Angle Sensor

GMR-Based Angle Sensor

TLE5012B

User’s Manual

Rev. 1.2, 2018-02

User’s Manual

Sense & Control

Edition 2018-02

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2018 Infineon Technologies AG

All Rights Reserved.

Legal Disclaimer

The information given in this document shall in no event be regarded as a guarantee of conditions or

characteristics. With respect to any examples or hints given herein, any typical values stated herein and/or any

information regarding the application of the device, Infineon Technologies hereby disclaims any and all warranties

and liabilities of any kind, including without limitation, warranties of non-infringement of intellectual property rights

of any third party.

Information

For further information on technology, delivery terms and conditions and prices, please contact the nearest

Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements, components may contain dangerous substances. For information on the types in

question, please contact the nearest Infineon Technologies Office.

Infineon Technologies components may be used in life-support devices or systems only with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

TLE5012B

Revision History

Page or Item Subjects (major changes since previous revision)

Rev. 1.2, 2018-02

Chapter 5.2.4 Update STAT and RESP in CRC calculation

Chapter 6.1.4 Add explanation when ANG_DIR = 1

Figure 6-1 Update STAT register

Chapter 3 Uptade Chapter 3

Chapter 5.6 Add footnote regarding maximum rotation speed

Chapter 6.2.1 Update S_MAGOL definition

Trademarks of Infineon Technologies AG

AURIX™, C166™, CanPAK™, CIPOS™, CIPURSE™, EconoPACK™, CoolMOS™, CoolSET™,

CORECONTROL™, CROSSAVE™, DAVE™, DI-POL™, EasyPIM™, EconoBRIDGE™, EconoDUAL™,

EconoPIM™, EconoPACK™, EiceDRIVER™, eupec™, FCOS™, HITFET™, HybridPACK™, I²RF™,

ISOFACE™, IsoPACK™, MIPAQ™, ModSTACK™, my-d™, NovalithIC™, OptiMOS™, ORIGA™,

POWERCODE™; PRIMARION™, PrimePACK™, PrimeSTACK™, PRO-SIL™, PROFET™, RASIC™,

ReverSave™, SatRIC™, SIEGET™, SINDRION™, SIPMOS™, SmartLEWIS™, SOLID FLASH™, TEMPFET™,

thinQ!™, TRENCHSTOP™, TriCore™.

Other Trademarks

Advance Design System™ (ADS) of Agilent Technologies, AMBA™, ARM™, MULTI-ICE™, KEIL™,

PRIMECELL™, REALVIEW™, THUMB™, µVision™ of ARM Limited, UK. AUTOSAR™ is licensed by AUTOSAR

development partnership. Bluetooth™ of Bluetooth SIG Inc. CAT-iq™ of DECT Forum. COLOSSUS™,

FirstGPS™ of Trimble Navigation Ltd. EMV™ of EMVCo, LLC (Visa Holdings Inc.). EPCOS™ of Epcos AG.

FLEXGO™ of Microsoft Corporation. FlexRay™ is licensed by FlexRay Consortium. HYPERTERMINAL™ of

Hilgraeve Incorporated. IEC™ of Commission Electrotechnique Internationale. IrDA™ of Infrared Data

Association Corporation. ISO™ of INTERNATIONAL ORGANIZATION FOR STANDARDIZATION. MATLAB™ of

MathWorks, Inc. MAXIM™ of Maxim Integrated Products, Inc. MICROTEC™, NUCLEUS™ of Mentor Graphics

Corporation. MIPI™ of MIPI Alliance, Inc. MIPS™ of MIPS Technologies, Inc., USA. muRata™ of MURATA

MANUFACTURING CO., MICROWAVE OFFICE™ (MWO) of Applied Wave Research Inc., OmniVision™ of

OmniVision Technologies, Inc. Openwave™ Openwave Systems Inc. RED HAT™ Red Hat, Inc. RFMD™ RF

Micro Devices, Inc. SIRIUS™ of Sirius Satellite Radio Inc. SOLARIS™ of Sun Microsystems, Inc. SPANSION™

of Spansion LLC Ltd. Symbian™ of Symbian Software Limited. TAIYO YUDEN™ of Taiyo Yuden Co.

TEAKLITE™ of CEVA, Inc. TEKTRONIX™ of Tektronix Inc. TOKO™ of TOKO KABUSHIKI KAISHA TA. UNIX™

of X/Open Company Limited. VERILOG™, PALLADIUM™ of Cadence Design Systems, Inc. VLYNQ™ of Texas

Instruments Incorporated. VXWORKS™, WIND RIVER™ of WIND RIVER SYSTEMS, INC. ZETEX™ of Diodes

Zetex Limited.

Last Trademarks Update 2011-11-11

User’s Manual 3 Rev. 1.2, 2018-02

TLE5012B

Table of Contents

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Application Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Functional Block Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.1 Internal Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.2 Oscillator and PLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2.3 SD-ADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.4 Digital Signal Processing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.5 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.6 Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Sensing Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4 Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5 Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 Application Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 IIF interface and SSC (IIF in push-pull configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 HSM interface and SSC (HSM in push-pull configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 HSM interface and SSC (HSM in open-drain configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 PWM interface (push-pull configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5 PWM interface (open-drain configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.6 SPC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.7 SSC interface (push-pull configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.8 SSC interface (open-drain configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.9 Sensor supply in bus mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1 Autocalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1.1 Angle Error adder with Autocalibration enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Prediction mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3 Calculation of the Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4 Calculation of the Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5 Switching to external clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Interfaces overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 Synchronous Serial Communication (SSC) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2.1 SSC Timing Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2.2 SSC Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2.3 TLE5012B in bus mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.4 Cyclic Redundancy Check (CRC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2.5 Angle Calculation with X-raw and Y-raw values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2.5.1 Angle Calculation using pre-calibrated compensation values . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2.5.2 Angle Calculation with end-of-line calibration values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

User’s Manual 4 Rev. 1.2, 2018-02

TLE5012B

5.3 Pulse Width Modulation Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.4 Short PWM Code (SPC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.4.1 Unit Time Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.4.2 Master Trigger Pulse Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.4.3 Checksum Nibble Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.5 Hall Switch Mode (HSM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.6 Incremental Interface (IIF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6 SSC Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.1 Registers Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.1.1 Bit Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1.2 Communication Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.1.3 Signed registers and Two’s complement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.1.4 Zero position configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2 Registers Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2.1 Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7 Pre-Configured Derivates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.1 IIF-type: E1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.2 HSM-type: E3005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.3 PWM-type: E5000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.4 PWM-type: E5020 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.5 SPC-type: E9000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.6 Fuse Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Table of Contents

User’s Manual 5 Rev. 1.2, 2018-02

TLE5012B

List of Figures

List of Figures

Figure 1-1 PG-DSO-8 package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 1-2 A usual application for TLE5012B is the electrically commutated motor . . . . . . . . . . . . . . . . . . . . 10

Figure 2-1 TLE5012B block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2-2 Laser Fuses burning process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 2-3 PRO-SIL

Figure 2-4 Sensitive bridges of the GMR sensor (not to scale) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 2-5 Ideal output of the GMR sensor bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 2-6 Pin configuration (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 3-1 Application circuit for TLE5012B with IIF interface and SSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 3-2 Application circuit for TLE5012B with HSM interface (push-pull configuration) and SSC . . . . . . . 17

Figure 3-3 Application circuit for TLE5012B with HSM interface (open-drain configuration) and SSC . . . . . . 18

Figure 3-4 Application circuit for TLE5012B with PWM (push-pull configuration) interface. . . . . . . . . . . . . . . 18

Figure 3-5 Application circuit for TLE5012B with PWM (open-drain configuration) interface . . . . . . . . . . . . . 19

Figure 3-6 Application circuit for TLE5012B with SPC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 3-7 SSC interface with push-pull configuration (high-speed application) . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 3-8 SSC interface with open-drain configuration (bus systems) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 3-9 Sensors’ supply in bus mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 4-1 Parameter correction with autocalibration mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 4-2 Parameter correction with autocalibration mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 4-3 Parameter correction with autocalibration mode 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 4-4 Cases where an angle error adder has to be included if autocalibration is enabled . . . . . . . . . . . 25

Figure 4-5 Delay of sensor output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 4-6 Revolution counter with prediction mode disabled/enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 5-1 SSC timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 5-2 SSC data transfer (data-read example) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 5-3 SSC data transfer (data-write example) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 5-4 SSC bit ordering (read example) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 5-5 Update of update registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 5-6 Example of four slaves connected to a bus with one master with SSC interface . . . . . . . . . . . . . . 36

Figure 5-7 Fast CRC polynomial division circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 5-8 TLE5012B’s CRC generator polynomial for the SSC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 5-9 CRC generation example with SSC interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 5-10 Flow-Chart of Angle Calculation from the X-raw and Y-raw values . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 5-11 Typical example of a PWM signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 5-12 Example of four slaves connected to a bus with one master with SPC interface . . . . . . . . . . . . . . 48

Figure 5-13 SPC frame example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 5-14 SPC pause timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 5-15 SPC configuration in open drain mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 5-16 SPC Master pulse timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 5-17 TLE5012B’s CRC generator polynomial for the SPC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 5-18 CRC generation example with SPC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 5-19 Hall Switch Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 5-20 HS hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 5-21 Incremental interface with A/B mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 5-22 Incremental interface with Step/Direction mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 5-23 Increcremental Interface startup pulses and first step movements at different speeds . . . . . . . . . 60

Figure 5-24 Increcremental Interface startup pulses frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 5-25 IIF Index pulse in A/B Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 5-26 IIF Index pulse in Step/Direction Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

TM

Logo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

User’s Manual 6 Rev. 1.2, 2018-02

TLE5012B

Figure 5-27 Phase A/B output during a rotation direction change due to the hysteresis threshold . . . . . . . . . . 62

