Page 1

Service Guide for the

DP8000/DP8000HB

Page 2

SAFETY PRECAUTION

WARNING: Service should not be attempted by anyone unfamiliar with the necessary precautions on this

projector. The following are the necessary precautions to be observed before servicing this chassis.

1 . An isolation Transformer should be connected in the power line between the projector and the AC Iine

before any service is performed on the projector.

2. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in

place, such as; non-metallic control knobs, insulating covers, shields, isolation resistor-capacitor network

etc.

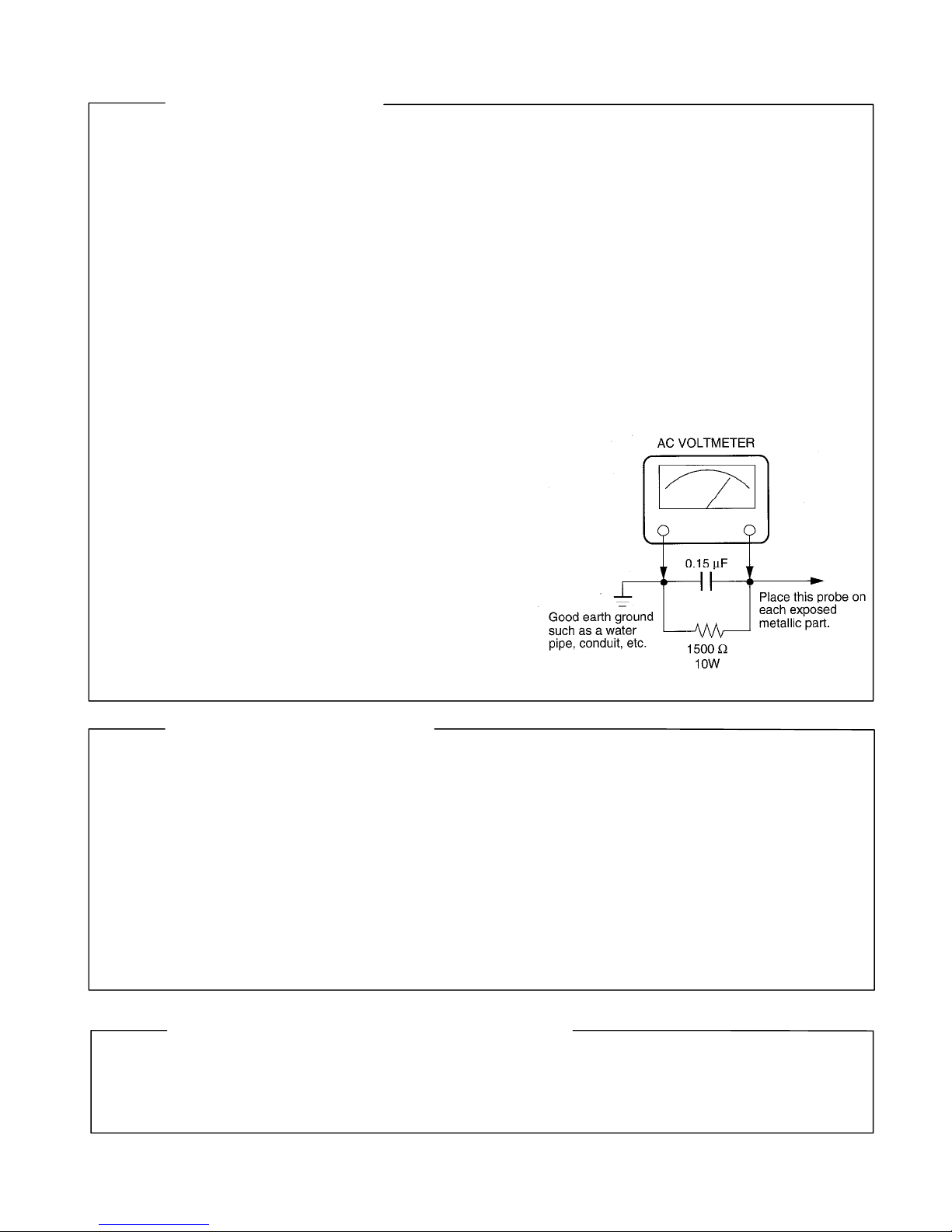

3. Before returning the set to the customer, always perform an AC Ieakage current check on the exposed

metallic parts of the cabinet, such as terminals, screwheads, metal overlays, control shafts etc. to be sure

the set is safe to operate without danger of electrical shock. Plug the AC Iine cord directly into a AC outlet

(do not use a line isolation transformer during this check). Use an AC voltmeter having 5000ohm per volt or

more sensitivity in the following manner: Connect a1500ohm 10W resistor, paralleled by a 0.15 µF, AC type

capacitor, between a known good earth ground (water

pipe, conduit, etc.) and the exposed metallic parts, one

at a time. Measure the AC voltage across the combina-

tion of 1500ohm resistor and 0.15 µF capacitor. Reverse

the AC plug at the AC outlet and repeat AC voltage mea-

surements for each exposed metallic part. Voltage mea-

sured must not exceed 5.25V(rms). This corresponds

to 3.5 mA(AC). Any value exceeding this limit consti-

tutes a potential shock hazard and must be corrected

immediately.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These charac-

teristics are often passed unnoticed by a visual inspection and the protection afforded by them cannot neces-

sarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts

which have these special safety characteristics are identified in this manual and its supplements; electrical

components having such features are identified by the international hazard symbols on the schematic diagram

and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute

replacement parts which do not have the same safety characteristics as specified in the parts list may create

shock, fire or other hazards.

ULTRAVIOLET DANGER IN SERVICE MODE

Eye damage may result from directly viewing the light produced by the lamp used in this product. Always turn

off lamp before opening this cover. Ultraviolet radiation eye protection required during servicing.

LP790 Service Manual 2

TLPB2 Service Manual Rev. 2.0

Page 3

Table of Contents

Safety Precautions........................................................................................................ 5

Important Precautions .................................................................................................. 5

Important Safety Instructions ...................................................................................... 6

Parts Replacement ........................................................................................................ 7

What is the difference between the DP8000 and the DP8000HB? 7

Replaceable Part Hierarchy 8

Remove and Replace the Lamp Door and Lamp Module 9

Remove and Replace the Dust Filter 11

Remove and Replace the Rear Feet 13

Remove and replace the Top Case and Keypad 14

Remove and Replace the Speakers 18

Remove and Replace the IR ECA and IR Window 20

Remove and Replace the Ballast 21

Remove and Replace the Handle 27

Remove and Replace the Engine Blower 28

Remove and Replace the Thermal Switch 30

Remove and Replace the Controller ECA 32

Remove and Replace the NV RAM Chip on the DP8000HB 37

Change the Logo Screen 40

Remove and Replace the Side Vent and Fans 44

Remove and Replace the Lamp Blower 46

Remove and Replace the Elevator Assembly 48

Remove and Replace the Power Supply 51

Remove and Replace the Optical Engine 54

Remove and Replace Lamp Housing 58

Remove and Replace the Interlock Switch and Interlock Switch Cable 62

Remove and Replace the Bottom Case 65

Remove and Replace the Focus and Zoom Rings 66

Functional Tests.......................................................................................................... 68

Required equipment 68

Before beginning 69

Perform the following tests 69

Troubleshooting.......................................................................................................... 72

Troubleshooting Power Problems 73

Troubleshooting Image Problems 77

Troubleshooting Audio Problems 81

Troubleshooting Remote Control Problems 85

Troubleshooting Keypad Problems 86

Troubleshooting Menu Problems 87

Check Controller Voltages 88

Check Speaker Resistance 89

Wiring Diagram 90

DP8000/8000HB Service Manual 3

Page 4

Parts Lists.................................................................................................................... 91

Exploded View 91

Legend 92

FRUs by alphabetic listing 94

Hardware Kit Contents 97

Standard Accessories 98

DP8000/8000HB Service Manual 4

Page 5

SAFETY PRECAUTIONS

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS

CAUTION: Laser beam is emitted when the laser button of the remote control is pressed. Do not

APPLIANCE T O RAIN OR M OIST URE. DANGEROUS HIGH VOLTAGES AR E

PRESENT INSIDETHE ENCLOSURE. DO NOT OPEN THE CABINET. REFER

SERVICING TO QUALIRED PERSONNEL ONLY.

look from the front of the remote contr ol. Do not face towar d a person or to a mirror.

The lightning flash with arrowhead

symbol, within an equilater al triangle,

is intended to alert the user to the

presenc e of uninsulated "dangerous

voltage" within the product's

enclosure that may be of sufficient

magnitude to c onstitute a risk of

electric shock to persons.

The exclamation point within an

equilateral triangle is intended to

alert the user to the presenc e of

important operating and

maintenance (s ervicing) instructions

in the literature accompanying the

appliance.

FCC Radio Frequency Interf erence Statement

Note: This equipment has been tested and found to c omply with the limits for a Class A

WARNING: Changes or modifications made to this equipment, not expressly approved by

Notice: This Class A digital apparatus complies with Canadian ICES-003.

IMPORTANT PRECAUTIONS

Save Original Packi ng Mater ials

The original shipping carton and packing materials will come in

handy if you ever have t o ship your LCD projector. For maximum

protection, repack the set as it was originally packed at the factory.

digital device, purs uant to part 15 of the FCC Rules. These limits are designed to

provide reasonable pr otection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiates radio frequency energy and, if not inst alled and used in accordance with the

instruction manual, may cause harmful interference t o radio communic ations.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interf erence at his

own expens e.

Toshiba, or parties authorized by Toshiba, could void the us er's authority to operate

the equipment.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du

Canada.

In the spaces provided below, record the Model and Serial No. Iocated

at the rear of your LCD projector.

Mode No. Serial No.

Retain this information for future reference.

Avoid Volatile Liquid

Do not us e volatile liquids, s uch as an insect spr ay, near the unit.

Do not leave rubber or plastic products t ouching the unit for a long

time. They will mar the finish.

Moisture Condensation

Never operate this unit immediately after moving it fr om a cold

location to a warm location. When the unit is exp osed to such a

change in temperature, moisture may condens e on the crucial

internal parts. To prevent the unit from possible damage, do not use

the unit for at least 2 hours when there is an extreme or sudden

change in temperature.

LP280/LP290 Service Manual 4

Page 6

IMPORTANT SAFETY INSTRUCTIONS

CAUTION: PLEASE READ AND OBSERVE

ALLWARNINGS AND

INSTRUCTIONS GIVEN IN THIS

OWNER'S MANUAL AND THOSE

MARKED ON THE UNIT. RETAIN

THIS BOOKLET FOR FUTURE

REFERENCE.

This set has been designed and manufactur ed

to assure personal safety. Improper use can

result in electric shock or fire hazard. The

safeguards inc orporated in this unit will protect

you if you observe the f ollowing procedures for

installation, us e and servicing. This unit is fully

transistorized and does not contain any parts

that can be repaired by the user.

DO NOT REMOVE THE CABINET COVER, OR

YOU MAY BE EXPOSED TO DANGEROUS

VOLTAGE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL ONLY.

1. Read Owner's Manual

After unpacking this product, read the

owner's manual carefully, and follow all

the operating and other instructions.

2. Power Sources

This product should be operated only from

the type of power source indicated on the

marking label. If you are not sure of the

type of power supply to your home,

consult your product dealer or local power

company.

For products intended to operate from

battery power, or other sources, refer to

the operating instructions.

3. Source of Light

Do not look into the lens while the lamp

is on. The strong light from the lamp may

cause damage to your eyes or sight.

4. Ventilation

Openings in the cabinet are provided for

ventilation and to ensure reliable

operation of the product and to pr otect it

from overheating, and these openings

must not be blocked or covered. The

openings should never be blocked by

placing the product on a bed, sofa, rug or

other similar surface. This product should

not be placed in a built-in installation such

as a bookcase or rack unless proper

ventilation is provided or the

manufacturer's instructions have been

adhered to.

IMPORTANT SAFETY INSTRUCTIONS

5. Heat

The product should be situated away from

heat sources such as radiators heat

registers, stoves, or other pr oducts

(including amplifiers) that produc e heat.

6. Water and Moisture

Do not use this product near water - for

example, near a bath tub, wash bowl,

kitchen sink, or laundry tub; in a wet

basement ; or near a swimming pool and

the like .

7. Cleaning

Unplug this pr oduct from the wall outlet

before cleaning. Do not use liquid cleaners

or aerosol cleaners. Use a damp cloth for

cleaning.

8. Power-Cord Protection

Power-supply c ords should be routed so

that they ar e not likely to be walked on or

pinched by items placed upon or against

them, paying particular attention to cords

at plugs, convenience receptacles, and

the point where they exit from the product.

9. Overloading

Do not overload wall outlets; extension

cords, or integral convenience

receptacles as this can result in a risk of

fire or electric shock.

10. Lightning

For added pr otection for this pr oduct

during storm, or when it is left unattended

and unused for long periods of time,

unplug it from the wall outlet.

This will prevent damage t o the product

due to lightning and power-line surges.

