Infloor Standard Electric Cable User Manual

INSTALLATION

MANUAL

800-608-0562 www.infloor.com

Please be aware that local codes may require this product and/or the

control to be installed or connected by an electrician. Please leave this manual with the end user.

2 Infloor Installation Manual

Welcome to Infloor Electric Cable

Infloor Electric Cable is a simple, economical way to

warm any floor, and provide years of lasting comfort.

This instruction manual provides complete details, suggestions, and safety precautions for installing this floorwarming system.

Fasten the cables to the floor. Then, depending on the

floor coverings to be used, put down a layer of thin-set,

thick-set, or self-leveling mortar on top of the cables.

Finally, install the floor coverings. It’s that simple!

Table of Contents

Phase 1: Design the System ...........................3

Phase 2: Preparation...................................4

Cautions ..........................................4

Tips ...............................................5

Items Needed .....................................5

Phase 3: Inspect the Cable and Sensor ...............5

Cable and Sensor Resistance Log...................6

Phase 4: Electrical Rough-in...........................7

New Construction .................................7

Existing Construction ..............................7

Phase 5: Install the Cable..............................8

Getting Started ....................................8

General Installation ................................9

Other Installations ................................10

Final Steps........................................11

Phase 6: Finish Wiring ................................12

New Construction ................................12

Existing Construction .............................12

Phase 7: Install the Control ...........................13

Phase 8: Install the Floor Coverings .................13

Phase 9: Install Insulation ............................13

Phase 10: System Operation .........................13

Appendix 1: Types of Construction .................14

Appendix 2: Typical Electrical Wiring Diagrams ...16

Appendix 3: Connecting Multiple Cables ..........18

Appendix 4: Connecting the LoudMouth™ .........19

Appendix 5: Sample Layouts........................20

Troubleshooting Guide...............................25

Installation Facts

Time to install

An average size bathroom should take

about two hours to install the cables and

about four hours to install the electrical box,

control, and power supply.

Skill level

Installation must be performed by qualified persons, in accordance with local codes,

ANSI/NFPA 70 (NEC Article 424) and CEC Part

1 Section 62 where applicable.

Prior to installation please consult the

local codes in order to understand what is

acceptable. To the extent this information

is not consistent with local codes, the local

codes should be followed. However, electrical

wiring is required from a circuit breaker or

other electrical circuit to the control. It is recommended that an electrician perform these

installation steps. Please be aware local codes

may require this product and/or the control

to be installed by an electrician.

Expected floor temperature

The floor temperature attainable is dependent on how well the floor is insulated, the

temperature of the floor before start up, and

in the case of uninsulated slab applications,

the thermal drain of the underlying materials.

These are the three most common installations:

1. Wood framing: With the cable

installed on a well-insulated wood subfloor,

and thin-set mortar and tile on top, most

floors can be heated up to 20°F warmer than

they would otherwise be.

2. Insulated concrete slab: With the

cables installed on an insulated concrete slab,

and thin-set mortar and tile on top, most

floors can be heated up to perhaps 15°F

warmer than they would otherwise be.

3. Uninsulated concrete slab: With the

cables installed on an uninsulated concrete

slab, and thin-set mortar and tile on top, most

floors can be heated up to perhaps 10°–15°F

warmer than they would otherwise be.

Please consult a designer or the factory if

questions remain about the surface temperature that can be expected from the cables in

any particular construction. Please see “Phase

9: Install Insulation” on page 13.

Specifications:

Infloor Electric Cable is a complete heating cable consisting of a series resistance heating cable and single power

lead for easy single-point connection. The heating cable cannot be cut to fit.

Voltages: 120, 240 VAC, 1-phase

Watts: 10 W/sqft (34 Btu/h/sqft) when spaced 3 inches on center, up to 15 W/sqft (51 Btu/h/sqft) when spaced 2

inches on center (see Table 1)

Maximum heater current: 10 amps

Maximum circuit load: 15 amps

Maximum circuit protection: 20 amps breaker

GFCI: (Ground Fault Circuit Interrupter) required for each circuit (included in the Infloor control)

Listing: UL Listed for U.S. and Canada under UL 1673 and CAN/CSA C22.2 No. 130-03, File No. E185866

Application: (-X) - (see UL Label on product) For indoor floor heating application only.

Minimum bend radius: 1 inch

Maximum exposure temperature: (continuous and storage) 194ºF (90ºC)

Minimum installation temperature: 50ºF (10ºC)

(-W) - (see UL Label on product) Wet Rated for use in wet locations per this manual.

Embedded in polymer-modified cement based mortar only (see Appendix 1).

Infloor Installation Manual 3

STEP 1.1

2” spacing

NEVER use less than 2” spacing.

Phase 1: Design the System

Infloor Electric Cable should be installed in all interior floor areas that are to be

warmed. It cannot be used for exterior applications, snow melting, or in ceilings. In some applications, it can be used to heat the room as well, but in gen-

eral it is not designed for this purpose (heat-loss calculations must be made to

determine if enough heat will be provided to match the heat loss of the room).

STEP 1.1 Make a sketch of the room. Measure the total square footage of

floor area to be warmed (measurements should be made all the way to the

edge of walls, cabinets, tub, etc., for now). Keep in mind the following:

• Heatwillnotradiatebeyondabout1-1/2”oneithersideofthecable,

therefore consistent coverage is important.

• Thecablescanbeinstalledinpermanentbenchseatswithtileorstone

coverings.

• Type (-W) cables only (see UL Label on product) may be installed into

shower floors and bench seats. However, do not install them into the walls.

Consider installing a dedicated cable in the shower area separate from the

rest of the bath floor. In case there is ever a problem with the shower installation, this cable could be disconnected without loss of heat to the rest of

the floor. Acceptance of this shower application must be verified by

the local inspector or authority having jurisdiction. See Step 5.20 and

Appendix 5 for details and precautions.

• Do install cable within about 1-1/2” to 2” from a counter or vanity in the

kick-space to ensure warmth in this area.

• Do not install the cables underneath cabinets or fixtures or inside a

wall. Excessive heat will build up and cause damage.

• Do not run the cables into small closets or other confined areas where

excessive heat will build up.

• Do not install the cables closer than 6” from toilet rings to avoid

possible melting of wax rings.

• Do not cross expansion joints. Install the heating wires 4” to 6” away from

the perimeter walls of the room. This will help avoid locating heating wire

underneath finish trim.

2-1/2” spacing

3” spacing

NEVER exceed 3” spacing.

Small bath design

5 ft

2 ft

Sink

Gross Room Area: 8 x 5 = 40 sf

Built-in Areas

Total Heated Area: 40 - (10 + 12.5) = 17.5 sf

Wire Coverage: 17.5 x 0.90 = 15.75 sf

Chosen Size: 15 sf.

