Page 1

MAINTENANCE

A

B

SECTION MA

CONTENTS

PRECAUTION ............................................... 3

PRECAUTIONS ................................................... 3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

PREPARATION ............................................ 4

PREPARATION ................................................... 4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

PERIODIC MAINTENANCE .......................... 5

GENERAL MAINTENANCE ................................ 5

FOR USA AND CANADA ............................................5

FOR USA AND CANADA : Explanation of General

Maintenance ..............................................................

FOR MEXICO ..............................................................6

FOR MEXICO : General Maintenance ......................7

PERIODIC MAINTENANCE ................................ 9

FOR USA AND CANADA ............................................9

FOR USA AND CANADA : Introduction of Periodic

Maintenance ..............................................................

FOR MEXICO ............................................................12

FOR MEXICO : Introduction of Periodic Mainte-

nance ......................................................................

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

FOR USA AND CANADA ..........................................15

FOR USA AND CANADA : Fluids and Lubricants ....15

FOR USA AND CANADA : Engine Oil Recom-

mendation ...............................................................

FOR USA AND CANADA : Engine Coolant Mix-

ture Ratio .................................................................

12

15

16

16

MAINTENANCE

FOR MEXICO .............................................................16

FOR MEXICO : Fluids and Lubricants .....................16

FOR MEXICO : Engine Coolant Mixture Ratio ........18

ENGINE MAINTENANCE (VQ35DE) ................19

3

DRIVE BELTS ............................................................19

DRIVE BELTS : Checking Drive Belts .....................19

DRIVE BELTS : Tension Adjustment ......................19

ENGINE COOLANT ...................................................19

ENGINE COOLANT : System Inspection ................19

ENGINE COOLANT : Changing Engine Coolant ....21

FUEL LINES ...............................................................24

FUEL LINES : Inspection .........................................24

AIR CLEANER FILTER .............................................24

AIR CLEANER FILTER : Exploded View ................25

5

9

AIR CLEANER FILTER : Removal and Installation

ENGINE OIL ...............................................................25

ENGINE OIL : Inspection .........................................25

ENGINE OIL : Changing Engine Oil ........................26

OIL FILTER ................................................................26

OIL FILTER : Removal and Installation ...................26

SPARK PLUG ............................................................27

SPARK PLUG : Exploded View ...............................28

SPARK PLUG : Removal and Installation ...............28

EVAP VAPOR LINES ................................................29

EVAP VAPOR LINES : Inspection ...........................29

CHASSIS AND BODY MAINTENANCE ...........30

IN-CABIN MICROFILTER ..........................................30

IN-CABIN MICROFILTER : Removal and Installa-

tion ...........................................................................

EXHAUST SYSTEM ...................................................30

EXHAUST SYSTEM : Inspection ............................30

....

C

D

E

F

G

H

I

J

K

25

L

M

N

O

MA

30

Revision: August 2014 2015 QX60 NAM

MA-1

Page 2

CVT FLUID ................................................................ 30

CVT FLUID : Inspection .......................................... 31

CVT FLUID : Changing ........................................... 31

FRONT BRAKE ......................................................... 40

FRONT BRAKE : Inspection of Pad ........................ 40

FRONT BRAKE : Inspection of Rotor ..................... 40

TRANSFER OIL ........................................................ 33

TRANSFER OIL : Inspection .................................. 33

TRANSFER OIL : Draining ..................................... 33

TRANSFER OIL : Refilling ...................................... 33

REAR DIFFERENTIAL GEAR OIL ........................... 34

REAR DIFFERENTIAL GEAR OIL : Inspection ...... 34

REAR DIFFERENTIAL GEAR OIL : Draining ......... 34

REAR DIFFERENTIAL GEAR OIL : Refilling ......... 35

PROPELLER SHAFT ................................................ 35

PROPELLER SHAFT : Inspection .......................... 35

WHEELS ................................................................... 36

WHEELS : Inspection ............................................. 36

WHEELS : Adjustment ........................................... 36

BRAKE FLUID LEVEL AND LEAKS ........................ 38

BRAKE FLUID LEVEL AND LEAKS : Inspection ... 38

BRAKE LINES AND CABLES .................................. 38

BRAKE LINES AND CABLES : Inspection ............. 39

BRAKE FLUID .......................................................... 39

BRAKE FLUID : Drain and Refill ............................ 39

REAR BRAKE ...........................................................40

REAR BRAKE : Inspection of Pad .......................... 40

REAR BRAKE : Inspection of Rotor ........................ 40

STEERING GEAR AND LINKAGE ........................... 41

STEERING GEAR AND LINKAGE : Inspection ...... 41

POWER STEERING FLUID AND LINES .................. 41

POWER STEERING FLUID AND LINES : Inspec-

tion ..........................................................................

41

AXLE AND SUSPENSION PARTS ........................... 42

AXLE AND SUSPENSION PARTS : Inspection ..... 42

DRIVE SHAFT ........................................................... 42

DRIVE SHAFT : Inspection ..................................... 43

LOCKS, HINGES AND HOOD LATCH ..................... 43

LOCKS, HINGES AND HOOD LATCH : Lubricat-

ing ...........................................................................

43

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS ......................................

43

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS : Inspection .................

43

Revision: August 2014 2015 QX60 NAM

MA-2

Page 3

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes dual stage front air bag modules. The SRS system may only deploy

one front air bag, depending on the severity of a collision and whether the front passenger seat is occupied.

Information necessary to service the system safely is included in the SR and SB section of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

