura lateral Zijgreep Mango lateral

5

Chiave per mandrino Boorhoudersleutel Volvedor de mandrill

6

Senso orario Rechtsom A derecha

7

Senso antiorario Linksom A izquierda

8

Rotazione e impatto Slagboorfunctie Rotación

9

Rotazione Normale boorfunctie Perilla de cambio

;

Manopola di regolazione Stelknop Perilla de ajuste

A

Alta velocità Hoge snelheid Alta velocidad

B

Bassa velocità Lage snelheid Baja velocidad

C

Fermo Stopper Retén

D

Manopola d’inter cambio Versnellingsknop No. de escobilla de carbón

E

2

Page 5

English

GENERAL SAFETY RULES

WARNING!

Read all instructions

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust.

Power tools create sparks which may ignite the

dust of fumes.

c) Keep children and bystanders away while operating

a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk

of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk

of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

b) Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in

the off position before plugging in.

Carrying power tools with your finger on the

switch or plugging in power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance

at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

Use of these devices can reduce dust related

hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off.

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing power tools.

Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation.

If damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits etc.,

in accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions

and the work to be performed.

Use of the power tool for operations different from

intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool

is maintained.

PRECAUTION

Keep children and infirm persons away.

When not in use, tools should be stored out of

reach of children and infirm persons.

3

Page 6

English

Additional rules for impact drills

- Wear ear protection

Exposure to noise can cause hearing loss.

- Use auxiliary handles supplied with the tool.

Loss of control can cause personal injury.

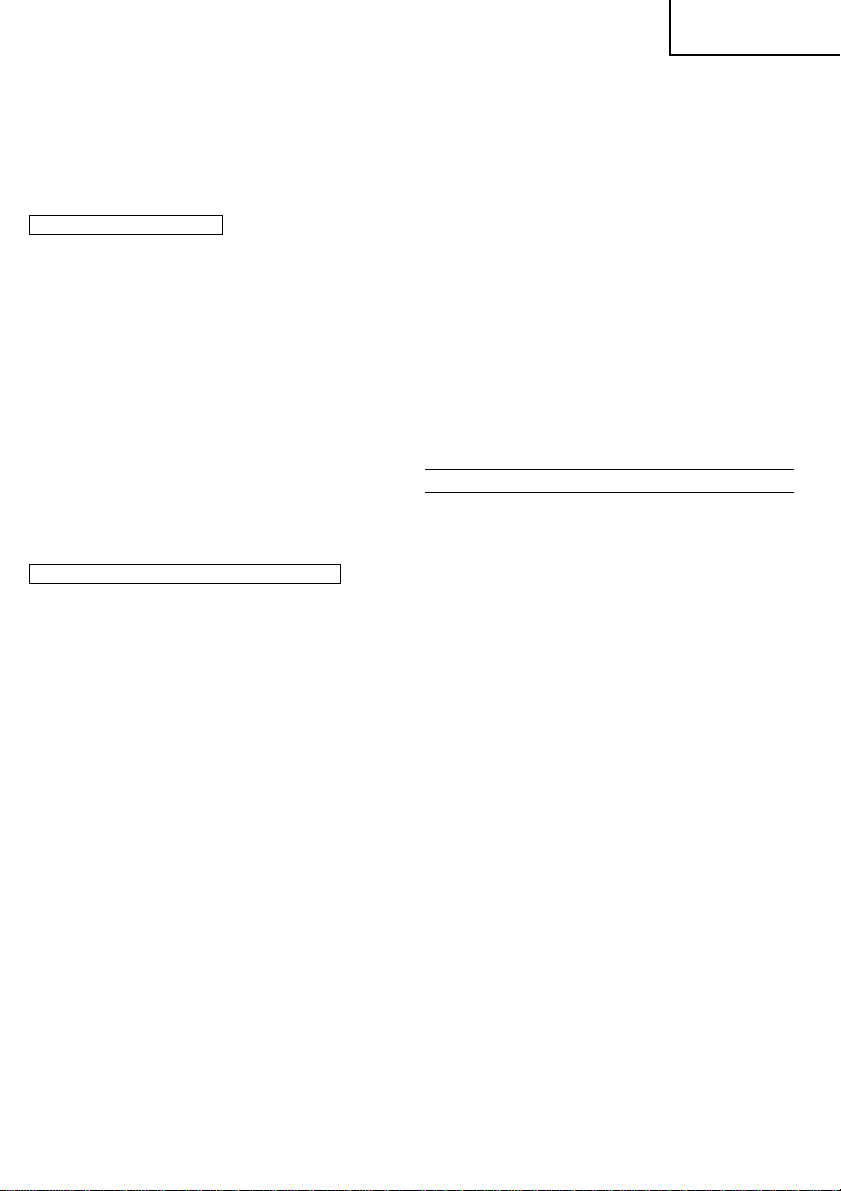

SPECIFICATIONS

Model FDV16VB FDV16T FDV16

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power Input 550W*

No-Load Speed 0 – 2900/min 2900/min

Capacity: Steel 13mm

Weight (w/o cord) 1.6kg

* Be sure to check the nameplate on product as it is subject to change by areas.

Concrete 16mm

Wood 25mm

High Low

2900/min 2300/min

STANDARD ACCESSORIES

For entire area

(1) Side handle ............................................................... 1

(2) Depth stopper ........................................................... 1

For partial areas

(1) Chuck wrench ........................................................... 1

(For drill chuck with chuck wrench)

(2) Plastic case................................................................ 1

Standard accessories are subject to change without

notice.

APPLICATION

䡬 By combined action of ROTATION and IMPACT:

Boring holes in concrete, marble, granite, tile, and

similar materials.

䡬 By ROTATION only:

Boring holes in metals, wood and plastics.

Tightening wood screws.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized con-

forms to the power requirements specified on the

product nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Side handle attachment

Attach the side handle to the mounting part.

Rotate the side handle grip in a clockwise direction

to secure it.

Set the side handle to a position that is suited to

the operation and then securely tighten the side

handle grip.

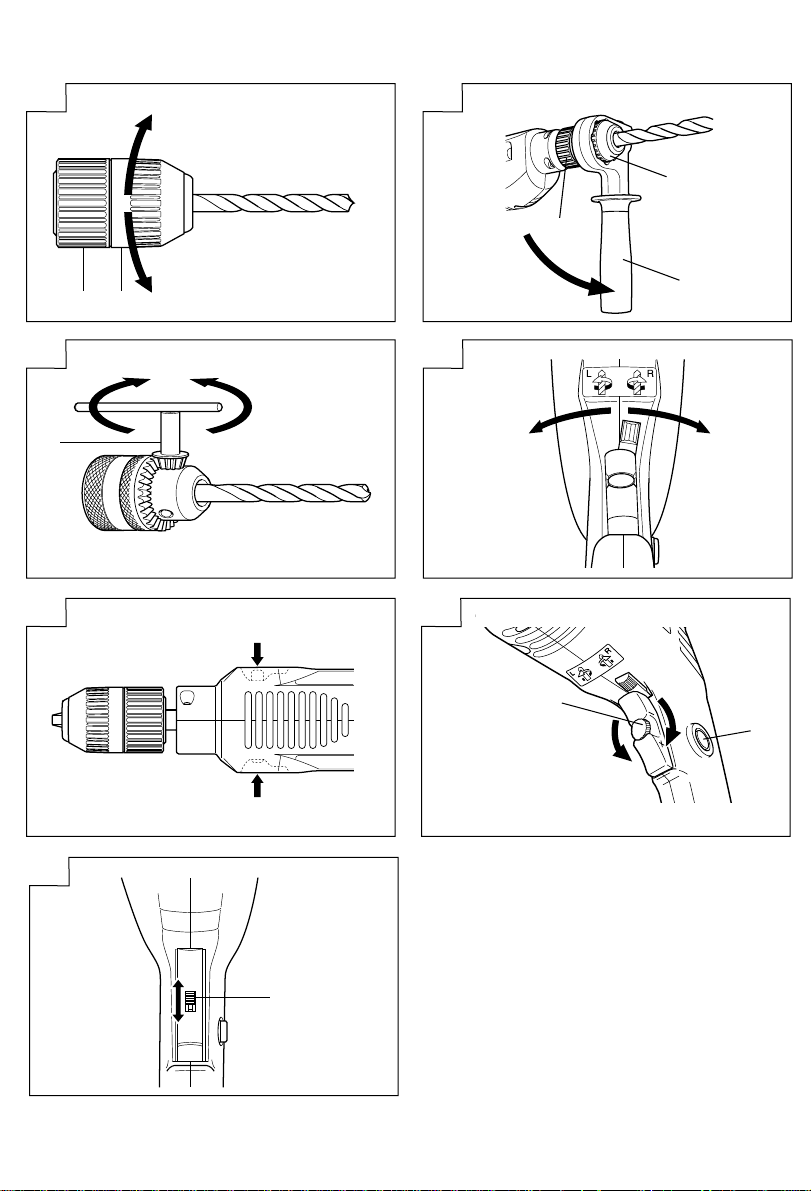

5. Mounting and dismounting of the bit.

For keyless chuck

(1) Mounting the bit

After inserting a driver bit, etc. into the keyless drill

chuck, firmly grasp the ring and tighten the sleeve

by turning it toward the right (in the clockwise

direction as viewed from the front). (See Fig.1)

䡬 If the sleeve becomes loose during operation, tighten

it further. The tightening force becomes stronger

when the sleeve is tightened.