Figure 6-1 Bitmap Part 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 6-2 Bitmap Part 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 6-3 Colour legend for the Bitmap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 6-4 SSC command to read angle value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 6-5 SSC command to read angle speed and angle revolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 6-6 SSC command to change Interface Mode2 register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 6-7 SSC data transfer sequence to change a configuration parameter . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 6-8 Example of a SSC data transfer sequence to change a configuration parameter . . . . . . . . . . . . . 69

Figure 6-9 Flow-Chart of ANG_BASE calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 6-10 SSC data transfer to configure the zero position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 6-11 Zero position configuration in different domains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 6-12 Timing of angle calculation in SPC. Trigger Nibble low time corresponds to slave number. . . . . . 96

Figure 7-1 Derivate-specific fuse settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

List of Figures

User’s Manual 7 Rev. 1.2, 2018-02

TLE5012B

List of Tables

List of Tables

Table 2-1 Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 4-1 Initialization via SSC / SPI to change ANG_DIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 4-2 Additional angle error examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 5-1 Main interface characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 5-2 SSC push-pull timing specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 5-3 SSC open-drain timing specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 5-4 Structure of the Command Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 5-5 Structure of the Safety Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 5-6 Bit Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 5-7 PWM interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 5-8 Frame configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 5-9 Structure of status nibble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 5-10 Predivider setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 5-11 Master pulse parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 5-12 Hall Switch Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 5-13 Incremental Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 6-1 Bit Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 6-2 Register Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

User’s Manual 8 Rev. 1.2, 2018-02

TLE5012B

Product Description

1 Product Description

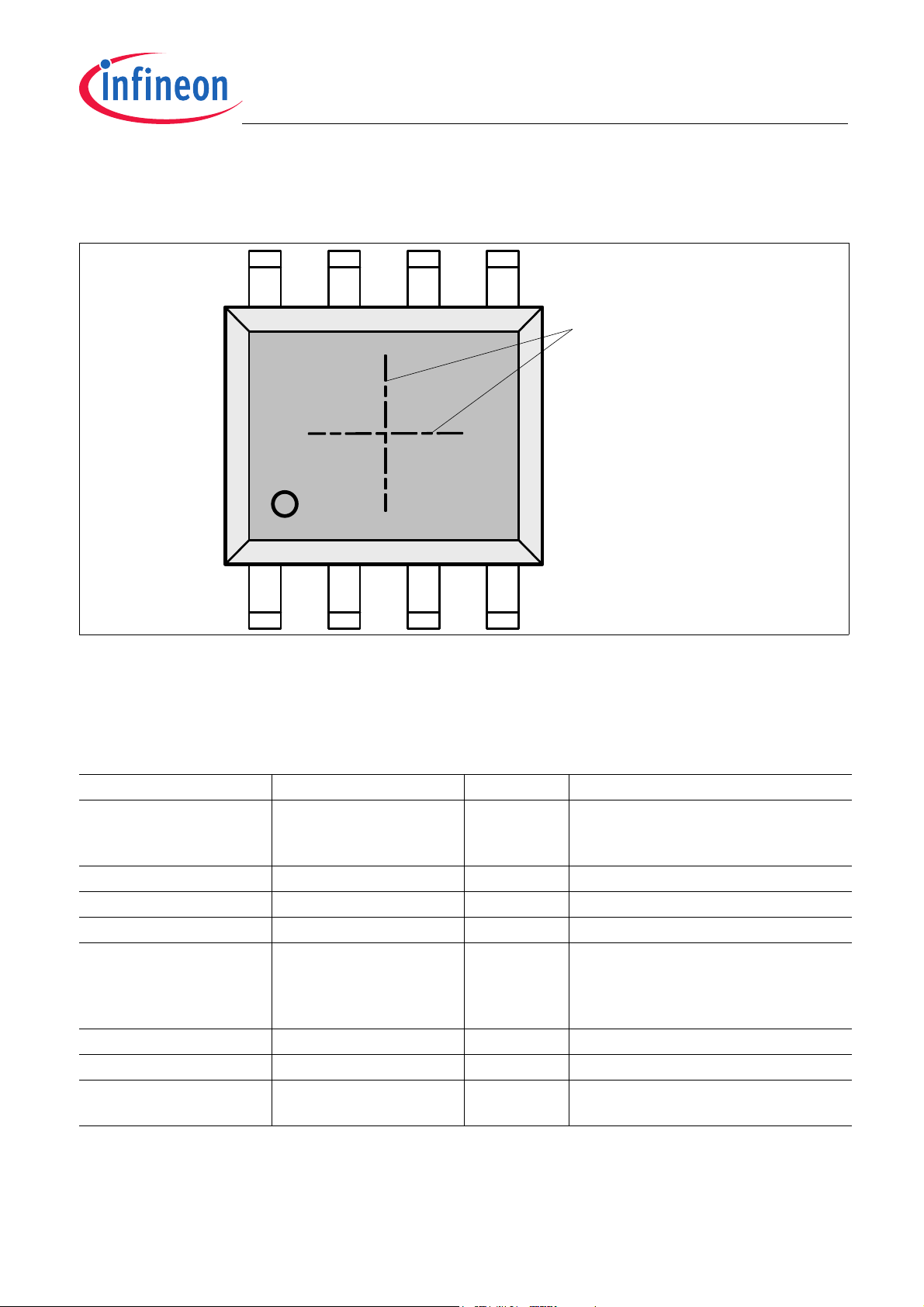

Figure 1-1 PG-DSO-8 package

1.1 Overview

The TLE5012B is a 360° angle sensor that detects the orientation of a magnetic field. This is achieved by

measuring sine and cosine angle components with monolithically integrated Giant Magneto Resistance (iGMR)

elements. These raw signals (sine and cosine) are digitally processed internally to calculate the angle orientation

of the magnetic field (magnet).

The TLE5012B is a pre-calibrated sensor. The calibration parameters are stored in laser fuses. At start-up the

values of the fuses are written into flip-flops, where these values can be changed to application-specific

parameters. The precision of the angle measurement, over a wide temperature range and a long lifetime, can be

improved by enabling an optional internal autocalibration algorithm.

Data communications are accomplished with a bi-directional Synchronous Serial Communication (SSC) that is

SPI-compatible. The sensor configuration is stored in registers, which are accessible by the SSC interface.

Additionally four other interfaces are available with the TLE5012B: Pulse-Width-Modulation (PWM) Protocol,

Short-PWM-Code (SPC) Protocol, Hall Switch Mode (HSM) and Incremental Interface (IIF). These interfaces can

be used in parallel with SSC or alone. Pre-configured sensor derivates with different interface settings are also

available. See the derivate ordering codes in the TLE5012B Data Sheet. A description of the derivates can also

be seen in Chapter 7.

Online diagnostic functions are provided to ensure reliable operation.

User’s Manual 9 Rev. 1.2, 2018-02

TLE5012B

M

Product Description

1.2 Features

• Giant Magneto Resistance (GMR)-based principle

• Integrated magnetic field sensing for angle measurement

• 360° angle measurement with revolution counter and angle speed measurement

• Two separate highly accurate single bit SD-ADC

• 15 bit representation of absolute angle value on the output (resolution of 0.01°)

• 16 bit representation of sine / cosine values on the interface

• Max. 1.0° angle error over lifetime and temperature-range with activated auto-calibration

• Bi-directional SSC Interface typ. 8Mbit/s

• Supports Safety Integrity Level (SIL) with diagnostic functions and status information

• Interfaces: SSC, PWM, Incremental Interface (IIF), Hall Switch Mode (HSM), Short PWM Code (SPC, based

on SENT protocol defined in SAE J2716)

• Output pins can be configured (programmed or pre-configured) as push-pull or open-drain

• Bus mode operation of multiple sensors on one line is possible with SSC or SPC interface in open-drain

configuration

•0.25 μm CMOS technology

• Automotive qualified: -40°C to 150°C (junction temperature)

• ESD > 4kV (HBM)

• RoHS compliant (Pb-free package)

• Halogen-free

1.3 Application Example

The TLE5012B GMR-based angle sensor is designed for angular position sensing in automotive applications such

as:

• Electrically commutated motor (e.g. Electric Power Steering (EPS), Brushless DC electric motors (BLDC))

• Rotary switches

• Steering angle measurements

• General angular sensing

The TLE5012B is also used in various non-automotive applications.

Figure 1-2 A usual application for TLE5012B is the electrically commutated motor

User’s Manual 10 Rev. 1.2, 2018-02

TLE5012B

VRG VRA VRD

TLE5012B

V

DD

X

GMR

Y

GMR

Temp

SD-

ADC

SD-

ADC

SD-

ADC

Digital

Signal

Processing

Unit

CORDIC

CCU

RAM

SSC Interface

Incremental IF

PWM

HSM

SPC

CSQ

SCK

DATA

IFA

IFB

GND

IFC

Osc PLL

ISM

Fuses

2 Functional Description

2.1 Block Diagram

Functional Description

Figure 2-1 TLE5012B block diagram

2.2 Functional Block Description

2.2.1 Internal Power Supply

The internal stages of the TLE5012B are supplied with several voltage regulators:

• GMR Voltage Regulator, VRG

• Analog Voltage Regulator, VRA

• Digital Voltage Regulator, VRD (derived from VRA)

These regulators are directly connected to the supply voltage V

2.2.2 Oscillator and PLL

The digital clock of the TLE5012B is provided by the Phase-Locked Loop (PLL), which is by default fed by an

internal oscillator. In order to synchronize the TLE5012B with other ICs in a system, the TLE5012B can be

User’s Manual 11 Rev. 1.2, 2018-02

.

DD

TLE5012B

DSPU

RAM

F

U

S

E

GND

0

F

U

S

E

GND

…

V

DD

0

V

DD

DSPU

RAM

F

U

S

E

GND

F

U

S

E

GND

…

0

V

DD

0

V

DD

DSPU

RAM

GND

F

U

S

E

GND

…

10

0

V

DD

1

V

DD

Functional Description

configured via SSC interface to use an external clock signal supplied on the IFC pin as the PLL source, instead of

the internal clock. External clock mode is only available in the PWM or SPC interface configurations.