INFOID:0000000011131980

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

MA

Revision: August 2014 2015 QX60 NAM

MA-3

Page 4

PREPARATION

< PREPARATION >

PREPARATION

PREPARATION

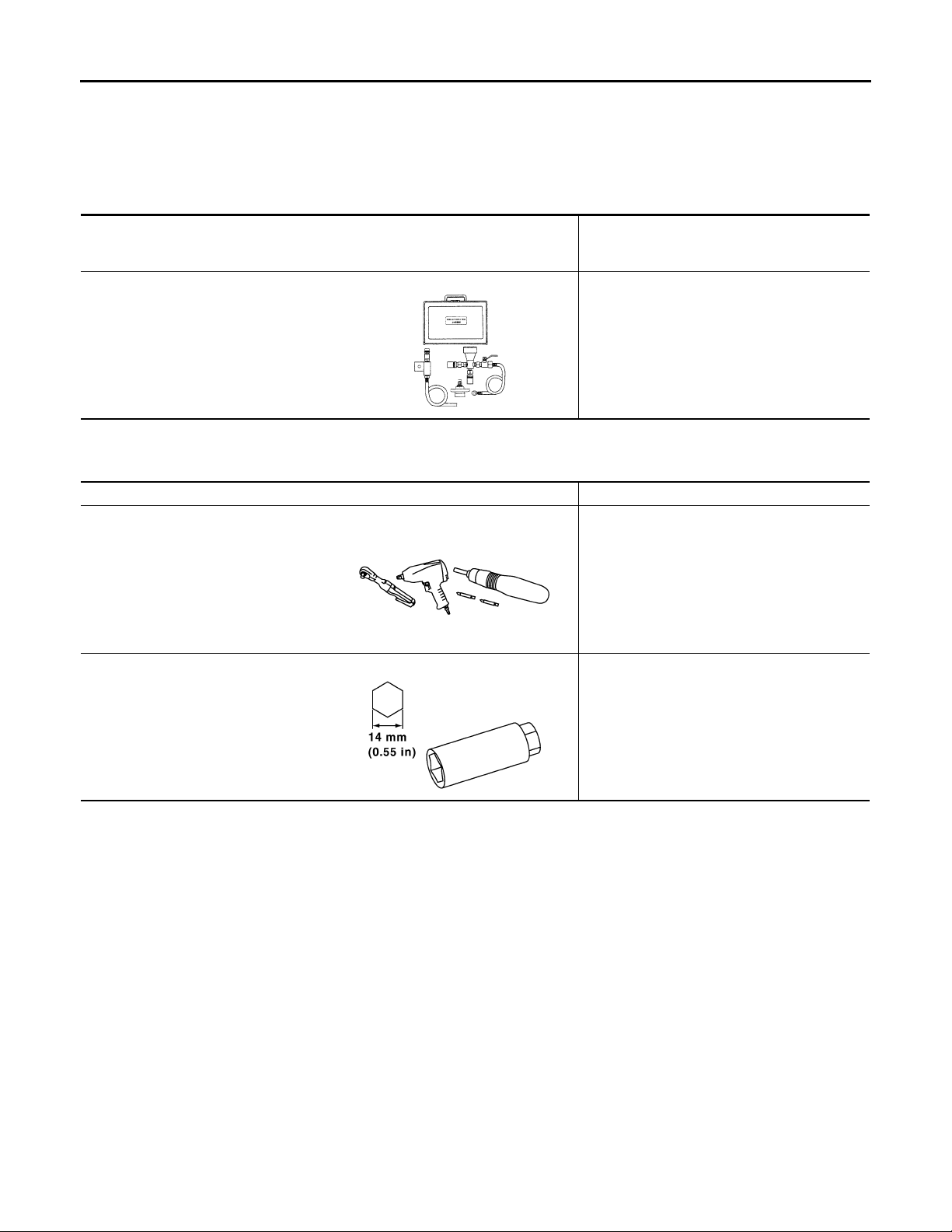

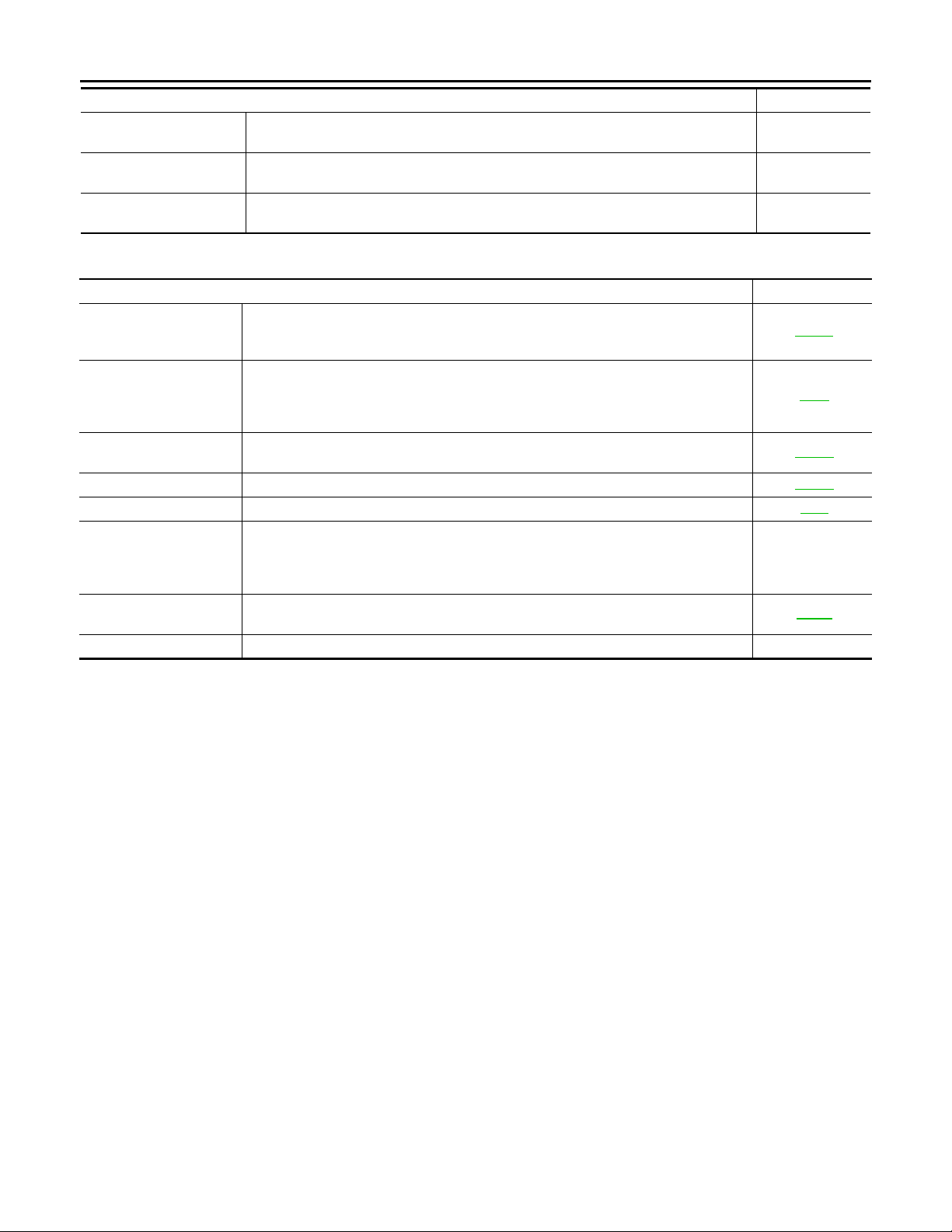

Special Service Tool INFOID:0000000011131981

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name

KV991J0070

(J-45695)

Coolant Refill Tool

LMA053

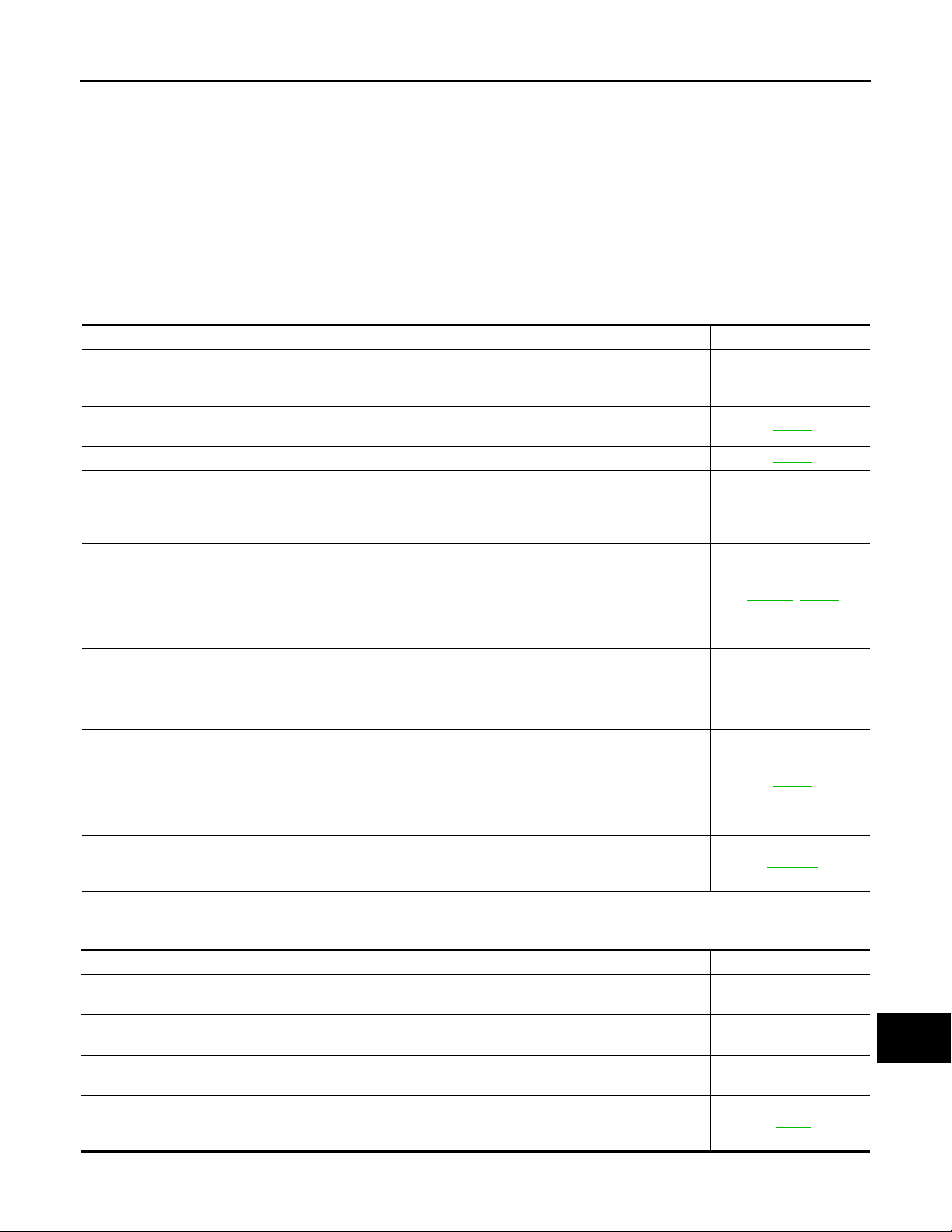

Commercial Service Tool INFOID:0000000011131982

Tool name Description

Power tool Loosening nuts, screws and bolts

Description

Refilling engine cooling system

PIIB1407E

Spark plug wrench Removing and installing spark plug

PBIC2982E

Revision: August 2014 2015 QX60 NAM

MA-4

Page 5

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

FOR USA AND CANADA

FOR USA AND CANADA : Explanation of General Maintenance INFOID:0000000011131983

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI retailers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear.

Wheel nuts When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary.

Tire rotation Tires should be rotated every 5,000 miles (8,000 km). MA-36

Tire pressure monitoring system (TPMS)

transmitter components

Wheel alignment and

balance

Windshield Clean the windshield on a regular basis. Check the windshield at least every six

Windshield wiper

blades

Doors and engine

hood

Lamps Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps and oth-

Replace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

If the vehicle should pull to either side while driving on a straight and level road

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. For additional information regarding tires, refer

to “Important Tire Safety Information” (US) or “Tire Safety Information” (Canada)

in the INFINITI Warranty Information Booklet.

months for cracks or other damage. Repair as necessary.

Check for cracks or wear if they do not wipe properly.

Check that all doors and the engine hood operate smoothly as well as the back

door, trunk lid and glass hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication frequently.

er lamps are all operating properly and installed securely. Also check headlamp

aim. Clean the headlamps on a regular basis.

MA-36

MA-36

MA-36

FSU-22

MA-43

EXL-162

, WT-52

—

—

A

B

C

D

E

F

G

H

I

J

K

L

M

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Warning lamps and

chimes

Windshield wiper and

washer

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

Steering wheel Check that it has the specified play. Check for changes in the steering condition,

Revision: August 2014 2015 QX60 NAM

Make sure that all warning lamps and chimes are operating properly.

Check that the wipers and washer operate properly and that the wipers do not

streak.

quantity when operating the heater or air conditioner.

such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)

MA-5

—

—

—

ST-47

N

O

MA

Page 6

GENERAL MAINTENANCE

< PERIODIC MAINTENANCE >

Item Reference page

Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every position. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks.

Seat belts Check that all parts of the seat belt system (e.g., buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.

Accelerator pedal Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal.

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster

Parking brake Check that the lever or pedal has the proper travel and make sure that the vehicle

CVT P (Park) position

mechanism

Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

the floor mats away from the pedal.

is held securely on a fairly steep hill when only the parking brake is applied.

On a fairly steep hill check that the vehicle is held securely with the shift selector

in the P (Park) position without applying any brakes.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g., each time you check the engine oil or refuel).

Item Reference page

Windshield washer

fluid

Engine coolant level Check the coolant level when the engine is cold. CO-10

Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves, etc., that

Brake fluid level Make sure that the brake fluid level is between the MAX and MIN lines on the res-

Battery Check the fluid level in each cell. It should be between the MAX and MIN lines.

Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. MA-19

Engine oil level Check the level on the oil level gauge after parking the vehicle on a level spot and

Power steering fluid

level and lines

Exhaust system Make sure there are no loose supports, cracks or holes. If the sound of the ex-

Underbody The underbody is frequently exposed to corrosive substances such as those

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

Check that there is adequate fluid in the tank.

may have accumulated. Make sure the hoses have no cracks, deformation, deterioration or loose connections.

ervoir.

Vehicles operated in high temperatures or under severe conditions require frequent checks of the battery fluid level.

turning off the engine.

Check the level on the dipstick with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.

haust seems unusual or there is a smell of exhaust fumes, immediately locate the

trouble and correct it.

used on icy roads or to control dust. It is very important to remove these substances, otherwise rust will form on the floor pan, frame, fuel lines and around the

exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate.

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately.

MA-43

BR-20

MA-38

PG-99

MA-25

MA-41

MA-30

—

—

, BR-31

PB-7

—

—

—

—

—

FOR MEXICO

Revision: August 2014 2015 QX60 NAM

MA-6

Page 7

GENERAL MAINTENANCE

< PERIODIC MAINTENANCE >

FOR MEXICO : General Maintenance INFOID:0000000011131984

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

Doors and hood Check that all doors and the hood operate smoothly as well as the back door, trunk lid

and hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary latch is

released. When driving in areas using road salt or other corrosive materials, check lubrication frequently.

Lamps Clean the headlamps on a regular basis. Make sure that the headlamps, stop lamps,

tail lamps, turn signal lamps, and other lamps are all operating properly installed securely. Also check the aim of the headlamps.

Tires Check the pressure with a gauge often and always prior to long distance trips. Adjust

the pressure in all tires, including the spare, to the pressure specified. Check carefully

for damage, cuts or excessive wear.

Tire rotation In the case that Two-Wheel Drive (2WD) and front & rear tires are same size; Tires

should be rotated every 10,000 km (6,000 miles). Tires marked with directional indicators can only be rotated between front and rear. Make sure that the directional indicators point in the direction of wheel rotation after the tire rotation is completed.

In the case that Four-Wheel Drive (4WD) and front & rear tires are same size; Tires

should be rotated every 5,000 km (3,000 miles). Tires marked with directional indicators can only be rotated between front and rear. Make sure that the directional indicators point in the direction of wheel rotation after the tire rotation is completed.

In the case that front tires are different size from rear tires; Tires cannot be rotated.

However, the timing for tire rotation may vary according to your driving habits and the

road surface conditions.

Tire Pressure Monitoring System (TPMS)

transmitter components

Wheel alignment and

balance

Windshield Clean the windshield on a regular basis. Check the windshield at least every six

Wiper blades Check for cracks or wear if not functioning correctly. Repair as necessary. —

Replace the TPMS transmitter grommet seal, valve core and cap when the tires are

replaced due to wear or age.