Toilet

Sink and Toilet: 2 x 5 = 10 sf

Bath Tub: 2.5x 5 = 12.5 sf

2-1/2 ft

Bath Tub

8 ft

STEP 1.2 Select the cable spacing. Below are typical spacings for various

types of rooms. This spacing can vary depending on the insulation of the floor

and room, and the desired effect. Never space cables closer than 2” apart; this

will cause a very hot area and may cause damage.

Typical uses:

• 2”spacing: Sunroom floors, basement slabs, and baths with exterior

walls. (NOTE: Insulation is always recommended due to high heat

losses in these areas. Performance is never guaranteed due to

construction and climate differences in these applications.)

• 2-1/2”spacing: Bathrooms, kitchens, living areas, and basements.

• 3”spacing: Hallways, entryways, and large areas with low heat loss.

STEP 1.3 Multiply the square footage measured in Step 1.1 by 0.90 to allow

for 3” spacing around the edges of the floor area. Use this resulting square

footage to select the appropriate cable from the tables on page 4.

Remember:

• Donotplaceover15ampsat120VAC(1800watts)or15amps

(3600watts)at240VACthroughacontrol.

• Selecteither120VACor240VACdependingonthepoweravailable.

DO NOT mix voltages on the same system if more than one cable is

to be installed to cover an area.

• Loadnomorethan12amps(1440watts)ona15-ampcircuitbreaker,

or 16 amps (1920 watts) on a 20-amp circuit breaker.

5 ft

• Ifyouhaveanareathatrequiresmorethan15ampsofcablestobe

controlled by one thermostat, use Infloor Relay(s) to take the

additional amp load.

• SeetheWiringDiagramsinAppendix2forhelp.

If the exact size of cable calculated is not found in the spool selection

tables on page 4, it may be necessary to adjust the warming area(s) or select

the next smaller spool size. Remember, the cable must never be cut shorter

to fit, and must be embedded completely in mortar in the floor. Be careful

not to select a spool that is too large.

STEP 1.4 Strapping is included to secure the cable to the floor. Additional

strapping can be ordered. One box contains 25 ft. of strap, enough to prepare

about 50 sq. ft. of floor at 4-ft. spacing. Strap is usually spaced every 3 to 4 ft.

Use of methods to secure the cable other than those described in this Manual

voids the Warranty and are not allowed unless authorized by the manufacturer

in writing. Do not use nails, staples, or similar.

4 Infloor Installation Manual

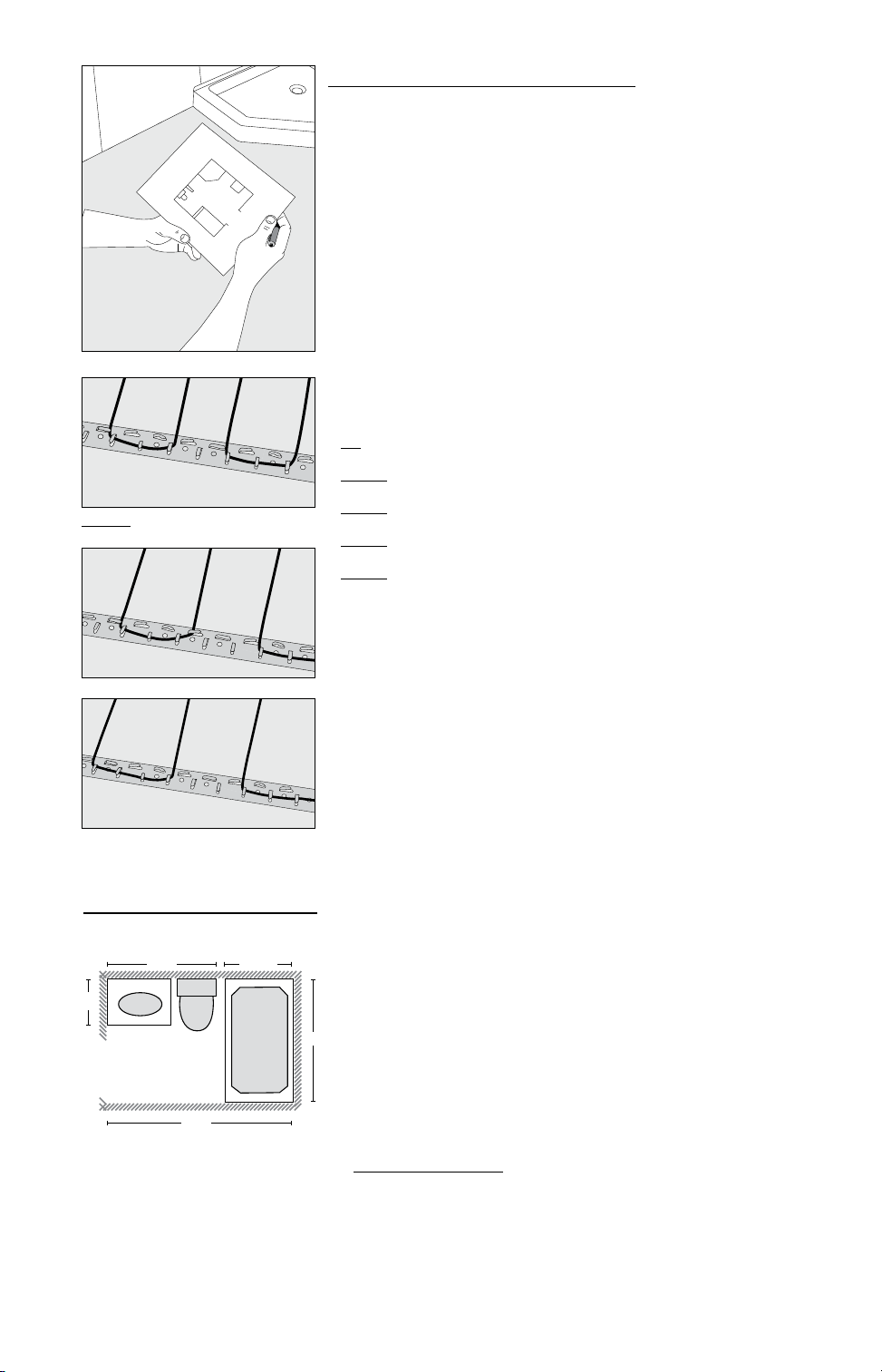

Table 1: (Cable Sizes)

120 VAC Spools

Part 2” Spacing 2-1/2” Spacing 3” Spacing Length Amperage Resistance

Number 15 watts/sq. ft. 12 watts/sq. ft. 10 watts/sq. ft. (ft.) Draw (ohms)

Example 1. There are

40 sq. ft. of bathroom

area to be warmed with

120VAC.Thecableisto

be spaced at 2-1/2” to

provide 12 watts/sq. ft.,

providing comfortable

warmth across the floor

area. As seen in Table

1, use Model Number

38606 .