(2) Dismounting the bit

Firmly grasp the ring and loosen the sleeve by

turning it toward the left (in the counterclockwise

direction as viewed from the front). (See Fig.1)

NOTE

When the sleeve does not become loose any further, fix the side handle to the sleeve. Then, strike

the grip of the side handle to the left in order to

loosen the sleeve,while holding the ring by hand.

(Fig.2)

CAUTION

Do not fix the side handle to the ring of the keyless

chuck because of a risk that doing so may damage

the ring.

For Drill chuck with chuck wrench

Fit the drill bit into the chuck and use the chuck

wrench to secure it, tightening the chuck by each

of the three holes in turn. (Fig.3)

6. Selecting the appropriate drill bit

䡬 When boring concrete or stone:

Use the drill bits for concrete.

䡬 When boring metal or plastic:

Use an ordinary metalworking drill bit.

4

Page 7

English

䡬 When boring wood:

Use an ordinary woodworking drill bit. However,

when drilling 6.5mm or smaller holes, use a

metalworking drill bit.

7. Selecting the driver bit

Screw heads or bits will be damaged unless a bit

appropriate for the screw diameter is employed to

drive in the screws.

8. Confirm the direction of bit rotation (Fig.4)

(FDV16VB)

The bit rotates clockwise (viewed from the rear) by

pushing the R-side of the reverse switch.

The L-side of the switch is pushed to turn screws

counterclockwise (i.e. to loosen them.)

CAUTION

䡬 Never change the direction of bit rotation during

operation.

Turn the power switch OFF before changing the

direction of bit rotation; otherwise, the motor will

burn.

䡬 Always use with clockwise rotation, when using it

as an impact drill.

9. IMPACT to ROTATION changeover (Fig.5)

The impact drill can be switched from IMPACT

(impact plus rotation) to ROTATION (rotation only)

by simply sliding the change lever. When boring

concrete, stone, tile or similar board materials, slide

the change lever right. The drill head impacts against

the material while continuing to rotate.

When boring metal, wood or plastic, slide the change

lever fully to the left. The drill simply rotates as

an ordinary electric drill.

CAUTION

Do not use the impact drill in the IMPACT mode

if the material can be bored by rotation only. Such

action will not only reduce drill efficiency, but may

also damage the drill tip.

When changing over, ensure the change lever is

slid as far as it will go.

HOW TO USE

1. Pressure

Drilling will NOT be accelerated by placing heavy

pressure on the drill. Such action will only result

in a damaged drill bit, decreased drilling efficiency

and/or shortened service life of the drill.

2. Using a large diameter drill bit

The larger the drill bit diameter, the larger the

reactive force on your arm. Be careful not to lose

control of the drill because of this reactive force.

To maintain firm control, establish a good foothold,

hold the drill tightly with both hands, and ensure

that the drill is vertical to the material being drilled.

3. When drilling completely through the material

When the drill bit bores completely through the

material, careless handling often results in a broken, drill bit or damage to the drill body itself due

to the sudden movement of the drill. Always be

alert and ready to release pushing force when drilling

through the material.

4. Speed adjustment and switch operation

䡬 FDV16VB

The drill speed can be adjusted from 0 through

maximum speed by regulating the trigger squeezing force.

The more the trigger is squeezed, the faster the drill

rotates. When the trigger is squeezed fully, the

speed becomes maximum speed. Turn the adjusting knob clockwise for higher speed and counterclockwise for lower speed. (Rotate the adjusting

knob approximately 2-2/3 turns.) (Fig.6)

䡬 FDV16T

To change speed, slide the shift knob in the

appropriate direction, as indicated by the arrow in

Fig.7.

The mark “H” printed on the shift knob denotes

High speed. The mark “L” denotes Low speed.

When the shift knob is in High speed position, the

rotation speed of the drill bit can be changed in

two stages (High speed/Low speed) according to

the method of pressing the switch trigger.

䡬 FDV16

The maximum speed can be obtained by pulling

the trigger switch.

䡬 Pull the trigger switch and push the stopper, this

keeps the switched in the on position, which is

convenient for continuous running. The stopper can

be released by pulling the trigger again.

CAUTION

Drill at a maximum rotation speed when drilling

wooden materials.

5. When driving wood screws (FDV16VB)

(1) Selecting a suitable driver bit

Employ plus-head screws, if possible, since the

driver bit easily slips off the heads of minus-head

screws.

(2) Driving in wood screws

䡬 Prior to driving in wood screws, make holes suit-

able for them on the wooden board. Apply the bit

to the screw head grooves and gently drive the

screws into the holes.

䡬 After rotating the screwdriver at low speed for a

while until a wood screw is partly driven into the

wood, squeeze the trigger more strongly to obtain

optimum driving force.

CAUTION

䡬 Exercise care in preparing a hole suitable for the

wood screws taking the hardness of the wood into

consideration.

Should the hole be excessively small or shallow,

requiring much power to drive the screw into it,

the thread of the wood screw may sometimes be

damaged.

䡬 Do not drive machine screws.

MAINTENANCE AND INSPECTION

1. Inspection the drill bit

Continued use of a worn and/or damaged drill bit

will result in reduced drilling efficiency and may

seriously overload the drill motor. Inspect the drill

bit often and replace it with a new bit as necessary.

2. Inspecting the mounting screws:

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Fail-

ure to do so could result in serious hazard.

5

Page 8

English

3. Maintenance of the motor

The motor unit winding is very “heart” of the power

tool. Exercise due care to ensure the winding does

not become damaged and/or wet oil or water.

4. Servicing

Consult an authorized Service Center in the event

of power tool failure.

NOTE

Due to HITACHI’s continuing program of research an

development, the specifications herein are subject to

change without prior notice.

IMPORTANT

Correct connection of the plug

The wires of the main lead are coloured in accordance

with the following code:

Blue: –Neutral

Brown: –Live

As the colours of the wires in the main lead of this tool

may not correspond with the coloured markings identifying the terminals in your plug proceed as follows:

The wire coloured blue must be connected to the terminal marked with the letter N or coloured black. The wire

coloured brown must be connected to the terminal

marked with the letter L or coloured red.

Neither core must be connected to the earth terminal.

NOTE

This requirement is provided according to BRITISH STANDARD 2769: 1984.

Therefore, the letter code and colour code may not be

applicable to other markets except the United Kingdom.

Information concerning airborne noise and vibration

The measured values were determined according to

EN 60745 and declared in accordance with ISO 4871.

Measured A-weighted sound power level: 108 dB(A)

Measured A-weighted sound pressure level: 97 dB(A)

Uncertainty KpA: 3 dB(A)

Wear ear protection.

The typical weighted root mean square acceleration value:

17 m/s2.

6

Page 9

Deutsch

ALLGEMEINE SICHERHEITSMASSNAHMEN

WARNUNG!

Lesen Sie sämtliche Hinweise durch

Wenn nicht sämtliche nachstehenden Anweisungen

befolgt werden, kann es zu Stromschlag, Brand und/

oder ernsthaften Verletzungen kommen.

Der Begriff „Elektrowerkzeug“ bezieht sich in den

folgenden Warnhinweisen auf Elektrowerkzeuge mit

Netz- (schnurgebunden) oder Akkubetrieb (schnurlos).

BEWAHREN SIE DIESE ANWEISUNGEN AUF

1) Arbeitsbereich

a) Sorgen Sie für einen sauberen und gut

ausgeleuchteten Arbeitsbereich.

Zugestellte und dunkle Bereiche ziehen Unfälle

förmlich an.

b) Verwenden Sie Elektrowerkzeuge niemals an

Orten, an denen Explosionsgefahr besteht – zum

Beispiel in der Nähe von leicht entflammbaren

Flüssigkeiten, Gasen oder Stäuben.

Bei der Arbeit mit Elektrowerkzeugen kann es

zu Funkenbildung kommen, wodurch sich Stäube

oder Dämpfe entzünden können.

c) Sorgen Sie bei der Arbeit mit Elektrowerkzeugen

dafür, dass sich keine Zuschauer (insbesondere

Kinder) in der Nähe befinden.

Wenn Sie abgelenkt werden, können Sie die

Kontrolle über das Werkzeug verlieren.

2) Elektrische Sicherheit

a) Elektrowerkzeuge müssen mit passender

Stromversorgung betrieben werden.

Nehmen Sie niemals irgendwelche Änderungen

am Anschlussstecker vor.

Verwenden Sie bei Elektrowerkzeugen mit

Schutzkontakt (geerdet) niemals Adapterstecker.

Stecker im Originalzustand und passende

Steckdosen reduzieren das Stromschlagrisiko.

b) Vermeiden Sie Körperkontakt mit geerdeten

Gegenständen wie Rohrleitungen, Heizungen,

Herden oder Kühlschränken.

Bei Körperkontakt mit geerdeten Gegenständen

besteht ein erhöhtes Stromschlagrisiko.

c) Setzen Sie Elektrowerkzeuge niemals Regen oder

sonstiger Feuchtigkeit aus.

