Page 1

Microcontrollers

XMC4000/1000

Microcontroller Series

for Industrial Applications

Application Guide

V1.0 2015-01

Introduction to Digital Power

Conversion

Page 2

Edition 2015-01

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2015 Infineon Technologies AG

All Rights Reserved.

Legal Disclaimer

The information given in this document shall in no event be regarded as a guarantee of conditions or

characteristics. With respect to any examples or hints given herein, any typical values stated herein and/or any

information regarding the application of the device, Infineon Technologies hereby disclaims any and all

warranties and liabilities of any kind, including without limitation, warranties of non-infringement of intellectual

property rights of any third party.

Information

For further information on technology, delivery terms and conditions and prices, please contact the nearest

Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements, components may contain dangerous substances. For information on the types in

question, please contact the nearest Infineon Technologies Office.

Infineon Technologies components may be used in life-support devices or systems only with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the

failure of that life-support device or system or to affect the safety or effectiveness of that device or system. Life

support devices or systems are intended to be implanted in the human body or to support and/or maintain and

sustain and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other

persons may be endangered.

Page 3

Introduction to Digital Power Conversion

Revision History

Page or Item

Subjects (major changes since previous revision)

V1.0, 2015-01

XMC4000/1000 Family

Revision History

Trademarks of Infineon Technologies AG

AURIX™, C166™, CanPAK™, CIPOS™, CIPURSE™, CoolMOS™, CoolSET™,

CORECONTROL™, CROSSAVE™, DAVE™, EasyPIM™, EconoBRIDGE™, EconoDUAL™,

EconoPIM™, EiceDRIVER™, eupec™, FCOS™, HITFET™, HybridPACK™, I²RF™, ISOFACE™,

IsoPACK™, MIPAQ™, ModSTACK™, my-d™, NovalithIC™, OptiMOS™, ORIGA™, PRIMARION™,

PrimePACK™, PrimeSTACK™, PRO-SIL™, PROFET™, RASIC™, ReverSave™, SatRIC™,

SIEGET™, SINDRION™, SIPMOS™, SmartLEWIS™, SOLID FLASH™, TEMPFET™, thinQ!™,

TRENCHSTOP™, TriCore™.

Other Trademarks

Advance Design System™ (ADS) of Agilent Technologies, AMBA™, ARM™, MULTI-ICE™, KEIL™,

PRIMECELL™, REALVIEW™, THUMB™, µVision™ of ARM Limited, UK. AUTOSAR™ is licensed by

AUTOSAR development partnership. Bluetooth™ of Bluetooth SIG Inc. CAT-iq™ of DECT Forum.

COLOSSUS™, FirstGPS™ of Trimble Navigation Ltd. EMV™ of EMVCo, LLC (Visa Holdings Inc.).

EPCOS™ of Epcos AG. FLEXGO™ of Microsoft Corporation. FlexRay™ is licensed by FlexRay

Consortium. HYPERTERMINAL™ of Hilgraeve Incorporated. IEC™ of Commission Electrotechnique

Internationale. IrDA™ of Infrared Data Association Corporation. ISO™ of INTERNATIONAL

ORGANIZATION FOR STANDARDIZATION. MATLAB™ of MathWorks, Inc. MAXIM™ of Maxim

Integrated Products, Inc. MICROTEC™, NUCLEUS™ of Mentor Graphics Corporation. Mifare™ of

NXP. MIPI™ of MIPI Alliance, Inc. MIPS™ of MIPS Technologies, Inc., USA. muRata™ of MURATA

MANUFACTURING CO., MICROWAVE OFFICE™ (MWO) of Applied Wave Research Inc.,

OmniVision™ of OmniVision Technologies, Inc. Openwave™ Openwave Systems Inc. RED HAT™

Red Hat, Inc. RFMD™ RF Micro Devices, Inc. SIRIUS™ of Sirius Satellite Radio Inc. SOLARIS™ of

Sun Microsystems, Inc. SPANSION™ of Spansion LLC Ltd. Symbian™ of Symbian Software Limited.

TAIYO YUDEN™ of Taiyo Yuden Co. TEAKLITE™ of CEVA, Inc. TEKTRONIX™ of Tektronix Inc.

TOKO™ of TOKO KABUSHIKI KAISHA TA. UNIX™ of X/Open Company Limited. VERILOG™,

PALLADIUM™ of Cadence Design Systems, Inc. VLYNQ™ of Texas Instruments Incorporated.

VXWORKS™, WIND RIVER™ of WIND RIVER SYSTEMS, INC. ZETEX™ of Diodes Zetex Limited.

Last Trademarks Update 2011-02-24

Page 4

Introduction to Digital Power Conversion

XMC4000/1000 Family

Table of Contents

Table of Contents

1 About this document ......................................................................................................................... 6

1.1 Scope and Purpose .............................................................................................................................. 6

1.2 Intendend Audience ............................................................................................................................. 6

2 Comparison of Power Conversion Methods ................................................................................... 7

2.1 What is Power Conversion ................................................................................................................... 7

2.2 Why Power Conversion ........................................................................................................................ 7

2.3 Methods of Power Conversion ............................................................................................................. 7

2.3.1 Linear Mode Power Conversion ..................................................................................................... 7

2.3.2 Switch Mode Power Conversion .................................................................................................... 9

2.3.2.1 Analog Switch Mode Controllers ............................................................................................. 11

2.3.2.2 Digital Switch Mode Controllers .............................................................................................. 11

2.3.2.3 ASIC controller versus MCU / DSP / DSC controllers ............................................................ 12

2.4 Infineon XMC-families for Switch Mode Power Control ..................................................................... 13

2.4.1 Power Conversion Oriented Peripheral Features ........................................................................ 14

2.4.1.1 Sensing ................................................................................................................................... 14

2.4.1.2 Stability and Software ............................................................................................................. 14

2.4.1.3 Modulation .............................................................................................................................. 14

2.4.1.4 PWM Generation .................................................................................................................... 15

3 Converter Topologies ...................................................................................................................... 16

3.1 Buck ................................................................................................................................................... 17

3.2 Boost .................................................................................................................................................. 18

3.3 PFC .................................................................................................................................................... 19

3.4 Phase-Shift Full-Bridge (PSFB) ......................................................................................................... 21

3.5 LLC (Inductor-Inductor-Capacitor) ..................................................................................................... 22

3.6 Generic Digital Power Converter ........................................................................................................ 23

4 PWM Generation............................................................................................................................... 24

4.1 Single Channel ................................................................................................................................... 24

4.2 Single Channel with Complementary Outputs ................................................................................... 24