If the vehicle should pull to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel alignment. If

the steering wheel or seat vibrates at normal highway speeds, wheel balancing may

be needed.

months for cracks or other damage. Repair as necessary.

MA-43

—

WT-61

WT-53

WT-56

FSU-5

—

A

B

C

D

E

F

G

H

I

J

K

L

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Accelerator pedal Check the pedal for smooth operation and make sure that the pedal does not catch or

require uneven effort. Keep the floor mats away from the pedal.

Brake pedal Check the pedal for smooth operation and make sure that it is the proper distance from

the floor mat when depressed fully. Check the brake booster function. Be sure to keep

the floor mats away from the pedal.

Parking brake Check the parking brake operation regularly. Check that the lever (if equipped) or the

pedal (if equipped) has the proper travel. Also make sure that the vehicle is held securely on a fairly steep hill when only the parking brake is applied.

Seat belts Check that all parts of the seat belt system (for example, buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.

Steering wheel Check for changes in the steering condition, such as excessive play, hard steering or

strange noises. Check that it has the specified play.

Free play: Less than 35 mm (1.38 in)

Revision: August 2014 2015 QX60 NAM

MA-7

—

BR-7

PB-4

MA-43

—

M

N

O

MA

Page 8

GENERAL MAINTENANCE

< PERIODIC MAINTENANCE >

Item Reference page

Warning lamps and

chimes

Windshield defogger Check that the air comes out of the defogger outlets properly and in good quantity when

Windshield wiper and

washer

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (for example, each time you check the engine oil or refuel.)

Battery Except for maintenance free battery; Check the fluid level in each cell. It should be be-

Brake (and clutch) fluid

level(s)

Coolant level Check the coolant level when the coolant is cold. Make sure that the coolant level is

Engine drive belt(s) Make sure that drive belt(s) is/are not frayed, worn, cracked or oily. EM-12

Engine oil level Check the level after parking the vehicle (on a level ground) and turning off the engine. LU-8

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has been

Power steering fluid

level and lines

Windshield washer fluid Check that there is adequate fluid in the reservoir. —

Make sure that all warning lamps and chimes are operating properly. —

operating the heater or air conditioner.

Check that the wipers and washer operate properly and that the wipers do not streak. —

Item Reference page

tween the “UPPER” and “LOWER” lines. Vehicles operated in high temperatures or under severe conditions require frequent checks of the battery fluid level.

For Manual Transmission (MT) model; Make sure that the brake and clutch fluid levels

are between the "MAX" and "MIN" lines on the reservoir(s).

Except for Manual Transmission (MT) model; Make sure that the brake fluid level is between the "MAX" and "MIN" lines on the reservoir.

between the “MAX” and “MIN” lines on the reservoir.

parked for a while. Water dripping from the air conditioner after use is normal. If you

should notice any leaks or if fuel fumes are evident, check for cause and have it corrected immediately.

Check the level when the fluid is cold, with the engine off. Check the lines for proper

attachment, leaks, cracks, etc.

PG-90

BR-8

CO-10

ST-21

—

—

Revision: August 2014 2015 QX60 NAM

MA-8

Page 9

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

FOR USA AND CANADA

FOR USA AND CANADA : Introduction of Periodic Maintenance INFOID:0000000011131985

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric conditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent maintenance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

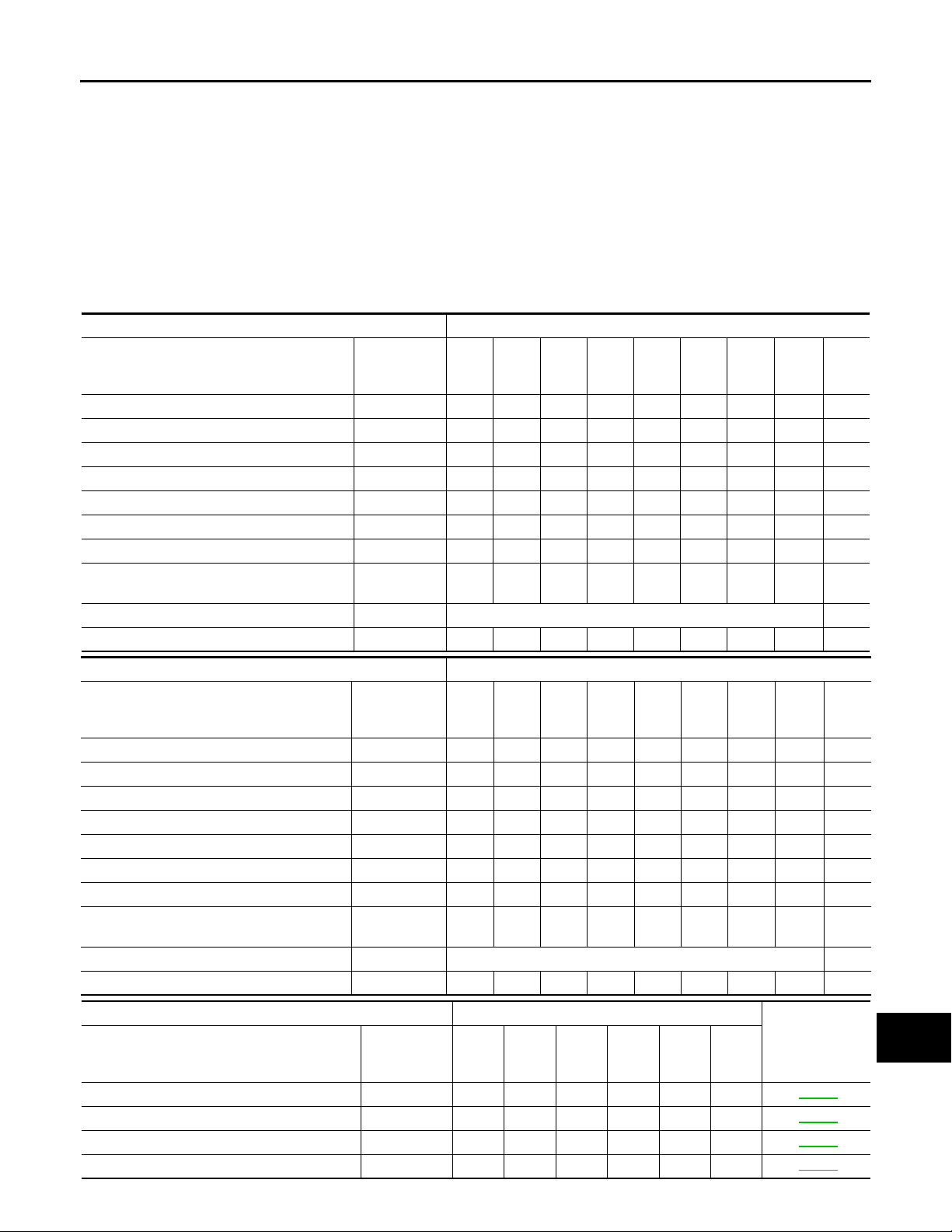

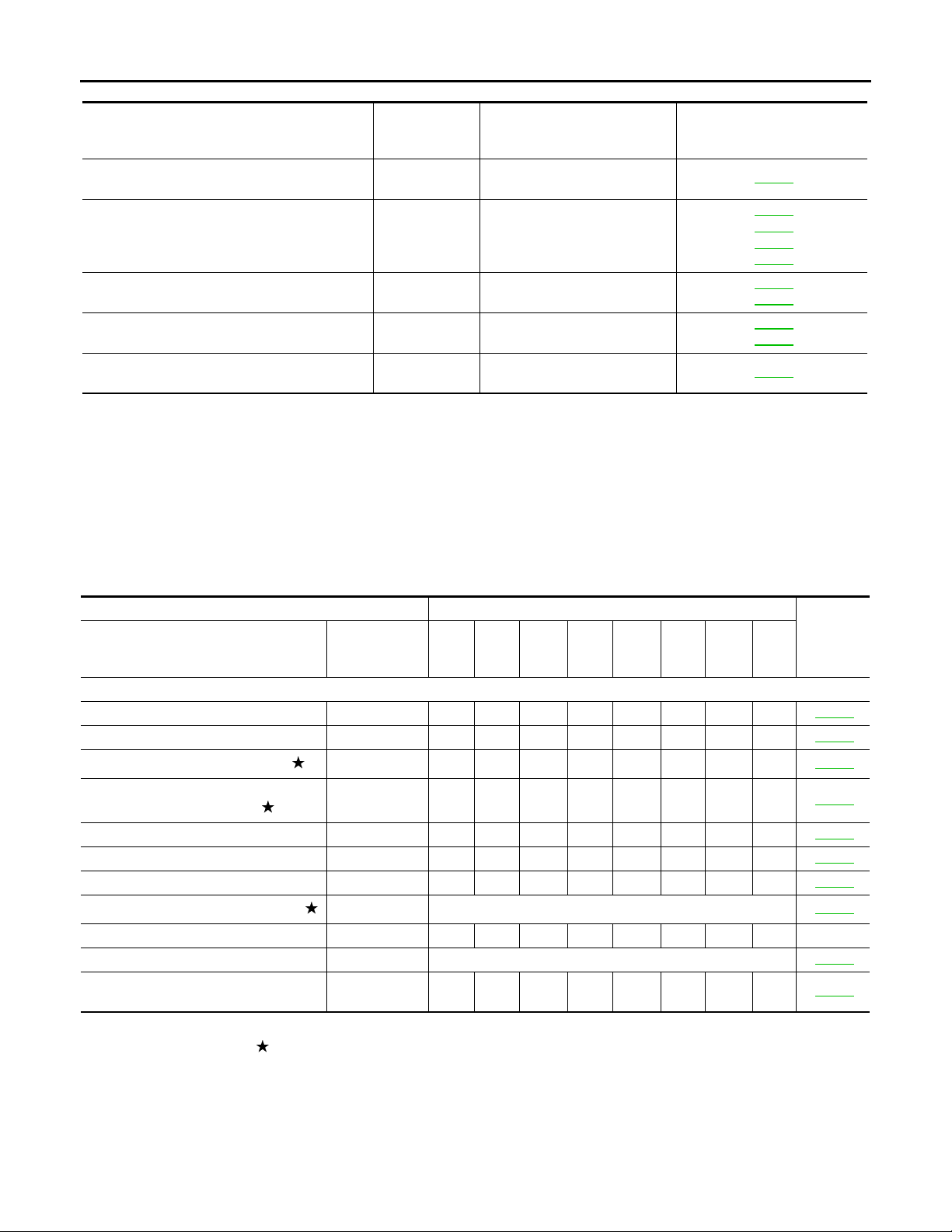

ENGINE AND EMISSION CONTROL MAINTENANCE

Abbreviations: R = Replace, I = Inspect and correct or replace as necessary

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers

or months, whichever comes first.