Wenn Flüssigkeiten in ein Elektrowerkzeug

eindringen, erhöht sich das Stromschlagrisiko.

d) Verwenden Sie die Anschlussschnur nicht

missbräuchlich. Tragen Sie das Elektrowerkzeug

niemals an der Anschlussschnur, ziehen Sie es

nicht damit heran und ziehen Sie den Stecker

nicht an der Anschlussschnur aus der Steckdose.

Halten Sie die Anschlussschnur von Hitzequellen,

Öl, scharfen Kanten und beweglichen Teilen fern.

Beschädigte oder verdrehte Anschlussschnüre

erhöhen das Stromschlagrisiko.

e) Wenn Sie ein Elektrowerkzeug im Freien

benutzen, verwenden Sie ein für den

Außeneinsatz geeignetes Verlängerungskabel.

Ein für den Außeneinsatz geeignetes Kabel

vermindert das Stromschlagrisiko.

3) Persönliche Sicherheit

a) Bleiben Sie wachsam, achten Sie auf das, was

Sie tun, und setzen Sie Ihren Verstand ein,

wenn Sie mit Elektrowerkzeugen arbeiten.

Benutzen Sie keine Elektrowerkzeuge, wenn Sie

müde sind oder unter Einfluss von Drogen,

Alkohol oder Medikamenten stehen.

Bei der Arbeit mit Elektrowerkzeugen können

bereits kurze Phasen der Unaufmerksamkeit zu

schweren Verletzungen führen.

b) Benutzen Sie Schutzausrüstung. Tragen Sie

immer einen Augenschutz.

Schutzausrüstung wie Staubmaske, rutschsichere

Sicherheitsschuhe, Schutzhelm und Gehörschutz

senken das Verletzungsrisiko bei angemessenem

Einsatz.

c) Vermeiden Sie unbeabsichtigten Anlauf. Achten

Sie darauf, dass sich der Schalter in der Aus(Off-) Position befindet, ehe Sie den Stecker

einstecken.

Das Herumtragen von Elektrowerkzeugen mit

dem Finger am Schalter und das Einstecken des

Steckers bei betätigtem Schalter zieht Unfälle

regelrecht an.

d) Entfernen Sie sämtliche Einstellwerkzeuge

(Einstellschlüssel), ehe Sie das Elektrowerkzeug

einschalten.

Ein an einem beweglichen Teil des

Elektrowerkzeugs angebrachter Schlüssel kann

zu Verletzungen führen.

e) Sorgen Sie für einen festen Stand. Achten Sie

jederzeit darauf, sicher zu stehen und das

Gleichgewicht zu bewahren.

Dadurch haben Sie das Elektrowerkzeug in

unerwarteten Situationen besser im Griff.

f) Kleiden Sie sich richtig. Tragen Sie keine lose

Kleidung oder Schmuck. Halten Sie Haar,

Kleidung und Handschuhe von beweglichen

Teilen fern.

Lose Kleidung, Schmuck oder langes Haar kann

von beweglichen Teilen erfasst werden.

g) Wenn Anschlüsse für Staubabsaug- und -

sammelvorrichtungen vorhanden sind, sorgen

Sie dafür, dass diese richtig angeschlossen und

eingesetzt werden.

Die Verwendung solcher Vorrichtungen kann

Staub-bezogene Gefahren mindern.

4) Einsatz und Pflege von Elektrowerkzeugen

a) Überanspruchen Sie Elektrowerkzeuge nicht.

Benutzen Sie das richtige Elektrowerkzeug für

Ihren Einsatzzweck.

Das richtige Elektrowerkzeug erledigt seine Arbeit

bei bestimmungsgemäßem Einsatz besser und

sicherer.

b) Benutzen Sie das Elektrowerkzeug nicht, wenn

es sich nicht am Schalter ein- und ausschalten

lässt.

Jedes Elektrowerkzeug, das nicht mit dem

Schalter betätigt werden kann, stellt eine Gefahr

dar und muss repariert werden.

c) Ziehen Sie den Netzstecker, ehe Sie

Einstellarbeiten vornehmen, Zubehörteile

tauschen oder das Elektrowerkzeug verstauen.

Solche präventiven Sicherheitsmaßnahmen

verhindern den unbeabsichtigten Anlauf des

Elektrowerkzeugs und die damit verbundenen

Gefahren.

d) Lagern Sie nicht benutzte Elektrowerkzeuge

außerhalb der Reichweite von Kindern, lassen

7

Page 10

Deutsch

Sie nicht zu, dass Personen das Elektrowerkzeug

bedienen, die nicht mit dem Werkzeug selbst

und/oder diesen Anweisungen vertraut sind.

Elektrowerkzeuge in ungeschulten Händen sind

gefährlich.

e) Halten Sie Elektrowerkzeuge in Stand. Prüfen

Sie auf Fehlausrichtungen, sicheren Halt und

Leichtgängigkeit beweglicher Teile,

Beschädigungen von Teilen und auf jegliche

andere Zustände, die sich auf den Betrieb des

Elektrowerkzeugs auswirken können.

Bei Beschädigungen lassen Sie das

Elektrowerkzeug reparieren, ehe Sie es benutzen.

Viele Unfälle mit Elektrowerkzeugen sind auf

schlechte Wartung zurückzuführen.

f) Halten Sie Schneidwerkzeuge scharf und sauber.

Richtig gewartete Schneidwerkzeuge mit scharfen

Schneidkanten bleiben weniger häufig hängen

und sind einfacher zu beherrschen.

g) Benutzen Sie Elektrowerkzeuge, Zubehör,

Werkzeugspitzen und Ähnliches in

Übereinstimmung mit diesen Anweisungen und

auf die für das jeweilige Elektrowerkzeug

bestimmungsgemäße Weise – beachten Sie

dabei die jeweiligen Arbeitsbedingungen und

die Art und Weise der auszuführenden Arbeiten.

Der bestimmungswidrige Einsatz von

Elektrowerkzeugen kann zu gefährlichen

Situationen führen.

5) Service

a) Lassen Sie Elektrowerkzeuge durch qualifizierte

Fachkräfte und unter Einsatz passender,

zugelassener Originalteile warten.

Dies sorgt dafür, dass die Sicherheit des

Elektrowerkzeugs nicht beeinträchtigt wird.

VORSICHT

Von Kindern und gebrechlichen Personen fernhalten.

Werkzeuge sollten bei Nichtgebrauch außerhalb der

Reichweite von Kindern und gebrechlichen Personen

aufbewahrt werden.

Weitere wichtige Hinweise zu Schlagbohrmaschinen

- Tragen Sie einen Gehörschutz.

Starke und/oder dauerhafte Lärmbelastung kann

zu Gehörverlust führen.

- Benutzen Sie die mit dem Werkzeug gelieferten

Zusatzgriffe.

Wenn Sie die Kontrolle über das Werkzeug

verlieren, kann es zu Verletzungen kommen.

TECHNISCHE DATEN

Modell FDV16VB FDV16T FDV16

Spannung (je nach Gebiet)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Leistungsaufnahme 550W*

Niedrig 0 – 2900/min 2900/min

Kapazität: Stahl 13mm

Gewicht (ohne Kabel) 1,6kg

*Vergessen Sie nicht, die Produktangaben auf dem Typenschild zu überprüfen, da sich diese je nach Verkaufsgebiet

ändern.

Beton 16mm

Holz 25mm

Hoch Niedrig

2900/min 2300/min

STANDARDZUBEHÖR

Für den gesamten Bereich

(1) Handgriff ....................................................................1

(2) Tiefenanschlag .......................................................... 1

Für Teilbereiche

(1) Bohrfutterschlüssel ................................................... 1

(Für Bohrfutter mit Futterschlüssel)

(2) Plastikgehäuse ........................................................... 1

Das Standardzubehör kann ohne vorherige Bekanntmachung

jederzeit geädert werden.

ANWENDUNGSGEBIETE

䡬 Schlagbohrfunktion:

Bohren von Löchern in Beton, Marmor, Granit, Ziegel

und ähnliche Materialien.

䡬 Normale Bohrfunktion:

Bohren von Löchern in Metall, Holz und Kunststoff.

Anziehen von Holzschrauben.

8

VOR INBETRIEBNAHME

1. Netzpannung

Prüfen, daß die zu verwendende Netzspannung der

Angabe auf dem Typenschild entspricht.

2. Netzschalter

Prüfen. Daß der Netzschalter auf “AUS” steht. Wenn

der Ste Stecker an das Netz angeschlossen wird,

während der Schalter auf “EIN” steht, beginnt das

Werkzeug sofort zu laufen, was gefährlich ist.

3. Verlängerungskabel

Wenn der Arbeitsbereich nicht in der Nähe des

Netzanschlusses liegt, ist ein Verlängerungskabel

ausreichenden Querschnitts und ausreichender

Nennleistung zu verwenden. Das Verlängerungskabel

sollte so kurz wie möglich gehalten werden.

4. Handgriffanbringung

Den Handgriff an der Halterung anbringen. Den

Griff des Handriffs zum Befestigen im Uhrzeigersinn

drehen.

Page 11

Deutsch

Den Handgriff in eine Position stellen, die der

Bedienung angemessen ist, und dann den Handgriff

sicher befestigen.

