Page 1

Pre-assembled distribution manifolds

for radiant panel systems

Function

Distribution manifolds for radiant panel systems are used to

optimally distribute the heating uid in oor heating system circuits

and ultimately improve the control of heat emission from the panels.

The manifolds ensure that the ow to each circuit is regulated

precisely and also control the shut-o, venting and automatic

removal of air from the system.

Special solutions devised during sizing have also enabled depth to

be reduced and connection between manifold and branches

facilitated.

Reference Documents

Product guides for additional components, such as thermal

actuators, ow meters, pressure dierential bypass valves

and darcel ttings.

range

Product

Pre-assembled distribution manifold for radiant panel systems Sizes 1” and 1 1/4”

Technical specication

Materials:

Flow manifold

- body: brass EN 1982 CB753S

Micrometric balancing valve

- body: PA

- control device upper part: brass EN 12164 CW614N

- obturator: POM

- obturator seal: EPDM

- knob: ABS

Return manifold

- body: brass EN 1982 CB753S

Shut-o valve

control device upper part:

-

- obturator stem: stainless steel

- obturator: EPDM

- springs: stainless steel

- seals: EPDM

- knob: ABS

Ball valve

- body: brass EN 12165 CW617N

- ball: brass EN 12164 CW614N, chrome plated

- handle: aluminium EN AB 46100

brass EN 12164 CW614N

and PA

End tting

Automatic air vent valve

- obturator stem: brass EN 12164 CW614N

- spring: stainless steel

- seals: EPDM

- oat: PP

Performance:

Medium: water, glycol solutions

Max. percentage of glycol: 30%

Max. working pressure: 10 bar

Max. end tting discharge pressure: 2,5 bar

Working temperature range: 0–80°C

Nr. adjustment curves: 10

Micrometric regulating valve scale: 0–10

Accuracy: ± 5%

Main connections: 1”, 1 1/4” F

Connection centre distance: 195 mm

Outlets: 3/4”M - Ø 18

Outlet centre distance: 50 mm

N716WC 56121 NE ssarb:ydob -

Page 2

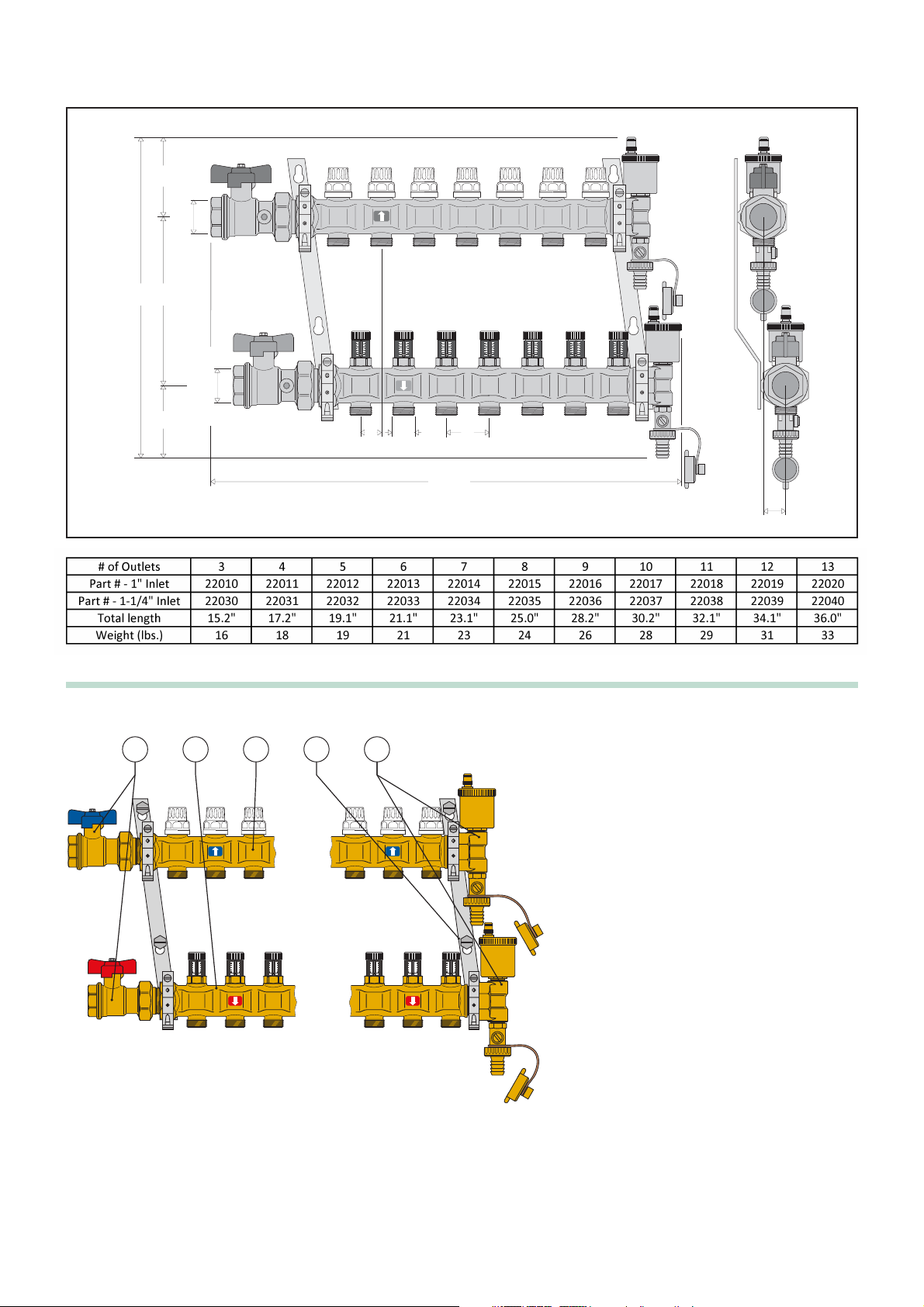

Dimensions

Characteristic components

1 Flow manifold complete with micrometric pre

regulating valves with flow curve number

indicator.

2 Return manifold complete with shut-off valves

that can be used with thermoelectric actuators.

3 Pair of shut-off ball valves

4 End fittings consisting of a 3-way end fitting,

automatic air vent valve and drain cock.

5 Pair of mounting brackets for use with series 659

boxes or direct wall installation.

