Page 1

Edition: November 2007

Publication No. SM8E-1J50U0

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmitted in any form, or by any

means, electronic, mechanical, recording or otherwise,

without the prior written permission of Nissan Motor

Company Ltd., Tokyo, Japan.

QUICK REFERENCE INDEX

A

GENERAL INFORMATION

B ENGINE

C HYBRID

D TRANSMISSION & DRIVE-

LINE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I VENTILATION, HEATER &

AIR CONDITIONER

J BODY INTERIOR

K BODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITY

L DRIVER CONTROLS

M ELECTRICAL & POWER

CONTROL

N DRIVER INFORMATION &

MULTIMEDIA

O CRUISE CONTROL

P MAINTENANCE

GI

General Information

EM

Engine Mechanical

LU

Engine Lubrication System

CO

Engine Cooling System

EC

Engine Control System

FL

Fuel System

EX

Exhaust System

STR

Starting System

ACC

Accelerator Control System

HBC

Hybrid Control System

HBB

Hybrid Battery System

HBR

Hybrid Brake System

CL

Clutch

TM

Transaxle & Transmission

DLN

Driveline

FAX

Front Axle

RAX

Rear Axle

FSU

Front Suspension

RSU

Rear Suspension

SCS

Suspension Control System

WT

Road Wheels & Tires

BR

Brake System

PB

Parking Brake System

BRC

Brake Control System

ST

Steering System

STC

Steering Control System

SB

Seat Belt

SBC

Seat Belt Control System

SR

SRS Airbag

SRC

SRS Airbag Control System

VTL

Ventilation System

HA

Heater & Air Conditioning System

HAC

Heater & Air Conditioning Control System

INT

Interior

IP

Instrument Panel

SE

Seat

ADP

Automatic Drive Positioner

DLK

Door & Lock

SEC

Security Control System

GW

Glass & Window System

PWC

Power Window Control System

RF

Roof

EXT

Exterior

BRM

Body Repair

MIR

Mirrors

EXL

Exterior Lighting System

INL

Interior Lighting Sys tem

WW

Wiper & Washer

DEF

Defogger

HRN

Horn

PWO

Power Outlet

BCS

Body Control System

LAN

LAN System

PCS

Power Control System

CHG

Charging System

PG

Power Supply, Ground & Circuit Elements

MWI

Meter, Warning Lamp & Indicator

WCS

Warning Chime System

SN

Sonar System

AV

Audio, Visual & Navigation System

CCS

Cruise Control System

MA

Maintenance

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Page 2

This manual contains maintenance and repair procedure for the 2008

INFINITI EX35.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in specifications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of

the technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a

manner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician

and the tools and parts available. Accordingly, anyone using service

procedures, tools or parts which are not specifically recommended

by NISSAN must first be completely satisfied that neither personal

safety nor the vehicle’s safety will be jeopardized by the service

method selected.

Page 3

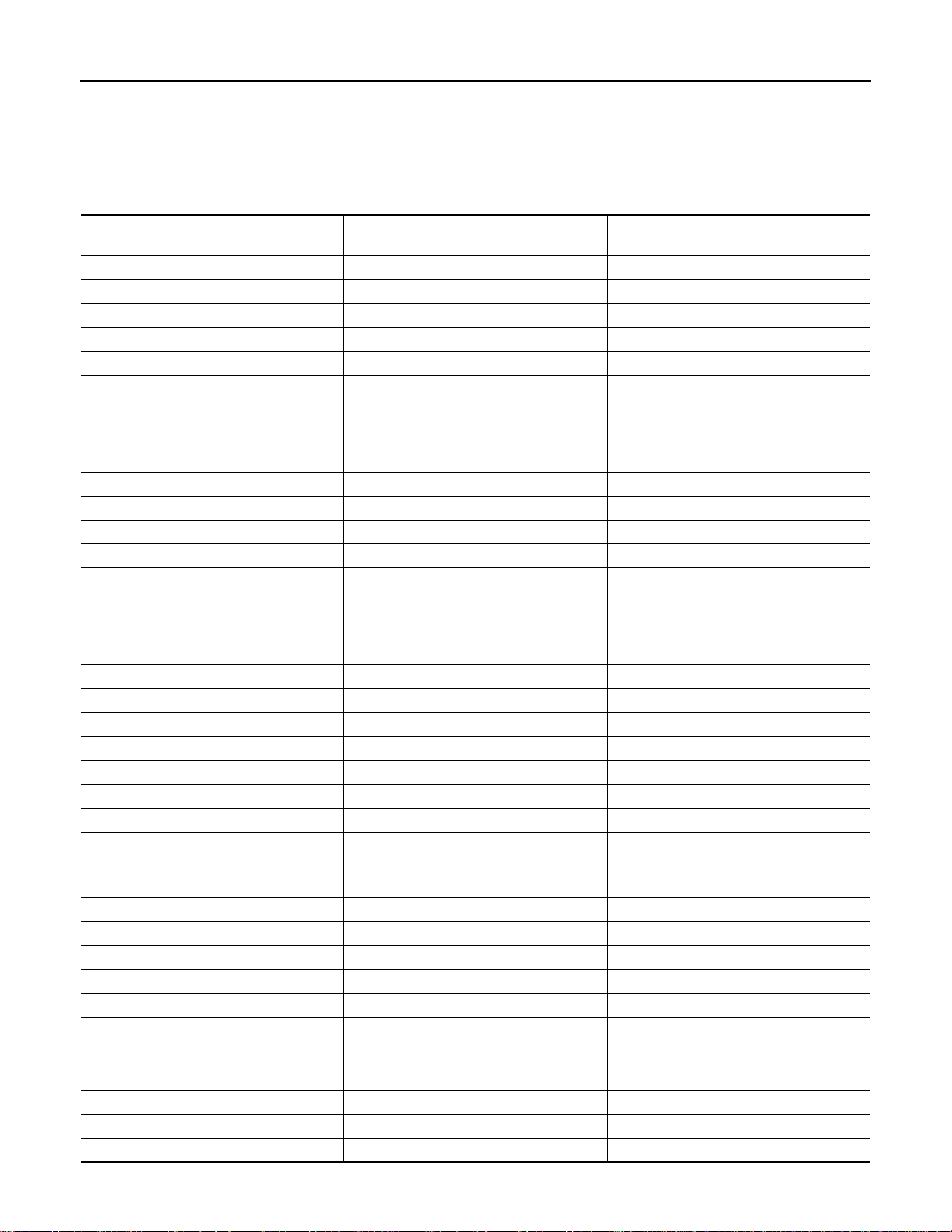

QUICK REFERENCE CHART EX35

2008

QUICK REFERENCE CHART EX35 PFP:00000

ENGINE TUNE-UP DATA (VQ35HR) ELS0003W

Engine model VQ35HR

Firing order 1-2-3-4-5-6

Idle speed

A/T (In “N” position)

Ignition timing

(BTDC at idle speed)

CO% at idle 0.7 - 9.9 % and engine runs smoothly

Tensions of drive belts Auto adjustment by auto tensioner

Radiator cap relief pressure

Standard 122.3 - 151.7 (1.2 - 1.5, 18 - 22)

Limit 107 (1.1, 16)

Cooling system leakage testing pressure

kPa (kg/cm

kPa (kg/cm

2

, psi)

2

, psi)

rpm 650 ± 50

16° ± 5° (without 4WAS)

11° ± 5° (with 4WAS)

157 (1.6, 23)

Compression pressure

Spark plug

(Iridium-tipped type)

2

kPa (kg/cm

Standard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Differential limit between cylinders 98 (1.0, 14)/300

Make DENSO

Standard type FXE22HR11

Gap (Nominal) mm (in) 1.1 (0.043)

, psi)/rpm

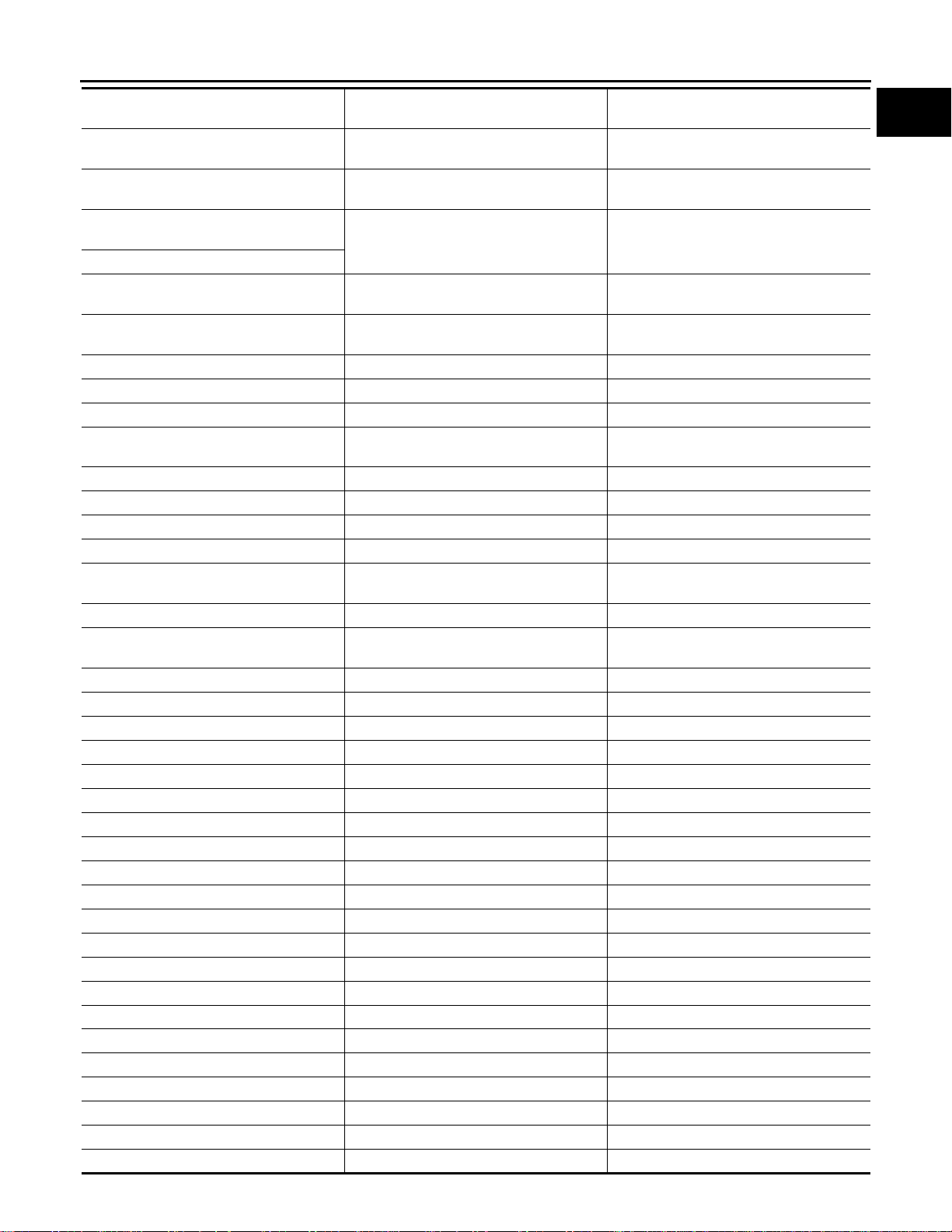

Page 4

QUICK REFERENCE CHART EX35

2008

FRONT WHEEL ALIGNMENT

2WD

Item Standard

Minimum –0° 40′ (–0.66°)

Camber

Degree minute (Decimal degree)

Caster

Degree minute (Decimal degree)

Kingpin inclination

Degree minute (Decimal degree)

Distance

Total toe-in

Angle (Left wheel or right wheel)

Degree minute (Decimal degree)

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

Nominal 0° 05′ (0.08°)

Maximum 0° 50′ (0.83°)

Left and right difference 0° 33′ (0.55°) or less

Minimum 3° 30′ (3.50°)

Nominal 4° 15′ (4.25°)

Maximum 5° 00′ (5.00°)

Left and right difference 0° 39′ (0.65°) or less

Minimum 6° 05′ (6.09°)

Nominal 6° 50′ (6.83°)

Maximum 7° 35′ (7.58°)

Minimum 0 mm (0 in)

Nominal In 1 mm (0.04 in)

Maximum In 2 mm (0.08 in)

Minimum 0° 00 (0.00°)

Nominal In 0° 02′ 24″ (0.04°)

Maximum In 0° 04′ 48″ (0.08°)

ELS0003X

AWD

Minimum –1° 05′ (–1.08°)

Camber

Degree minute (Decimal degree)

Caster

Degree minute (Decimal degree)

Kingpin inclination

Degree minute (Decimal degree)

Distance

Total toe-in

Angle (Left wheel or right wheel)

Degree minute (Decimal degree)

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

Nominal –0° 20′ (–0.33°)

Maximum 0° 25′ (0.42°)

Left and right difference 0° 33′ (0.55°) or less

Minimum 3° 25′ (3.42°)

Nominal 4° 10′ (4.17°)

Maximum 4° 55′ (4.91°)

Left and right difference 0° 39′ (0.65°) or less

Minimum 6° 35′ (6.58°)

Nominal 7° 20′ (7.33°)

Maximum 8° 05′ (8.08°)

Minimum 0 mm (0 in)

Nominal In 1 mm (0.04 in)

Maximum In 2 mm (0.08 in)

Minimum 0° 00′ (0.00°)

Nominal In 0° 02′ 24″ (0.04°)

Maximum In 0° 04′ 48″(0.08°)

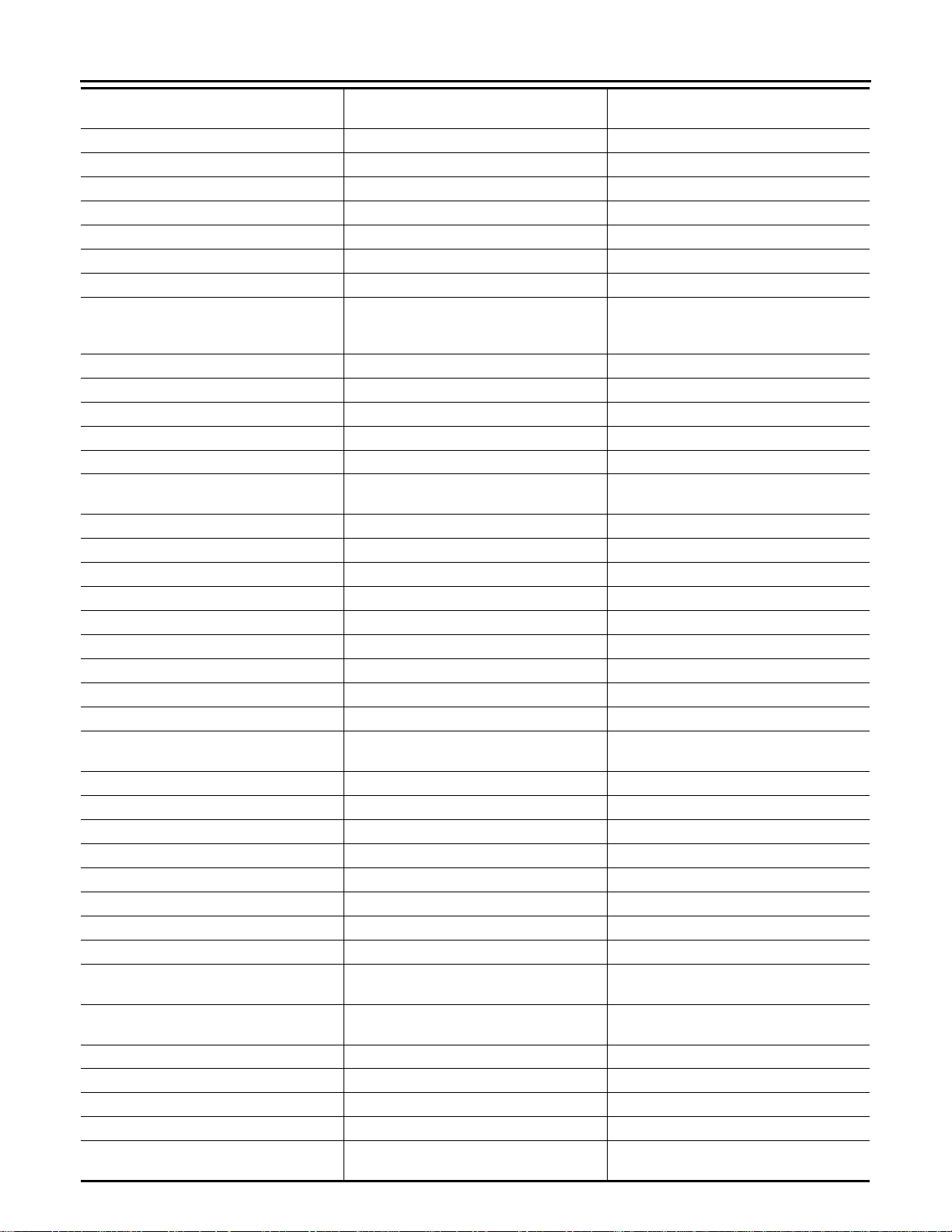

Page 5

QUICK REFERENCE CHART EX35

2008

REAR WHEEL ALIGNMENT

Item Standard

Minimum –1° 05′ (–1.08°)

Camber

Degree minute (Decimal degree)

Distance

Total toe-in

Angle (Left wheel or right wheel)

Degree minute (Decimal degree)

Measure value under unladen* conditions.

*: Fuel, engine coolant and l ubricant are full. Spare tire, jack, hand tools and mats are in design ated positions.

