Page 1

Edition: February 2002

Revision: April 2004

Publication No. SM3E-1V35U9

QUICK REFERENCE INDEX

A

GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEX

GI

General Information

EM

Engine Mechanical

LU

Engine Lubrication System

CO

Engine Cooling System

EC

Engine Control System

FL

Fuel System

EX

Exhaust System

ACC

Accelerator Control System

CL

Clutch

MT

Manual Transmission

AT

Automatic Transmission

PR

Propeller Shaft

RFD

Rear Final Drive

FAX

Front Axle

RAX

Rear Axle

FSU

Front Suspension

RSU

Rear Suspension

WT

Road Wheels & Tires

BR

Brake System

PB

Parking Brake System

BRC

Brake Control System

PS

Power Steering System

SB

Seat Belts

SRS

Supplemental Restraint System

(SRS)

BL

Body, Lock & Security System

GW

Glasses, Window System & Mirrors

RF

Roof

EI

Exterior & Interior

IP

Instrument Panel

SE

Seat

ATC

Automatic Air Conditioner

SC

Starting & Charging System

LT

Lighting System

DI

Driver Information System

WW

Wiper, Washer & Horn

BCS

Body Control System

LAN

LAN System

AV

Audio, Visual,Navigation & Telephone System

ACS

Auto Cruise Control System

PG

Power Supply, Ground & Circuit Elements

MA

Maintenance

IDX

Alphabetical Index

A

B

C

D

E

F

G

H

I

J

K

L

M

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or

transmitted in any form, or by any means, electronic, mechanical, recording or otherwise, without the prior

written permission of Nissan Motor Company Ltd., Tokyo, Japan.

Page 2

This manual contains maintenance and repair procedure for the 2003

INFINITI G35.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in specifications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of

the technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a

manner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician

and the tools and parts available. Accordingly, anyone using service

procedures, tools or parts which are not specifically recommended

by NISSAN must first be completely satisfied that neither personal

safety nor the vehicle’s safety will be jeopardized by the service

method selected.

Page 3

PLEASE HELP MAKE THIS SERVICE MANUAL BETTER!

I N F I N I T I

Your comments are important to INFINITI and will help us to improve our Service Manuals.

Use this form to report any issues or comments you may have regarding our Service Manuals.

Please print this form and type or write your comments below. Mail or fax to:

SERVICE MANUAL: Model: Year:

PUBLICATION NO. (Refer to Quick Reference Index ):

Please describe any Service Manual issues or problems in detail:

Page number(s)

R

Nissan North America, Inc.

Technical Service Information

39001 Sunrise Drive, P.O. Box 9200

Farmington Hills, MI USA 48331

FAX: (248) 488-3910

Note: Please include a copy of each page, marked with your comments.

Are the trouble diagnosis procedures logical and easy to use? (circle your answer) YES NO

If no, what page number(s)?

Please describe the issue or problem in detail:

Is the organization of the manual clear and easy to follow? (circle your answer) YES NO

Please comment:

What information should be included in INFINITI Service Manuals to better support you in servicing or

repairing customer vehicles?

Note: Please include a copy of each page, marked with your comments.

DATE: YOUR NAME: POSITION:

DEALER: DEALER NO.: ADDRESS:

CITY: STATE/PROV./COUNTRY: ZIP/POSTAL CODE:

Page 4

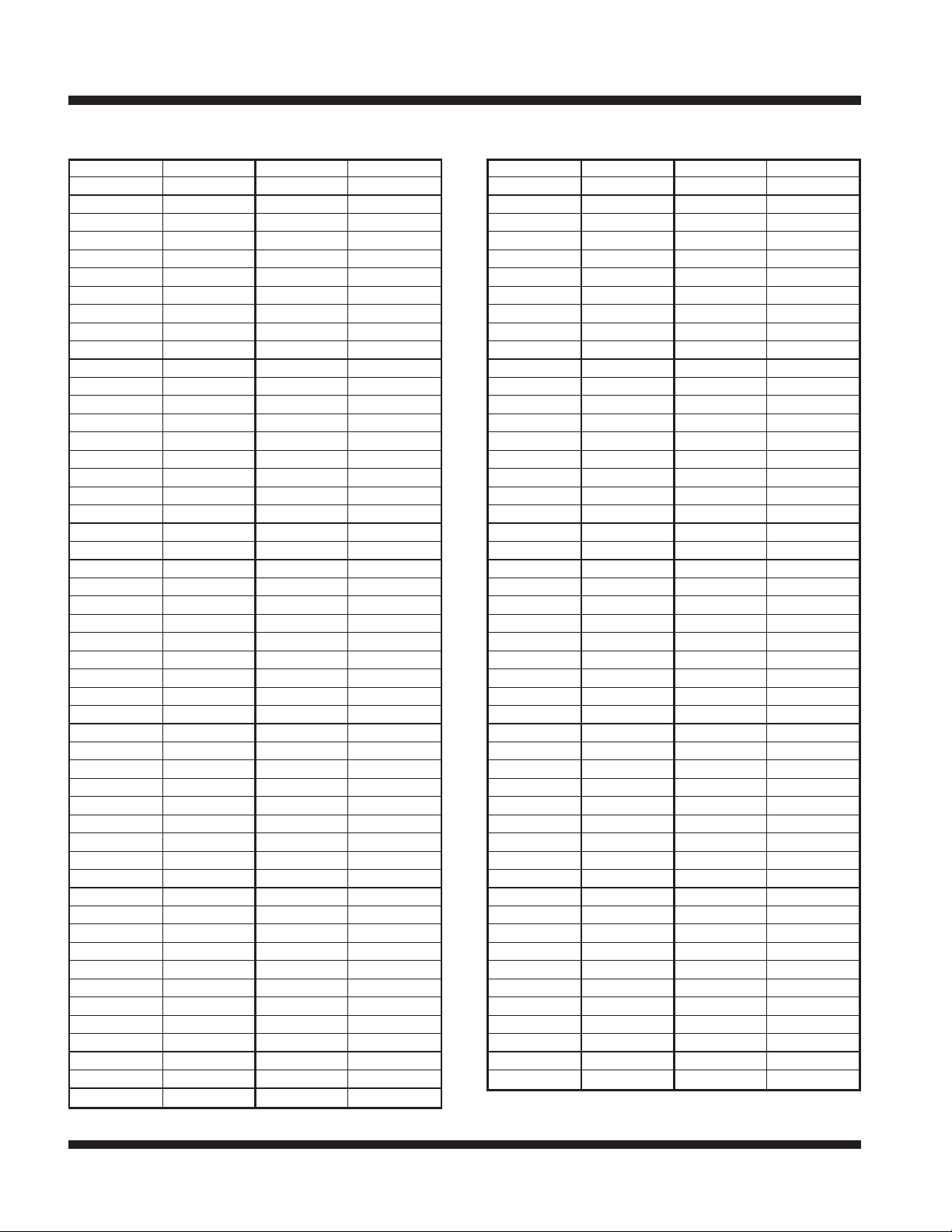

INCH TO METRIC CONVERSION TABLE

(Rounded-off for automotive use)

inches mm inches mm

.100 2.54 .610 15.49

.110 2.79 .620 15.75

.120 3.05 .630 16.00

.130 3.30 .640 16.26

.140 3.56 .650 16.51

.150 3.81 .660 16.76

.160 4.06 .670 17.02

.170 4.32 .680 17.27

.180 4.57 .690 17.53

.190 4.83 .700 17.78

.200 5.08 .710 18.03

.210 5.33 .720 18.29

.220 5.59 .730 18.54

.230 5.84 .740 18.80

.240 6.10 .750 19.05

.250 6.35 .760 19.30

.260 6.60 .770 19.56

.270 6.86 .780 19.81

.280 7.11 .790 20.07

.290 7.37 .800 20.32

.300 7.62 .810 20.57

.310 7.87 .820 20.83

.320 8.13 .830 21.08

.330 8.38 .840 21.34

.340 8.64 .850 21.59

.350 8.89 .860 21.84

.360 9.14 .870 22.10

.370 9.40 .880 22.35

.380 9.65 .890 22.61

.390 9.91 .900 22.86

.400 10.16 .910 23.11

.410 10.41 .920 23.37

.420 10.67 .930 23.62

.430 10.92 .940 23.88

.440 11.18 .950 24.13

.450 11.43 .960 24.38

.460 11.68 .970 24.64

.470 11.94 .980 24.89

.480 12.19 .990 25.15

.490 12.45 1.000 25.40

.500 12.70 2.000 50.80

.510 12.95 3.000 76.20

.520 13.21 4.000 101.60

.530 13.46 5.000 127.00

.540 13.72 6.000 152.40

.550 13.97 7.000 177.80

.560 14.22 8.000 203.20

.570 14.48 9.000 228.60

.580 14.73 10.000 254.00

.590 14.99 20.000 508.00

.600 15.24

METRIC TO INCH CONVERSION TABLE

(Rounded-off for automotive use)