383

10119587

1” o 1 1/4”

1” o 1 1/4”

10

10

10

8

8

8

6

6

6

4

4

4

2

2

2

0

0

0

25

3/4”

10

10

10

8

8

6

6

4

4

2

2

0

0

10

10

8

8

6

6

4

4

2

2

0

0

10

10

8

8

6

6

4

4

2

2

0

0

10

10

8

8

6

6

4

4

2

2

0

0

10

10

8

8

8

6

6

6

4

4

4

2

2

2

0

0

0

50

total

L

27

21345

10

10

8

6

4

2

0

10

10

8

8

6

6

4

4

2

2

0

0

10

10

8

8

8

6

6

6

4

4

4

2

2

2

0

0

0

10

10

8

6

4

2

0

10

10

8

8

6

6

4

4

2

2

0

0

10

10

8

8

8

6

6

6

4

4

4

2

2

2

0

0

0

Page 3

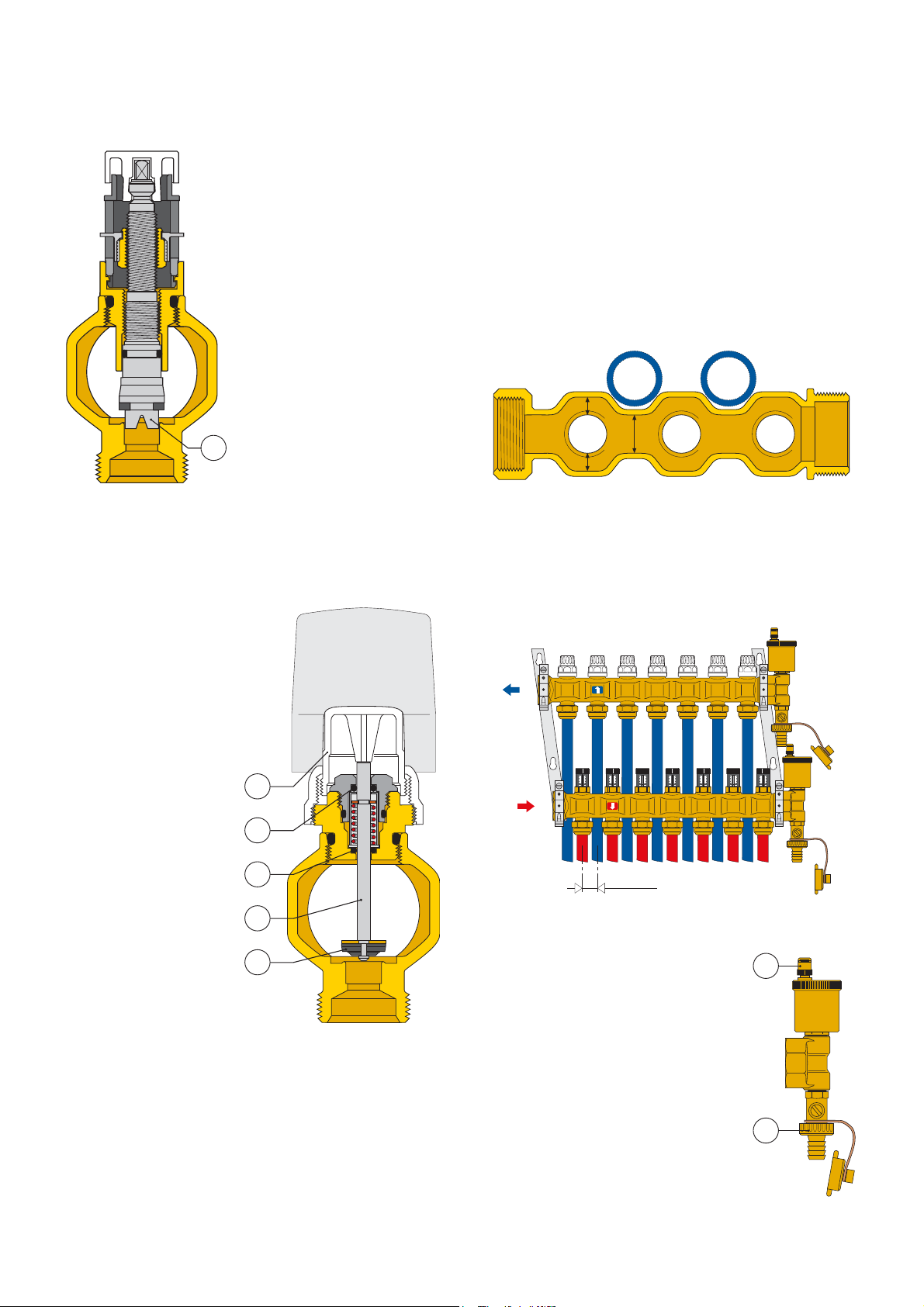

Construction details

Flow manifold

The micrometric regulating valve

obturator is made of plastic (POM)

and features an upside down V

channel (1) to provide greater

precision when regulating the flow

delivered to the floor system circuits.

This solution offers the following

advantages with respect to the

traditional conically shaped

obturator:

- greater precision, particularly for

the low flow rates usually

encountered in this kind of system.

- proportional flow rates due to the

ability to mould the fluid passage

profiles.

- absolute dimensional consistency

during manufacture due to the

die-cast obturator.

Return manifold

The return manifold is equipped with manual shut-off valves (1)

which are used to shut off the flow to individual circuits.

They can also be used with a

thermoelectric actuator

which, when used with an

ambient thermostat,

maintains the ambient

temperature at the set limits

when thermal load varies.

The obturator stem (2) is

made of polished stainless

steel to minimise friction and

prevent harmful encrustation

from forming.

The control device upper part

features a double EPDM

O-ring seal (3) – (4) on the

sliding stem.

The obturator (5) is made of

EPDM and is moulded to

optimise the hydraulic

characteristics of the valve

and reduce noise to a

minimum as the fluid

passes through and as it

gradually opens and closes

when operating with a

thermo-electric actuator.

1

Exterior shape of the manifolds and mounting brackets

The exterior of the manifold deserves special mention because it

can be cast in any shape to meet any requirements.

In the example shown below, indentations have been created in the

manifold to correspond to the plastic pipes exiting from the upper

manifold, thus partially accommodating the pipes and reducing

their overall thickness. This does not interfere with the pressure loss

values because the sections with the indentations (a) are equal to

the sections in which the pipes are branched (b) and (c) and where

the regulating parts (micrometric regulating and shut-off valve

obturators) obstruct the passage of the fluid.

b

a

c

The partial accommodation of the pipes in the indentations created

in the manifold is further enhanced by the shape of the mounting

brackets, which are slanted to create a 3/4 in. offset between the

upper and lower manifolds.

1

3

4

2

5

As shown in the figure below, this offset positions the pipes so that

they perfectly match the profile of the manifold during installation.

10

10

10

10

10

10

10

10

10

10

10

10

10

8

8

8

8

8

8

8

8

8

6

6

6

6

6

4

4

2

2

0

0

6

4

4

4

4

2

2

2

2

0

0

0

0

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

10

8

8

8

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

25 mm

End fitting and automatic air vent valve

The end fitting consists of a fill/drain cock (1)

and an automatic air vent valve with a

hygroscopic safety cap (2). It has been

specifically designed to close the air vent valve

automatically if there is water near the vent

itself.