Drive belts NOTE (1) I*

Air cleaner filter NOTE (2) R

EVAP vapor lines I* I*

Fuel lines I* I*

Fuel filter NOTE (3)

Engine coolant* NOTE (4)(5)

Engine oil RRRRRRRR R

Engine oil filter (Use genuine NISSAN engine oil filter or equivalent)

Spark plugs (Iridium-tipped type) NOTE (6) Replace every 105,000 miles (168,000 km)

Intake & exhaust valve clearance* NOTE (7)

Miles x 1,000

(km x 1,000)

Months

5

10

(8)

(16)

6

12

RRRRRRRR R

15

(24)

18

20

(32)

24

25

(40)

30

30

(48)

36

35

(56)

42

40

(64)

48

45

(72)

48

A

B

C

D

E

F

G

H

I

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers

or months, whichever comes first.

Drive belts NOTE (1) I* I* I* I* I*

Air cleaner filter NOTE (2) R R

EVAP vapor lines I* I*

Fuel lines I* I*

Fuel filter NOTE (3)

Engine coolant* NOTE (4)(5)

Engine oil RRRRRRRRR

Engine oil filter (Use genuine NISSAN engine oil filter or equivalent)

Spark plugs (Iridium-tipped type) NOTE (6) Replace every 105,000 miles (168,000 km)

Intake & exhaust valve clearance* NOTE (7)

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers

or months, whichever comes first.

Drive belts NOTE (1) I* I* I* MA-19

Air cleaner filter NOTE (2) R MA-25

EVAP vapor lines I* I* MA-29

Fuel lines I* I* MA-24

Miles x 1,000

(km x 1,000)

Months

Miles x 1,000

(km x 1,000)

Months

50

(80)

60

55

(88)

66

RRRRRRRRR

95

(152)

114

100

(160)

120

60

(96)

72

105

(168)

126

65

(104)

78

110

(176)

132

70

(112)

84

115

(184)

138

75

(120)

90

(128)

12

(192)

14

80

96

0

4

85

(136)

102

Reference Page

90

(144)

108

J

K

L

M

N

O

MA

Revision: August 2014 2015 QX60 NAM

MA-9

Page 10

PERIODIC MAINTENANCE

< PERIODIC MAINTENANCE >

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers

or months, whichever comes first.

Fuel filter NOTE (3) —

Engine coolant* NOTE (4)(5) MA-19

Engine oil RRRRRR MA-25

Engine oil filter (Use genuine NISSAN engine

oil filter or equivalent)

Spark plugs (Iridium-tipped type) NOTE (6) Replace every 105,000 miles (168,000 km) MA-28

Intake & exhaust valve clearance* NOTE (7)

NOTE:

• (1) After 40,000 miles (64,000 km) or 48 months, inspect every 10,000 miles (16,000 km) or 12 months. Replace the drive belts if

found damaged.

• (2) If operating mainly in dusty conditions, more frequent maintenance may be required.

• (3) Maintenance-free item. For service procedures, refer to FL section.

• (4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles

(120,000 km) or 60 months.

• (5) Use only Genuine NISSAN Long Life Antifreeze / Coolant (blue) or equivalent with proper mixture ratio of 50% antifreeze and 50%

demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life expectancy of the

factory-fill coolant.

• (6) Replace spark plug when the spark plug gap exceeds 1.4 mm (0.055 in), even if within specified periodic replacement mileage.

• (7) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

*: Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are

required.

Miles x 1,000

(km x 1,000)

Months

95

(152)

114

100

(160)

120

RRRRRR MA-26

105

(168)

126

110

(176)

132

115

(184)

138

120

(192)

144

Reference Page

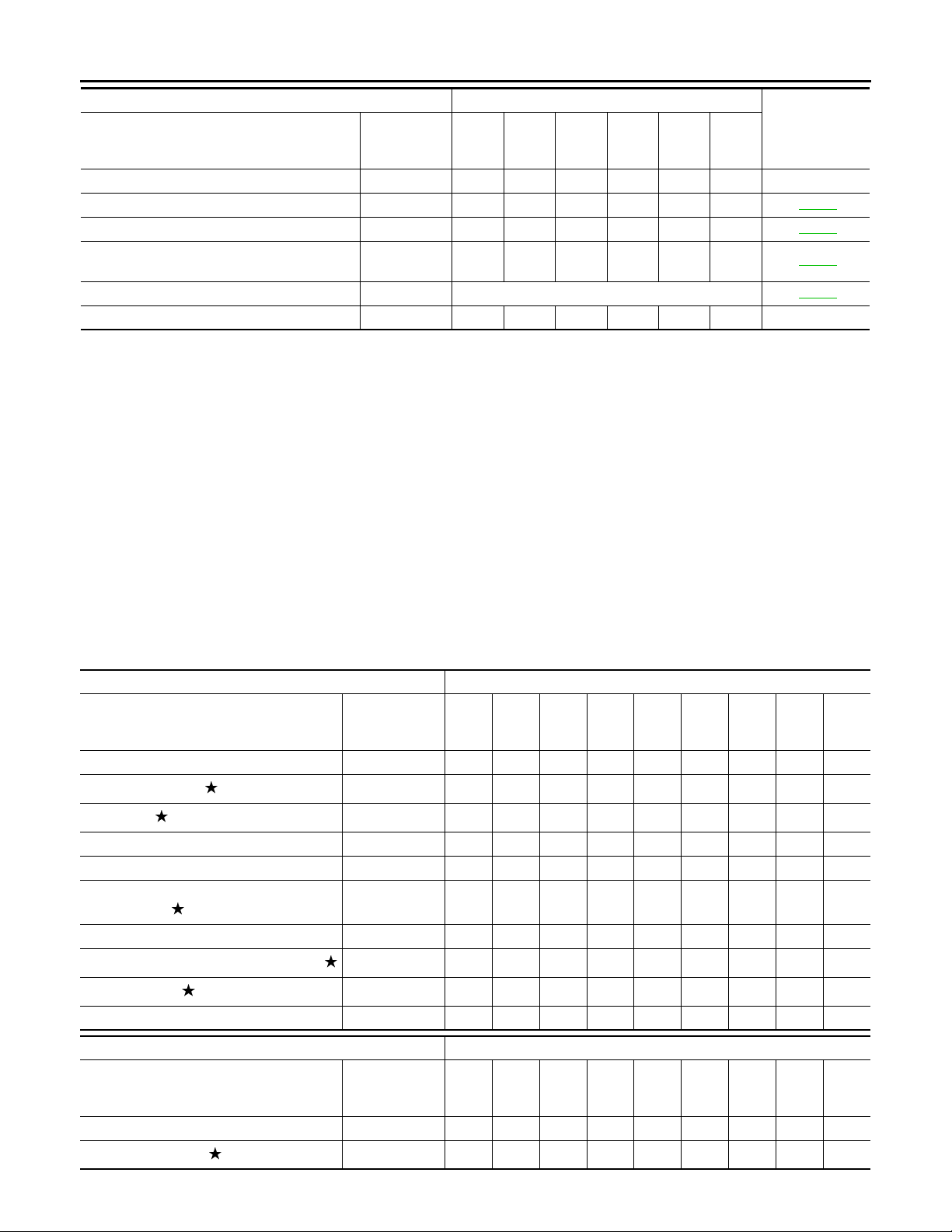

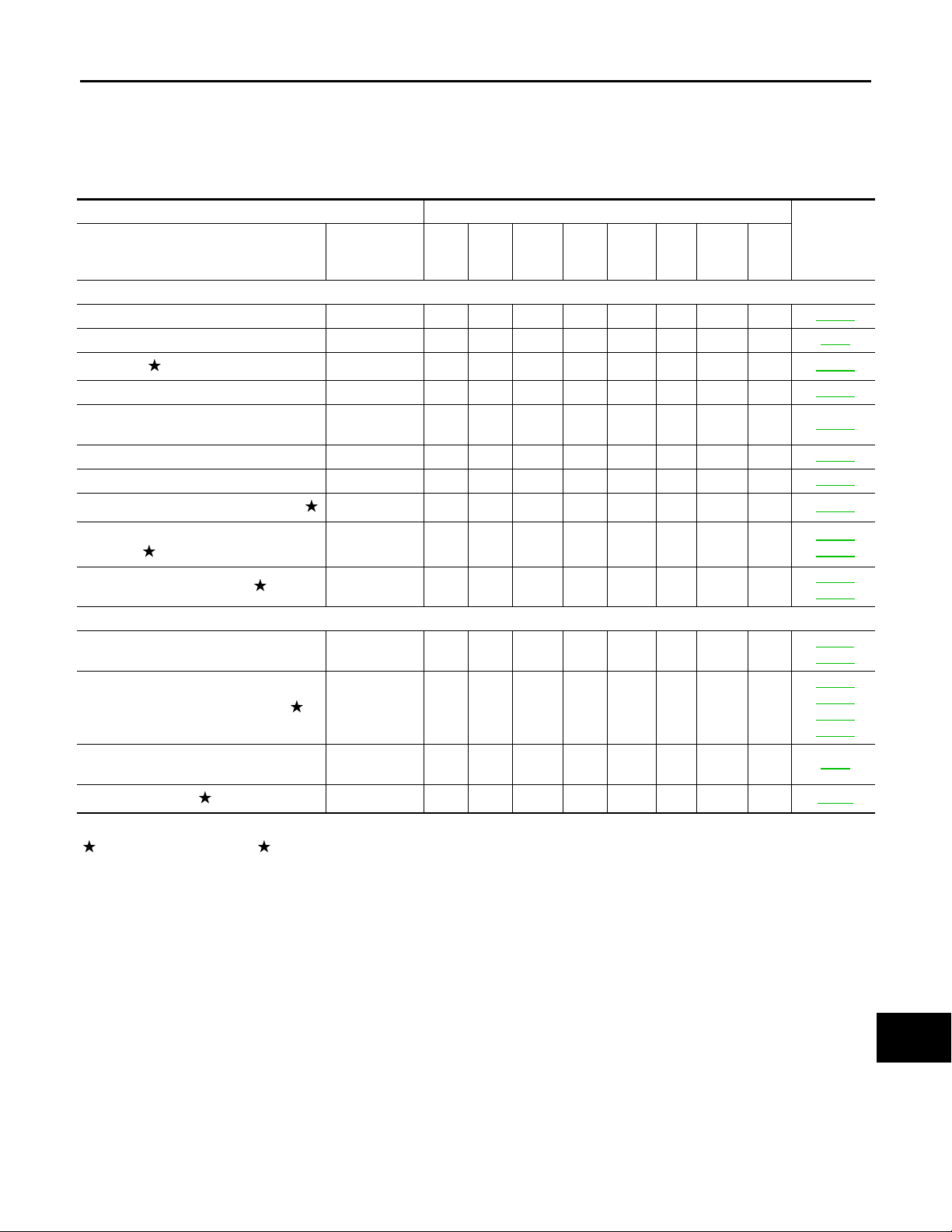

CHASSIS AND BODY MAINTENANCE

Abbreviations: R= Replace. I = Inspect. Correct or replace if necessary.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers or months, whichever comes first.

Brake line & cables I I I I

Brake pads & rotors

Brake fluid

CVT fluid NOTE (1) I I I I

Transfer oil & differential gear oil NOTE (2) I I I I

Steering gear and linkage, axle and sus-

pension parts

Tire rotation NOTE (3)

Propeller shaft (AWD) & drive shaft boots

Exhaust system

In-cabin microfilter R R R

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers or months, whichever comes first.