mm inches mm inches

1 .0394 51 2.008

2 .079 52 2.047

3 .118 53 2.087

4 .157 54 2.126

5 .197 55 2.165

6 .236 56 2.205

7 .276 57 2.244

8 .315 58 2.283

9 .354 59 2.323

10 .394 60 2.362

11 .433 61 2.402

12 .472 62 2.441

13 .512 63 2.480

14 .551 64 2.520

15 .591 65 2.559

16 .630 66 2.598

17 .669 67 2.638

18 .709 68 2.677

19 .748 69 2.717

20 .787 70 2.756

21 .827 71 2.795

22 .866 72 2.835

23 .906 73 2.874

24 .945 74 2.913

25 .984 75 2.953

26 1.024 76 2.992

27 1.063 77 3.031

28 1.102 78 3.071

29 1.142 79 3.110

30 1.181 80 3.150

31 1.220 81 3.189

32 1.260 82 3.228

33 1.299 83 3.268

34 1.339 84 3.307

35 1.378 85 3.346

36 1.417 86 3.386

37 1.457 87 3.425

38 1.496 88 3.465

39 1.535 89 3.504

40 1.575 90 3.543

41 1.614 91 3.583

42 1.654 92 3.622

43 1.693 93 3.661

44 1.732 94 3.701

45 1.772 95 3.740

46 1.811 96 3.780

47 1.850 97 3.819

48 1.890 98 3.858

49 1.929 99 3.898

50 1.969 100 3.937

Page 5

QUICK REFERENCE CHART G35

2003

QUICK REFERENCE CHART G35 PFP:00000

ENGINE TUNE-UP DATA (VQ35DE) ELS0003W

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed

A/T (In “N” position)

M/T

Ignition timing

(BTDC at idle speed)

CO% at idle 0.7 - 9.9 % and engine runs smoothly

Deflection adjustment Unit: mm (in)

Drive Belt

Limit After adjustment Limit After adjustment

Alternator, power steering

oil pump and fan belt*

Air conditioner compressor belt

Applied pushing force 98 N (10 kg, 22 lb) —

Radiater cap relief pressure

Cooling system leakage testing pressure

7 (0.28)

12 (0.47)

Standard

Limit 59 (0.6, 9)

Used belt

4 - 5

(0.16 - 0.20)

9 - 10

(0.35 - 0.39)

kPa (kg/cm

kPa (kg/cm

2

, psi)

2

, psi)

rpm

(0.138 - 0.177)

New belt

3.5 - 4.5

8 - 9

(0.31- 0.35)

650±50

15°±5°

Te ns i on ad ju s tm e n t

Used belt

730 - 818

294 (30, 66)

196 (20, 44)

78 - 98 (0.8 - 1.0, 11 - 14)

157(1.6, 23)

(74.5 - 83.5,

164 - 184)

348 - 436

(35.5 - 44.5,

78 - 98)

Unit: N(kg, Ib)

New belt

838 - 926

(85.5 - 94.5,

188 - 208)

470 - 559

(48 - 57,

106 - 126)

Compression pressure

Standard

Minimum 981 (10.0, 142)/300

Make NGK

Standard type PLFR5A - 11

Spark plug

(Platinum-tipped type)

*: Alternator and power steering oil pump for M/T models

Hot type PLFR4A - 11

Cold type PLFR6A - 11

Gap (Nominal) mm(in) 1.1 ( 0.043 )

kPa (kg/cm

2

, psi)/rpm

1,275 (13.0, 185) /300

Page 6

QUICK REFERENCE CHART G35

2003

FRONT WHEEL ALIGNMENT (Unladen* )

Camber Degree minute (Decimal degree) Minimum – 0° 50′ ( – 0.83° )

Nominal – 0° 05′ ( – 0.08° )

Maximum 0° 40′ ( 0.67° )

Left and right difference 45′ ( 0.75° )

Caster Degree minute (Decimal degree) Minimum 7° 00′ ( 7.00° )

Nominal 7° 45′ ( 7.75° )

Maximum 8° 30′ ( 8.50° )

Left and right difference 45′ ( 0.75° )

Kingpin inclination Degree minute (Decimal degree) Minimum 3° 45′ ( 3.75° )

Nominal 4° 30′ ( 4.50° )

Maximum 5° 15′ ( 5.25° )

To ta l t o e- i n m m ( in ) M i ni m um 0 ( 0 )

Distance (A – B) Nominal 1 ( 0.04 )

Maximum 2 ( 0.08 )

Wheel turning angle (Full turn) Inside MInimum 37° 30′ ( 37.5° )

Degree minute (Decimal degree) Nominal 40° 30′ ( 40.5° )

Maximum 41° 30′ ( 41.5° )

Outside

Degree minute (Decimal degree)

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Nominal 32° 30′ ( 32.5° )

ELS0003X

REAR WHEEL ALIGNMENT (Unladen*) ELS0003Y

Camber Degree minute (Decimal degree) Minimum – 1° 05′ ( – 1.08° )

Nominal – 0° 35′ ( – 0.58° )

Maximum – 0° 05′ ( – 0.08° )

To ta l -i n m m ( in ) M i ni m um 0 ( 0 )

Distance ( A – B ) Nominal 2.7 ( 0.11 )

Maximum 5.4 ( 0.21 )

* : Fuel, engine coolant and oil full. Spare tire, jack, hand tools and mats in designated positions.

BRAKE ELS0003Z

Unit : mm ( in )

Front brake Pad wear limit 2.0 ( 0.079 )

Rotor repair limit 22.0 ( 0.866 )

Rear brake Pad wear limit 2.0 ( 0.079 )

Rotor repair limit 14.0 ( 0.551 )

Pedal free height

Pedal depressed height*

* : Under force of 490 N( 50 kg, 110 lb ) with engine running.

M/T model 154 - 164 ( 6.06 - 6.46 )

A/T model 162 - 172 ( 6.38 - 6.77 )

M/T model More than 90 ( 3.54 )

A/T model More than 95 ( 3.74 )

Page 7

QUICK REFERENCE CHART G35

2003

REFILL CAPACITIES

UNIT Liter US measure

Fuel tank 76 20 gal

Coolant ( With reservoir tank )

Engine

Transmission

Differential carrier 1.4 3 pt

Power steering system 1.0 1 - 1/8 qt

Air conditioning system

A/T 8.5 9 qt

M/T 8.7 9 - 1/4 qt

Drain and refill

With oil filter change 4.7 5 qt

Without oil filter change 4.4 4 - 5/8 qt

Dry engine (Overhaul) 5.4 5 - 3/4 qt

A/T 10.3 10 - 7/8 qt

M/T 2.9 3 - 1/4 qt

Compressor oil 0.18 6.0 fl oz

Refrigerant 0.55 kg 1.21 lb

ELS00040

Page 8

WIPER, WASHER & HORN

K ELECTRICAL

A

B

SECTION

CONTENTS

PRECAUTION ............................................................ 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

FRONT WIPER AND WASHER SYSTEM .................. 4

Components Parts and Harness Connector Loca-

tion ........................................................................... 4