Example 2. There are

270 sq. ft. of kitchen and

dining area to be warmed

with240VAC.Thecableis

to be spaced at 3” to provide 10 watts/sq. ft., providing warmth across the

entire floor area. As seen

in Table 1, choose Model

Numbers 38713 and 38700

to end up with about 264

sq. ft. covered.

38600 8 10 12 47 1.0 112–137

38601 12 15 18 71 1.5 78–96

38602 16 20 24 94 2.0 58–72

38603 20 25 30 118 2.5 44–55

38604 24 30 36 141 3.0 34–42

38605 28 35 42 165 3.5 29-36

38606 32 40 48 188 4.0 25-32

38607 36 45 54 212 4.5 22–28

38608 40 50 60 235 5.0 20-26

38609 48 60 72 282 6.0 17-22

38610 56 70 84 329 7.0 14-19

38611 64 80 96 376 8.0 12–16

38612 72 90 108 423 9.0 11-15

38613 80 100 120 470 10.0 10-13

240 VAC Spools

Part 2” Spacing 2-1/2” Spacing 3” Spacing Length Amperage Resistance

Number 15 watts/sq. ft. 12 watts/sq. ft. 10 watts/sq. ft. (ft.) Draw (ohms)

38700 16 20 24 94 1.0 223-274

38701 24 30 36 142 1.5 155-191

38702 32 40 48 188 2.0 116-143

38703 40 50 60 236 2.5 88-109

38704 48 60 72 282 3.0 68-84

38705 56 70 84 330 3.5 58-72

38706 64 80 96 376 4.0 51-63

38707 72 90 108 424 4.5 45-56

38708 80 100 120 470 5.0 41-51

38709 96 120 144 564 6.0 34-42

38710 112 140 168 658 7.0 29-36

38711 128 160 192 752 8.0 25-32

38712 144 180 216 846 9.0 22-28

38713 160 200 240 940 10.0 20-26

Total Sq. ft. Total Sq. ft. Total Sq. ft. Wire

Total Sq. ft. Total Sq. ft. Total Sq. ft. Wire

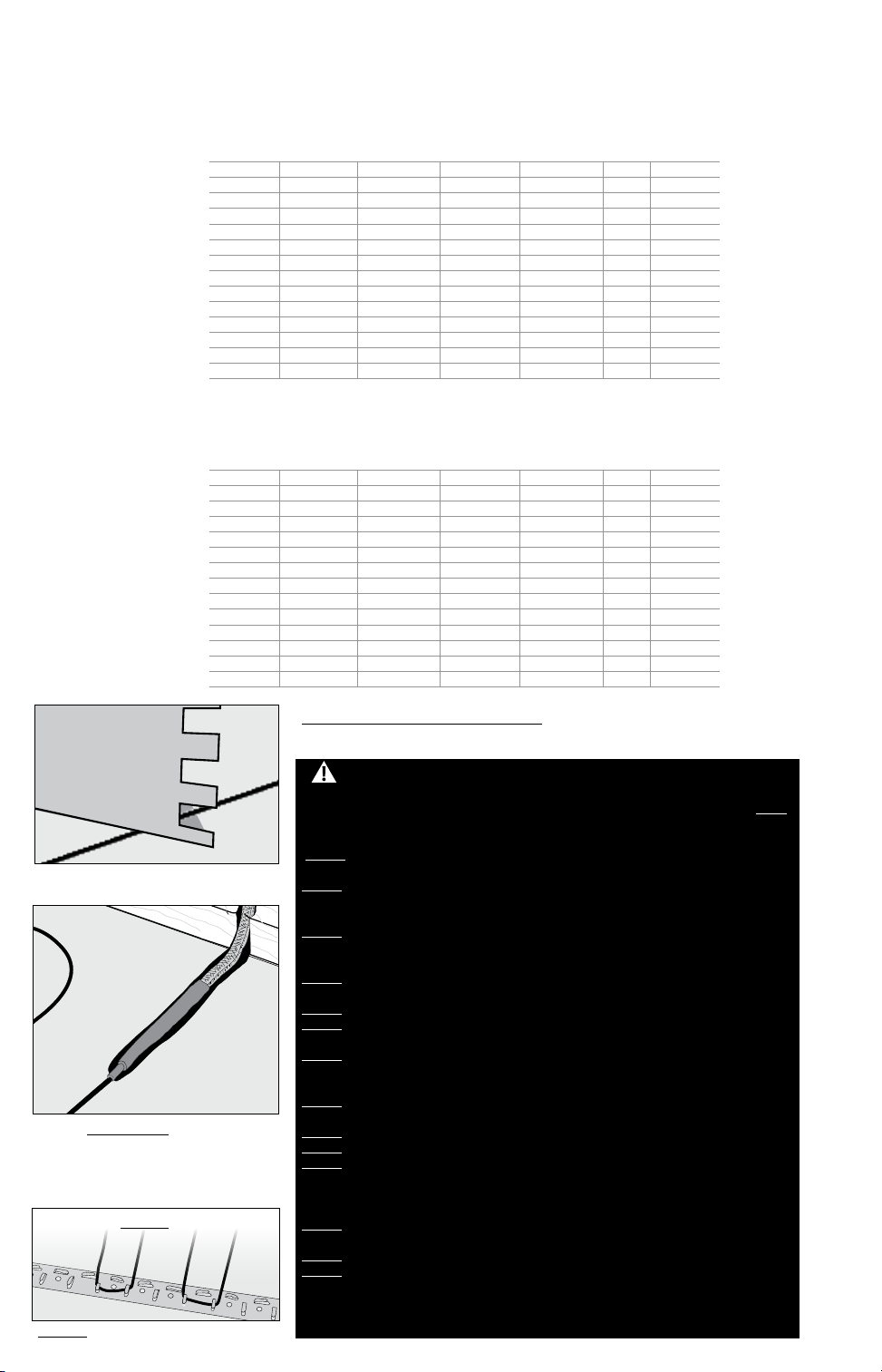

NO!

NEVER bang a trowel or other

tool on the heating cable.

ALWAYS!

Always completely embed the

factory splice and all heating wire

in mortar. NEVER bend the splice

or place any part of it in the wall

or through the floor.

NEVER use 1” spacing

NO!

Phase 2: Preparation

Table 2 - Cautions

CAUTION!