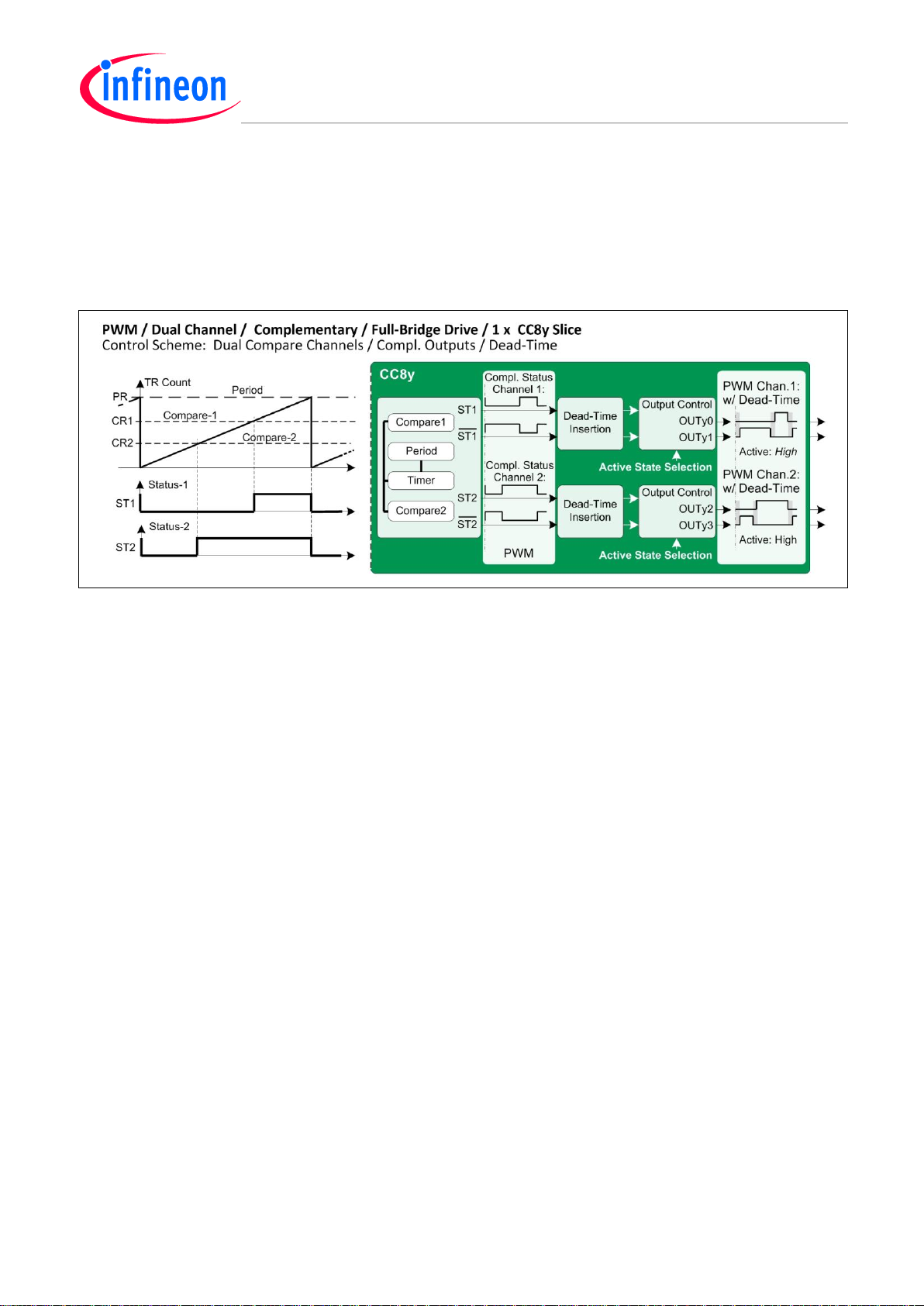

4.3 Dual Channel with Complementary Outputs with Dead-Time, using CCU8 ...................................... 25

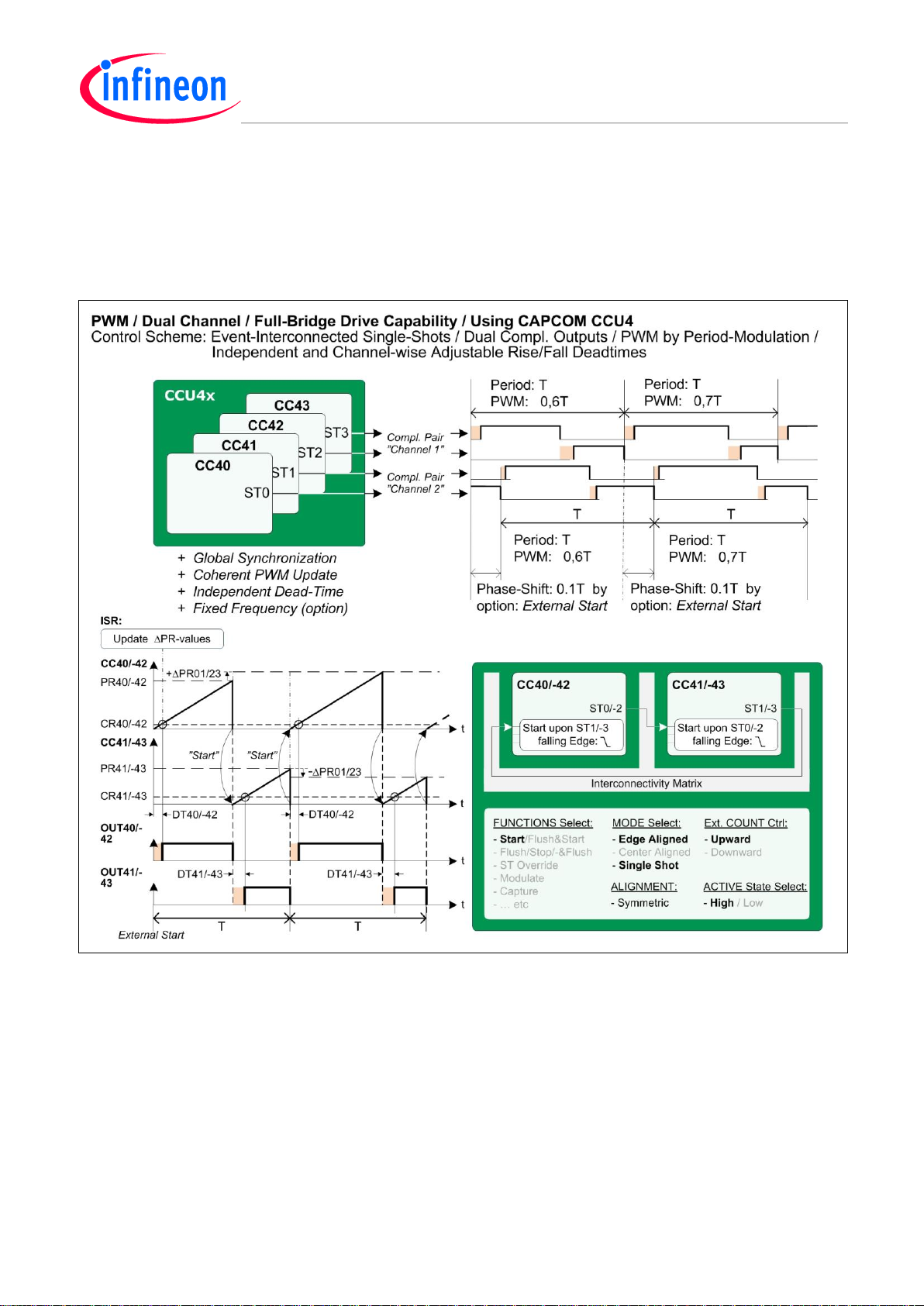

4.4 Dual Channel with Complementary Outputs with Dead-Time, using CCU4 ...................................... 25

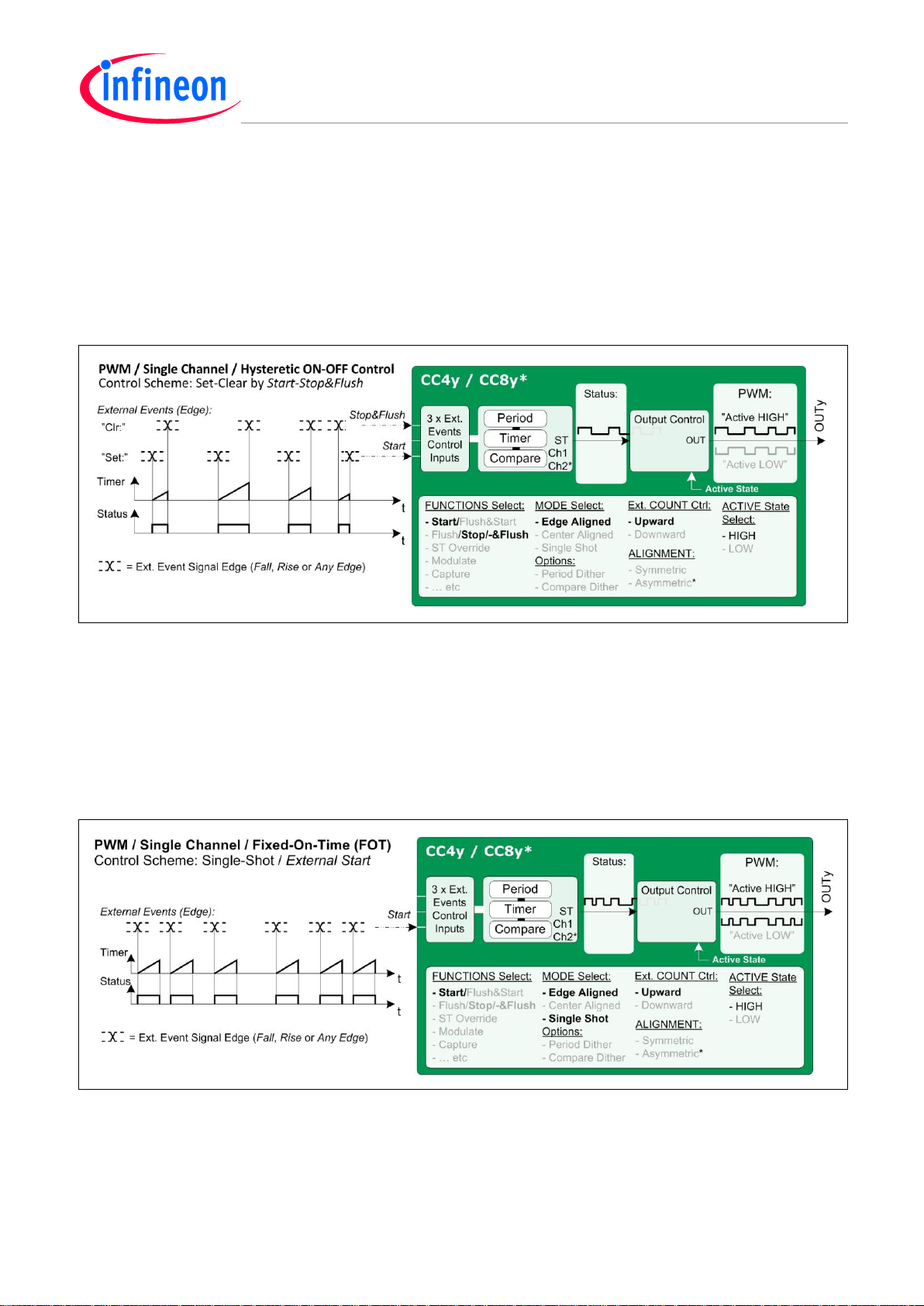

4.5 ON/OFF Control ................................................................................................................................. 27

4.6 Fixed ON-Time (FOT) ........................................................................................................................ 27

4.7 Fixed ON-Time with Frequency Limit Control .................................................................................... 28

4.8 Fixed Off-Time (FOFFT) .................................................................................................................... 31

4.9 Phase Shift Control ............................................................................................................................ 32

4.10 Fixed Phase-Shift ............................................................................................................................... 32

4.10.1 Center Aligned Mode ................................................................................................................... 32

4.10.2 Edge Aligned Mode ...................................................................................................................... 33

4.10.3 Interleave ..................................................................................................................................... 34

4.11 Variable Phase-Shift .......................................................................................................................... 35

4.11.1 Power Conversion Control Example ............................................................................................ 37

4.11.2 Zero-Voltage Switching (ZVS) Control ......................................................................................... 38

4.12 Adding High Resolution Channel (HRC) – HRPWM .......................................................................... 39

4.12.1 PWM Dead-Time Compensation ................................................................................................. 40

4.13 Half-Bridge LLC Control using ½ CCU4............................................................................................. 41

4.14 Half-Bridge LLC Control - Synchronous Rectification using CCU4 ................................................... 42

4.15 Full-Bridge LLC Control Using HRC – Synchronous Rectification ..................................................... 43

4.16 Full-Bridge LLC Control – Synchronous Rectification Using HRC ..................................................... 44

5 Sensing ............................................................................................................................................. 46

5.1 Analog Signal Sensing ....................................................................................................................... 46

5.1.1 Level Crossing Detection, Fast Compare mode .......................................................................... 46

5.1.2 PWM with Fast Compare mode Hysteretic Switching ................................................................. 47

5.1.3 Peak Control Using Fast Compare mode .................................................................................... 48

5.1.4 ZCD Control Using Fast Compare mode ..................................................................................... 49

Application Guide 4 V1.0, 2015-01

Page 5

Introduction to Digital Power Conversion

XMC4000/1000 Family

Table of Contents

5.2 Over Voltage and Over Current Protection (OVP / OCP) .................................................................. 50

6 Modulation ........................................................................................................................................ 51

6.1 Voltage Control (VC) .......................................................................................................................... 52

6.1.1 Timing Scheme ............................................................................................................................ 53

6.2 Current Control ................................................................................................................................... 55

6.2.1 Average Current Control (ACC) ................................................................................................... 55

6.2.2 Average Current Control, Edge-Aligned Scheme ........................................................................ 56

6.2.3 Discontinuous to Continuous Current Recovery by Timer-Load ................................................. 58

6.2.4 ACC Center Aligned Scheme ...................................................................................................... 59

6.3 Peak Current Control (PCC) .............................................................................................................. 60