System Description .................................................. 4

LOW SPEED WIPER OPERATION ...................... 4

HI SPEED WIPER OPERATION ........................... 5

INTERMITTENT OPERATION .............................. 5

AUTO STOP OPERATION .................................... 6

WASHER OPERATION ......................................... 6

MIST OPERATION ................................................ 6

FAI L-SAFE FUNCTIO N ...... . ........................... ....... 6

BCM WIPER SWITCH READING FUNCTION ..... 7

CAN Communication System Description .............. 10

CAN Communication Unit ...................................... 10

TYPE 1/TYPE 3 .................................................. 10

TYPE 2 ................................................................ 12

Schematic .............................................................. 14

Wiring Diagram — WIPER — ................................ 15

Ter mi na ls a nd R ef er en ce Va lue s fo r BC M .. ... .. .. .... 18

Ter mi na ls a nd R ef er en ce Va lu es f or I PD M E/ R . .... 18

How to Proceed With Trouble Diagnosis ................ 18

Preliminary Inspection ............................................ 19

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 19

CONSULT-II Functions ........................................... 20

CONSULT-II OPERATION .................................. 20

DATA MONITOR ................................................. 21

ACTIVE TEST ..................................................... 21

Front Wiper Does Not Operate .............................. 21

Front Wiper Stop Position Is Incorrect .................... 23

Only Front Wiper Low Does Not Operate .............. 24

Only Front Wiper Hi Does Not Operate .................. 26

Only Front Wiper Intermittent Does Not Operate ... 27

Front Wiper Intermittent Operation Switch Position

WIPER, WASHER & HORN

Cannot Be Adjusted ................................................ 27

Wipers Do Not Wipe When Front Washer Operates ... 28

Removal and Installation for Front Wiper Arms,

Adjustment for Wiper Arms Stop Location .............. 29

REMOVAL ........................................................... 29

INSTALLATION ................................................... 29

ADJUSTMENT .................................................... 29

Removal and Installation of Front Wiper Motor

Assembly ................................................................ 29

REMOVAL ........................................................... 29

INSTALLATION ................................................... 29

Disassembly and Assembly Front Wiper Motor

Assembly ................................................................ 30

DISASSEMBLY ................................................... 30

ASSEMBLY ......................................................... 30

Washer Nozzle Adjustment .................................... 31

Washer Tube Layout .............................................. 32

Removal and Installation for Front Washer Nozzle ... 32

Removal and Installation for Front Washer Joint .... 32

Inspection for Washer Nozzle ................................. 32

CHECK VALVE INSPECTION ............................. 32

Removal and Installation for Front Wiper and

Washer Switch ........................................................ 32

Removal and Installation for Washer Tank ............. 33

REMOVAL ........................................................... 33

INSTALLATION ................................................... 33

Removal and Installation for Washer Pump ........... 33

REMOVAL ........................................................... 33

INSTALLATION ................................................... 34

CIGARETTE LIGHTER ............................................. 35

Wiring Diagram — CIGAR — ................................. 35

Removal and Installation ........................................ 36

POWER SOCKET ..................................................... 37

Wiring Diagram — P/SCKT — ................................ 37

Removal and Installation for Console Power Socket ... 38

REMOVAL ........................................................... 38

INSTALLTION ...................................................... 38

HORN ........................................................................ 39

C

D

E

F

G

H

I

J

WW

L

M

Revision; 2004 April 2003 G35 Sedan

WW-1

Page 9

Wiring Diagram — HORN — .................................. 39

Removal and Installation ........................................ 40

REMOVAL ........................................................... 40

INSTALLATION .................................................... 40

Revision; 2004 April 2003 G35 Sedan

WW-2

Page 10

PRECAUTION

PRECAUTION PFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

AKS008YI

A

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To a void renderi ng th e SR S inope r a tive, which could increas e th e risk of p e rsonal injury or d eath

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Wiring Diagrams and Trouble Diagnosis AKS000AG

When You Read Wiring Diagrams, Refer to the Following:

● Refer to GI-14, "How to Read Wiring Diagrams" .

● Refer to PG-3, "POWER SUPPLY ROUTING CIRCUIT" for power distribution circuit.

When You Perform Trouble Diagnosis, Refer to the Following:

● Refer to GI-10, "How to Follow Trouble Diagnoses" .

● Refer to GI-26, "How to Perform Efficient Diagnosis for an Electrical Incident" .

B

C

D

E

F

G

H

I

J

WW

L

M

Revision; 2004 April 2003 G35 Sedan

WW-3

Page 11

FRONT WIPER AND WASHER SYSTEM

FRONT WIPER AND WASHER SYSTEM PFP:28810

Components Parts and Harness Connector Location AKS004T5

SKIA2211E

System Description AKS004T6

● All front wiper relays (HI, LO) are included in IPDM E/R (intelligent power distribution module engine

room).

● Wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input termi-

nals. Terminal combination status is read by BCM (body control module) when switch is turned ON.

● BCM (body control module) controls front wiper LO, HI, and INT (intermittent) operation.

● IPDM E/R (intelligent power distribution module engine room) operates wiper motor according to CAN

communication signals from BCM.

LOW SPEED WIPER OPERATION

Power is supplied at all times

● from BCM (input 1) terminal 48

● to combination switch terminal 17

● to 20A fuse (No. 74, located in IPDM E/R) and

● through IPDM E/R terminal 42

● to wiper motor terminal 4.

When the ignition switch is in the ON or START position, and front wiper switch is turned to LO position,

front wiper LO contact in combination switch comes ON, and

Power is supplied

● through combination switch terminal 10

● to BCM (output 3) terminal 41.

When BCM determines that wiper switch is in LO position, it uses CAN communications and

Front wiper request signal (LO) is sent

● from BCM terminals 70 and 71

● to IPDM E/R terminals 48 and 49.

Revision; 2004 April 2003 G35 Sedan

WW-4

Page 12

FRONT WIPER AND WASHER SYSTEM

When IPDM E/R receives front wiper request signal (LO), it turns ON front wiper LO relay (in IPDM E/R).

Ground is supplied

● from wiper motor terminal 3,

● through IPDM E/R terminal 31 and front wiper HI and LO relays

● to IPDM E/R terminal 14

● through grounds E17 and E43.

With power and ground supplied, the front wiper motor operates at low speed.

HI SPEED WIPER OPERATION

Power is supplied at all times

● from BCM (input 2) terminal 49

● to combination switch terminal 2

● to 20A fuse (No. 74, located in IPDM E/R) and

● through IPDM E/R terminal 42

● to wiper motor terminal 4.

When the ignition switch is the ON or START position, and the front wiper switch is turned to HI position,

front wiper HI contact in combination switch comes ON, and

Power is supplied

● through combination switch terminal 6

● to BCM (output 1) terminal 47.

When BCM determines that wiper switch is in HI position, it uses CAN communications and

Front wiper request signal (HI) is sent to IPDM E/R

● from BCM terminals 70 and 71

● to IPDM E/R terminals 48 and 49.

When the IPDM E/R receives front wiper request signal (HI), it turns ON front wiper LO relay and front wiper HI

relay. (in IPDM E/R),

Ground is supplied

● to front wiper motor terminal 2

● through IPDM E/R terminal 30 and front wiper HI relay and front wiper LO relay

● to IPDM E/R terminal 14

● through grounds E17 and E43.

With power and ground supplied, the front wiper motor operates at high speed.

A

B

C

D

E

F

G

H

I

J

WW

INTERMITTENT OPERATION

Power is supplied at all times

● from BCM (input 2) terminal 49

● to combination switch terminal 2.

When the ignition switch is in ON or START position, and the front wiper switch is turned to INT position,

the front wiper INT contact in the combination switch comes ON,

and power is supplied

● from combination switch terminal 10

● to BCM (output 3) terminal 41.

When BCM determines that combination switch status is front wiper INT ON, it performs the following operations.

● When BCM detects ON/OFF status of intermittent operation dial positions 1, 2, and 3 (in same way as

wiper INT), it determines wiper dial position status.

● BCM calculates operation interval from wiper dial position and vehicle speed signal received from combi-

nation meter through CAN communications.

● BCM sends front wiper request signal (INT) to IPDM E/R at calculated operation interval.

When IPDM E/R receives front wiper request signal (INT), it turns ON internal front wiper relay. It then sends

auto-stop signal to BCM, and conducts intermittent front wiper motor operation.

Revision; 2004 April 2003 G35 Sedan

WW-5

L

M

Page 13

FRONT WIPER AND WASHER SYSTEM

AUTO STOP OPERATION

With wiper switch turned OFF, wiper motor will continue to operate until wiper arms reach windshield base.

When wiper arms are not located at base of windshield with wiper switch OFF, ground is provided

● from IPDM E/R terminal 31

● to front wiper motor terminal 3, in order to continue wiper motor operation at low speed.

Ground is also supplied

● through IPDM E/R terminal 38

● to front wiper motor terminal 1

● through front wiper motor terminal 5, and

● through grounds E17 and E43.

When wiper arms reach base of windshield, front wiper motor terminals 1 and 4 are connected instead of terminals 1 and 5.

Then the IPDM E/R sends auto stop operation signal to BCM with CAN communication line.

When BCM receives auto-stop operation signal, BCM sends wiper stop signal to IPDM E/R with CAN communication line.

IPDM E/R stops wiper motor. Wiper motor will then stop wiper arms at the STOP position.

WASHER OPERATION

When the ignition switch is in ON or START position, power is supplied

● from BCM (input 1) terminal 48

● to combination switch terminal 1

● through 10A fuse (No. 87 located in IPDM E/R)

● through IPDM E/R terminal 18

● to washer motor terminal 2.

When front wiper switch is turned to washer position,

Ground is supplied

● to washer motor terminal 1

● through combination switch terminal 11

● through combination switch terminal 12

● from grounds M30 and M66.

With ground supplied, the front washer motor is operated, and at the same time,

Power is supplied

● through combination switch terminal 7

● to BCM (output 2) terminal 40.

When BCM detects that front washer motor has operated for 0.4 seconds or longer, BCM uses CAN communication and sends wiper request signal to IPDM E/R for low speed operation of wipers.

When BCM detects that washer switch is OFF, low speed operation cycles approximately 3 times and then

stops.

MIST OPERATION

When the wiper switch is turned to the mist position, wiper low speed operation cycles once and then stops.

For additional information about wiper operation under this condition, refer to WW-4, "

LOW SPEED WIPER

OPERATION" .

If the switch is held in the mist position, low speed operation continues.

FAIL-SAFE FUNCTION

IPDM E/R includes a fail-safe function to prevent malfunction of electrical components controlled by CAN communications in CAN communications occurs.

When fail-safe status is initiated, IPDM E/R remains in steady unit signals are received.

Revision; 2004 April 2003 G35 Sedan

WW-6

Page 14

FRONT WIPER AND WASHER SYSTEM

BCM WIPER SWITCH READING FUNCTION

BCM reads combination switch (wiper switch) status, and controls front wipers based on the results.

BCM is a combination of 5 output terminals (OUTPUT 1 - 5) and 5 input terminals (INPUT 1 - 5). It reads 20

types of switch data and 5 types of diagnosis data.

A

B

C

D

E

F

G

SKIA3873E

OPERATION DESCRIPTION

BCM continuously outputs power voltage from input terminals (INPUT 1 - 5). At this time, output terminals

(OUTPUT 1 - 5) operate transistors in sequence and carry current. If any switch (or switches) becomes ON at

this time, the input terminal corresponding to that switch detects current flowing, and BCM determines that the

switch is ON.