2

1

Page 4

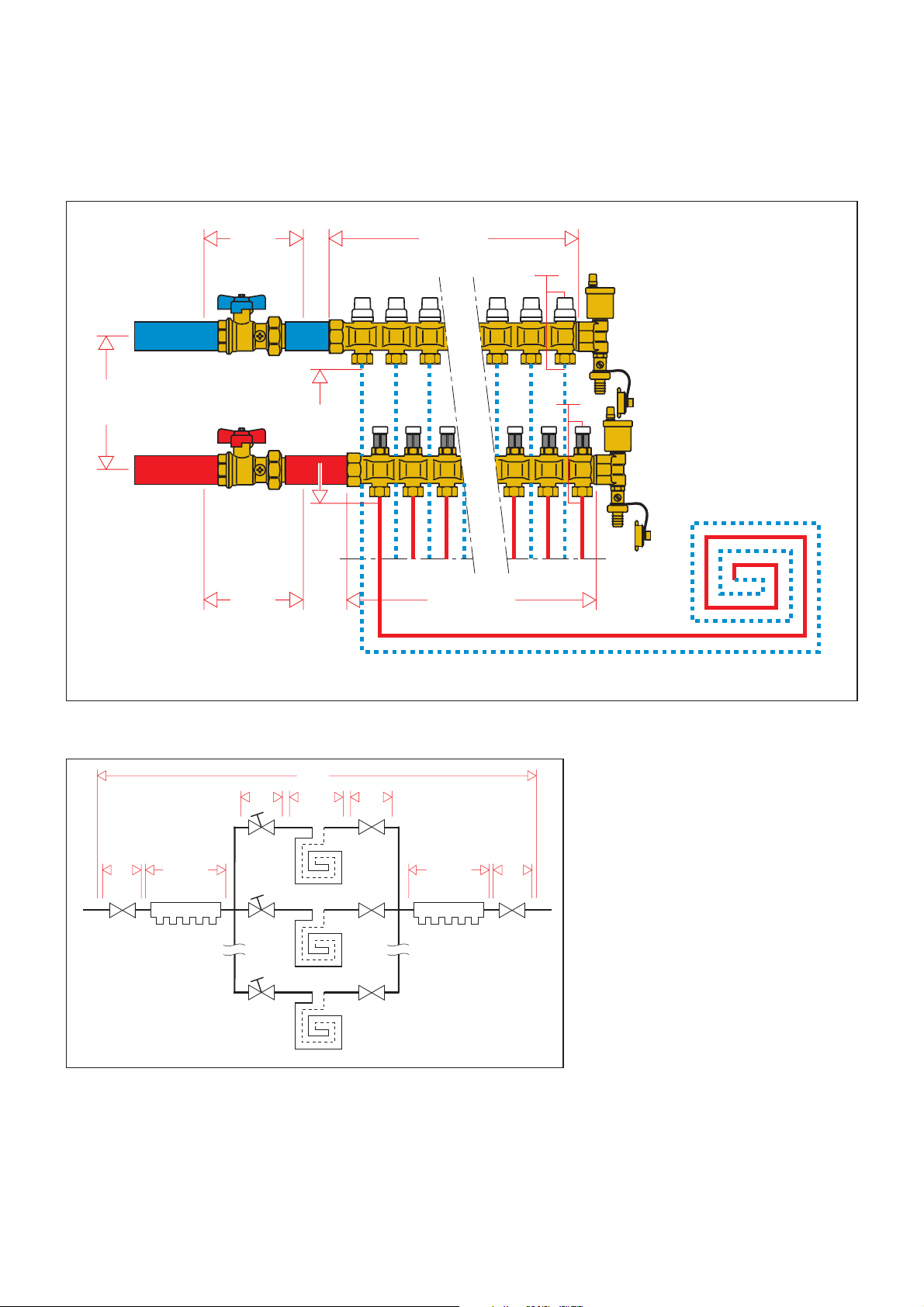

Hydraulic characteristics

To determine the hydraulic characteristics of the circuit, we must calculate the total pressure loss experienced by the flow of fluid as it passes

through the manifold unit parts and the radiant panel circuits.

From a hydraulic standpoint, the manifold unit and circuits can be shown as an assembly of hydraulic elements that are arranged in series and

parallel to each other.

ΔP

Tot = Total loss at the manifold heads

(Flow + Return + Loop)

ΔPMV = Localised loss at the micrometric

regulating valve loop (loop flow)

ΔPLoop = Loop loss (loop flow)

ΔPSV = Localised loss at the shut-off valve in the

panel circuit (loop flow)

ΔPFM = Distributed loss of the flow manifold

(total flow)

ΔPRM = Distributed loss of the return manifold

(total flow)

ΔPBV = Ball valve loss (total flow)

ΔPTo t =

ΔPMV +ΔPLoop+ΔPSV

+ ΔPFM + ΔPRM +ΔPBV x 2

After noting the hydraulic characteristics of the individual components and the design flows, the total loss can be calculated as the sum of the

partial pressure losses of each specific component in the system, as shown in the formula

(1.1)

.

ΔP

Anello

(1.1)

ΔP

BV

To t

ΔP

RM

ΔP

SV

ΔP

VM

ΔP

Loop

ΔP

G

To t

ΔP

BV

ΔP

FM

G

Loop

ΔP

Tot

ΔP

ΔP

BV

G

Tot.

ΔP

FM

MV

ΔP

Loop

ΔP

SV

G

Loop

ΔP

RM

ΔP

BV

G

Tot

Page 5

ΔP (mm w.g.)

Example of how to calculate the total pressure loss

Suppose we need to calculate the pressure loss of a manifold with three circuits with the following characteristics:

Total manifold flow: 400 l/h

The flow and pressure loss characteristics of the three piping loops are as follows:

Circuit 1 Circuit 2 Circuit 3

Δ

P1= 10 kPa

Δ

P2= 15 kPa

Δ

P3= 7 kPa

(1.2)

G1= 120 l/h G2= 200 l/h G3= 80 l/h

Each segment of the formula

(1.1)

, is calculated using the following relationship:

ΔP=G2/Kv

0,01

2

· G= flow in l/h

·ΔP = pressure loss in kPa (1 kPa =100 mm w.g.)

· K

v

0,01

= flow in l/h through the device in question, with a pressure loss of 1 kPa

Note that the

Δ

PTot must be calculated taking into account the circuit with the greatest pressure losses distributed along the entire piping loop of

the panel.

The circuit in question in our example is circuit 2.

Thus:

Δ

PMV= 2002/1152= 3 kPa

Δ

P

Loop

= 15 kPa

Δ

PSV= 2002/2872= 0,5 kPa

Δ

PFM= 4002/24002= 0,03 kPa

}

Values obtained disregarding variations due to flow rate delivered to each branch circuit

Δ

PRM= 4002/33502= 0,01 kPa

Δ

PBV= 4002/47502= 0,007 kPa

Using the formula

(1.1)

we can add all the calculated terms to obtain:

Δ

P

Tot

= 3 +15 + 0,5 + 0,03 + 0,01 + 0,0071 ≈ 18,5 kPa

Note:

We can ignore the three terms for the pressure losses associated with the ball valves and manifolds because their values are so low. Generally

speaking, the total pressure loss is fairly close to the pressure loss of the branched circuit of the panel.

- Kv = flow in m3/h for a pressure loss of 1 bar

- Kv

0,01

= flow in l/h for a pressure loss of 1 kPa

1000

900

800

700

600

500

450

400

350

300

250

200

180

160

140

120

100

90

80

70

60

50

45

40

35

30

25

20

18

16

14

12

10

20

253035404550607080

ΔP (kPa)

10

9

8

7

6

5

4,5

4

3,5

3

2,5

2

1,8

1,6

1,4

1,2

1

0,9

0,8

0,7

0,6

0,5

0,45

0,4

0,35

0,3

0,25

0,2

0,18

0,16

0,14

0,12

90

120

140

100

250

160

180

300

200

0,1

350

400

450

500

G (l/h)

ΔP (mm w.g.)