6.3.1 PCC Timing Scheme.................................................................................................................... 62

6.4 Blanking, Filtering and Clamping ....................................................................................................... 63

6.5 Slope Compensation .......................................................................................................................... 64

6.5.1 A Necessity in Fixed Frequency PCC .......................................................................................... 64

6.5.2 Fast Average Current Mode PCC ................................................................................................ 65

6.5.3 VIN independent Average Current mode ...................................................................................... 66

6.5.4 Slope Compensation Conditions – PCC ...................................................................................... 67

6.5.5 Slope Compensation Conditions: PCC ‘Stable Area’ examples .................................................. 70

6.5.6 Without Slope Compensation, Fixed-ON-Time (FOT) ZCD Control ............................................ 71

6.5.7 Without Slope Compensation, Fixed-OFF-Time (FOFFT) PCC .................................................. 71

6.6 CCM, CRM (CrCM) and DCM ............................................................................................................ 72

6.7 CRM: PFC using Fixed-On-Time (FOT)............................................................................................. 74

6.8 CCM / (DCM): PFC using Fixed-Off-Time (FOFFT) .......................................................................... 75

6.9 CCM: PFC example using Average Current Mode Control ............................................................... 76

7 Control Loops ................................................................................................................................... 77

7.1 Using CSG (HRPWM) with an Internal Comparator and Slope Generator........................................ 77

7.2 Using embedded ACMP and external Slope Compensation Ramp .................................................. 78

7.3 Using FADC Compare Mode; Slope Compensation Add-On ............................................................ 81

7.4 Open Loop Gain Stabilization (Frequency Compensation)................................................................ 83

7.4.1 Open Loop Gain Voltage Mode ................................................................................................... 84

7.4.2 Open Loop Gain Bode Plot, Voltage Mode Stabilization ............................................................. 85

7.4.3 Open Loop Gain Current Mode w/ Slope Compensation ............................................................ 86

7.4.4 Open Loop Gain Bode Plot, Current Mode Stabilization ............................................................. 87

8 Application Software ....................................................................................................................... 88

8.1 Advanced Algorithms / User software IP for Power Conversion ........................................................ 88

8.2 Multi-stage, multi-functional, multi-tasking control by a single controller ........................................... 88

8.3 Safety ................................................................................................................................................. 89

8.4 Communication capabilities ............................................................................................................... 89

8.5 Data logging / Firmware updates ....................................................................................................... 89

8.6 Human Machine Interface .................................................................................................................. 89

8.7 Digital Switch Mode Control by New Feed-Forward Techniques ...................................................... 90

8.8 Non-linear Slope Compensation ........................................................................................................ 90

Application Guide 5 V1.0, 2015-01

Page 6

Introduction to Digital Power Conversion

XMC4000/1000 Family

About this document

1 About this document

1.1 Scope and Purpose

This document aims to stimulate and challenge accepted solutions in the field of power applications

with digital control, by revisiting the basics of electric energy transfer and creating a summarized

picture of what can be achieved today with a weighted mix of embedded dedicated peripherals and

computing power.

1.2 Intendend Audience

The information is intended for persons in charge or executive position, with a diverse background in

the subject – as well as to people with deeply rooted experience in the field, such as power supply

designers, for which we want to show the possibilities XMC families can offer.

Application Guide 6 V1.0, 2015-01

Page 7

Introduction to Digital Power Conversion

Category

Type

General Purpose

DC / DC

DC-to-DC converter

Regulator / Stabilizer / Voltage Adapter

AC / DC

AC-to-DC converter

Rectifier / Mains Power Supply Unit (PSU)

DC / AC

AC-to-DC converter

Inverter

AC / AC

AC-to-AC converter

Transformer / Variable frequency Converter

XMC4000/1000 Family

Comparison of Power Conversion Methods

2 Comparison of Power Conversion Methods

2.1 What is Power Conversion

Power conversion is the conversion of electric energy from one form to another. As long as it does not

concern electro-mechanic equivalent energy that consumes energy (e.g. motors) or produces energy

(e.g. generators), then it is about pure power transfer, in any form, from the following categories:

Table 1 Power conversion categories

2.2 Why Power Conversion

According to the global environmental context, each case of electric energy transfer between an

energy source and an energy consuming unit, should consume as little energy as possible to perform

the task by optimal adaption. This is generally unachievable without some form of power conversion.

2.3 Methods of Power Conversion

There are two significantly different ways to convert a DC supply voltage to another DC voltage:

Linear Power Conversion

Switch Mode Power Conversion

When Switch Mode is chosen (e.g. for High Power) the next choice is between:

Analog (discrete) control

Digital (ASIC/MCU/DSP) control

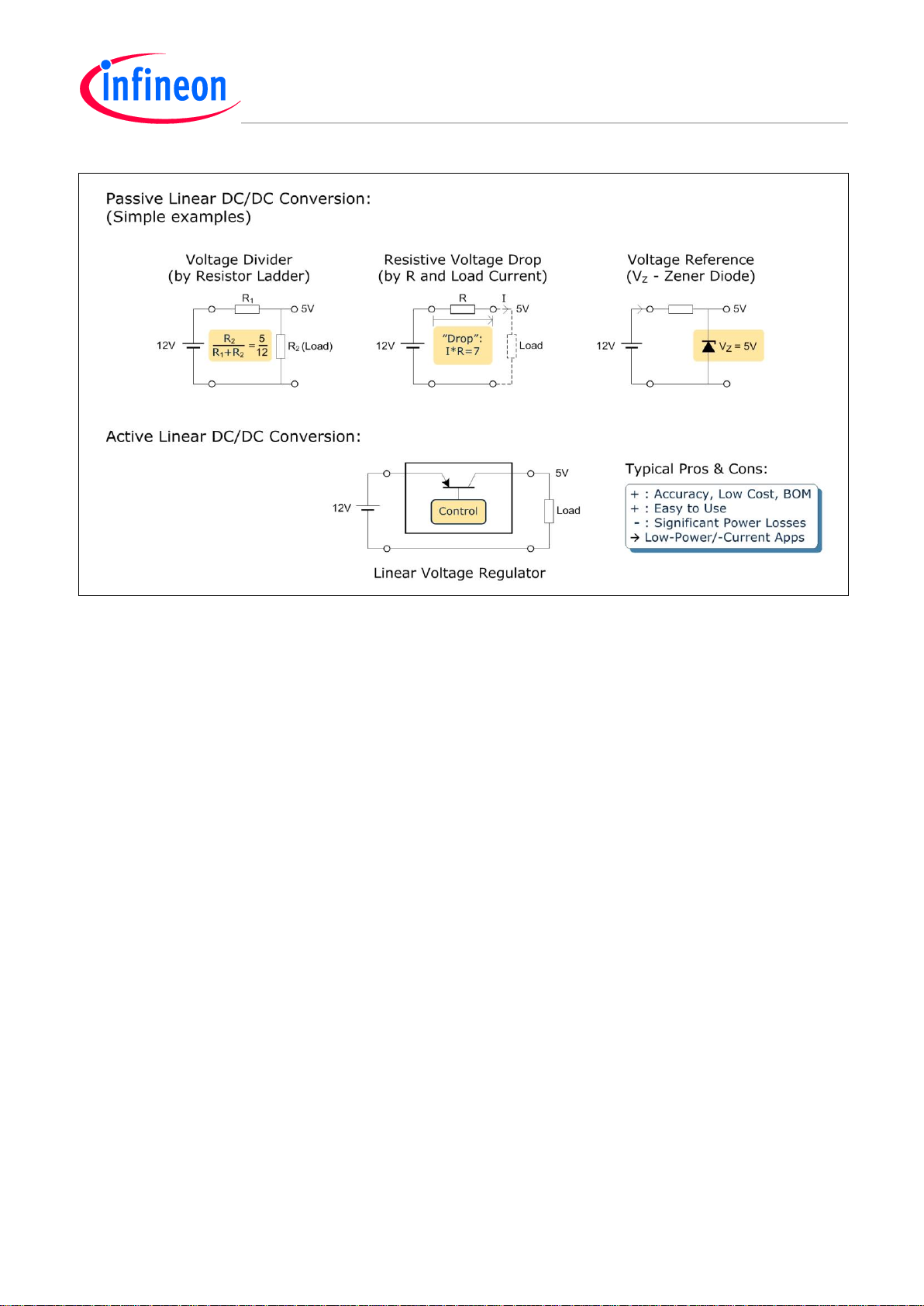

2.3.1 Linear Mode Power Conversion

A Linear DC/DC Converter output/input voltage ratio is < 1 and the output/input current ratio is < 1, so

there is always a significant power loss.

Linear voltage regulators meet such demands as ‘Easy-to-Use’, Accuracy, Low Cost and EMC. They

are therefore the “best-choice” in low power / low current DC-converters.

Application Guide 7 V1.0, 2015-01

Page 8

Introduction to Digital Power Conversion

XMC4000/1000 Family

Comparison of Power Conversion Methods

Figure 1 Linear DC/DC Conversion

Passive Linear Conversion

Passive conversion means that there are no control components involved in the process that are

capable of changing the conversion properties in any way; i.e. the steady state input-to-output transfer

function is not adjustable in runtime. The consequence of this is Load dependent output voltage.

Active Linear Conversion

By “active” conversion we mean that there are components involved that are capable of influencing

the conversion activity; i.e. there is at least one semiconductor capable of controlling the conversion

by at least one additional input signal. This might be to stabilize the output to a reference level for

example.