2.2.3 SD-ADC

The Sigma-Delta Analog-Digital-Converters (SD-ADC) transform the analog GMR voltages and temperature

voltage into the digital domain.

2.2.4 Digital Signal Processing Unit

The Digital Signal Processing Unit (DSPU) contains the:

• Intelligent State Machine (ISM), which does error compensation of offset, offset temperature drift, amplitude

synchronicity and orthogonality of the raw signals from the GMR bridges, and performs additional features

such as auto-calibration, prediction and angle speed calculation

• COordinate Rotation DIgital Computer (CORDIC), which contains the trigonometric function for angle

calculation

• Capture Compare Unit (CCU), which is used to generate the PWM and SPC signals

• Random Access Memory (RAM), which contains the configuration registers

• Laser Fuses, which contain the calibration parameters for the error-compensation and the IC default

configuration, which is loaded into the RAM at startup

Laser fuses configuration

The laser fuse settings are derivate specific. During production, each and every TLE5012B chip is specifically

configured according to a derivate interface (PWM, SPC, HSM or IIF) and to its specific calibration values (e.g.

offset, amplitude synchronicity, orthogonality). These default values are set by laser fuses, where they remain

stored permanently. At power-on the values stored in the fuses are loaded into flip-flops (placed in the RAM).

Via the SSC interface, these derivate specific configuration values can be overwritten in the RAM. This allows

some programmability such as change of interface (using a IIF derivate as a PWM derivate for example) or to

correct the calibration values (if running the autocalibration mode for example). It is highly recommended to

configure the sensor with customized settings right after a Hardware reset (within the first 120µs, prior to start of

the Built-In Self-Test). If this interval is not sufficient, it is also possible to configure the sensor after the power-on

time. To ensure a correct configuration after power-on time, see recommendations on Chapter 6. When powered

off or reset, the overwritten values will be lost and the default values stored in the fuses will be reloaded into the

RAM at the next power up.

The Figure 2-2 shows how the fuse burning process works. In the original state all fuses are connected to ground

(GND). Once the calibration and derivate specific values are calculated, the information is burned into the fuses,

so that some remain connected to GND (“low” or logical “0”) and some are now pulled up by a resistor (“high” or

logical “1”). When powering the sensor, the RAM is initialized with the values from the fuses.

Figure 2-2 Laser Fuses burning process

User’s Manual 12 Rev. 1.2, 2018-02

TLE5012B

Functional Description

2.2.5 Interfaces

Bi-directional communication with the TLE5012B is enabled by a three-wire SSC interface. In parallel to the SSC

interface, one secondary interface can be selected, which is available on the IFA, IFB, IFC pins:

•PWM

• Incremental Interface

• Hall Switch Mode

• Short PWM Code

By using pre-configured derivates (see Chapter 7), the TLE5012B can also be operated with the secondary

interface only, without SSC communication.

2.2.6 Safety Features

The TLE5012B offers a multiplicity of safety features to support the Safety Integrity Level (SIL). Infineon’s sensors

that are intended for this purpose are identified by the following logo:

Figure 2-3 PRO-SIL

Disclaimer

PRO-SIL™ is a Registered Trademark of Infineon Technologies AG.

The PRO-SIL™ Trademark designates Infineon products which contain SIL Supporting Features.

SIL Supporting Features are intended to support the overall System Design to reach the desired SIL (according

to IEC61508) or A-SIL (according to ISO26262) level for the Safety System with high efficiency.

SIL respectively A-SIL certification for such a System has to be reached on system level by the System

Responsible at an accredited Certification Authority.

SIL stands for Safety Integrity Level (according to IEC 61508)

A-SIL stands for Automotive-Safety Integrity Level (according to ISO 26262)

Safety features are:

• Test vectors switchable to ADC input (activated via SSC interface)

• Inversion or combination of filter input streams (activated via SSC interface)

• Data transmission check via 8-bit Cyclic Redundancy Check (CRC) for SSC communcation and 4-bit CRC

nibble for SPC interface

• Built-in Self-test (BIST) routines for ISM, CORDIC, CCU, ADCs performed at startup

• Two independent active interfaces possible

• Overvoltage and undervoltage detection

TM

Logo

User’s Manual 13 Rev. 1.2, 2018-02

TLE5012B

V

DD

GNDADCX+

GMR Resistors

ADCX-ADC

Y

+ADCY-

V

X

V

Y

0°

N

S

90°

Functional Description

2.3 Sensing Principle

The Giant Magneto Resistance (GMR) sensor is implemented using vertical integration. This means that the

GMR-sensitive areas are integrated above the logic part of the TLE5012B device. These GMR elements change

their resistance depending on the direction of the magnetic field.

Four individual GMR elements are connected to one Wheatstone sensor bridge for each of the two components

of the applied magnetic field:

• X component, V

• Y component, V

With this full-bridge structure the maximum GMR signal is available and temperature effects cancel out each other.

(cosine) and the

x

(sine)

y

Figure 2-4 Sensitive bridges of the GMR sensor (not to scale)

Attention: Due to the rotational placement inaccuracy of the sensor IC in the package, the sensors 0°

position may deviate by up to 3° from the package edge direction indicated in Figure 2-4.

In Figure 2-4, the arrows in the resistors represent the magnetic direction which is fixed in the Reference Layer.

On top of the Reference Layer, and separated by a non magnetic layer, there is a Free Layer. When applying an

external magnetic field the Free Layer moves in the same direction as the external magnetic field, while the

Reference Layer remains fix. The resistance of the GMR elements depends on the magnetic direction difference

between the Reference Layer and the Free Layer.

When the external magnetic field is parallel to the direction of the Reference Layer, the resistance is minimal

(Reference Layer and Free Layer are parallel). When the external magnetic field and the Reference Layer are antiparallel (Reference Layer and Free Layer are anti-parallel), resistance is maximal.

The output signal of each bridge is only unambiguous over 180° between two maxima. Therefore two bridges are

oriented orthogonally to each other to measure 360°.

With the trigonometric function ARCTAN2, the true 360° angle value is calculated out of the raw X and Y signals

from the sensor bridges.

User’s Manual 14 Rev. 1.2, 2018-02

TLE5012B

V

Angle α

90° 180° 270° 360°0°

VX (COS)

Y Component (SIN)

VY (SIN)

V

Y

V

X

X Component (COS)

Figure 2-5 Ideal output of the GMR sensor bridges

Functional Description

User’s Manual 15 Rev. 1.2, 2018-02

TLE5012B

12 34

5678

Center of Sensitive

Area

2.4 Pin Configuration

Functional Description

Figure 2-6 Pin configuration (top view)

2.5 Pin Description

Table 2-1 Pin Description

Pin No. Symbol In/Out Function

1IFC

(CLK / IIF_IDX / HS3)

2 SCK I SSC Clock

3 CSQ I SSC Chip Select

4 DATA I/O SSC Data

5IFA

6V

7GND-Ground

8IFB

1) External clock feature is not available in IIF or HSM interface mode

(IIF_A / HS1 / PWM / SPC)

DD

(IIF_B / HS2)

I/O Interface C:

External Clock

Signal 3

I/O Interface A:

IIF Phase A / Hall Switch Signal 1 /

PWM / SPC output (input for SPC trigger

only)

- Supply Voltage

O Interface B:

IIF Phase B / Hall Switch Signal 2

1)

/ IIF Index / Hall Switch

User’s Manual 16 Rev. 1.2, 2018-02

TLE5012B

TLE5012B

CSQ

SCK

DATA

IFA

IFB

IFC

GND

VDD

3.0 – 5.5V

Rs1

SSC

IIF

100nF

(IIF_A)

(IIF_B)

(IIF_IDX)

Rs1

Rs2

Rs1 recommended, e.g. 100

Rs2 recommended, e.g. 470

TLE5012B

CSQ

SCK

DATA

IFA

IFB

IFC

GND

VDD

3.0 – 5.5V

Rs1

SSC

HSM

100nF

(HS1)

(HS2)

(HS3)

Rs1

Rs2

Rs1 recommended, e.g. 100

Rs2 recommended, e.g. 470

Application Circuits

3 Application Circuits

The application circuits in this chapter show the various communication possibilities of the TLE5012B. The pin

output mode configuration is device-specific and it can be either push-pull or open-drain. The bit IFAB_OD

(register IFAB, 0DH) indicates the output mode for the IFA, IFB and IFC pins. The SSC pins are by default pushpull (bit SSC_OD, register MOD_3, 09H). Every application circuits below are using otherwise specified SSC with

push-pull configuration and the internal clock.

3.1 IIF interface and SSC (IIF in push-pull configuration)

Figure 3-1 shows a block diagram of a TLE5012B with Incremental Interface (IIF) and SSC interface. The derivate

TLE5012B - E1000 is by default configured with push-pull IFA (IIF_A), IFB (IIF_ B) and IFC (IIF_IDX) pins. When

the output pins are configurated as open-drain, three pull-up resistors should be added (e.g. 2k2Ω) between the

data lines and VDD.

Figure 3-1 Application circuit for TLE5012B with IIF interface and SSC

3.2 HSM interface and SSC (HSM in push-pull configuration)

Figure 3-2 shows a block diagram of the TLE5012B with Hall Switch Mode (HSM) and SSC interface. The derivate

TLE5012B - E3005 is by default configurated with push-pull IFA (HS1), IFB (HS2) and IFC (HS3) pins.

Figure 3-2 Application circuit for TLE5012B with HSM interface (push-pull configuration) and SSC

User’s Manual 17 Rev. 1.2, 2018-02

TLE5012B

TLE5012B

CSQ

SCK

DATA

IFA

IFB

IFC

GND

VDD

3.0 – 5.5V

Rs1

SSC

HSM

100nF

(HS1)

(HS2)

(HS3)

Rs1

Rs2

Rs1 recommended, e.g. 100

Rs2 recommended, e.g. 470

Rpu

Rpu

Rpu

Rp u re q uir ed, e. g. 2K2

TLE5012B

CSQ

SCK

DATA

IFA

IFB

IFC

GND

VDD

3.0 – 5.5V

100nF

(PWM)

Rpd recommended, e.g. 10k

PWM

Application Circuits

3.3 HSM interface and SSC (HSM in open-drain configuration)

As shown in Figure 3-3 when IFA, IFB and IFC are configurated via the SSC interface as open drain pins, three

pull-up resistors (Rpu) should be added on the output lines.