Brake line & cables I I I I I

Brake pads & rotors

Miles x 1,000

(km x 1,000)

Months

Miles x 1,000

(km x 1,000)

Months

5

10

15

(8)

(16)

6

50

(80)

(88)

60

IIIII

(24)

12

18

IIII

IIII

55

60

(96)

66

72

20

(32)

24

65

(104)

78

25

(40)

30

RR

II

II

70

(112)

84

30

(48)

36

75

(120)

90

35

(56)

42

80

(128)

96

40

(64)

48

85

(136)

102

45

(72)

54

90

(144)

108

Revision: August 2014 2015 QX60 NAM

MA-10

Page 11

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers or months, whichever comes first.

Brake fluid

CVT fluid NOTE (1)IIIII

Transfer oil & differential gear oilNOTE (2)IIIII

Steering gear and linkage, axle and sus-

pension parts

Tire rotation NOTE (3)

Propeller shaft (AWD) & drive shaft boots

Exhaust system

In-cabin microfilter R R R

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers or months, whichever comes first.

Brake line & cables I I I MA-38

Brake pads & rotors

Brake fluid

CVT fluid NOTE (1) I I I MA-31

Transfer oil & differential gear oil NOTE (2) I I I MA-33

Steering gear and linkage, axle and sus-

pension parts

Tire rotation NOTE (3) MA-36

Propeller shaft (AWD) & drive shaft boots

Exhaust system

In-cabin microfilter R R MA-30

NOTE:

• Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

• (1) Use only Genuine NISSAN CVT fluid. If towing a trailer, using a camper or a car-top carrier, of driving on rough or muddy roads,

inspect CVT fluid deterioration at an INFINITI retailer every 60,000 miles (96,000 km), then change CVT fluid if necessary. And if the

inspection is not performed, change (not just inspect) CVT fluid every 60,000 miles (96,000 km).

• (2) If tower a trailer, using a camper or car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every 20,000

miles (32,000 km) or 24 months.

• (3) Refer to "Tire rotation" under "GENERAL MAINTENANCE" heading earlier in this section.

Miles x 1,000

(km x 1,000)

Months

Miles x 1,000

(km x 1,000)

Months

50

(80)

60

(152)

114

55

(88)

66

IIIII

95

(160)

60

(96)

72

100

120

III

RRMA-39

II

III

IIMA-30

65

(104)

78

RR

II

II

105

(168)

126

110

(176)

132

70

(112)

84

115

(184)

138

75

(120)

90

(128)

120

(192)

90

80

96

85

(136)

102

Reference Page

MA-40

MA-40

MA-41

MA-42

MA-43

MA-35

90

(144)

108

A

B

C

D

E

F

G

H

I

J

K

L

M

N

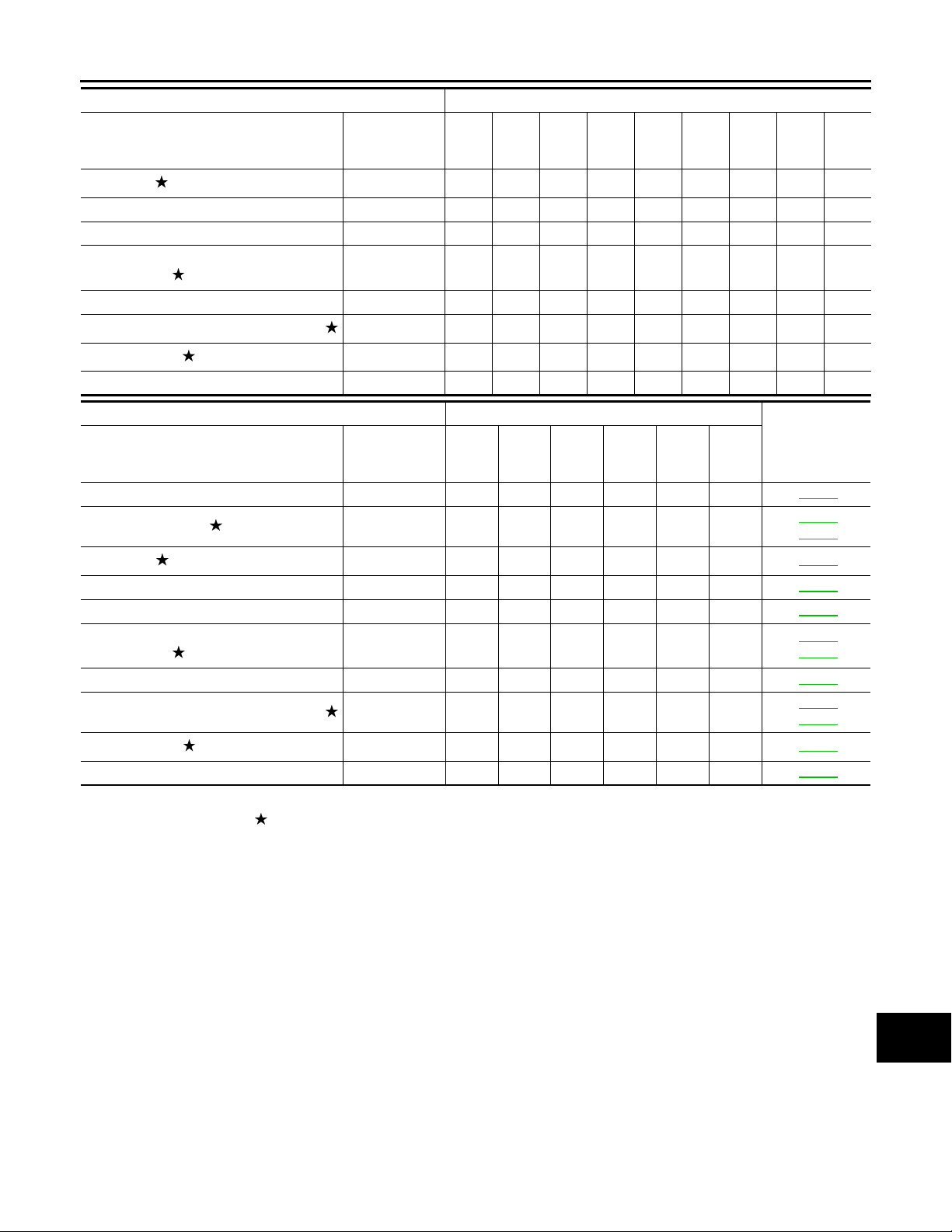

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be performed on the following items as shown in the table.

Severe driving conditions

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures remaining below freezing.

• Operating in hot weather in stop-and-go "rush hour" traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer, using a camper or a car-top carrier

Revision: August 2014 2015 QX60 NAM

MA-11

O

MA

Page 12

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

Maintenance operation: Check = Check and correct or replace as necessary.

Maintenance item

Brake fluid Replace

Brake pads & rotors Inspect

Steering gear & linkage, axle & suspension parts Inspect

Propeller shaft (AWD) & drive shaft boots Inspect

Exhaust system Inspect

Maintenance

operation

Maintenance interval Reference page

Every 10,000 miles (16,000 km)

or 12 months

Every 5,000 miles (8,000 km) or

6 months

Every 5,000 miles (8,000 km) or

6 months

Every 5,000 miles (8,000 km) or

6 months

Every 5,000 miles (8,000 km) or

6 months

MA-39

MA-40

MA-40

MA-40

MA-40

MA-41

MA-42

MA-35

MA-43

MA-30

FOR MEXICO

FOR MEXICO : Introduction of Periodic Maintenance INFOID:0000000011131986

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric conditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent maintenance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

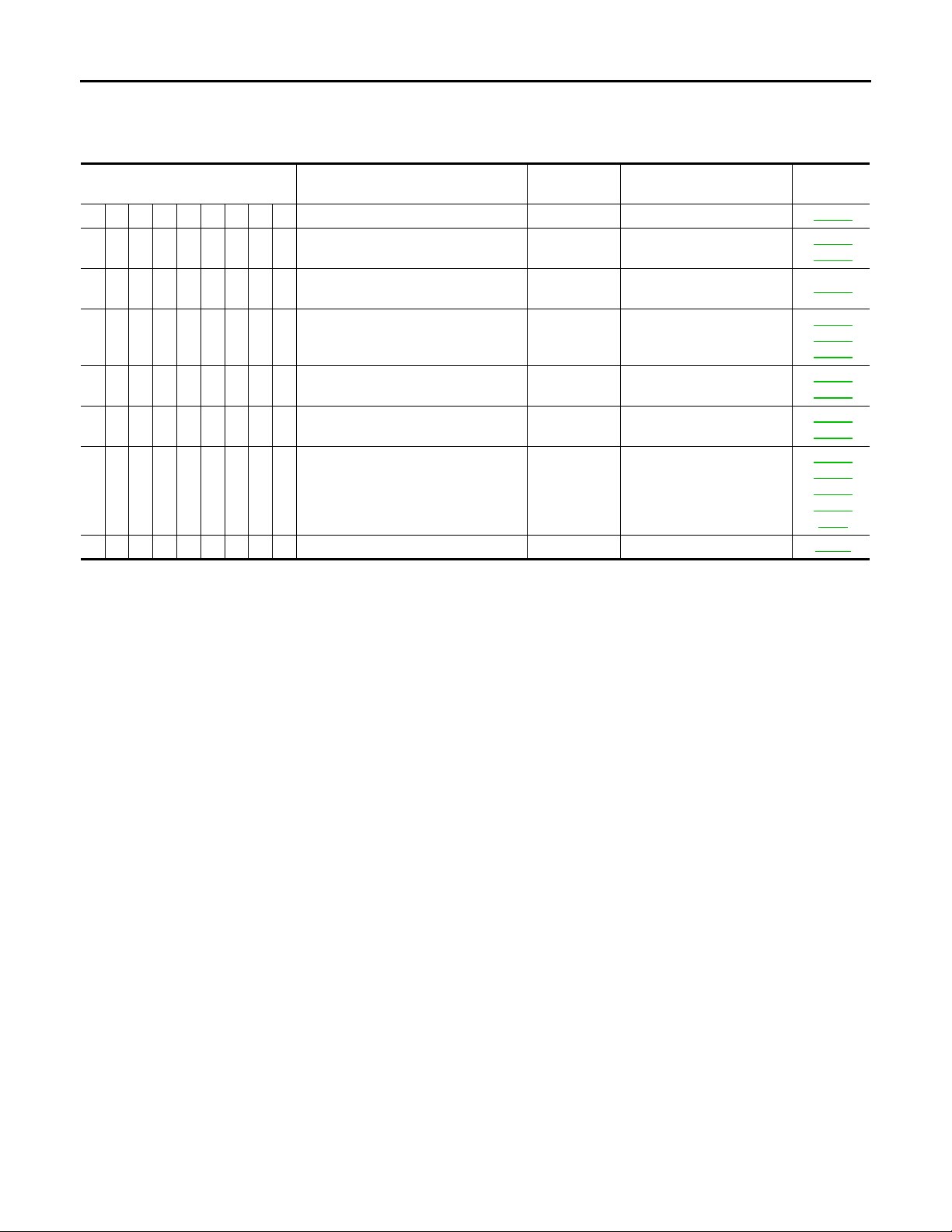

ENGINE AND EMISSION CONTROL MAINTENANCE

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, E = Check and correct the engine coolant mixture ratio

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of kilometers

(miles) or months, whichever comes

first.