Application Guide 8 V1.0, 2015-01

Page 9

Introduction to Digital Power Conversion

XMC4000/1000 Family

Comparison of Power Conversion Methods

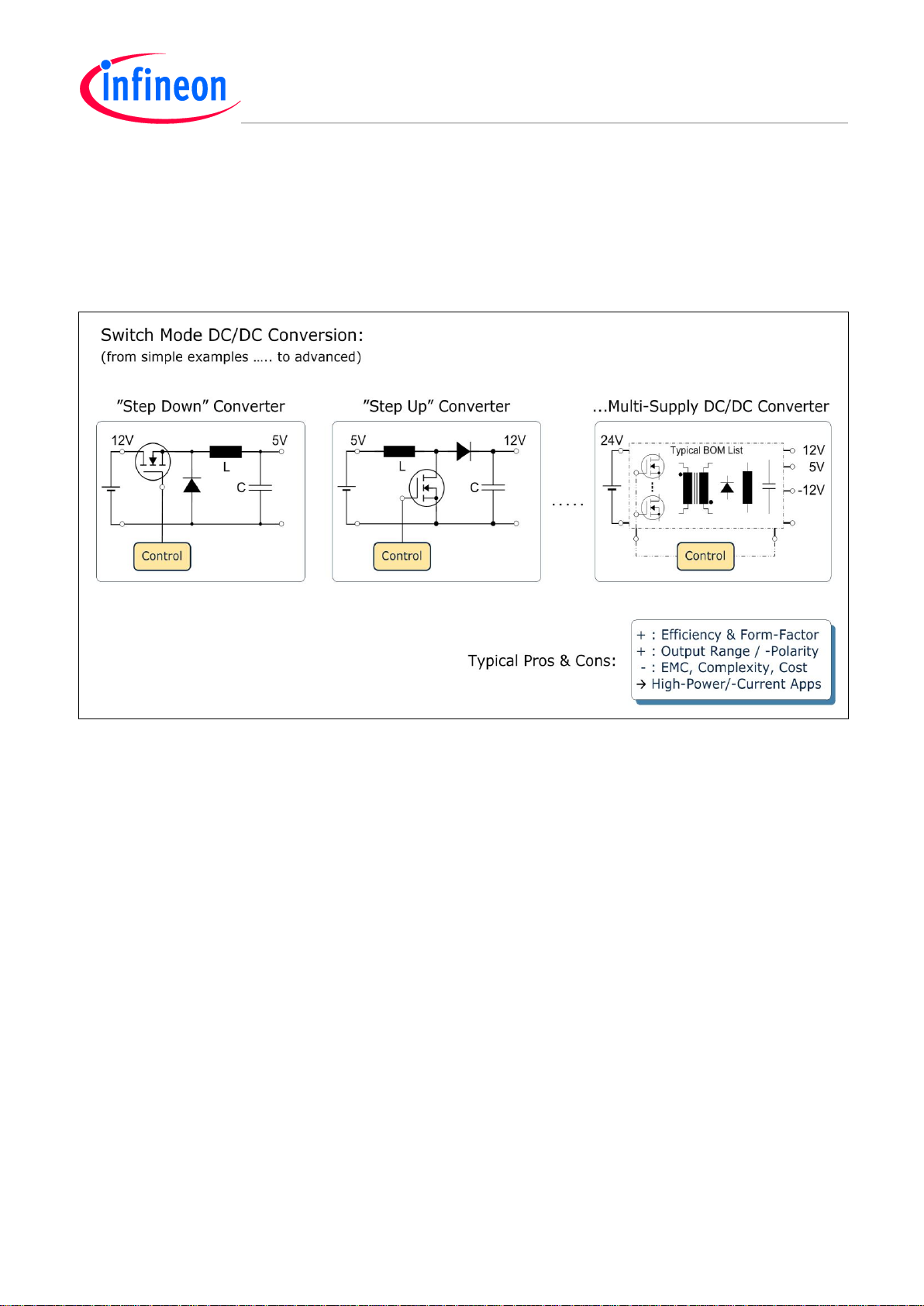

2.3.2 Switch Mode Power Conversion

A Switch Mode DC/DC Converter output/input voltage ratio can be any value, including a negative

value. That property is not covered by any Linear Voltage Converter, so most power conversion usecases can be solved by Switch Mode, especially in the area of high power, where efficiency and formfactor are vital.

Figure 2 Switch Mode DC/DC Conversion

Switch mode conversion is always an “active” conversion, in the sense there has to be active, working

semiconductors in the input-to-output transfer path. The presence of at least one winded component,

such as an inductor, is also essential.

Application Guide 9 V1.0, 2015-01

Page 10

Introduction to Digital Power Conversion

XMC4000/1000 Family

Comparison of Power Conversion Methods

Switch Mode Power Conversion Principle – Compared to Linear Mode

In switch mode voltage conversion, portions of energy, divided by switching in time lengths (T1 or T2),

are transferred from a voltage source to an inductor (L) current as magnetic energy, cyclic in periods

(T). During the rest of each period (T), the energy is moved into a capacitor (C), for the output voltage.

This principle is true for any DC/DC converter topology.

Interesting similarities with linear conversion can be seen in the output/input voltage ratios, when

replacing ‘R’ with ‘T’. This comparison is true as long as the magnetic energy of the inductor is never

emptied before the end of each period (T); i.e. Continuous Conduction Mode (CCM) is assumed.

Figure 3 Power Conversion Principles and Similarities - Demo Model

Power Loss Comparison

The voltage drop (V

) in linear mode is maintained by a resistor (R) and constant current, causing

1 – V2

active power loss.

The voltage (V

) in switch mode is reactive by self-inductance (L) during rising or falling current in

1 – V2

the switch time intervals (T1 or T2) respectively, resulting (ideally) in no power loss.

Application Guide 10 V1.0, 2015-01

Page 11

Introduction to Digital Power Conversion

Positive properties

Negative properties

Fast

Do not adapt to new conditions during run-time

Well known

Sensitivity of parasitic effects and ageing

Simple IPs

Limited range of topologies

Standard discreet components

Narrow input / load range with efficiency

XMC4000/1000 Family

Comparison of Power Conversion Methods

2.3.2.1 Analog Switch Mode Controllers

Traditional Analog Controllers have a significant BOM (Bill of Materials) list of OpAmps, comparators,

filters, and so on. They cover just a limited range of topologies and do not adapt autonomously to

condition changes in run-time. Form factor can be poor and reusability is limited, but they are fast and

well known.

Table 2 Properties of Analog Controllers

2.3.2.2 Digital Switch Mode Controllers

Digital controllers are flexible, with a wide load / input range, and sophisticated reactions to condition

changes during run-time through multi-control loops. They are reconfigurable by software and can

connect to a network / HMI. A smart system can predict ageing or process variations, enabling

scalability and portability of IPs.

Digital Controllers – Positive properties

Cost is higher and complexity is higher too, but there are many positive properties:

Highest efficiency over wide load and input range

Sophisticated start-up algorithms

Overload condition reactions

Auto-switch between power modes (CCMCRMDCMBurst)

Programmable / configurable by software

Multiple control loops are possible

Correct real-time performance

Prediction of system behavior

Reduction of parasitic effects

Scalable for wider ranges

IPs are easily portable: lowhigh end

Fast time to market

Sophisticated reactions to events

Communication and HMI feature

Application Guide 11 V1.0, 2015-01

Page 12

Introduction to Digital Power Conversion

XMC4000/1000 Family

Comparison of Power Conversion Methods

2.3.2.3 ASIC controller versus MCU / DSP / DSC controllers

Here we outline some of the guiding properties to be considered, for the type of controller to choose

when selecting for High-end versus Low-end.

ASIC

ASIC controllers offer gate drivers and fixed optimized solutions at the lowest possible cost. They are

easy to use and they fit Low-end switch mode converters very well.

However, on the downside, they only handle known changes in load and input conditions during runtime, and reusability is limited because they are a customized solution.

Positive properties:

Custom design for known conditions

Fixed and optimized settings

Lowest possible cost

Easy to use

Embedded gate drivers

Form factor

MCU / DSP / DSC

An MCU, DSP or DSC controller brings a platform approach, a smart system with high computation

capability, and embedded power conversion orientated peripherals.

Condition changes are handled in run-time, ensuring the highest efficiency and correct real-time

performance. These features mean that the MCU, DSP or DSC solution is particularly suited to Highend power converters.

Positive properties:

Platform approach (Reuse, Extend)

When highest efficiency is required

Mixed power mode capability

Variable load / inputs

Programmable dwith software IP

Flexible communication

Application Guide 12 V1.0, 2015-01

Page 13

Introduction to Digital Power Conversion

XMC4000/1000 Family

Comparison of Power Conversion Methods

2.4 Infineon XMC-families for Switch Mode Power Control

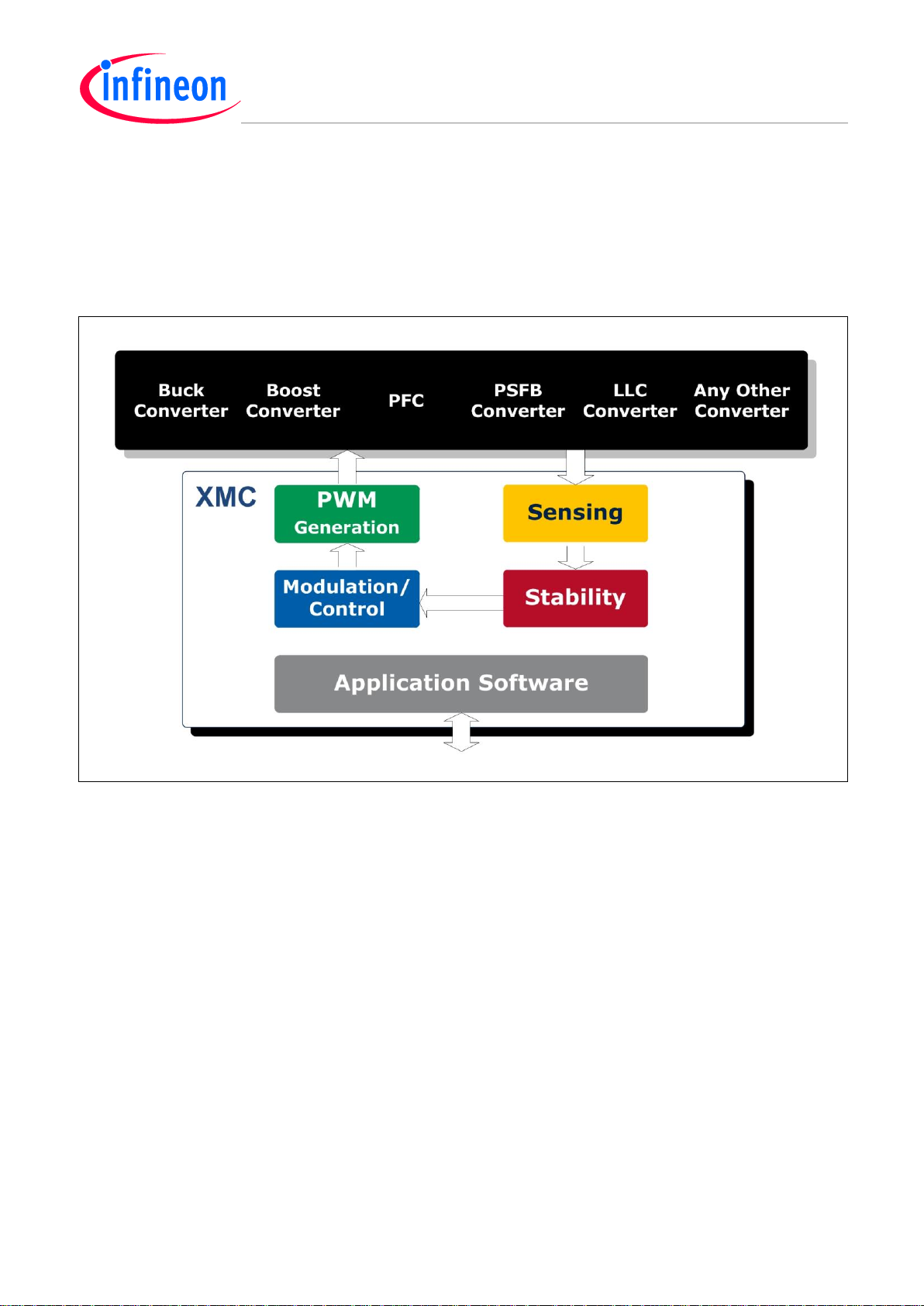

The Infineon XMC power conversion oriented devices offer flexible 3-level control architectures, for

sense-compute-modulate-and-drive of any power converter topology.