Figure 3-3 Application circuit for TLE5012B with HSM interface (open-drain configuration) and SSC

3.4 PWM interface (push-pull configuration)

The TLE5012B can be configured with PWM only (Figure 3-4). The derivate TLE5012B - E5000 is by default

configurated with push-pull configuration for IFA (PWM) pin. Internal pull-up resistors are always available for

DATA and CSQ pins (see Datasheet). It is recommended to connect CSQ pin to V

avoid unintentional activation of the SSC interface. DATA pin should be left open. The figure below shows a typical

implementation of the TLE5012B - E5000.

Figure 3-4 Application circuit for TLE5012B with PWM (push-pull configuration) interface

User’s Manual 18 Rev. 1.2, 2018-02

to provide a high level and

DD

TLE5012B

TLE5012B

CSQ

SCK

DATA

IFA

IFB

IFC

GND

VDD

3.0 – 5.5V

100nF

(PWM)

Rpd recommended, e.g. 10k

Rpu required, e.g. 2K2

PWM

Rpu

TLE5012B

CSQ

SCK

DATA

IFA

IFB

IFC

GND

VDD

3.0 – 5.5V

100nF

(SPC)

Rpd recommended, e.g. 10k

Rpu required, e.g. 2K2

SPC

Rpu

Application Circuits

3.5 PWM interface (open-drain configuration)

The TLE5012B - E5020 is also a PWM derivate but with open drain for IFA (PWM) pin. A pull-up resistor (e.g.

2.2kΩ) should be added between the IFA line and VDD, as shown in Figure 3-5.

Internal pull-up resistors are always available for DATA and CSQ pins (see Datasheet). It is recommended to

connect CSQ pin to V

pin should be left open. The figure below shows a typical implementation of the TLE5012B - E5020.

to provide a strong level and avoid unintentional activation of the SSC interface. DATA

DD

Figure 3-5 Application circuit for TLE5012B with PWM (open-drain configuration) interface

3.6 SPC interface

The TLE5012B can be configured with SPC only (Figure 3-6). This is only possible with the TLE5012B - E9000

derivate, which is by default configurated with an open-drain IFA (SPC) pin.

In Figure 3-6 the IFC (S_NR[1]) and SCK (S_NR[0]) pins are set to ground to generate the slave number (S_NR)

0

(or 00B). In case of SCK (S_NR[0]) needs to be set to VDD to generate another slave address, CSQ pin should

D

be set to ground instead. Internal pull-up resistors are always available for DATA and CSQ pins (see Datasheet).

DATA pin should be left open. Since SCK and CSQ pins should have opposite level, it is not recommended to use

the SSC interface in parallel.

Figure 3-6 Application circuit for TLE5012B with SPC interface

User’s Manual 19 Rev. 1.2, 2018-02

TLE5012B

Shift Reg.

Shift Reg.

Clock Gen.

DATA

MTSR

MRST

SCK

SCK

(SSC Slave) TLE 5012B µC (SSC Master)

CSQ CSQ

EN

EN

Rs1 recommended, e.g. 100

Rs2 recommended, e.g. 470

Rs1

Rs1

Rs2

Shift Reg.

Shift Reg.

Clock Gen.

DATA

MTSR

MRST

SCK

SCK

(SSC Slave) TLE 5012B µC (SSC Master)

CSQ CSQ

Rs1 recommended, e.g. 100

Rpu required, e.g. 1k

Rs1

Rs1

Rs1 Rs1

Rpu

EN

EN

Application Circuits

3.7 SSC interface (push-pull configuration)

In Figure 3-1, Figure 3-2 and Figure 3-3 the SSC interface has the default push-pull configuration (see details in

Figure 3-7). A series resistor on the DATA line is recommended to limit the current in erroneous cases (e.g. the

sensor pushes high and the microcontroller pulls low at the same time or vice versa). Resistors on SCK and CSQ

lines are recommended in case of disturbances or noise.

Figure 3-7 SSC interface with push-pull configuration (high-speed application)

3.8 SSC interface (open-drain configuration)

It is possible to use an open-drain configuration for the DATA line. This setup can be used to communicate with a

microcontroller in a bus system, together with other SSC slaves (e.g. two TLE5012B devices for redundancy

reasons). This mode can be activated using the bit SSC_OD.

Even though, push-pull configuration in a bus system is also possible since the addressing of the sensor is

perfomed with CSQ pin.

The open-drain configuration can be seen in Figure 3-8. Series resistors on the DATA line are recommended to

limit the current in erroneous cases. Resistors on SCK and CSQ lines are recommended in case of disturbances

or noise A pull-up resistor of typ. 1 kΩ is required on the DATA line.

Figure 3-8 SSC interface with open-drain configuration (bus systems)

User’s Manual 20 Rev. 1.2, 2018-02

TLE5012B

Sensor 1

OUT

VDD

VDD

CCU

VDD

GND

VDD

GND

MCU

VDD

Rpu

VDD

Sensor x

OUT

VDD

GND

Application Circuits

3.9 Sensor supply in bus mode

When using two or more devices in a bus configuration (SSC or SPC interface). It is recommended to use the

same supply for every sensors connected to the bus. In case of a power loss the unpowered device is sinking

current through the OUT pin. Depending on the external circuitry the additional current flow might disturb the bus

behavior.

The figure below (Figure 3-9) shows a typical implementation of a bus mode using SPC interface. External

components such as EMC filter or additional series resistors are not represented for clarity purpose. Only the pullup resistor Rpu is shown.

Figure 3-9 Sensors’ supply in bus mode

User’s Manual 21 Rev. 1.2, 2018-02

TLE5012B

Fused Offsets:

X_Offset: -633

Y_Offset: -653

Acquire

Max-Min

pairs

Calculate:

Offs ets, Synch

X_Offset: -646

Y_Offset: -658

Acquire

Max-Min

pairs

Calculate:

Offs ets, Synch

X_Offset: -651

Y_Offset: -664

Tempe-

rature

Check

Tempe-

rature

Check

Parameters

Correct ion

Parameters

Correction

-633

-646

-651

-653

-658

-664

-670

-665

-660

-655

-650

-645

-640

-635

-630

-625

-620

Offset

Filter update period (t

upd

)

X_Offset Y_Offset

Parameters Correction

Acquire MaxMin pairs

Parameters

Correction

Acquire Max-Min pairs

-633

-634

-635

-653

-654

-655

-660

-655

-650

-645

-640

-635

-630

-625

-620

01234

Revolutions

X_Offset Y_Offset

Parameters

Correction

Acquire Max-Min

pairs

Parameters

Correction

Acquire Max-Min pairs

Fused Offsets:

X_Offset: -633

Y_Offset: -653

Acquire

Max-Min

pairs

Calculate:

Offs ets, Synch

X_Offset: -646

Y_Offset: -658

Acquire

Max-Min

pairs

Calculate:

Offs ets, Synch

X_Offset: -651

Y_Offset: -664

Tempe-

rature

Check

Tempe-

rature

Check

Parameters

Correct ion

by only 1

LSB

Parameters

Correction

Offset

Specification

4 Specification

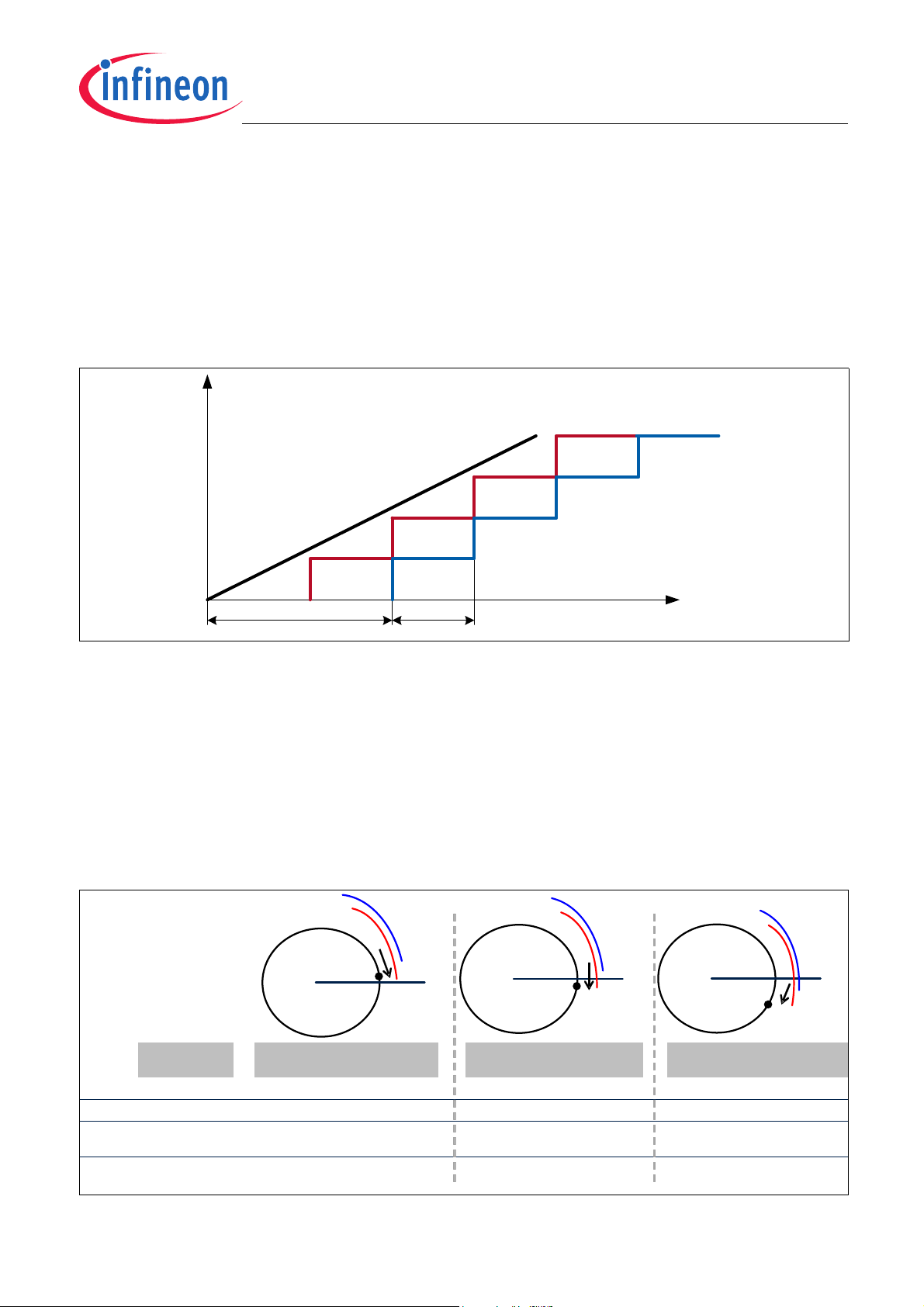

4.1 Autocalibration

Autocalibration enables online parameter calculation, and therefore reduces angle error due to temperature and

lifetime drifts.