As with any electrical product, care should be taken to guard against the potential risks of fire, electric shock, and injury to persons. The following cautions must

be observed:

NEVER install under carpet, wood, vinyl, or other non-masonry flooring without

embedding it in thin-set, thick-set, or self-leveling mortar.

NEVER install in adhesives or glues intended for vinyl tile or other laminate floor-

ing, or in pre-mix mortars. It must be embedded in polymer-modified, cement

based mortar.

NEVER cut the heating wire. Doing so will cause dangerous overheating and will

void the warranty. The power lead may be cut shorter if necessary, but never

remove completely from the heating wire.

NEVER bang a trowel or other tool on the heating wire. Be careful not to nick, cut,

or pinch the wire causing it to be damaged.

NEVER use nails, staples, or similar to fasten the heating wire to the floor.

NEVER attempt to repair a damaged heating wire, splice, or power lead using

unauthorized parts. Use only factory authorized repair parts and methods.

NEVER splice one heating wire to another heating wire to make it longer.

Multiple power leads must be connected in parallel in a junction box or to the

thermostat.

NEVER install one heating wire on top of another or overlap the heating wire on

itself. This will cause dangerous overheating.

NEVER forget to install the floor sensor included with the thermostat.

NEVER install in any walls, or over walls or partitions that extend to the ceiling.

NEVER install under cabinets or other built-ins having no floor clearance, or in

small closets. Excessive heat will build up in these confined spaces, and the

heating wire can be damaged by fasteners (nails, screws, etc.) used to install

built-ins.

NEVER remove the nameplate label from the power leads. Make sure it is viewable

for inspection later.

NEVER extend the heating wire beyond the room or area in which it originates.

NEVER allow a power lead or sensor wire to cross over or under a heating cable.

Damage could result.

NEVER use less than 2” spacing.

ALWAY S

Infloor Installation Manual 5

AL WAY S completely embed the heating wire and factory splices in the floor mortar.

AL WAY S maintain a minimum of 2” spacing between heating wires.

AL WAY S pay close attention to voltage and amperage requirements of the breaker,

thethermostat,andtheheatingwire.Forinstance,donotsupply240VACpower

to120VACwireasdamagewillresult.

AL WAY S make sure all electrical work is done by qualified persons in accordance

with local building and electrical codes, Section 62 of the Canadian Electrical Code

(CEC) Part I, and the National Electrical Code (NEC), especially Article 424.

AL WAY S use copper only as supply conductors to the thermostat. Do not use alumi-

num.

AL WAY S seek help if a problem arises. If ever in doubt about the correct installation

procedure to follow, or if the product appears to be damaged, the factory must be

called before proceeding with the installation.

Some Tips

Trowel. Use a plastic trowel to reduce the possibility of cable damage.

Insulation. The better insulation that is provided, the more efficiently

the system operates, and the better the floor is heated. Concrete slab surfaces offer the most thermal drain and should be insulated before applying

the cables, if at all possible. See “Phase 9: Install Insulation” as well as the

cross sections in Appendix 1.

Controls. The Infloor controls will provide direct floor-warming control

for better comfort. Other controls are not approved for use with Infloor

Cables.

Mortars. Self-leveling mortars are becoming more popular to use

because of their ease of application over the cables. If laying tile, another

layer of thin-set will need to be applied in order to lay the tile. Always

use polymer-modified cement-based mortar. Do not use solvent-based

adhesives or pre-mixes because they are not as heat resistant.

LoudMouth

the cable during installation. The LoudMouth stays connected to the power

leads throughout cable and tile installation. A small screwdriver for connecting the leads is included with the LoudMouth monitor.

™

. The LoudMouth sounds an alarm if damage occurs to

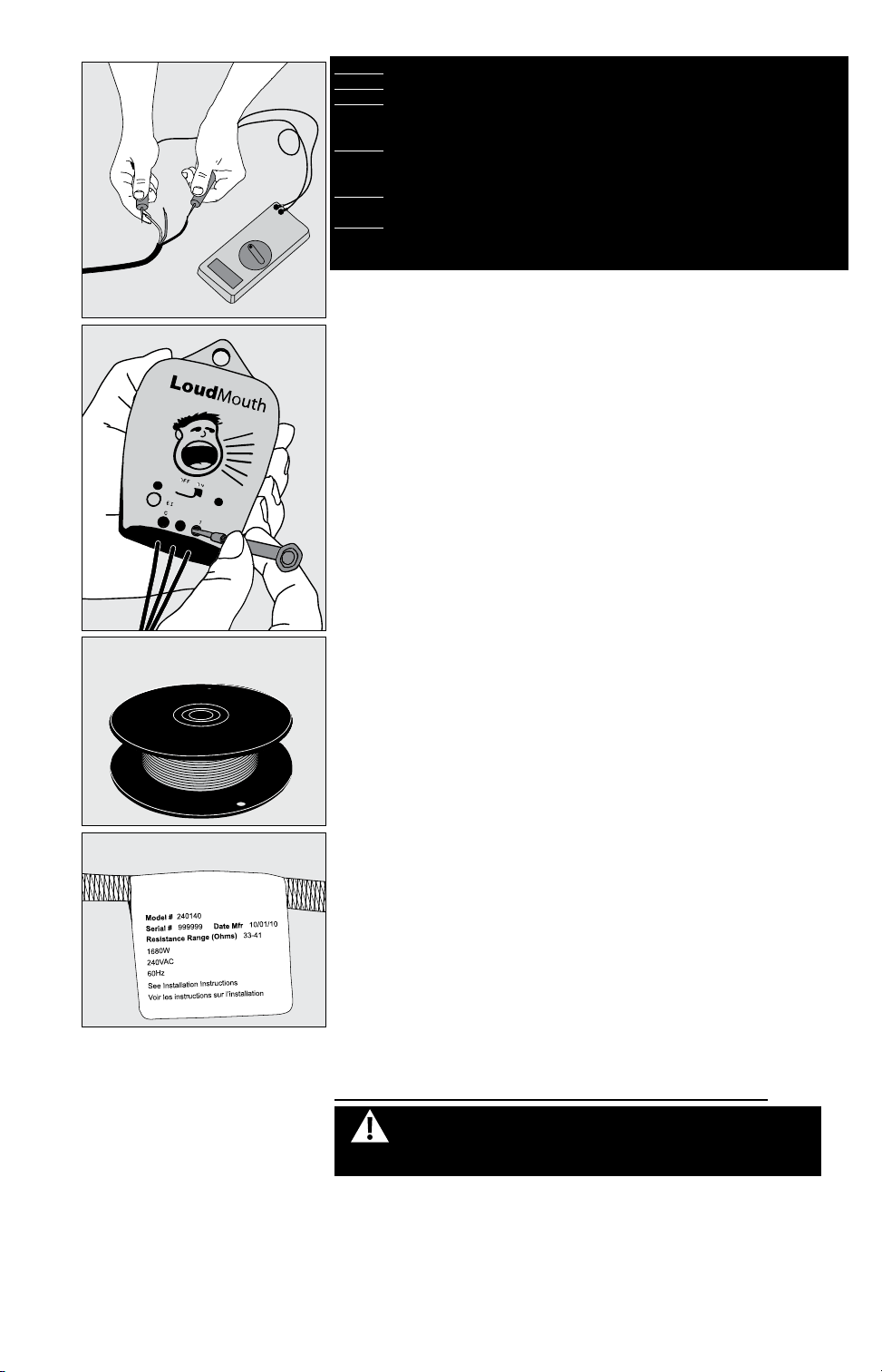

STEP 3.1

STEP 3.2

Items Needed

Materials:

• Infloor Electric Cable system

• Strapping (provided with cable)

• Thermostatcontrolwithfloorsensor

• 20-ampcircuitbreaker(singlefor120-VACanddualfor240-VAC

systems)

• Electricalbox(extradeep)forthecontrol;single-gang(notagangable

type) or 4”-square deep box with a single-gang “mud ring” cover

• 4”junctionboxwithacover,ifneeded

• Cableclampsforjunctionbox(fornewconstruction)

• Flexibleorrigidconduit(fornewconstruction)

• InfloorSensorTubep/n29011

•12-gaugeor14-gaugeelectricalwiringcable(consultlocalcode)

• Wirenutsifusingajunctionbox

• Nailplate

• Polymer-modifiedcementbasedmortar

Tools:

• Digitalmulti-meter[forohmstesting;mustreadupto20,000ohms(Ω)

to measure sensor]

• Drillwith1/2”bit

• Hammerandchisel

• Wirestrippers

• Phillipsscrewdriver

• Fishtape(forexistingconstruction)

• Holesaw(forexistingconstruction)

• Trowel(plasticpreferred)with3/8”notches(orgreater)

Phase 3: Inspect the Cable and Sensor

WARNING: To prevent the risk of personal injury and/or death, make

sure power is not applied to the product until it is fully installed and

ready for final testing. All work must be done with power turned off

to the circuit being worked on.

STEP 3.1 Take the cable out of the box and inspect it to make sure

thereisnovisibledamage.Verifyeverythingisthecorrectsizeandtype

according to the plan and the order. Do not attempt to install a damaged

product.

STEP 3.2 Record the product information. There is a factory-applied

nameplate label on the power leads. Do not remove this label. Record the

cable serial number, model number, voltage, and cable resistance range in

the Cable and Sensor Resistance Log (Table 4). If installing more than one

cable, do this for each of them.

6 Infloor Installation Manual

Ground Lead

200 ohm setting

Ground Lead

Ground Lead

White or Blue Lead

Black Lead

Black wire to COM

Red wire to Ω

White or Blue Lead

Black Lead

White or Blue Lead

Black Lead

IMPORTANT! To retain the Limited Warranty, the following measurements

must be recorded, and all steps of this manual followed.

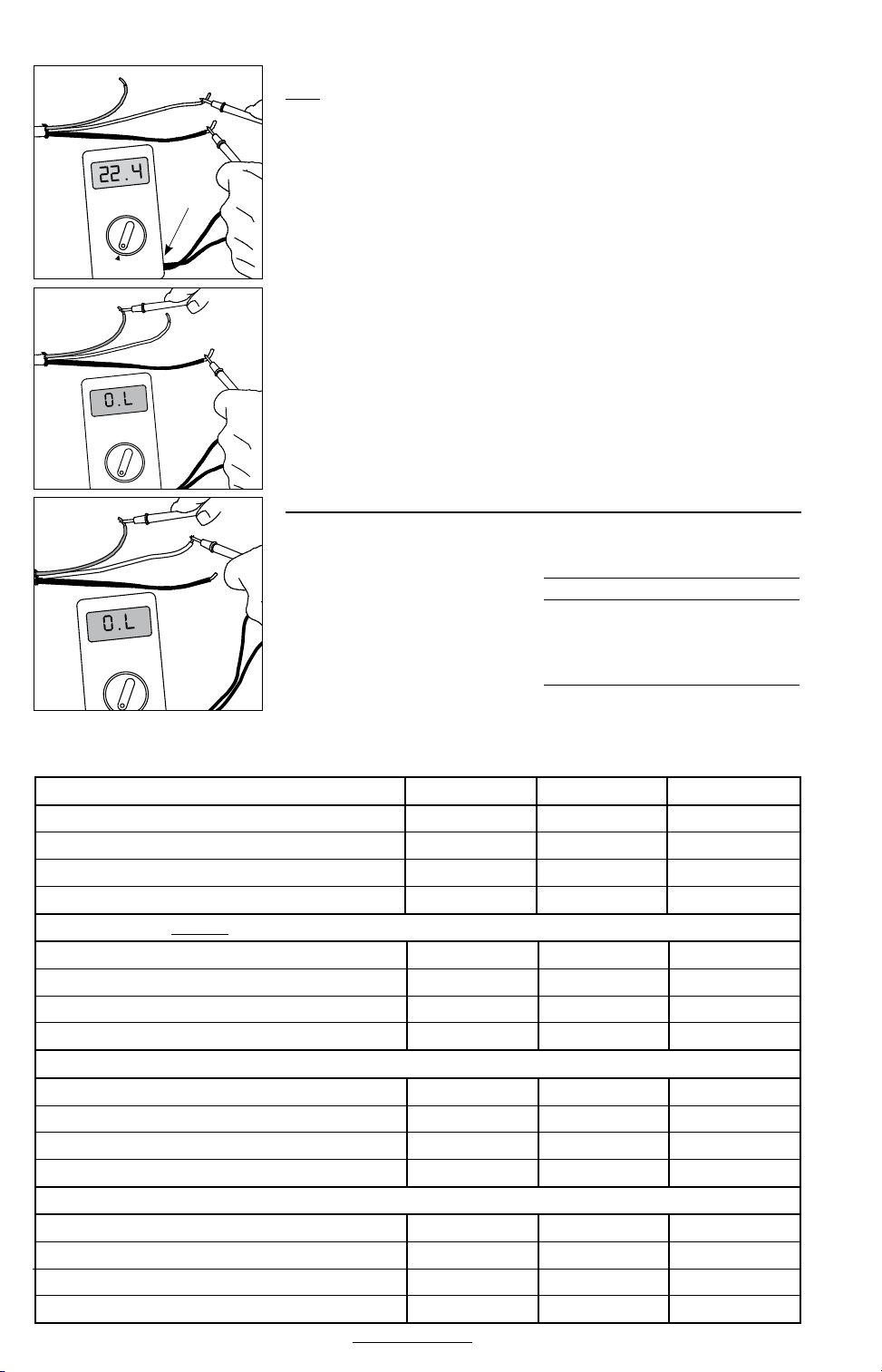

STEP 3.3 Use a digital multi-meter set to the 200Ω or 2000Ω (2kΩ) range

to measure the resistance between the black and white wires of the cable

powerleads(orblackandbluewiresfor240VAC).Recordtheseresistances

in Table 4 under “Out of the box before installation”. The resistance should

measure within the resistance range on the nameplate label. If it is a little

high or low, it may be due to air temperatures or meter calibration. Consult

the factory if in doubt.