5. Anbringen und Abnehmen der Werkzeugspitze

Für Schnellspann-Bohrfutter

(1) Anbringen der Werkzeugspitze

Nach dem Einsetzen einer Schraubenzieherspitze o.

sergl. oder eines entsprechenden Teils in das

Schnellspann-Bohrfutter den Ring fest greifen und

die Manschette durch Drehung nach rechts (im

Unrzeigersinn von vorne gesehen) festdrehen. (Siehe

Abb.1)

䡬 Sollte sich die Manschette während des Betriebs

lockern, ist diese wieder festzudrehen. Eine fest

zugedrehte gewährleistet erhöhte Spannkraft.

(2) Abnehmen der Werkzeugspitze

Den Ring fest greifen und die Manschette durch

Drehung nach links (gegen den Uhrzeigersinn von

vorne gesehen) lösen. (Siehe Abb.1)

HINWEIS

Wenn sich die Buchse nicht weiter lockert, den

Seitenhandgriff an der Buchse anbringen. Dann den

Griff am Seitenhandgriff nach links schlagen, um

die Buchse zu lösen, während der Ring von Hand

gehalten wird.

VORSICHT

Den Seitenhandgriff nicht am Ring des

schlüssellosen Futters anbringen, da die Gefahr

besteht, daß hierdurch der Ring beschädigt wird.

Für Bohrfutter mit Futterschlüssel

Der Bohrer wird in das Bohrfutter eingesetzt und

der Bohrfutterschlüssel zum Festziehen benutzt.

Zum Festziehen der Backen wird zweckmäßigerweise

der Bohrfutterschlüssel nacheinander in jedes der

drei Löcher gesteckt. (Abb.3)

6. Wahl des geeigneten Bohrers

䡬 Beim Bohren von Beton oder Stein:

Die Bohrer für Beton verwenden.

䡬 Beim Bohren von Metall oder Kunststoff:

Einen normalen Metallbohrer verwenden.

䡬 Beim Bohren von Holz:

Einen normalen Holzspiralbohrer verwenden. Für

Löcher von 6,5mm oder kleiner wird ein Metallbohrer

verwendet.

7. Wahl der Bohrerspitze

Die Schraubenköpfe oder die Bohrerspitze werden

beschädigt falls die angewandte Bohrerspitze nicht

dem Schraubendurchschnitt gemäß ist.

8. Überprüfung der Drehrichtung der Bohrerspitze

(Abb.4) (FDV16VB)

Die Bohrerspitze dreht sich im Uhrzeigersinn (von

der Hinterseite aus gesehen) beim Drücken der RSeite des Umkehrschalters. Um die Schrauben gegen

den Uhrzeigersinn zu drehen (bzw. um sie

loszuschrauben) auf die L-Seite des Umkehrschalters

drücken.

䡬 VORSICHT

Niemals die Drehrichtung einer Bohrerspitze

während des Betriebs wechseln. Den Hauptschalter

auf OFF abschalten bevor die Drehrichtung der

Bohrerspitze gewechselt werden soll; ansonsten

würde der Motor brennen.

䡬 Immer im Uhrzeigersinn treiben, wenn das Werkzeug

als Schlagbohrer gebraucht wird.

9. Wechsel von SCHLAG auf DREHUNG (Abb.5)

Der Schlagbohrer kann von SCHLAG (Schlag plus

Drehung) auf DREHUNG (einfache Drehung) durchSchieben des Wechselhebels umgestellt werden.

Zum Bohren von Beton, Stein, Kachel oder von

anderen harten Material den Wechselhebel nach

rechs schieben. Der Bohrerkopf schlägt gegen das

Material an, während er sich weiter dreht.

Zum Bohren von Metall, Holz oder plastischem

Material den Wechselhebel vollkommen nach links

schieben. Dadurch wird das Werkzeug sich als

gewöhnlicher elektrischer Bohrer drehen.

VORSICHT

Den Schlagbohrer nicht auf SCHLAG-Art einstellen,

wenn das Arbeitsstück mit einfacher Drehung

gebohrt werden kann. Sonst würde nicht nur die

Bohrleistung vermindert weden, sondern die

Bohrerspitze könnte auch beschädigt werden.

Beim Umwechseln sich vergewissern, daß der Hebel

so weit wie möglich geschoben wurde.

VERWENDUNGSMÖGLICHKEITEN

1. Druck

Das Bohren wird nicht durch Ausübung eines starken

Drucks auf den Bohrer beschleunigt.

Zusätzlicher Druck führt nur zu Beschädigung am

Bohrer, verminderter Bohrleistung und/oder

verkürzter Lebensdauer der Bohrmaschine.

2. Verwendung eines Bohrers mit großem

Druchmesser

Je größer der Bohrerdurchmesser desto stärker ist

die auf den Arm rückwirkende Kraft. Man muß

darauf achten, daß man aufgrund dieser

rückwirkenden Kraft nicht die Kontrolle über die

Bohrmaschine verliert.

Für eine gute Kontrolle ist ein sicherer Stand

erfoderlich, man muß die bohrmaschine mit beiden

Händen festhalten und dafür sorgen, daß die

Bohrmaschine senkrecht zum Material steht, in das

gebohrt wird.

3. Beim Durchbohren durch das Material

Wenn der Bohrer ganz durch das Material bohrt,

führt eine unachtsame Handhabung oft zum

Abbrechen des Bohrer oder einer Beschädigung des

Bohrergehäuses selbst aufgrund der plötzlichen

Bewegung der Bohrmaschine. Man muß immer

darauf gefaßt und bereit sein, den Druck beim

Durchbohren des Materials zu verringern.

4. Geschwindigkeitseinstellung und Schalterbetrieb

䡬 FDV16VB

Die Drehzahl kann von 0 bis Maximaldrehzahl durch

Regeln der Triggerdruckkraft eingestellt werden. Je

stärker der Trigger gedrückt wird, desto schneller

dreht sich der Bohrer. Wenn der Trigger voll gedrückt

wird, ist maximale Drehzahl eingestellt. Den

Einstellknopf für höhere Geschwindigkeit nach rechts

und für niedrigere Geschwindigkeit nach links

drehen. (Den Einstellknopf etwa 2-2/3 Umdrehungen

drehen.) (Abb. 6)

䡬 FDV16T

Zum Ändern der Drehzahl den Umschaltknopf in die

gewünschte Richtung schieben, wie sie durch den

Pfeil in Abb.7 gekennzeichnet ist. Die Markierung

“H” auf dem Umschaltknopf bezeichnet die hohe

9

Page 12

Deutsch

Drehzahlstufe und die Markierung “L” die niedrige.

Wenn der Umschaltknopf auf die Stellung für die

hohe Drehzahl gestellt ist, kann die

Drehgeschwindigkeit des Bohrers zweistufig

geändert werden (hohe/niedrige Geschwindigkeit),

wenn die Schaltertaste entsprechend gedrückt wird.

䡬 FDV16

Die maximale Drehzahl kann durch Betätigung des

Abzugschalters erhalten werden.

䡬 Den Trigger ziehen und Halter drücken; dadurch

bleibt das Werkzeug eingeschaltet, was bei

Dauerbetrieb notwendig ist. Beim Abschalten kann

der Halter durch nochmaliges Ziehen des Triggers

gelöst werden.

VORSICHT

Beim Bohren von Holz mit maximaler Drehzahl

bohren.

5. Einschrauben von Holzschrauben (FDV16VB)

(1) Wahl einer passenden Bohrerspitze

So oft wie möglich Kreuzkopfschrauben verwenden,

da die Bohrerspitze leicht von gewöhnlichen

Schraubenköpfen abrutscht.

(2) Einschrauben

Vor dem Einschrauben von Holzschrauben passende

Löcher im Holz vorbereiten die Bohrerspitze an die

Schraubenkopfspalten ansetzen und die Schraube

sanft ins Holz einschrauben.

Nachdem sich der Bohrer bei kleiner Geschwindigkeit

für eine Weile gedreht hat, bis die Schraube zum

Teil eingeschraubt wurde, fester auf den Trigger

drücken, um optimale Antriebskraft zu erreichen.

VORSICHT

䡬 Gut darauf achten, daß die Vorbereitung eines

passenden Loches für die Schraube gemäß der

Härte des Holzes durchgeführt wird. Falls das Loch

zu klein oder nicht tief genug sein sollte, und dadurch

große Kraftanwendung zum Einschrauben

erforderlich wird, kann das Schraubengewinde

manchmal beschädigt werden.

䡬 Keine Machinenschrauben einschrauben.

4. Instandhaltung:

Im Falle eines Versagens eine autorisierte

Wartungswerkstatt zu Rate ziehen.

ANMERKUNG

Aufgrund des ständigen Forschungs-und

Entwicklungsprogramms von HITACHI sind Änderungen

der hierin gemachten technischen Angaben nicht

ausgeschlossen.

Information über Betriebslärm und Vibration

Die gemessenen Werte wurden entsprechend EN60745

bestimmt und in Übereinstimmung mit ISO 4871

ausgewiesen.

Gemessener A-gewichteter Schallpegel: 108 dB(A)

Gemessener A-gewichteter Schalldruck: 97 dB(A)

Messunsicherheit KpA: 3 dB(A)

Bei der Arbeit immer einen Ohrenschutz tragen.

Der typische gewogene quadratische Mittelwert für die

Beschleunigung ist 17 m/s2.