Page 7

Parts Replacement

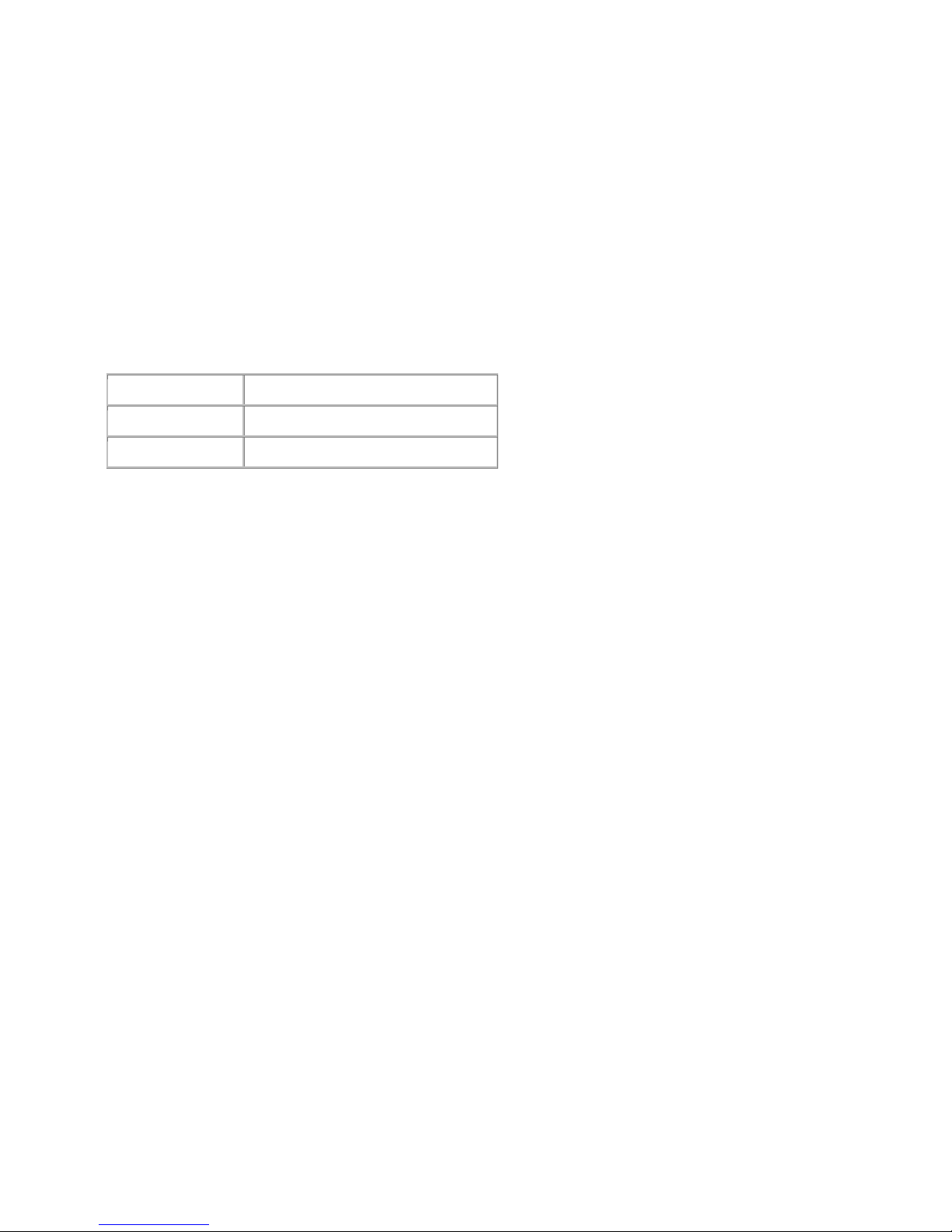

What is the difference between the DP8000 and the DP8000HB?

PROXIMA has released a new version of the DP8000 called the DP8000HB. The revised model has

higher lumen output and an improved cooling system. The DP8000HB also allows you to replace the

optical engine or the controller ECA separately rather than as a kit.

From the outside, the DP8000 and DP8000HB are identical. You must refer to the serial number label on

the bottom case to determine which model you are working on (see the table below). It is important that

you do this because many internal parts differ between the models. However, troubleshooting and parts

replacement procedures are the same for both.

Model Serial Number Prefix

DP8000 ABCxxxxxx

DP8000HB AFWxxxxxx

DP8000/8000HB Service Manual 7

Page 8

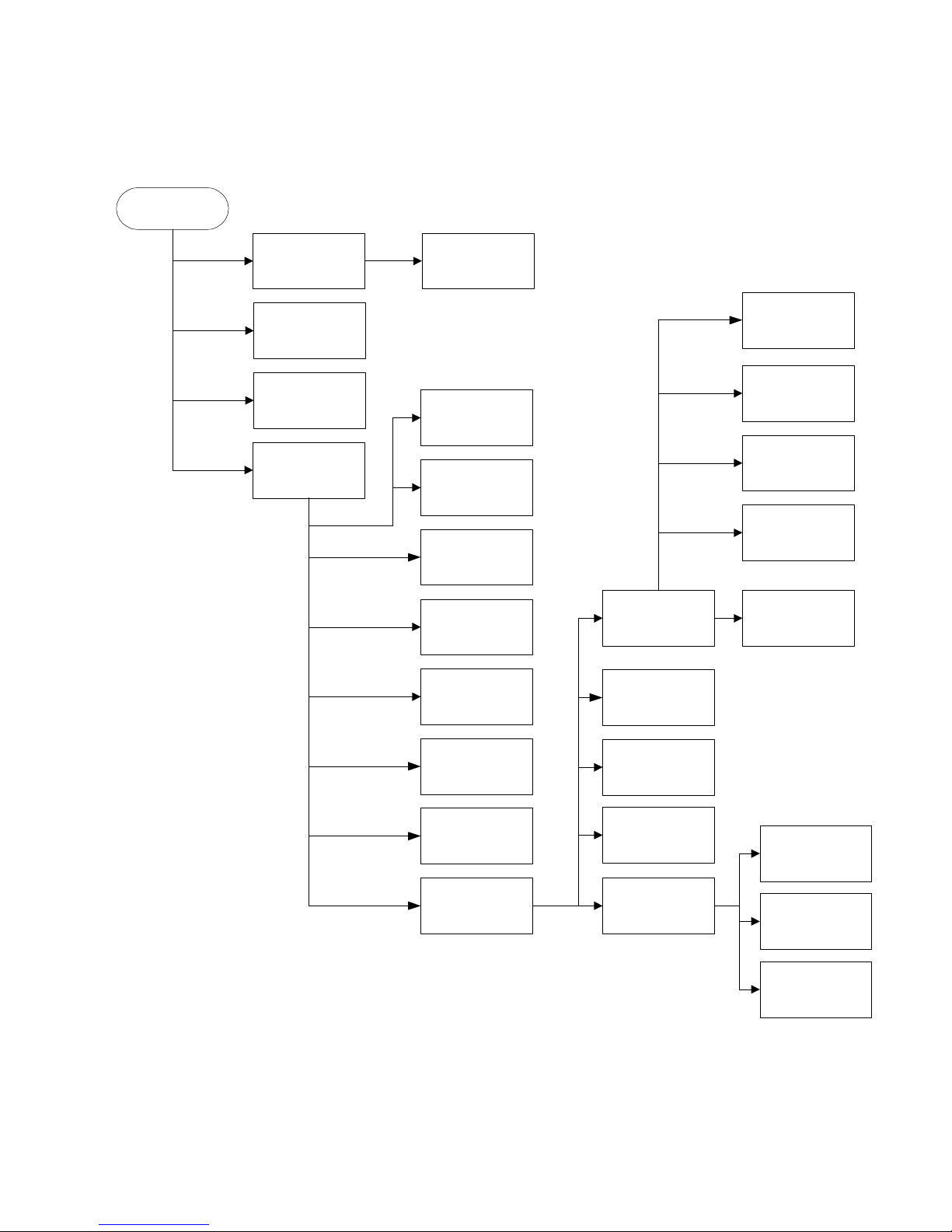

Replaceable Part Hierarchy

The flow chart below shows what parts must be removed to access each replaceable part in the projector.

The parts on the first level (the lamp door, for example) are accessible without removing any other parts.

The more levels down a part is, the more parts you need to remove.

Start

Lamp door

Dust Filter

Right & Left

Rear Feet

Top Case

Lamp Module

Speakers

Keypad

IR Window and

IR ECA

Ballast

Handle &

Handle Bracket

Optical Engine

Power Supply

Elevator Actuator

Zoom Ring and

Focus Ring

Bottom Case

Interlock Switch

and Cable

Lamp Housing

Engine Blower

Thermal Switch

Controller ECA

Elevator Foot

Lamp Blower

Side Vent

92mm Lamp Fan

60mm Power

Supply Fan

80mm Engine Fan

DP8000/8000HB Service Manual 8

Page 9

Remove and Replace the Lamp Door and Lamp Module

The lamp door (4009073) is located on the bottom of the projector. It covers the lamp module (DP8000:

SP-LAMP-001, DP8000HB: SP-LAMP-008). When the lamp door is shut properly, it closes an interlock

switch, which allows the lamp to strike when the projector is powered up.

1 Place the projector upside down on the work surface.

2 Loosen the captive screw that fastens the lamp door to the bottom case, then lift the door off of

the projector.

DP8000/8000HB Service Manual 9

Page 10

3 Loosen the three captive screws that fasten the lamp module to the lamp housing. Then grasp

the module using the recessed handle and lift the lamp module out of the projector.

Assembly Note

♦ If you install a new lamp, you need to reset the lamp counter.

1. Turn the projector on, then press Menu on the remote control or the keypad.

2. In the Basic menu, select Setup.

3. In the Setup menu, select Service.

4. In the Service menu, select Reset Lamp timer.

DP8000/8000HB Service Manual 10

Page 11

Remove and Replace the Dust Filter

The dust filter (300728) traps dust particles before they pass through the engine blower and then into the

optical engine. You can replace or clean the dust filter without disassembling the projector.

1 Place the projector upside down on the work surface.

2 Loosen the captive screw that fastens the dust filter to the bottom case. Do not remove the screw.

3 Use a small bladed screwdriver to pry the edge of the dust filter away from the bottom case. Then

pull the filter out of the bottom case.

DP8000/8000HB Service Manual 11

Page 12

4 To clean the dust filter use a vacuum on the ribbed side of the filter (shown below), or blow

compressed air through the other side.

Assembly Note

♦ Insert the end opposite the captive screw into the slot in the bottom case first, then slide the filter

into position. Do not over tighten the screw.

DP8000/8000HB Service Manual 12

Page 13

Remove and Replace the Rear Feet

Two rubber rear feet (4009084xx) fasten to back corner of bottom of the projector. Both feet are

adjustable, allowing the user to adjust the image so that it is level. The rear feet are also included with a

new bottom case.

1 Turn the projector upside down on the work surface.

2 To remove a damaged rear foot, turn it counter-clockwise. To install a rear foot, turn it clockwise.

Do not over tighten the foot.

DP8000/8000HB Service Manual 13

Page 14

Remove and replace the Top Case and Keypad

The top case (4009070) encloses the top half of the projector. When you replace the top case, you must

adhere a new logo label, front label and rear label to the top case. All labels are available in the label

kit (401941).

Once you have removed the top case, you have access to the keypad (4008088). See step 6 below.

1 Turn the projector upside down on the work surface.

2 Remove the two M3x104 Phillips Plastite screws on the bottom case.

3 Turn the projector right side up on the work surface.

DP8000/8000HB Service Manual 14

Page 15

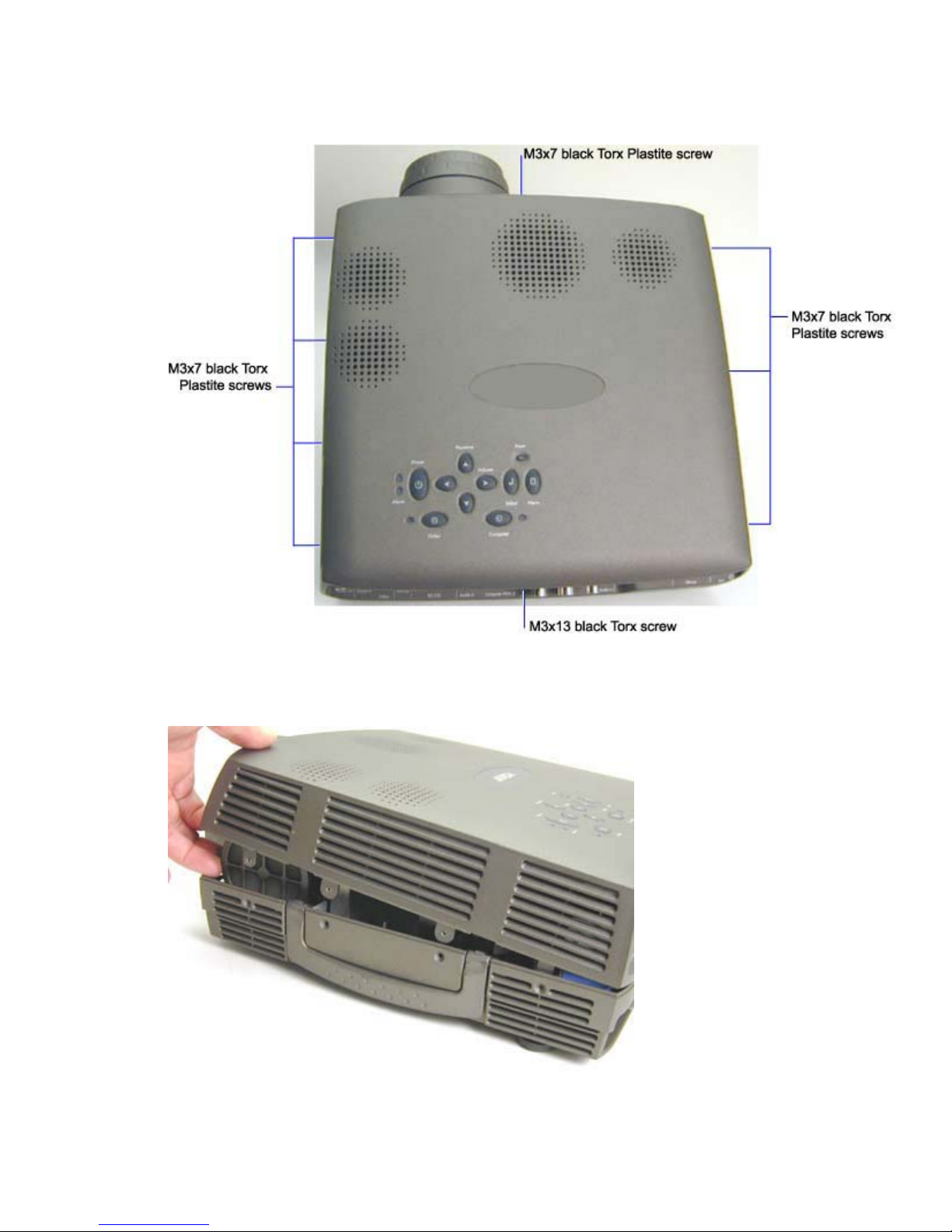

4 Remove the eight M3x7 black Torx Plastite screws and the M3x13 black Torx screw that fasten

the top case to the projector.

5 To separate the top case from the bottom case, do the following:

Lift the top case near the projection lens.

DP8000/8000HB Service Manual 15

Page 16

While holding the top case up, flex the rear of the top case below the I/O panel. Flex it just

enough to clear the I/O ports.

Once the two case halves are separate, unplug the I/R-speaker cable from its connector on the

controller ECA.