Measure the resistance between either of the white or black leads and

ground lead. This measurement should be “open”, usually indicated by an

“OL” or a “I”. This is the same as displayed when the test leads are not touching anything.

If there is any change in the reading, record this information and contact

the factory before continuing. This could indicate damage, test lead problems, or a number of other issues. Try “pinning” the test leads to the cable

lead wires against a hard non-metal surface if the readings continue to

fluctuate.

Change the meter to the 20,000 ohms (20 kΩ) range. Measure between

the lead wires of the Infloor control sensor. This resistance varies according

to the temperature sensed. Table 3 provides approximate resistance-totemperature values for reference.

Press the test lead tips to the Black and

White (or Blue for 240 VAC) power lead

wires. This reading should correspond to

the factory resistance range on the nameplate label attached to the Power lead.

Readings between the Black and Ground

and the White (or Blue for 240 VAC) and

Ground power lead wires should measure

“open”, or “O.L”, or the same as displayed

when the test leads are not touching

anything.

Table 3::

Floor Sensor Resistance Values

Temperature TypicalValues

55°F (13°C) 17,000 ohms

65°F (18°C) 13,000 ohms

75°F (24°C) 10,000 ohms

85°F (29°C) 8,000 ohms

Table 4: Cable and Sensor Resistance Log

CABLE 1 CABLE 2 CABLE 3

Cable serial number

Cable model

Cable voltage

Factory cable resistance range

OUT OF THE BOX BEFORE INSTALLATION (ohms)

Cableblacktowhite(blacktobluefor240VAC)

Cable black to ground

Cablewhitetoground(bluetogroundfor240VAC)

Sensor wire

AFTER CABLE AND SENSOR ARE FASTENED TO FLOOR (ohms)

Cableblacktowhite(blacktobluefor240VAC)

Cable black to ground

Cablewhitetoground(bluetogroundfor240VAC)

Sensor wire

AFTER FLOOR COVERINGS ARE INSTALLED (ohms)

Cableblacktowhite(blacktobluefor240VAC)

Cable black to ground

Cablewhitetoground(bluetogroundfor240VAC)

Sensor wire

RETAIN THIS LOG TO RETAIN THE WARRANTY! DO NOT DISCARD!

Infloor Installation Manual 7

STEP 4.2

Install an extra-deep single-gang

box if connecting one or two cables

to the control. Use a 4”-square deep

box with a single-gang mud ring

cover if connecting three cables,

because the extra room is needed

for the wire, wire nuts, and control.

STEP 4.5

Phase 4: Electrical Rough-in

See wiring diagrams in Appendix 2 for different voltages and applications.

For additional help see www.infloor.com.

New Construction (see below for existing construction)

OVERVIEW We recommend the floor-warming system be installed on a

dedicated circuit coming directly from the circuit breaker panel. Follow

all National Electric Code (NEC), Canadian Electrical Code (CEC), and other

local electrical code requirements when installing this system. Work

should be done with great care and with the power turned off to the

circuit being worked on.

STEP 4.1 Install a maximum 20-amp circuit breaker(s) into the breaker

panel,dependingontheloadofthesystem.Usea120-VACsingle-pole

breakerfora120-VACsystem.Usea240-VACdouble-polebreakerfora240VACsystem.

For systems that are too large to directly power through one control

but must be operated by one floor-sensing control, use a Infloor control in

combination with up to 10 Infloor Relay Controls. Contact the dealer or the

factory for more information.

STEP 4.2 Install an electrical box for the control. If installing one to two

cables, use an extra-deep single-gang box to allow plenty of room for the

wiring. Use a 4”-square box if installing three cables. The box can be located

almost anywhere that is well ventilated. However, the best place is in the

same room as the cable, typically about 60” above the floor, and within

reach of the power lead wires of the cable. If installing more than three

cables, it will be necessary to connect their power leads in a junction box

first (see Step 4.4) to keep from overfilling the control electrical box. Then

route one power supply from this junction box to the control box.

See Step 5.22 for special requirements if the control will connect to a

heating cable entering a shower area.

STEP 4.3 Following code, feed 14- or 12-gauge NM type electrical wiring

from the circuit breaker panel to the control electrical box. Leave about

6”–8” of extra wire extended from the box to work with.

STEP 4.4 If the control box must be mounted in a location that is too far

to reach with the power lead wires, it will be necessary to mount a junction

box where the lead wires can be terminated. Use a standard junction box

with a cover, mounting it below the floor, in the attic, or in another easily

accessible location. It must remain easily accessible and not located behind

a wall, cabinet, or similar obstruction. Then use 14- or 12-gauge NM type or

other accepted electrical wiring to connect from the junction box to the

control box.

STEP 4.5 Drill two 1/2” holes in the baseplate directly below the control

electrical box. Then, as close to the floor surface as possible, drill two

horizontal holes, intersecting the top holes.

STEP 4.6 If conduit is required by local electrical code, cut a length of

1/2” to 3/4” electrical conduit to run from the control box down to the baseplate. At the baseplate it may be necessary to chisel out more of the wood

to make it easier to feed the wires up through the conduit.

STEP 4.7 Mark the circuit breaker in the panel which feeds the system

with “Floor warming/bath” or similar description.

Existing Construction

OVERVIEW It is recommended that the system be installed on a separate,

dedicated circuit coming directly from the breaker panel. In existing construction, however, it may be difficult to do this depending on the location

of wiring and the breaker panel. Tapping off an existing circuit may be possible, but only if there is enough load capacity to handle both the system

and any additional loads that may be placed on the circuit. Keep in mind

that typical hair dryers can pull up to 10 amps (1200 watts) of load.

Follow all NEC, CEC, and other local electrical code requirements when

installing this system. Work should be done with great care and with the

power turned off to the circuit being worked on.

8 Infloor Installation Manual

STEP 4.9

STEP 4.10

STEP 4.11

STEP 4.8 Install a maximum 20-amp circuit breaker(s) into the breaker

panel,dependingontheloadofthesystem.Usea120-VACsingle-pole

breakerfora120-VACsystem.Usea240-VACdouble-polebreakerfora

240-VACsystem.