The TLE5012B is a pre-calibrated sensor; at start-up the parameters stored in the laser fuses are loaded into flipflops. During operation, the TLE5012B needs 1.5 revolutions to generate new autocalibration parameters. The

parameters are updated with new autocalibration parameters according to the mode selected via the AUTOCAL

bits (Mode 2 register). The parameters are updated in a smooth way to avoid an angle jump on the output; only

one Least-Significant Bit (LSB) will be changed within the chosen range or time. Once the parameters are updated,

a new autocalibration parameter generation starts, as autocalibration is done continuously.

AUTOCAL Modes:

• 00: No autocalibration

• 01: Autocalibration Mode 1. Parameters are updated by one LSB at every update time t

FIR_MD setting) till the new autocalibration parameter values are reached.

• 10: Autocalibration Mode 2. Parameters are updated by one LSB only. After the update, autocalibration will

already calculate new parameters again.

• 11: Autocalibration Mode 3. Parameters are updated by one LSB at every angle range of 11.25° till the new

autocalibration parameter values are reached.

(dependent on

upd

Figure 4-1 Parameter correction with autocalibration mode 1

Figure 4-2 Parameter correction with autocalibration mode 2

User’s Manual 22 Rev. 1.2, 2018-02

TLE5012B

-633

- 646

-651

- 653

-658

- 664

-670

-665

-660

-655

-650

-645

-640

-635

-630

-625

-620

Angle [°]

X_Offset Y_Offset

Parameters Correction

Acquire Max-Min

pairs

Parameters

Correction

Acquire Max-Min pairs

Fused Offsets:

X_Offset: -633

Y_Offset: -653

Acquire

Max-Min

pairs

Calculate:

Offs ets, Synch

X_Offset: -646

Y_Offset: -658

Acquire

Max-Min

pairs

Calculate:

Offs ets, Synch

X_Offset: -651

Y_Offset: -664

Tempe -

rature

Check

Tempe-

rature

Check

Parameters

Correct ion

Parameters

Correction

Offset

Specification

Figure 4-3 Parameter correction with autocalibration mode 3

The autocalibration mode 1 is the quickest mode to correct the parameters. Mode 2 is the slowest method, but

since the parameters are updated by one digit only, it offers robustness against corrupted maxima - minima pair

(in case of a spike, for example).

Condition for usability of Autocalibration:

The autocalibration algorithm relies on the collection of maximum and minimum values of the raw X- and Y-signals

of the sensing elements, therefore it is suitable for applications where a rotor is continuously turning (full 360°

rotations). Compensation parameters for offset and amplitude synchronicity error are calculated from these

minima and maxima only if the temperature did not change by more than 5 Kelvin during their collection, to avoid

temperature-drift induced errors.

For the sensor to be accurate in autocalibration mode, it has to be assured in the application that the calibration

parameters are updated frequently. Thus, autocalibration should only be used in applications where the magnet

regularly rotates by at least one full turn (internal TLE5012B check of full turn requires maximum 1.5 revolutions)

at a temperature which is constant within 5 Kelvin.

Enabling/Disabling of Autocalibration:

When switching autocalibration on or off, the TLE5012B may erroneously trigger the S_FUSE error bit in the status

register, which indicates a configuration CRC error, which is also displayed permanently in the Safety Word of the

SSC communication.

When autocalibration is ON and has to be disabled: write the correct CRC for autocalibration OFF before disabling

autocalibration. This way the sensor will see a consistent state when the first runtime CRC check is done again

and no CRC error will occur. The correct CRC must be calculated on the microcontroller side.

When autocalibration is OFF and has to be enabled or just restarted: after switching the autocalibration mode ON,

the Status Register should be read via SSC after three t

periods and an occurring S_FUSE error should be

update

ignored.

Changing TLE5012B default Configuration, if Autocalibration is enabled

Changing certain TLE5012B default configurations while autocalibration is enabled could lead to corrupted

autocalibration parameters. Therefore, disable autocalibration prior to change the angle direction (ANG_DIR bit

on MOD_2 register), prediction (PREDICT bit on MOD_2 register) or the angle base (ANG_BASE bits on MOD_3

register). Once these parameters have been changed, enable autocalibration again.

An initialization sequence for the case of changing angle direction is shown in Table 4-1. This sequence is also

valid for prediction and for angle base. In case of angle base additonal write after the first write is required in order

to re-configure the new angle base value.

User’s Manual 23 Rev. 1.2, 2018-02

TLE5012B

Specification

Table 4-1 Initialization via SSC / SPI to change ANG_DIR

Step Command type Register Value Description

0 (default) - MOD_2 0x0801 Angle Range = 360°, Angle Direction = counter clockwise,

Autocal = on

This is the default value.

1 W (write) MOD_2 0x0808 Angle Range = 360°, Angle Direction = clockwise, Autocal =

off

Autocal is being deactivated, and Angle direction can be

changed. The deactivated autocal stops any running

min/max search and clears the min/max_x/y registers before

any offset (and amplitude) parameters can change.

2 Wait - 128µs A minimum of two t

periods are needed until all settings

update

have been adopted by the sensor. Since this delay depends

on the timing of the SPI write in comparison to the sensors

internal execution timing it is recommended to wait three

t

(3*42.7µs by default) for time margin. In case t

update

update

is

configured to 85µs (or higher), extend the time to fulfill

3*t

update

.

This waiting time is also important before reading the default

parameters (OFFX, OFFY, SYNCH, IFAB, MOD4, TCO_Y,

T25O) in case it is necessary.

3 W MOD_2 0x0809 Angle Range = 360°, Angle Direction = clockwise, Autocal =

on

Angle direction has been changed previously and now

autocal is again activated.

4 Wait - 128µs Similar to wait above. Sensor needs time to recognize that

the CRC check of the parameter registers (Addresses

0x08...0x0F) need to be disabled due to reactivated autocal.

5 R (read) STAT S_FUSE

error

S_FUSE error may be present due to reconfiguration (as

explained on Note on Page 23). Reading out the STAT

register the S_FUSE is reset (SPI Safety Word will not show

anymore an error because it has been cleared).

6 R STAT S_FUSE

cleared

This read is only necesary if the previosu SPI Safety Word is

not checked for a system-error (includes S_FUSE).