DP8000/8000HB Service Manual 16

Page 17

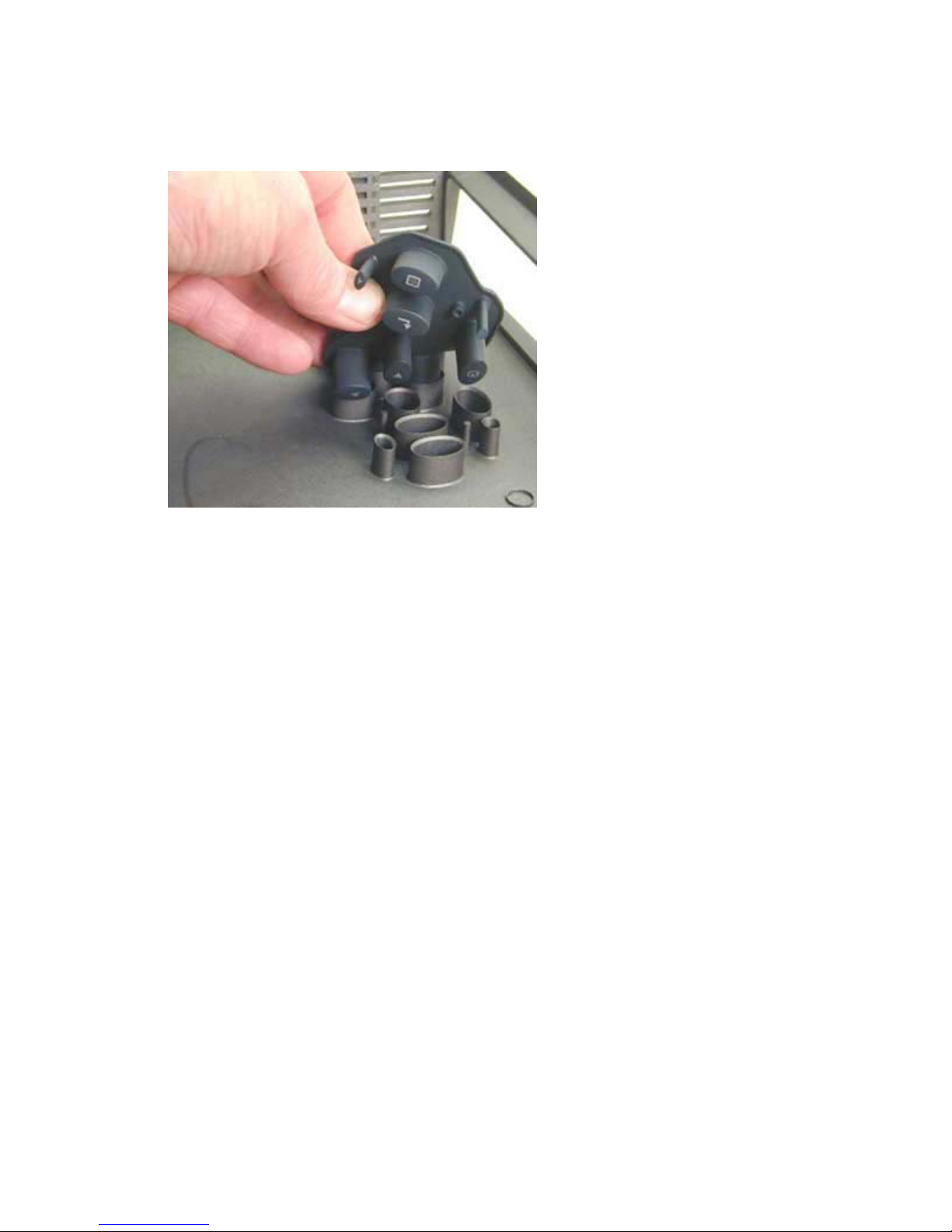

6 Once the top case is removed, you can remove the rubberized keypad. To do this, press the keys

from the outside of the top case. To install a new keypad, press the keys and guides into the

holes in the top case.

If you are replacing the top case with a new one, remove the following items:

Speakers (see page 18)

IR ECA and window (see page 20

Assembly Notes

♦ Install the speakers, the IR ECA, the IR window, and the IR-speaker cable in the new top case.

♦ To install the top case, you need to flex the portion of the top case so the I/O panel fits into its

opening in the top case.

♦ Tighten all screws to 6 in-lbs (.7 Nm).

♦ Adhere a new logo label to the recessed area adjacent to the keypad.

♦ Adhere a new rear label to space beneath the M-1 connector on the rear of the projector. Refer

to the old top case for positioning.

♦ Adhere a new front label to the left side the front IR window. Make sure to position the label so

that it does not cover the transparent portion of the window. Refer to the old top case for

positioning.

DP8000/8000HB Service Manual 17

Page 18

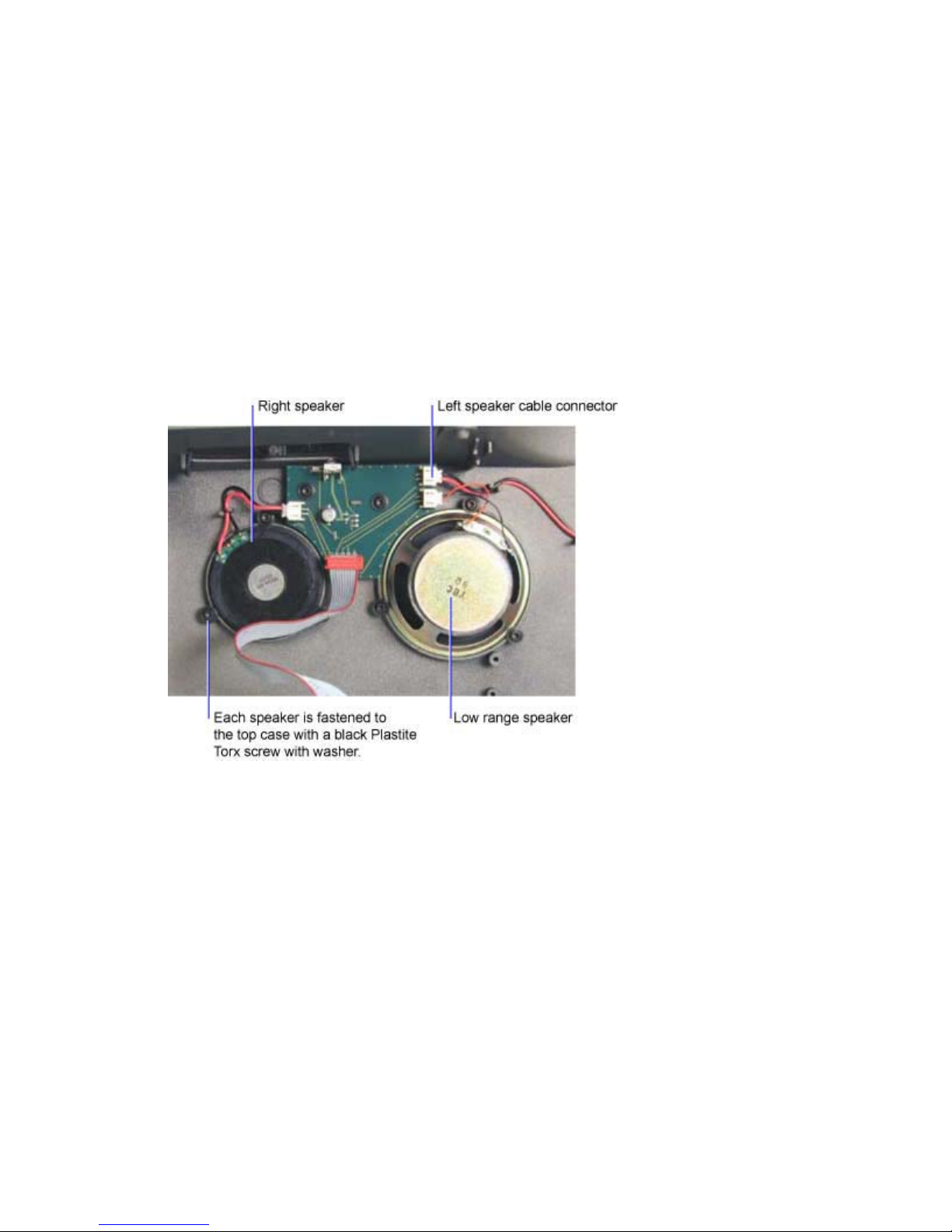

Remove and Replace the Speakers

There are three speakers mounted to the top case:

♦ low range speaker (505538)

♦ right speaker with a 55mm cable (506499)

♦ left speaker with a 210mm cable (506536)

The right and left speakers are identical with the exception of the cable length.

The procedure to remove and replace all three speakers is identical.

1 Remove the top case (see page 14)

2 Unplug the speaker cable from its connector on the IR ECA.

3 Remove the three M3x6 black Plastite Torx screws with captive washers that fasten the speaker

to the top case. Then remove the speaker.

DP8000/8000HB Service Manual 18

Page 19

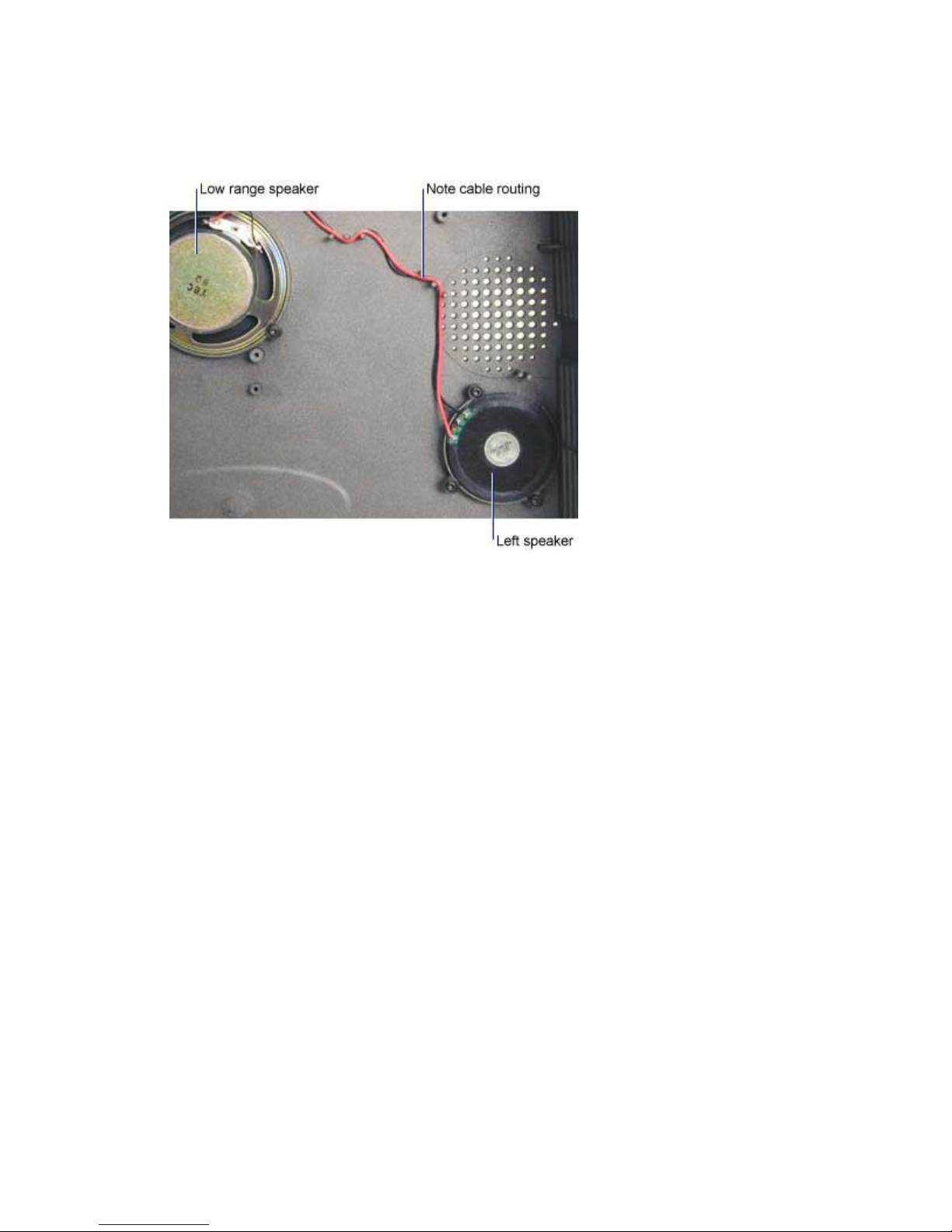

Assembly Notes

♦ If you are replacing the left speaker, make sure to route the speaker cable through the cable

guides in the top case.

♦ Torque all screws to 6 in-lbs (.68 Nm).

DP8000/8000HB Service Manual 19

Page 20

Remove and Replace the IR ECA and IR Window

The IR ECA (DP8000: 308230x, DP8000HB: 308246x) and the IR window (4009077) fasten to the inside

of the top case. The IR ECA includes the IR receiver and the circuitry that carries the audio signals to the

three speakers.

1 Remove the top case (see page 14)

2 To remove the IR window, pry the hooks on either end of the IR window so that they clear the

tabs in the top case. Then remove the IR window from the outside of the case.

3 To remove the IR ECA, do the following:

Unplug the controller/IR cable and the three speaker cables from the IR ECA.

Remove the two black Plastite Torx screws and lift the ECA out of the bottom case.

Assembly Note

♦ Torque the two screws to 5 in-lbs (.55 Nm).

DP8000/8000HB Service Manual 20

Page 21

Remove and Replace the Ballast

The ballast (DP8000: 300162x, DP8000HB: 525-0061-xx) provides the high voltage necessary to strike

and run the projection lamp. It receives power from the power supply. The ballast is located in the front of

the projector, adjacent to the projection lens and the lamp housing. The ballast air guide (available in the

hardware kit [410389]) fastens to the ECA portion of the ballast. It directs the flow of air over the ballast

to provide maximum cooling.