TABL E OF BC M - CO MBI NATI ON SWI TCH OP ERATION S

BCM reads operation status of combination switch using combinations shown in table below.

H

I

J

WW

L

M

SKIA2101E

Revision; 2004 April 2003 G35 Sedan

WW-7

Page 15

FRONT WIPER AND WASHER SYSTEM

SAMPLE OPERATION: (WIPER SWITCH TURNED TO LO POSITION)

● When wiper switch is turned to LO position, front wiper LO contact inside combination switch becomes

ON. At this time, OUTPUT 3 transistor operates and BCM detects flow of current at INPUT 1.

● When OUTPUT 3 transistor is ON and BCM detects current flowing at INPUT 1, BCM determines that

wiper switch is at LO. BCM uses CAN communication and sends front wiper signals to IPDM E/R.

● When OUTPUT 3 transistor operates again and BCM again detects current flowing at INPUT 1, it confirms

that front wiper LO operation is continuing.

SKIA4468E

NOTE:

Each OUTPUT terminal transistor operates at 10 ms intervals. Therefore, a delay occurs between the

switch becoming ON and operation of the electric load. However, this delay is so small it is undetectable.

OPERATING MODES

The following operation modes exist for combination switch reading function.

Normal Status

When BCM is not in sleep status, OUTPUT terminals (1 - 5) each turn ON-OFF every 10 ms.

Sleep Status

When BCM is in sleep status, output from OUTPUT 1 and 2 transistors stops, with BCM entering a power-saving mode. OUTPUT (3 - 5) turns ON-OFF every 60 ms, and only input from lighting switch system is accepted.

SKIA3097E

Revision; 2004 April 2003 G35 Sedan

WW-8

Page 16

FRONT WIPER AND WASHER SYSTEM

INTERMITTENT OPERATION

Wiper intermittent operation delay interval is determined from a combination of 3 switches (intermittent operation dial position 1, intermittent operation dial position 2, and intermittent operation dial position 3) and vehicle

speed signal.

During each intermittent operation delay interval, BCM sends front wiper request signal to IPDM E/R.

Wiper Dial Position Setting

Wiper dial position

Wiper dial position 1

Wiper dial position 2 ON ON OFF

Wiper dial position 3 ON OFF OFF

Wiper dial position 4 OFF OFF OFF

Wiper dial position 5 OFF OFF ON

Wiper dial position 6 OFF ON ON

Wiper dial position 7 OFF ON OFF

Intermittent operation

interval

Small

↓

Large

Intermittent operation

dial position 1

ON ON ON

Example: For wiper dial position 1...

Using combination switch reading function, BCM detects ON/OFF status of intermittent operation dial positions 1, 2, and 3.

When combination switch status is as listed below, BCM determines that it is wiper dial position 1.

● Intermittent operation dial position 1: ON (input 3 and output 1 are conducting.)

● Intermittent operation dial position 2: ON (input 5 and output 1 are conducting.)

● Intermittent operation dial position 3: ON (input 4 and output 2 are conducting.)

BCM determines front wiper intermittent operation delay interval from wiper dial position 1 and vehicle speed,

and sends wiper request signal (INT) to IPDM E/R.

Combination switch

Intermittent operation

dial position 2

Intermittent operation

dial position 3

A

B

C

D

E

F

G

H

I

J

WW

L

M

Revision; 2004 April 2003 G35 Sedan

WW-9

Page 17

FRONT WIPER AND WASHER SYSTEM

CAN Communication System Description AKS005L7

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle multiplex communication line with high data communication speed and excellent error detection ability. Many electronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication Unit AKS0093Q

Body type Sedan

Axle 2WD

Engine VQ35DE

Transmission

Brake control VDC

ECM ××

TCM ×

Data link connector ××

Combination meter ××

BCM ××

Steering angle sensor ××

VDC/TCS/ABS control unit ××

IPDM E/R ××

CAN communication type WW-10, "

×: Applicable

*:For further information, refer to GI-47, "

Up to serial 329287* From serial 329288*

CAN communication unit

IDENTIFICATION NUMBER" .

A/T

TYPE 1/TYPE 3" WW-12, "TYPE 2"

M/T

TYPE 1/TYPE 3

System Diagram

Input/Output Signal Chart

T: Transmit R: Receive

Signals ECM TCM

Engine torque signal T R

Engine speed signal T R R R

Engine coolant temperature signal T R R

Accelerator pedal position signal T R R

Closed throttle position signal T R

Combina-

tion meter

BCM

Steeri ng

angle

sensor

VDC/TCS/

ABS con-

trol unit

SKIA1880E

IPDM E/R

Revision; 2004 April 2003 G35 Sedan

WW-10

Page 18

FRONT WIPER AND WASHER SYSTEM

Signals ECM TCM

Wide open throttle position signal T R

Battery voltage signal T R

Stop lamp switch signal R T

Fuel consumption monitor signal T R

A/T self-diagnosis signal R T

A/T CHECK indicator lamp signal T R

A/T position indicator signal T R R

ABS operation signal R T

A/T shift schedule change demand

signal

A/C switch signal R T

A/C compressor request signal T R

A/C compressor feedback signal T R

Blower fan motor switch signal R T

Cooling fan motor operation signal T R

Position lights request signal R T R

Low beam request signal T R

Low beam status signal R T

High beam request signal R T R

High beam status signal R T

Front fog lights request signal T R

Vehicle s peed si gna l

Sleep request 1 signal R T

Sleep request 2 signal T R

Wake up request 1 signal R T R

Wake up request 2 signal R T R

Door switch signal (without navigation system)

Door switch signal (with navigation

system)

Turn indicato r signal R T

Seat belt buckle switch signal T R

Oil pressure switch signal R T

Buzzer output signal R T

ASCD SET lamp signal T R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

Output shaft revolution signal R T

Front wiper request signal T R

Front wiper stop position signal R T

Rear window defogger switch signal T R

RRT R

RT

Combina-

tion meter

RT

RT R

TR

BCM

Steering

angle

sensor

VDC/TCS/

ABS con-

trol unit

IPDM E/R

A

B

C

D

E

F

G

H

I

J

WW

L

M

Revision; 2004 April 2003 G35 Sedan

WW-11

Page 19

FRONT WIPER AND WASHER SYSTEM

Signals ECM TCM

Rear window defogger control signal

Manual mode signal R T

Not manual mode signal R T

Manual mode shift up signal R T

Manual mode shift down signal R T

Manual mode indicator signal T R

Hood switch signal R T

Theft warning horn request signal T R

Horn chirp signal T R

Steering angle sensor signal TR

Malfunction indicator lamp signal

(Type 3 only: From serial 329288*)

Fuel level sensor signal

(Type 3 only: From serial 329288*)

Turbine revolution signal

(Type 3 only: From serial 329288*)

*:For further information, refer to GI-47, "IDENTIFICATION NUMBER" .

R T

TR

RT

RT

Combination meter

BCM

Steeri ng

angle

sensor

VDC/TCS/

ABS con-

trol unit

IPDM E/R

TYPE 2

System Diagram

SKIA4474E

Input/Output Signal Chart

T: Transmit R: Receive

Signals ECM

Engine speed signal T R R

Engine coolant temperature signal T R

Accelerator pedal position signal T R

Fuel consumption monitor signal T R

A/C switch signal R T

A/C compressor request signal T R

A/C compressor feedback signal T R

Blower fan motor switch signal R T

Cooling fan motor operation signal T R

Position lights request signal R T R

Low beam request signal T R

Low beam status signal R R T

Combination meter

BCM

Steeri ng

angle sen-

sor

VDC/TCS/

ABS con-

trol unit

IPDM E/R

Revision; 2004 April 2003 G35 Sedan

WW-12

Page 20

FRONT WIPER AND WASHER SYSTEM

Signals ECM

High beam request signal R T R

High beam status signal R R T

Front fog lights request signal T R

Veh icle s peed si gna l

Sleep request 1 signal R T

Sleep request 2 signal T R

Wake up request 1 signal R T

Wake up request 2 signal R T

Door switch signal (without navigation system) R T R

Door switch signal (with navigation system) T R

Turn indicato r signal R T

Seat belt buckle switch signal T R

Oil pressure switch signal R T

Buzzer output signal R T

Malfunction indicator lamp signal T R

ASCD SET lamp signal T R

ASCD CRUISE lamp signal T R

Fuel level sensor signal R T

Front wiper request signal T R

Front wiper stop position signal R T

Rear window defogger switch signal T R

Rear window defogger control signal R R T

Hood switch signal R T

Theft warning horn request signal T R

Horn chirp signal T R

Stee ri ng angle sensor signal T R

RTR

Combination meter

RT

BCM

Steering

angle sen-

sor

VDC/TCS/

ABS con-

trol unit

IPDM E/R

A

B

C

D

E

F

G

H

I

J

WW

L

Revision; 2004 April 2003 G35 Sedan

WW-13

M

Page 21

FRONT WIPER AND WASHER SYSTEM

Schematic AKS004T8

TKWT0265E

Revision; 2004 April 2003 G35 Sedan

WW-14

Page 22

FRONT WIPER AND WASHER SYSTEM

Wiring Diagram — WIPER — AKS004T9

A

B

C

D

E

F

G

H

I

J

WW

L

M

TKWT0266E

Revision; 2004 April 2003 G35 Sedan

WW-15

Page 23

FRONT WIPER AND WASHER SYSTEM

TKWT0724E

Revision; 2004 April 2003 G35 Sedan

WW-16

Page 24

FRONT WIPER AND WASHER SYSTEM

A

B

C

D

E

F

G

H

I

J

WW

L

M

TKWT0725E

Revision; 2004 April 2003 G35 Sedan

WW-17

Page 25

FRONT WIPER AND WASHER SYSTEM

Terminal s and Reference Values for BCM AKS004TA

Te rm i na l N o.