Advanced analog and digital peripherals interact on events in real-time via a hardware matrix,

supported by DMA, Software, DSP (Digital Signal Processing) or over a network.

Figure 4 The Power Conversion Oriented XMC Devices 3-Level Architecture Control Loop

The XMC series for power control meets the performance challenges and demands of today’s

embedded control applications. The high performance, real-time capability is achieved with an ARMCortex architecture, with or without DSP, and a Floating Point Unit (FPU).

Application Guide 13 V1.0, 2015-01

Page 14

Introduction to Digital Power Conversion

XMC4000/1000 Family

Comparison of Power Conversion Methods

2.4.1 Power Conversion Oriented Peripheral Features

Here we highlight features of the XMC-family embedded peripherals that are essential for the

significant tasks required in power conversion control loops.

2.4.1.1 Sensing

Analog values are monitored, or detected upon crossing level limits, via Versatile Analog-to-Digital

Converter (VADC) channels (featuring fast compare mode), or by Analog Comparator (ACMP/CSG).

These units are interconnected with events via hardware action providers, or softwre routines via

interrupts.

The functionality of the ADCs includes:

Automatic scheduling of complex conversion sequences with priority for time-critical conversions

Synchronous sampling of up to 4 signals / Independent result registers, selectable for 8/10/12 bits

Sampling rates up to 2MHz / Flexible data rate reduction / FIR/IIR filter with selectable coefficients

Adjustable conversion speed and sampling timing

4 independent converters with up to 8 inputs w/ channel wise selectable reference voltage source

2.4.1.2 Stability and Software

An important property of conversion control loops is the frequency response of the duty-cycle-tooutput-voltage transfer function. Stabilization is provided via softwre actions in the open loop gain

paths, using DSP operations on discrete time variables, maintained by sampling at rates triggered by

a CCU (Capture and Compare Unit).

2.4.1.3 Modulation

The steady state duty-cycle-to-output-voltage transfer function is controlled by sense-modulate-drive

algorithms in hardware, with some optional add -on attributes, including (but not limited to):

Fixed-Frequency (FF)

Fixed-On-Time (FOT)

Fixed-Off-Time (FOFFT)

Conduction Mode Switching

Comparator & Slope Generation (CSG)

Blanking

Clamping

Filtering

XMC modulation modes

Voltage Mode Control (VC)

Average Current Mode Control (ACC)

Peak Current Mode Control (PCC)

Valley Current Mode Control (VCC)

Zero Crossing Detection Mode (ZCD)

The XMC peripherals handle modulation dynamically, with mode-switch on changed conditions in runtime (on load variation for example). A set of resources can be exchanged “on-the-fly” by a Mode-Bit.

Application Guide 14 V1.0, 2015-01

Page 15

Introduction to Digital Power Conversion

XMC4000/1000 Family

Comparison of Power Conversion Methods

2.4.1.4 PWM Generation

The XMC CAPCOM Units (CCU4 or CCU8) timer slices can be regarded as “timer-cells” that can

cooperate and fit together like “puzzle pieces” to form matrices of sophisticated and compound timing

functions. These can interact for certain function request events and event profile conditions.

Theoretically, any on-chip module can be considered to act on a slice via one of (up to 3) inputs. A

flexible library of modular timing control applications (PWM “Apps”) can be created and then be

reused across projects.

The XMC single and multi-channel PWM drive capabilities include:

Global Synchronization

− to ensure a fully synchronized start with any combination of CAPCOM units

PWM

− by Symmetric / Asymmetric Modulation (Edge-Aligned or Center-Aligned)

− with Active / Passive Output Level Control / Trap Handling Protocol in hardware

− with Dithering (4 bits)

− by Status Events (by Compare or Period-Control)

− by external Set/Clear (by various conditional Start/Stop functions, which can be combined with

Status Events)

− by Matrix Interactions (on specific function request events and event profile conditions)

Examples

Peak, Valley or Hysteretic On-Off PWM

Fixed-On-TIme (FOT) PWM

Fixed-Off-TIme (FOFFT) PWM

Phase-Shift / Fixed Phase-Shift (Interleave) PWM

Half Bridge (HB) control with optional Synchronous-Rectification (SR)

Full Bridge (FB) control (w/ SR)

HB / FB Drive of LLC Resonance Converters

HRPWM Attributes

High Resolution Control (HRC) Insertion – down to 150 ps accuracy:

- HRC can handle switch frequencies up to 5 MHz with 10 bit resolution PWM

- Highly Accurate Low-Load Scenario Control

- Converter Efficiency Improvement: Each HRC can operate with two set of resources

Dead Time Insertion, with “On-the-Fly” optimization during run-time.

Application Guide 15 V1.0, 2015-01

Page 16

Introduction to Digital Power Conversion

XMC4000/1000 Family

Converter Topologies

3 Converter Topologies

The fundamental power converter topologies that we focus on in this document are:

Buck (“Step-Down”) (Section 3.1)

− Conventional

− Interleaved

− Synchronous

− Inverted

Boost (“Step-Up”) (Section 3.2)

− Conventional

− Interleaved

− Synchronous

− Inverted (Buck-Boost)

PFC (”Power-Factor-Correction” (Section 3.3)

− Conventional Boost PFC

− Interleaved Boost PFC

− Bridgeless Boost PFC

− Totem-Pole Bridgeless PFC

PSFB (“Phase-Shift-Full-Bridge”) (Section 3.4)

− (Principle Scheme)

LLC (”L-L-C-resonant”) (Section 3.5)

− (Principle Scheme)

The Generic Digital Power Converter (Section 3.6)

Application Guide 16 V1.0, 2015-01

Page 17

Introduction to Digital Power Conversion

XMC4000/1000 Family

Converter Topologies

3.1 Buck

A Buck converter can only generate lower output average voltage (V

) than the input voltage (VIN),

OUT

and is therefore also referred to as a “Step-Down” converter.

The DC/DC conversion is non-isolating, in the sense that there is a common ground between input

and output. Some improved versions exist:

Figure 5 Buck

Interleaved Buck Converter

When reduced ripple and smaller components are required, especially in high-voltage applications,

then a realistic approach is to interleave the output currents from a multiphase Buck converter stage.

For example a 2-phase Buck converter controlled by fixed 180o phase-shifted PWM from an XMC

CCU4/8

Synchronous Buck Converter

When reduced power conversion loss is required, the rectifying diode D may be replaced by an active

switch that can offer a lower voltage drop. In such a solution the rectification will be synchronously

invoked by a signal that is complementary to the control signal, from a CC8 timer or CC4 timer pair.

Inverted Buck Converter

When a simplified current measurement is required, then an Inverted Buck controller is an alternative,

assuming common ground between input and output voltage is not necessary. By sensing the voltage

over a resistor (R) to ground, the inductor current (IL) can be monitored by a VADC or ACMP.

Application Guide 17 V1.0, 2015-01

Page 18

Introduction to Digital Power Conversion

XMC4000/1000 Family

Converter Topologies

3.2 Boost

A Boost converter is non-isolating and can only generate a higher output average voltage than the

input supply voltage. It is therefore called a “Step-Up” converter.

There is one exception to note however. The Inverted Buck-Boost converter theoretically generates

an output voltage from 0 to minus infinity.

Figure 6 Boost

Interleaved Boost Converter

Similar to the Buck converter, i.e. the ripple will be reduced and smaller components can be used, by

having interleaved output currents from a multiphase Boost converter stage – here by a 2-phase

Boost converter that is controlled by fixed 180o phase-shifted PWM from an XMC CCU4/-8.

Synchronous Boost Converter

A synchronous Boost works similar to a synchronous Buck – however, this variant of improvement is

not often used, since reduced power conversion loss by replacing the rectifying diode D by an active

switch is not very significant in the high voltage range – where this topology more frequently appears.