1 Remove the top case (see page 14)

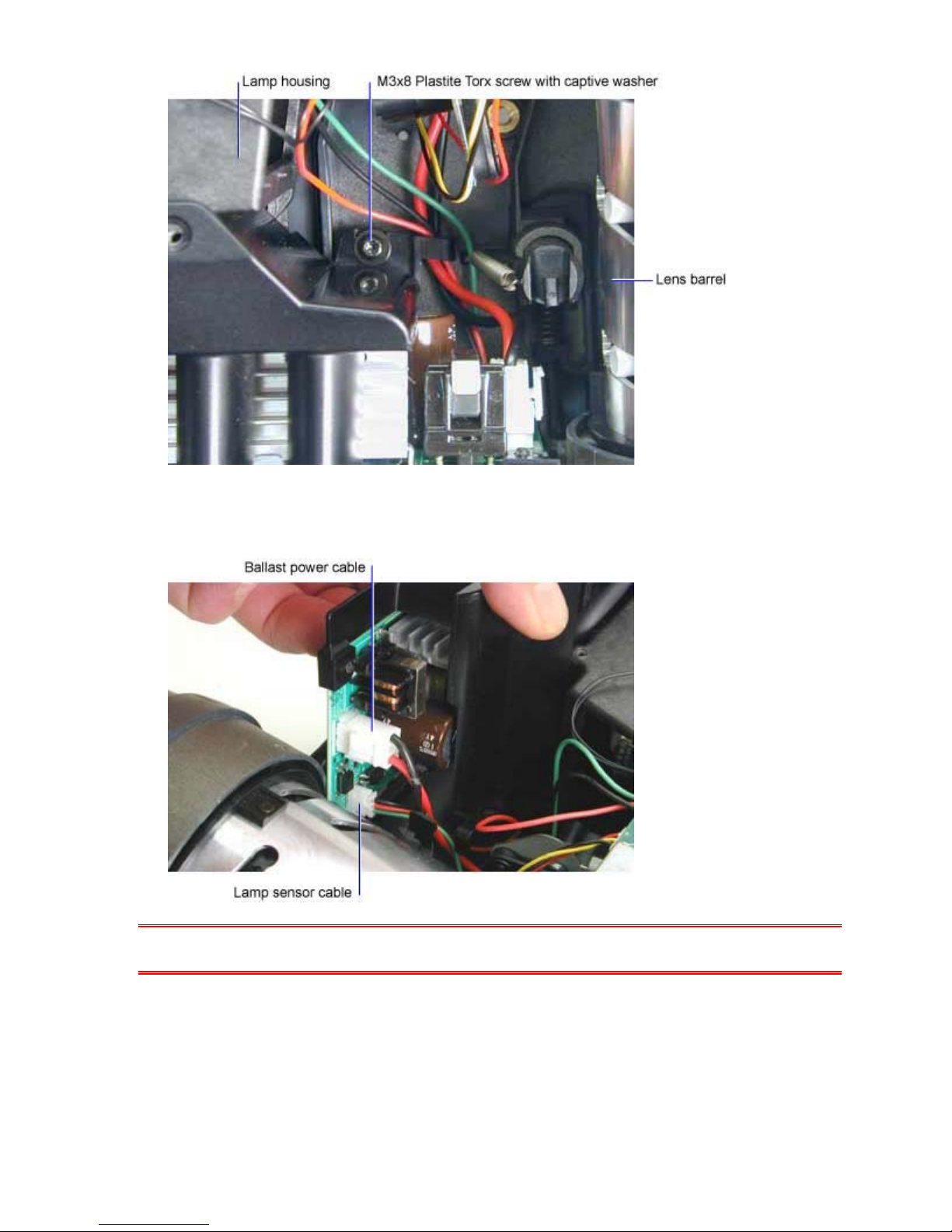

2 Remove the two M3x6 black Plastite Torx screws that fasten the ballast to the lamp housing.

Note that the screws have a beveled head.

3 Remove the M3x8 black Plastite Torx screw with a captive washer that fastens the ballast to the

bottom case. The screw is located in the cavity between the lamp housing and the projection lens

barrel.

DP8000/8000HB Service Manual 21

Page 22

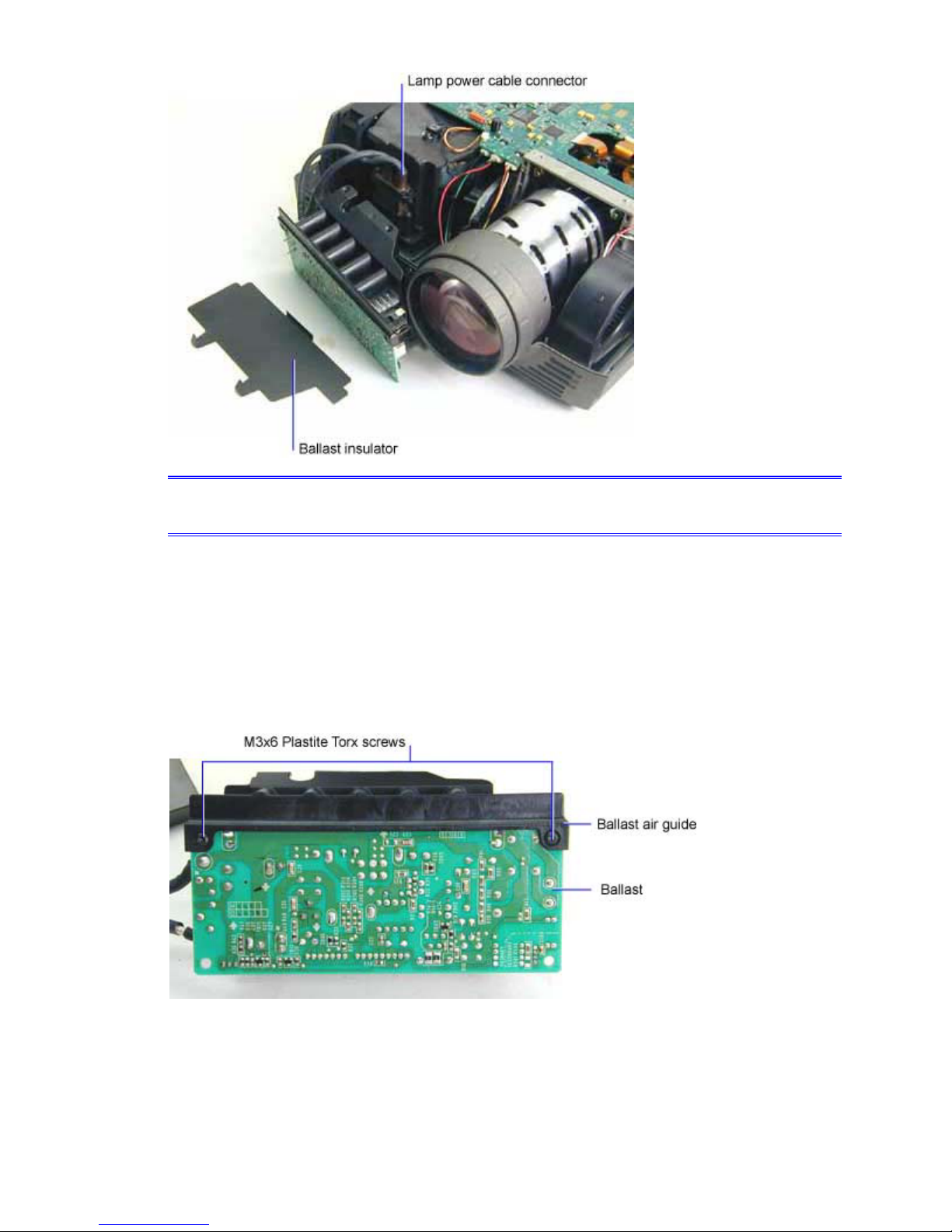

4 Lift the end of the ballast adjacent to the lens barrel so that you can unplug the lamp sensor cable

and the ballast power cable.

CAUTION The solder points on the outside of the ballast are very sharp. Take care when you grasp

the ballast.

5 Lift the ballast out of the bottom case. You may need to flex the case outward slightly. Note that

the lamp power cable connector is fastened to the lamp housing.

6 Remove the two M3x8 black Plastite Torx screws with captive washers that fasten the lamp

power connector to the lamp housing. Then unplug the connector.

DP8000/8000HB Service Manual 22

Page 23

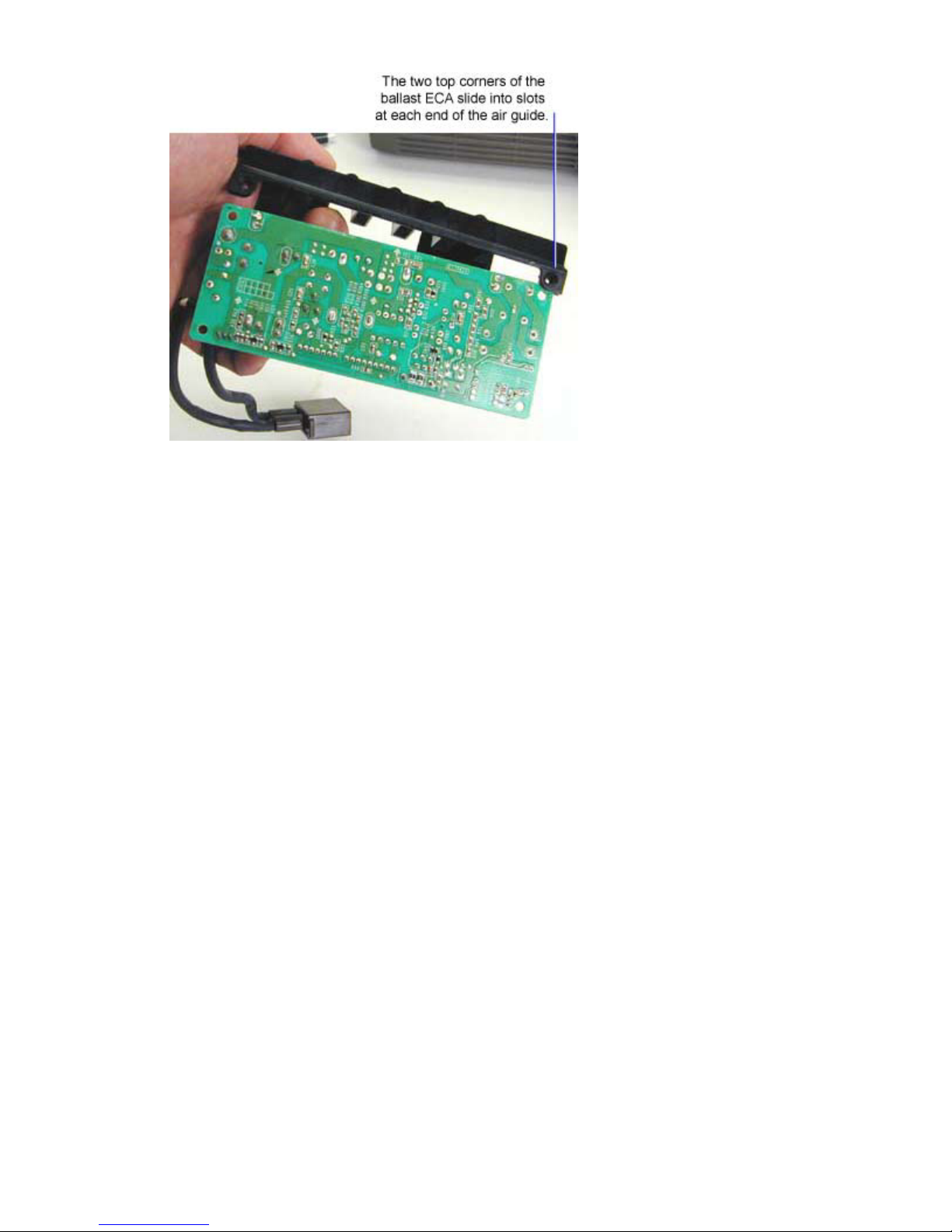

NOTE The ballast insulator protects the outside of the ballast ECA. Make sure to replace it when

installing the ballast.

Assembly Notes

♦ If you are installing a new ballast, you need to fasten the ballast air guide to the new ballast.

You can remove the air guide from the old ballast and attach it to the new one. Or you can install

a new air guide, which is available in the hardware kit (410389).

To separate the ballast air guide and the ballast, remove the two M3x6 black Plastite Torx screws

from the right and left top corner of the ballast. Then slide the air guide off of the ballast ECA.

To install the ballast air guide, insert the two top corners of the ballast ECA into the slots in the air

guide. Then tighten the M3x6 black Plastite Torx screws to 5 in-lbs (.55 Nm).

DP8000/8000HB Service Manual 23

Page 24

DP8000/8000HB Service Manual 24

Page 25

♦ To install the ballast and air guide, do the following:

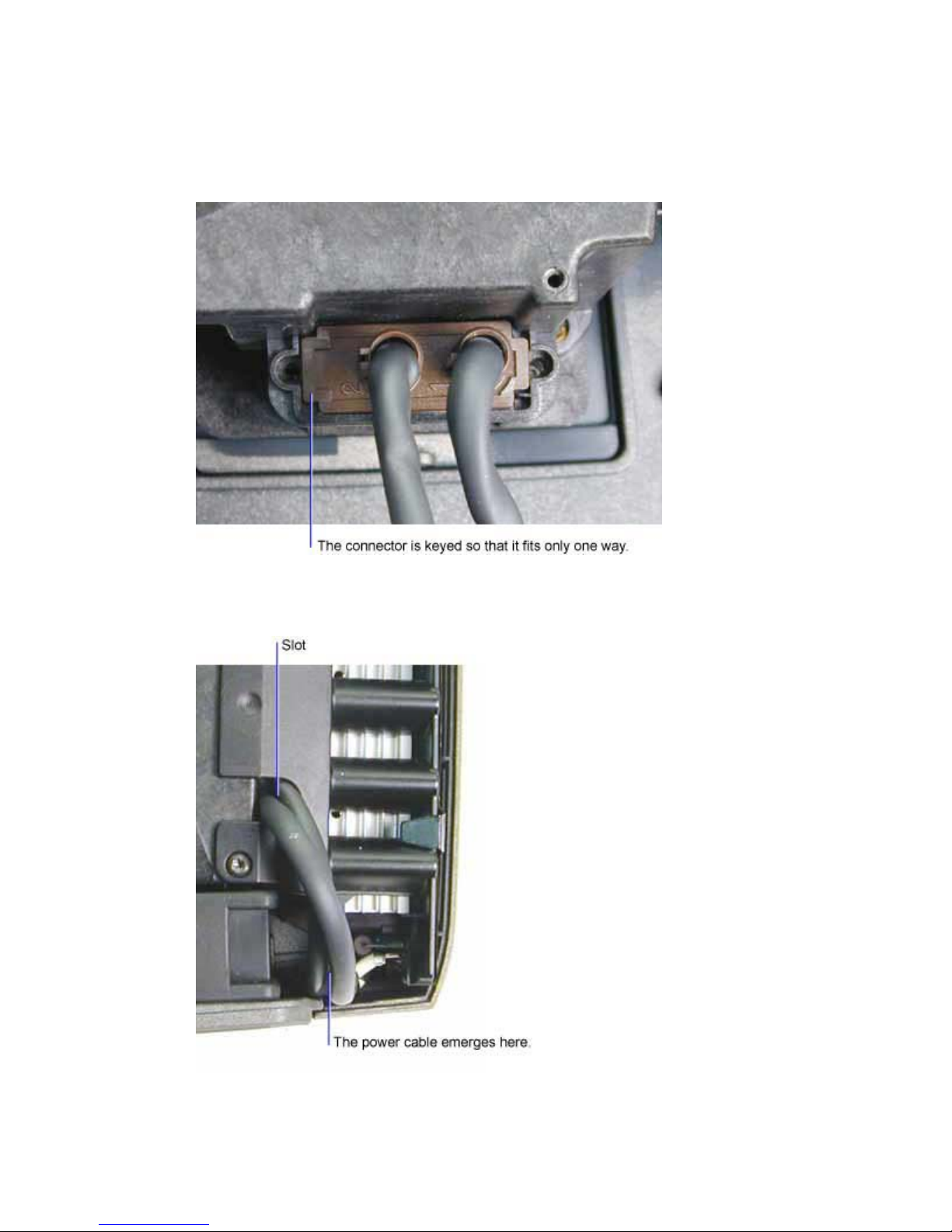

1. Fasten the lamp power cable connector to the lamp housing. Tighten the two black

M3x8 Plastite Torx screws with captive washers to 5 in-lbs (.55 Nm). Do not over

tighten the screws.