(Wire color)

7 (W/R) Battery power supply ON — Battery voltage

8 (B) Ground ON — Approx. 0V

35 (W/L) Ignition switch (ON) ON — Battery voltage

40 (Y/R) Combination switch output 2

41 (PU) Combination switch output 3

42 (L) Combination switch output 4

43 (GY) Combination switch output 5

47 (Y) Combination switch output 1

48 (W/R) Combination switch input 1 ON

49 (W/G) Combination switch input 2 ON

50 (W/L) Combination switch input 3 ON

51 (G) Combination switch input 4 ON

52 (G/R) Combination switch input 5 ON

70 (L) CAN− H — — —

71 (R) CAN− L — — —

72 (PU) K-LINE — — —

Signal name

Ignition

switch

ON Lighting switch and wiper switch OFF

Measuring condition

Operation or condition

Lighting switch and wiper switch OFF 4.5V or more

Reference value

SKIA1119J

Terminal s and Reference Values for IPDM E/R AKS004TY

Te rm i na l N o.

(Wire color)

14 (B) Ground ON — Approx. 0V

18 (OR) Washer motor power ON Wiper switch

30 (L/B) High speed signal ON Wiper switch

31 (PU) Low speed signal ON Wiper switch

38 (L/Y) Wiper auto stop signal ON

42 (L/R) Wiper motor power source — — Battery voltage

45 (B) Ground — — Approx. 0V

48 (L) CAN− H — — —

49 (R) CAN− L — — —

Signal name

Ignition

switch

Measuring condition

Operation or condition

OFF Battery voltage

LO Approx. 0V

OFF Battery voltage

HI Approx. 0V

OFF Battery voltage

LO Approx. 0V

Wiper operating Approx. 0V

Wiper stopped Battery voltage

Reference value

How to Proceed With Trouble Diagnosis AKS004TC

1. Confirm the symptoms and customer complaint.

2. Understand operation description and function description. Refer to WW-4, "System Description" .

3. Carry out the Preliminary Inspection. Refer to WW-19, "Preliminary Inspection" .

4. Check symptom and repair or replace the cause of malfunction.

5. Does the warning chime operate normally? If YES: GO TO 6. If NO: GO TO 4.

6. INSPECTION END

Revision; 2004 April 2003 G35 Sedan

WW-18

Page 26

FRONT WIPER AND WASHER SYSTEM

Preliminary Inspection AKS004TD

CHECK POWER SUPPLY AND GROUND CIRCUIT

Inspection Procedure

1. CHECK FUSE

● Check if wiper and washer fuse is blown.

Unit Power source Fuse No.

Front washer motor Ignition ON or START position 87

Front wiper motor, front wiper relay, front wiper high relay Battery 74

Front wiper relay, front wiper high relay Ignition ON or START position 80

Combination switch Ignition ON or START position 12

Refer to WW-15, "Wiring Diagram — WIPER —"

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-

3, "POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

Te rm i na ls I gn it i on sw it c h po s it i on

(+)

Connector Terminal (Wire color)

E105 7 (W/R)

M1 35 (W/L) 0V Battery voltage

OK or NG

OK >> GO TO 3.

NG >> Check harness for open or short between BCM and fuse.

(-) OFF ON

Ground

Battery voltage Battery voltage

SKIA3195E

A

B

C

D

E

F

G

H

I

J

WW

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Ter mi na ls

Connector Terminal (Wire color)

E105 8 (B) Ground Yes

OK or NG

OK >> INSPECTION END

NG >> Check harness ground circuit.

Revision; 2004 April 2003 G35 Sedan

Continuity

SKIA3193E

WW-19

L

M

Page 27

FRONT WIPER AND WASHER SYSTEM

CONSULT-II Functions AKS004TE

CONSULT-II performs the following functions communicating with BCM.

BCM diagnosis position Check item, Diagnosis mode Description

Wiper

BCM C/U CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

CONSULT-II OPERATION

1. With the ignition switch OFF, connect CONSULT-II and CON-

SULT-II CONVERTER to the data link connector, then turn ignition switch ON.

DATA MONITOR Displays BCM input data in real time.

ACTIVE TEST Device operation can be checked by applying a drive signal to device.

PIIA1095E

2. Touch “START (NISSAN BASED VHCL)”.

3. Touch “BCM” on “SELECT SYSTEM” screen.

If “BCM” is not indicated, refer to GI-38, "

CONSULT-II Data Link

Connector (DLC) Circuit" .

4. Touch “WIPER”.

SKIA3098E

LKIA0071E

LKIA0099E

Revision; 2004 April 2003 G35 Sedan

WW-20

Page 28

FRONT WIPER AND WASHER SYSTEM

DATA MONITOR

Operation Procedure

1. Touch “WIPER” on “SELECT TEST ITEM” screen.

2. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Touch either “ALL SIGNALS” or “SELECTION FROM MENU” on “DATA MONITOR” screen.

All signals Monitors all the items.

Selection from menu Selects and monitors the individual item selected.

4. Touch “START”.

5. When “SELECTION FROM MENU” is selected, touch items to be monitored. When “ALL SIGNALS” is

selected, all the items will be monitored.

6. Touch “RECORD” while monitoring, then the status of the monitored item can be recorded. To stop

recording, touch “STOP”.

Display Item List

Monitor item name

“operation or unit”

IGN ON SW “ON/OFF” Displays “IGN Position (ON)/OFF, ACC Position (OFF)” status as judged from ignition switch signal.

FR WIPER INT “ON/OFF” Displays “Front Wiper INT (ON)/Other (OFF)” status as judged from wiper switch signal.

FR WIPER LOW “ON/OFF” Displays “Front Wiper LOW (ON)/Other (OFF)” status as judged from wiper switch signal.

FR WIPER HI “ON/OFF” Displays “Front Wiper HI (ON)/Other (OFF)” status as judged from wiper switch signal.

FR WASHER SW “ON/OFF” Displays “Front Washer Switch (ON)/Other (OFF)” status as judged from wiper switch signal.

INT VOLUME (1 - 7) Displays intermittent operation dial position setting (1 - 7) as judged from wiper switch signal.

VHCL SPEED SEN “ON/OFF” Displays “Driving (ON)/Stopped (OFF)” status as judged from vehicle speed signal.

FR WIPER STOP “ON/OFF” Displays “Stopped (ON)/Operating (OFF)” status as judged from the auto-stop signal.

Contents

A

B

C

D

E

F

G

H

I

ACTIVE TEST

Operation Procedure

1. Touch “WIPERS” on the “SELECT TEST ITEM” screen.

2. Touch “ACTIVE TEST” on the “SELECT DIAG MODE” screen.

3. Touch item to be tested and check operation of the selected item.

4. During the operation check, touching “BACK” deactivates the operation.

Display Item List

Test item Display on CONSULT-II screen Description

Front wiper HI output FR WIPER (HI) Front wiper HI can be operated by any ON–OFF operation.

Front wiper LO output FR WIPER (LO) Front wiper LO can be operated by any ON-OFF operation.

Front wiper INT output FR WIPER (INT) Front wiper INT can be operated by any ON-OFF operation.

Front Wiper Does Not Operate AKS004TF

1. INSPECTION 1: IPDM E/R TO FRONT WIPERS (1) INSPECTION

1. Turn on front wipers using active test. Refer to WW-21, "

2. Confirm front wiper operation.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

ACTIVE TEST" .

J

WW

L

M

Revision; 2004 April 2003 G35 Sedan

WW-21

Page 29

FRONT WIPER AND WASHER SYSTEM

2. INSPECTION: IPDM E/R TO FRONT WIPERS

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front wiper motor connector.

3. Check continuity between harness connector of IPDM E/R and

harness connector of front wiper motor.

Ter mi na ls

IPDM E/R Front wiper motor

Connector

E8

Te rm i na l

(Wire color)

30 (L/B)

42 (L/R) 4 (L/R)

Connector

E52

Ter mi na l

(Wire color)

2 (L/B)

4. Check continuity between IPDM E/R harness connector terminal

and ground.

Ter mi na ls C ont in ui ty

IPDM E/R

Ground YesConnector Terminal (Wire color)

E6 14 (B)

OK or NG

OK >> GO TO 3.

NG >>

● Check for short circuit or open circuit in harness

between IPDM E/R and front wiper motor.

● Check for open circuit in harness between IPDM E/R and ground.