WARTUNG UND INSPEKTION

1. Inspektion des Bohrers:

Fortgesetzte Verwendung eines stumpfen oder

beschädigten Bohrers führt zu verminderter

Bohrleistung und kann den Motor der Bohrmaschine

erheblich überlasten. Den Bohrer regelmäßig prüfen

und erforderlichenfalls durch einen neun Bohrer

ersetzen.

2. Inspektion der Befestigungsschrauben:

Alle Befestigungsschrauben werden regelmäßig

inspiziert und geprüft, ob sie gut angezogen sind.

Wenn sich eine der Schrauben lockert, muß sie

sofort wieder angezogen werden. Geschieht das

nicht, kann das zu erheblichen Gefahren führen.

3. Wartung des Motor:

Die Motorwicklung ist das, “Herz” des

Elektrowerkzeugs. Daher ist besonder sorgfältig

darauf zu achten, daß die Wicklung nicht beschädigt

wird und/oder mit Öl oder Wasser in Berührung

kommt.

10

Page 13

Français

CONSIGNES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT!

Lire toutes les instructions

Tout manquement à observer ces instructions peut

engendrer des chocs électriques, des incendies et/ou des

blessures graves.

Le terme "outil électrique" qui figure dans l'ensemble des

avertissements ci-dessous se réfère aux outils électriques

(câblé) ou aux outils à piles (sans fil).

CONSERVER CES INSTRUCTIONS

1) Aire de travail

a) Maintenir l'aire de travail propre et bien éclairée.

Les endroits encombrés et sombres sont propices

aux accidents.

b) Ne pas utiliser d'outils électriques en présence

de liquides, gaz ou poussière inflammables, au

risque de provoquer une explosion.

Les outils électriques créent des étincelles

susceptibles d'enflammer la poussière.

c) Ne pas laisser les enfants et les visiteurs

s'approcher de vous lorsque vous utiliser un

outil électrique.

Les distractions peuvent faire perdre le contrôle.

2) Sécurité électrique

a) Les prises de l'outil électrique doivent

correspondre à la prise secteur.

Ne jamais modifier la prise.

Ne pas utiliser d'adaptateurs avec les outils

électriques mis à la masse.

Les prises non modifiées et les prises secteurs

correspondantes réduisent les risques de choc

électrique.

b) Eviter tout contact avec les surfaces mises à la

masse telles que les tuyaux, radiateurs, bandes

et réfrigérateurs.

Le risque de choc électrique est accru en cas de

mise à la masse du corps.

c) Ne pas exposer les outils électriques à la pluie

ou à des conditions humides.

Si l'eau pénètre dans l'outil, cela augmente les

risques de choc électrique.

d) Ne pas utiliser le cordon à tort. Ne jamais utiliser

le cordon pour transporter ou débrancher l'outil

électrique.

Maintenir le cordon loin de la chaleur, de l'huile,

des bords pointus ou des pièces mobiles.

Les cordons endommagés ou usés augmentent

les risques de choc électrique.

e) En cas d'utilisation d'un outil électrique à

l'extérieur, utiliser un cordon de rallonge adapté

à un usage extérieur.

L'utilisation d'un cordon adapté à l'usage extérieur

réduit les risques de choc électrique.

3) Sécurité personnelle

a) Restez alerte, regarder ce que vous faites et

usez de votre bon sens en utilisant un outil

électrique.

Ne pas utiliser d'outil électrique si vous êtes

sous l'influence de drogues, d'alcool ou de

médicaments.

Pendant l'utilisation d'outils électrique, un instant

d'inattention peut entraîner des blessures graves.

b) Utiliser des équipements de sécurité. Toujours

porter des verres de protection.

L'utilisation d'équipements de sécurité tels que

les masques anti-poussière, les chaussures de

sécurité anti-dérapantes, les casques ou les

protections auditives dans des conditions

appropriées réduisent les risques de blessures.

c) Eviter les démarrages accidentels. Veiller à ce

que l'interrupteur soit en position d'arrêt avant

de brancher l'outil.

Transporter les outils électriques avec le doigt sur

l'interrupteur ou brancher les outils électriques

avec l'interrupteur en position de marche peut

entraîner des accidents.

d) Retirer toute clé de sécurité ou clé avant de

mettre l'outil électrique en marche.

Laisser une clé ou une clé de sécurité sur une

partie mobile de l'outil électrique peut engendrer

des blessures.

e) Ne pas trop se pencher. Toujours garder une

bonne assise et un bon équilibre pendant le

travail.

Cela permet un meilleur contrôle de l'outil

électrique dans des situations imprévisibles.

f) Porter des vêtements adéquats. Ne pas porter

de vêtements amples ni de bijoux. Maintenir les

cheveux, les vêtements et les gants loin des

pièces mobiles.

Les vêtements amples ou les cheveux longs

peuvent se prendre dans les pièces mobiles.

g) En cas de dispositifs destinés au raccordement

d'installations d'extraction et de recueil de la

poussière, veiller à ce qu'ils soient correctement

raccordés et utilisés.

L'utilisation de ces dispositifs peut réduire les

dangers associés à la poussière.

4) Utilisation et entretien d'un outil électrique

a) Ne pas forcer sur l'outil électrique. Utiliser l'outil

électrique adapté à vos travaux.

Le bon outil électrique fera le travail mieux et en

toute sécurité au régime pour lequel il a été conçu.

b) Ne pas utiliser l'outil électrique si l'interrupteur

ne le met pas en position de marche et d'arrêt.

Tout outil ne pouvant être contrôlé par

l'interrupteur est dangereux et doit être réparé.

c) Débrancher la prise avant de procéder à des

réglages, au remplacement des accessoires ou

au stockage des outils électriques.

Ces mesures préventives de sécurité réduisent les

risques de démarrage accidentel de l'outil électrique.

d) Stockez les outils électriques inutilisés hors de

la portée des enfants et ne pas laisser des

personnes non familiarisées avec l'outil ou ces

instructions utiliser l'outil électrique.

Les outils électriques sont dangereux entre les

mains d'utilisateurs non habilités.

e) Entretenir les outils électriques. Vérifier l'absence

de mauvais alignement ou d'arrêt,

d'endommagement de pièces ou toute autre

condition susceptible d'affecter l'opération de

l'outil.

Si l'outil est endommagé, le faire réparer avant

utilisation.

De nombreux accidents sont dus à des outils mal

entretenus.

11

Page 14

Français

f) Maintenir les outils coupants aiguisés et propres.

Des outils coupants bien entretenus avec des

bords aiguisés sont moins susceptibles de se

coincer et plus simples à contrôler.

g) Utiliser l'outil électrique, les accessoires et les

mèches de l'outil, etc. conformément à ces

instructions et de la manière destinée pour le

type précis d'outil électrique, en tenant compte

des conditions d'utilisation et du travail à réaliser.

L'utilisation de l'outil électrique pour des

opérations différentes de celles pour lesquelles il

a été conçu est dangereuse.

5) Service

a) Faire entretenir l'outil électrique par un technicien

habilité à l'aide de pièces de rechange identiques

exclusivement.

Cela garantira le maintien de la sécurité de l'outil

électrique.

PRECAUTIONS

Maintenir les enfants et les personnes infirmes

éloignés.

Lorsque les outils ne sont pas utilisés, ils doivent

être rangés hors de portée des enfants et des

personnes infirmes.

Règles complémentaires pour les perceuses à

percussion

- Porter des bouchons d’oreilles

L’exposition au bruit peut entraîner une perte de

l’audition.

- Utiliser les poignées auxiliaires fournies avec l’outil.

La perte de contrôle peut entraîner des blessures.

SPECIFICATIONS

Modéle FDV16VB FDV16T FDV16

Tension (par zone)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Puissance 550W*

Vitesse sans charge 0 – 2900/min 2900/min

Capacité: Acier 13mm

Poids (sans fil) 1,6kg

*Assurez-vous de vérifier la plaque signalétique sur le produit, car elle peut changer suivant les régions.

Béton 16mm

Bois 25mm

ACCESSOIRES STANDARD

Pour la surface entière

(1) Poignée latérale........................................................ 1

(2) Témoin de profondeur ............................................ 1

Pour des surfaces partielles

(1) Clef pour mandrin ................................................... 1

(Pour mandrin porte-foret avec clé à mandrin)

(2) Boîtier en plastique ................................................. 1

Les accessoires standard sont sujets à changement sans

préavis.

APPLICATION

䡬 Per action combinée de ROTATION et PERCUS-

SION:

Perçage de trous dans le béton, le marbre, le granit,

la tuile et des matériaux similaires.

䡬 Par action de ROTATION seulement:

Perçage de trous dans le métal, le bois et le plastique.

Serrage des vis de bois.

AVANT LA MISE EN MARCHE

1. Source de puissance

S’assurer que la source de puissance à utiliser

correspond à la puissance indiquée sur la plaque

signalétique du produit.

12

Grand Petit

2900/min 2300/min

2. Interrupteur de puissance

S’assurer que l’interrupteur de puissance est en

position ARRET. Si la fiche est branchée alors que

l’interrupteur est sur MARCHE, l’outil démarre

immédiatement et peut provoquer un grave accident.