2. Make sure the lamp power cable emerges from the end of the ballast and is then

routed through the slot in the air guide flange that fits over the lamp housing.

DP8000/8000HB Service Manual 25

Page 26

3. Lower the ballast into the bottom case. You may need to flex the case outward

slightly to clear the ballast. Make sure that each end of the ballast fits into the

alignment slots in the bottom case.

4. Route the lamp sensor and ballast power cables beneath the cable clip adjacent to

the M3x8 black Plastite Torx screw with a captive washer. Then tighten the screw

to 8 in-lbs (.95 Nm)

5. Tighten the two black M3x6 Plastite Torx screws that fasten the ballast to the lamp

housing to 5 in-lbs (.55 Nm).

DP8000/8000HB Service Manual 26

Page 27

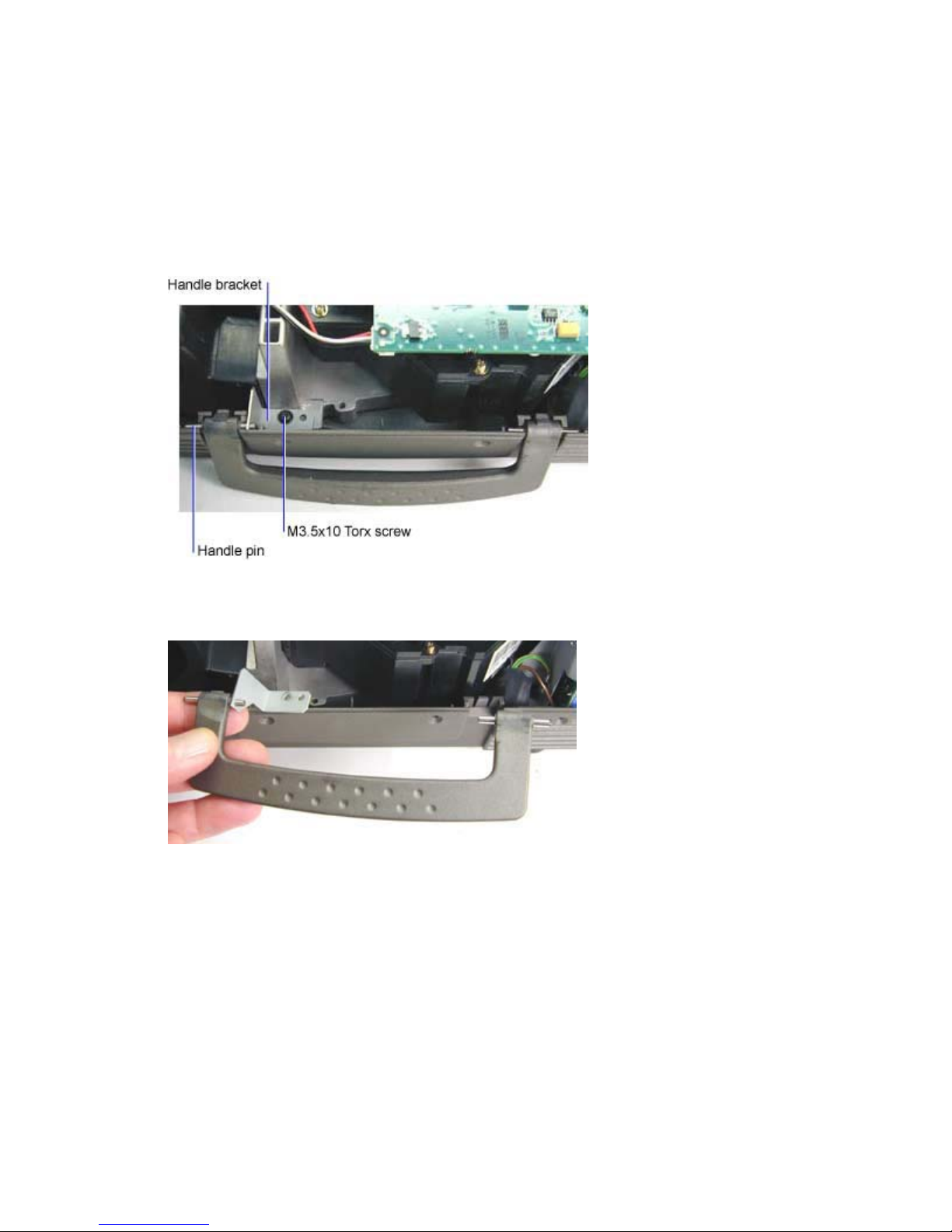

Remove and Replace the Handle

The handle (4009081) fastens to the side of the bottom case adjacent to the engine blower fan. The

handle is held in place by the handle bracket and handle pins, both of which are available in the

hardware kit (410389)

1 Remove the top case (see page 14)

2 Remove the M3.5x10 black Torx screw that fastens the handle bracket to the bottom case.

3 Lift both ends of the handle up so that the handle pins disengage from the slots in the bottom

case.

Assembly Note

♦ To install the handle, insert the handle pin into the hole in the handle bracket. While holding the

bracket in place, press the pins into their slots in the bottom case.

♦ Torque the M3.5x10 Torx screw to 8 in-lbs (.95 Nm).

DP8000/8000HB Service Manual 27

Page 28

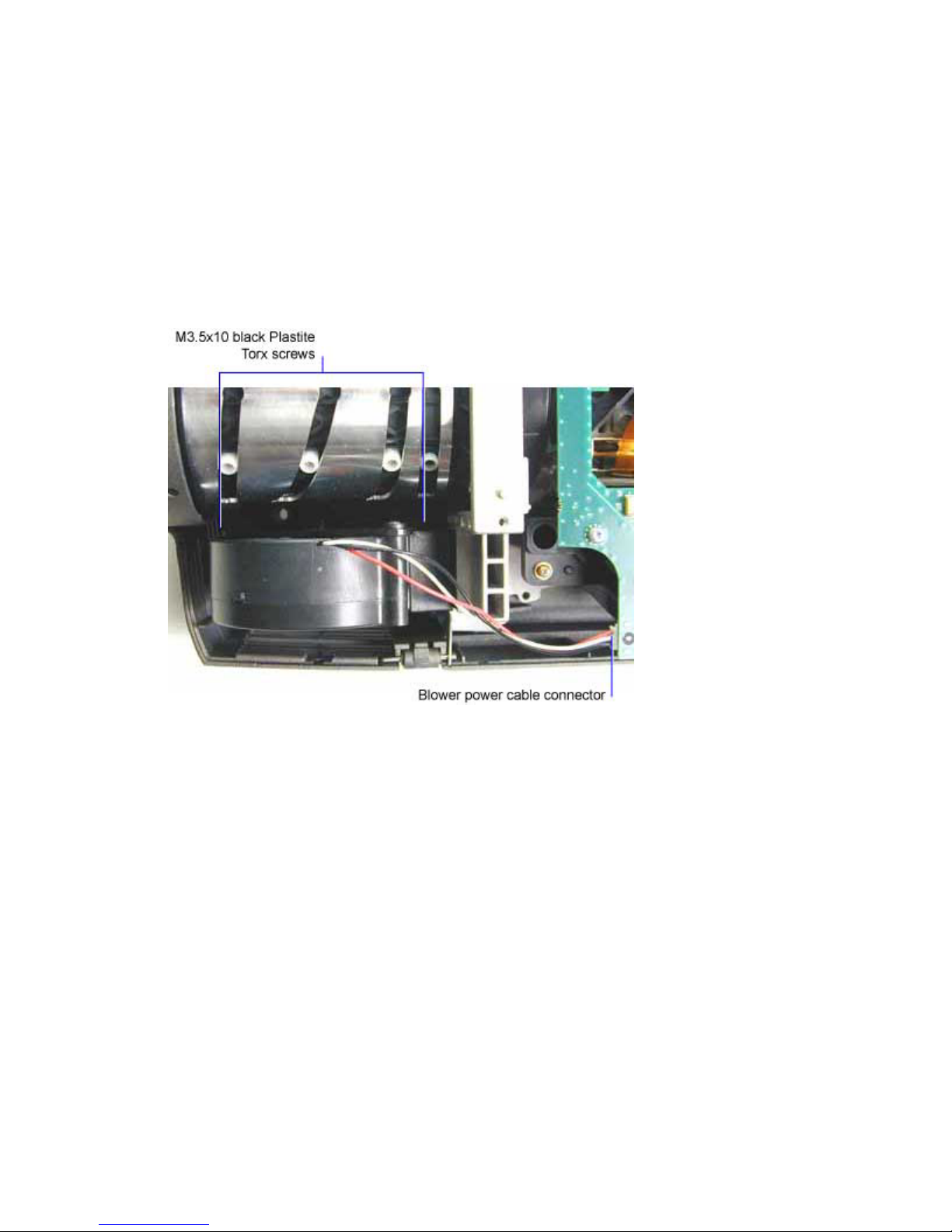

Remove and Replace the Engine Blower

The engine blower (DP8000: 300732, DP8000HB: 505-1436-xx) is located in the front of the projector

adjacent to the projection lens barrel. It draws outside air through the dust filter and blows cool air into the

optical engine.

1 Remove the top case (see page 14)

2 Disconnect the blower power cable from the controller ECA (see step 3 below).

3 Remove the two black M3.5x10 Plastite Torx screws that fasten the blower to the bottom case.

The screws are located in the cavity between the projection lens and the blower.

DP8000/8000HB Service Manual 28

Page 29

4 Lift the front of the blower out of the bottom case first, then slide the blower duct out of the

engine.

Assembly Note

♦ Insert the blower duct into the engine first, then lower the rest of the blower into the bottom case.

Make sure the blower seats properly in the bottom case. There are two spacers that fit into

recesses in the screw holes. Torque the two screws to 5 in-lbs (.55 Nm).

DP8000/8000HB Service Manual 29

Page 30

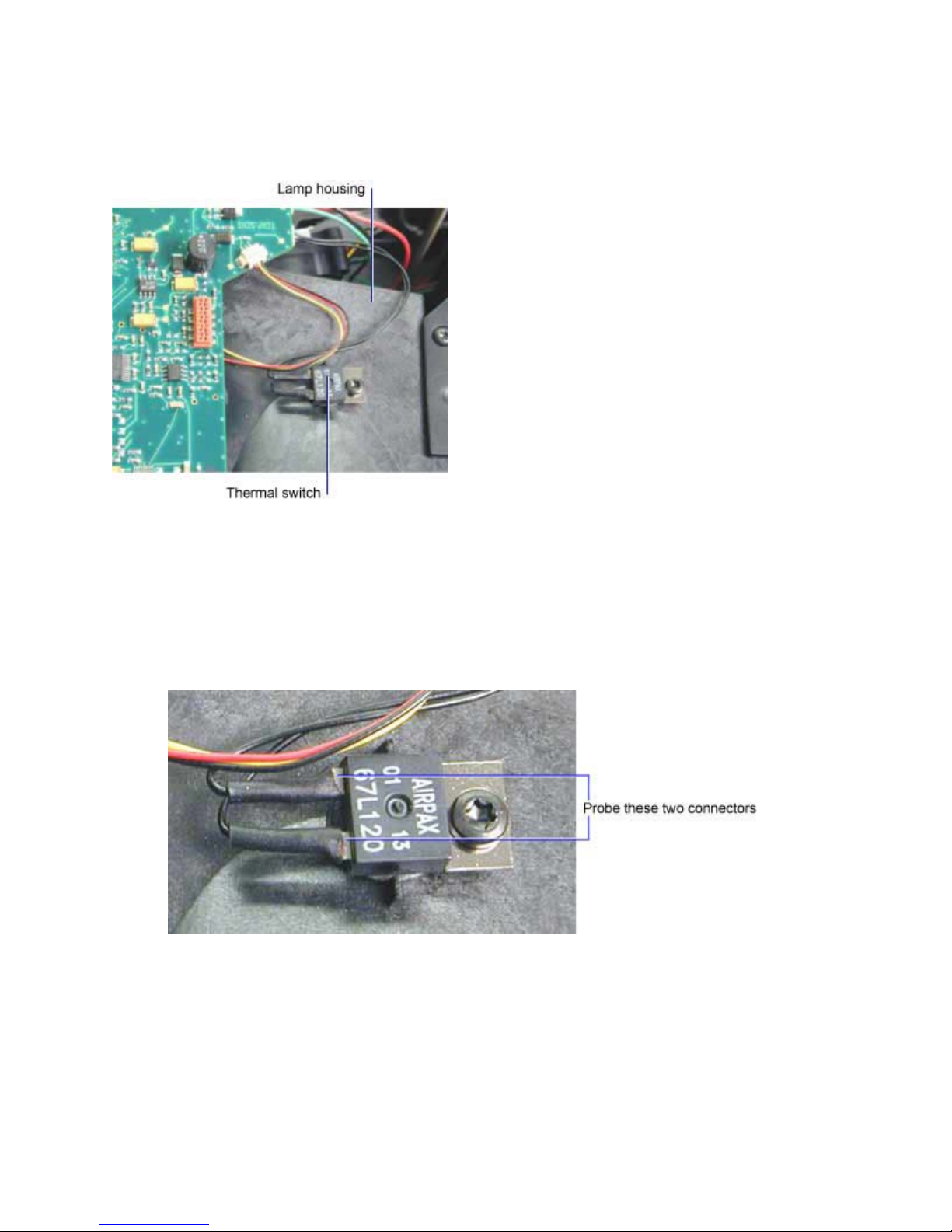

Remove and Replace the Thermal Switch

The thermal switch (301572xx) is located on the top of the lamp housing. If the temperature in the

housing becomes too high, the switch opens, shutting down the projector.