1000

900

800

700

600

500

450

400

350

300

250

200

180

160

140

120

100

90

80

70

60

50

45

40

35

30

25

20

18

16

14

12

10

500

600

700

800

900

1200

1400

1600

1800

1000

2500

2000

3000

ΔP (kPa)

3500

G (l/h)

9

8

7

6

4,5

4

3,5

3

2,5

1,8

1,6

1,4

1,2

0,9

0,8

0,7

0,6

0,45

0,4

0,35

0,3

0,25

0,18

0,16

0,14

0,12

4000

10

5

2

1

0,5

0,2

0,1

Kv

Micrometric balancing valve fully open

Shut-off valve

Kv

1,15

2,87

115

287

0,01

Flow manifold 3–7 outlets

Flow manifold 8–13 outlets

Return manifold 3–7 outlets

Return manifold 8–13 outlets

Ball valve

* Average value

Kv

24*

17*

33,5*

23,5*

47,5

Kv

0,01

2400*

1700*

3350*

2350*

4750

Page 6

Example of preregulating the valve

Suppose that we need to balance three circuits that have the same pressure loss and loop flow characteristics shown in example

(1.2)

:

Since circuit 2 is the most disadvantaged because it experienced the greatest pressure loss in the panel piping, the remaining circuits must be

adjusted as follows:

Circuit 2 Circuit 1 Circuit 3

ΔP

Loop

= 15 kPa ΔP

Loop

= 10 kPa ΔP

Loop

= 7 kPa

G2 = 200 l/h G1 = 120 l/h G3 = 80 l/h

ΔP

MV

= 2002/1152= 3 kPa

ΔP

SV

= 2002/2872= 0,5 kPa ΔP

SV

=1202/287

2

= 0,2 kPa ΔP

SV

= 802/287

2

= 0,1 kPa

With the relationship

(1.4)

: with the relationship

(1.3)

: with the relationship

(1.3)

:

ΔP

Circuit =

3 + 15 + 0,5 = 18,5 kPa

ΔPCircuit = 10 + 0,2 = 10,2 kPa ΔPCircuit = 7 + 0,1 = 7,1 kPa

+ disadvantaged

HPredetermined ≥ΔPCircuit = 18,5 kPa

+ disadvantaged

To adjust circuits 1 and 3, we need the

following information to determine the

adjustment position of the micrometric

valves:

Circuit 1

Δ

PMV1 = 8,3 kPa

G1 = 120 l/h

Adjustment position ~ 5.5

Circuit 2

Adjustment position completely open

Circuit 3

Δ

PMV3 = 11,4 kPa

G3 = 80 l/h

Adjustment position ~ 3,5

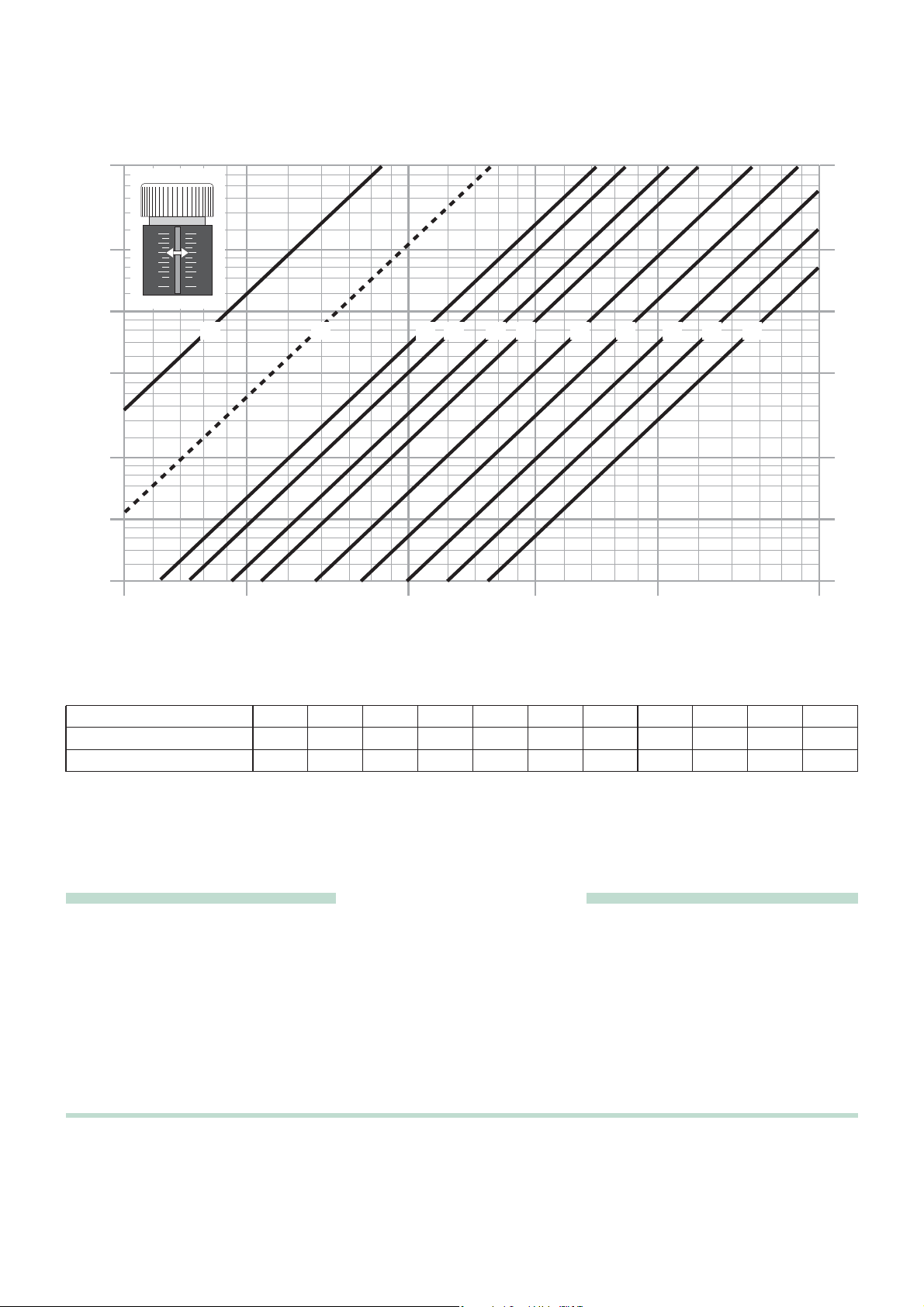

Use of the micrometric balancing valve

The micrometric balancing valves balance each individual circuit in the panels so that the actual design flow is obtained in each one.

Each individual circuit consists of a micrometric balancing valve, panel piping and shut-off valve. The following information must be taken into

account in order to calibrate the system correctly:

· The flow of fluid that must pass through each circuit (design data).

· The pressure loss that occurs in each circuit in accordance with the flow:

Δ

PCircuit = ΔPLoop + ΔPSV

(1.3)

· The available head on the panel circuit or predetermined head:

HPredetermined ≥ΔPCircuit = ΔPMV + ΔPLoop + ΔPSV

(1.4)

+ disadvantaged

In accordance with the passage of the flow GLoop the

micrometric valve must ensure an additional pressure loss

in all the circuits equal to the difference, indicated as

Δ

PMV

(Δp micrometric valve).

To allow for an eventual increase in flow, the micrometric

valve of the circuit with the greatest pressure loss may

sometimes be considered as 80% open.