Nominal –0° 35′ (–0.58°)

Maximum –0° 05′ (–0.09°)

Minimum 0 mm (0 in)

Nominal In 2.9 mm (0.114 in)

Maximum In 5.8 mm (0.228 in)

Minimum 0° 00′ (0.00°)

Nominal In 0° 07′ (0.12°)

Maximum In 0° 14′ (0.23°)

BRAKE PEDAL

Item Standard

Brake pedal height 171.5 – 181.5 (6.75 – 7.15)

Clearance between the stop lamp switch and ASCD brake switch

threaded end and the stopper rubber

Brake pedal play 3.0 – 11.0 (0.118 – 0.433)

Depressed brake pedal height

[Depressing 490 N (50 kg, 110 lb) while turning the engine ON]

0.74 – 1.96 (0.0291 – 0.0772)

114.0 (4.49) or more

ELS0003Y

Unit: mm (in)

FRONT DISK BRAKE

Unit: mm (in)

Item Limit

Brake pad Wear thickness 2.0 (0.079)

Disc rotor Wear thickness 26.0 (1.024)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.035 (0.0014)

REAR DISK BRAKE

Unit: mm (in)

Item Limit

Brake pad Wear thickness 2.0 (0.079)

Disc rotor Wear thickness 14.0 (0.551)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.055 (0.0022)

REFILL CAPACITIES ELS00040

UNIT Liter US measure

Fuel tank Applox. 76 20 gal

Engine Coolant ( With reservoir tank ) at MAX level 8.6 9-1/8 qt

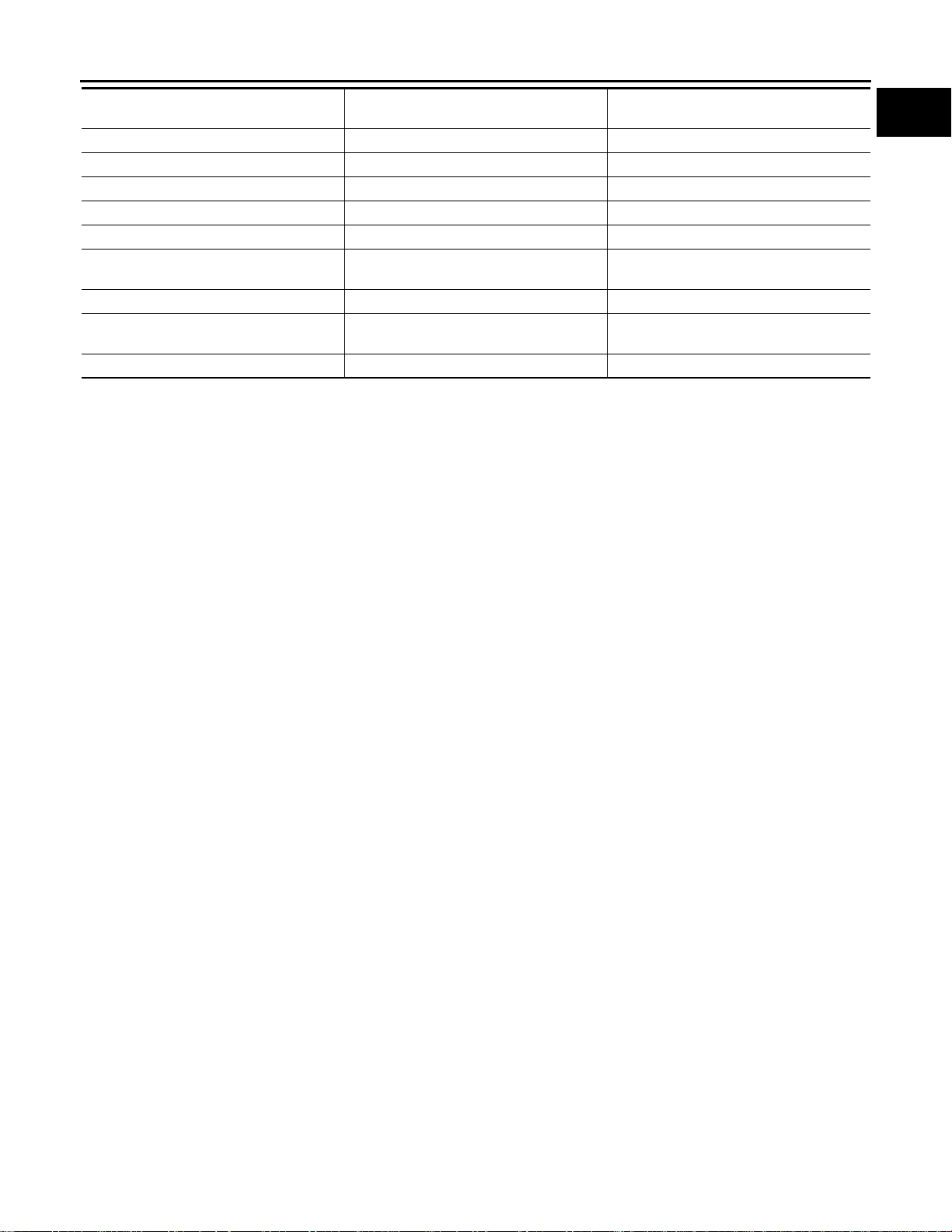

Page 6

QUICK REFERENCE CHART EX35

UNIT Liter US measure

Drain and refill

Engine oil

Dry engine (Overhaul) 5.7 6 qt

Transmission A/T 10.3 10-7/8 qt

Transfer 1.25 2-5/8 pt

Final drive

Power steering system 1.0 1-1/8 qt

Air conditioning system

Front 0.65 1-3/8 pt

Rear 1.4 3 pt

Compressor oil 0.15 5.03 fl oz

Refrigerant 0.55 kg 1.21 lb

With oil filter change 4.9 5-1/8 qt

Without oil filter change 4.6 4-7/8 qt

2008

Page 7

GENERAL INFORMATION

Revision: 2007 November 2008 EX35

GI

B

SECTION GI

CONTENTS

HOW TO USE THIS MANUAL ......................3

HOW TO USE THIS MANUAL ............................ 3

Description ................................................................3

Terms ........................................................................3

Units ..........................................................................3

Contents .......................... ..........................................3

Relation between Illustrations and Descriptions .......4

Components .................... ..........................................4

HOW TO FOLLOW TROUBLE DIAGNOSES .....6

Description ................................................................6

How to Follow Test Groups in Trouble Diagnosis ......6

Key to Symbols Signifying Measurements or Pro-

cedures .....................................................................

HOW TO READ WIRING DIAGRAMS ................ 9

Connector Symbols ...................................................9

Sample/Wiring Diagram -Example- .........................10

Description ..............................................................11

ABBREVIATIONS ..............................................13

Abbreviation List ......................................................13

TIGHTENING TORQUE OF STANDARD

BOLTS ................................................................

Tightening Torque Table .........................................14

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ................................................

Recommended Chemical Products and Sealants ....15

TERMINOLOGY .................................................16

SAE J1930 Terminology List ...................................16

FEATURES OF NEW MODEL .....................20

IDENTIFICATION INFORMATION .....................20

Model Variation .......................................................20

Information About Identification or Model Code ......20

Dimensions .............................................................22

Wheels & Tires ........................................................22

14

15

GENERAL INFORMATION

PRECAUTION ..............................................23

PRECAUTIONS .................................................23

Description ....................... ...... ....... ...... ....... ...... ........23

Precaution for Supplemental Restrain t Syste m

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

Precautions For Xenon Headlamp Service .............23

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect ...................................

Precaution for Procedure without Cowl Top Cove r ....24

General Precautions ................................................24

Three Way Catalyst .................................................26

7

Multiport Fuel Injection System or Engine Control

System ............................. ...... ....... ...... ....... ...... ........

Hoses ......................................................................26

Engine Oils ..............................................................27

Air Conditioning .......................................................27

FUEL ..........................................................................27

FUEL : Unleaded Premium Gasoline Recom-

mended ............................ ...... ....... ...... ....... ...... ........

LIFTING POINT .................................................29

Commercial Service Tools .......................................29

Garage Jack and Safety Stand and 2-Pole Lift .......29

Board-On Lift ...........................................................30

TOW TRUCK TOWING .....................................31

Tow Truck Towing ...................................................31

Vehicle Recovery (Freeing a Stuck Vehicle) ...........32

BASIC INSPECTION ...................................34

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ..........................................................

Work Flow ................................................................34

Control Units and Electrical Parts ................. ... ... .....34

How to Check Terminal ...........................................35

Intermittent Incident .................................................38

Circuit Inspection .....................................................41

23

23

26

28

34

C

D

E

F

G

H

I

J

K

L

M

N

O

P

GI-1

Page 8

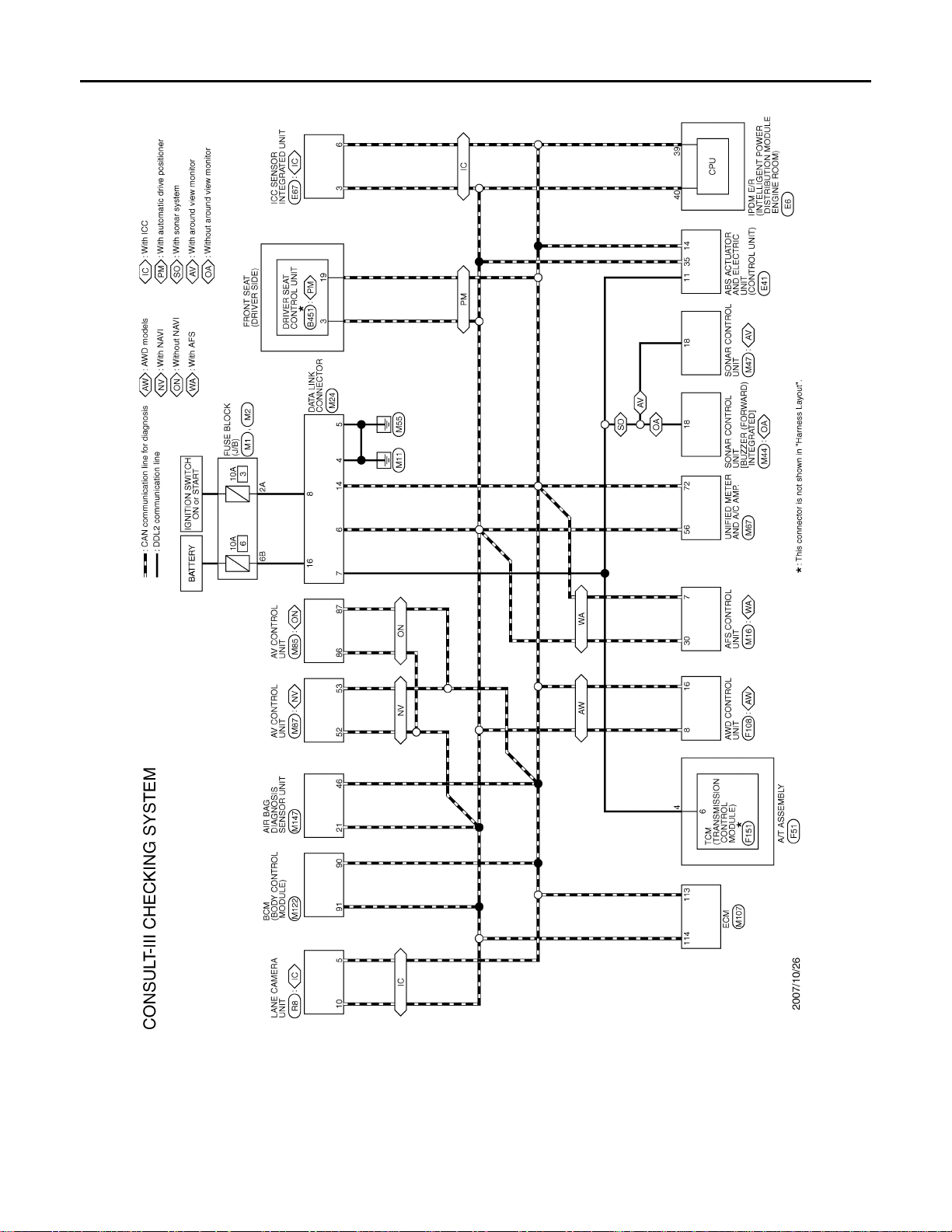

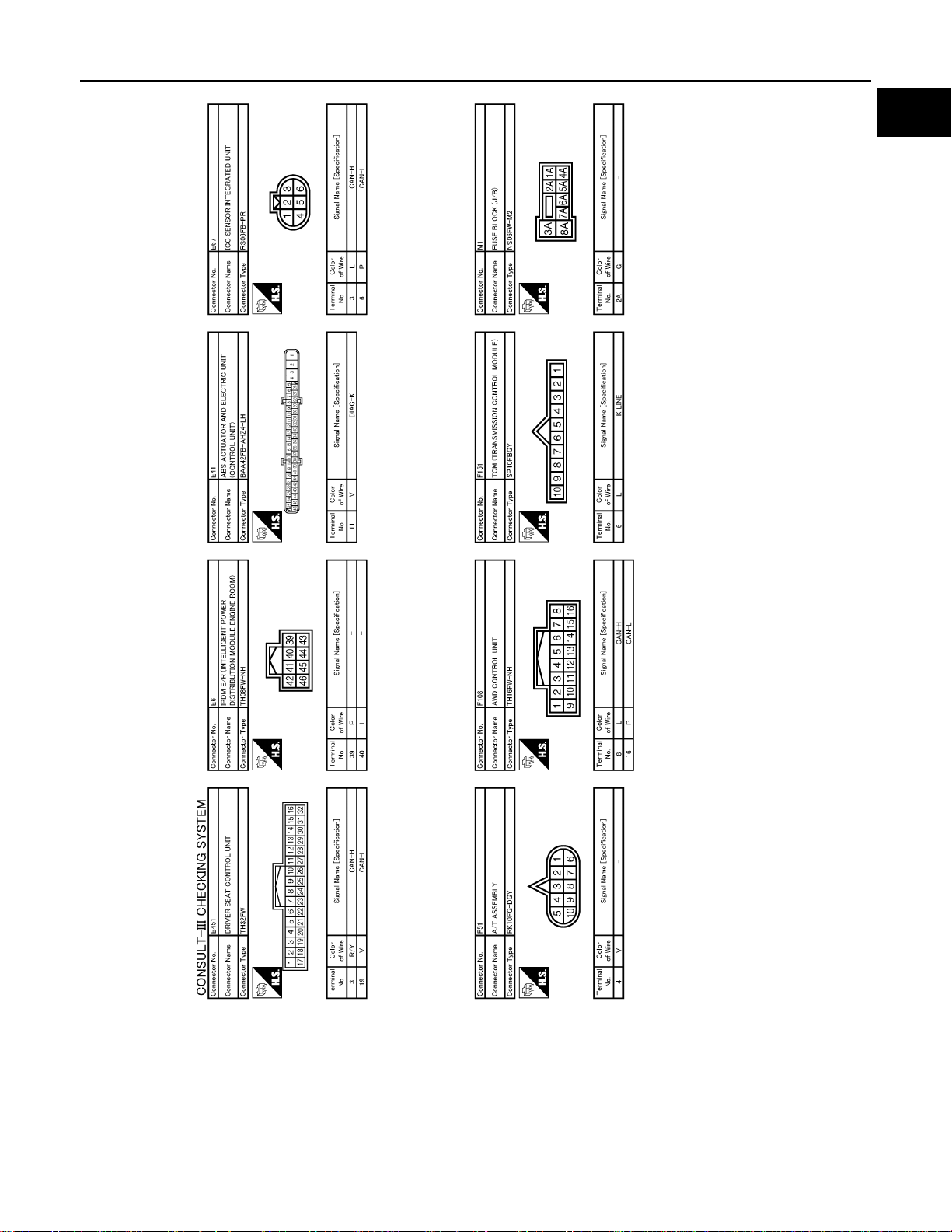

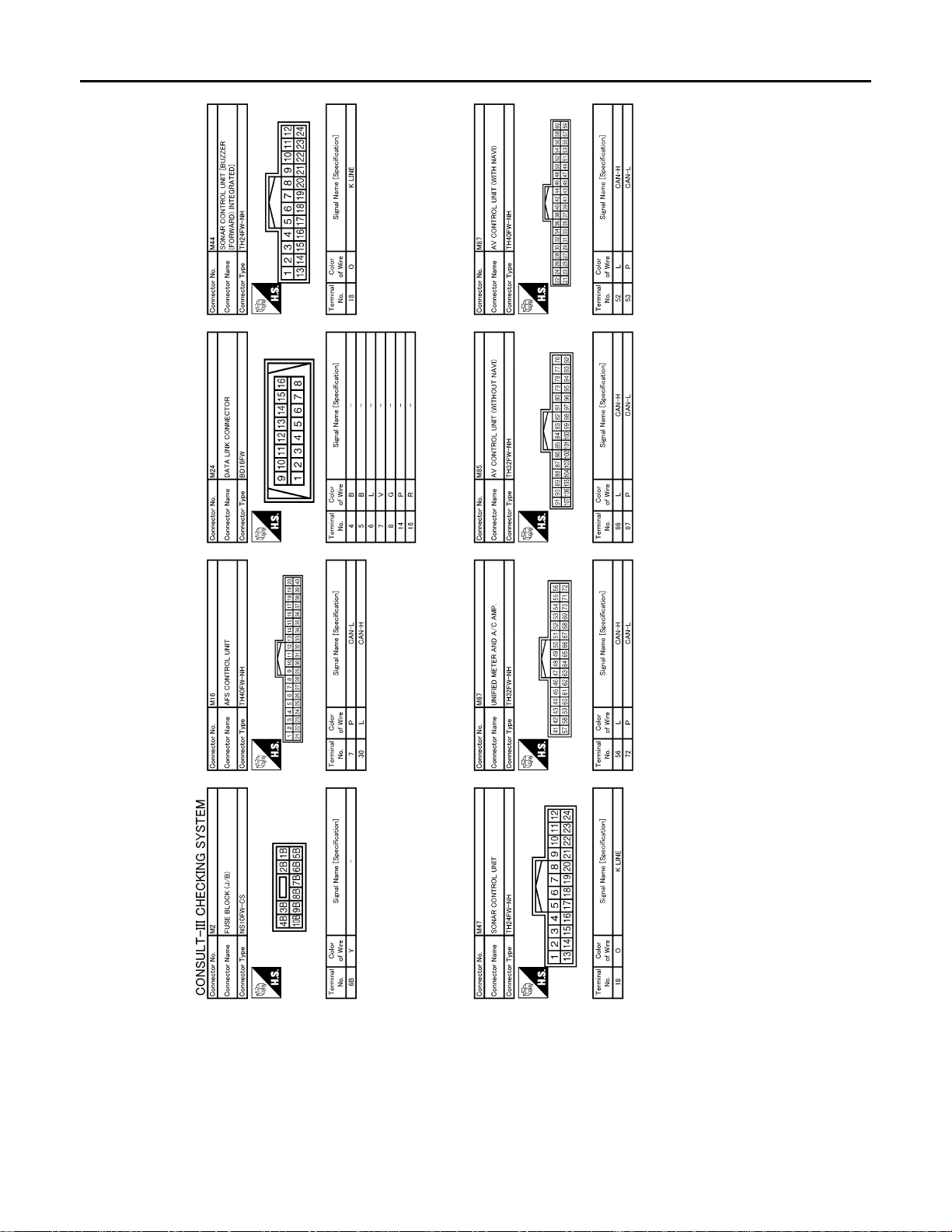

CONSULT-III/GST CHECKING SYSTEM ......... 46

Revision: 2007 November 2008 EX35

Description ....................... .......................... ............. 46

CONSULT-III Function and System Application*1 ... 46

CONSULT-III/GST Data Link Connector (DLC)

Circuit .....................................................................

Wiring Diagram - CONSULT-III/GST CHECKING

SYSTEM - ............................................ ...................

46

48

INSPECTION AND ADJUSTMENT ...................52

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ..................................

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Required

Procedure After Battery Disconnection ...................

52

52

GI-2

Page 9

< HOW TO USE THIS MANUAL >

Revision: 2007 November 2008 EX35

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

Description INFOID:0000000003131598

This volume explains “Removal, Disassembly, Installation, Inspection and Adjustment” and “Trouble Diagnoses”.

Terms INFOID:0000000003131599

• The captions WARNING and CAUTION warn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

WARNING indicates the possibility of personal injury if instructions are not followed.

CAUTION indicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTS except WARNING and CAUTION give you helpf ul information.

Standard value: Tolerance at inspection and adjustment.

Limit value: The maximum or minimum limit value that should not be exceeded at inspection and adjustment.

Units INFOID:0000000003131600

• The UNITS given in this manual are primarily expressed as the SI UNIT (International System of Unit), and

alternatively expressed in the metric system and in the yard/pound system.