To check the thermal switch

When a projector shuts down after operating for a few minutes, you need to check the thermal switch

operation. First, power up the projector with the top off. Let the projector run until it shuts down. Measure

the resistance at the cable connections. If the resistance is infinity (open), replace the thermal switch.

1 Probe the connections indicated below:

DP8000/8000HB Service Manual 30

Page 31

To replace the thermal switch

1 Unplug the thermal switch cable at the connector on the controller ECA. Then remove the black

M3x6 Plastite Torx screw.

DP8000/8000HB Service Manual 31

Page 32

Remove and Replace the Controller ECA

The controller ECA is located beneath the top case. It fastens to the top of the optical engine. It provides

all control functions and processes the data and video signals.

In the DP8000, the controller ECA is part of the engine/controller kit (410393). Both parts are matched,

and must be installed as a set.

In the DP8000HB, the controller ECA (308244x) and optical engine (410469) are available separately.

Each part may be replaced independently. A replaceable zone chip on the controller ECA is matched to

the engine. When you replace the controller, you remove the zone chip and install it on the new controller.

Likewise, when you install a new engine, you must install the matched zone chip on the controller. The

old zone chip is returned with the old engine.

The directions to remove the controller ECA are the same for both models.

1 Remove the Top Case (see page 14).

2 Unplug the eight cables that connect to the outside edge of the controller ECA.

DP8000/8000HB Service Manual 32

Page 33

3 Unplug the three ribbon cables at the center of the controller ECA. Each cable plugs into a ZIF

connector on the underside of the controller ECA.

Find the small black tabs on either side of the connector.

These tabs are part of a sliding bar that locks the cable in the connector. To unlock the connector,

use a pick to move the tabs away from the connector and toward the cable about a 1/8th of an

inch. Then pull the cable out of the connector.

CAUTION The connectors are extremely delicate.

DP8000/8000HB Service Manual 33

Page 34

4 Remove the four M3x6 Torx screws and the single black Plastite screw that fasten the controller

ECA to the optical engine.

5 Remove the M3x6 Torx screw that fastens the I/O shield to the power supply.

DP8000/8000HB Service Manual 34

Page 35

6 Carefully lift the right rear corner of the controller ECA to disengage the controller/power supply

connector. You can now remove the controller from the projector.

7 Do one of the following:

If you are replacing the controller ECA on an DP8000, go to Removing the Optical Engine (see

page 21).

If you are replacing the controller ECA on an DP8000HB, to Remove and Replace the NV RAM

Chip (see page 37.

Assembly Notes

♦ If you are replacing the engine/controller kit in the DP8000, you may need to change the logo

screen to reflect the correct company name. See Change the Logo Screen (page 72) for more

information.

♦ Make sure all the ribbon connector locks are open before fastening the controller to the engine.

♦ Connect the cables for the three fans that are attached to the side vent before fastening the

controller to the engine. The side vent is located on the right side of the projector in the pictures

above.

DP8000/8000HB Service Manual 35

Page 36

♦ Align the screw holes in the controller ECA with the standoffs on the engine. Once the holes are

aligned, press the controller/power supply connector together.

♦ When you seat the controller, make sure the metal tab on the I/O shield fits behind the matching

plastic tab on the bottom case.

♦ Torque all screws to 7 in-lbs (.8 Nm).

DP8000/8000HB Service Manual 36

Page 37

Remove and Replace the NV RAM Chip on the DP8000HB

The NV RAM chip plugs into a socket on the controller ECA. Each NV RAM chip is set up to maximize

the color reproduction of a specific optical engine. A unique chip ships with each new optical engine.

Thus, when an engine is replaced, the NV RAM chip installed on the controller ECA must be removed

and replaced with the chip that came with the new engine. Likewise, when you replace the controller

ECA, you need to remove the chip from the old controller and install it on the new one.

The NV RAM chip is not available as a separate replaceable part.

The procedure assumes that the controller ECA is already removed from the projector.

Remove the NV RAM chip

1 Turn the controller upside down on the work surface.

NOTE If you cannot locate the NV RAM chip or if you cannot remove the chip, you may not be

working on an DP8000HB. Check the serial number label on the bottom case. The

DP8000HB serial number prefix is AFW.

DP8000/8000HB Service Manual 37

Page 38

2 Use an IC puller or a small flat bladed screwdriver to remove the chip from its base on the

controller.

DP8000/8000HB Service Manual 38

Page 39

Install the NV RAM chip

1 Align the chip so that the eight pins align with the eight holes on the base. Then press the chip

into place.

CAUTION The pins on the NV RAM chip are delicate. Make sure that the pins are straight and

that they align with the corresponding holes in the socket. Press straight down, making

sure that you do not bend the pins while inserting them into the socket.

DP8000/8000HB Service Manual 39

Page 40

Change the Logo Screen

When you install a new engine/controller kit, you may need to change the logo screen. The logo screen,

or splash screen, is the screen that appears when you start the projector. The logo screen can be

changed to one of several manufacturers, or it can be made blank. The default logo screen on a new

engine/controller kit is the PROXIMA screen.

To change the logo screen, you must access the Service Menu. To access the Service Menu, you must

have the remote control that ships with the projector.

WARNING When you enter the Service Menu, do not change any of the settings except the Customer

Version options. Making changes to factory-set image calibrations may require that you return

the unit to a factory service center for recalibration. Recalibration in such circumstances is

considered a non-warranty repair.

1 Connect a data source to the projector. Power up both units. Make sure you can see the desktop

of source you connected.

The Service Menu is not available unless a source is connected to the projector.

2 Turn the remote control on, then press the menu button.

3 In the Basic menu, select Setup. Use the arrow keys on the remote to move up and down the

menu. Use the Select button to make a menu selection.

4 In the Setup menu, select Service.

DP8000/8000HB Service Manual 40

Page 41

5 In the Service menu, select Service Code.

A small window appears to the right of the Service menu.

NOTE If the Service Code menu choice is dimmed, the projector does not recognize the source

you connected in step 1. Make sure you can see source's desktop in the projected image.

6 On the remote control, press the following buttons in order.

Computer

Volume Up

Volume Down

Power

Video

Menu

DP8000/8000HB Service Manual 41

Page 42

As you press each button, an asterisk appears in the small window (see above). After you enter

the Menu button, a Service State Warning message appears.

NOTE If the Service Code menu does not appear, re-enter the button sequence. If too much time

elapses before you begin to enter button presses or between button presses, the small

window disappears and you must begin again.

7 In the Service State Warning box, select Enter.

8 In the Service Menu, select Customer Ver..

DP8000/8000HB Service Manual 42

Page 43

9 In the submenu that appears, use the trackball on the remote to select the appropriate projector

logo screen.

10 Press the left mouse button on the remote to accept the change, then select Close Menu to close

the Service Menu. Press the Menu button to close all the menus.

11 To confirm that the logo screen is correct, restart the projector.

DP8000/8000HB Service Manual 43

Page 44

Remove and Replace the Side Vent and Fans

The side vent (4009072) covers the side of the projector opposite the projection lens. The 92mm lamp

fan (DP8000: 400177, DP8000HB: 232-0218-xx), the 80mm engine fan (DP8000: 400056, DP8000HB:

232-0219-xx), and the 60mm power supply fan (DP8000: 400057, DP8000HB: 232-0220-xx) all fasten

to the side vent. Each fan is available separately.

To remove the side vent and fans

1 Remove the top case (see page 14).

2 Remove the controller ECA (see page 32).

3 Turn the projector on its side and remove the M3x6 Plastite Torx screw that fastens the side vent

to the bottom case.

4 Lift the side vent and fans out of the bottom case.

DP8000/8000HB Service Manual 44

Page 45

To remove the fans on the side vent

1 Use a narrow shafted T-10 Torx driver to remove the M3x6 Plastite screws that fasten the top left

and bottom right corner of the fan you want to replace.

Assembly Notes

♦ Make sure you fasten the fan onto the side vent so that the fan cable is routed properly. See step

1 above.

♦ Make sure the side vent edges mate properly when you install the unit into the bottom case.

♦ Torque all screws to 6 in-lbs (.7 Nm).

DP8000/8000HB Service Manual 45

Page 46

Remove and Replace the Lamp Blower

The lamp blower (DP8000: 300733, DP8000HB: 526-0147-xx) is located near the front of the projector,

in the cavity between the projection lens and the lamp housing. The blower is an assembly, comprised of

an air guide, a metal bracket and the blower itself. The assembly fastens to the bottom case with two

screws.

1 Remove the top case (see page 14).

2 Remove the controller ECA (see page 32).

3 Remove the M3x6 and the M3.5x10 black Plastite Torx screws that fasten the lamp blower and

bracket to the optical engine and bottom case.

4 Lift the lamp blower out of the bottom case.

DP8000/8000HB Service Manual 46

Page 47

Assembly Notes

♦ Place the lamp blower into the bottom case so that the pins on the optical engine and bottom

case align with the slots in the two brackets on the blower. Make sure that you do not pinch the

blower power cable or the interlock switch cable that runs along the bottom case.

♦ The M3.5x10 Plastite screw fastens the front bracket to the engine base. Torque it to 8 in-lbs (.95

Nm)

♦ The M3x6 Plastite screw fastens the rear bracket to the bottom case. Torque it to 5 in-lbs (.55

Nm).

DP8000/8000HB Service Manual 47

Page 48

Remove and Replace the Elevator Assembly

The elevator assembly comprises three pieces, the elevator actuator, which includes the button

(4009083), the elevator foot and shaft (4009082), and a small spring.

The elevator shaft is accessible in the cavity between the projection lens and the lamp housing. To

replace the elevator actuator, you must remove the optical engine.

Remove the elevator foot and shaft

1 Remove the top case (see page 14).

2 Press the elevator button and extend the shaft all the way.

3 Use a pick to detach the spring that attaches to the top of the elevator shaft. The shaft is located

adjacent to the projection lens, just to the rear of the ballast.

4 To remove the foot and shaft, do the following:

DP8000/8000HB Service Manual 48

Page 49

Press the elevator button all the way in. Then use a needlenose pliers to squeeze the top of the

shaft in so that it can pass through the housing in the bottom case.

To remove the elevator actuator

1 Remove the optical engine (see page 54)

2 Use a pick to pry the actuator spring away from the elevator shaft.

DP8000/8000HB Service Manual 49

Page 50

3 Lift the actuator out of the bottom case.

Assembly Notes

♦ When you replace the actuator spring, make sure to insert the front first, then press the rear of

the spring into place.

♦ It's easier to replace the elevator foot/shaft when the engine is out of the bottom case.

DP8000/8000HB Service Manual 50

Page 51

Remove and Replace the Power Supply

The power supply (DP8000: 300162x, DP8000HB: 300163x) is located in the rear of the projector,

behind the optical engine. The power supply includes the AC plug and the power switch. It routes high

voltage to the ballast, which steps up the power to strike the lamp. The power supply provides low voltage

to the controller ECA, the optical engine and the fans. The power supply bracket must be attached to

the right side of the power supply before installing a new supply. You can use the one on the old power

supply or you can order a new one. The bracket is included in the hardware kit (410389).

1 Remove the top case (see page 14).

2 Remove the controller ECA (see page 32).

3 Remove the four M3x6 black Plastite Torx screws that fasten the power supply to the bottom

case. There is a bracket on each end of the power supply. Two screws secure the bracket to the

bottom case.

4 Unplug the interlock switch cable from its connector on the power supply.

5 Press the power switch to the "O" position.

DP8000/8000HB Service Manual 51

Page 52

6 Lift the power supply out of the bottom case.

7 If you are replacing the power supply, remove the metal bracket from the right side of the power

supply. The bracket fastens to the power supply ECA with one M3x6 Torx screw.

DP8000/8000HB Service Manual 52

Page 53

Assembly Notes

♦ If you are installing a new power supply, fasten the metal bracket to the right side of the power

supply. Torque the M3x6 Torx screw to 7 in-lbs (.8 Nm)

♦ Press the power button to the "I" position.

♦ When you place the power supply into the bottom case, make sure each end of the power supply

ECA fits into the alignment slots in the bottom case.

♦ Torque the four M3x6 black Plastite Torx screws to 7 in-lbs (.8 Nm).

♦ Make sure you plug the safety interlock cable into its connector.

DP8000/8000HB Service Manual 53

Page 54

Remove and Replace the Optical Engine

In the DP8000, the optical engine is part of the engine/controller kit (410393). The two units are

matched in the factory and must be replaced as a set. If you replace only the engine and not the

controller ECA, one or both of the parts may fail.

In the DP8000HB, the optical engine (410469) is available separately. Each optical engine includes a

matched gamma chip, which plugs into the controller ECA. Each time you replace an engine, you must

remove the old gamma chip from the controller and install the new one.

CAUTION Before replacing the engine, make sure you know which version of the projector you are working on. If

in doubt, check the serial number label, which is affixed to Certification label on the bottom of the

projector. The DP8000 has a serial number prefex of ABCxxxxxx. The DP8000HB has a serial

number prefex of AFWxxxxxx.

1 Remove the following items:

Lamp door and lamp (see page 9)

Top case (see page 14)

Handle (see page 27)

Engine blower (see page 28)

Controller ECA (see page 32)

Lamp blower (see page 46)

Ballast (see page 21)

2 Remove the two black M3.5x10 Plastite Torx screws that fasten the rear of the optical engine to

the bottom case.

DP8000/8000HB Service Manual 54

Page 55

3 Lift the engine and attached lamp housing out of the bottom case.

4 If you are replacing the engine, do the following:

Remove the five M3x7 standoffs from the top of the engine.