User’s Manual 24 Rev. 1.2, 2018-02

TLE5012B

T

rpm

Additional

Ang le Er ror

OKOK OK

Specification

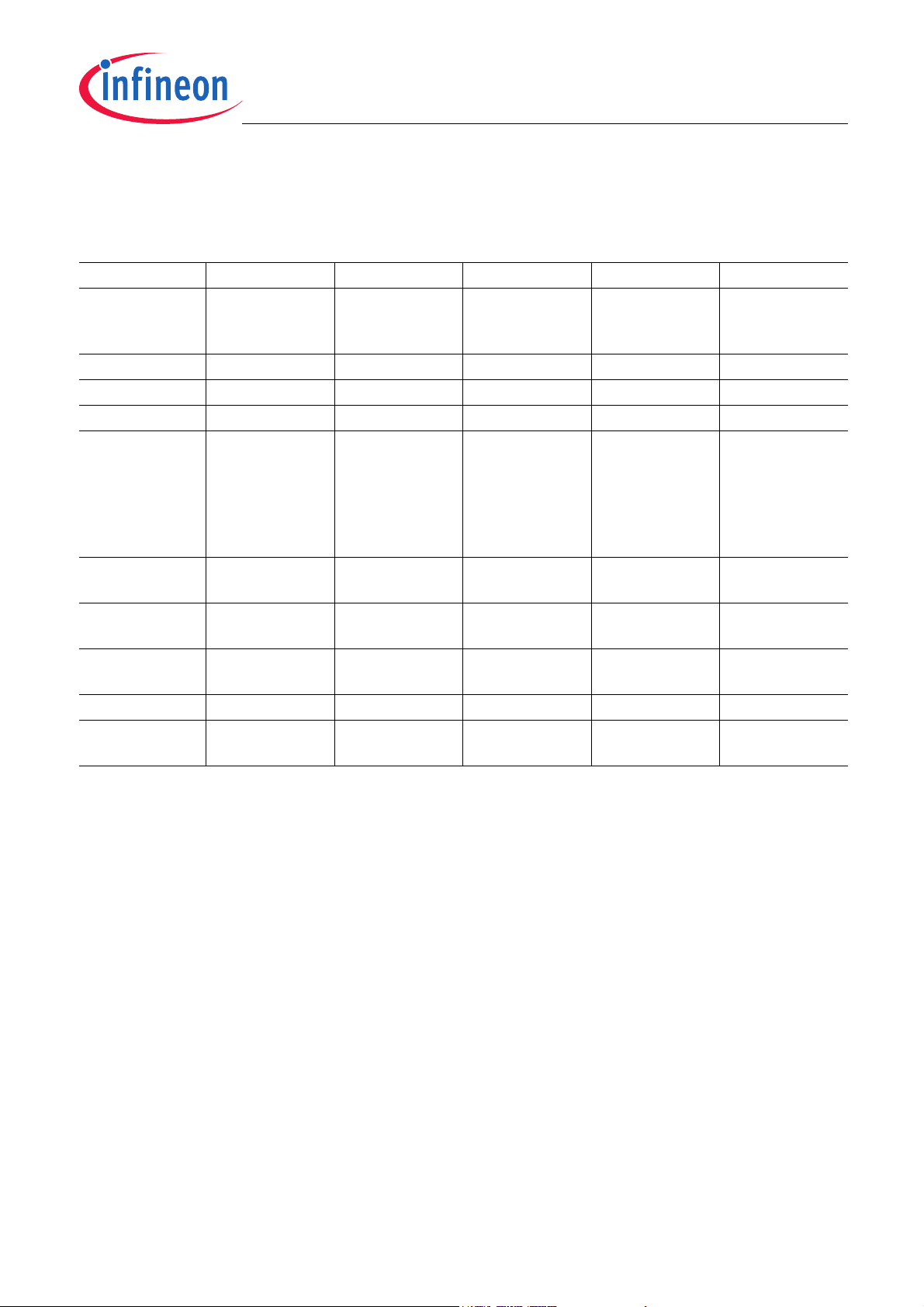

4.1.1 Angle Error adder with Autocalibration enabled

With constant temperatures (ΔT < 5 Kelvin) or parts rotating faster than the temperature changes, the

autocalibration angle error is as specified in the TLE5012B Data Sheet. If autocalibration is enabled when the

temperature changes by more than 5 Kelvin within 1.5 revolutions, the last valid autocalibration parameters will

still be used, leading to an additional angle error. Such cases will happen when the rotating part is halted and the

temperature is changing by more than 5 Kelvin or the rotating part is moving too slowly compared to the external

temperature changes (see Figure 4-4).

Figure 4-4 Cases where an angle error adder has to be included if autocalibration is enabled

The angle error adder is described in the TLE5012B Data Sheet (Figure 4-3, page #25 on the TLE5012B Data

Sheet, Rev. 2.0 from 2014-02) and depends on the initial temperature. To read the right angle error adder select

the initial temperature and move through the x-axis as many degrees as the delta between the final temperature

and the initial temperature. Then read the y-axis value at this delta and add it to the specified angle error, which

already contains lifetime drifts. Some cases are shown in Table 4-2:

Table 4-2 Additional angle error examples

T

range Autocal T/1.5 revolutions Additional angle error

junction

-40°C ... 150°C Off - No additional angle error

-40°C ... 150°C On < 5 Kelvin No additional angle error

-40°C ... 150°C On 10 Kelvin <0.2°

-40°C ... 150°C On 20 Kelvin <0.35°

-40°C ... 150°C On 50 Kelvin <0.85°

>135°C On 15 Kelvin <3.3°

As the magnetic field decreases with higher temperatures, angle errors due to increases of temperature are more

critical than decreases of temperature. As the additional angle error described in the TLE5012B Data Sheet

applies to the worst case (temperature increasing), the angle error adder due to decreasing temperature changes

will always be smaller.

If a parallel SSC interface is in place, autocalibration can be disabled when a critical case described in Figure 4-4

occurs. A temperature check in the microcontroller can be implemented to disable and enable autocalibration (and

thus to reset any wrong minima and maxima) on temperature changes by more than 5 Kelvin during 1.5

revolutions. When autocalibration is disabled the default calibration parameters stored in the laser fuses will be

used for the X and Y raw values correction, and the angle error will fulfill the specifications described in the

TLE5012B Data Sheet.

User’s Manual 25 Rev. 1.2, 2018-02

TLE5012B

)2()1()()1(

tttt

ααα

α

time

Angle

With

Prediction

Without

Prediction

t

adel

t

upd

Magnetic field

direction

Sensor output

Prediction

Angle

Value

Revolution

counter

Angle

Value

Revolution

counter

Angle

Value

Revolution

counter

Regi ster MOD_ 2; 08

H

AVAL; 02

H

AREV; 04

H

AVAL; 02

H

AREV; 04

H

AVAL; 02

H

AREV; 04

H

Field PREDICT [2] ANG_VAL [14:0] REVOL [8:0] ANG_VAL [14:0] REVOL [8:0] ANG_VAL [14:0] REVOL [8:0]