Also with regard to tightening torque of bolts and nuts, there are descriptions both about range and about the

standard tightening torque.

“Example”

Range

Outer Socket Lock Nut : 59 - 78 N·m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

GI

B

C

D

E

F

G

H

I

Standard

Drive Shaft Installation Bolt : 44.3 N·m (4.5 kg-m, 33 ft-lb)

Contents INFOID:0000000003566430

• A QUICK REFERENCE INDEX, a black tab (e.g. ) is provided on the first page. You can quickly find the

first page of each section by matching it to the section's black tab.

• THE CONTENTS are listed on the first page of each section.

• THE TITLE is indicated on the upper portion of each page and shows the part or system.

• THE PAGE NUMBER of each section consists of two or three letters which designate the particular section

and a number (e.g. “BR-5”).

• THE SMALL ILLUSTRATIONS show the important steps such as inspection, use of special tools, knacks of

work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle

or transmission, etc. are presented in a step-by-step format where necessary.

J

K

L

M

N

O

P

GI-3

Page 10

< HOW TO USE THIS MANUAL >

Revision: 2007 November 2008 EX35

HOW TO USE THIS MANUAL

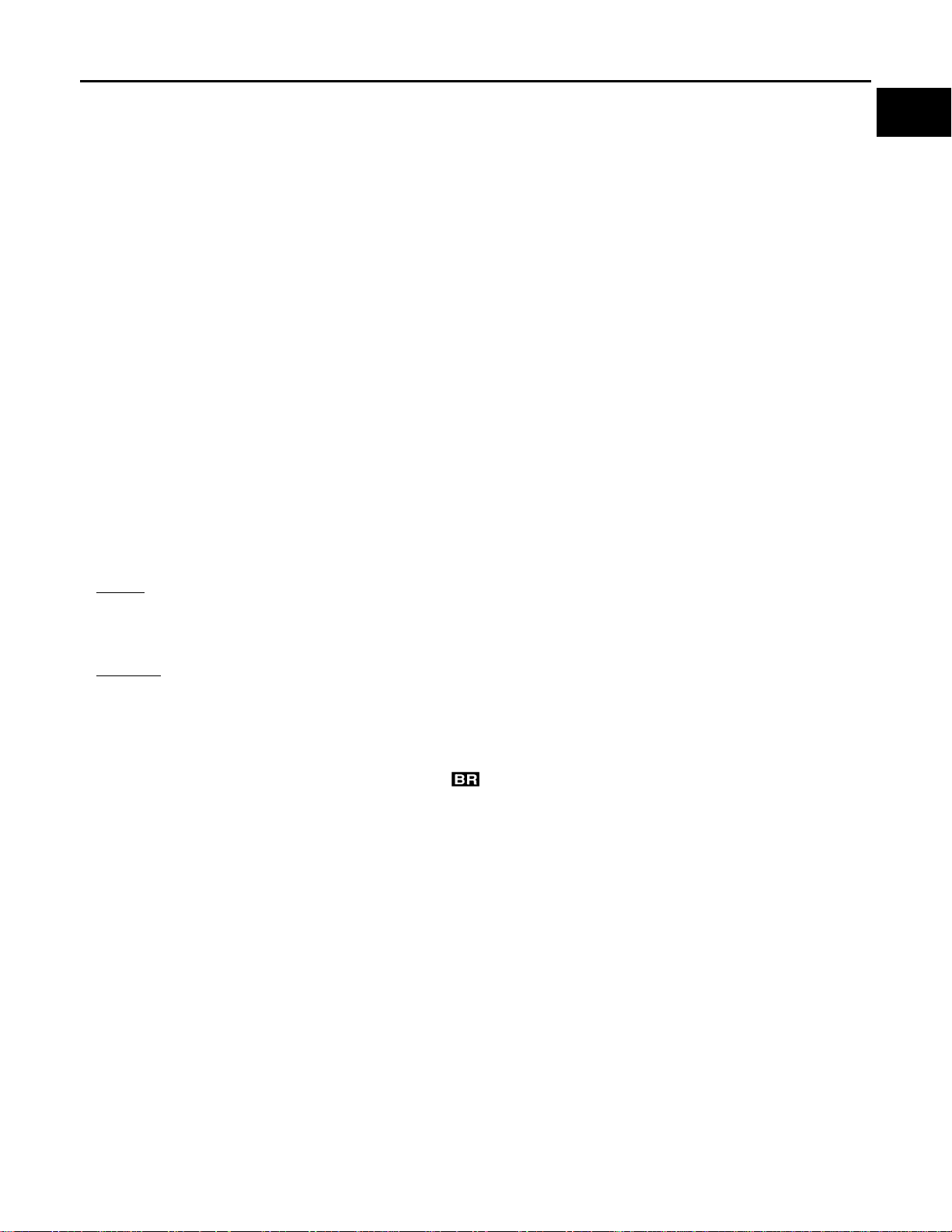

Relation between Illustrations and Descriptions

The following sample explains the relationship between the part description in an illustration, the part name in

the text and the service procedures.

INFOID:0000000003131602

SAIA0519E

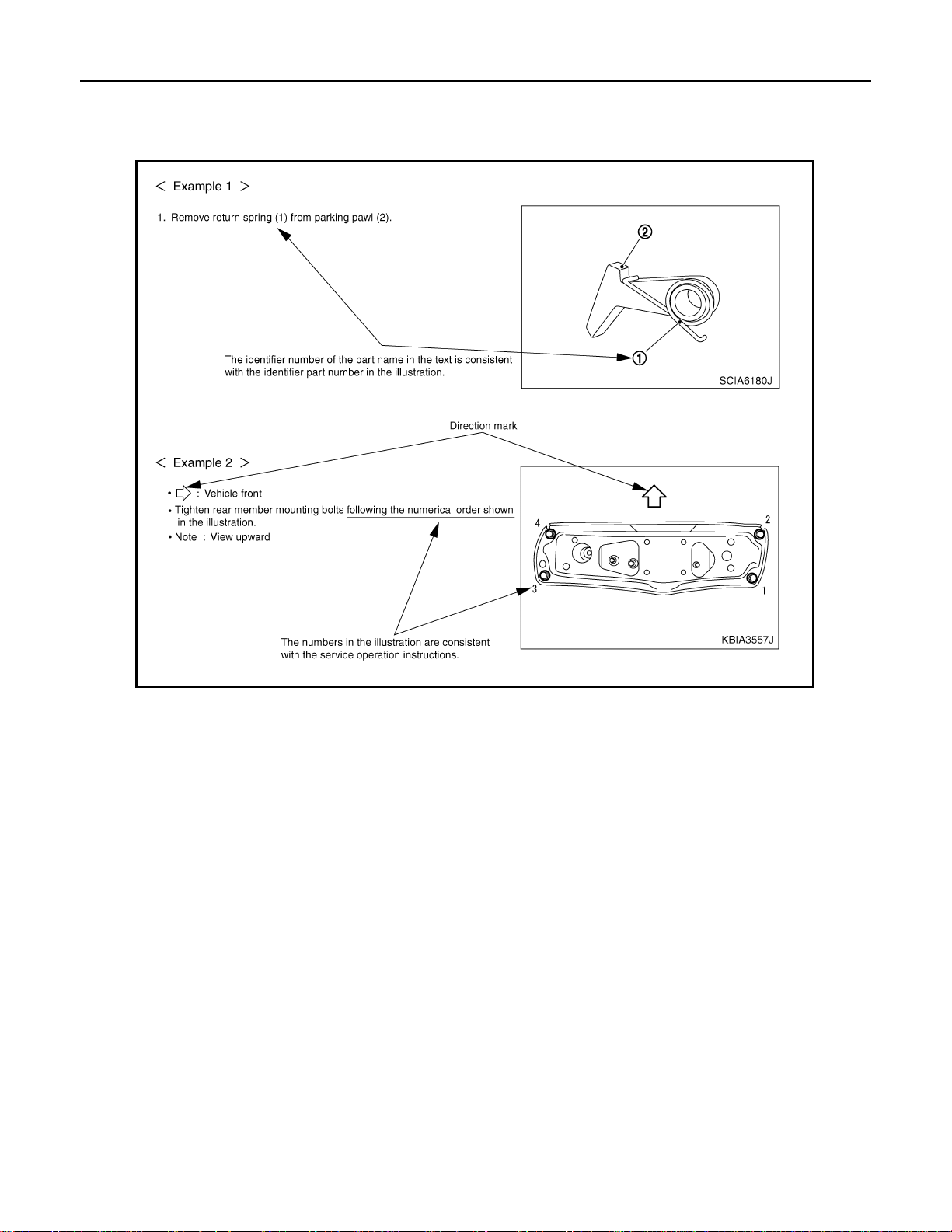

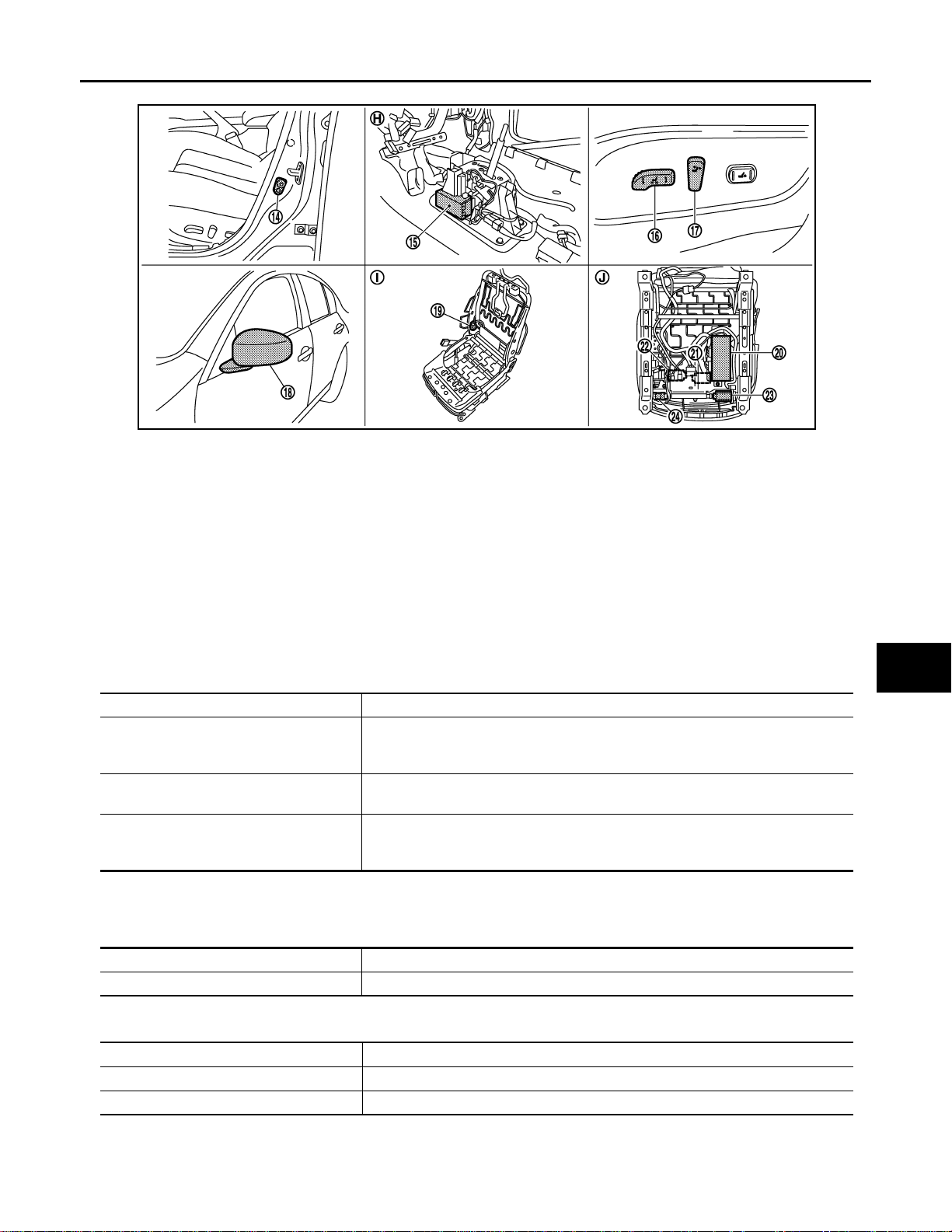

Components INFOID:0000000003131603

• THE LARGE ILLUSTRA TIONS are exploded views (see the following) and contain ti ghtening torques, lubrication points, section number of the PARTS CATALOG (e.g. SEC. 440) and other information necessary to

perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the appropriate PARTS CATALOG.

Components shown in an illustration may be identified by a circled number. When this style of illustration is

used, the text description of the components will follow the illustration.

GI-4

Page 11

< HOW TO USE THIS MANUAL >

Revision: 2007 November 2008 EX35

HOW TO USE THIS MANUAL

GI

B

C

D

E

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Outer shim 24. Outer shim cover

1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease

Refer to GI section for additional symbol definitions.

2: Rubber grease : Brake fluid

SYMBOLS

SFIA2959E

F

G

H

I

J

K

L

M

SAIA0749E

GI-5

N

O

P

Page 12

HOW TO FOLLOW TROUBLE DIAGNOSES

Revision: 2007 November 2008 EX35

< HOW TO USE THIS MANUAL >

HOW TO FOLLOW TROUBLE DIAGNOSES

Description INFOID:0000000003131604

NOTICE:

Trouble diagnoses indicate work procedures required to diagnose problems effectively. Observe the following

instructions before diagnosing.

• Before performing trouble diagnoses, read the “Work Flow” in each section.

• After repairs, re-check that the problem has been completely eliminated.

• Refer to Component Parts and Harness Connector Location for the Systems described in each section for

identification/location of components and harness connectors.

• When checking circuit continuity, ignition switch should be OFF.

• Refer to the Circuit Diagram for quick pinpoint check.

If you need to check circuit continuity between harness connectors in more detail, such as when a sub-harness is used, refer to Wiring Diagram in each individual section and Harness Layout in PG section for identification of harness connectors.

• Before checking voltage at connectors, check battery voltage.

• After accomplishing the Diagnosis Procedures and Electrical Components Inspection, make sure that all

harness connectors are reconnected as they were.

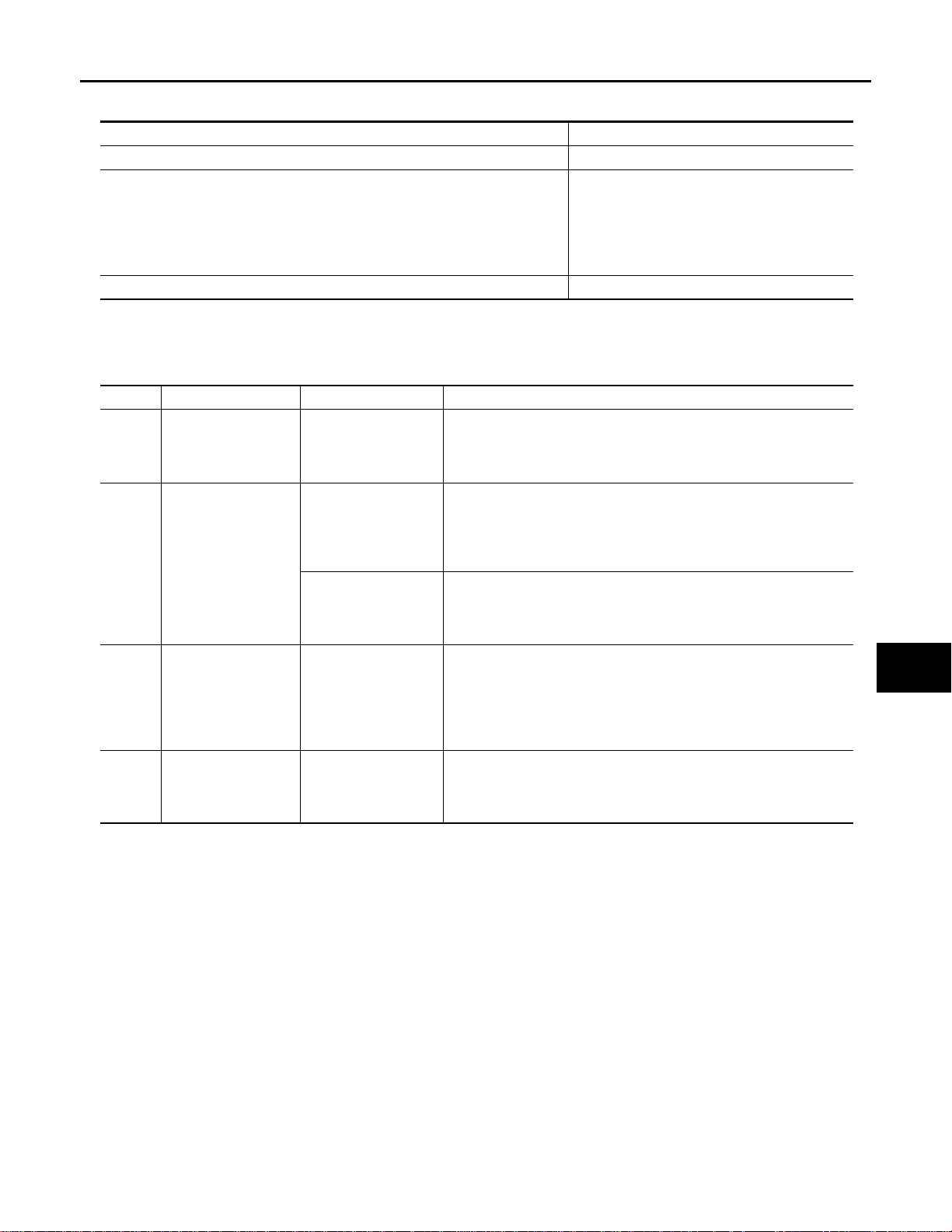

How to Follow Test Groups in Trouble Diagnosis INFOID:0000000003131605

JPAIA0021GB

1. Test group number and test group title

• Test group number and test group title are shown in the upper portion of each test group.

2. Work and diagnosis procedure

• Start to diagnose a problem using procedures indicated in enclosed test groups.

3. Questions and results

• Questions and required results are indicated in test group.

4. Action

• Next action for each test group is indicated based on result of each question.