Once the two pieces of information,

Δ

PMV and GLoop,

are known for each circuit, the optimal adjustment curve

corresponding to the adjustment position of the valve must

be chosen from the graph.

SV

ΔP

Tot

ΔPCircuit

HPredetermined ≥ ΔPCircuit

+ disadvantaged

MV

ΔP

MV

H

Predetermined

≥

ΔP

Circuit +

disadvantaged

ΔP

ΔP

1

ΔP

MV1

ΔP

3

2

ΔP

MV2

ΔP (mm w.g.)

5000

4500

4000

3500

3000

2500

2000

1800

1600

1400

1200

1000

900

800

700

600

500

450

400

350

300

250

200

180

160

140

120

100

90

80

70

60

50

10

ΔP (kPa)

50

45

40

35

30

10

10

8

8

6

6

4

4

2

2

0

0

1

4 5 6 7 8 9 101,5 32

12

14

16

18

25

303540

20

4550607080

90

120

140

160

100

250

180

300

200

25

20

18

16

14

12

10

9

8

7

6

5

4,5

4

3,5

3

2,5

2

1,8

1,6

1,4

1,2

1

0,9

0,8

0,7

0,6

350

0,5

400

450

500

Q (l/h)

Page 7

SPECIFICATION SUMMARIES

1

0,06

6

1,5

0,09

9

2

0,18

18

3

0,21

21

4

0,27

27

5

0,31

31

6

0,42

42

7

0,53

53

8

0,7

70

9

0,89

89

10

1,15

115

Adjustment position

Kv

Kv

0,01

Hydraulic characteristics of the micrometric valve

- Kv = flow in m3/h for a pressure loss of 1 bar

- Kv

0,01

= flow in l/h for a pressure loss of 1 kPa

ΔP (mm w.g.)

5000

4500

4000

3500

3000

2500

2000

1800

1600

1400

1200

1000

900

800

700

600

500

450

400

350

300

250

200

180

160

140

120

100

90

80

70

60

50

10

ΔP (kPa)

50

45

40

35

30

10

10

8

8

6

6

4

4

2

2

0

0

4 5 6 7 8 9 101,5 321

25

18

16

14

12

9

8

7

6

4,5

4

3,5

3

2,5

1,8

1,6

1,4

1,2

0,9

0,8

0,7

0,6

20

10

5

2

1

0,5

12

14

16

18

20

25

30

354045

50

60

70

80

90

120

140

160

180

100

200

250

300

350

400

450

500

G (l/h)

Pre-assembled distribution manifold for radiant panel systems with 3 (from 3 to 13) outlets. Brass body. EPDM seals. 1” (1” and

1 1/4”) threaded F connections. 3/4"M outlet connections. Medium: water, glycol solutions. Maximum percentage of glycol: 30%.

Maximum working pressure 10 bar. Temperature range 0–80°C. End fitting maximum discharge pressure 2,5 bar.

Consists of:

- Flow manifold complete with micrometric preregulating valves with graduated scale from 1 to10. Accuracy ± 5%.

- Return manifold complete with shut-off valves for use with thermo-electric actuator.

- Pair of end fittings consisting of a fitting with automatic air vent and drain cock.

- Pair of shut-off ball valves.

- Pair of mounting brackets.