Without

prediction

0 3 43 1 43 359 42

With

prediction

1 1 43 359 43 357 42

0°

0°

0°

Specification

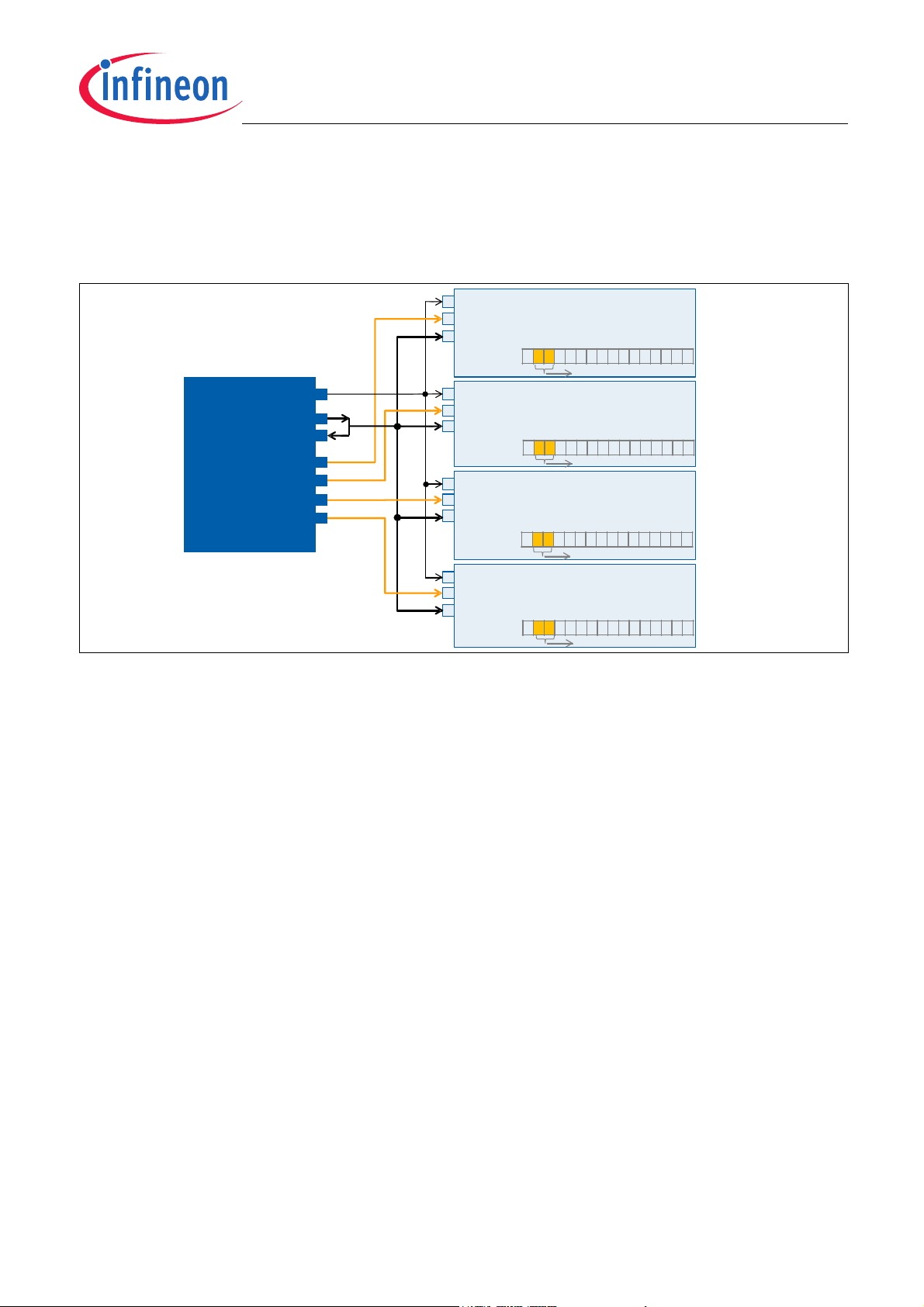

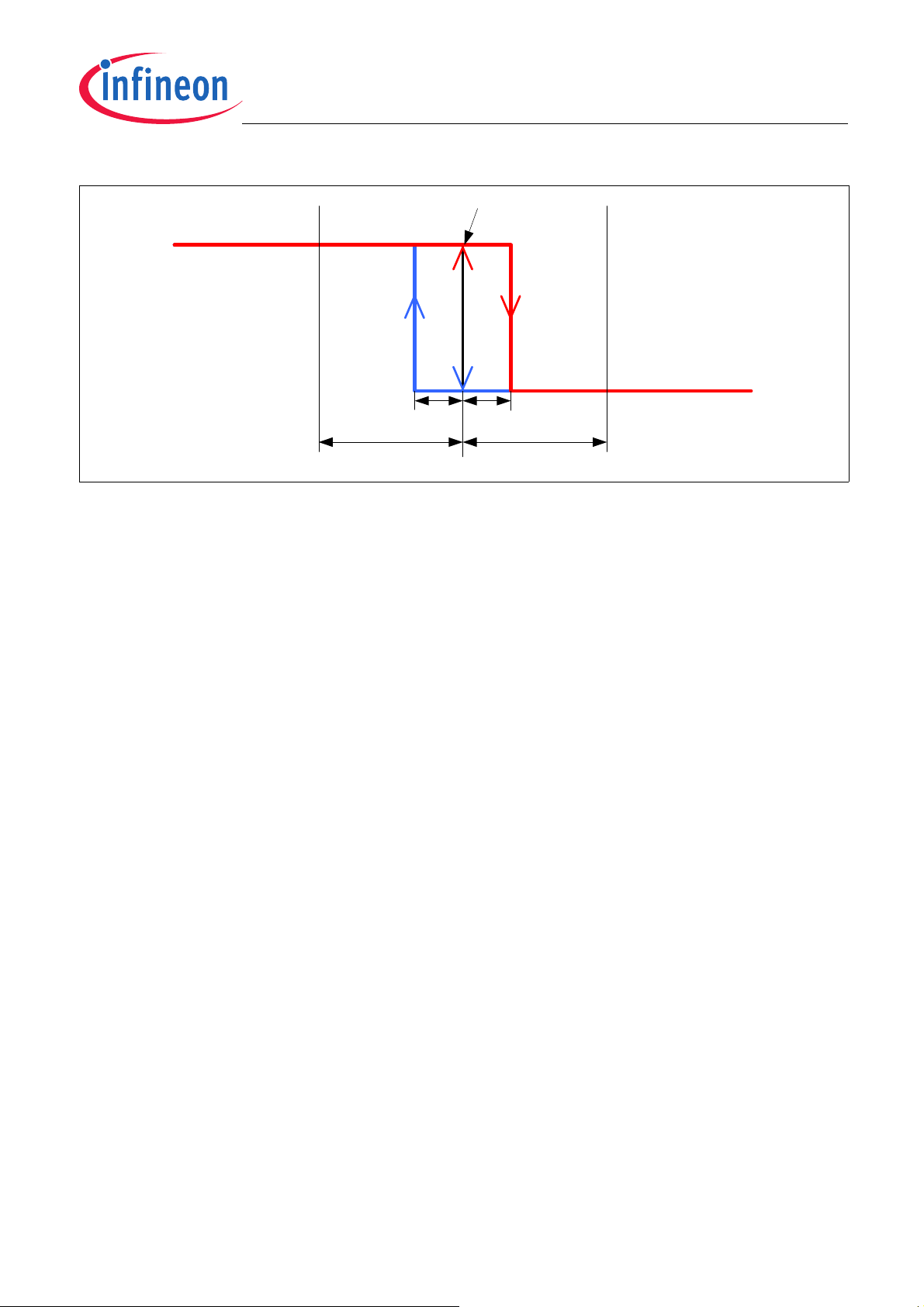

4.2 Prediction mode

The TLE5012B has an optional prediction feature, which serves to reduce the speed dependent angle error in

applications where the rotation speed does not change abruptly. Prediction (enable PREDICT bit on MOD_2

register) uses the difference between current and last two angle values to approximate the angle value which will

be present after the delay time (see Figure 4-5). The output value is calculated by adding this difference to the

measured value, according to Equation (4.1).

−−−+=+

(4.1)

Figure 4-5 Delay of sensor output

Revolution counter on prediction mode

The revolution counter (REVOL bits on AREV register) counts full rotations of the magnetic field. It increments

when the measured angle crosses the 0° point in counter-clockwise rotation direction, and it decrements when the

0° point is crossed in clockwise rotation direction. The revolution counter always works with the measured angle

(current angle and not predicted angle). Therefore, the prediction angle may already indicate that the 0° has been

crossed but the revolution counter may still not increase or decrease if the current calculated angle has not yet

changed quadrant. Once the current calculated angle crosses 0°, the revolution counter will be updated. The

Figure 4-6 illustrates an example; in the second picture the angle value with prediction has already crossed the

0° (from 1° to 359°), but the revolution counter has not yet decreased (remains 43):

Figure 4-6 Revolution counter with prediction mode disabled/enabled

User’s Manual 26 Rev. 1.2, 2018-02

TLE5012B

)(

∑

×+××=×=Δ

Δ+=

Q

QQDDDDthJATOTthJA

AJ

thCAthJCthJA

IVIVRPRT

TTT

RRR

(IDD, IQ> 0, if direction is into IC)

[] [] [ ]

()

KVAAV

W

K

T

mAI

VV

DD

DD

5.100014.05150

14

5

=+××

⎥

⎦

⎤

⎢

⎣

⎡

=Δ

=

7281632128256

2*12*12*12*12*12*02*02*02*1

2*12*12*02*12*122

3457899897969

5949392919

2

0

1

−=++++−=

=++++−=++++

+++++−=∗+∗−=

−−−−

−−−−−

−

=

−

∑

N

i

i

i

N

MSB

bbValu e

C

Cdig

digdigTEMPER

CT °==

+

−

=

°

+

=° 8.28

776.2

80

776.2

15272

]/[776.2

][152][

][

][530][25][_][ digdigOTdigRAWTdigTEMPER

−

4.3 Calculation of the Junction Temperature

The total power dissipation P

above the ambient temperature.

The power multiplied by the total thermal resistance R

R

is the sum of the two components Junction to Case and Case to Ambient.

thJA

of the chip leads to self-heating, which increases the junction temperature T

TOT

(junction to ambient) yields the junction temperature.

thJA

+=

Example (assuming no load on V

out

):

=

Specification

J

(4.2)

(4.3)

4.4 Calculation of the Temperature

The TLE5012B provides the temperature in the TEMPER bits of the FSYNC register via the SSC interface (see

Chapter 6.2) or with an extended SPC frame (see Table 5-8). TEMPER is a compensated value of the

temperature at the ADC. The compensation is done with an offset value at 25°C temperature (T25O), which is

specific for each device. The T25O value is measured for each device during production and it is stored in the

fuses.

The temperature in degrees Celsius (°C) can be calculated using the formula provided in Chapter 6.2 and reading

the TEMPER bits. TEMPER is a signed register, to convert the value to digits proceed as described in

Chapter 6.1.3. As an example, for a TEMPER value of 110111000

Equation (4.4):

Therefore, the temperature in degrees Celsius is calculated in Equation (4.5):

, the value in digits is calculated in

B

(4.4)

(4.5)

TEMPER typical accuracy error is around +/-5°C across the whole temperature range.

TEMPER is a limited register. For a whole temperature range use the T_RAW register, which can be compensated

with the T25O register. The relation between TEMPER and T_RAW is shown in Equation (4.6):

User’s Manual 27 Rev. 1.2, 2018-02

−=

(4.6)

TLE5012B

Specification

4.5 Switching to external clock

External clock operation is possible for the interface configurations SSC only, SSC & PWM, and SSC & SPC. To

switch the TLE5012B to external clock supply the following procedure is used:

• Trigger a chip reset by writing a “1” to the AS_RST bit (address 01

• Within 120µs after the reset command, write a “1” to the CLK_SEL bit (address 06

• After the power-on time (max. 7 ms), read the CLK_SEL bit via SSC interface to confirm that external clock is

selected

Note: If the clock source (CLK_SEL) bit is switched to external clock during operation of the sensor it may occur

(at a chance of roughly 1%) due to an internal timing conflict, that the switching command is not accepted

and the chip keeps operating on internal clock.

[0]) via SSC interface

H

[4])

H

User’s Manual 28 Rev. 1.2, 2018-02

TLE5012B

Interfaces

5 Interfaces

5.1 Interfaces overview

The TLE5012B supports five interfaces which can be choosen depending on the specific application:

• SSC (Synchronous Serial Communication)

• PWM (Pulse Width Modulation)

• SPC (Short PWM Code)

• HSM (Hall Switch Mode)

• IIF (Incremental Interface)

SSC: the SSC is a digital interface which allows bi-directional data transfer. The TLE5012B uses 3-pin as

described in the Chapter 5.2. SSC allows to read additional data to the angle value from registers (angle speed,

raw values, temperature, etc.) and to setup different configurations (resolution, enable/disable of features such as

prediction or autocalibration, etc.). Check Chapter 6 for details. SSC allows a high data transfer with CRC (Cyclic

Redundancy Check) and secure communication (use of the Safety Word after data transfer). Up to 4 sensors can

be used with SSC. SSC is meant for short distances (TLE5012B and ECU to be placed on the same PCB)

PWM: the PWM is an unidirectional interface. Only one line is needed in which the angle value is transmitted. The

angle value corresponds to the duty cycle of the signal, with 0° represented by a 6.25% duty cycle and 93.75%

representing the maximum angle. Safety Analysis results would be communicatd via duty cycle below 2% or above

98%. The frequency of the PWM interface can be set via SSC interface. PWM is meant to support distances up

to 5 meters.

SPC: the SPC is an interface based on the SENT protocol. The ECU (master µC) sends a Trigger Nibble which

wakes up the TLE5012B to transmit the angle value (12bit or 16bit resolution depending on the number of nibbles).

If desired, the temperature can also be transmitted in two extra nibbles. The SPC also sends a CRC and an endpulse to terminate the communication. One line is needed for the transmission and the pins #1 and #2 are used

to set the slave number. Up to four slaves can be connected to one ECU; the ECU Trigger Nibble length will wake

up the respective sensor. SAE International describes the SENT protocol (SAE J2716) distance as up to 5 meters:

“Combined resistance for all connector shall have less than 1 Ohms per line over total vehicle life. The bus wiring

shall utilize cables with less than 0.1nF per meter of wire length. the maximum cable length shall be 5 meters”.

HSM: the HSM is an interface that emulates the output of three Hall switches, therefore three uni-directional lines

are required. Only the angle position can be calculated from the output. The switching hysteresis and the pole-pair

configuration can be selected via SSC. By default the number of pole pairs is set to 5.

IIF: the IIF is an interface that emulates an optical encoder. Three uni-directional lines are required: two for Phase

A and Phase B and a third one for the IIF Index (which indicates a 0° pass). Phase A and Phase B pulse out phaseshifted pulses for each “step resolution” that the angle moved. The two Phases are needed to also track the

rotation direction (clockwise or counter-clockwise). At start-up the IIF pulses out the angle value. Different IIF

modes, step resolutions and hysteresis values can be configurated via SSC. IIF interface is meant for short

distances (TLE5012B and ECU to be placed on the same PCB). It is used for high-speed applications such as

electrically commutated motor drives.