GI-6

Page 13

HOW TO FOLLOW TROUBLE DIAGNOSES

Revision: 2007 November 2008 EX35

< HOW TO USE THIS MANUAL >

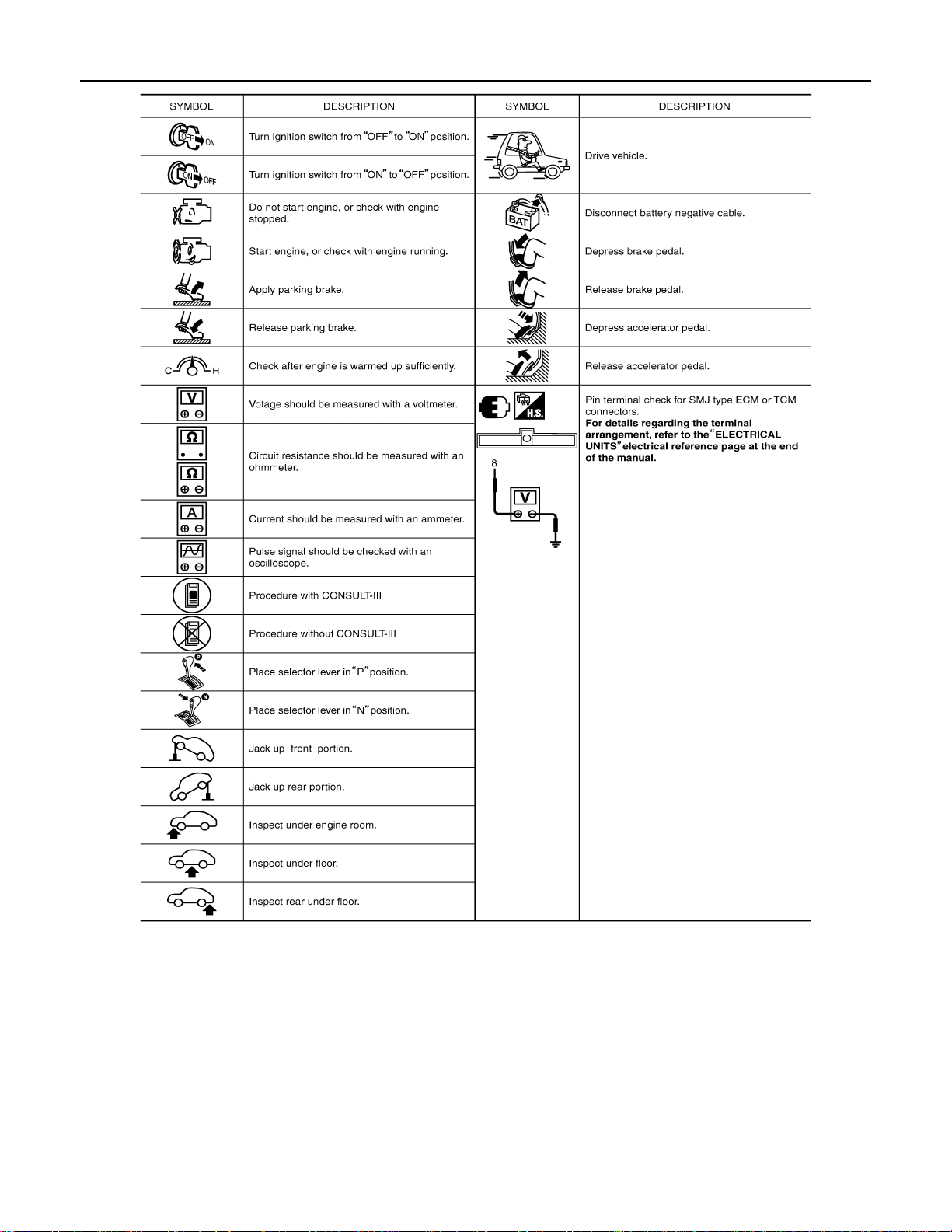

Key to Symbols Signifying Measurements or Procedures INFOID:0000000003131606

GI

B

C

D

E

F

G

SAIA1539E

H

I

J

K

L

M

N

O

GI-7

P

Page 14

HOW TO FOLLOW TROUBLE DIAGNOSES

Revision: 2007 November 2008 EX35

< HOW TO USE THIS MANUAL >

SAIA1540E

GI-8

Page 15

HOW TO READ WIRING DIAGRAMS

Revision: 2007 November 2008 EX35

< HOW TO USE THIS MANUAL >

HOW TO READ WIRING DIAGRAMS

Connector Symbols INFOID:0000000003131607

Most of connector symbols in wiring diagrams are shown from the terminal side.

• Connector symbols shown from the terminal side are enclosed by

a single line and followed by the direction mark.

• Connector symbols shown from the harness side are enclosed by

a double line and followed by the direction mark.

• Certain systems and components, especially those related to

OBD, may use a new style slide-locking type harness connector.

For description and how to disconnect, refer to PG section,

“Description”, “HARNESS CONNECTOR”.

GI

B

C

D

E

F

G

H

• Male and female terminals

Connector guides for male terminals are shown in black and

female terminals in white in wiring diagrams.

SAIA0257E

SGI363

I

J

K

L

M

N

O

P

GI-9

Page 16

HOW TO READ WIRING DIAGRAMS

B

Revision: 2007 November 2008 EX35

< HOW TO USE THIS MANUAL >

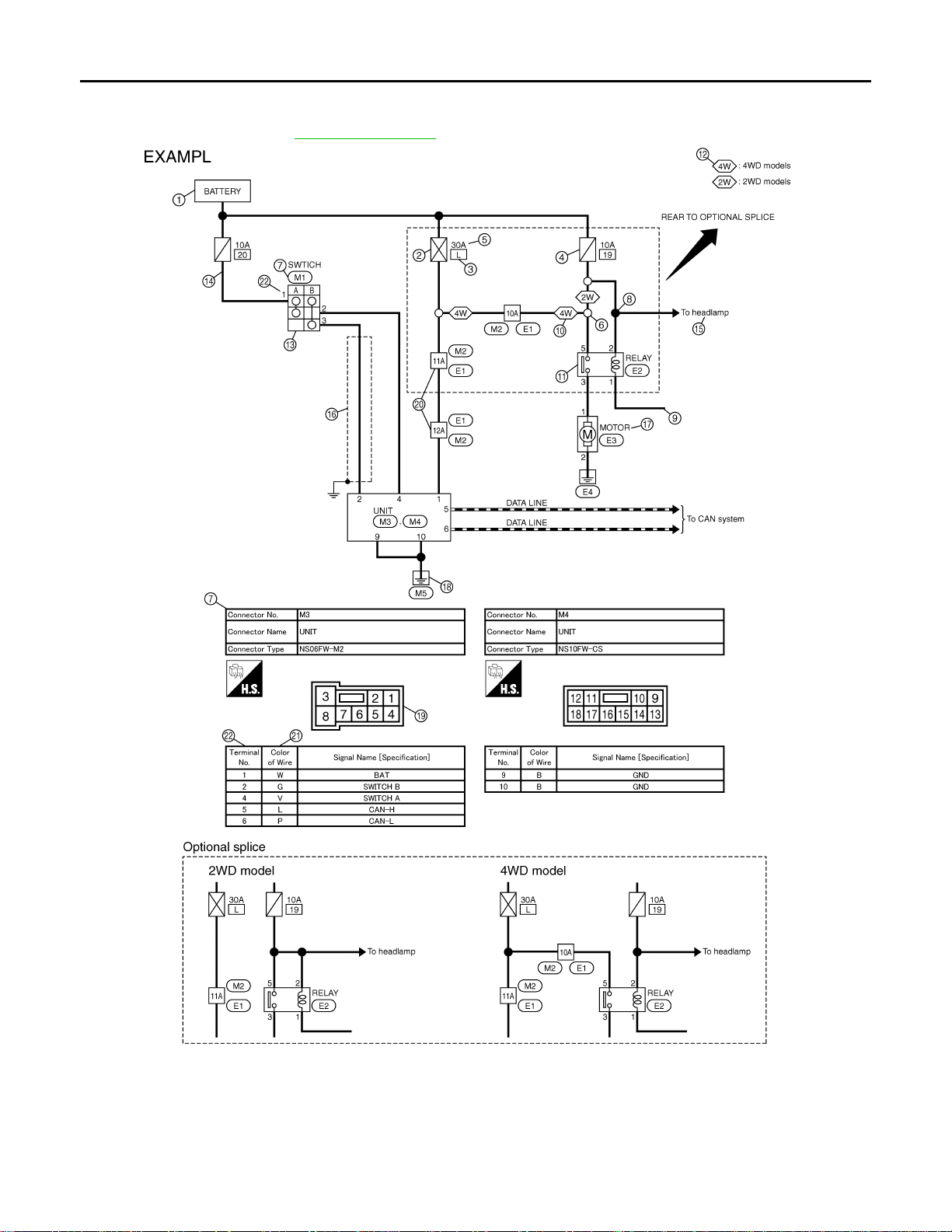

Sample/Wiring Diagram -Example-

• For detail, refer to following GI-11, "Description".

INFOID:0000000003131608

JCAWA0005G

GI-10

Page 17

HOW TO READ WIRING DIAGRAMS

Revision: 2007 November 2008 EX35

< HOW TO USE THIS MANUAL >

Description INFOID:0000000003131609

Number Item Description

1 Power supply • This means the power supply of fusible link or fuse.

2 Fusible link • “X” means the fusible link.

3

4 Fuse • “/” means the fuse.

5

6 Optional splice • The open circle shows that the splice is optional depending on vehicle application.

7 Connector number

Number of fusible link/

fuse

Current rating of fusible link/fuse

• This means the number of fusible link or fuse location.

• This means the current rating of the fusible link or fuse.

• The letter shows which harness the connector is locate d in.

• Example “M”: main harness. For detail and to locate the connector, refer to PG-78, "

To Read Harness Layout", PG-80, "Main Harness".

How

GI

B

C

D

E

8Splice

9 Page crossing • This circuit continues to an adjacent page.

10 Option abbreviation

11 Relay • This shows an internal representation of the relay.

12 Option description • This shows a description of the option abbreviation used on the page.

13 Switch

14 Circuit (Wiring) • This means the wiring.

15 System branch • This shows that the circuit is branched to other systems.

16 Shielded line • The line enclosed by broken line circle shows shield wire.

17 Component name • This shows the name of a component.

18 Ground (GND) • This shows the ground connection.

19 Connector

20 Connectors • This means that a transmission line bypasses two connect ors or more.

21 Wire color

22 Terminal number • This means the terminal number of a connector.

• The shaded circle “ ” means the splice.

• This means the vehicle specifications which layouts the circuit between “ ”.

• This shows that continui ty exists between terminals 1 and 2 when the switch is in the A

position. Continuity exist s between termi nals 1 and 3 when the sw itch is in the B posit ion.

• This means the connector information.

• This unit-side is described by the connector symbols.

• This shows a code for the color of the wire.

B = Black

W = White

R = Red

G = Green

L = Blue

Y = Yellow

LG = Light Green

• When the wire color is striped, t he base color is gi ven first, follo wed by the stripe c olor as

shown below:

Example: L/W = Blue with White Stripe

BR = Brown

OR or O = Orange

P = Pink

PU or V (Violet) = Purple

GY or GR = Gray

SB = Sky Blue

CH = Dark Brown

DG = Dark Green

F

G

H

I

J

K

L

M

N

O

SWITCH POSITIONS

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

GI-11

P

Page 18

HOW TO READ WIRING DIAGRAMS

Revision: 2007 November 2008 EX35

< HOW TO USE THIS MANUAL >

• ignition switch is “OFF”,

• doors, hood and trunk lid/back door are closed,

• pedals are not depressed, and

• parking brake is released.

MULTIPLE SWITCH

The continuity of multiple switch is described in two ways as shown below.

• The switch chart is used in schematic diagrams.

• The switch diagram is used in wiring diagrams.

SGI860

JSAIA0017GB

GI-12

Page 19

< HOW TO USE THIS MANUAL >

Revision: 2007 November 2008 EX35

ABBREVIATIONS

ABBREVIATIONS

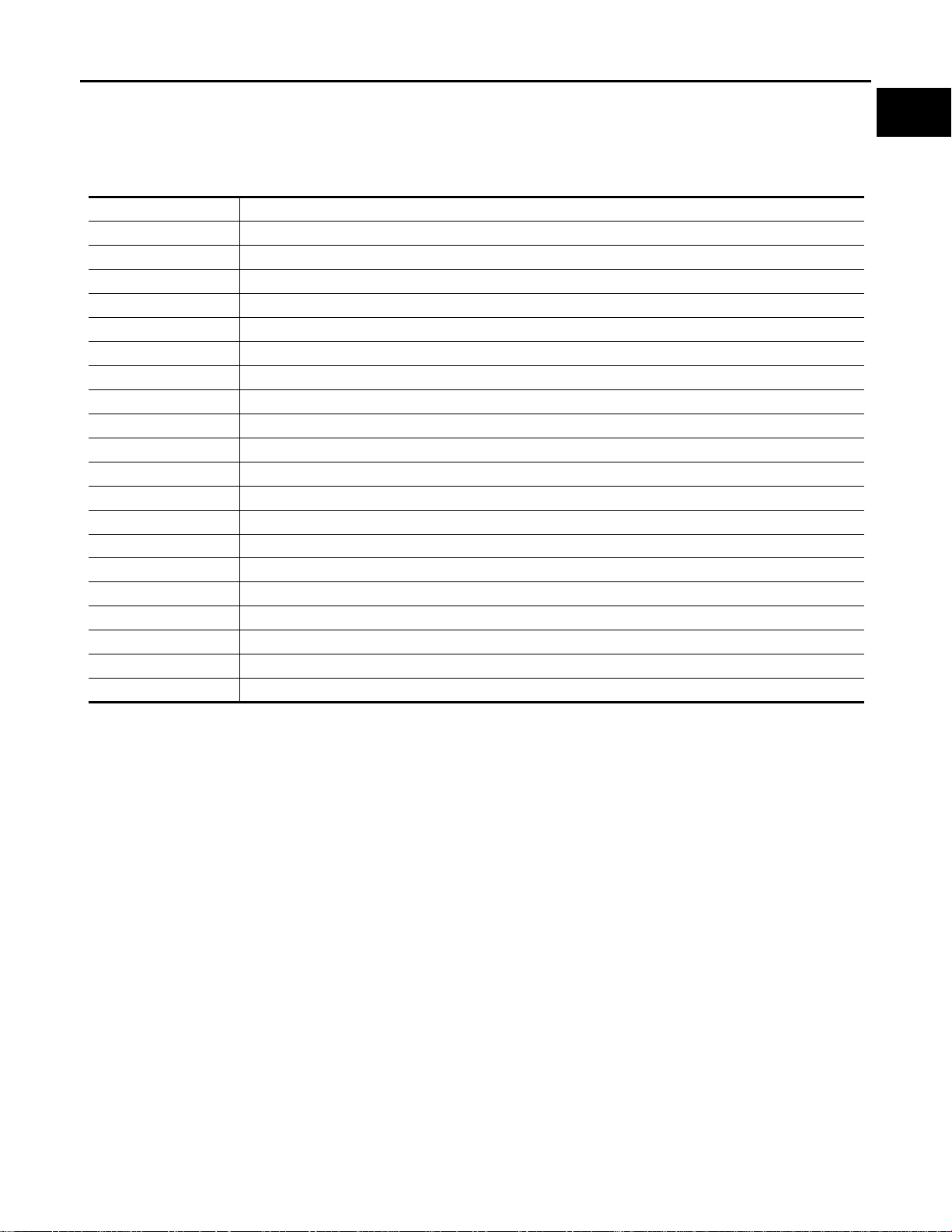

Abbreviation List INFOID:0000000003131610

The following ABBREVIATIONS are used:

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

1 Drive range 1st gear

D

2 Drive range 2nd gear

D

3 Drive range 3rd gear

D

4 Drive range 4th gear

D

FR, RR Front, Rear

LH, RH Left-Hand, Right-Hand

M/T Manual Transaxle/Transmission

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Da ta and Specifications

SST Special Service Tools

2WD 2-Wheel Drive

2 2nd range 2nd gear

2

1 2nd range 1st gear

2

2 1st range 2nd gear

1

1 1st range 1st gear

1

GI

B

C

D

E

F

G

H

I

J

M

N

O

K

L

P

GI-13

Page 20

TIGHTENING TORQUE OF STANDARD BOLTS

Revision: 2007 November 2008 EX35

< HOW TO USE THIS MANUAL >

TIGHTENING TORQUE OF STANDARD BOLTS

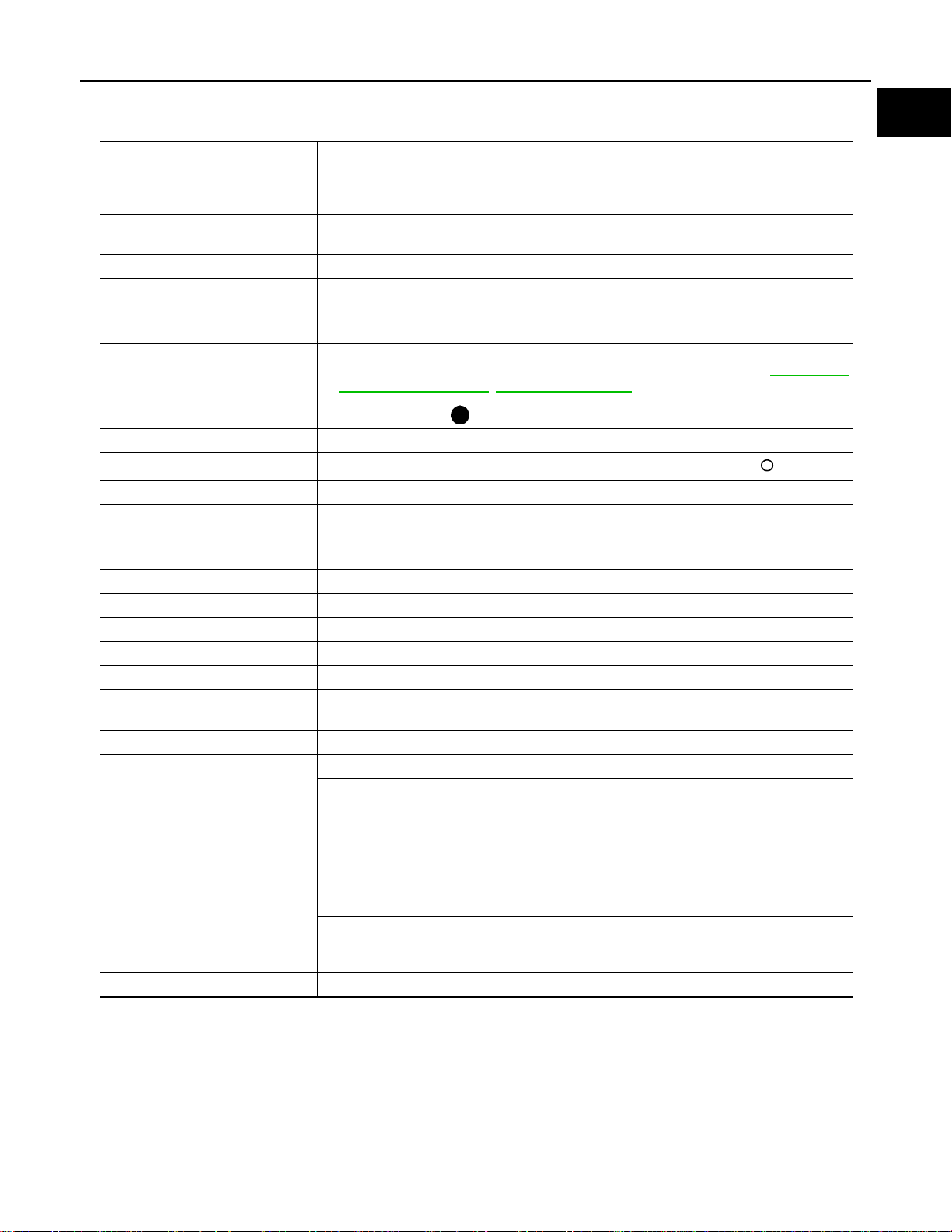

Tightening Torque Table INFOID:0000000003131611

Bolt diam-

Grade Bolt size

M6 6.0 1.0 5.5 0.56 4 49 7 0.71 5 62

M8 8.0

4T

7T

9T

*: Nominal diameter

1. Special parts are excluded.

2. This standard is applicable to bolts having the following marks embossed on the bolt head.

M10 10.0

M12 12.0

M14 14.0 1.5 80 8.2 59 — 100 10 74 —

M6 6.0 1.0 9 0.92 7 80 11 1.1 8 97

M8 8.0

M10 10.0

M12 12.0

M14 14.0 1.5 130 13 96 — 170 17 125 —

M6 6.0 1.0 11 1.1 8 — 13.5 1.4 10 —

M8 8.0

M10 10.0

M12 12.0

M14 14.0 1.5 170 17 125 — 210 21 155 —

eter *

mm

Pitch

mm

N·m kg-m ft-lb in-lb N·m kg-m ft-lb in-lb

1.25 13.5 1.4 10 — 17 1.7 13 —

1.0 13.5 1.4 10 — 17 1.7 13 —

1.5 28 2.9 21 — 35 3.6 26 —

1.25 28 2.9 21 — 35 3.6 26 —

1.75 45 4.6 33 — 55 5.6 41 —

1.25 45 4.6 33 — 65 6.6 48 —

1.25 22 2.2 16 — 28 2.9 21 —

1.0 22 2.2 16 — 28 2.9 21 —

1.5 45 4.6 33 — 55 5.6 41 —

1.25 45 4.6 33 — 55 5.6 41 —

1.75 80 8.2 59 — 100 10 74 —

1.25 80 8.2 59 — 100 10 74 —

1.25 28 2.9 21 — 35 3.6 26 —

1.0 28 2.9 21 — 35 3.6 26 —

1.5 55 5.6 41 — 80 8.2 59 —

1.25 55 5.6 41 — 80 8.2 59 —

1.751001074—1301396—

1.251001074—1301396—

Hexagon head bolt Hexagon flange bolt

Tightening torque (Without lubricant)

MGI044A

GI-14

Page 21

RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

Revision: 2007 November 2008 EX35

< HOW TO USE THIS MANUAL >

RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

Recommended Chemical Products and Sealants INFOID:0000000003131612

Refer to the following chart for help in selecting the appropriate chemical product or sealant.