DP8000/8000HB Service Manual 55

Page 56

5 Remove the five black M2x4 Torx screws that fasten the air guide to the bottom of the engine.

Then separate the air guide from the engine.

Place the air guide aside. You need to install it on the new engine. The air guide is also available

in the hardware kit (410389).

Assembly Notes

♦ If you are installing a new engine, do the following

1. Fasten the air guide to the bottom of the engine (see step 5 above). Torque the five

M2x4 screws to 4 in-lbs (.452 Nm)

DP8000/8000HB Service Manual 56

Page 57

2. Fasten the five M3x7 standoffs to the top of the engine (see step 4 above). Torque

the standoffs to 5 in-lbs (.55 Nm).

♦ When you place the engine into the bottom case, make sure that the two registration pins on

either side of the projection lens fit into the matching holes on the engine.

♦ Torque the four M3x6 black Plastite Torx screws to 7 in-lbs (.8 Nm).

♦ If you are replacing the engine/controller kit, you may need to change the logo screen to reflect

the correct company name. See Change the Logo Screen (page 72) for more information.

DP8000/8000HB Service Manual 57

Page 58

Remove and Replace Lamp Housing

The lamp housing (DP8000: 4009076, DP8000HB: 340-1019-xx) fastens to the optical engine. It helps

direct cool air around the lamp module. It also insulates the optical engine from some of the heat radiated

by the lamp.

When you replace the optical engine, you can remove a good lamp housing from the old engine and

install it on the new engine.

1 Remove the optical engine (see page 54).

2 Place the optical engine right side up on the work surface.

3 Remove the M3x6 Torx screw that fastens the top of the lamp housing to the optical engine.

NOTE If you are replacing the lamp housing with a new one, remove the thermal switch from the

top of the lamp housing.

4 Turn the optical engine upside down on the work surface.

DP8000/8000HB Service Manual 58

Page 59

5 Remove the black M2.5x6 Torx screw and the M3x6 Torx screw that fasten the lamp housing to

the optical engine.

DP8000/8000HB Service Manual 59

Page 60

6 Gently lift the tab on each side of the lamp housing to release the locking pin on the optical

engine. Once both tabs are free, you can separate the lamp housing and engine.

CAUTION If you bend a tab too far, it will break. If you break a tab, you must replace the lamp

housing with a new one.

DP8000/8000HB Service Manual 60

Page 61

Assembly Notes

♦ To install the lamp housing, do the following:

1. Engage the locking pins in their holes on the top of the lamp housing.

2. Press the bottom of the lamp housing toward the optical engine until the two

locking pins on the bottom of the optical engine engage their holes in the lamp

housing.

3. If you are installing a new lamp housing, make sure to fasten the thermal switch to

the top of the housing. See step 3 above.

4. Torque all screws to 5 in-lbs (.55 Nm).

DP8000/8000HB Service Manual 61

Page 62

Remove and Replace the Interlock Switch and Interlock Switch Cable

The interlock switch (506418) fastens to the inside of the bottom case adjacent to the lamp door

opening. The interlock switch cable (301570xx) connects the interlock switch to the power supply and

ballast. It consists of two cable sets with a ferrite on each.

When the lamp door is removed, the switch opens, interrupting the circuit between the power supply and

ballast. When the switch is open, the lamp will not ignite.

Both parts come with a new bottom case, and both parts may be ordered separately.

1 Remove the optical engine (see page 54).

2 To replace the interlock switch, remove the two black M3x14 Plastite screws that fasten the

switch to the bottom case. Then use a needlenose pliers to unplug the cables attached to it.

DP8000/8000HB Service Manual 62

Page 63

3 To replace a cable, use a bladed screwdriver to pry the ferrite from the bottom case. Then unplug

the cables from the interlock switch.

DP8000/8000HB Service Manual 63

Page 64

Assembly Notes

♦ Torque the screws on the interlock switch to 5 in-lbs (.55 Nm).

♦ Take care when pressing the ferrite between the two locking tabs in the bottom case. It is a tight

fit, and you may need to slightly pry one of the tabs outward.

♦ Be sure to plug the rear cable back into its connector on the power supply.

♦ Be sure to route the front cable between the posts in the bottom case.

DP8000/8000HB Service Manual 64

Page 65

Remove and Replace the Bottom Case

The bottom case (4009071xx) encloses the bottom half of the projector. A new bottom case also

includes the rear feet (4009084xx), the elevator foot (4009082), the elevator lever (4009083), the

interlock switch (506418) and the interlock switch cable (301570xx). Each of these parts are also

available separately. When you replace a bottom case, you also need to adhere a new bottom label,

which is available in the label kit (401941).

To replace the bottom case, you remove all the replaceable parts with the exception of those listed

above.

1 Remove the following items:

Lamp door and lamp module (see page 9)

Dust filter (see page 11)

Top Case (see page 14)

Controller ECA (see page 32)

Ballast (see page 21)

Power supply (see page 51)

Side vent and attached fans (see page 37)

Engine blower (see page 28)

Lamp blower (see page 46)

Optical engine and attached lamp housing (see page 54)

2 Affix a new bottom label to the outside of the bottom case. Use the old bottom case for

positioning.

DP8000/8000HB Service Manual 65

Page 66

Remove and Replace the Focus and Zoom Rings

The focus ring (340-1156-xx) fastens to the end of the lens barrel. The zoom ring (340-1157-xx) fastens

to the lens barrel just inside of the focus ring. The focus and zoom rings allow independent adjustment of

the image size and focus. The focus and zoom rings come with a new optical engine. They are also

available separately.

3 Remove the optical engine (see page 54).

1 Use a small Phillips driver to remove the four M2x4 black Phillips screws that fasten the zoom

ring to the lens barrel. The screws are oriented 90 degrees to each other.

DP8000/8000HB Service Manual 66

Page 67

2 Separate the zoom and focus rings so that the four screws that fasten the focus ring are

accessible. Then remove the four M2x4 black Phillips screws that fasten the zoom ring to the lens

barrel.

3 Work the focus ring off of the lens barrel, then remove and replace the zoom ring if necessary.

Assembly Notes

♦ Make sure to slide the zoom ring on the lens barrel first.

♦ Fasten the focus ring to the lens barrel before fastening the zoom ring.

♦ Torque the screws to 5 in-lbs (.55 Nm). Do not over tighten the screws. You can crack the plastic

zoom or focus ring.

DP8000/8000HB Service Manual 67

Page 68

Functional Tests

You perform the functional tests after you’ve repaired the projector to make sure all components of the

projector operate properly. You can also perform the functional tests if you’re having trouble determining

what is wrong with the projector. For additional help in diagnosing trouble with the projector, see

Troubleshooting on page 72.

Required equipment

Equipment Test

Video player Make sure the video player has an S-video Out port and cables. The player should

also have a Composite video output port (RCA). PROXIMA strongly suggests you

use a DVD player to test the video quality. DVD players reproduce colors better and

project sharper images. The least preferable is a VCR. If you must use a VCR, make

sure you use a commercially produced recording, not one recorded from a broadcast

source. The VCR must include an S-video connector in addition to a composite

connector.

Commercially

produced video

Audio & Video

cables

RGB test screens Use the Test Patterns on the InFocus website to check image quality.

External amplified

speakers

PC multimedia

presentation

Remote control Ensure that the remote has fresh AA batteries.

Projection screen Use a flat screen, not a curved one.

PC with digital

video and sound

card

You'll need the video in DVD, laser disc, or video cassette format. PROXIMA strongly

suggests you use Video Essentials, Optimizing Your Audio/Video System (DVD

International, 1997).

Use the cables that come with the projector, including the Digital Video Interface

(DVI) cable.

For example, you can use a PowerPoint presentation with sound, photographs,

graphics and .avi files.

Make sure the card has an M1 Digital Video Interface (DVI) output port. The stereo

audio card should have either a 3.5mm stereo audio jack or RCA left and right output

ports. The computer must have a CD-ROM and must have outputs for RGBHV,

VESA, M1 Analog and M1 Digital.

DP8000/8000HB Service Manual 68

Page 69

Before beginning

Make sure the work surface where you perform the functional tests is level and clean. Place the projector

on a soft surface (such as an anti-static mat) when running the tests.

Connect the following to the I/O panel on the projector:

♦ DVI Digital data source (PC)

♦ USB cable (USB port on computer to USB port on projector)

♦ Audio in to DVI from PC

♦ RGBHV (RGB data signal & component video)

♦ Composite video

♦ Audio in from video source

♦ Audio out to external powered speakers

♦ Serial communication (RS-232)

Perform the following tests

Test Verification

Power Up

Connect AC power, and turn the unit

on.

Cosmetics and mechanicals

Adjust the projector so that the image is

square. Make sure the lens is at a 90°

angle to the wall.

Composite video from video source

Connect the yellow composite (RCA)

video connector to the projector.

S-Video from video source

Connect the S-video cable to the

projector.

Disconnect the yellow composite (RCA)

video connector.

Audio from audio source

On the keypad, press the Volume up

(right arrow), then the Volume down

(left arrow) buttons.

Verify that the proper splash (logo) screen appears. (If the

wrong logo screen appears, go to Change the Logo Screen on

page 72)

Verify image quality.

Verify that the elevator and leveling foot are functional.

Verify that the focus and zoom rings operate properly.

Verify cosmetics.

Verify that the video automatically synchronizes.

Verify there is no distortion, noise or other abnormalities.

Verify that the video automatically synchronizes.

Verify there is no distortion, noise or other video abnormalities.

Verify that the audio source plays through the projector's

speaker.

Verify that the volume controls function correctly.

Manual source selection

On the keypad, press the Source/Select

DP8000/8000HB Service Manual 69

Verify that the projector switches to the manually-selected

source.

Page 70

button.

Manually select a connected source.

Verify there is no distortion, noise or other video abnormalities.

Software Version / Lamptime Used

On the keypad, press the Menu button.

Navigate through the Basic menu to the

Setup menu.

Navigate to the Service menu.

Select Info from the Service menu.

The next step is to observe 3 computer

images. These will confirm that the

computer input works properly, and will

test image quality.

Image #1: Focus Test Image

Turn off any local light.

Turn the zoom ring to make the

smallest image.

Focus the image so the middle icon is

clearly focused.

Focus the image on the 4 green

squares.

After focusing on the green squares on

the middle icon, turn the zoom ring to

make the largest image, then repeat the

focus tests.

Verify software version.

Verify the keys are not sticky.

Verify that the software version is current and that the lamp is

within its service life.

Verify that the image synchronizes properly through the M1

input.

Verify that all four corner icons have clear resolution.

Verify that the white space is visible on all 5 bar/line icon areas

(between green).

Verify that the image focuses through the full zoom range.

Verify that the image remains in focus when the Image Shift

knob is turned.

Image #2: Color Ramp

Project the Color Ramp image.

DP8000/8000HB Service Manual 70

Verify there are no missing parts of the ramp.

Verify that the bars are not flashing.

Verify that the transitions from light to dark are smooth and

gradual.

Page 71

Image #4: SMPTE133

Project the SMPTE133 image.

Verify that there are no noise, tint, duplicating columns, or other

general image abnormalities present.

USB Mouse

System Reset

On the keypad, press the Menu button.

Navigate through the Basic menu to

the Reset function.

Select Reset.

Power Down

After all tests are complete turn the

power off and disconnect all cables.

Attach the lens cap.

Verify that the mouse operates correctly.

Verify that the image synchronizes after system reset.

Verify unit is powered off before disconnecting cables.

DP8000/8000HB Service Manual 71

Page 72

Troubleshooting

You use this section to diagnose problems with the projector.

In addition to the troubleshooting trees on the following pages, you will also find the following items:

♦ Check Controller Voltages (page 72)

♦ Check Speaker Resistance (page 89)

♦ Wiring diagram (page 90)

DP8000/8000HB Service Manual 72

Page 73

Troubleshooting Power Problems

Fan out message appears

One or more fans do not work. The "fan out" message appears

and the projector shuts down.

Power supply voltages

OK?

(page 88)

Yes

Fan voltages O K?

(page 88)

Yes

No

No

Replace power supply

(page 51)

Replace bad fan

Engine blower (page 28)

92mm lamp fan (page 44)

60mm power supply fan

(page 44)

80mm engine fan (page 44)

Lamp blower (page 46)

DP8000: replace controller ECA/engine kit

(page 32)

DP8000HB: replace controller ECA

(page 32)

Note: Voltage for bad fan or

blower is 12v fan power and 3.2v

fan sense.

Shuts down

DP8000/8000HB Service Manual 73

Page 74

Projector shuts off

Projector shuts off after a period of time

Clean the dust filter.

(page 11)

Does the unit

operate normall y?

No

Replace the lamp with a known good lamp

(page 9)

Does the unit

operate normall y?

No

Does

the thermal switch

have the roper

resistance?

(page 30)

Yes

No

Issue resolvedYes

Replace lamp

Make sure that you run the

unit long enough to ascertain

whether the unit still shuts

down

Replac e the

thermal switch.

(page 30)

DP8000 Replace engine/controller kit

DP8000HB Replace controller ECA

DP8000/8000HB Service Manual 74

Yes

Repl ace ballast

(page 21)

Does the unit

operate normall y?

Yes

(page 32)

Yes

Issue resolved

Page 75

Dead. No lamps, no fans

Dead. No

fans, no lamp,

no LED

Substitute a

known good

power cord.

No

Replace power supply

(page 51)

If you're plugging the

projector into a power

strip, make sure the

power strip is turned

on.

DP8000/8000HB Service Manual 75

Page 76

No lamp. Fans run, LED lights.

Lamp does not light. Fans run

and LED lights.

Substitute known good lamp

(page 9)

Does the

lamp work?

No

Proper voltages

at lamp enable cable

connector on controller ECA?

(page 88)

No

Yes

Yes

Replace Lamp

Replace ballas t

(page 21)

Thermal switch voltage

good?

(page 30)

Yes

Power supply

voltages good?

(page 88)

No

Replace power supply

(page 51)

Yes

No

Replace thermal switch

(page 30)

DP8000 Replac e engine/controller kit

DP8000HB Replace controller ECA

(page 32)

In rare cases, the interlock

switch goes bad. You can try

replacing the switch before

you replace the entire

controller ECA/optical

engine kit. See page62.

DP8000/8000HB Service Manual 76

Page 77

Troubleshooting Image Problems

Image not correct

The Image is not correct.

The projector starts and runs normally.

The menus are accessible. The lamp is lit.