Intake & exhaust valve clearance See NOTE (1) EM-18

Drive belts See NOTE (2) I I MA-19

Engine oil (Use recommended oil.)

Engine oil filter (Use Genuine NISSAN

engine oil filter or equivalent.)

Engine coolant See NOTE (3) E E MA-19

Cooling system I I MA-19

Fuel lines IIMA-24

Air cleaner filter (Viscous paper type)

Fuel filter (In-tank type) See NOTE (4) —

Spark plugs (Iridium-tipped type) See NOTE (5) Replace every 96,000 km (60,000 miles) MA-28

EVAP vapor lines

(With carbon canister)

NOTE:

• Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

(1) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belts if found damaged or if the auto belt tensioner reading reaches the maximum limit.

(3) Use Genuine NISSAN Engine Coolant (blue) or equivalent in its quality, in order to avoid possible aluminium corrosion within the

engine cooling system caused by the use of non-genuine engine coolant. Check and correct the engine coolant mixture ratio every

48,000 km (30,000 miles) or 24 months. First replacement interval is 168,000 km (105,000 miles) or 96 months. After first replacement,

replace every 84,000 km (52,500 miles) or 48 months.

km x 1,000

(Miles x 1,000)

Months

Engine compartment and under vehicle

12

24

36

(7.5)

(15)

(22.5)

6

12

18

RRRRRRRRMA-25

RRRRRRRRMA-26

Replace every 36,000 km (22,500 miles) or 24 months MA-25

48

60

72

84

96

(30)

(37.5)

24

IIMA-29

30

(45)

36

(52.5)

42

(60)

48

Refer-

ence page

Revision: August 2014 2015 QX60 NAM

MA-12

Page 13

PERIODIC MAINTENANCE

< PERIODIC MAINTENANCE >

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Replace spark plug when the plug gap exceeds 1.25 mm (0.049 in) even within specified periodic replacement mileage.

CHASSIS AND BODY MAINTENANCE

A

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L=Lubricate

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of kilometers

(miles) or months, whichever comes first.

Brake line & cables I I I I MA-39

Brake fluid (For level & leaks) I I I I BR-8

Brake fluid

CVT fluid (For level & leaks) NOTE (1) I I I I MA-31

Power steering fluid & lines (For level &

leaks)

Exhaust system I I MA-30

Transfer fluid (For level & leaks) I I I I MA-33

Differential gear oil (For level & leaks)

Steering gear & linkage, axle & suspen-

sion parts

Propeller shaft & drive shafts

Wheel alignment (If necessary, rotate &

balance wheels)

Brake pads, rotors, drums & linings

Foot brake & parking brake

(For free play, stroke & operation)

Air conditioner filter

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

• (1) Use only Genuine NISSAN CVT fluid. If towing a trailer, using a camper or a car-top carrier or driving on a rough or muddy roads,

inspect CVT fluid deterioration at INFINITI dealers every 96,000 km (60,000 miles), then change CVT fluid if necessary. And if the

inspection is not performed, change (not just inspect) CVT fluid every 96,000 km (60,000 miles).

km x 1,000

(Miles x 1,000)

Months

Underhood and under vehicle

12

24

(7.5)

(15)

(22.5)

6

12

IIIIMA-41

IIIIMA-34

IIII

Outside and inside

IIII

IIII

IIIIPB-4

RRRRVTL-6

36

18

48

60

72

84

(30)

(37.5)

24

RRMA-39

II

30

(45)

36

(52.5)

42

96

(60)

48

Reference

page

MA-41

MA-42

MA-35

MA-43

FSU-5

RSU-6

MA-40

MA-40

MA-40

MA-40

B

C

D

E

F

G

H

I

J

K

L

M

N

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be performed on the following items as shown in the table.

Severe driving conditions

A — Driving under dusty conditions

B — Driving repeatedly short distances

C — Towing a trailer or caravan

D — Extensive idling

E —Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity or mountainous areas

Revision: August 2014 2015 QX60 NAM

MA-13

O

MA

Page 14

PERIODIC MAINTENANCE

< PERIODIC MAINTENANCE >

G — Driving in areas using salt or other corrosive areas

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

Maintenance operation: Inspect = Check and correct or replace as necessary.

Driving condition Maintenance item

A........Air cleaner filter (Viscous paper type)Replace More frequently MA-25

A B C D . . . . . Engine oil & engine oil filter Replace

.....F...Brake fluid Replace

..C....H.Differential gear oil Replace

......GH.

......GH.Propeller shaft & drive shafts Inspect

A . C . . . G H I Brake pads, rotors, drums & linings Inspect

A........Air conditioner filter Replace More frequently VTL-6

Steering gear & linkage, axle & suspension parts

Maintenance

operation

Inspect

Maintenance interval

Every 6,000 km (3,750

miles) or 3 months

Every 24,000 km (15,000

miles) or 12 months

Every 36,000 km (22,500

miles) or 24 months

Every 24,000 km (15,000

miles) or 12 months

Every 12,000 km (7,500

miles) or 6 months

Every 12,000 km (7,500

miles) or 6 months

Reference

page

MA-26

MA-26

MA-39

MA-34

MA-34

MA-35

MA-41

MA-42

MA-35

MA-43

MA-40

MA-40

MA-40

MA-40

PB-4

Revision: August 2014 2015 QX60 NAM

MA-14

Page 15

RECOMMENDED FLUIDS AND LUBRICANTS

< PERIODIC MAINTENANCE >

RECOMMENDED FLUIDS AND LUBRICANTS

FOR USA AND CANADA

FOR USA AND CANADA : Fluids and Lubricants INFOID:0000000011131987

The following are approximate capacities, The actual refill capacities may be slightly different.

When refilling, follow the procedures described elsewhere in this manual.

Description

Fuel

With oil filter

change

Without oil filEngine oil

Drain and refill

Cooling system

(with reservoir at MAX level)

CVT fluid

Differential gear oil

Transfer fluid

Power steering fluid (E-PSF)

Brake fluid — — —

Multi-purpose grease — — — NLGI No. 2 (Lithium soap base)

Windshield washer fluid

Air conditioning system refrigerant 0.80 ± 0.03 kg 1.80 ± 0.07 lb 1.80 ± 0.07 lb

Air conditioning system oil

ter change

Dry engine

(Overhaul)

Metric US measure Imp measure

74.0

4.8

4.5

5.1

9.6

8.8

0.5

0.31

1.0

5.0

230 m

Capacity (Approximate)

19-1/2 gal 16-1/4 gal

5-1/8 qt 4-1/4 qt

4-3/4 qt 4 qt

5-3/8 qt 4-1/2 qt

10-1/8 qt 8-1/2 qt

9-1/4 qt 7-3/4 qt

1-1/8 pt 7/8 pt

5/8 pt 1/2 pt

2-1/8 pt 1-3/4 pt

5-1/4 qt 4-3/8 qt

7.8 fl oz 8.1 fl oz

Recommended Fluids/Lubricants

Unleaded gasoline with an octane rating of

at least 91 AKI (RON 96)

Genuine NISSAN engine oil or equivalent

• Engine oil with API Certification Mark

(For further details, see “Engine Oil Recommendation”.), Viscosity SAE 0W-20

(As an alternative to this recommended oil,

SAE 5W-30 conventional petroleum based

oil may be used and meet all specifications

and requirements necessary to maintain the

New Vehicle Limited Warranty.)

Pre-diluted Genuine NISSAN Long Life Antifreeze/ Coolant (blue) or equivalent

Genuine NISSAN CVT Fluid NS-3

(Use only Genuine NISSAN CVT Fluid

NS-3. Using transmission fluid other

than Genuine NISSAN CVT Fluid NS-3

will damage the CVT, which is not covered by the INFINITI new vehicle limited

warranty.)

Genuine NISSAN Differential Oil Hypoid

Super Semi-synthetic API GL-5, Viscosity

SAE 75W-90

(The use of differential gear oil other than

the specified may cause vehicle malfunctions and result in non-warranty vehicle repairs.)

API GL-5, Viscosity SAE 80W-90 or equivalent

Genuine NISSAN E-PSF or equivalent

(Use of a power steering fluid other than

Genuine NISSAN E-PSF will prevent the

power steering system from operating properly.)

Genuine NISSAN Super Heavy Duty Brake

Fluid or equivalent

DOT 3 (US FMVSS No. 116)

(Available in mainland U.S.A. through an

INFINITI retailer.)

Genuine NISSAN Windshield Washer Concentrate Cleaner & Antifreeze or equivalent

HFC-134a (R-134a)

(For further information, see “Air conditioning specification label”.)

A/C System Oil Type S (DH-PS)

(For further information, see “Air conditioning specification label”.)

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

MA

Revision: August 2014 2015 QX60 NAM

MA-15

Page 16

RECOMMENDED FLUIDS AND LUBRICANTS

< PERIODIC MAINTENANCE >

FOR USA AND CANADA : Engine Oil Recommendation

INFOID:0000000011131988

INFINITI recommends the use of an energy conserving oil in order to improve fuel economy. Select only

engine oils that meet the American Petroleum Institute (API) certification and International Lubricant Standardization and Approval Committee (ILSAC) certification and SAE viscosity standard. These oils have the API

certification mark on the front of the container. Oils which do not have the specified quality label should not be

used as they could cause engine damage.

ALPIA0008ZZ

1. API certification mark 2. API service symbol

FOR USA AND CANADA : Engine Coolant Mixture Ratio INFOID:0000 000011131989

The engine cooling system is filled at the factory with a pre-diluted mixture of 50% Genuine NISSAN Long Life

Antifreeze/Coolant (blue) and 50% water to provide year-round anti-freeze and coolant protection. The antifreeze solution contains rust and corrosion inhibitors. Additional engine cooling system additives are not necessary.

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

• When adding or replacing coolant, be sure to use only Genuine NISSAN Long Life Antifreeze/Coolant (blue) or equivalent. Genuine NISSAN Long Life Antifreeze/Coolant (blue) is pre-diluted to provide antifreeze protection to -34°F (-37°C). If additional freeze protection is needed due to weather

where the vehicle is operated, add Genuine NISSAN long life Antifreeze/Coolant (blue) concentrate

following the directions on the container. If an equivalent coolant other than Genuine NISSAN Long

Life Antifreeze/Coolant (blue) is used, follow the coolant manufacturer’s instructions to maintain

minimum antifreeze protection to -34°F (-37°C). The use of other types of coolant solutions other

than Genuine NISSAN Long Life Antifreeze/Coolant (blue) or equivalent may damage the engine

cooling system.

• Mixing any other type of coolant other than Genuine NISSAN Long Life Antifreeze/Coolant (blue),

including Genuine NISSAN Long Life Antifreeze/Coolant (green) or the use of non-distilled water will

reduce the life expectancy of the factory filled coolant.