Product Description Purpose

Rear View Mirror Adhe-

1

sive

Anaerobic Liquid Gas-

2

ket

High Performance

3

Thread Sealant

4 Silicone RTV

High Temperature,

5

High Strength Thread

Locking Sealant (Red)

Medium Stre ngth

6

Thread Locking Sealant (Blue)

Used to permanently remount rear view mirrors to

windows.

For metal-to-metal flange

sealing.

Can fill a 0.38 mm (0.015

inch) gap and provide instant sealing for most powertrain applications.

Provides instant sealing on

any threaded straight or

parallel threaded fitting.

(Thread sealant only, no

locking ability.)

• Do not use on plastic.

Gasket Maker

Gasket Maker for Maxima/

Quest 5-speed automatic

transmission

(RE5F22A)

Threadlocker 999MP-AM004P 999MP-AM004P

Threadlocker (service tool

removable)

Nissan North America

Part No. (USA)

999MP-AM000P 99998-50505 Permatex 81844

999MP-AM001P 99998-50503

999MP-AM002P 999MP-AM002P Permatex 56521

999MP-AM003P

(Ultra Grey)

––

999MP-AM005P 999MP-AM005P

Nissan Canada Part

No. (Canada)

99998-50506

(Ultra Grey)

Aftermarket Cross-

reference Part Nos.

Permatex 51813 and

51817

Permatex Ultra Grey

82194;

Three Bond

1207,1215, 1216,

1217F, 1217G and

1217H

Nissan RTV Part No.

999MP-A7007

Three Bond 1281B

or exact equivalent in

its quality

Permatex 27200;

Three Bond 1360,

1360N, 1305 N&P,

1307N, 1335,

1335B, 1363B,

1377C, 1386B, D&E

and 1388

Loctite 648

Permatex 24200,

24206, 24240,

24283 and 09178;

Three Bond 1322,

1322N, 1324 D&N,

1333D, 1361C,

1364D, 1370C and

1374

GI

B

C

D

E

F

G

H

I

J

K

L

M

N

O

GI-15

P

Page 22

TERMINOLOGY

Revision: 2007 November 2008 EX35

< HOW TO USE THIS MANUAL >

TERMINOLOGY

SAE J1930 Terminology List INFOID:0000000003131613

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch sw itch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programma ble read

only memory

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature senso r ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

EEPROM ***

NEW ACRONYM /

ABBREVIATION

OLD TERM

GI-16

Page 23

< HOW TO USE THIS MANUAL >

Revision: 2007 November 2008 EX35

TERMINOLOGY

NEW TERM

Exhaust gas recirculation control-BPT

valve

Exhaust gas recirculation control-solenoid

valve

Exhaust gas recirculation te mperat ure sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memory

Flash erasable programmable read only

memory

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differentia l pressure MDP ***

Manifold differentia l pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

EGRC-BPT valve BPT valve

EGRC-solenoid valve EGR control solenoid valve

EGRT sensor Exhaust gas temperature sensor

FEEPROM ***

FEPROM ***

*** PRVR control solenoid valve

IACV-AAC valve Auxiliary air control (AAC) valve

IACV-idle up control solenoid valve Idle up control solenoid valve

NEW ACRONYM /

ABBREVIATION

OLD TERM

GI

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

GI-17

Page 24

< HOW TO USE THIS MANUAL >

Revision: 2007 November 2008 EX35

TERMINOLOGY

NEW TERM

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control sol e-

noid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

Simultaneous multiport fuel injection sys-

tem

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

system

Throttle body TB

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve

PAIRC solenoid valve AIV control solenoid valve

*** Simultaneous fuel injection

TWC + OC system ***

NEW ACRONYM /

ABBREVIATION

Park/neutral switch

Inhibitor switch

Neutral position switch

Throttle chamber

SPI body

Lock-up cancel solenoid

Lock-up solenoid

OLD TERM

GI-18

Page 25

< HOW TO USE THIS MANUAL >

Revision: 2007 November 2008 EX35

TERMINOLOGY

NEW TERM

Transmission control module TCM A/T control unit

Turbocharger TC Turbocharger

Vehicle speed sensor VS S Vehicle speed sensor

Volume air flow sensor VAFS Air flow meter

Warm up oxidation catalyst WU-OC Catalyst

Warm up oxidation catalytic converter sys-

tem

Warm up three way catalyst WU-TWC Catalyst

Warm up three way cat alytic c onverter s ys-

tem

Wide open throttle position switch WOTP switch Full switch

***: Not applicable

WU-OC system ***

WU-TWC system ***

NEW ACRONYM /

ABBREVIATION

OLD TERM

GI

B

C

D

E

F

G

H

M

N

O

I

J

K

L

P

GI-19

Page 26

IDENTIFICATION INFORMATION

Revision: 2007 November 2008 EX35

< FEATURES OF NEW MODEL >

FEATURES OF NEW MODEL

IDENTIFICATION INFORMATION

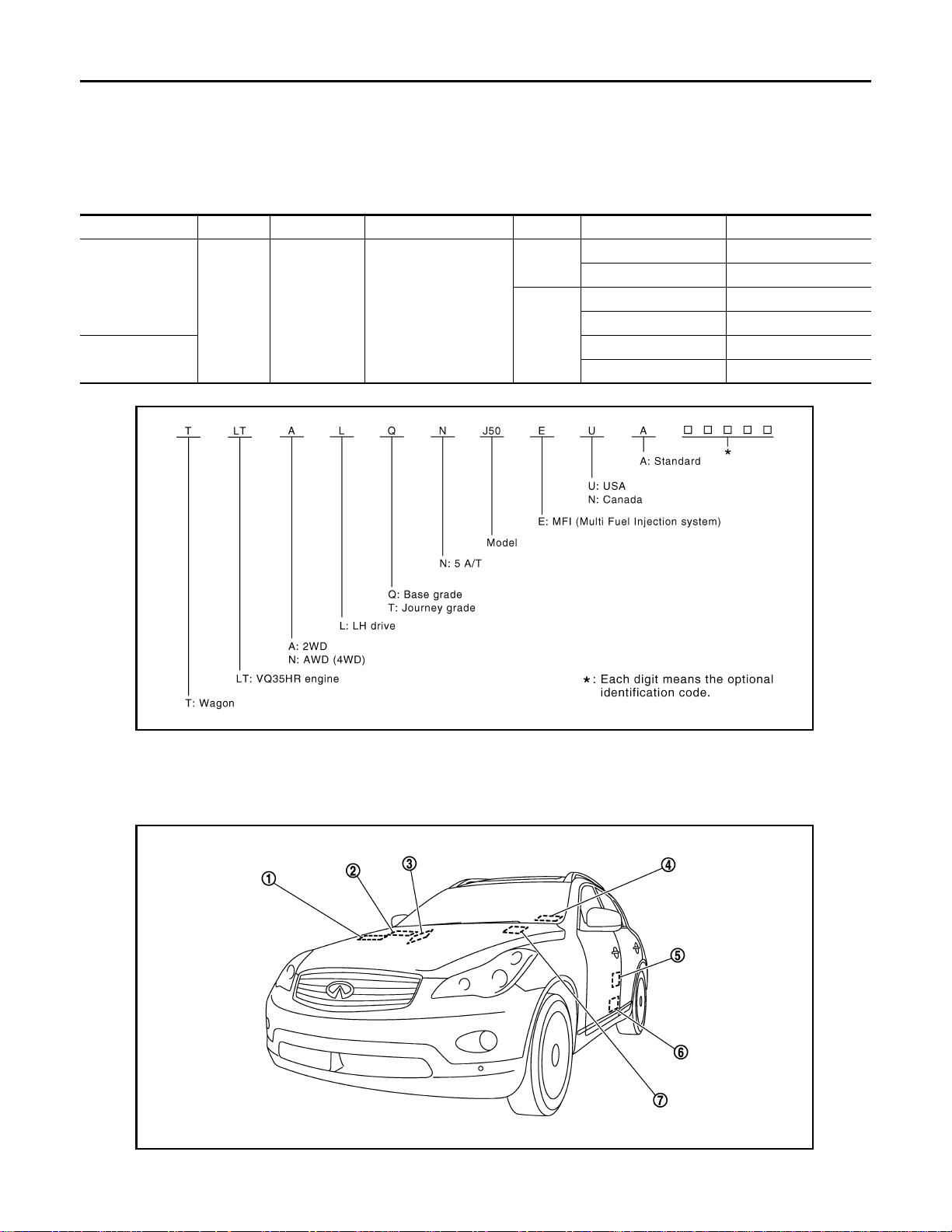

Model Variation INFOID:0000000003131614

Dstination Body Engine Transmission Axle Grade Model

2WD

USA

Wagon VQ35HR 5A/T

AWD

Canada

Model variation code (Prefix and suffix designations)

Base TLTALQN-EUA

Journey TLTALTN-EUA

Base TLTNLQN-EUA

Journey TLTNLTN-EUA

Base TLTNLQN-ENA

Journey TLTNLTN-ENA

JPAIA0240GB

Information About Identification or Model Code INFOID:0000000003131615

IDENTIFICATION NUMBER

JPAIA0241ZZ

GI-20

Page 27

IDENTIFICATION INFORMATION

Revision: 2007 November 2008 EX35

< FEATURES OF NEW MODEL >

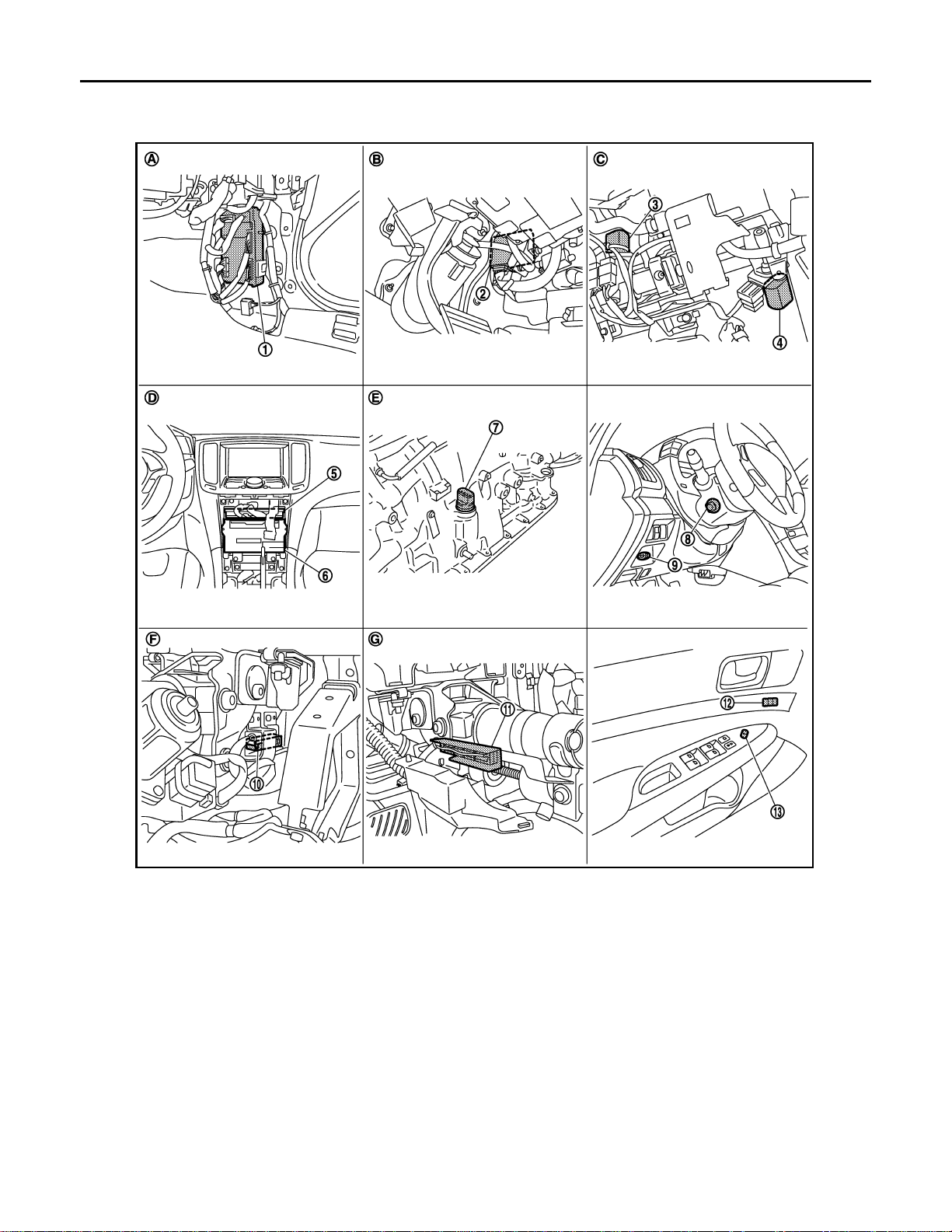

1. Vehicle identification plate 2. Emission control information labe l 3 .

4. Vehicle identification number plate 5. Tire and loading information label 6. FMVSS certification label

7. Air conditioner specification labe

Vehicle identification number (Chassis

number)

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

IDENTIFICATION PLATE

GI

B

C

D

E

F

G

JPAIA0242GB

H

1. Type 2. Vehicle identification number (Chassis number) 3. Model variation code

4. Body color code 5. Trim color code 6. Engine model

7. Engine displacement 8. Transmission model 9. Axle model

ENGINE SERIAL NUMBER

JPAIA0004ZZ

JPAIA0005ZZ

I

J

K

L

M

N

O

P

GI-21

Page 28

IDENTIFICATION INFORMATION

Revision: 2007 November 2008 EX35

< FEATURES OF NEW MODEL >

AUTOMATIC TRANSMISSION NUMBER

PAIA0054E

Dimensions INFOID:0000000003131616

Unit: mm (in)

Overall length 4,630 (182.3)

Overall width 1,800 (70.9)

Overall height

Front tread

Rear tread

Wheelbase 2,850 (112.2)

*1: 2WD 17-in tire models

*2: 2WD 18-in tire models

*3: AWD 17-in tir e models

*4: AWD 18-in tir e models

*5: Models without roof rack

*6: Models with roof rack

1,570 (61.8)*

1,590 (62.6)*

1,535 (60.4)*

1,530 (60.2)*

1,545 (60.8)*

1,540 (60.6)*

1,550 (61.0)*

1,545 (60.8)*2,*

5

6

1

2

3

4

1,*3

4

Wheels & Tires INFOID:0000000003131617

Application Conventional Spare

Road wheel/offset mm (in)

Tire size

17 X 7-1/2J Aluminum/4 5 (1.77)

18 X 8J Aluminum/47 (1.85)

P225/60R17 98V

P225/55R18 97V

17 × 4T Aluminum/30 (1.18)

T165/80R17

GI-22

Page 29

< PRECAUTION >

Revision: 2007 November 2008 EX35

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Description INFOID:0000000003131618

Observe the following precautions to ensure safe and proper servicing. These precautions are not

described in each individual section.

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIRBAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

INFOID:0000000003566319

GI

B

C

D

E

F

G

H

I

Precautions For Xenon Headlamp Service INFOID:0000000003131620

WARNING:

Comply with the following warnings to prevent any serious accident.

• Disconnect the battery cable (negative terminal) or the power supply fuse before installing, removing, or touching the xenon headlamp (bulb included). The xenon headlamp contains high-voltage

generated part s.

• Never work with wet hands.

• Check the xenon headlamp ON-OFF status after assembling it to the vehicle. Never turn the xenon

headlamp ON in other conditions. Connect the power supply to the vehicle-side connector.

(Turning it ON outside the lamp case may cause fire or visual impairments.)

• Never touch the bulb glass immediately after turning it OFF. It is extremely hot.

CAUTION:

Comply with the following cautions to prevent any error and malfunction.

• Install the xenon bulb securely. (Insufficient bulb socket installation may melt the bulb, the connector, the housing, etc. by high-voltage leakage or corona discharge.)

• Never perform HID circuit inspection with a tester.

• Never touch the xenon bulb glass with hands. Never put oil and grease on it.

• Dispose of the used xenon bulb after packing it in thick vinyl without breaking it.

• Never wipe out dirt and contamination with organic solvent (thinner, gasoline, etc.).

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003691858

NOTE:

• Before removing and installing any control units, first turn the push-button ignition switch to the LOCK position, then disconnect both battery cables.

• After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

J

K

L

M

N

O

P

GI-23

Page 30

PRECAUTIONS

Revision: 2007 November 2008 EX35

< PRECAUTION >

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables disconnected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top Cover INFOID:0000000003566320

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

PIIB3706J

General Precautions INFOID:0000000003131623

• Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any inflammable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or other enclosed area, be sure to properly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

SGI285

• Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After jacking up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehicle.

These operations should be done on a level surface.

• When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

GI-24

SGI231

Page 31

PRECAUTIONS

Revision: 2007 November 2008 EX35

< PRECAUTION >

• Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

• If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

• To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

• Dispose of drained oil or the solvent used for cleaning parts in an

appropriate manner.

• Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulti ng in fuel spray

and possibly a fire.

• Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

• Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

• Replace inner and outer races of tapered roller bearings and needle bearings as a set.

• Arrange the disassembled parts in accordance with their assembled locations and sequence.

• Do not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

• After disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

• Use only the fluids and lubricants specified in this manual.

• Use approved bonding agent, sealants or their equivalents when required.

• Use hand tools, power tools (disassembly only) and recommended

special tools where specified for safe and efficient service repairs.

• When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

GI

B

C

SEF289H

D

E

F

G

SGI233

H

I

J

K

• Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

GI-25

L

M

PBIC0190E

N

O

P

SGI234

Page 32

PRECAUTIONS

Revision: 2007 November 2008 EX35

< PRECAUTION >

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Three Way Catalyst INFOID:0000000003131624

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

• Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

• When checking for ignition spark or measuring engine compression, make tests quickly and only when necessary.

• Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Multiport Fuel Injection System or Engine Control System INFOID:0000000003131625

• Before connecting or disconnecting any harness connector for the

multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

• Before disconnecting pressurized fuel line from fuel pump to injectors, be sure to release fuel pressure.

• Be careful not to jar components such as ECM and mass air flow

sensor.

SGI787

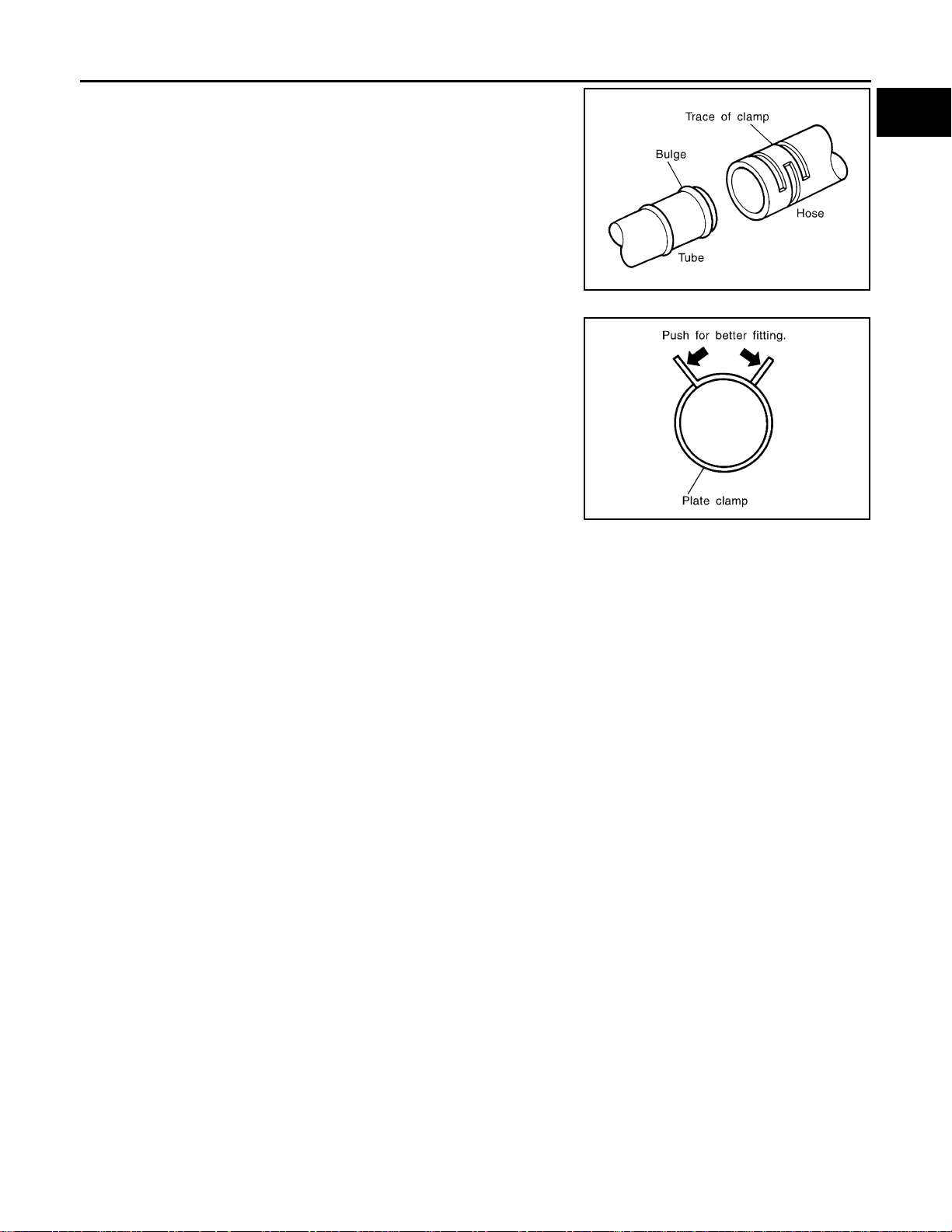

Hoses INFOID:0000000003131626

HOSE REMOVAL AND INSTALLATION

• To prevent damage to rubber hose, do not pry off rubber hose with

tapered tool or screwdriver.

SMA019D

• To reinstall the rubber hose securely, make sure that hose insertion

length and orientation is correct. (If tube is equipped with hose

stopper, insert rubber hose into tube until it butts up against hose

stopper.)

HOSE CLAMPING

GI-26

SMA020D

Page 33

PRECAUTIONS

Revision: 2007 November 2008 EX35

< PRECAUTION >

• If old rubber hose is re-used, install hose clamp in its original position (at the indentation where the old clamp was). If there is a trace

of tube bulging left on the old rubber hose, align rubber hose at

that position.

• Discard old clamps; replace with new ones.

• After installing plate clamps, apply force to them in the direction of

the arrow, tightening rubber hose equally all around.

GI

B

C

SMA021D

D

E

F

G

SMA022D

Engine Oils INFOID:0000000003131627

Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin contact

with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

HEALTH PROTECTION PRECAUTIONS

• Avoid prolonged and repeated contact with oils, particularly used engine oils.

• Wear protective clothing, including impervious gloves where practicable.

• Do not put oily rags in pockets.

• Avoid contaminating clothes, particularly underpants, with oil.

• Heavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regularly.

• First aid treatment should be obtained immediately for open cuts and wounds.

• Use barrier creams, applying them before each work period, to help the removal of oil from the skin.

• Wash with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). Preparations containing lanolin replace the natural skin oils which have been removed.

• Do not use gasoline, kerosene, diesel fuel, gas oil, thinners or solvents for cleaning skin.

• If skin disorders develop, obtain medical advice without delay.

• Where practical, degrease components prior to handling.

• Where there is a risk of eye contact, eye protection should be worn, for example, chemical goggles or face

shields; in addition an eye wash facility should be provided.

ENVIRONMENTAL PROTECTION PRECAUTIONS

Dispose of used oil and used oil filters through authorized waste disposal contractors to licensed waste disposal sites, or to the waste oil reclamation trade. If in doubt, contact the local authority for advice on disposal

facilities.

It is illegal to pour used oil on to the ground, down sewers or drains, or into water sources.

The regulations concerning pollution vary between regions.

Air Conditioning INFOID:0000000003131628

H

I

J

K

L

M

N

O

P

Use an approved refrigerant recovery unit any time the air conditioning system must be discharged. Refer to

HA section “REFRIGERANT” for specific instructions.

FUEL

GI-27

Page 34

< PRECAUTION >

Revision: 2007 November 2008 EX35

PRECAUTIONS

FUEL : Unleaded Premium Gasoline Recommended

INFINITI recommends the use of unleaded premium gasoline with an octane rating of at least 91 AKI (AntiKnock Index) number (Research octane number 96).

If unleaded premium gasoline is not available, you may use unleaded regular gasoline with an octane rating of

at least 87 AKI number (Research octane number 91), but you may notice a decrease in performance.

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unleaded gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fuel other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

INFOID:0000000003131629

GI-28

Page 35

< PRECAUTION >

Revision: 2007 November 2008 EX35

LIFTING POINT

LIFTING POINT

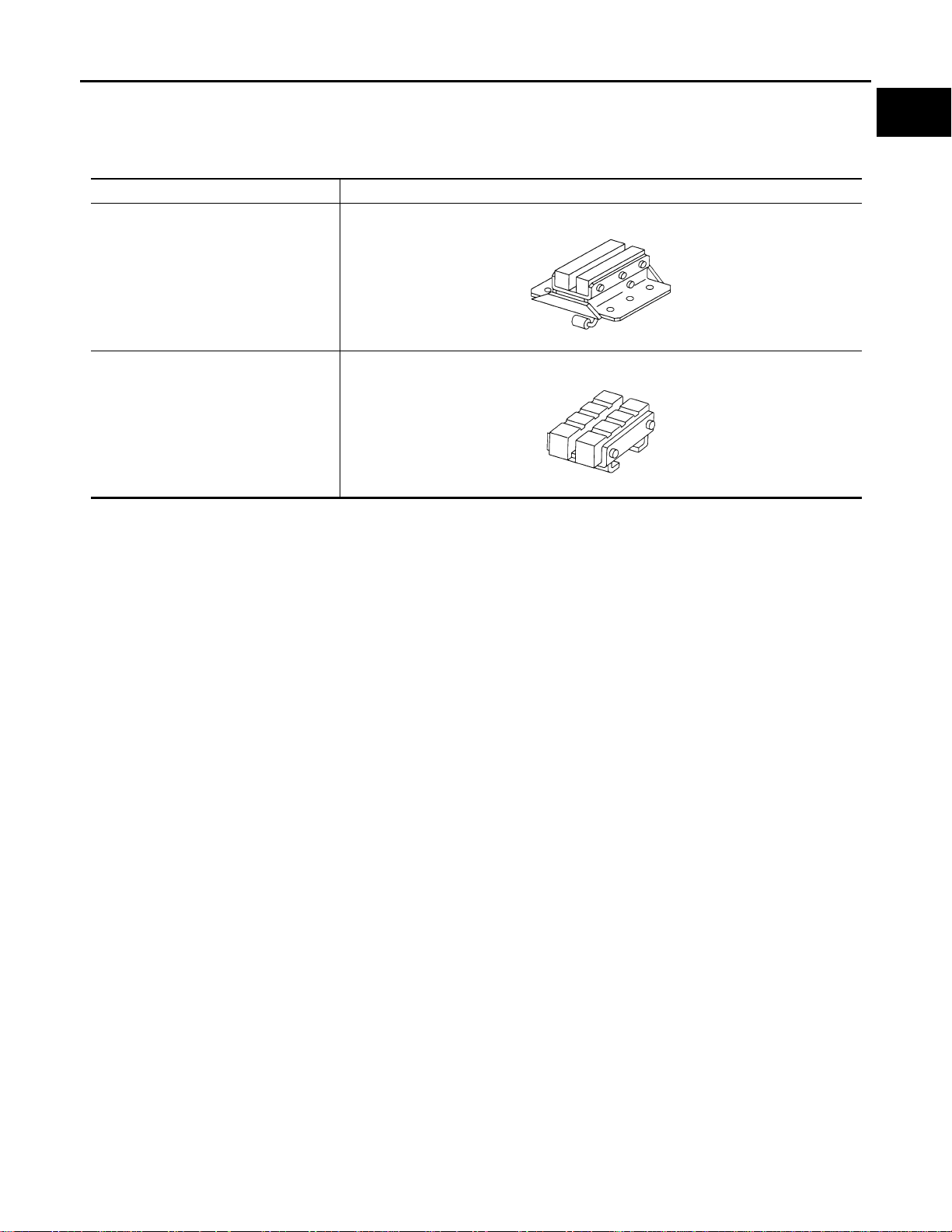

Commercial Service Tools INFOID:0000000003131630

Tool name Description

Board on attachment

S-NT001

Safety stand attachment

S-NT002

CAUTION:

• Every time the vehicle is lifted up, maintain the complete vehicle curb condition.

• Since the vehicle's center of gravity changes when removing main parts on the front side (engine,

transmission, suspension etc.), support a jack up point on the rear side garage jack with a mission

jack or equivalent.

• Since the vehicle's center of gravity changes when removing main parts on the rear side (rear axle,

suspension, etc.), support a jack up point on the front side garage jack with a mission jack or equivalent.

• Be careful not to smash or do not do anything that would affect piping parts.

Garage Jack and Safety Stand and 2-Pole Lift INFOID:0000000003131631

GI

B

C

D

E

F

G

H

I

J

WARNING:

• Park the vehicle on a level surface when using the jack. Make sure to avoid damaging pipes, tubes,

etc. under the vehicle.

• Never get under the vehicle while it is supported only by the jack. Always use safety stands when

you have to get under the vehicle.

• Place wheel chocks at both front and back of the wheels on the ground.

• When lifting the vehicle, open the lift arms as wide as possible and ensure that the front and rear of

the vehicle are well balanced.

• When setting the lift arm, do not allow the arm to contact the brake tubes, brake cable, fuel lines and

sill spoiler.

K

L

M

N

O

P

GI-29

Page 36

< PRECAUTION >

Revision: 2007 November 2008 EX35

LIFTING POINT

JMAIA0085ZZ

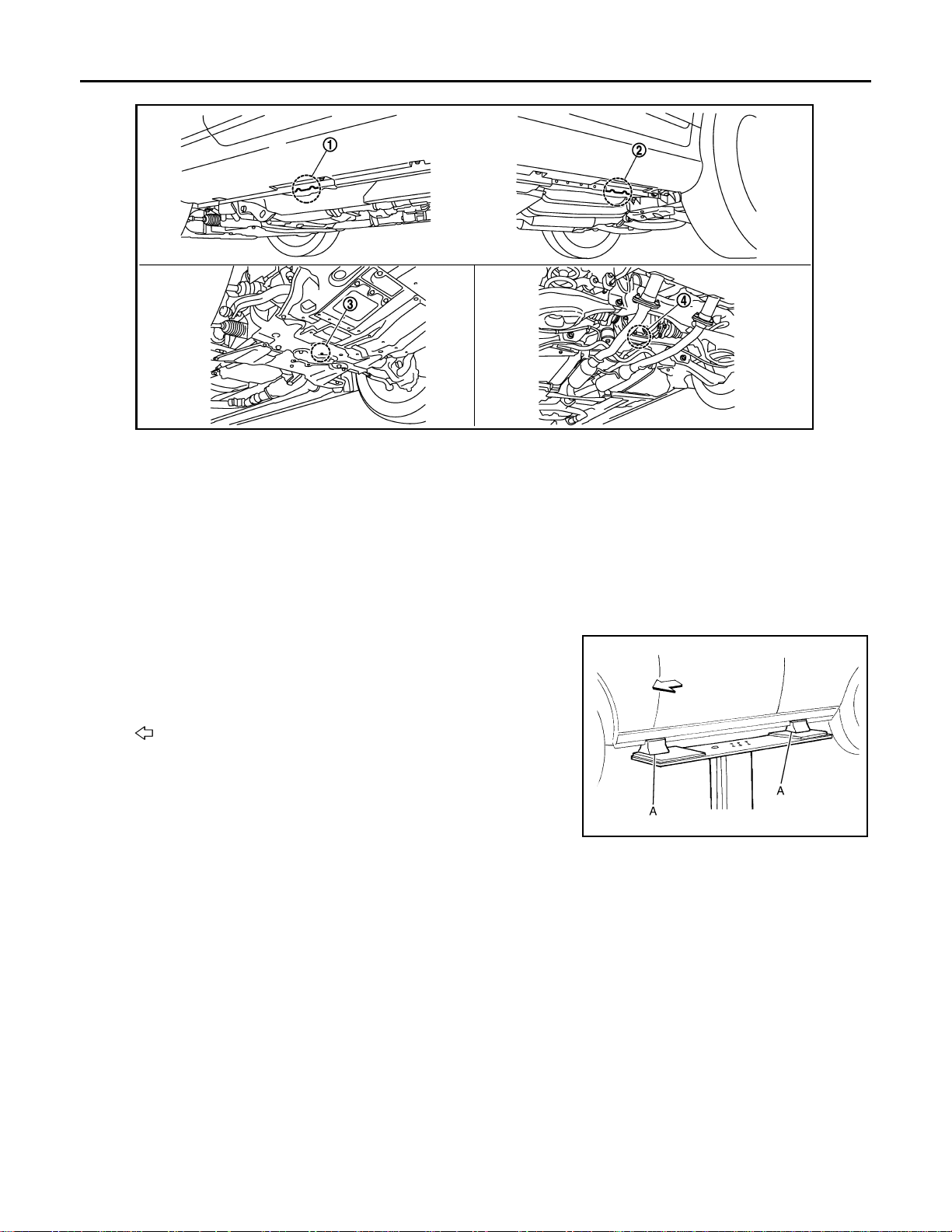

1. Safety stand point and lift up point (front) 2. Safety stand point and lift up point

(rear)

4. Garage jack point (rear)

3. Garage jack point (front)

CAUTION:

There is canister just behind Garage jack point rear. Jack up be carefully.

Board-On Lift INFOID:0000000003131632

CAUTION:

Make sure vehicle is empty when lifting.

• The board-on lift attachment (A) set at front end of vehicle

should be set on the front of the sill under the front door

opening.

• Position attachments at front and rear ends of board-on lift.