Continuity

Yes31 (PU) 3 (PU)

SKIA4176E

SKIA4177E

3. CHECK IPDM E/R

1. Connect IPDM E/R connector and front wiper motor connector.

2. Select “FR WIPER HI” during active test. Refer to WW-21,

"ACTIVE TEST" . When front wiper relay, and front wiper HI

relay are operating, check voltage between harness connector

of IPDM E/R and ground.

Te rm i na ls

Volta geIPDM E/R (+)

Connector Terminal (Wire color)

31 (PU)

E8

30 (L/B)

42 (L/R) — Battery voltage

Ground

OK or NG

OK >> Replace front wiper motor.

NG >> Replace IPDM E/R.

(-) Condition

Stop ped Ba tt ery voltag e

LO operation Approx. 0V

Stop ped Ba tt ery voltag e

HI operation Approx. 0V

SKIA4178E

Revision; 2004 April 2003 G35 Sedan

WW-22

Page 30

FRONT WIPER AND WASHER SYSTEM

4. INSPECTION1: COMBINATION SWITCH TO BCM

Select “BCM” on CONSULT-II. Carry out self-diagnosis of “BCM C/

U”.

Displayed self-diagnosis results

No malfunction detected>>GO TO 5.

CAN communications or CAN system>>Inspect the BCM CAN

communications system. Go to BCS-16, "CAN Commu-

nication Inspection Using CONSULT-II (Self-Diagnosis)"

.

OPEN DETECT 1 - 5>>Combination switch system malfunction.

Go to LT- 125, "Combination Switch Inspection Accord-

ing to Self-Diagnostic Results" .

5. INSPECTION 2: COMBINATION SWITCH TO BCM

Select “BCM” on CONSULT-II. With “WIPER” data monitor, make

sure “FR WIPER INT”, “FR WIPER LOW” and “FR WIPER HI” turn

ON-OFF according to operation of wiper switch.

OK or NG

OK >> Replace BCM. Refer to BCS-23, "Removal and Installa-

tion of BCM" .

NG >> Replace wiper switch.

A

B

C

D

LKIA0073E

E

F

G

H

LKIA0102E

Front Wiper Stop Position Is Incorrect AKS004TG

1. INSPECTION: IPDM E/R TO WIPER MOTOR

Select “BCM” on CONSULT-II. With “WIPER” data monitor, make

sure “FR WIPER STOP” turns ON-OFF according to wiper operation.

OK or NG

OK >> Replace IPDM E/R.

NG >> GO TO 2.

LKIA0102E

I

J

WW

L

M

Revision; 2004 April 2003 G35 Sedan

WW-23

Page 31

FRONT WIPER AND WASHER SYSTEM

2. INSPECTION: IPDM E/R AND WIPER MOTOR

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front wiper motor connector.

3. Check continuity between harness connector of IPDM E/R and

harness connector of front wiper motor.

Te rm i na ls

IPDM E/R Front wiper motor

Connector

E8 38 (L/Y) E52 1 (L/Y) Yes

Te rm i na l

(Wire color)

Connector

Te rm i na l

(Wire color)

4. Check continuity between front wiper motor harness connector

terminal and ground.

Te rm i na l s

GroundConnector Terminal (Wire color)

E52 5 (B) Yes

OK or NG

OK >> GO TO 3.

NG >>

● Check for short circuit or open circuit in harness

between IPDM E/R and front wiper motor.

● Check for open circuit in harness between front wiper motor and ground.

Continuity

ContinuityFront wiper motor

SKIA4011E

SKIA4179E

3. CHECK IPDM E/R

While front wiper motor is stopped and while operating, measure

voltage between IPDM E/R harness connector terminal and ground.

Te rm i na l s

Volta geIPDM E/R (+)

Connector Terminal (Wire color)

E8 38 (L/Y) Ground

(-) Condition

Wiper operating Approx. 0V

Wiper stopped Battery voltage

OK or NG

OK >> Replace IPDM E/R.

SKIA4180E

NG >> Replace front wiper motor.

Only Front Wiper Low Does Not Operate AKS004TH

1. INSPECTION 1: IPDM E/R TO FRONT WIPERS

1. Select “FR WIPER LOW” during active test. Refer to WW-21, "

2. Make sure front wipers operate in LOW operation mode.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

ACTIVE TEST" .

Revision; 2004 April 2003 G35 Sedan

WW-24

Page 32

FRONT WIPER AND WASHER SYSTEM

2. INSPECTION 2: IPDM E/R TO FRONT WIPERS

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front wiper motor connector.

3. Check continuity between harness connector of IPDM E/R and

harness connector of front wiper motor.

Te rm i na ls

IPDM E/R Front wiper motor

Connector

E8 31 (PU) E52 3 (PU) Yes

Te rm i na l

(Wire color)

Connector

Te rm i na l

(Wire color)

Continuity

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK IPDM E/R

1. Connect IPDM E/R connector and front wiper motor connector.

2. Select “FR WIPER LOW” during active test. Refer to WW-21,

"ACTIVE TEST" . When front wiper relay are operating, check

voltage between harness connector of IPDM E/R and ground.

Ter mi na ls

Volta geIPDM E/R (+)

Connector Terminal (Wire color)

E8 31 (PU) Ground

OK or NG

OK >> Replace front wiper motor.

NG >> Replace IPDM E/R.

(-) Condition

Stoppe d Bat tery vo ltage

LO operation Approx. 0V

SKIA4015E

SKIA3593E

A

B

C

D

E

F

G

H

I

J

WW

4. INSPECTION 1: COMBINATION SWITCH TO BCM

Select “BCM” on CONSULT-II. Carry out self-diagnosis of “BCM C/

U”.

Displayed self-diagnosis results

No malfunction detected>>GO TO 5.

CAN communications or CAN system>>Inspect the BCM CAN

communications system. Go to BCS-16, "CAN Commu-

nication Inspection Using CONSULT-II (Self-Diagnosis)"

.

OPEN DETECT 1 - 5>>Combination switch system malfunction.

Go to LT- 125, "

ing to Self-Diagnostic Results" .

Revision; 2004 April 2003 G35 Sedan

Combination Switch Inspection Accord-

LKIA0073E

WW-25

L

M

Page 33

FRONT WIPER AND WASHER SYSTEM

5. INSPECTION 2: COMBINATION SWITCH TO BCM

Select “BCM” on CONSULT-II. With “WIPER” data monitor, make

sure “FR WIPER LOW” turns ON-OFF according to operation of

wiper switch.

OK or NG

OK >> Replace BCM. Refer to BCS-23, "Removal and Installa-

tion of BCM" .

NG >> Replace wiper switch.

LKIA0102E

Only Front Wiper Hi Does Not Operate AKS004TI

1. INSPECTION 1: IPDM E/R TO FRONT WIPERS

1. Select “FR WIPER HI” during active test. Refer to WW-21, "

ACTIVE TEST" .

2. make sure front wipers operate in HI operation mode.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2. INSPECTION 2: IPDM E/R TO FRONT WIPERS

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front wiper motor connector.

3. Check continuity between harness connector of IPDM E/R and

harness connector of front wiper motor.

Ter mi na ls

IPDM E/R Front wiper motor

Connector

E8 30 (L/B) E52 2 (L/B) Yes

Te rm i na l

(Wire color)

Connector

Ter mi na l

(Wire color)

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

Continuity

SKIA4016E

3. CHECK IPDM E/R

1. Connect IPDM E/R connector and front wiper motor connector.

2. Select “FR WIPER HI” during active test. Refer to WW-21,

"ACTIVE TEST" . When front wiper relay, and front wiper HI

relay are operating, check voltage between harness connector

of IPDM E/R and ground.

Te rm i na l s

Connector Terminal (Wire color)

E8 30 (L/B) Ground

(-) Condition

Stopped Battery voltage

HI operation Approx. 0V

OK or NG

OK >> Replace front wiper motor.

NG >> Replace IPDM E/R.

Revision; 2004 April 2003 G35 Sedan

VoltageIPDM E/R (+)

SKIA3172E

WW-26

Page 34

FRONT WIPER AND WASHER SYSTEM

4. INSPECTION 1: COMBINATION SWITCH TO BCM

Select “BCM” on CONSULT-II. Carry out self-diagnosis of “BCM C/

U”.

Displayed self-diagnosis results

No malfunction detected>>GO TO 5.

CAN communications or CAN system>>Inspect the BCM CAN

communications system. Go to BCS-16, "CAN Commu-

nication Inspection Using CONSULT-II (Self-Diagnosis)"

.

OPEN DETECT 1 - 5>>Combination switch system malfunction.

Go to LT- 125, "Combination Switch Inspection Accord-

ing to Self-Diagnostic Results" .

5. INSPECTION 2: COMBINATION SWITCH TO BCM

Select “BCM” on CONSULT-II. With “WIPER” data monitor, make

sure “FR WIPER HI” turns ON-OFF according to operation of wiper

switch.

OK or NG

OK >> Replace BCM. Refer to BCS-23, "Removal and Installa-

tion of BCM" .

NG >> Replace wiper switch.