Page 8

Dimensions

MANIFOLDS AND ACCESSORIES

Technical specification

Materials: - body: brass EN 12165 CW617N

- measuring spring: stainless steel

- seals: EPDM

- transparent cylinder and internal protection: PSU

- float-indicator: POM/PTFE

Medium: water, glycol solutions

Max. percentage of glycol: 30%

Max. working pressure: 6 bar

Temperature range: 5–80 °C

Flow measurement scale: 1–4 l/min

Accuracy: ± 10%

Dual readout scale

Connections: 3/4” M – Ø 18 x 3/4” F nut

4 11 1 25 378691013 12

40

60

20

80

0

°C

10

10

8

8

6

6

4

4

2

2

0

40

60

20

80

0

°C

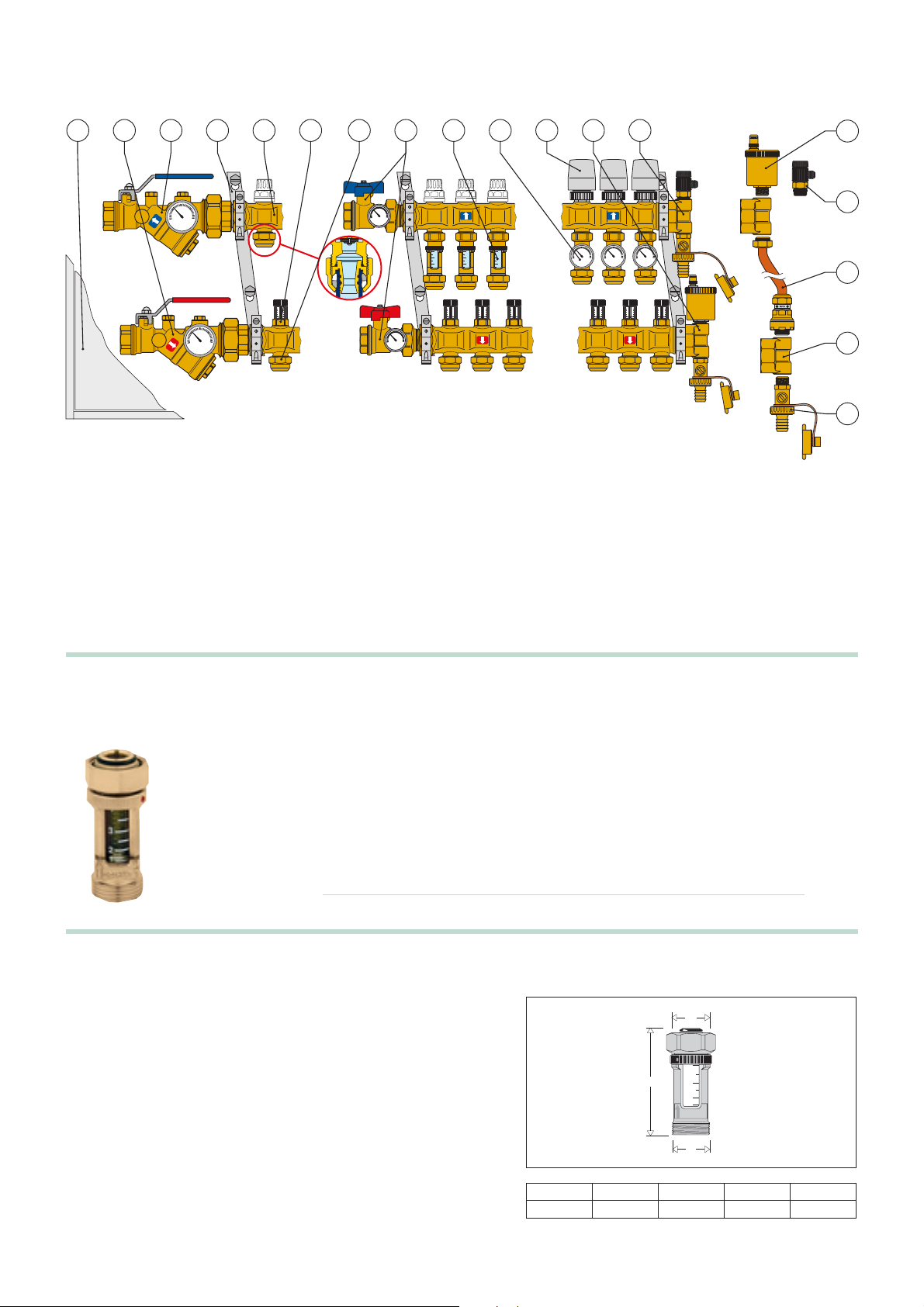

1. Manifold complete with shut-off valves

2. Manifold complete with micrometric balancing valves

3. Shut-off ball valve

4. Autoflow, series 120

5. Strainer, series 120

6. Thermo-electric actuator

7. Flow meter

8. Temperature gauge fitting

9. End fitting complete with automatic air vent valve

0

14

40

60

20

80

0

°C

40

40

60

20

80

0

°C

40

60

60

20

20

80

80

0

0

°C

°C

15

16

10

10

10

10

10

8

8

6

6

4

4

2

2

0

0

40

60

20

80

0

°C

10

8

8

8

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

10

10

10

10

10

8

8

6

6

4

4

2

2

0

0

10

8

8

8

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

17

18

10. End fitting complete with manual air vent valve

11. Pair of mounting brackets

12. DARCAL fitting

13. Inspection wall box

14. Automatic air vent valve

15. Mini drain cock

16. Eccentric bypass kit

17. Double radial end fitting

18. Drain cock

Flow meter

Function

The flow meter is a device that is mounted on the return manifold of panel systems. It instantaneously controls the actual

flow values in each individual circuit during the regulating phase, making the balancing operations of the system easier and

more accurate.

Patented

Product range

Part # 22081 Flow meter Size 3/4”

Code

22081

A

3/4"

A

4

3

C

2

1

L/MIN

B

B

3/4"

C

2.75"

Weight (lb)

1/3

Page 9

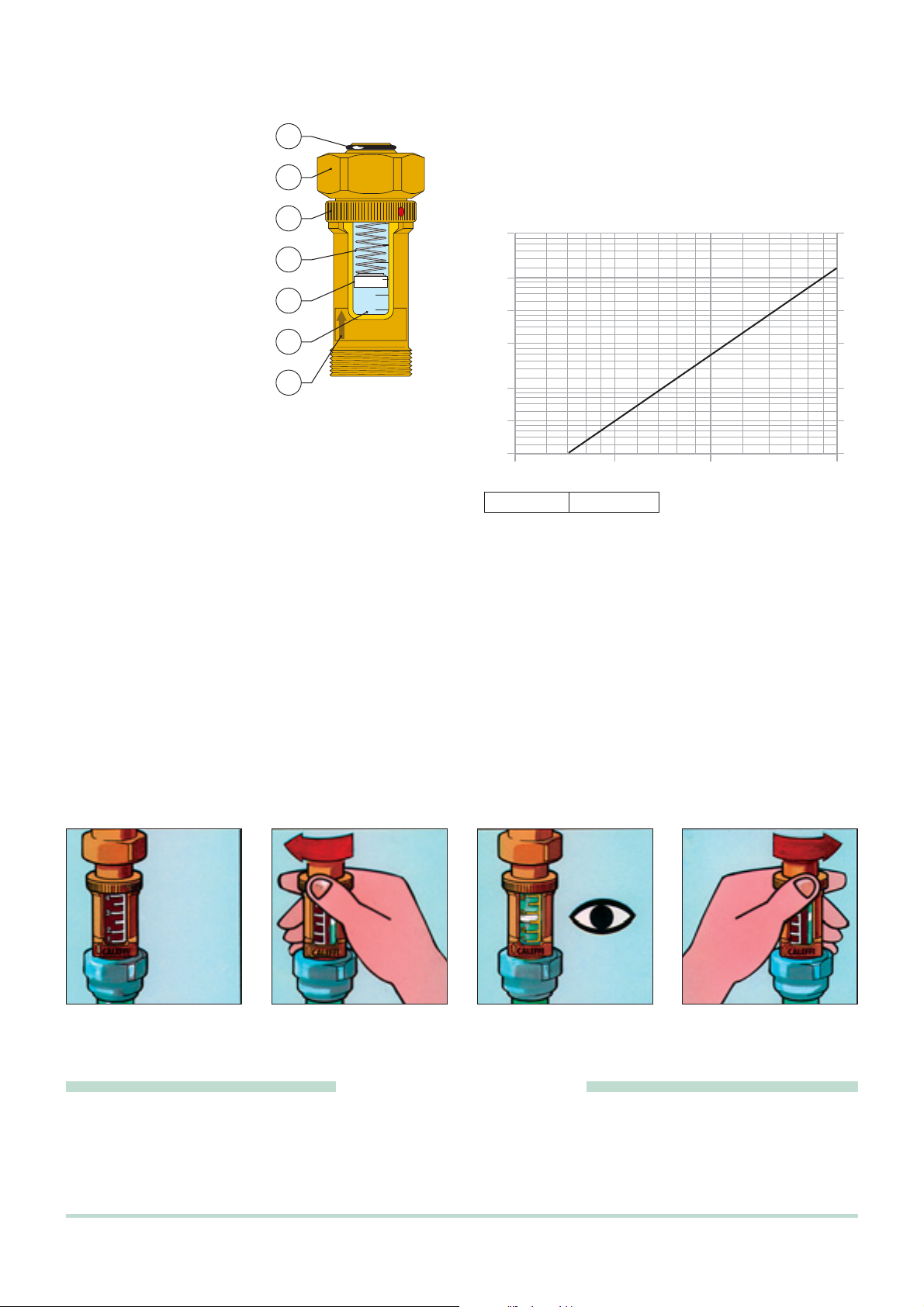

Operating principle

Installation

The flow meter must always be installed in a vertical position with

the flow indication arrow pointing up (7) to ensure the greatest

accuracy when measuring the flow.

Hydraulic characteristics

Kv = 1 Kv

0,01

= 100

- Kv = flow in m3/h for a pressure loss of 1 bar

- Kv

0,01

= flow in l/h for a pressure loss of 1 kPa

A spring (1) connected to a float

(2) is located inside the flow meter.

The force applied by the water to

the float as it flows through the

flow meter is countered in

proportion to the force applied by

the spring. When the flow

becomes stabilised at a particular

value, the float reaches a specific

position of equilibrium which also

serves as an indicator. The

system is balanced by moving the

calibration valve on the flow

manifold until it corresponds to the

design flow, which can be read on

the graduated scale printed on the

transparent cylinder (3).

The flow (gpm) readout value

corresponds to the lower edge of

the float.

5

4

6

1

2

3

4

3

2

1

L/MIN

7

ΔP (mm w.g.)

5000

4500

4000

3500

3000

2500

2000

1800

1600

1400

1200

1000

900

800

700

600

500

450

400

350

300

250

200

180

160

140

120

100

90

80

70

60

50

50

60

708090

120

100

250

140

160

180

200

300

ΔP (kPa)

50

45

40

35

30

25

20

18

16

14

12

10

9

8

7

6

5

4,5

4,0

3,5

3,0

2,5

2

1,8

1,6

1,4

1,2

1

0,9

0,8

0,7

0,6

400

450

G (l/h)

0,5

500

350

Construction details

Easy installation

The flow meter is equipped with a captive nut (4) that is mounted onto the manifold and sealed with an O-ring (5) mounted on the tail piece.