: Vehicle front

JMAIA0004ZZ

GI-30

Page 37

< PRECAUTION >

Revision: 2007 November 2008 EX35

TOW TRUCK TOWING

TOW TRUCK TOWING

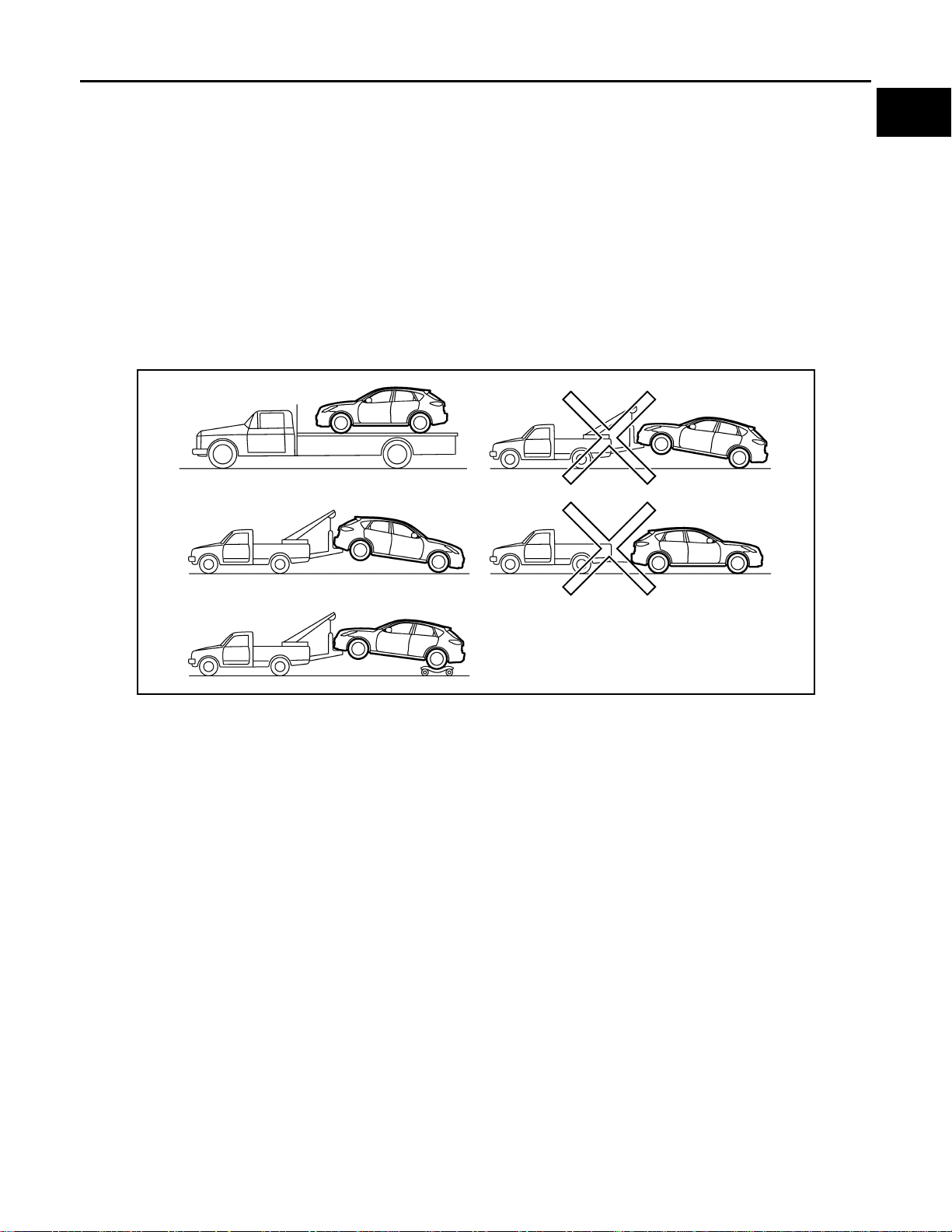

Tow Truck Towing INFOID:0000000003131633

CAUTION:

• All applicable state or Provincial (in Canada) laws and local laws regarding the towing operation

must be obeyed.

• It is necessary to use proper towing equipment to avoid possible damage to the vehicle during towing operation. Towing is in accordance with Towing Procedure Manual at dealer.

• Always attach safety chains before towing.

• When towing, make sure that the transmission, steering system and powertrain are in good order. If

any unit is damaged, dollies must be used.

• Never tow automatic transmission model from the rear (that is backward) with four wheels on the

ground. This may cause serious and expensive damage to the transmission.

2WD MODELS

GI

B

C

D

E

F

G

H

JMAIA0088ZZ

INFINITI recommends that vehicle be towed with the driving (rear) wheels off the ground or that a dolly be

used as illustrated.

CAUTION:

• Never tow automatic transmission models with the rear wheels on the ground or four wheels on the

ground (forward or backward), as this may cause serious and expensive damage to the transmission.

If it is necessary to tow the vehicle with the front wheels raised, always use towing dollies under the

rear wheels.

• When towing rear wheel drive models with the front wheels on the ground or on towing dollies:

- Turn the ignition key to the OFF position, and secure the steering wheel in a straight ahead position

with a rope or similar device.Never secure the steering wheel by turning the ignition key to the LOCK

position. This may damage the steering lock mechanism.

- Move the selector lever to the N (Neutral) position.

• When the battery of vehicle equipped with the Intelligent Key system is discharged, your vehicle

should be towed with the front wheels on towing dollies or place the vehicle on a flat bed truck.

If the speed or distance must necessarily be greater, remove the propeller shaf t before towing to prevent damage to the transmission.

I

J

K

L

M

N

O

P

GI-31

Page 38

TOW TRUCK TOWING

Revision: 2007 November 2008 EX35

< PRECAUTION >

AWD MODELS

JMAIA0089ZZ

INFINITI recommends that a dolly be used as illustrated when towing AWD models.

CAUTION:

Never tow AWD models with any of the wheels on the ground as this may cause serious and expensive damage to the powertrain.

Vehicle Recovery (Freeing a Stuck Vehicle) INFOID:0000000003131634

FRONT

Securely install the vehicle recovery hook stored with jacking tools.

Make sure that the hook is properly secured in the stored place after

use.

WARNING:

• Stand clear of a stuck vehicle.

• Do not spin your tires at high speed. This could cause them to

explode and result in serious injury. Parts of your vehicle

could also overheat and be damaged.

CAUTION:

• Tow chains or cables must be attached only to the vehicle

recovery hooks or main structural members of the vehicle.

Otherwise, the vehicle body will be damaged.

• Do not use the vehicle tie downs to free a vehicle stuck in sand, snow, mud, etc. Never tow the vehicle using the vehicle tie downs or recovery hooks.

• Always pull the cable straight out from the front of the vehicle. Never pull on the hook at an angle.

• Pulling devices should be routed so they do not touch any part of the suspension, steering, brake or

cooling systems.

• Pulling devices such as ropes or canvas straps are not recommended for use in vehicle towing or

recovery.

REAR

WARNING:

JMAIA0086ZZ

GI-32

Page 39

< PRECAUTION >

Revision: 2007 November 2008 EX35

• Rear hook is not available.

AUTOMATIC TRANSMISSI ON

TOW TRUCK TOWING

GI

B

C

JMAIA0087ZZ

D

To tow a vehicle equipped with an automatic transmission, an appropriate vehicle dolly MUST be placed under

the towed vehicle's drive wheels. Always follow the dolly manufacture's recommendations when using their

product.

If the vehicle is stuck in sand, snow, mud, etc., use the following procedure:

1. Turn off the Vehicle Dynamic Control System.

2. Make sure the area in front and behind the vehicle is clear of obstructions.

3. Turn the steering wheel right and left to clear an area around the front tires.

4. Slowly rock the vehicle forward and backward.

Shift back and forth between R (reverse) and D (drive).

Apply the accelerator as little as possible to maintain the rocking motion.

Release the accelerator pedal before shifting between R and D.

Do not spin the tires above 35 mph (55 km/h).

5. If the vehicle can not be freed after a few tries, contact a professional towing service to remove the vehicle.

E

F

G

H

I

J

K

L

GI-33

M

N

O

P

Page 40

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Revision: 2007 November 2008 EX35

< BASIC INSPECTION >

BASIC INSPECTION

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Work Flow INFOID:0000000003131635

WORK FLOW

STEP DESCRIPTION

Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHAT Vehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5 Repair or replace the incident circuit or component.

STEP 6

WHEN Date, Time of Day, Weather Conditions, Frequency.

WHERE Road Conditions, Altitude and Traffic Situation.

HOW

Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

Get the proper diagnosis materials together including:

• Power Supply Routing

• System Operation Descriptions

• Applicable Service Manual Sections

• Check for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and t he customer comments.

Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and co mponents are involv ed and diagnose using the Power Supply Routing and Harness Layouts.

Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inadvertently created a new incident during your diagnosis or repair steps.

System Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

SGI838

Control Units and Electrical Parts INFOID:0000000003131636

PRECAUTIONS

• Never reverse polarity of battery terminals.

• Install only parts specified for a vehicle.

• Before replacing the control unit, check the input and output and functions of the component parts.

• Do not apply excessive force when disconnecting a connector.

GI-34

Page 41

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Revision: 2007 November 2008 EX35

< BASIC INSPECTION >

• Do not apply excessive shock to the control unit by dropping or hit-

ting it.

• Be careful to prevent condensation in the control unit due to rapid

temperature changes and do not let water or rain get on it. If water

is found in the control unit, dry it fully and then install it in the vehicle.

• Be careful not to let oil to get on the control unit connector.

• Avoid cleaning the control unit with volatile oil.

• Do not disassemble the control unit, and do not remove the upper

and lower covers.

• When using a DMM, be careful not to let test probes get close to

each other to prevent the power transistor in the control unit from

damaging battery voltage because of short circuiting.

• When checking input and output signals of the control unit, use the

specified check adapter.

GI

B

C

SAIA0255E

D

E

F

G

SEF348N

How to Check Terminal INFOID:0000000003131637

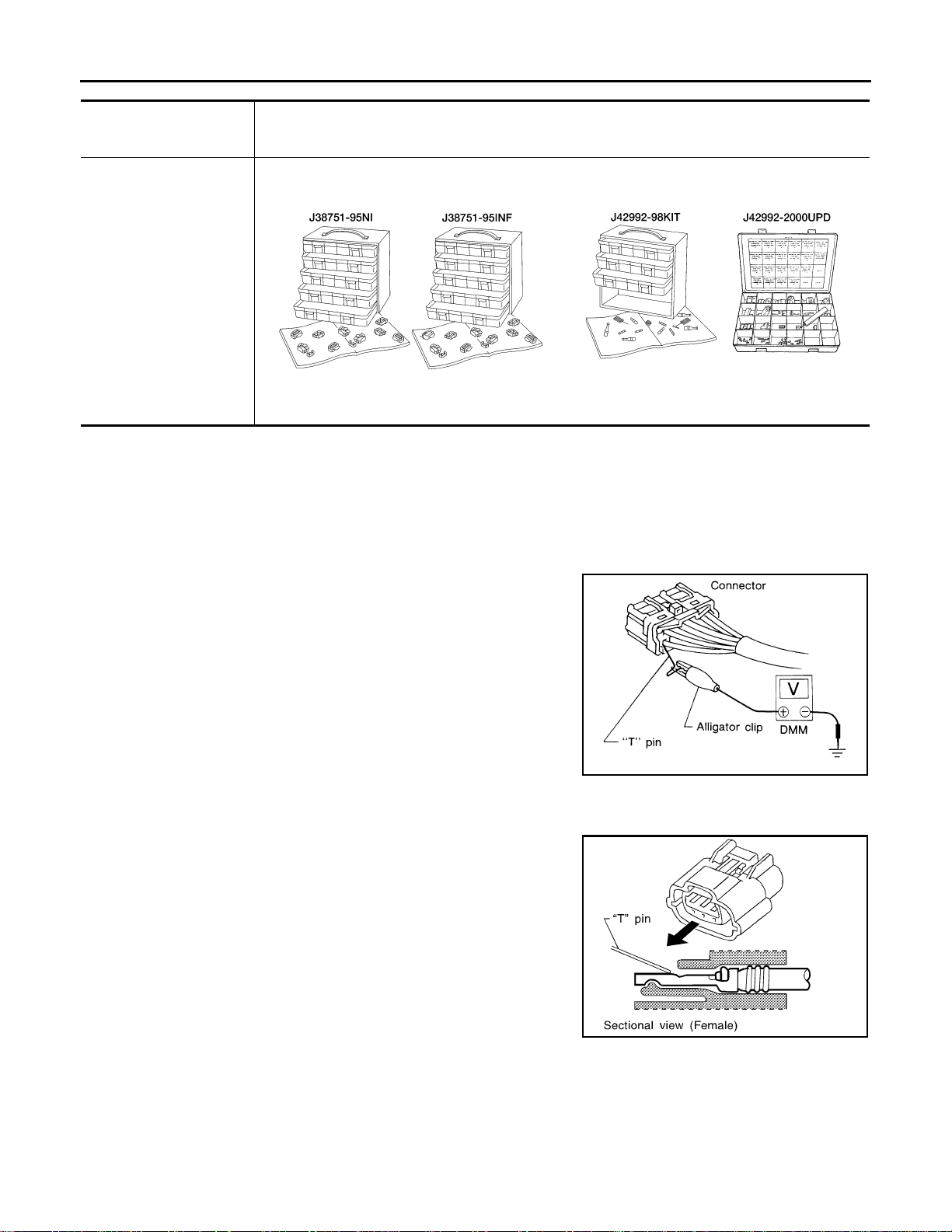

CONNECTOR AND TERMINAL PIN KIT

• Use the connector and terminal pin kits listed below when replacing connectors or terminals.

• The connector and terminal pin kits contain some of the most commonly used NISSAN/INFINITI connectors

and terminals. For detailed connector and terminal pin replacement procedures, refer to the latest NISSAN/

INFINITI CONNECTOR AND TERMINAL PIN SERVICE MANUAL.

H

I

J

K

L

M

N

O

GI-35

P

Page 42

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Revision: 2007 November 2008 EX35

< BASIC INSPECTION >

Tool number

(Kent-Moore No.)

Tool name

(J38751-95NI)

Connector and terminal

pin kit (NISSAN)

(J38751-95INF)

Connector and terminal

pin kit (INFINITI)

(J42992-98KIT)

OBD and terminal repair

kit

(J42992-2000UPD)

OBD-II Connector Kit Update

HOW TO PROBE CONNECTORS

• Connector damage and an intermittent connection can result from improperly probing of the connector during circuit checks.

• The probe of a digital multimeter (DMM) may not correctly fit the connector cavity. To correctly probe the

connector, follow the procedures below usi ng a “T” pin. For the best contact grasp the “T” pin using an alli gator clip.

Description

WAIA0004E WAIA0005E

Probing from Harness Side

Standard type (not waterproof type) connector should be probed

from harness side with “T” pin.

• If the connector has a rear cover such as a ECM connector,

remove the rear cover before probing the terminal.

• Do not probe waterproof connector from harness side. Damage to

the seal between wire and connector may result.

Probing from Terminal Side

FEMALE TERMINAL

• There is a small notch above each female terminal. Probe each

terminal with the “T” pin through the notch.

Do not insert any object other than the same type male terminal

into female terminal.

SGI841

GI-36

SEL265V

Page 43

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Revision: 2007 November 2008 EX35

< BASIC INSPECTION >

• Some connectors do not have a notch above each terminal. To

probe each terminal, remove the connector retainer to make contact space for probing.

MALE TERMINAL

• Carefully probe the contact surface of each terminal using a “T”

pin.

CAUTION:

Dot not bend terminal.

GI

B

C

SEL266V

D

E

F

G

SEL267V

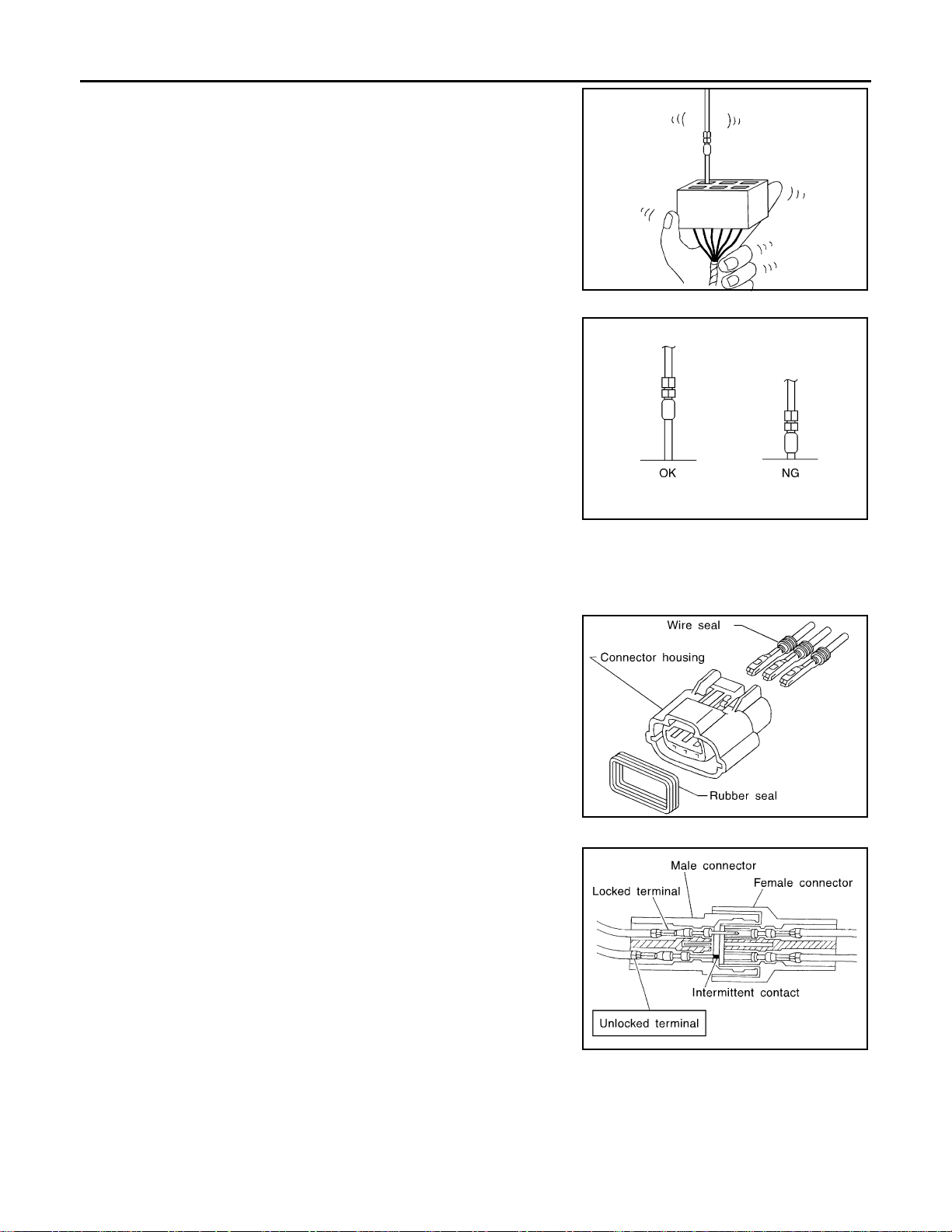

How to Check Enlarged Contact Spring of Terminal

• An enlarged contact spring of a terminal may create intermittent signals in the circuit.

• If the intermittent open circuit occurs, follow the procedure below to inspect for open wires and enlarged contact spring of female terminal.

1. Assemble a male terminal and approx. 10 cm (3.9 in) of wire.

NOTE:

Use a male terminal which matches the female terminal.

2. Disconnect the suspected faulty connector and hold it terminal

side up.

SEL270V

3. While holding the wire of the male terminal, try to insert the male

terminal into the female terminal.

CAUTION:

Do not force the male terminal into the female terminal with

your hands.

H

I

J

K

L

M

N

O

GI-37

SEL271V

P

Page 44

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Revision: 2007 November 2008 EX35

< BASIC INSPECTION >

4. While moving the connector, check whether the male terminal

can be easily inserted or not.

• If the male terminal can be easily inserted into the female ter-

minal, replace the female terminal.

SEL272V

Waterproof Connector Inspection

If water enters the connector, it can short interior circuits. This may lead to intermittent problems.

Check the following items to maintain the original waterproof characteristics.

RUBBER SEAL INSPECTION

• Most waterproof connectors are provided with a rubber seal

between the male and female connectors. If the seal is missing,

the waterproof performance may not meet specifications.

• The rubber seal may come off when connectors are disconnected.

Whenever connectors are reconnected, make sure the rubber seal

is properly installed on either side of male or female connector.

WIRE SEAL INSPECTION

• The wire seal must be installed on the wire insertion area of a

waterproof connector. Be sure that the seal is installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connector .

An unlocked terminal may create intermittent signals in the circuit.

SEL273V

SEL275V

Intermittent Incident INFOID:0000000003131638

DESCRIPTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The fol-

GI-38

SEL330V

Page 45

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Revision: 2007 November 2008 EX35

< BASIC INSPECTION >

lowing section illustrates ways to simulate the conditions/environment under which the owner experiences an

electrical incident.