A

B

C

D

LKIA0073E

E

F

G

H

LKIA0102E

Only Front Wiper Intermittent Does Not Operate AKS004TJ

1. INSPECTION: COMBINATION SWITCH TO BCM

Select “BCM” on CONSULT-II. With “WIPER” data monitor, make

sure “FR WIPER INT” turns ON-OFF according to operation of wiper

switch.

OK or NG

OK >> Replace BCM. Refer to BCS-23, "Removal and Installa-

tion of BCM" .

NG >> Replace wiper switch.

LKIA0102E

Front Wiper Intermittent Operation Switch Position Cannot Be Adjusted AKS00 4TK

1. INSPECTION: COMBINATION SWITCH TO BCM

Select “BCM” on CONSULT-II. With “WIPER” data monitor, make

sure “INT VOLUME” changes in order from 1 to 7 according to operation of the intermittent switch dial position.

OK or NG

OK >> Replace BCM. Refer to BCS-23, "Removal and Installa-

tion of BCM" .

NG >> Replace wiper switch.

I

J

WW

L

M

LKIA0102E

Revision; 2004 April 2003 G35 Sedan

WW-27

Page 35

FRONT WIPER AND WASHER SYSTEM

Wipers Do Not Wipe When Front Washer Operates AKS004TL

1. INSPECTION: COMBINATION SWITCH TO BCM

Select “BCM” on CONSULT-II. With “WIPER” data monitor, make

sure “FR WASHER SW” turns ON-OFF according to operation of

front washer switch.

OK or NG

OK >> Replace BCM. Refer to BCS-23, "Removal and Installa-

tion of BCM" .

NG >> Replace wiper switch.

LKIA0102E

Revision; 2004 April 2003 G35 Sedan

WW-28

Page 36

FRONT WIPER AND WASHER SYSTEM

Removal and Installation for Front Wiper Arms, Adjustment for Wiper Arms

Stop Location

REMOVAL

1. Operate wiper motor, and stop it at the auto stop position.

2. Remove washer tube from washer tube joint.

3. Remove wiper arm mounting nuts and wiper arm from vehicle.

AKS004TZ

A

B

INSTALLATION

1. Clean up the pivot area as illustrated. This will reduce possibility

of wiper arm looseness.

2. Prior to wiper arm installation, turn on wiper switch to operate

wiper motor and then turn it “OFF” (Auto Stop).

3. Push wiper arm onto pivot shaft, paying attention to blind spline.

4. Attach washer tube to washer tube joint.

5. Lift the blade up and then set it down onto glass surface to set

the blade center to clearance “L1” & “L2” immediately before

tightening nut.

6. Eject washer fluid. Turn on wiper switch to operate wiper motor

and then turn it “OFF”.

7. Ensure that wiper blades stop within clearance “L1” & “L2”.

Clearance “L1” : 56.5 - 71.5 mm (2.22 - 2.82 in)

Clearance “L2” : 25 - 38 mm (0.98 - 1.50 in)

● Tighten wiper arm nuts to specified torque.

Front wiper arm nuts : 23.6 N·m (2.4 kg-m, 17 ft-lb)

SEL024J

PKIA7843E

C

D

E

F

G

H

I

J

WW

CAUTION:

Don't operate the front wiper when engine hood is being open.

ADJUSTMENT

Refer to WW-29, "INSTALLATION"

Removal and Installation of Front Wiper Motor Assembly AKS004U0

REMOVAL

1. Remove wiper arm. Refer to WW-29, "REMOVAL" .

2. Remove cowl top cover. Refer to EI-21, "COWL TOP" in “EI”

section.

3. Remove washer tube.

4. Disconnect wiper motor connector.

5. Remove wiper motor assembly screws, and remove wiper motor

assembly.

PKIA1142E

INSTALLATION

1. Install wiper motor assembly to the vehicle.

Revision; 2004 April 2003 G35 Sedan

WW-29

L

M

Page 37

FRONT WIPER AND WASHER SYSTEM

2. Connect wiper motor assembly to the connector. Turn wiper switch ON to operate wiper motor, then turn

wiper switch OFF (auto stop).

3. Attach washer tube to connector joint.

4. Install cowl top cover. Refer to EI-21, "

5. Install wiper arms. Refer to WW-29, "

COWL TOP" in “EI” section.

Removal and Installation for Front Wiper Arms, Adjustment for Wiper

Arms Stop Location" .

6. Attach wiper arm washer tube.

Wiper motor assembly bolts : 5.5 N·m (0.56 kg-m, 49 in-lb)

CAUTION:

● Do not drop the wiper motor or cause it to contact other parts.

● Check grease conditions of the motor arm and wiper link joint (at retainer). Apply grease if neces-

sary.

Disassembly and Assembly Front Wiper Motor Assembly AKS004U1

1. Wiper link 2. Wiper link 3. Wiper frame

4. Wiper motor

DISASSEMBLY

1. Remove wiper link from wiper frame and the motor arm.

2. Remove wiper motor bolts, and remove wiper motor from wiper frame.

ASSEMBLY

Paying attention to the work listed below, assemble in reverse order of disassembly.

Wiper motor bolts : 5.5 N·m (0.56 kg-m, 49 in-lb)

PKIA4877E

Revision; 2004 April 2003 G35 Sedan

WW-30

Page 38

FRONT WIPER AND WASHER SYSTEM

Washer Nozzle Adjustment AKS004U2

1. When wiper blade position is in auto stop condition, remove wiper motor connector to ensure wiper arms

do not move.

2. Adjust each nozzle position (A, B, E, F, and G) so that spray positions are in the range of shaded parts.

CAUTION:

Only washer nozzles (A, B, E, F, and G) can be adjusted. Washer nozzles (C, D, H, I, and J) cannot

be adjusted because of fixed nozzles.

A

B

C

D

E

F

G

Unit: mm (in)

Spray position h (height)

A25 (0.98)339 (13.35)

B25 (0.98)176 (6.93)

(C) — —

(D) — —

E53 (2.09)306 (12.05)

F39 (1.54)158 (6.22)

G −32 (−1.26) 244 (9.61)

(H) — —

(I) — —

(J) — —

(width)

H

I

J

WW

L

PKIA1143E

M

PKIA1144E

Revision; 2004 April 2003 G35 Sedan

WW-31

Page 39

FRONT WIPER AND WASHER SYSTEM

Washer Tube Layout AKS004U3

PKIA1145E

Removal and Installation for Front Washer Nozzle AKS004U4

Replace wiper arm assembly. Refer to WW-29, "Removal and Installation for Front Wiper Arms, Adjustment

for Wiper Arms Stop Location" .

CAUTION:

Removal/installation of the washer nozzle as a unit must not be done.

Removal and Installation for Front Washer Joint AKS004U5

1. Remove upwards while pressing the tab on reverse side.

2. Remove washer tube.

PKIA1900E

Inspection for Washer Nozzle AKS004U6

CHECK VALVE INSPECTION

Blow air in the injection direction, and check that air flows only one

way. Make sure that the reverse direction (inhale) is not possible.

PKIA1901E

Removal and Installation for Front Wiper and Washer Switch AKS004U7

1. Remove steering column cover. Refer to IP-10, "INSTRUMENT

PANEL ASSEM B LY " in “IP” section.

2. Remove mounting bolts of clusterlid A and combination meter.

Refer to IP-10, "

tion.

3. Pull wiper and washer switch toward the passenger door while

pressing pawls in direction shown by the arrow in the figure, and

remove it from the base.

4. Remove wiper and washer switch connector.

INSTRUMENT PANEL ASSEMBLY" in “IP” sec-

PKIA1146E

Revision; 2004 April 2003 G35 Sedan

WW-32

Page 40

FRONT WIPER AND WASHER SYSTEM

Removal and Installation for Washer Tank AKS004U8

REMOVAL

1. Pull out washer tank inlet.

PKIA1147E

A

B

C

D

2. Remove fender protector in the right side. Refer to EI-22,

"FENDER PROTECTOR" in “EI” section.

3. Remove right half of front bumper fascia. Refer to EI-14,

"FRONT BUMPER" in “EI” section.

4. Remove washer pump connector.

5. Remove washer tank installation screw and nuts.

PKIA1148E

6. Remove washer tube, and remove washer tank from the vehicle.

PKIA1149E

INSTALLATION

Note the following, and install in reverse order of removal.

CAUTION:

After installation, add water up to the upper level of the washer tank inlet, and check for water leaks.

Washer tank installation screw

Tightening torque : 5.5 N·m (0.56 kg-m, 49 in-lb)

E

F

G

H

I

J

WW

L

M

Removal and Installation for Washer Pump AKS004U9

REMOVAL

1. Remove fender protector in the right side. Refer to EI-22,

"FENDER PROTECTOR" in “EI” section.

2. Remove washer pump connector and tube.

3. Pull out washer pump in direction shown by the arrow in the figure. Remove washer pump from washer tank.

PKIA1150E

Revision; 2004 April 2003 G35 Sedan

WW-33

Page 41

FRONT WIPER AND WASHER SYSTEM

INSTALLATION

Paying attention to the following, install in reverse order of removal.

CAUTION:

When installing washer pump, there should be no packing twists, etc.