For systems that are too large to directly power through one Infloor

Control but must be operated by one floor-sensing control, use a Infloor

Control in combination with up to 10 Infloor Relay Controls. Contact the

dealer or the factory for more information.

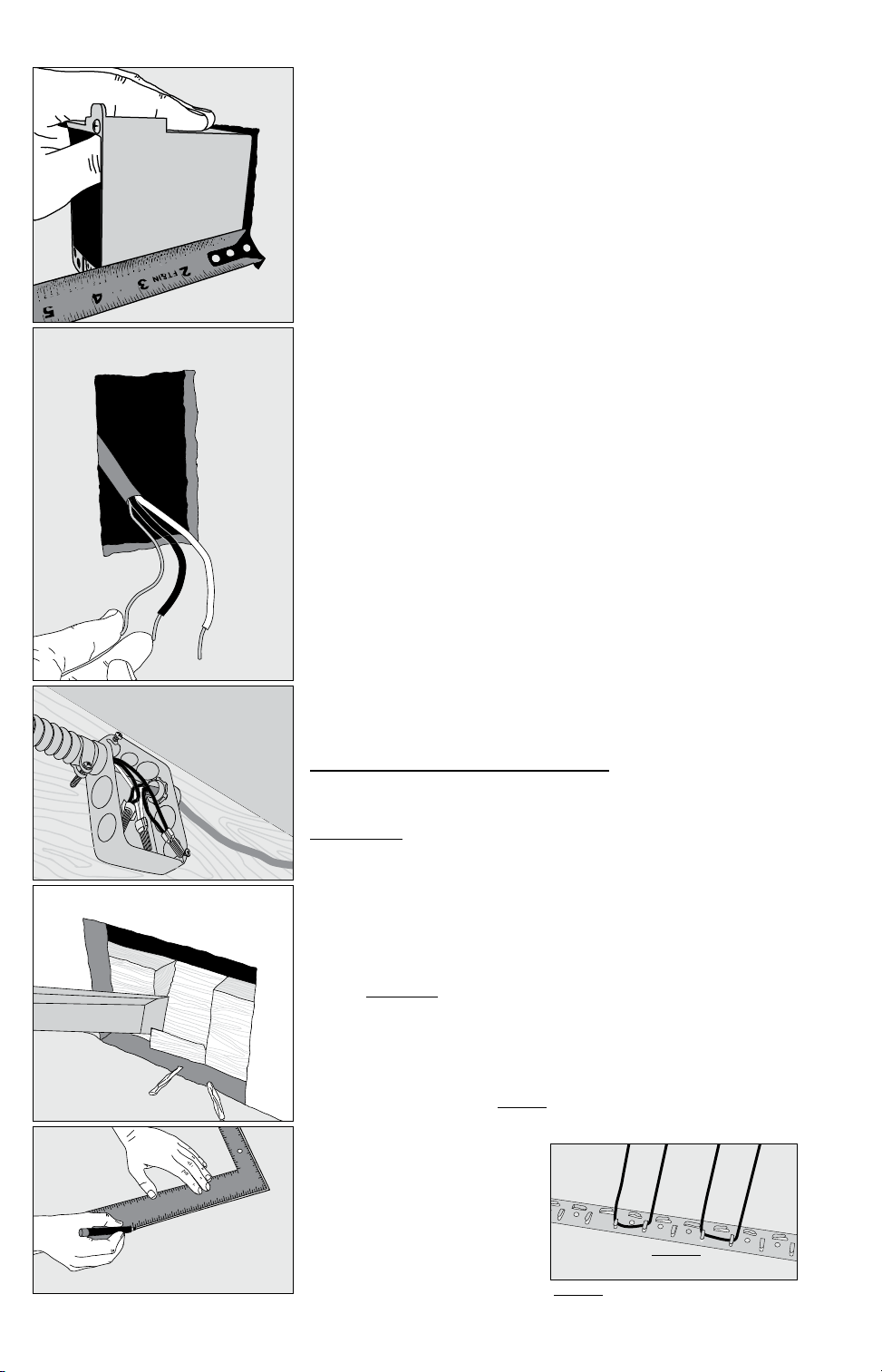

STEP 4.9 Cut an opening in the wall for the control electrical box.

If installing one to two cables, use an extra-deep single-gang box to

allow plenty of room for the wiring. Use a 4”-square box if installing

three cables. The box can be located almost anywhere that is well ventilated. However, the best place is in the same room as the cable, typically

about 60” above the floor, and within reach of the power lead wires of

the cable. If installing more than three cables, it will be necessary to

connect their power leads in a junction box first (see Step 4.11) to keep

from overfilling the control box. Then route one power supply from this

junction box to the control box. See Step 5.22 for special requirements

if the control will connect to a heating cable entering a shower area.

STEP 4.10 Following code, feed 14- or 12-gauge NM type electrical

wiring from the circuit breaker panel to the control electrical box

opening. Leave about 6”–8” of extra wire extended from the opening.

STEP 4.11 If the control box must be mounted in a location that is

too far to reach with the power lead wires, it will also be necessary to

mount a junction box where the lead wires can terminate. Use a

standard junction box with a cover, mounting it below the floor, in

the attic, or in another easily accessible location. It must remain easily

accessible and not located behind a cabinet or similar obstruction. Then

use 14- or 12-gauge NM type or other accepted electrical wiring to connect from the junction box to the control electrical box.

STEP 4.12 At the floor level below the control box, cut a 2”x 2”-wide

piece from the wall surface. Use a wood chisel to notch out a channel in

the baseplate to make it easier to route the wires up the wall.

STEP 4.13 Mark the circuit breaker in the panel which feeds the

system with “Floor warming/bath” or similar.

STEP 4.12

STEP 5.3

Phase 5: Install the Cables

Getting Started

IMPORTANT! Refer to Phase 8 and Appendix 1 to make sure the

floor is properly prepared for installation of the cable(s), especially

the use of reinforcement, leveling, and insulation on concrete slab.

STEP 5.1 Use the sketch and design considerations made earlier in

Phase 1 to begin laying the cables. Do not install the cables closer

than about 6” from wax toilet rings and plumbing to keep from overheating these items.

STEP 5.2 Make sure to space the cables to provide the warmth

desired. WARNING This heating cable CANNOT be cut shorter to fit! Do

not overlap or cross over heating cable on itself. Do not space heating

cables less than 2” apart. Failure to do so may result in damage to the

product and dangerous overheating.