FOR MEXICO

FOR MEXICO : Fluids and Lubricants INFOID:0000000011131990

The following are approximate capacities, The actual refill capacities may be slightly different.

When refilling, follow the procedures described elsewhere in this manual.

Capacity (Approximate)

Metric US measure Imp measure

Fuel

Revision: August 2014 2015 QX60 NAM

74.0

19-1/2 gal 16-1/4 gal

MA-16

Recommended Fluids/Lubricants

Unleaded gasoline with an octane rating of

at least 91 AKI (RON 96)

Page 17

RECOMMENDED FLUIDS AND LUBRICANTS

< PERIODIC MAINTENANCE >

Capacity (Approximate)

Metric US measure Imp measure

With oil filter

change

Engine oil

Drain and refill

Cooling system

(with reservoir at MAX line)

CVT fluid

Differential gear oil

Transfer fluid

Power steering fluid

Brake fluid — — —

Multi-purpose grease — — — NLGI No. 2 (Lithium soap base)

Windshield washer fluid

Air conditioning system refrigerant 0.80 ± 0.03 kg 1.80 ± 0.07 lb 1.80 ± 0.07 lb

Air conditioning system oil

Without oil filter

change

Dry engine (engine

overhaul)

4.8

4.5

5.1

9.6

8.8

0.5

0.31

1.0

5.0

230 m

5-1/8 qt 4-1/4 qt

4-3/4 qt 4 qt

5-3/8 qt 4-1/2 qt

10-1/8 qt 8-1/2 qt

9-1/4 qt 7-3/4 qt

1-1/8 pt 7/8 pt

5/8 pt 1/2 pt

2-1/8 pt 1-3/4 pt

5-1/4 qt 4-3/8 qt

7.8 fl oz 8.1 fl oz

Recommended Fluids/Lubricants

Nippon oil (Genuine NISSAN engine oil

API grade SM, Viscosity SAE 5W-30)

Genuine NISSAN Engine Coolant (blue) or

equivalent

(Use Genuine NISSAN Engine Coolant or

equivalent in its quality, in order to avoid

possible aluminum corrosion within the engine cooling system caused by the use of

non-genuine engine coolant.Note that any

repairs for the incidents within the engine

cooling system while using non-genuine

engine coolant may not be covered by the

warranty even if such incidents occurred

during the warranty period.)

Genuine NISSAN CVT fluid NS-3

(Use only Genuine NISSAN CVT Fluid

NS-3. Using transmission fluid other

than Genuine NISSAN CVT Fluid NS-3

will damage the CVT, which is not covered by the INFINITI new vehicle limited

warranty.)

Genuine NISSAN Diff oil Hypoid Super

Semi-synthetic GL-5 75W-90

(Use Genuine NISSAN Diff Oil Hypoid Super semi-synthetic GL-5. Using differential

gear oil other than Genuine NISSAN Diff

Oil Hypoid Super semi-synthetic will damage the differential gear, which is not covered by the warranty.)

Genuine NISSAN Differential Oil Hypoid

Super GL-5 80W-90 or API GL-5, Viscosity

SAE 80W-90

Genuine NISSAN E-PSF or equivalent

(Use of a power steering fluid other than

Genuine NISSAN E-PSF will prevent the

power steering system from operating

properly.)

Genuine NISSAN Brake Fluid or equivalent DOT 3 (US FMVSS No. 116)

Genuine NISSAN Windshield Washer

Concentrate Cleaner & Antifreeze or

equivalent

HFC-134a (R-134a)

(For further information, see “Air conditioning specification label”.)

A/C System Oil Type S (DH-PS)

(For further information, see “Air conditioning specification label”.)

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

MA

Revision: August 2014 2015 QX60 NAM

MA-17

Page 18

RECOMMENDED FLUIDS AND LUBRICANTS

< PERIODIC MAINTENANCE >

FOR MEXICO : Engine Coolant Mixture Ratio

INFOID:0000000011131992

The engine cooling system is filled at the factory with a high-quality, year-round and extended life engine coolant. The high quality engine coolant contains the specific solutions effective for the anti-corrosion and the antifreeze function. Therefore, additional cooling system additives are not necessary.

Coolant Mixture Ratios

For outside temperatures down to: Anti-freeze coolant mixture ratio

° C ° F

– 15° 5° 30 % 70 %

– 35° – 30° 50 % 50 %

Genuine NISSAN Engine

Coolant or equivalent

Demineralized water or distilled

water

CAUTION:

• When adding or replacing coolant, be sure to use only a Genuine NISSAN Engine Coolant or equivalent in its quality with the proper mixture ratio. See the examples shown in the figure.

The use of other types of engine coolant may damage the engine cooling system.

• When checking the engine coolant mixture ratio by the coolant hydrometer, use the chart below to correct

your hydrometer reading (specific gravity) according to coolant temperature.

Mixed coolant specific gravity

Unit: specific gravity

Engine coolant mixture

ratio

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

15 (59) 25 (77) 35 (95) 45 (113)

Coolant temperature °C (°F)

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter

turn to allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

Revision: August 2014 2015 QX60 NAM

MA-18

Page 19

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE (VQ35DE)

DRIVE BELTS

DRIVE BELTS : Checking Drive Belts INFOID:0000000011131993

AWBIA1225GB

1. Drive belt auto-tensioner 2. Generator 3. A/C compressor

4. Drive belt 5. Crankshaft pulley A. Indicator

B. Range when new drive belt is installed C. Possible use range D. View D

Engine front

A

B

C

D

E

F

G

H

I

WARNING:

Inspect and check the drive belt with the engine off.

1. Visually check entire drive belt for wear, damage or cracks.

2. Check that the drive belt auto-tensioner indicator is within the possible use range.

NOTE:

• When new drive belt is installed, the drive belt auto-tensioner indicator should be within the new drive

belt range.

• Check the drive belt auto-tensioner indicator when the engine is cold.

3. If the drive belt auto-tensioner indicator is out of the possible use range or belt is damaged, replace drive

belt.

DRIVE BELTS : Tension Adjustment INFOID:0000000011131994

• Drive belt tension is automatically adjusted by the drive belt auto-tensioner.

• Drive belt tension is not manually adjustable.

ENGINE COOLANT

ENGINE COOLANT : System Inspection INFOID:0000000011131995

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter

turn to allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for the following:

• Improper attachment

• Leaks

•Cracks

J

K

L

M

N

O

MA

Revision: August 2014 2015 QX60 NAM

MA-19

Page 20

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

• Damage

• Loose connections

• Chafing

• Deterioration

CHECKING RESERVOIR LEVEL

• Check the coolant reservoir tank level when the engine is cool.

• Adjust engine coolant level, if necessary, to ensure that the engine

coolant level is within the MIN to MAX range.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leaks, apply pressure to the cooling system using suitable tools (A and B).

Testing pressure : Refer to CO-28, "Radiator".

AWBIA1183GB

WARNING:

Do not remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure engine coolant escaping

from the radiator.

CAUTION:

Higher test pressure than specified may cause radiator damage.

CHECKING RADIATOR CAP

1. Inspect the radiator cap.

• Replace the cap if the metal plunger cannot be seen around the edge of the black rubber gasket.

• Replace the cap if deposits of waxy residue or other foreign material are on the black rubber gasket or

the metal retainer.

NOTE:

Thoroughly wipe out the radiator filler neck to remove any waxy residue or foreign material.

2. Pull the negative-pressure valve to open it and check that it

closes completely when released.

• Check that there is no dirt or damage on the valve seat of the

radiator cap negative-pressure valve.

• Check that there are no abnormalities in the opening and clos-

ing conditions of the negative-pressure valve.

AWBIA1188GB

SMA967B

Revision: August 2014 2015 QX60 NAM

MA-20

Page 21

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

3. Check radiator cap relief pressure using suitable tools (A and B).

Standard : Refer to CO-28, "Radiator"

• Apply water or engine coolant to the cap seal surface before

connecting the radiator cap to the tester,

• Replace the radiator cap if there is an abnormality in the negative-pressure valve, or if the open-valve pressure is outside of

the standard values.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

CAUTION:

• Be careful not to bend or damage the radiator fins.

• When radiator is cleaned on-vehicle, remove surrounding parts in order to access the radiator core.

Tape the harness and harness connectors to prevent water from entering.

1. Spray water to the back side of the radiator core using a side to side motion from the top down.

2. Stop spraying when debris no longer flows from radiator core.

3. Blow air into the back side of radiator core using a side to side motion from the top down.

• Use compressed air lower than 490 kPa (5.00 kg/cm

(11.8 in).

4. Continue to blow air until no water sprays out.

5. Check for engine coolant leaks. Repair as necessary.

.

AWBIA1189GB

2

, 71.1 psi) and keep distance more than 30 cm

A

B

C

D

E

F

G

H

ENGINE COOLANT : Changing Engine Coolant INFOID:0000000011131996

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter

turn to allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

DRAINING ENGINE COOLANT

1. Open radiator drain plug (1) at the bottom of radiator and

remove the radiator filler cap.

CAUTION:

Do not allow the engine coolant to contact the drive belt.

: Front

AWBIA1180GB

2. Remove water drain plug (A) and copper sealing washer (B).

CAUTION:

Do not reuse copper sealing washers.

: Front

I

J

K

L

M

N

O

MA

AWBIA1202GB

Revision: August 2014 2015 QX60 NAM

MA-21

Page 22

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

3. For a complete cooling system drain, remove the reservoir tank and drain the engine coolant, and then

clean the reservoir tank before installation.

CAUTION:

Do not allow the engine coolant to contact the drive belt.

4. When performing a complete cooling system drain, remove the

water drain plug (B), connector bolt (C), and copper sealing

washer (A) on the cylinder block.

CAUTION:

Do not reuse copper sealing washers.

NOTE:

• For Canada, water drain plug (B) is a block heater, not a drain

plug.

• Remove water drain plug (D) and copper sealing washer (E)

during engine overhaul.

CAUTION:

Do not reuse copper sealing washers.

: Front

5. Check the drained engine coolant for contaminants such as rust, corrosion or discoloration.

• If contaminated, flush the engine cooling system. Refer to FLUSHING COOLING SYSTEM.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug and the reservoir tank, (if removed).

2. Install the water drain plug (A) and copper sealing washer (B).

Tighten water drain plug to specification.

CAUTION:

Do not reuse copper sealing washers.

: Front

Water drain plug (A) : 12.25 N·m (1.2 kg-m, 9.0 ft-lb)

AWBIA1194GB

AWBIA1202GB

Revision: August 2014 2015 QX60 NAM

MA-22

Page 23

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

3. Install the cylinder block drain plugs (if removed).

• Apply sealant to the thread of the water drain plug (B), connector bolt (C) and water drain plug (D), (if removed).

CAUTION:

Do not reuse copper sealing washers.

: Front

A

B

NOTE:

• For Canada, water drain plug (B) in is a block heater, not a

water drain plug.

• Install copper sealing washers (E) and (A), (if removed).

• Use Genuine High Performance Thread Sealant or equiva-

lent. Refer to GI-22, "Recommended Chemical Products and

Sealants".

• Tighten each plug and connector bolt to specifications.