3. Fil de rallonge

Lorsque la zone de travail est éloignée de la source

de puissance, utiliser un fil de rallonge d’une

épaisseur suffisante et d’une capacité nominale

suffisante. Le fil de rallonge doit être aussi court

que possible.

4. Fixation de la poignée latérale

Fixer la poignée latérale à la pièce de montage.

Tourner la griffe de la poignée latérale dans le sens

des aiguilles d’une montre pour la serrer.

Régler la poignée sur une position correspondant

au fonctionnement, puis serrer la griffe de la poignée

latérale.

5. Montage et démontage des forets.

Pour mandrin sans clé

(1) Montage de la foret

Aprés avoir mis un foret de tournevis etc dans le

mandrin sans clè, maintenir fermement l’anneau et

serrre le manchon en le tournant vers la droite

(dans le sens des aiguilles d’une montre, vu de

l’avant). (Voir en Fig.1)

䡬 Si le manchon se desserre pendant le fonctionnement,

le resserrer. La force de serrage augmente lorsque

le manchon est resserré.

Page 15

Français

(2) Démontage de la foret

Maintenir fermement l’anneau et desserrer le

manchon en le tournant vers la gauche (dans le

sens contraire des aiguilles d’une montre, vu de

l’avant). (Voir en Fig.1)

REMARQUE

Si le manchon ne se desserre pas davantage, fixer

la poignée latérale sur le manchon. Puis, donner

des coups sur la saisie de la poignée latérale vers

la gauche de façon à desserrer le manchon, tout

en tenant la bague avec la main. (Fig.2)

ATTENTION

Ne pas fixer la poignée latérale sur la bague du

mandrin sans clé car cela pourrait endommager la

bague.

Pour le mandrin porte-foret avec clé à mandrin

Fixer le foret de perçage dans le mandrin et utiliser

la clef à mandrin pour le serrer, en serrant le

mandrin par ses trois trous. (Fig.3)

6. Choix du foret de perçage.

䡬 Pour perçage du béton ou de la pierre:

Utiliser les forets de perçage pour béton.

䡬 Pour perçage du métal ou du plastique.

Utiliser un foret de perçage ordinaire pour métal.

䡬 Pour perçage du bois:

Utiliser un foret de perçage ordinaire pour bois.

Toutefois, pour percer des trous dont le diamètre

est inférieur ou égal à 6,5mm, utiliser un foret de

perçage pour métal.

7. Sélection de la mèche

Les têtes de vis ou les mèches seront endommagées

si la mèche utilisée n’est pas conforme au diamètre

de la vis.

8. Vérifiez la direction de rotation de la mèche (Fig.4)

(FDV16VB)

La mèche tourne dans le sens horaire (vue de

l’arrière) quand on appuie sur le côté R du

commutateur-inverseur. Appuyez sur le côté L du

commutateur pour faire tourner les vis dans le sens

antihoraire (c’est-à-dire pour les dévisser).

ATTENTION

䡬 Ne jamais changer la direction de rotation de la

mèche pendant le fonctionnement. Mettez

l’interrupteur principal sur “OFF” avant de changer

la direction de rotation de la mèche sinon le moteur

prend deu.

䡬 Quand vous utilisez l’outil en tant que perceuse à

percussion, feites-le toujours tourner dans le sens

horaire.

9. Changement de PERCUSSION à ROTATION (Fig.5)

La perceuse à percussion peut être changée de

PERCUSSION (percussion plus rotation) à ROTATION (rotation seulement) en faisant simplement

glisser le levier de changement.

Lors du perçage du béton, de la pierres, de la tuile

ou de matériels, faites glisser le levier de changement

vers la droite: la tête de la perceuse frappe contre

le matériau tout en continuant à tourner.

Lors du perçage de métaux, du bois ou de matières

plastiques, faites glisser le levier de changement à

fond vers la gauche. La perceuse fonctionnera alors

en tant que perceuse ordinaire électrique.

ATTENTION

N’utilisez pas la perceuse à percussion en mode

PERCUSSION si le matériau peut être percé par

rotation seulement. Une telle action pourrait non

seulement réduire l’efficacité de la perceuse mais

endommagerait aussi le bout de la perceuse. Lors

du changement, assurez-vous d’avoir fait glisser le

levier de changement à fond.

UTILISATION

1. Pression

Le perçage n’est pas accéléré si on applique une

pression forte à la perceuse. Ceci ne peut qu’abîmer

le foret de perçage, diminuer l’efficacité de perçage,

et/ou réduire la durée de vie de la perceuse.

2. Utilisation d’un foret de large diamètre

Plus le diamètre du foret est grand, plus la force

de réaction sur votre bras est grande. Attention à

ne pas perdre le contrôle de la perceuse à cause

de cette force de réaction.

Pour avoir la perceuse bien en main, se tenir bien

d’aplomb, tenir la perceuse fermement à deux mains,

et s’assurer que la perceuse est perpendiculaire au

matériau en cours de perçage.

3. Le matériau est entièrement percé

Lorsque le foret perce complétement le matériau,

un maniement négligent conduit souvent à la rupture du foret ou à la détérioration du corps même

de la perceuse par suite du mouvement brusque

de la perceuse. Soyez toujours sur vos gardes et

prêts à relâcher la force de pression lorsque le

matériau est percé en entier.

4. Réglage de la vitesse et manipulation de

l’interrupteur

䡬 FDV16VB

La vitesse de perçage peut être réglée (de 0 à la

vitesse maximale) en réglant la force de serrage du

déclencheur.

Plus le déclencheur est serré, plus la perceuse tourne

vite. Lorsque le déclencheur est complètement serré,

on obtient, la vitesse maximale.

Tourner le bouton de réglage vers la droite pour

augmenter la vitesse, et vers la gauche pour

diminuer la vitesse.(Tourner le bouton de réglage

d’environ 2-2/3 de tour.) (Fig. 6)

䡬 FDV16T

Pour modifier la vitesse, faire glisser le sélecteur

dans la direction appropriée, tout comme le montre

la flèche à la Fig.7.

La lettre “H” sur le sélecteur indique la grande

vitesse, tandis que la lettre “L” indique la petite

vitesse.

Lorsque le sélecteur est placé sur la position grande

vitesse, la vitesse de rotation du foret peut être

modifiée en deux phases (petite vitesse/grande

vitesse), selon la manière dont on appuie sur la

gâchette de l’interrupteur.

䡬 FDV16

La vitesse maximale s’obtient en tirant sur la

gâchette.

䡬 Tirez l’interrupteur-déclencheur et poussez l’arrêtoir;

ceci maintient l’interrupteur en position de marche,

quand un fonctionnement continu est requis. Lors

de la mise en arrêt, l’arrêtoir peut être relâché en

tirant de nouveau le déchencheur.

ATTENTION

Percer en vitesse de rotation maximale pour les

matériaux en bois.

13

Page 16

Français

5. Enfoncement des vis de bois (FDV16VB)

(1) Sélection de la mèche appropriée:

utilisez de préférence des vis à tête cruciforme,

étant donné que la mèche glisse souvent de la tête

de vis ordinaires.

(2) Enfoncement de la vis

䡬 Avant d’enfoncer des vis de bois, préparaz d’abord

des trous appropriés aux vis utilisées dand le bois.

Appliquez la mèche aux fentes de la tête de la vis

et enfoncez la vis dans le bois en douceur.

䡬 Après avoir fait tourner la visseuse à petite vitesse

pendant un moment jusqu’à ce que la vis de bois

soit partiellement enfoncé, pressez le déclencheur

plus fortement afin d’obtenir la force d’entraînement

maximale.

ATTENTION

䡬 Ne manquez pas de prendre en considération la

duretè du bois quand vous préparaz un trou

approprié à recevoir la vis de bois. Si le trou est

trop petit ou pas assez profond, ce qui demande

beaucoup de force pour y enfoncer la vis, il se peut

que le filet de la vis de bois soit parfois endommagé.

䡬 N’enfoncez pas de vis mécaniques.

ENTRETIEN ET CONTROLE

1. Contrôle du foret de perçage:

L’utilisation continue d’un foret usé et/ou abîmé

réduit l’efficacité de perçage et peut sérieusement

surcharger le moteur de la perceuse. Contrôler

souvent le foret et le remplacer si nécessaire.

2. Contrôle des vis de montage:

Vérifier régulièrement les vis de montage et s’assurer

qu’elles sont correctement serrées. Resserrer

immédiatement toute vis desserrée. Sinon, il y a

danger sérieux.

3. Entretien du moteur:

Le bobinage de l’ensemble moteur est le “coeur”

même de l’outil électro-portatif. Veiller

soigneusement à ce que ce bobinage ne soit pas

endommagé et/ou mouillé par de l’huile ou de

l’eau.

4. Entretien:

Consulter un agent agréé en cas de panne.

Au sujet du bruit et des vibrations

Les valeurs mesurées ont été déterminées en fonction

de la norme EN60745 et déclarées conforme à ISO

4871.

Niveau de puissance acoustique pondérée A type:

Niveau de pression acoustique pondérée A type:

Incertitude KpA: 3 dB(A)

Porter un casque de protection.

Valeur d’accélération moyenne quadratique pondérée

type: 17 m/s2.

108 dB(A)

97 dB(A)

NOTE

Par suite du programme permanent de recherche et de

développement HITACHI, ces spécifications peuvent faire

l’objet de modifications sans avis préalable.