The captive nut solution simplifies assembly because it allows the flow meter to be mounted at the front of the manifold without having to change

the optimal readout position.

Dual readout scale

The flow meter is equipped with a spare graduated scale that can be used if flow needs to be checked or the system rebalanced but the float

can no longer be seen due to deposits on the transparent cylinder.

Turning the knurled nut (6) to the left will bring into view another scale in yellow that always stays clean due to the hermetic seal that prevents

water from entering while the system is operating.

The nut must be returned into the original position on the white scale after reading the measurement.

SPECIFICATION SUMMARIES

Flow meter with float. 3/4”M x 3/4”F nut threaded connections. Brass body, stainless steel measuring spring, EPDM seals,

transparent cylinder and internal protection in PSU, float-indicator in POM/PTFE. Medium: water and glycol solutions.

Maximum percentage of glycol 30%. Maximum working pressure: 6 bar. Temperature range 41–176 °F. Flow measurement scale:

1/4–1 gal/min. Accuracy ± 10%. Dual readout scale.

Page 10

Fitting with self-adjusting diameter for simple and multi-layer plastic pipes series 680

SPECIFICATION SUMMARIES

Function

The self-adjusting fitting for simple and multi-layer plastic pipes is a mechanical device that allows the pipes, the radiant

panel system circuits and the manifolds to be connected easily and securely. This versatile fitting has been specifically

designed to adapt to the varying pipe diameters of these types of systems.

Patented

Product range

Self-adjusting fitting for simple and multi-layer plastic pipes Size 3/4”

Technical specification

Materials:- nut: brass EN 12164 CW614N

Medium: water, glycol solutions

Max. percentage of glycol: 30%

Max. working pressure 45 psi

Temperature range: 41-176°F

Construction details

Versatility of pipe-fitting

This fitting has been specifically designed to adapt to several pipe diameters. The large variety of simple

and multi-layer plastic pipes available on the market and the wide range of permissible tolerances have

made it necessary to find an innovative solution for mechanical fittings. While maintaining the nominal

dimensions of the fittings currently available on the market, this new solution has been constructed so that

the same fitting can be used for pipes with differences on external diameters of up to .075" and differences

on internal diameters of up to .02".

Resistance to pull out

This adapter offers a high degree of resistance to pull out of pipe. Its special clamping system makes it

suitable for every application and ensures a leak tight fit.

Low pressure losses

The internal profile of the adapter (1) has been shaped to obtain a Venturi effect when the fluid passes

through, reducing pressure losses by 20% compared to those created by passages with a similar diameter.

Insulation ring

The fitting is equipped with a rubber insulation element (2) to prevent contact between the aluminium in the multi-layer pipe and the brass fitting,

thus preventing galvanic corrosion generated by the two different metals.

Dual O-ring seal

The adapter is equipped with two O-ring seals (3) and (4) in EPDM to prevent leaks even when operating at high pressure.

- adapter: brass EN 12164 CW614N

- seals: EPDM

- insulation ring: EPDM

- olive: PA 66 GF

(PEX)

41–122°F (Multilayer)

Characteristic components

1) Adapter

2) Olive

3) Nut

1

2

3

Code Ø

680502

680503

680500

680501

680506

680515

680517

680524

680526

680535

680537

680544

680546

680555

680564

680505

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

3/4”

1

2

3

4

internal

7,5–8,0

8,5–9,

9–9,5

9,5–10

9,5–10

10,5–11,

10,5–11,0

11,5–12,0

11,5–12,0

12,5–13,0

12,5–13,0

13,5–14,0

13,5–14,0

14,5–15,0

15,5–16,0

1716,0

Pipe (mm)

Ø

external

12–14

12

14

12

14

14

16

14

16

16

18

16

18

18

18

22,5

–

–

–

–

–

–

–

–

–

–

–

–

–

–

14

16

14

16

16

18

16

18

18

20

18

20

20

20

0

Self-adjusting fitting for simple and multi-layer plastic pipes with internal Venturi effect profile to limit pressure losses. 3/4”F

connection. Brass nut and adapter, EPDM seals, EPDM insulation ring, PA 66 GF olive coupling. Medium: water and glycol solutions.

Maximum percentage of glycol: 30%. Maximum working pressure: 10 bar. Temperature range: 5–80°C

(PEX); 5–50°C (Multilayer).

Page 11

Operating principle

The by-bass valve contains a

non-return obturator connected to a

contrast spring. When the fixed

setting pressure is reached, the

valve obturator gradually opens,

recirculating the flow in proportion

to the closing of the thermo-electric

valves and maintaining a constant

differential pressure in the manifold

circuit.

Construction details

The differential bypass assemby

features a fixed setting that cannot

be changed because it does not

contain accessible adjustment

parts. The small, compact size and

offset connections makes this kit

particularly easy to mount after

installing thermo-electric valves on

the manifold. It does not require a

larger or deeper zone box than

those used for normal manifolds.

Hydraulic characteristics

Bypass differential pressure: 25 kPa (2500 mm w.g.)

Technical specification

Materials: - body: brass EN 12164 CW614N

- nuts: brass EN 12165 CW617N

- Ø 18 pipe with plate: copper

- check valve obturator: PA

- spring: stainless steel

- seals: EPDM

- gaskets: asbestos-free fibre

Medium: water, glycol solutions

Max. percentage of glycol: 30%

Max. working pressure: 10 bar

Temperature range: -10–110°C

Fixed setting pressure: 25 kPa (2500 mm w.g.)

Connections: 1/2” M x 1/2” M

Dimensions

Off-centre bypass assembly with fixed setting

Function

The distribution circuits of the heating fluid in radiant panel systems may be totally or partially shut off by closing the

thermoelectric valves inside the manifolds.

When the flow decreases, the differential pressure inside the circuit may rise to levels that could cause problems with noise,

high rates of fluid speed, mechanical erosion and hydraulic imbalance of the system itself. The differential bypass kit for

manifolds maintains the pressure of the flow and return manifold circuits in balance if the flow changes.

The valve can be quickly connected to the manifolds, reducing overall size to a minimum.

Product range

Part #22090 Off-centre bypass assembly with fixed setting Size 1/2” x 1/2”

A

137÷150

B

C

Code

22090

A

1/2"

B

1/2"

C

1.4"

Weight (lb)

.75

ΔP (mm w.g.)