Water drain plug (B) : 62.0 N·m (6.3 kg-m, 46 ft-lb)

Connector Bolt (C) : 27.0 N·m (2.8 kg-m, 20 ft-lb)

Water drain plug (D) : 78.0 N·m (8.0 kg-m, 58 ft-lb)

AWBIA1194GB

4. If disconnected, reattach the upper radiator hose at the engine side.

5. Set the vehicle heater controls to the full HOT and heater ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

6. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tube and the Venturi assembly to the radiator cap

adapter.

Tool number : KV991J0070 (J-45695)

C

D

E

F

G

H

I

J

7. Insert the refill hose into the engine coolant mixture container

that is placed at floor level. Make sure the ball valve is in the

closed position.

• Use the specified engine coolant or equivalent. Refer to

MA-15, "FOR USA AND CANADA : Fluids and Lubricants"

(United States and Canada) or MA-16, "FOR MEXICO : Flu-

ids and Lubricants" (Mexico).

Engine Coolant capacity

(with reservoir tank)

: Refer to MA-15, "FOR USA

AND CANADA : Fluids and

Lubricants" (United States

and Canada) or MA-16, "FOR

MEXICO : Fluids and Lubricants" (Mexico).

LLIA0058E

8. Install an air hose to the Venturi assembly. The air pressure must be within specification.

Compressed air supply pressure

: 549 - 824 kPa (5.6 - 8.4 kg/cm

2

, 80 - 119 psi)

CAUTION:

The compressed air supply must be equipped with an air dryer.

9. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open

the ball valve on the refill hose slightly. Rising engine coolant will be visible in the refill hose. After the refill

hose is full of engine coolant, close the ball valve. This will purge air trapped in the refill hose.

K

L

M

N

O

MA

Revision: August 2014 2015 QX60 NAM

MA-23

Page 24

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

10. Continue to draw the vacuum until the gauge reaches 28 inches

of vacuum. The gauge may not reach 28 inches in high altitude

locations. Refer to the following table for expected vacuum readings.

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

11. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses vacuum. If the vacuum level drops, perform necessary repairs to the system

and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for leaks.

12. Place the engine coolant container (with the refill hose inserted) at the same level as the top of the radiator. Then open the ball valve on the refill hose so the engine coolant will be drawn up to fill the cooling system. The cooling system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the engine coolant container to get too low when filling to prevent air from being

inadvertently drawn into the cooling system.

13. Remove the Tool from the radiator neck opening and install the radiator cap.

14. Fill the cooling system reservoir tank to the specified level. Run the engine to warm up the cooling system

and top up the system as necessary.

LLIA0057E

FLUSHING COOLING SYSTEM

1. Fill the radiator from the filler neck above the radiator upper hose and reservoir tank with clean water and

reinstall radiator filler cap.

2. Run the engine until it is at normal operating temperature.

3. Rev the engine two or three times under no-load.

4. Stop the engine and wait until it cools down.

5. Drain the water from the system. Refer to MA-21, "ENGINE COOLANT : Changing Engine Coolant"

6. Repeat steps 1 through 5 until clear water begins to drain from the radiator.

.

FUEL LINES

FUEL LINES : Inspection INFOID:0000000011131997

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration.

Repair or replace damaged parts as necessary.

SMA803A

AIR CLEANER FILTER

Revision: August 2014 2015 QX60 NAM

MA-24

Page 25

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

AIR CLEANER FILTER : Exploded View INFOID:0000000011131998

A

B

C

D

E

F

G

AWBIA1624ZZ

1. Air duct hose and resonator assembly 2. Front air duct 3. Grommet

4. Air cleaner case (lower) 5. Grommets 6. Air cleaner case mounting bracket

7. Bracket 8. Air cleaner filter 9. Air cleaner case (upper)

10. Mass air flow sensor A. Air cleaner case side

clips

To electric throttle control actuator

AIR CLEANER FILTER : Removal and Installation INFOID:0000000011131999

REMOVAL

CAUTION:

It is not necessary to remove the front air duct to replace the air cleaner filter.

NOTE:

Replace the air cleaner filter per the periodic maintenance schedule or as necessary. Refer to MA-9, "FOR

USA AND CANADA : Introduction of Periodic Maintenance" (USA and Canada) or MA-12, "FOR MEXICO :

Introduction of Periodic Maintenance" (Mexico).

1. Unhook air cleaner case side clips and lift air cleaner case (upper).

2. Remove the air cleaner filter.

INSTALLATION

Installation is in the reverse order of removal.

ENGINE OIL

H

I

J

K

L

M

N

O

ENGINE OIL : Inspection INFOID:0000000011132000

OIL LEVEL

NOTE:

Revision: August 2014 2015 QX60 NAM

MA-25

MA

Page 26

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

• Before starting the engine, check the oil level. If the engine is

already started, stop it and allow 10 minutes before checking.

• Check that the oil level is within the range as indicated on the dipstick.

• If it is out of range, add oil as necessary until the dipstick indicates

the correct level.

JMA122D

ENGINE OIL : Changing Engine Oil INFOID:0000000011132001

WARNING:

• Be careful not to burn yourself, as the engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Position the vehicle so it is level on the hoist.

2. Warm up the engine and check for engine oil leaks.

3. Stop engine and wait for 10 minutes.

4. Remove the oil pan drain plug and oil filler cap.

5. Drain the engine oil.

6. Install the oil pan drain plug with a new washer and refill the engine with new engine oil.

Oil specification and viscosity : For North America, refer to MA-16, "FOR

USA AND CANADA : Engine Oil Recommendation". For Mexico, refer to MA-16, "FOR

MEXICO : Fluids and Lubricants".

Oil pan drain plug : 34.3 N·m (3.5 kg-m, 25 ft-lb)

CAUTION:

• Be sure to clean the oil pan drain plug and install with a new washer.

• The refill capacity depends on the engine oil temperature and drain time. Use the specifications

for reference only. Always use the dipstick to determine when the proper amount of engine oil is

in the engine.

7. Warm up the engine and check around the oil pan drain plug and oil filter for oil leaks.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level using the dipstick.

CAUTION:

Do not overfill the engine with engine oil.

OIL FILTER

OIL FILTER : Removal and Installation INFOID:0000000011132002

REMOVAL

1. Drain engine oil. Refer to LU-9, "Changing Engine Oil".

2. Remove front fender protector side cover RH. Refer to EXT-28, "FENDER PROTECTOR : Exploded

View".

Revision: August 2014 2015 QX60 NAM

MA-26

Page 27

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

3. Remove the oil filter using Tool (A) as shown.

Tool number : KV10115801 (J-38956)

WARNING:

Be careful not to burn yourself, as the engine oil may be

hot.

CAUTION:

• When removing, prepare a shop cloth to absorb any oil

leaks or spills.

• Do not allow engine oil to adhere to the drive belts.

• Completely wipe off any oil that adheres to the engine and

the vehicle.

A

B

C

ALBIA0617GB

D

• The oil filter is provided with a relief valve. Use a genuine

NISSAN oil filter or equivalent.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply clean engine oil to the oil seal contact surface of the new

oil filter.

ALC094

SMA010

E

F

G

H

I

J

K

L

3. Screw the oil filter manually until it touches the installation surface, then tighten it by turning another 2/3 turn or tighten to

specification using Tool.

Oil filter : 18.0 N·m (1.8 kg-m, 13 ft-lb)

Tool number : KV10115801 (J-38956)

SMA229B

4. Refill the engine with new engine oil. Refer to LU-9, "Changing Engine Oil"

5. Check the oil level and add engine oil as necessary. Refer to LU-8, "Inspection"

.

.

6. After warming up the engine, check for engine oil leaks.

7. Install front fender protector side cover RH. Refer to EXT-28, "FENDER PROTECTOR : Exploded View"

SPARK PLUG

Revision: August 2014 2015 QX60 NAM

MA-27

M

N

O

MA

.

Page 28

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

SPARK PLUG : Exploded View

INFOID:0000000011132003

AWBIA0203GB

1. Ignition coil 2. Spark plug 3. Rocker cover RH

4. Rocker cover LH

SPARK PLUG : Removal and Installation INFOID:0000000011132004

REMOVAL

1. Remove the ignition coil. Refer to EM-42, "Removal and Installation LH" and EM-42, "Removal and Instal-

lation RH".

2. Remove the spark plug with a suitable spark plug wrench.

PBIC2982E

INSPECTION AFTER REMOVAL

Revision: August 2014 2015 QX60 NAM

MA-28

Page 29

ENGINE MAINTENANCE (VQ35DE)

< PERIODIC MAINTENANCE >

Use the standard type spark plug for normal condition.

Spark plug : Refer to EM-135, "Spark Plug"

CAUTION:

• Do not drop or shock spark plug.

• Do not use a wire brush for cleaning.

• If plug is covered with carbon, a spark plug cleaner may be

used.

: less than 588 kPa (6 kg/cm

Cleaner air pressure

85 psi)

Cleaning time : less than 20 seconds

• Spark plug gap adjustment is not required between replacement

intervals.

• Measure spark plug gap. When it exceeds the limit, replace spark

plug even if it is within the specified replacement mileage. Refer to

EM-135, "Spark Plug"

.

.

2

,

A

B

C

SMA773C

D

E

F

G

SMA806CA

INSTALLATION

Installation is in the reverse order of removal.

Make DENSO

Standard type* FXE22HR11

Gap (nominal) 1.1 mm (0.043 in)

*: Always check with the Parts Department for the latest parts information.

EVAP VAPOR LINES

EVAP VAPOR LINES : Inspection INFOID:000000001113200 5

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

H

I

J

K

L

M

N

O

Revision: August 2014 2015 QX60 NAM

MA-29

MA

Page 30

CHASSIS AND BODY MAINTENANCE

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

IN-CABIN MICROFILTER

IN-CABIN MICROFILTER : Removal and Installation INFOID:0000000011132006

REMOVAL

1. Remove center console side finisher (RH). Refer to IP-18, "Exploded View".

2. Release the in-cabin microfilter cover tab (A) and remove the

cover from under the RH side of the instrument panel.

CAUTION:

Use care when lifting up on the tab to avoid damaging it.

AWIIA1577ZZ

3. Remove the in-cabin microfilter.

CAUTION:

If the filter is deformed/damaged when removing, replace it with a new one. A deformed or damaged filter may affect the dust collecting performance.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

When installing, handle the filter with extreme care to avoid deforming or damaging the filter.

NOTE:

The in-cabin microfilter is marked with an air flow arrow. The end of the microfilter with the arrow should face

the passenger side of the vehicle. The arrow should point towards the rear of the vehicle.

EXHAUST SYSTEM

EXHAUST SYSTEM : Inspection INFOID:0000000011132007

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage or deterioration. Repair or replace as necessary.

SMA211A

CVT FLUID

Revision: August 2014 2015 QX60 NAM

MA-30

Page 31

CHASSIS AND BODY MAINTENANCE

< PERIODIC MAINTENANCE >

CVT FLUID : Inspection INFOID:0000000011132008

FLUID LEAKAGE

• Check transaxle surrounding area (oil seal and plug etc.)for fluid

leakage.

• If anything is found, repair or replace damaged parts and adjust