14

Page 17

Italiano

NORME DI SICUREZZA GENERALI

AVVERTENZA!

Leggere tutte le istruzioni

La mancata osservanza di tutte le istruzioni di seguito

riportata potrebbe essere causa di scosse elettriche,

incendi e/o gravi lesioni.

Il termine “elettroutensili” riportato in tutte le avvertenze di

seguito elencate si riferisce agli elettroutensili azionati con

alimentazione di rete (via cavi) o a batterie (senza cavi).

CONSERVARE QUESTE ISTRUZIONI

1) Area operativa

a) Mantenere l'area operativa pulita e ordinata.

Aree operative sporche e disordinate possono

favorire gli infortuni.

b) Non utilizzare gli elettroutensili in atmosfere

esplosive, ad es. in presenza di liquidi , gas o

polveri infiammabili.

Gli elettroutensili generano delle scintille che

potrebbero accendere la polvere dei fumi.

c) Tenere lontani bambini e astanti durante l'utilizzo

degli elettroutensili.

Qualsiasi distrazione può essere causa di perdita

di controllo.

2) Sicurezza elettrica

a) Le spine degli elettroutensili devono essere idonee

alle prese disponibili.

Non modificare mai le prese.

Con gli elettroutensili a massa (messi a terra),

non utilizzare alcun adattatore.

L'utilizzo di spine intatte e corrispondenti alle

prese disponibili ridurrà il rischio di scosse

elettriche.

b) Evitare qualsiasi contatto con le superfici a massa

o a terra, quali tubi, radiatori, fornelli e frigoriferi.

In caso di messa a terra o massa del corpo,

sussiste un maggior rischio di scosse elettriche.

c) Non esporre gli elettroutensili alla pioggia o

all'umidità.

La penetrazione di acqua negli elettroutensili

aumenterà il rischio di scosse elettriche.

d) Non tirare il cavo. Non utilizzarlo per il trasporto,

o per tirare o scollegare l'elettroutensile.

Tenere il cavo lontano da fonti di calore, oli, bordi

appuntiti o parti in movimento.

Cavi danneggiati o attorcigliati possono

aumentare il rischio di scosse elettriche.

e) Durante l'uso degli elettroutensili all'esterno,

utilizzare una prolunga idonea per usi esterni.

L'utilizzo di cavi per esterno riduce il rischio di

scosse elettriche.

3) Sicurezza personale

a) Durante l'uso degli elettroutensili, state all'erta,

verificate ciò che state eseguendo e adottate

sempre il buon senso.

Non utilizzate gli elettroutensili qualora siate

stanchi, sotto l'influenza di farmaci, alcol o cure

mediche.

Anche un attimo di disattenzione durante l'uso

degli elettroutensili potrebbe essere causa di

gravi lesioni personali.

b) Indossate l'attrezzatura di sicurezza. Indossate

sempre le protezioni oculari.

L'attrezzatura di sicurezza, quali maschera

facciale, calzature antiscivolo, caschi o protezioni

oculari ridurrà il rischio di lesioni personali.

c) Ponete attenzione alle accensioni involontarie.

Prima dell'attivazione dell'alimentazione,

verificate che l'interruttore sia posizionato su OFF.

Il trasporto degli elettroutensili tenendo le dita

sull'interruttore o con alimentazione elettrica attivata

dall'interruttore su ON, implica il rischio di incidenti.

d) Prima di attivare l'elettroutensile, rimuovete

qualsiasi chiave di regolazione.

Lasciando la chiave in un componente in

rotazione dell'elettroutensile, sussiste il rischio

di lesioni personali.

e) Mantenersi in equilibrio. Mantenersi sempre su

due piedi, in equilibrio stabile.

Ciò consente di controllare al meglio

l'elettroutensile in caso di situazioni impreviste.

f) Vestirsi in modo adeguato. Non indossare abiti

larghi o gioielli. Tenere i capelli, gli abiti e i guanti

lontano dalle parti in movimento.

Abiti allentati, gioielli e capelli lunghi potrebbero

impigliarsi nelle parti in movimento.

g) In caso di dispositivi provvisti di collegamento ad

apparecchiature di rimozione e raccolta polveri,

verificare che queste siano collegate e utilizzate

in modo adeguato.

L'utilizzo di questi dispositivi può ridurre i rischi

connessi alle polveri.

4) Utilizzo e manutenzione degli elettroutensili

a) Non utilizzare elettroutensili non idonei. Utilizzare

l'elettroutensile idoneo alla propria applicazione.

Utilizzando l'elettroutensile corretto, si garantirà

un'esecuzione migliore e più sicura del lavoro,

alla velocità di progetto.

b) Non utilizzare l'elettroutensile qualora non sia

possibile accenderlo/spegnerlo tramite

l'interruttore.

É pericoloso utilizzare elettroutensili che non

possano essere azionati dall'interruttore.

Provvedere alla relativa riparazione.

c) Prima di effettuare qualsiasi regolazione, sostituire

gli accessori o depositare gli elettroutensili,

scollegare la spina dalla presa elettrica.

Queste misure di sicurezza preventive riducono

il rischio di avvio involontario dell'elettroutensile.

d) Depositare gli elettroutensili non utilizzati lontano

dalla portata dei bambini ed evitare che persone

non esperte di elettroutensili o non a conoscenza

di quanto riportato sulle presenti istruzioni

azionino l'elettroutensile.

É pericoloso consentire che utenti non esperti

utilizzino gli elettroutensili.

e) Manutenzione degli elettroutensili. Verificare che

non vi siano componenti in movimento disallineati

o bloccati, componenti rotti o altre condizioni

che potrebbero influenzare negativamente il

funzionamento dell'elettroutensile.

In caso di guasti, provvedere alla riparazione

dell'elettroutensile prima di riutilizzarlo.

Molti incidenti sono causati da una scarsa

manutenzione.

f) Mantenere gli strumenti di taglio affilati e puliti.

Gli strumenti di taglio in condizioni di

manutenzione adeguata, con bordi affilati, sono

15

Page 18

Italiano

meno soggetti al bloccaggio e sono più

facilmente controllabili.

g) Utilizzare l'elettroutensile, gli accessori, le

barrette, ecc. in conformità a quanto riportato

nelle presenti istruzioni e secondo l'uso preposto,

tenendo in debita considerazione le condizioni

operative e il tipo di lavoro da eseguire.

L'utilizzo di elettroutensili per operazioni diverse

da quanto previsto, può essere causa di situazioni

pericolose.

5) Assistenza

a) Affidate le riparazioni dell'elettroutensile a

persone qualificate che utilizzino solamente parti

di ricambio identiche.

Ciò garantirà il mantenimento della sicurezza

PRECAUZIONI

Tenere lontano dalla portata di bambini e invalidi.

Quando non utilizzati, gli strumenti dovranno essere

deposti lontano dalla portata di bambini e invalidi.

Norme aggiuntive per trapano battente

- Indossare protezioni per le orecchie

L’esposizione al rumore può provocare la perdita

dell’udito.

- Utilizzare le leve ausiliarie fornite in dotazione

con l’utensile.

La perdita del controllo può provocare lesioni alle

persone.

dell'elettroutensile.

CARATTERISTICHE

Modello FDV16VB FDV16T FDV16

Voltaggio (per zona)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Potenza assorbita 550W*

Velocitàá senza carico 0 – 2900/min 2900/min

Capacitá del mandrino:

Peso (senza il cavo) 1,6kg

*Accertatevi di aver controllato bene la piastrina perchè essa varia da zona a zona.

Acciaio 13mm

Cemento 16mm

Legno 25mm

Bassa Alta

2900/min 2300/min

ACCESSORI STANDARD

Per aree intere

(1) Impugnatura laterale................................................ 1

(2) Bacchetta d’arresto della penetrazione ................ 1

Per aree parziali

(1) Chiave per mandrino .............................................. 1

(Per mandrino trapano con chiave mandrino)

(2) Custodia in plastica ................................................. 1

L’accessorio standard può essere modificato senza

preavviso.

APPLICAZIONI

䡬 Con l’azione combinata di ROTAZIONE e IMPATTO:

Per praticate fori nel cemento, marmo, granito,

mattonelle e materiali similari.

䡬 Con sola ROTAZIONE:

Per praticare fori in metalli, legno e plastiche.

Viti del legno

PRIMA DI INIZIARE LE OPERAZIONI

1. Alimentazione

Assicurarsi che la rete di alimentazione che si vuole

usare sia compatibile con le caratteristiche relative

all’alimentazione di corrente specificate nella

piastrina dell’apparecchio.

16

2. Interruttore di corrente

Mettere l’interruttore in posizione SPENTO. Se la

spina è infilata in una presa mentre l’interruttore

è acceso, l’utensile elettrico si mette immediatamente

in moto, facilitando il verificarsi di incidenti gravi.

3. Prolunga del cavo

Quando l’ambiente di lavoro è lontano da una presa

di corrente, usare una prolunga del cavo di sufficiente

spessore e di prestazione adeguata. La prolunga

deve essere più corta possibile.

4. Attacco dell’impugnatura laterale

Attaccare l’impugnatura laterale alla sezione di

montaggio.

Ruotare il gancio dell’impugnatura laterale in senso

orario per fissarla.