SSC can be used in parallel to any other interface (PWM, SPC, HSM or IIF).

More details on the default configuration of each derivate are described in Chapter 7.

User’s Manual 29 Rev. 1.2, 2018-02

TLE5012B

Interfaces

Table 5-1 summarizies the key characteristics and parameters that have to be considered when choosing an

interface:

Table 5-1 Main interface characteristics

Characteristics IIF PWM SPC HSM SSC

Data/Values angle steps

(angle value at

start-up)

Distance

1)

short-medium long (up to 5m) long (up to 5m) medium short

angle value angle value

(temperature

optional)

angle value

period

many data

available in the

registers

Data rate high low-medium low high high

Resolution high high high low high

Check IIF Index (0°

pulse). Phase

A/B as

complementary

signal.

Duty cycle range

diagnostics.

CRC HS1/HS2/HS3 as

complementary

signals.

Safety Word in

the data transfer.

Availability of

status and

diagnostics

registers.

Max. slaves in

no bus mode no bus mode 4 no bus mode 4

bus mode

Communication

2)

lines

Communication unidirectional unidirectional unidirectional

3 (only two

without IIF Index)

1133

unidirectional bidirectional

(triggered)

SSC possible Yes Yes Yes Yes Yes

Other Emulates Optical

Encoder

1) Not subject to production test. Distance subject to application circuit and environment.

2) Communication lines between slave (TLE5012B) and master (microcontroller). External clock not included

Based on SENT

protocol

Emulates (three)

Hall Switches

3-wire SPI

User’s Manual 30 Rev. 1.2, 2018-02

TLE5012B

SCK

t

CSs

t

SCKp

t

SCKh

t

CSh

CSQ

t

SCKl

t

CSoff

t

DATAs

DATA

t

DATAh

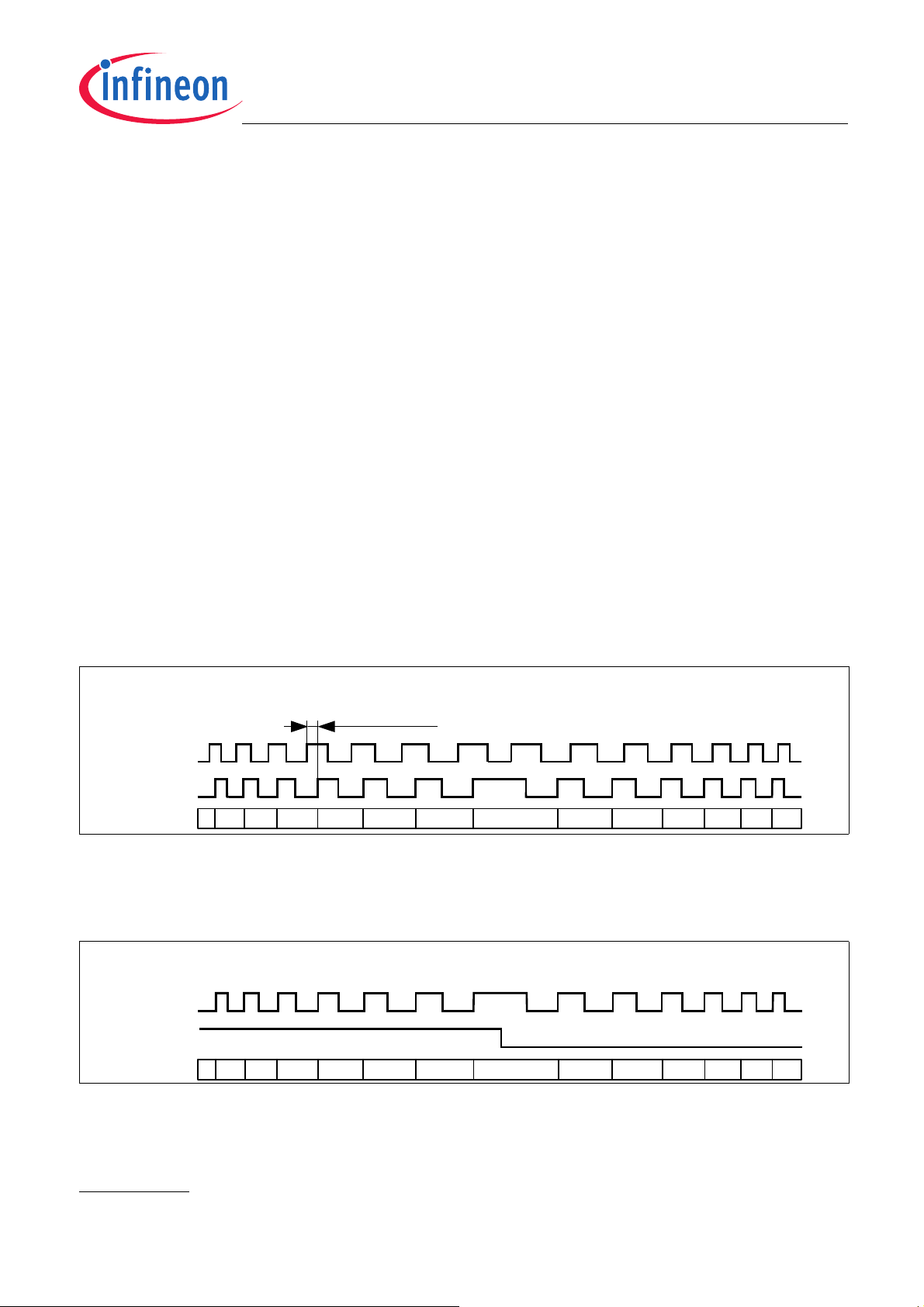

5.2 Synchronous Serial Communication (SSC) Interface

5.2.1 SSC Timing Definition

Figure 5-1 SSC timing

Interfaces

SSC Inactive Time (CS

off

)

The SSC inactive time defines the delay time after a transfer before the TLE5012B can be selected again.

Table 5-2 SSC push-pull timing specification

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

SSC baud rate f

CSQ setup time t

CSQ hold time t

CSQ off t

SCK period t

SCK high t

SCK low t

DATA setup time t

DATA hold time t

Write read delay t

Update time t

SCK off t

1) Not subject to production test - verified by design/characterization

SSC

CSs

CSh

CSoff

SCKp

SCKh

SCKl

DATAs

DATAh

wr_delay

CSupdate

SCKoff

105 ns

105 ns

600 ns SSC inactive time

120 125 ns

40 ns

30 ns

25 ns

40 ns

130 ns

170 ns

8.0 Mbit/s

1 μsSee Figure 5-5

User’s Manual 31 Rev. 1.2, 2018-02

TLE5012B

Interfaces

Table 5-3 SSC open-drain timing specification

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

SSC baud rate f

CSQ setup time t

CSQ hold time t

CSQ off t

SCK period t

SCK high t

SCK low t

DATA setup time t

DATA hold time t

Write read delay t

Update time t

SCK off t

SSC

CSs

CSh

CSoff

SCKp

SCKh

SCKl

DATAs

DATAh

wr_delay

CSupdate

SCKoff

300 ns

400 ns

600 ns SSC inactive time

500 ns

25 ns

40 ns

130 ns

170 ns

1) Not subject to production test - verified by design/characterization

2.0 Mbit/s Pull-up Resistor = 1k

1)

1)

1)

190 ns

190 ns

1)

1)

1)

1)

1)

1 μsSee Figure 5-5

1)

1)

1)

1)

User’s Manual 32 Rev. 1.2, 2018-02

TLE5012B

COMMAND READ Data 1 READ Data 2

SAFETY-WORD

SSC-Master is driving DATA

SSC-Slave is driving DATA

t

wr_delay

COMMAND WRITE Data 1

SAFETY-WORD

SSC-Master is driving DATA

SSC-Slave is driving DATA

t

wr_delay

5.2.2 SSC Data Transfer

The SSC data transfer is word-aligned. The following transfer words are possible:

• Command Word (to access and change operating modes of the TLE5012B)

• Data words (any data transferred in any direction)

• Safety Word (confirms the data transfer and provides status information)

Figure 5-2 SSC data transfer (data-read example)

Interfaces

Figure 5-3 SSC data transfer (data-write example)

Command Word

SSC Communication between the TLE5012B and a microcontroller is generally initiated by a command word. The

structure of the command word is shown in Table 5-4, where the Update (UPD) bit allows the access to current

values or updated values. If an update command is issued and the UPD bit is set, the immediate values are stored

in the update buffer simultaneously. This enables a snapshot of all necessary system parameters at the same

time. Bits with an update buffer are marked by an “u” in the Type column in register descriptions. The initialization

of such an update is described on page 35.

Table 5-4 Structure of the Command Word

Name Bits Description

RW [15] Read - Write

0: Write

1: Read

Lock [14..11] 4-bit Lock Value

0000

0x30

1010

: Default operating access for addresses 0x00:0x04, 0x14:0x15, 0x20,

B

: Configuration access for addresses 0x05:0x11

B

User’s Manual 33 Rev. 1.2, 2018-02

TLE5012B

Interfaces

Table 5-4 Structure of the Command Word (cont’d)

Name Bits Description

UPD [10] Update-Register Access

0: Access to current values

1: Access to values in update buffer

ADDR [9..4] 6-bit Address

ND [3..0] 4-bit Number of Data Words (if bits set to 0000

, no safety word is provided)

B

Safety Word

The safety word consists of the following bits:

Table 5-5 Structure of the Safety Word

Name Bits Description

1)

STAT

Chip and Interface Status

[15] Indication of chip reset or watchdog overflow (resets after readout) via SSC

0: Reset occurred

1: No reset

[14] System error (e.g. overvoltage; undervoltage; V

-, GND- off; ROM;...)

DD