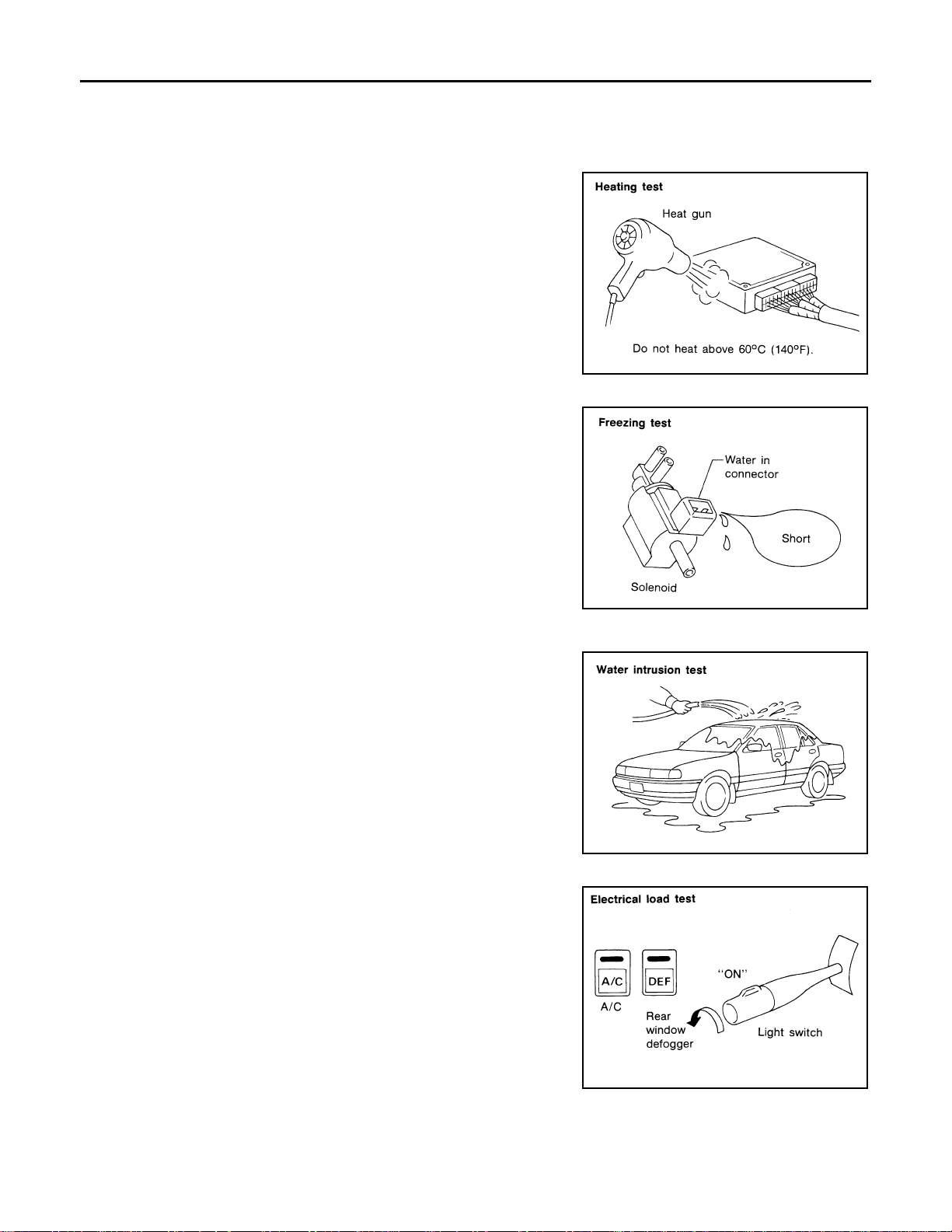

The section is broken into the six following topics:

• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold or hot start up

Get a thorough description of the incident from the customer . It is important for simulating the conditions of the

problem.

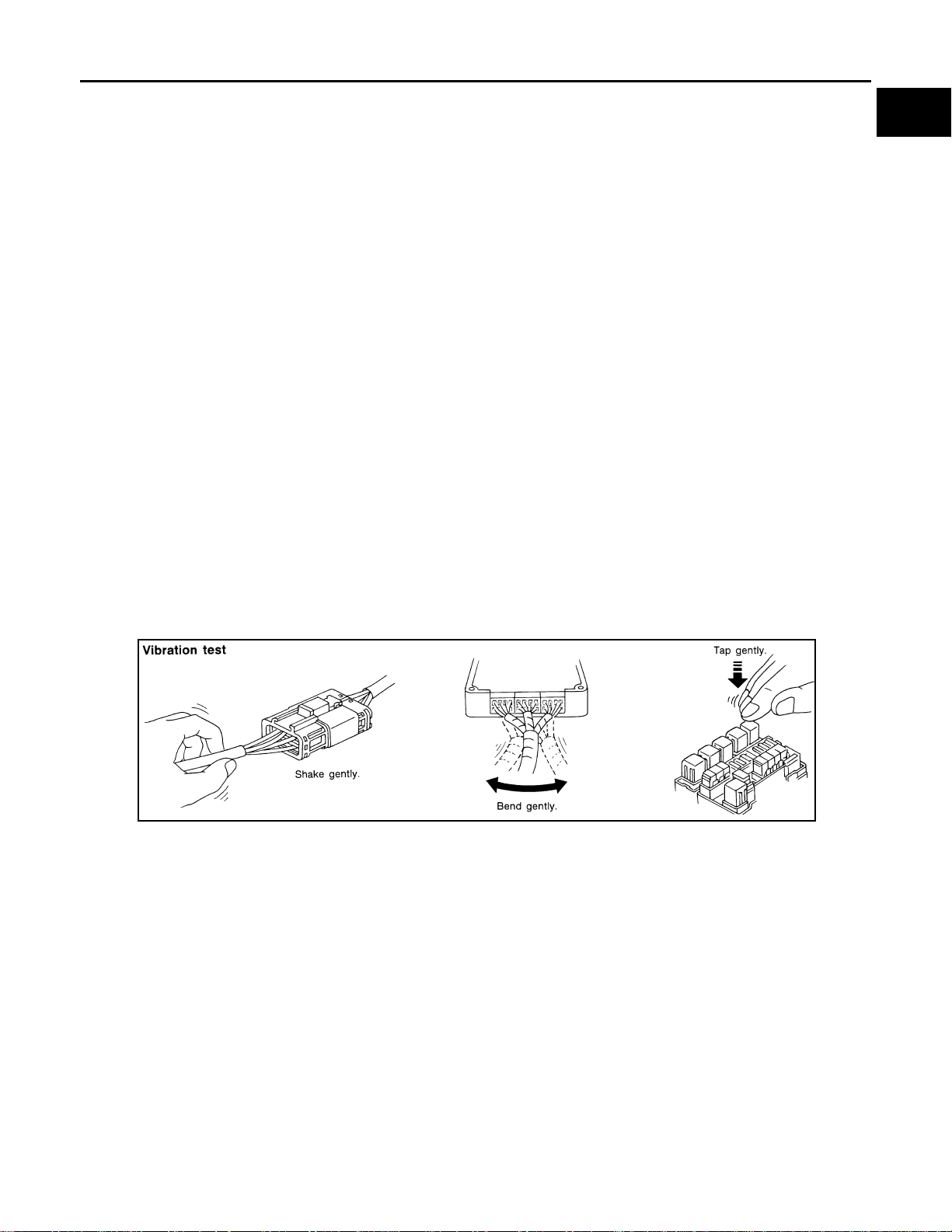

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the following illustration.

GI

B

C

D

E

Connector & Harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the system for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector terminals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

Engine Compartment

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

• Connectors not fully seated.

• Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

• Wires laying across brackets or moving components.

• Loose, dirty or corroded ground wires.

• Wires routed too close to hot components.

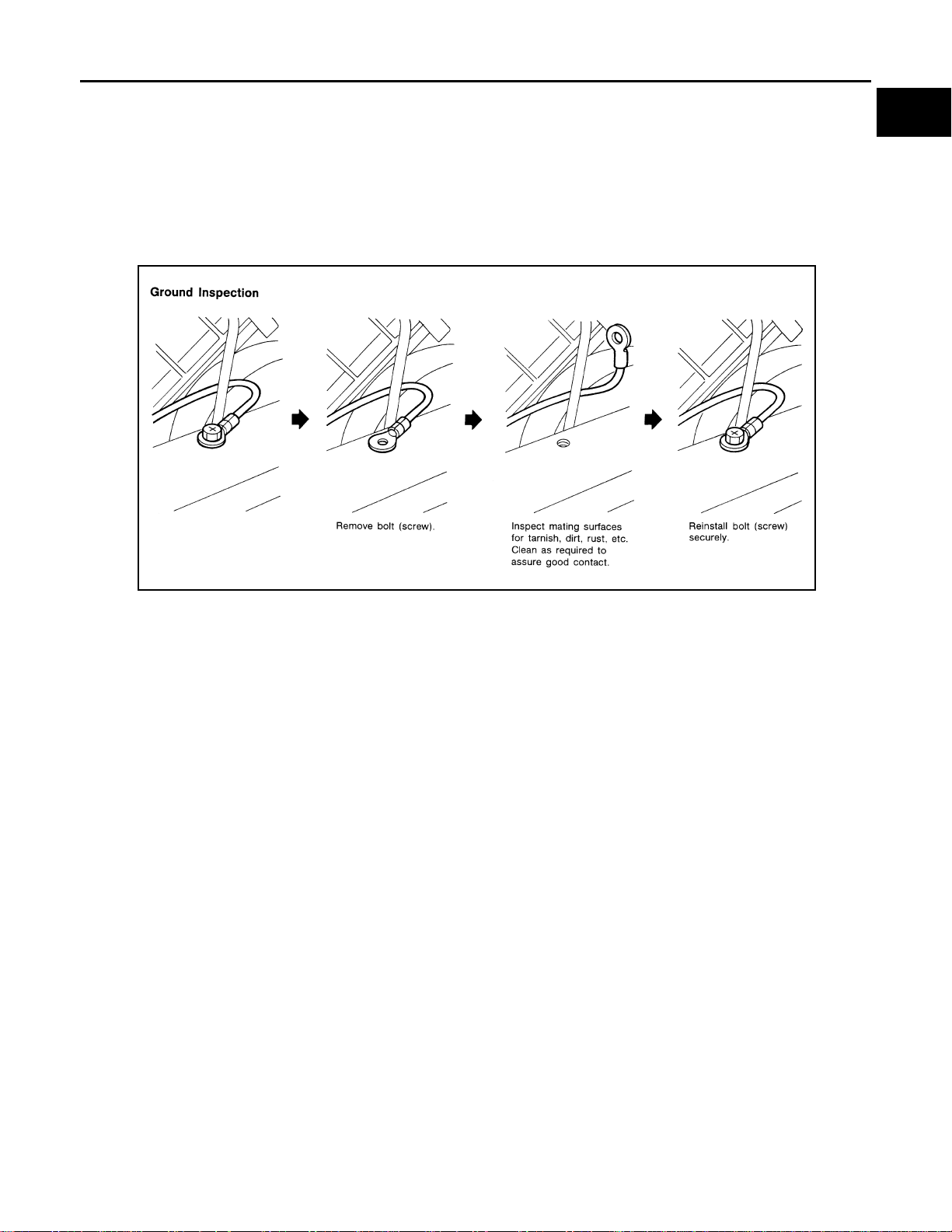

To inspect components under the hood, start by verifying the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previously explained. Using the wiring diagrams inspect the

wiring for continuity .

Behind the Instrument Panel

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehicle vibration can aggravate a harness which is routed along a bracket or near a screw.

F

G

H

I

J

K

L

M

N

O

P

Under Seating Areas

GI-39

Page 46

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Revision: 2007 November 2008 EX35

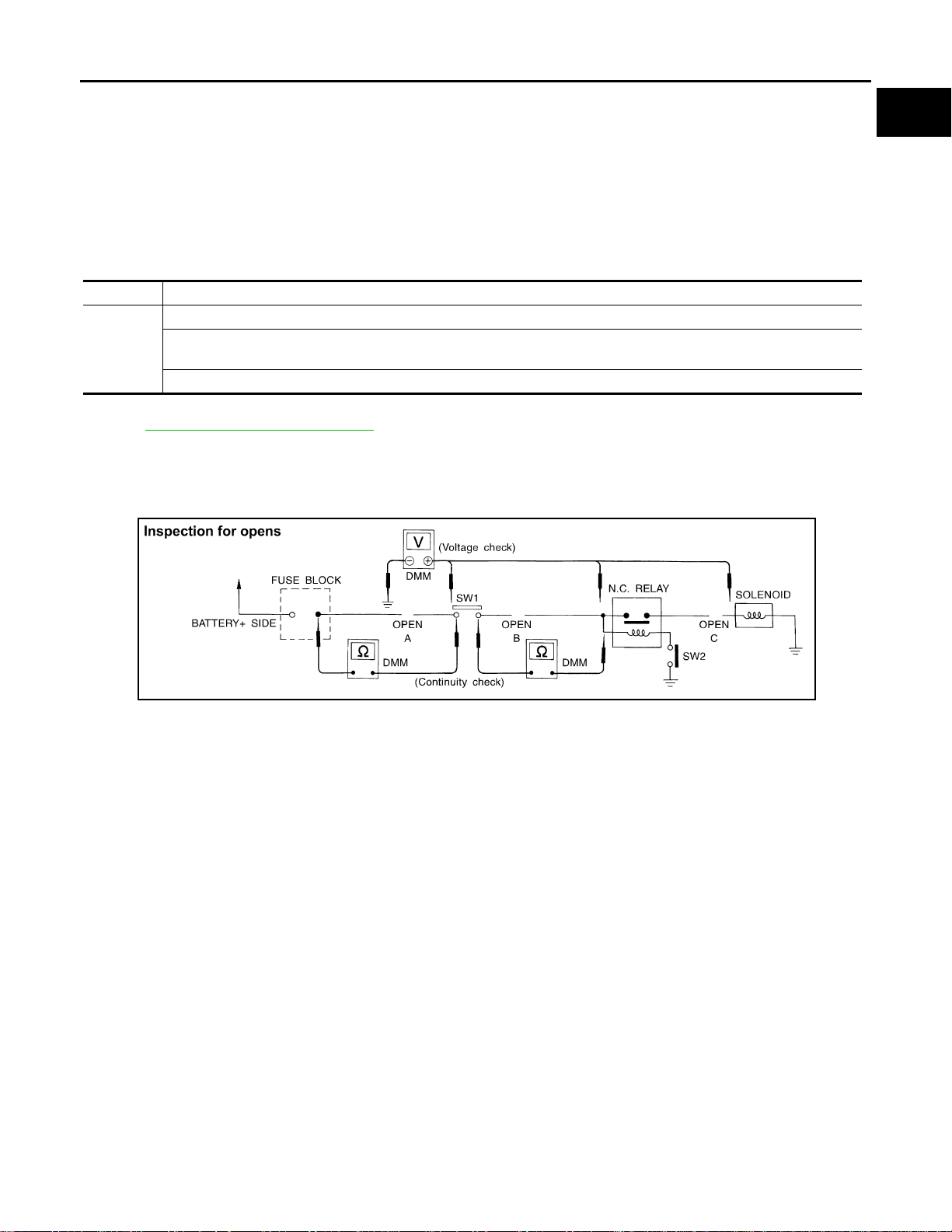

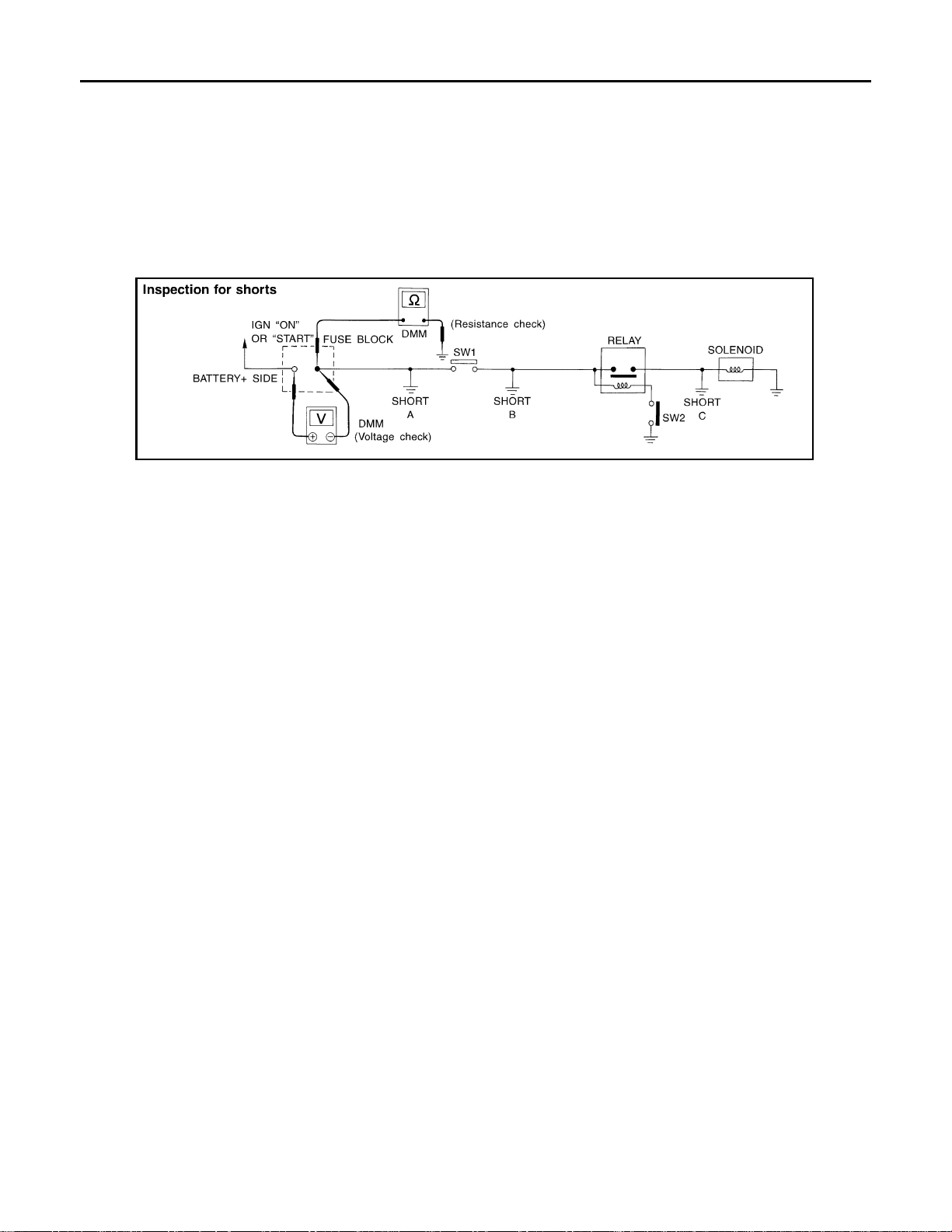

< BASIC INSPECTION >