10000

9000

8000

7000

6000

5000

4500

4000

3500

3000

2500

2000

1800

1600

1400

1200

1000

100

120

140

160

180

200

250

300

350

400

450

500

600

700

800

900

1000

1200

1400

1600

1800

ΔP (kPa)

100

90

80

70

60

50

45

40

35

30

25

20

18

16

14

12

10

2000

G (l/h)

Page 12

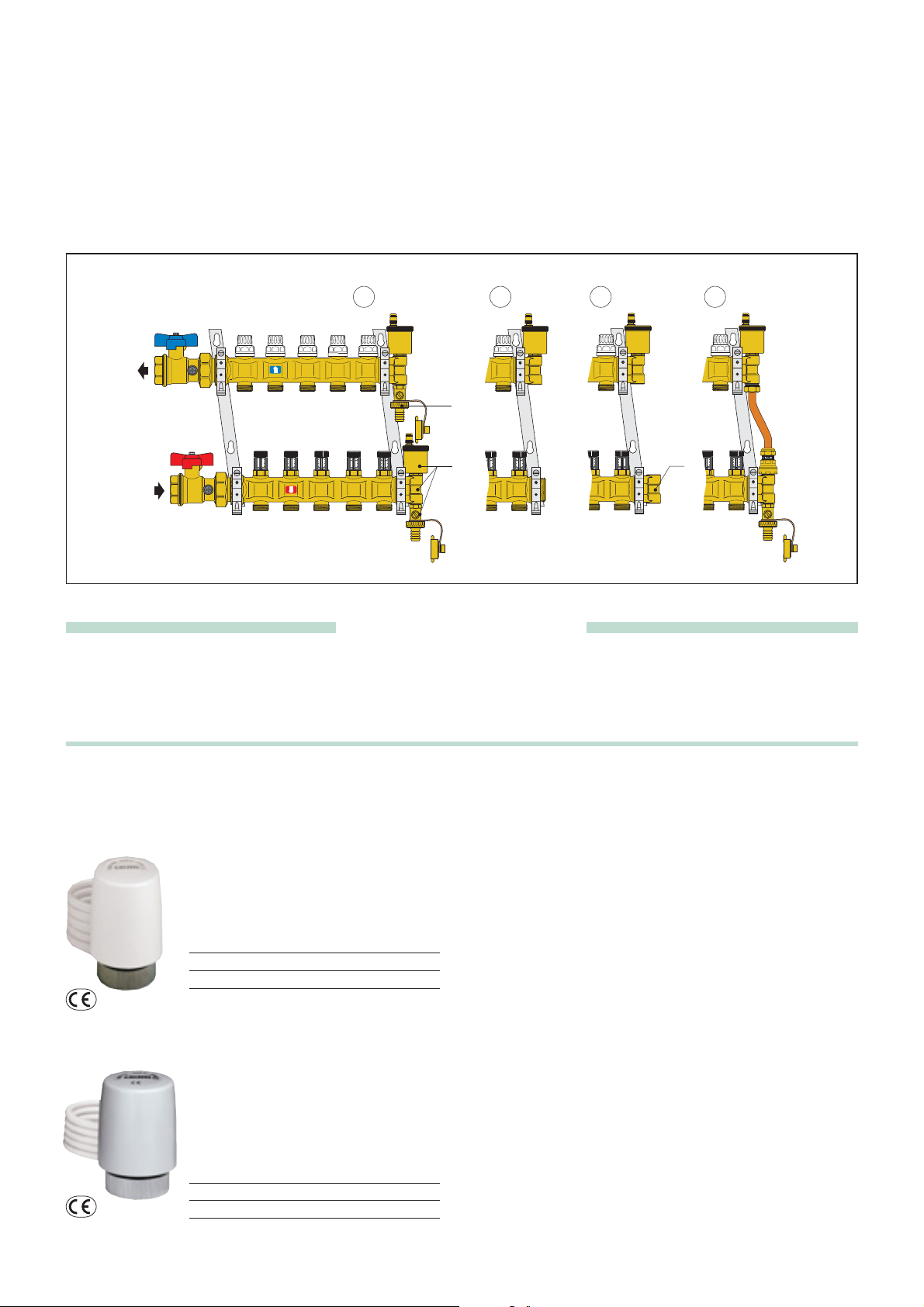

Installation of the differential bypass valve on manifolds

SPECIFICATION SUMMARIES

Thermo-electric actuators

Technical specification

- Materials: - protection shell self-extinguishing polycarbonate

- colour RAL 9010 white

version with micro: RAL 9002 grey

- Normally closed

- Electric supply: 230 V

(ac) - 24 V (ac) - 24 V (cc)

- Peak current: ≤ 1 A

- Working current: 230 V (ac) = 13 mA

24 V

(ac) - 24 V (cc) = 140 mA

- Power consumption: 3 W

-

Auxiliary microswitch contacts rating (code 656112/114): 0,8 A (230 V)

- Protection class: IP 44 (in vertical position)

- Double insulation construction: CE

- Max. ambient temperature: 50°C

- Operating time: opening and closing from 120 s to 180 s

- Length of supply cable: 80 cm

The differential bypass on manifolds is mounted by following the procedure below:

1) Remove the drain cock (A) from the terminal connector on the upper manifold.

2) Remove the end fitting (B) on the lower manifold.

3) Install the new terminal connector C on the lower manifold.

4) Install the differential bypass and reinstall the drain cock on the new terminal connector of the lower manifold.

1 2 3

4

A

10

10

10

10

10

8

8

6

6

4

4

2

2

0

0

10

10

10

10

8

8

6

6

4

4

2

2

0

0

10

10

10

8

8

6

6

4

4

2

2

0

0

10

8

8

8

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

B

10

10

10

10

8

8

8

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

10

8

8

8

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

10

10

10

10

8

8

8

C

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

Off-centre bypass assembly with fixed setting. 1/2”M threaded connections. Brass body and nuts. Copper pipe. PA check valve

obturator, stainless steel spring, EPDM seals, asbestos-free fibre gaskets. Medium: water and glycol solutions. Maximum

percentage of glycol: 30%. Maximum working pressure: 145 psi. Temperature range: 14–230 °F. Fixed setting pressure: 3.6 psi.

22000 depl. 01042

Thermo-electric actuator.

Normally closed.

Code Voltage (V)

656102

656104

22001 depl. 01042

Thermo-electric actuator.

Normally closed.

With auxiliary microswitch

Code

656112

656114

230

224

Voltage (V)

230

224

Page 13

Box

We reserve the right to change our products and their relevant technical data, contained in this publication, at any time and without prior notice.

Part # (l x w x d, in. )

22100

22101

22102

22103

22104

17.75 x 115.75 x 4.33 –5.5

17.75 x 123.6 6 x 4.33 –5.5

17.75 x 131.50 x 4.33 –5.5

17.75 x 39.37 x 4.33 –5.5

17.75 x 47.25 x 4.33 –5.5

Inspection wall box for

manifold systems.

Wall and installations

(with 660 series).

With lock.

In painted sheet steel.

Adjustable depth from 110 to

140 mm.

For manifolds series 668.

inspection wall box dimension choice

in accordance with the number of outlets

For max n. 6+6 outlets

40

60

20

80

0

°C

10

10

10

10

10

10

8

8

8

8

8

8

6

6

6

6

6

6

4

4

4

4

4

4

2

2

2

2

2

2

0

0

0

0

0

40

60

20

80

0

°C

0

For max n. 17+17 outlets

For max n. 14+14 outlets

For max n. 10+10 outlets

600

10

10

10

10

8

8

8

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

10

10

10

10

8

8

8

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

800

10

10

10

10

8

8

8

8

6

6

6

6

4

4

4

4

2

2

2

2

0

0

0

0

1000

1200

Infloor Sales Service PO Box 4945· Buena Vista, CO 81211 · TEL. 800-608-0562 · FAX 719-395-3555

· ht tp://www · E-m ail: m ·

Loading...

Loading...