Regolare l’impugnatura laterale in una posizione

che sia comoda per l’operazione e quindi stringerne

fermamente il gancio.

5. Installazione e rimozione delle punte.

Per mandrino senza chiave

(1) Per montare un attrezzo sulla punta

Dopo aver inserito una punta di trapano, ecc. nel

mandrino autoserrante, afferrare saldamente l’anello

e stringere il collare girandolo verso destra (in senso

orario quando visto da davanti). (Vedere Fig.1)

䡬 Se il collare dovesse allentarsi durante il

funzionamento, stringerlo ulteriormente. La forza

serrante aumenta quando il collare viene stretto.

Page 19

Italiano

(2) Per staccare l’attrezzo dalla punta

Afferrare saldamente l’anello e allentare il collare

girandolo verso sinistra (in senso antioratio quando

visto da davanti). (Vedere Fig.1)

NOTA

Quando il collare non si allenta ulteriormente, fissare

la maniglia laterale al collare. Quindi colpire

l’impugnatura della maniglia laterale verso sinistra

per allentare il collare, trattenendo l’anello con la

mano. (Fig.2)

ATTENZIONE

Non fissare la maniglia laterale all’anello del

mandrino senza chiave perché c’è il rischio che tale

azione danneggi l’anello.

Per mandrino trapano con chiave mandrino

Mettere la punta nel mandrino e usare la chiave

per mandrino per fissare la punta, serrando il

mandrino in ognuno dei tre fori, uno dopo l’altro.

(Fig.3)

6. Scelta della punta appropriata

䡬 Quando si fora cemento o pietra:

Usare le punte per cemento.

䡬 Quando si fora metallo o plastica:

Usare una punta normale da metallo.

䡬 Quando si fora il legno:

Usare una punta normale da legno. Tuttavia, quando

si fanno fori da 6,5mm o inferiori, usare una punta

da metallo.

7. Scelta della punta

Se la punta scelta non è adatta per il diametro della

vite, è facile danneggiare lo stelo o la punta della

vite.

8. Controllare la direzione di rotazione della punta

(Fig.4). (FDV16VB)

Spingendo il lato R dell’interruttore di inversamento,

la punta gira in senso orario (visto dal di dietro).

Per girare le viti in senso antiorario, spingere il lato

L dell’interruttore (allentandolo).

ATTENZIONE

䡬 Non cambiare mai la direzione di rotazione della

punta mentre si sta usando l’utensile. Prima di

cambiare la direzione di rotazione, spegnere l’utensile

(spento), altrimenti si rischia di bruciare il motore.

䡬 Usando il trapano ad impulso, usare sempre e solo

la direzione di rotazione in senso orario.

9. Commutazione tra IMPATTO e ROTAZIONE (Fig.5)

Il trapano ad impulsi può essere commutato tra

IMPATTO (rotazione ad impulsi) e ROTAZIONE (sola

rotazione) semplicemente spostando l’apposita

levetta.

Quando si fanno fori nel cemento, nella pietra, nelle

mattonelle o in materiali similari duri, spostare la

levetta di cambio. La testa del trapano batte contro

il materiale mentre continua a rotare. Forando del

metallo, legno o plastica, spostare la levetta di

commutazione veso sinistra. Il trapano gira come

un trapano elettrico comune.

ATTENZIONE

Non usare il trapano nel modo IMPATTO se il

materiale da forare può essere forato con la funzione

di rotazione comune. Cosi facendo, non solo si

ridurrebbe l’efficacia del trapano, ma si

danneggerebbe pure la punta. Commutando da una

posizione all’altra, assicuratevi di spostare la levetta

a fondo.

MODO DELL’USO

1. Pressione

Sul lavoro di foratura NON bisogna accellerare se

si esercita una forte pressione sul trapano. Una tale

azione avrà conseguenze solo in un danneggiamento

della punta, in una minore efficacia di perforazione

e/o in una diminuzione della vita del trapano.

2. Quando si usa una punta a grande diametro

Più è grande il diametro della punta, più fare

attenzione a non perdere il controllo del trapano

a causa di questa forza di reazione. Per manenere

un solido controllo, prendere un assetto stabile sui

piedi, tenere stretto il trapano con ambedue le mani

e tenere il trapano perpendicolare al materiale da

perforare.

3. Quando si perfora il materiale da parte a parte:

Quando la punta perfora tutto il materiale, un

maneggio non attento ha spesso come risultato una

punta spezzata o danni al corpo stesso del trapani,

dovuti all’improvviso movimento del trapano.

Restare sempre in guardia e pronti a rilasciar la

pressione quando si perfora il materiale da parte

a parte.

4. Regolazione della velocità e messa in moto

䡬 FDV16VB

La velocità di perforamento può essere regolata da

0 alla massima velocità mediante la forza di

compressione del grilletto.

Più Si preme il grilletto, più velocemente gira la

punta.

Premendo completamente il grilletto, si ottiene la

massima velocità.

Girare la manopola di regolazione in senso orario

per ottenere una velocità maggiore o in senso

antiorario per una velocità minore.

(Girare la manopola di regolazione di circa 2-2/3 di

giro.) (Fig. 6)

䡬 FDV16T

Per cambiare la velocità, spingere l’apposita

manopola nella direzione desiderata, come indicato

dalla freccia nella Fig.7. Il sengo “H” impresso sulla

manopola indica l’alta velocità.

Quando la manopola di rotazione della velocità si

trova nella posizione “H”, la velocità di rotazione

della punta può essere cambiata in due fasi (alta

velocità/basa belocità) a seconda del modo in cui

viene premuto l’interruttore di avviamento.

䡬 FDV16

La velocità massima può essere ottenuta tirando

l’interruttore a grilletto.

䡬 Premere l’interruttore a grilletto e inserire il fermo.

Si inserisce socì l’accensione in modo fisso, il che

è conveniente; per l’operazione continua spegnendo

l’apparecchio, il fermo viene rilasciato semplicemente

permendo il grilletto ancora una volta.

ATTENZIONE

Quando si perforano materiali legnosi, innestare la

massima velocità.

5. Avvitand viti del legno (FDV16VB)

(1) Scelta della punta più Adatta

Se possibile, usare delle viti con testa a croce. Con

le viti con testa a meno, è più facile che la punta

scivoli fuori.

17

Page 20

Italiano

(2) Per avvitare viti nel legno

䡬 Prima di avvitare delle viti nel legno, eseguire

innanzitutto un foro guida nel legno. Esporre la

punta sulla testa della vite a avvitare con cura.

䡬 Dopo avr fatto girare il trapano a bassa velocità fino

a quando la vite è parzialmente inserita nel legno,

applicare una maggiore forza, cosi da avvitare con

forza ottimale.

ATTENZIONE

䡬 Prepare il foro guida per la vite del legno con la

massima cura, tenendo in considerazione la durezza

del legno, se il foro fosse troppo piccolo o troppo

profondo, sarabbe necessaria una forza di

avvitamento eccessiva, il che potrebbe danneggiare

il passo della vite del legno.

䡬 Non avvitare viti per macchina.

MANUTENZIONE E CONTROLLO

1. Controllo della punta

L’uso continuato di punta logore e/o danneggiate

comporta una reduxione dell a efficacia di perfora

zione e può seriamente sovraccaricare il motore.

Controllare spesso la punta e sostituirla con una

nuova quando necessario.

2. Controllo delle viti di tenuta:

Controllare regolarmente tutte le viti di tenuta e

assicurarsi che siano esclusìvamente serrate. Nel

caso che una di queste viti dovesse allentarsi

riserrarla immediatamente. Se si non ottiene di

farlo, si può causare un grave incidente.

3. Manutenzione del motore:

L’avvolgimento del motore il vero e proprio “cuore”

degli attezzi elettrici. Fare attenzione a non

danneggiare l’avvolgimento e/o non bagnarlo con

olio o acqua.

4. Manutenzione

In caso di mancato funzionamento di un utensile

elettrico, rivolgersi ad una officina autorizzata.

NOTA

A causa del continuo programma di recerca e sviluppo

della HITACHI, le caratteristiche riportate in questo

foglio sono soggette a cambiamenti senza preventiva

comunicazione.

Informazioni riguardanti i rumori trasmessi dall’aria

e le vibrazioni

I valori misurati sono stati determinati in conformitá a

EN60745 e descritti in conformità alla normativa ISO 4871.

Livello di potenza acustica A misurato: 108 dB(A)

Livello di pressione acustica A misurato: 97 dB(A)

Incertezza KpA: 3 dB(A)

Indossare protezioni per le orecchie.

Il valore efficace pesato tipico dell’accelerazione è di 1 7

m/s2.

18

Page 21

Nederlands

ALGEMENE VEILIGHEIDSVOORSCHRIFTEN

WAARSCHUWING!

Lees alle instructies aandachtig door

Nalating om de hieronderstaande voorschriften op te

volgen kan in elektrische schok, brand en/of ernstig letsel

resulteren.

De term “elektrisch gereedschap” heeft zowel betrekking

op elektrisch gereedschap dat via de netvoeding van

stroom wordt voorzien als gereedschap dat via een accu

(snoerloos) van stroom wordt voorzien.

BEWAAR DEZE INSTRUCTIES

1) Werkplek

a) Zorg voor een schone en goed verlichte