Application Guide 18 V1.0, 2015-01

Page 19

Introduction to Digital Power Conversion

XMC4000/1000 Family

Converter Topologies

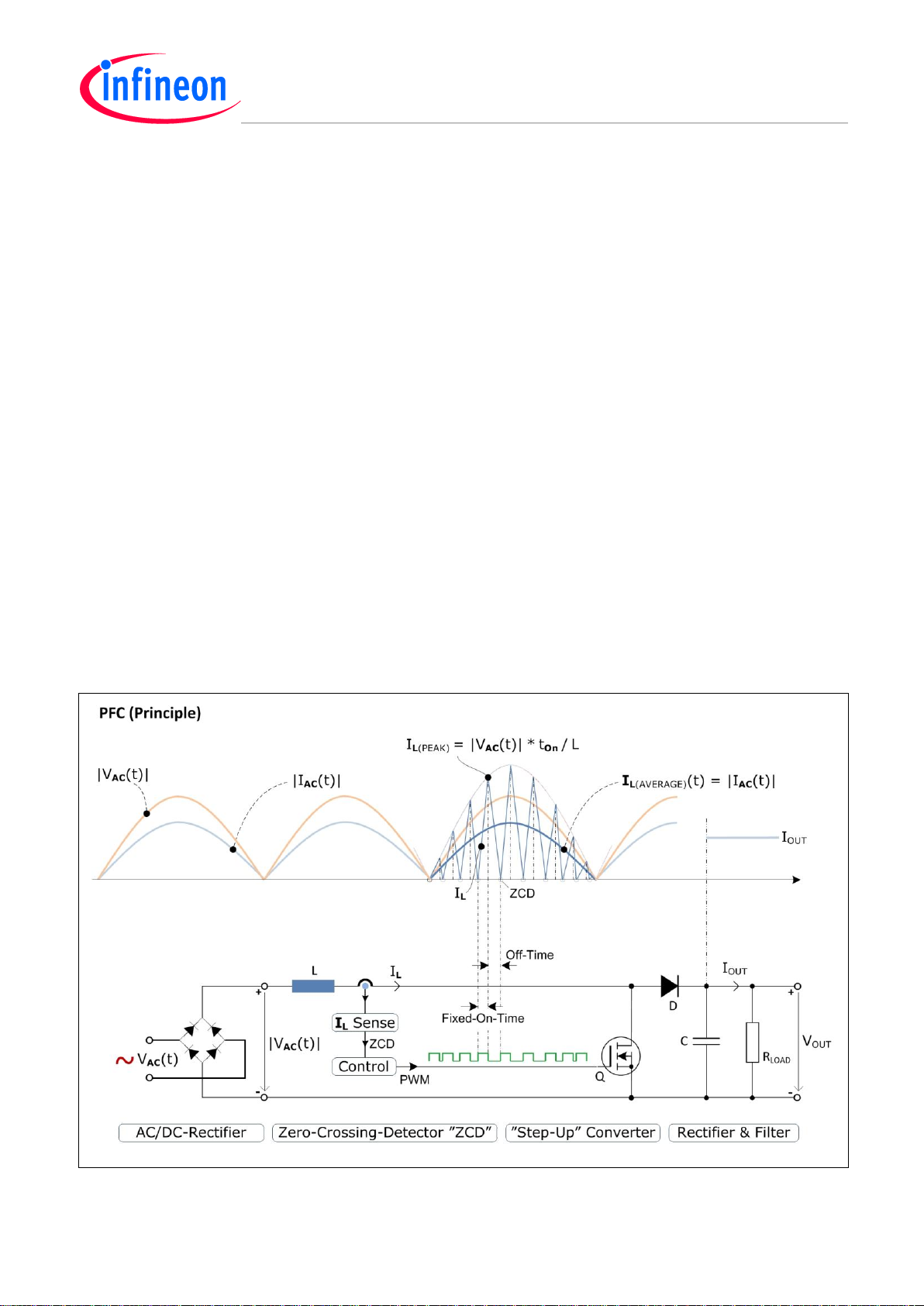

3.3 PFC

Abstract

The Power Factor (PF) is defined as the transfer ratio of real power [Watt] to apparent power [VA]:

PF = Real Power / Apparent Power [Watt / VA]

The Power-Factor-Correction (PFC) purpose is (according to the environmental context) to achieve:

Real Power = Apparent Power

i.e.:

PF = 1

PFC Rectifier

A PFC rectifier accomplishes “PF = 1” by phase correct rectification of the mains AC voltage – so that

the current conduction angle becomes fully 180o in both half periods – phase correct to the mains AC

voltage – i.e. without any parasitic or reactive signal components reflected back into the mains lines:

See Figure 7.

In principle, the mains is rectified into a sinusoidal half-wave rippling DC voltage. In turn it is converted

to a ripple-free DC output voltage by a Boost PFC – e.g. by Fixed-On-Time inductor current (IL) mode

control. (Each Off-Time interval lasts till the current (IL) falls back to Zero-Crossing-Detection, ZCD.)

Since all tOn pulses are fixed, the I

L(PEAK)

and I

L(AVERAGE)

envelopes will follow the |VAC(t)| in proportion.

Figure 7 Boost Power-Factor-Correction (PFC) – E.g. in Fixed On-Time Current Mode Control

Application Guide 19 V1.0, 2015-01

Page 20

Introduction to Digital Power Conversion

XMC4000/1000 Family

Converter Topologies

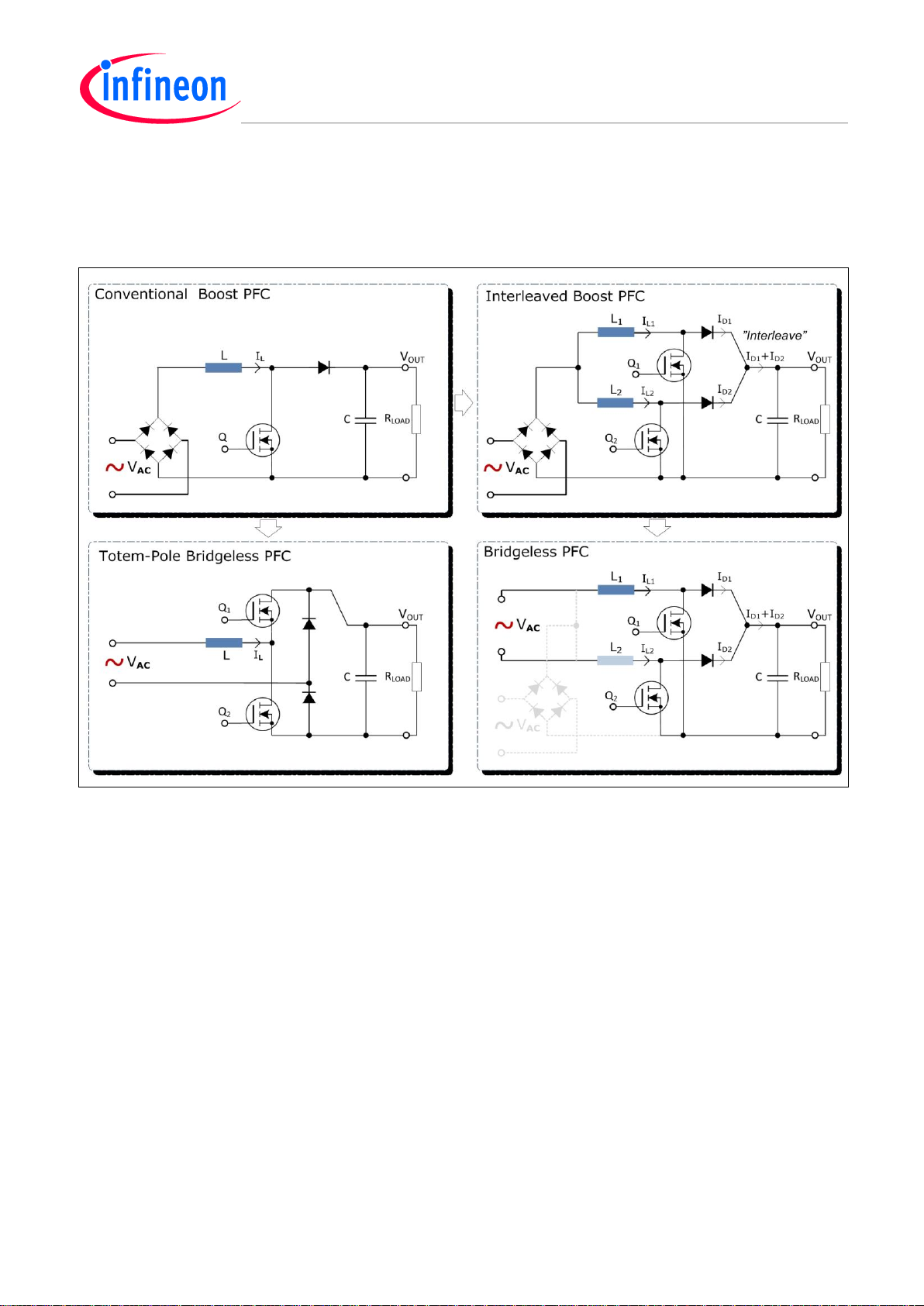

PFC Variants

There are different types of PFC circuits, which mix a balance of complexity versus performance.

Here we show just some of the basic topologies. These can be mixed into more sophisticated, multiphased, interleaved, full-bridgeless PFCs by Synchronous rectification.

Figure 8 PFC Types such as – Conventional – Bridge Interleave – Bridgeless – Totem pole

PFC Performance

High Power Factor (PF) and low Total Harmonic Distortion (THD) are directly related, so the basic

circuits can be listed in performance order, as follows:

Conventional Boost PFC

− Low cost BOM solution.

Interleaved Boost PFC (High Power)

− Even though there still is a diode bridge, the continuous interleaved current offers the advantage

of using smaller components.

Bridgeless/Totem-Pole Bridgeless PFC (High Power)

− The diode bridge is replaced by a MOSFET semi-bridge / half-bridge Totem-Pole rectifier.

Bridgeless Interleaved PFC (High power)

− (Not shown) Enables use of successive expansion of multi-phase bridgeless interleaved boost

PFC.

Application Guide 20 V1.0, 2015-01

Page 21

Introduction to Digital Power Conversion

XMC4000/1000 Family

Converter Topologies

3.4 Phase-Shift Full-Bridge (PSFB)

The PSFB is a Phase-Shift-Full-Bridge DC/DC converter. Power is transferred in a Phase-Shift (PS)

via a Full-Bridge (FB), a transformer, a rectifier and filter. The PSFB is an isolating converter.

Figure 9 PSFB Principle

PSFB power conversion stages

Stage one

− Split the DC rail input voltage (V

) into two Phase-Shifted pulse streams (PhA , PhB) according

IN

to the Full-Bridge control signals.

Stage two

− A transformer, which is fed onto its primary coil (n

) with the phase difference voltage (PhA ,

p

PhB). This difference voltage will be transformed with a ratio (ns : np) to two secondary coils (ns ,

ns).

Stage three

− A “step-down” converter configuration with two diodes (D

positive levels of the two secondary voltages respectively into a PWM pulse stream. These

PWM pulses have a duty cycle that corresponds to the phase shift |Ph

, DB) that rectify and interleave the

A

o

Ao – PhB

|, and will be

filtered via the inductor (L) into the output capacitor (C), and result as an output voltage (V

− The PSFB total voltage conversion ratio (V

ratio (ns : np) times the phase-shift |Ph

Ao – PhB

/ VIN) is proportional to the transformer winding-

OUT

o

|:

V

/ VIN = (ns : np) * |Ph

OUT

Ao – PhB

o

| / 180

o

OUT

).