STEP 5.3 If this is new construction, draw lines on the floor or use templates to outline the area of any cabinets, fixtures, or future walls that

will be placed in the room. NEVER install the cables under cabinets,

fixtures, or walls. Excess heat may build up under these items and cause

damage.

STEP 5.4 Decide which direction the cables will run on the

floor for the easiest coverage.

Refer to the sample layouts

in this manual for assistance.

Depending on the shape of the

area, it may help to think of it in

terms of several smaller areas.

NO!

NEVER use less than 2” spacing.

NEVER

use 1” spacing

Infloor Installation Manual 9

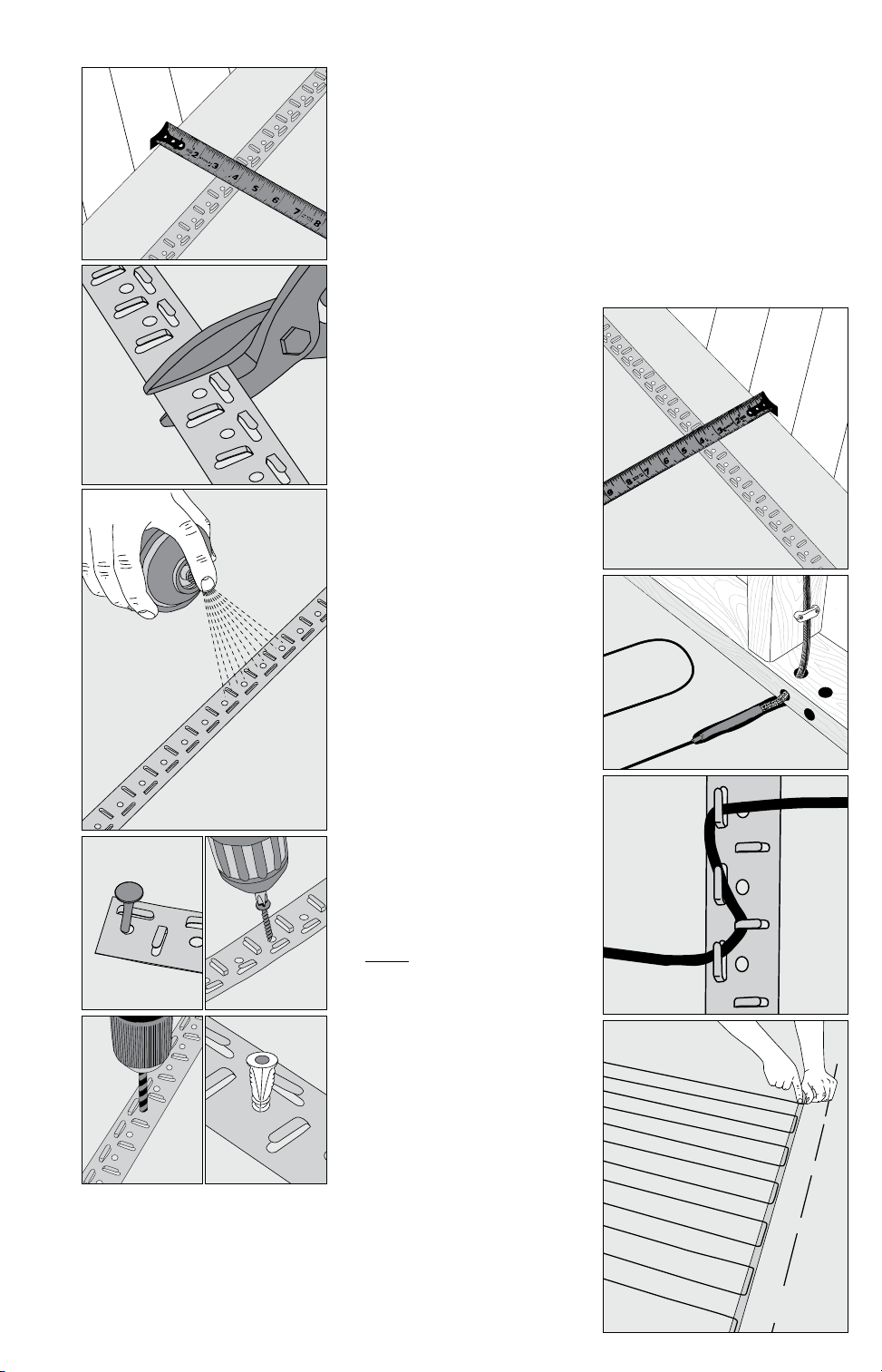

STEP 5.5

STEP 5.7

STEP 5.6

General Installation

STEP 5.5 Measure about 3” from the wall for the strap. In counter or vanity

kick-spaces, install the strap so the cable will be 1-1/2” to 2” away from the

vanity base.

STEP 5.6 Cut the strap to fit the length of the first area.

STEP 5.7 Secure the strap to the floor. Depending on the floor type, differ-

ent methods may be used. Refer to the instructions provided with the strap

for full details.

· Plywood, cement board, or similar: Galvanized nails or screws may be

used to secure the strap every 6” to 10”.

· Concrete or similar: Concrete nails or similar. Double-sided tape (if

factory supplied with your cable), hot glue, or strong spray adhesive may

be used if the floor is well cleaned

and the strap is wiped free of any oils.

However, it is highly recommended to

also screw the strap down in several

places to ensure it does not come

loose. If using a strong spray adhesive,

apply to both the back of the strap

and the floor where it will be placed,

and carefully follow all spray manufac-

turer’s instructions and cautions.

STEP 5.8 Cut another piece of strap

for the other end of the area and

secure 3” from the wall(s) or other

obstruction(s).

STEP 5.9 Unreel the power leads of

the cable up to the factory splice. Let

the coil of power leads sit on the floor

for now. Beyond the factory splice is

the heating cable itself. Factory splice

must be installed in the mortar bed.

CAUTION: Completely embed the

factory splices and heating cable in

the mortar, and never bend the fac-

tory splices. NEVER allow any part of

the splice or heating cable to enter a

wall or drop through the subfloor.

STEP 5.8

STEP 5.9

STEP 5.10 Before installing more

strap, fill in the first section with cable.

Begin by making a “strain-relief” at the

beginning so the cable is not acciden-

tally pulled loose. Zigzag the cable

under the tabs only as shown. Press

the tabs down to secure the cable.

STEP 5.11 Weave the cable back and

forth across the area at the desired

spacing until the other side of the

room has been reached. Once this

area is completed, press down all the

tabs. NEVER space the cables less than

2” apart.

STEP 5.12 If there are additional

areas to cover with cable, cut the

lengths of strap necessary, attach

them to the floor, and begin weaving

the cable into that area.

STEP 5.10

STEP 5.11

Loading...

Loading...