Revision; 2004 April 2003 G35 Sedan

WW-34

Page 42

CIGARETTE LIGHTER

CIGARETTE LIGHTER PFP:35330

Wiring Diagram — CIGAR — AKS000 AZ

A

B

C

D

E

F

G

H

I

J

WW

L

M

TKWT0726E

Revision; 2004 April 2003 G35 Sedan

WW-35

Page 43

CIGARETTE LIGHTER

Removal and Installation AKS000B0

1. Remove the instrument side panel. Refer to IP-10, "INSTRU-

MENT PANEL ASSEMBLY" “IP” section.

2. Pull out the cigarette lighter.

3. Remove socket.

4. Press out ring from the back of instrument side panel.

PKIA1152E

Revision; 2004 April 2003 G35 Sedan

WW-36

Page 44

POWER SOCKET

POWER SOCKET PFP:253A2

Wiring Diagram — P/SCKT — AKS005L5

A

B

C

D

E

F

G

H

I

J

WW

L

M

TKWT0951E

Revision; 2004 April 2003 G35 Sedan

WW-37

Page 45

POWER SOCKET

Removal and Installation for Console Power Socket AKS005QP

REMOVAL

1. Remove console box assembly. Refer to IP-10, "INSTRUMENT

PANEL ASSEM B LY " in “IP” section.

2. Disconnect power socket connector.

3. Remove inner socket from the ring, while pressing the hook on

the ring out from square hole.

4. Remove ring from console box while pressing pawls.

PKIA2419E

INSTALLTION

Install in the reverse order of removal.

Revision; 2004 April 2003 G35 Sedan

WW-38

Page 46

HORN

HORN PFP:25610

Wiring Diagram — HORN — AKS000B3

A

B

C

D

E

F

G

H

I

J

WW

L

M

TKWT0270E

Revision; 2004 April 2003 G35 Sedan

WW-39

Page 47

HORN

Removal and Installation AKS000B4

REMOVAL

1. Remove front grille. Refer to EI-20, "FRONT GRILLE" in “EI” section.

2. Disconnect all horn connectors.

3. Remove horn bolt and remove horn from vehicle.

PKIA1151E

INSTALLATION

Tighten horn bolt to specified torque.

Horn bolt : 17.1 N·m (1.7 kg·m, 13 ft-lb)

Revision; 2004 April 2003 G35 Sedan

WW-40

Page 48

ROAD WHEELS & TIRES

E SUSPENSION

A

B

SECTION

CONTENTS

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 2

NVH Troubleshooting Chart ..................................... 2

ROAD WHEEL ............................................................ 3

Inspection ................................................................. 3

ALUMINUM WHEEL ............................................. 3

ROAD WHEEL TIRE ASSEMBLY .............................. 4

ROAD WHEELS & TIRES

Balancing Wheels (Bonding Weight Type) ............... 4

REMOVAL ............................................................. 4

WHEEL BALANCE ADJUSTMENT ....................... 4

Rotation .................................................................... 5

SERVICE DATA .......................................................... 6

Road Wheel .............................................................. 6

Tire ........................................................................... 6

C

D

WT

F

G

H

I

J

K

M

L

Revision; 2004 April 2003 G35 Sedan

WT-1

Page 49

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING PFP:00003

NVH Troubleshooting Chart AES0000T

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page

Possible cause and SUSPECTED PARTS

Noise ЧЧЧЧЧЧ ×××× ××××

Shake ЧЧЧЧЧ ×× ×× ××××

Vibration ×××××××

Tires

Symptom

Road wheel

×: Applicable

Shimmy ЧЧЧЧЧЧЧ ×× × ××

Judder ЧЧЧЧЧ × ×× × ××

Poor quality ride

or handling

Noise ×× × ЧЧЧЧЧ ×××

Shake ×× × × ××× ×××

Shimmy, Judder ×× × ××× ××

Poor quality ride

or handling

—

—

—

—

—

WT-3

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

ЧЧЧЧЧ × ×× ×

×× × ×××

—

NVH in PR section.

NVH in RFD section.

NVH in FAX and FSU sections.

NVH in RAX and RSU sections.

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

Non-uniformity

Incorrect tire size

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEEL

NVH in RAX section.

DRIVE SHAFT

NVH in BR section.

NVH in PS section.

BRAKE

STEERING

Revision; 2004 April 2003 G35 Sedan

WT-2

Page 50

ROAD WHEEL

ROAD WHEEL PFP:40300

Inspection AES000 0U

ALUMINUM WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If

deformed, remove wheel and check wheel runout.

a. Remove tire from aluminum wheel and mount on a tire balance

machine.

b. Set dial indicator as shown in the illustration.

A

B

C

Wheel runout (Dial indicator value):

Refer to WT-6, "

SERVICE DATA"

SFA975B

D

WT

F

G

H

I

J

K

Revision; 2004 April 2003 G35 Sedan

WT-3

L

M

Page 51

ROAD WHEEL TIRE ASSEMBLY

ROAD WHEEL TIRE ASSEMBLY PFP:40300

Balancing Wheels (Bonding Weight Type) AES0002H

REMOVAL

1. Remove inner and outer balance weights from the road wheel.

CAUTION:

Be careful not to scratch the road wheel during removal.

2. Using releasing agent, remove double-faced adhesive tape from the road wheel.

CAUTION:

● Be careful not to scratch the road wheel during removal.

● After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

WHEEL BALANCE ADJUSTMENT

● If a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting,

select and adjust a drive-in weight mode suitable for road wheels.

1. Set road wheel on wheel balancer using the center hole as a guide. Start the tire balance machine.

2. When inner and outer unbalance values are shown on the wheel balancer indicator, multiply outer unbalance value by 5/3 to determine balance weight that should be used. Select the outer balance weight with

a value closest to the calculated value above and install it to the designated outer position of, or at the

designated angle in relation to the road wheel.

CAUTION:

● Do not install the inner balance weight before installing the outer balance weight.

● Before installing the balance weight, be sure to clean the

mating surface of the road wheel.

Indicated unbalance value × 5/3 = balance weight to be installed

Calculation example:

23 g (0.81 oz) × 5/3 = 38.33 g (1.35 oz) = 40 g (1.41 oz) balance

weight (closer to calculated balance weight value)

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 = 35 g (1.23 oz)

37.5 = 40 g (1.41 oz)

SMA054D

a. Install balance weight in the position shown in the figure.

b. When installing balance weight to road wheels, set it into the

grooved area on the inner wall of the road wheel as shown in the

figure so that the balance weight center is aligned with the wheel

balancer indication position (angle).

CAUTION:

● Always use genuine Nissan adhesion balance weights.

● Balance weights are unreusable; always replace with new

ones.

● Do not install more than three sheets of balance weight.

SEIA0271E

Revision; 2004 April 2003 G35 Sedan

WT-4

Page 52

ROAD WHEEL TIRE ASSEMBLY

c. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start wheel balancer again.

4. Install drive-in balance weight on inner side of road wheel in the

wheel balancer indication position (angle).

CAUTION:

Do not install more than two balance weights.

SMA056D

5. Start wheel balancer. Make sure that inner and outer residual

unbalance values are 10 g (0.35 oz) each or below.

● If either residual unbalance value exceeds 10 g (0.35 oz), repeat installation procedures.

Wheel balance (Maximum allowable unbalance):

Maximum allowable

unbalance

Dynamic (At rim flange) Less than 10 g (0.35 oz) (one side)

Static ( At rim flange) Less than 20 g (0.70 oz)

Rotation AES0000W

● Follow the maintenance schedule for tire rotation service intervals. Refer to MA-6, "PERIODIC MAINTE-

NANCE" .

● Do not include the T-type spare tire when rotating the tires.

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Tightening torque of wheel nut:

:98 - 118 N·m (10 - 12 kg-m, 72- 87 ft-ib)

A

B

C

D

WT

F

G

H

I

J

SMA829C

K

L

M

Revision; 2004 April 2003 G35 Sedan

WT-5

Page 53

SERVICE DATA

SERVICE DATA PFP:00030

Road Wheel AES0001F

Allowable value

Standard item

Aluminum Steel (for emergency

use)

Deflection limit

Allowable quantity of

residual unbalance

Lateral deflection Less than 0.3 mm

(0.012 in)

Vertical defl ection Less tha n 0.3mm

(0.012 in)

Dynamic

(At rim flange)

Static

(At rim flange)

Less than 10g (0.35 oz) (per side)

Less than 20g (0.70 oz)

Less than 1.0 mm

(0.039 in)

Less than 1.2mm

(0.047 in)

Tire AES0001G

Unit: kPa (kg/cm2 , psi)

Tire size

P205/65R16 94V

P215/55R17 93V

P215/55R17 93W

T145/90D16 420 (4.2, 60) 420 (4.2, 60)

Front tire Rear tire

210 (2.1, 30) 210 (2.1, 30)

Air pressure

Revision; 2004 April 2003 G35 Sedan

WT-6

Page 54

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

H RESTRAINTS

A

B

SECTION

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

CONTENTS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for SRS “AIR BAG” and “SEAT BELT

PRE-TENSIONER” Service ..................................... 3

Wiring Diagrams and Trouble Diagnosis .................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 5

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ....... 6