Application Guide 21 V1.0, 2015-01

Page 22

Introduction to Digital Power Conversion

XMC4000/1000 Family

Converter Topologies

3.5 LLC (Inductor-Inductor-Capacitor)

The LLC converter is a series resonant converter. Power is transferred in a sinusoidal manner, so the

switching devices are softly commutated by ZVS (Zero-Voltage-Switching) and without capacitive

loss. A transformer takes part in the process, making the LLC an isolating converter.

Figure 10 LLC Principle – Using Half-Bridge Control

Performance

A resonant converter enables high voltage and faster switching, which allows for smaller components

thanks to the reduced switching losses.

An LLC converter, with two inductors (Lr ,Lm) and a capacitor (Cr), is superior to all other types of

resonant converters, especially with respect to a wide load range.

Properties

The LLC inductor Lm shunts the transformer primary coil when the impedance becomes infinite:

If there is no diode current, the resonant tank will become “(L

If there is diode current, the tank is “L

“. Therefore open load can be handled. The power

rCr

r +Lm)Cr

“

transfer is tuned by frequency or PWM.

Application Guide 22 V1.0, 2015-01

Page 23

Introduction to Digital Power Conversion

XMC4000/1000 Family

Converter Topologies

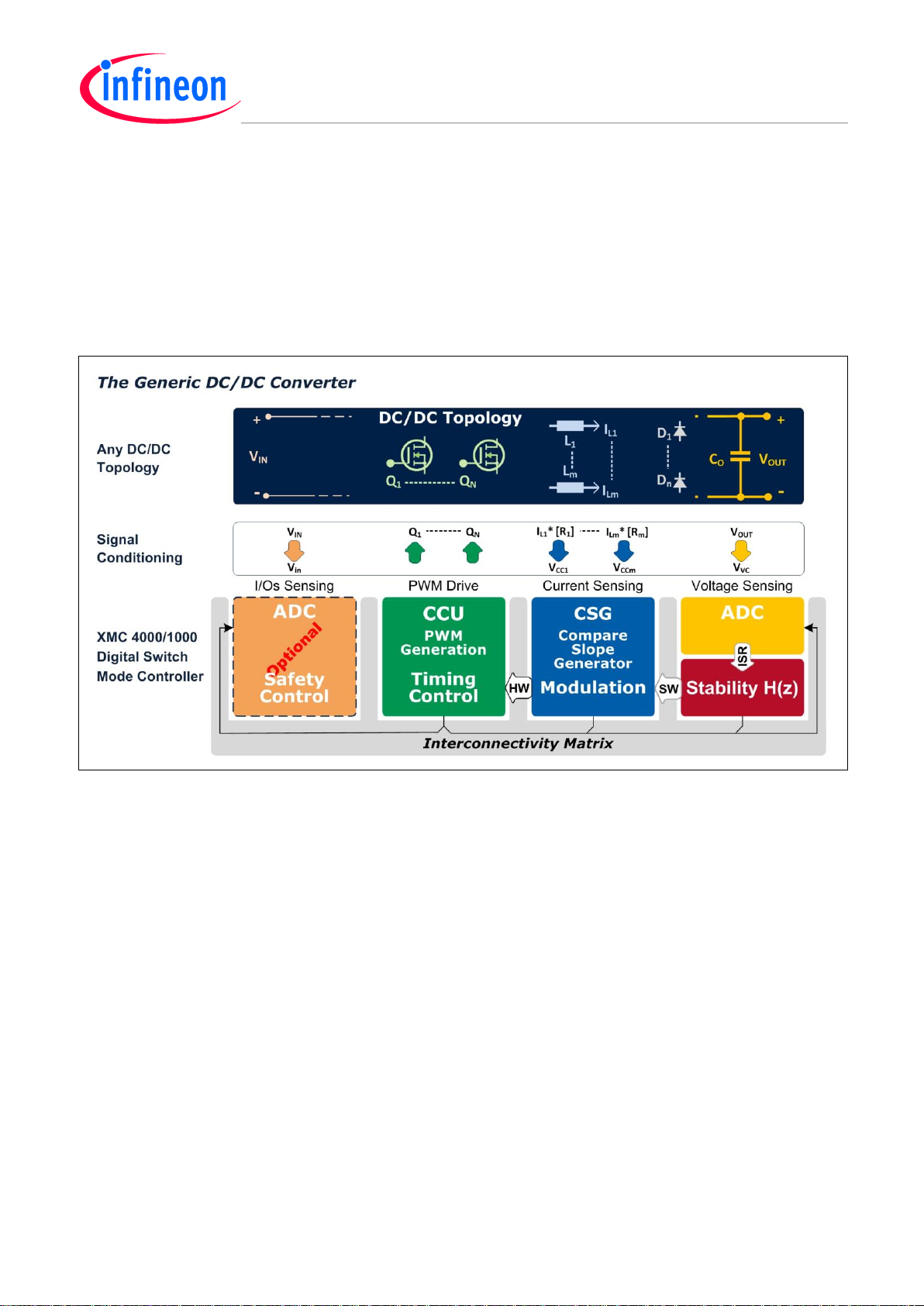

3.6 Generic Digital Power Converter

There is a mutual property of all DC/DC power converters: Energy from an input power source is

periodically stored as magnetic energy in the air-gap of inductors (L), and converted into certain

output power voltage-current pairs via some rectifier-and-capacitor (C) filter configuration.

Because of this property, the essential components and control loops for Switch Mode DC/DC power

converters can be described by a “Generic DC/DC Converter” that is representative for all topologies

of this type.

Figure 11 The Generic Switch Mode DC/DC Converter.

Key Attributes

Generic hardware protocol

Flexible Drive and Sense Interfaces for Feed-Back Loop Control of Voltage and Current Transfers

Modular Loop Control by Event Interconnection Paths between XMC Embedded Unit Functions

Global Start and Synchronization Features

Application Guide 23 V1.0, 2015-01

Page 24

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4 PWM Generation

4.1 Single Channel

The PWM duty cycle range is 0 – 100% for all available combinations of alignments, count and

in/output modes.

Status bit ST can be set to 1 or 0 by timer compare or period events, or by external events (even if

stopped timer).

An output can be set active high or low (and with Dead-Time in CC8).

Figure 12 PWM – Single Channel

4.2 Single Channel with Complementary Outputs

A single channel (Ch1/-2) of a CC8y timer slice can output a complementary PWM signal pair in any

alignment mode. It may include Dead-Time Insertion of individual rise-/fall times, as well as accurate

active level settings for 1 or 2 half-bridges. The Trap input coordinates shut-down in correct real-time.

Figure 13 PWM – Single Channel Half-Bridge Drive

Application Guide 24 V1.0, 2015-01

Page 25

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.3 Dual Channel with Complementary Outputs with Dead-Time, using CCU8

By using both channels (Ch1 and Ch2) in a CC8y timer slice, it is possible to output a dual pair of

complementary PWM signals to target 1 or 2 full-bridges.

Dead-Time insertion of individual rise-/fall times can be provided independently, as well as accurate

output active level settings and trap care.

Figure 14 PWM – Dual Channel Full-Bridge Drive

4.4 Dual Channel with Complementary Outputs with Dead-Time, using CCU4

A ‘sea’ of individual ‘timer-cells’

The timer slices of all CCUs can be regarded as a ‘sea’ of individual ‘timer-cells’ that are

interconnectable to act upon each other’s event requests, and accomplish dedicated and compound

timing functions.

Event sources and function commands are easily mapped by registers: CC4(8)yINS and

CC4(8)yCMC.

A typical example is a CCU4 Full-Bridge drive with complementary outputs and individual Deadtimes

(see Figure 15).

PWM with Complementary Outputs by Using CCU4 Single-Shot Timers

A complementary PWM output pair can be built from two timer slices (e.g. CC40 and CC41) in singleshot mode. The timers run, one at a time so that when one timer stops after its single-shot, it starts

the other timer with an event request Input Function ‘Start’. This can be mapped via interconnect

settings.

PWM with Dual Complementary Outputs by Using Synchronized Single-Shot Timer Pairs

When adding the other two timer slices of a CCU4 (e.g. CC42 and CC43), Full-Bridge control is

possible. Dead-Time insertion can be added and the ‘channel 1’ and ‘channel 2’ (CC40/41 and

CC42/43) can be synchronized with a Global Start.

PWM with Complementary Outputs Including Dead-Time Insertions

By using a preset compare register to shorten the output width of each single-shot, it is possible to get

individual deadtimes for different switch delays, and enable a Full-Bridge drive capability with a

CCU4.

Note: The pulse width modulating role is performed by period registers – not by compare registers.

Application Guide 25 V1.0, 2015-01

Page 26

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

PWM Duty-Cycle Control by Period Register

PWM modulation (with fixed cycle period target option) is achieved by adding a ∆PR-value and

respectively substracting the same ∆PR-value to the period registers of the PWM channel single-shot

timer pair. Updates are via period shadow registers, by compare-ISR, and are set on shadow

transfers.

Figure 15 PWM – Dual Channel / Complementary Outputs w/ Individual Deadtime

PWM Phase-Shift Control by External Start of Single-Shot Timer Pairs

The coherent update mechanism via shadow transfers can be used to control a certain Phase-Shift

magnitude between the two slice-pairs, in this instance CC40/41 and CC42/43 respectively.

A good example, using just a CCU4 in this concept, is Fixed Phase-Shift Control with Zero-Voltage

Switching (ZVS) (See Figure 27).

Application Guide 26 V1.0, 2015-01

Page 27

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.5 ON/OFF Control

Since all the individual ‘timer-cells’ of a CCU can be mapped to act upon virtually any external event

and function request, then theoretically any on-chip module can be considered to control a PWM. For

example, an ADC or comparators can join in the PWM control loops in this way, acting on analog

events. With such configurations, variable frequency and/or PWM pattern control is easily

accomplished.

Figure 16 PWM On/Off Control by External Events

4.6 Fixed ON-Time (FOT)

Fixed-On-Time (FOT) PWM has two essential properties:

1. The FOT Pulse Width is generated by a fixed active output state of a timer, by single-shot mode

for example.

2. The FOT Pulse Rate is controlled by external events; i.e. the timer does not decide pulse density.

Duty-cycle should be monitored for example, to enable feed-back control in the start-up phase.

Figure 17 PWM with Fixed-On-Time (FOT)

Use Case

FOT can be used in a PFC with inductor current ZCD in the control loop (See Figure 18).