Perf orm Fac tory

Reset

Subtitute known good data or

video c able.

Open the projector menu. In the Basic menu,

select Setup. In the Setup menu, select

Service. In the Service menu, select Factory

Reset.

Flickering Image

(page 78)

Dark Spot in image

(page 79)

Reconnect flex

cables on the

controller ECA

What is the

Problem?

The image out of alignment

clusters of dark or over-

or includes

bright pixels

(page 80)

See step 2 and the As sembly Notes in

Replacing the Controller ECA (page 32)

The image is white or black only,

garbled or sc rambled,

faded, discolored, displays lines

over image

(page 81)

DP8000/8000HB Service Manual 77

Page 78

Flickering Image

Flickering image or shifting brightness

Clean dus t filter

(page 11)

Also verify that the engine fan visible through the controller ECA

is running. This fan is not sensed, and will not cause the

projector to shut down. Instead, it can cause the engine to

overheat .

Is the image

stable?

No

Substitute known good lamp

(page 9)

Is the image

stable?

No

Substitute known good ballast

(page 21)

Is the image

stable?

Yes

Yes

Yes

Problem resolved

Replace lamp

Replace ballast

No

DP8000

Replace controller ECA

and optical engine

(page 32)

DP8000/8000HB Service Manual 78

No

DP8000HB

Substitute good optical engine

(page 54)

Is the image

stable?

No

Replace the controller ECA

(page 32)

Yes

Replace engine

Page 79

Dark spot in image

Dark spot in image: gets larger as

projector runs

Clean dus t f ilters

(page 11)

Is the image

fixed?

No

DP8000: replace controller ECA

and optical engine

(page 32)

DP8000HB: replace optical engine

(page 54)

Problem resolvedYes

DP8000/8000HB Service Manual 79

Page 80

Image out of alignment

Bad color

The image out of alignment or includes

clusters of dark or over-bright pixels

DP8000

Replace controller ECA

and optical engine

(page 32)

DP8000HB

Replace optical engine

(page 54)

DP8000/8000HB Service Manual 80

Page 81

Bad color

The image is white or black only, garbled or scrambled,

faded, discolored, displays lines over image

DP8000

Replace controller ECA

and optical engine

(see page 32)

Substitute good optical engine

(see page 54)

Good image?

Replace the controller ECA

(see page 32)

DP8000HB

No

Yes

The NV RAM chip is matched to

each optical engine. If the engine

was replaced, but not the NV

RAM chip, a variety of image

problems could result.

(see page 37)

Replace engine

(see page 54)

DP8000/8000HB Service Manual 81

Page 82

Troubleshooting Audio Problems

No Audio

No audio

Before beginning, verify that the IR/

speaker cable is plugged in at both

ends.

(see page 14)

Substitue a new IR ECA

(see page 20)

Audio work?

No

Substitute a new top case

(see page 14)

This projector has three speakers. If there is no audio, it

probably is not a speaker problem.

Yes

Problem

resolved

A new top case

includes a new

IR/speaker c able.

Audio work? Yes

No

DP8000 Replace engine/controller kit

DP8000HB Replace controller ECA

(page 32)

Problem

resolved

DP8000/8000HB Service Manual 82

Page 83

One or more speakers bad

No audio from one or two speakers

Substitute good speaker.

(see page 18)

Sound

good?

No

DP8000 Replace engine/controller kit

DP8000HB Replace controller ECA

(page 32)

Chec k resistance on bad s peaker(s)

Yes

(see page 89)

Does

it measure

7 - 8

ohms?

A shorted speaker can damage the

audio amp on the contr oller EC A.

Run the projector with audio for 30 minutes. If the

problem returns, replace both the controller ECA and

the speaker if the resistanc e acr oss no longer

measures between 7.5 and 8.5 ohms.

No No

Replace the speaker

But note

Measure

less than

4 ohms?

Yes

Replace

speaker

(see page 18)

DP8000/8000HB Service Manual 83

Page 84

Distorted audio

One or more speakers sound

scratchy or distorted

Substitute a known good speaker for

the bad one(s)

(see page 18)

Sound good?

No

DP8000 Replace engine/controller kit

DP8000HB Replace controller ECA

(page 32)

Yes

Problem

resolved

DP8000/8000HB Service Manual 84

Page 85

Troubleshooting Remote Control Problems

Infrared remote problem

Use known good batteries in

the remote.

Replace the

remote.

If the remote works through the

front IR window only or not at

all,

DP8000 Replace engine/controller kit

DP8000HB Replace controller ECA

(page 32)

YesIssue resolved

Use a known good remote with the

Yes

No

Does the remote

work?

projector.

Does the remote

work?

Does the remote

work through the the rear IR

lens?

No

No

Yes

Confirm that the IR/

speaker cable is

connected to both the IR

ECA and the controller

ECA.

If the remote works through the

rear IR window only, replace the

IR ECA in the top case.

(see page 20)

DP8000/8000HB Service Manual 85

Does the remote

work?

No

C300B Replace engine/controller kit

C300HB Replace controller ECA

(page 32)

Yes Issue resolved

Page 86

Troubleshooting Keypad Problems

Keypad does not respond to key presses

Flash the projector with

the latest software before

replacing any parts.

If the remote works and t he keypad

doesn't, the problem is either a bad

keypad or the c ontroller ECA. You c an try

replacing the rubber keypad, but it rare

that a keypad f ails.

Does the menu

appear?

No

DP8000 Replace engine/controller kit

DP8000HB Replace c ontroller ECA

(page 32)

Yes

Make sure the top case is

fastened flush against the

bottom case.

Does the remote control

work?

No

DP8000 Replace engine/

controller kit

DP8000HB Replac e controller

ECA

(page 32)

DP8000/8000HB Service Manual 86

Page 87

Troubleshooting Menu Problems

Menu does not appear onscreen.

Startup screen and other images appear normal.

Make sure the top case is

fastened flush agains t the

bottom case.

Try pressing the Menu button

on both the remote and

Flash the projector with

the latest software before

replacing any parts.

keypad.

If the remote works and the keypad

doesn't, the problem is either a bad

keypad or the c ontr oller ECA. You can try

replacing the rubber keypad, but it rare

that a keypad f ails .

Does the menu

appear?

Yes

No

DP8000

Replace the

engine/controller kit

(page 32)

Does the menu

appear?

Yes

No

DP8000HB

Replace the

controller ECA

(page 32)

If the keypad works and the

remote doesn't, go to Remote

problems.

(pag e 85)

DP8000/8000HB Service Manual 87

Page 88

Check Controller Voltages

To check voltages, you need to power up the projector with the top case removed (see page 13). Use the

remote control to power up the projector once the top case is off the projector.

Go to page 89 to see about checking speaker resistance.

DP8000/DP8000HB Service Manual 88

Page 89

Check Speaker Resistance

DP8000/8000HB Service Manual 89

Page 90

Wiring Diagram

DP8000/8000HB Service Manual 90

Page 91

Parts Lists

Exploded View

See Legend on page 92.

DP8000/8000HB Service Manual 91

Page 92

Legend

See FRUs by Alphabetic Listing on page 94 for details

Item Part Name Part Number

1

2

3

4

5

6

7

8

9

10

11

IR ECA

Keypad 4008088

Thermal switch 301572xx

Lamp housing

Lamp blower

Bottom case 4009071xx

60mm power supply fan

Side vent 4009072

80mm engine fan

92mm lamp fan

Rear foot 4009084xx

DP8000: 308230xx, DP8000HB:

308246xx

DP8000: 4009076, DP8000HB: 3401019-xx

DP8000: 300733, DP8000HB: 5260147-xx

DP8000: 400057, DP8000HB: 2320220-xx

DP8000: 400056, DP8000HB: 2320219-xx

DP8000: 400177, DP8000HB: 2320218-xx

12

13

14

15

16

17

18

19

20

21

22

23

24

Lamp door 4009073

Elevator shaft / foot 4009082

Dust filter 300728

Elevator actuator 4009083

Power supply

Ballast

Engine blower

Handle 4009081

Interlock switch cable 301570xx

Interlock switch 506418

Focus ring 340-1156-xx

Zoom ring 340-1157-xx

Optical engine and controller ECA kit DP8000: 410393

DP8000: 300162xx, DP8000HB:

300163xx

DP8000: 30016, DP8000HB: 525-0061xx

DP8000: 300732, DP8000HB: 5051436-xx

DP8000/8000HB Service Manual 92

Page 93

Controller ECA DP8000HB: 308244xx

25

26

27

28

29

Optical engine DP8000HB: 410469

IR window 4009077

Low range speaker 505538

Right and left speakers 506499 & 506536

Top case 4009070

Hardware kit 410389

DP8000/8000HB Service Manual 93

Page 94

FRUs by alphabetic listing

Below is an alphabetically arranged list of replaceable parts for this projector. Beneath the name for each

part or assembly is the official part name from the PROXIMA Bill of Materials (BOM). The second name is

for reference only. It may help clarify questions about shipping.

Part Name Part Number Notes

Ballast

(POWER LAMP SHP 270W C13)

Bottom case

(HOUSING BOTTOM)

Cable, interlock switch

(CABLE INT C13 SAFETY SWITCH)

Cable, lamp

(CABLE INT C13 LAMP CONTROL)

Controller ECA

Dust filter

(DUST FILTER COMPLETE C13)

Elevator actuator

(FOOTMECH C13)

Elevator shaft / foot

(FOOT C13)

DP8000: 300161

DP8000HB: 525-0061-xx

4009071xx Includes case, elevator, rear

301570xx Also included with new bottom

301571xx

DP8000: see Engine/controller

kit

DP8000HB: 308244xx

300728

4009083 Also included with new bottom

4009082 One piece. Also included with

feet, interlock switch cable and

switch.

case.

case.

new bottom case.

Engine/controller kit

(ENGINE XGA w/MAIN

CONTROLLER BOARD)

Fan, 80mm engine

(FAN 80x80x25MM C13)

Fan, engine blower

(LCD FAN COMPLETE C13)

Fan, 92mm lamp

(FAN 92x92x25MM)

Fan, lamp blower

(FAN BLOWER

LAMP COMPLETE C13)

Fan, 60mm power supply

DP8000/8000HB Service Manual 94

410393 Includes zoom ring, focus ring

and lens cap. Both units must

be replaced at the same time.

Do not replace only the

controller ECA or the optical

engine.

DP8000: 400056

DP8000HB: 232-0219-xx

DP8000: 300732

DP8000HB: 505-1436-xx

DP8000: 400177

DP8000HB: 232-0218-xx

DP8000: 300733

DP8000HB: 526-0147-xx

DP8000: 400057 Fastens to side vent.

Fastens to side vent.

Includes bracket

Fastens to side vent.

Page 95

(FAN 60x60x20MM C13) DP8000HB: 232-0220-xx

Focus ring

(FOCUS RING C13)

Handle

(HANDLE C13)

Hardware kit

(MOUNTING DETAILS)

Interlock switch

(SWITCH SAFETY

15A XTD22AZ1P)

IR ECA

(MODUL PCB C13 IR)

IR window

(IR GLAS C13)

Keypad

(KEYPAD C13)

Label kit

(DECAL SET PROXIMA DP8000)

340-1156-xx Also included with new optical

engine.

4009081

410389 See page 97 to see the

contents of the hardware kit.

506418 Also included with new bottom

case.

DP8000: 308230xx

DP8000HB: 308246xx

4009077

4008088

401941 Includes the front, rear, top and

bottom adhesive labels.

Lamp door

(LAMP COVER C13)

Lamp housing

(LAMP HOUSE C13)

Lamp module

(POWER LAMP SHP 270W C13)

Optical Engine

(OPTICAL ENGINE & ZONE

CORRECTION CHIP C13HB)

Power supply

(POWER PFE/DC C13 REV. B)

Rear foot

(REAR FOOT C13)

Side vent

(SIDE COVER C13)

Speaker, right

(SPEAKER DSH 344 W/210MM

CABLE)

4009073

DP8000: 4009076

DP8000HB: 340-1019-xx

DP8000: SP-LAMP-001

DP8000HB: SP-LAMP-008

DP8000: see Engine/controller

kit

DP8000HB: 410469

DP8000: 300162xx

DP8000HB: 300163xx

4009084xx Two required. Also included

with new bottom case.

4009072 Includes engine fan, lamp fan

and power supply fan.

506499 With 55mm cable.

Speaker, low range

(SPEAKER YD66-5A/W55-

DP8000/8000HB Service Manual 95

505538

Page 96

JST PHR-2)

Speaker, left

(SPEAKER DSH 344 W/55MM

CABLE)

Thermal switch

(CABLE INT C13 THERMO SWITCH)

Top case

(HOUSING TOP)

Zoom ring

(ZOOM RING C13)

506536 With 210mm cable.

301572xx

4009070 Includes three speakers,

keypad, IR/speaker cable, IR

ECA and IR window.

340-1157-xx Also included with new optical

engine.

DP8000/8000HB Service Manual 96

Page 97

Hardware Kit Contents

Part Name Quantity

Front light shield 1

Kensington bracket 10

Lamp fan bracket 1

Power supply bracket 1

Handle bracket 1

Handle pin 2

Ground bracket 1

Ballast air guide 1

Optical engine air guide 1

Lamp air guide 1

M3x6 Torx screw (14) 14

M3x6 black Plastite Torx screw 9

M3.5x10 black Plastite Torx screw 4

M3x6 black Plastite Torx screw with washer 11

M3x14 black Plastite Torx screw 10

M3.5x8 black Plastite Torx screw 9

M3x8 black Plastite Torx screw 2

M3x7 black Plastite Torx screw with beveled head 13

M3x7 standoff 5

M2.5x6 black Plastite Torx screw 1

M3x6 Torx screw with waster 1

M3x12 Torx screw 5

M4x7.5 black Plastite Torx screw 5

M3x104 black Plastite Torx screw 2

.4x4x25mm spring 10

DP8000/8000HB Service Manual 97

Page 98

Standard Accessories

Below is a list of accessories packaged with the projector. See Optional Accessories on the PROXIMA

web site for a complete list of optional accessories.

Description Part Number Notes

User's Guide 801466B

Lens Cap 4009080

Remote control 420078

Lamp Module SP-LAMP-001 Installed in projector.

Computer cable 301376B

USB cable 301160

Audio/Video cable 301377A

S-video cable 301106

Power Cords (Power cord depends upon destination country)

US 300095

Europe 300093

DP8000/8000HB Service Manual 98

Loading...

Loading...