Application Guide 27 V1.0, 2015-01

Page 28

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.7 Fixed ON-Time with Frequency Limit Control

In power switch control with FOT PWM, it is mandatory to have pulse rate limiting add-ons in the loop,

ensuring a minimum of off-time to be fed back by the conversion process in each FOT start request.

Another extreme is maximum off-time.

Both extremes will require ‘f

timer’ add-ons in the loop.

max–min

Figure 18 FOT Control with Frequency Limits Supervision

The FOT Timer (Slice1)

Assume that this single-shot FOT timer works in a CRM or DCM mode PFC controller. In each switch

cycle the timer waits for a start request in the control loop, after a certain off-time. Then it will switch

on the inductor current for a fixed time, to rise from zero again, on any of the following conditions:

ZCD AND f

An early ZCD event AND before expired f

f

Application Guide 28 V1.0, 2015-01

-period expires AND there was no ZCD event in the meantime // DCM, FOT at ‘Time-Out’

min

-period is due // CRM, FOT density OK

max

-period // DCM, FOT pulse delayed

max

Page 29

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

The ZCD Event Window (Slice3)

There is a memory function required to keep track of a ZCD event that might happen before a FOT

pulse is allowed to start, due to the f

Instead of using an ERU, a timer slice (Slice3) can be used to define an ‘allow’ window by ‘Start-uponZCD and Stop&Flush upon falling FOT’.

-period restriction.

max

Figure 19 Interconnectivity between CCU4 slices for PWM FOT Control with Frequency Limits

Application Guide 29 V1.0, 2015-01

Page 30

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

Monitoring the FOT pulse rate

The FOT pulse rate is monitored by the free running f

each FOT timer start.

If the next ZCD event occurs before the f

because of f

-period. If no ZCD occurs, then the FOT-start has to wait for the timeout.

max

The FOT timer will start on the falling edge of the f

-period compare event, then the next FOT start must wait

max

max–min

There can be any of three different event flow scenarios behind a FOT pulse start, depending on

whether the ZCD-event occurs after or before the ZCD, or if there is no ZCD at all, in relation to the

f

-period compare event (here named CMP-event).

max

All event flow scenarios will terminate by an end-of-FOT event, alias EOF-event.

Notes:

1. For readability, all redundant actions in the event flows described here have been removed.

2. All event flow scenarios will begin and end with the status bit of all timers = 0; i.e. ST0=0, ST1=0, ST2=0,

ST3=0.

3. = “consequently the successive event will follow”.

4. // = “a parallel (synchronous) event flow, connected to the root event”.

5. STn=STm means “Status-bit Override; i.e. status bit STn is copied with status bit STm”.

6. # = “inverted value of”.

timer (Slice2). This timer is flushed on

max–min

timer status.

CRM Mode: Event Flow ‘after’

i.e. ZCD-event > CMP-event

1. CMP-event: ST2=1

2. ZCD-event: ST1=ST2 ( FOT) flush-Slice2 ST2=0 start-Slice1

3. EOF-event: ST1=0

DCM Mode: Event Flow ‘before’

i.e. ZCD-event < CMP-event

1. ZCD-event: Start-Slice0 // Start-Slice3 ST3=1 (delayed 1 clk by compare)

2. CMP-event: ST2=1 capture-Slice0 ST0=1 ST2=#ST3 start-Slice1 ST1=1 (

FOT) (flush-Slice2 + stop&flush-Slice0)

3. EOF-event: ST1=0 stop&flush-Slice3 ST3=0

Event Flow “No ZCD”

No ZCD at all until due f

-period = Timeout at Slice2 Period-Match

min

1. CMP-event: ST2=1

2. Timeout: ST2=0 Start-Slice1 ST1=1 ( FOT) flush-Slice2

3. EOF-event: ST1=0

The Auxiliary Timer (Slice0). Monitoring the DCM Window

This timer is essential for the status bit-override “ST2=#ST3” operation specifically, since there is no

direct “ST2=1 ST2=#ST3” event interconnectivity path; i.e. a slice cannot event request itself.

Optionally, Slice0 will work as a DCM window monitor.

Application Guide 30 V1.0, 2015-01

Page 31

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.8 Fixed Off-Time (FOFFT)

In Fixed Off-Time switch mode, each PWM On-Time pulse is variable and terminated when the

inductor current slope hits the peak-current detection level.

On each of these events the current slope will fall, with a fixed Off-time, before next pulse, controlled

by a timer. This could be the PWM timer itself for example.

FOFFT by Load Timer Function – How it works

The load-timer mode is an alternative way of creating a fixed Off-time interval.

The compare register value is copied into the timer register by a load-timer request on a peak

detection event.

From this event, until period match, the rest of the timer cycle is a fixed time (period value minus

compare value).

FOFFT mode with On-Time Limitation

The advantage of using the load-timer mode solution in Fixed Off-Time PWM generation, is that an

optional On-Time limitation is left “for free”, to be an add-on feature in the extension; i.e. a compare

event will come and terminate the On-Time even if a load-timer request does not appear.

FOFFT with Blanking

To avoid inaccurate peak current detections due to noise from the power switches, blanking time

zones should be invoked, during which all detection events by the analog comparator should be

rejected.

Blanking should be synchronized to the start event of each PWM cycle (See section 6.4).

Figure 20 PWM with Fixed-Off-Time (FOFFT)

Application Guide 31 V1.0, 2015-01

Page 32

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.9 Phase Shift Control

There are two types:

Fixed Phase Shift (180

Variable Phase Shift

o

, 120o, 90o, and so on)

Fixed Phase Shift

This is used for interleave applications with multi-phase converters. The interleave function has the

benefit of overlapping discontinuities in the current path, reducing ripple and therefore allowing for

higher frequency and smaller components. EMC quality is also improved.

Variable Phase Shift

This is used for DC/DC conversion applications, and for energy transfer adaption and isolation, by

using a transformer in the path. The changes in the phase-shift modify the power transfer from

primary to secondary.

4.10 Fixed Phase-Shift

4.10.1 Center Aligned Mode

Dual PWM channels with guaranteed 180o fixed phase-shift even during the PWM update, is provided

by a single CCU8 slice in symmetric compare mode for two PWM channel outputs: OUT01, OUT02.

Passive/Active Level:

− for OUT01 is “ACTIVE HIGH”

− for OUT02 is “ACTIVE LOW”

Figure 21 Fixed Phase-Shift – Using a CC8-Slice in Center Aligned Symmetric Compare Mode

Application Guide 32 V1.0, 2015-01

Page 33

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.10.2 Edge Aligned Mode

Dual PWM channels with fixed phase-shift can be provided by two CCU4 slices in edge-aligned

compare mode, representing each PWM channel by the associated output of each status bit.

There should be a Global Start and Synchronization sequence, before the system is prepared for runtime.

Figure 22 PWM – Fixed Phase-Shift in Edge Aligned Mode for Interleave

Start-up sequence

During the start-up phase the duty-cycle of CC40 is set to 0 by pre-setting a high compare level,

exceeding the period register value pre-set, which implies no PWM generation during the start-up. A

similar situation prevents the CC41 from generating a PWM stream too early.

Fixed Phase-Shift with Different Duty-Cycles

There is no negative effect, but there can be a benefit, to using fixed phase-shift in edge aligned

mode with different duty-cycles, especially in split converters using a mutual controller. The split in

time will mean that the EMC qualities will be better.

Application Guide 33 V1.0, 2015-01

Page 34

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.10.3 Interleave

The Interleave approach offers reduced current ripple and a continuous current flow into the rectifier

and filter output stage of the converter. A higher frequency and smaller components can be used.

This concept is often used in high power, high voltage (e.g. PFC) and/or ZVS quasi-resonant

converters.

Figure 23 PWM – Interleave – Fixed Phase-Shift – (Modulation 50%)

Application Guide 34 V1.0, 2015-01

Page 35

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.11 Variable Phase-Shift

A Phase-Shift Full-Bridge (PSFB) offers the benefits of using a transformer in the DC/DC conversion

path, for level adaption or isolation.

The phase-shift of two PWM signals to the bridge control inputs converts the bridge DC rail voltage

proportionally to a transformable AC-voltage, with a defined ratio (See also Figure 9).

The target DC output voltage is rectified and LC-filtered after the secondary coils of the transformer.

PWM Phase-Shift by Master-Slave Timer Configuration

The PSFB phase-shift control signal-pair should be generated by one master timer that can guarantee

a fixed PWM pulse rate, and one slave timer in single-shot mode for the phase-shifted PWM pulses,

which should be controlled by the master timer as follows:

CC80-Channel1 controls the phase-shift by variable compare events that starts the slave PWM

cycle as single shots

CC80-Channel2 compare events generate the free-running master PWM

Other setups might cause issues on big phase-shifts.

Note:

1. The suggested timer configuration allows for the highest possible phase-shift dynamic (-180o to +180o).

However, in most practical power conversion use cases with PSFB, 180o dynamic range is enough.

2. It is possible to vary the Duty-Cycles of each signal in the PWM phase-shift pair to any extent (Not shown

here).

Figure 24 PWM – Variable Phase-Shift by Master-Slave Timer Configuration

Application Guide 35 V1.0, 2015-01

Page 36

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

PWM Phase-Shift Master-Slave Principle

A CC8-slice (e.g. CC80) and its two compare channels can be used as a master for the PSFB control

as follows:

Channel1

− The CC80CR1 compare events control the phase-shift of the PWM pulse stream (S) from a

slave timer (e.g. CC81), by requesting one single-shot PWM pulse upon each compare event.

Channel2

− The CC80CR2 compare events generate the fixed PWM pulse stream (M).

Figure 25 PWM – Variable Phase-Shift Master-Slave Principle in Detail

Application Guide 36 V1.0, 2015-01

Page 37

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.11.1 Power Conversion Control Example

The PSFB controller performs DC/DC power conversion in stages:

1. Split the DC input voltage (VIN) in to two phase-shifted pulse streams (PhA and PhB), controlled by

a PWM Phase-Shift-Master-Slave configuration with the CCU8 slice pair CC80/-81 (See also

Figure 24).

2. Invoke a transformer, which offers an isolating path for the voltage difference PhA minus PhB, on its

primary coil, over to the next stage, via two complementary secondary coils.

3. A “step-down” converter configuration is used, with synchronous rectification with the switch-pair

(Q3, Q4), as an efficient replacement for diodes by offering lower voltage drop.

− The switch-pair (Q

voltages from the transformer into a PWM pulse stream. The PWM will get a duty cycle that is

proportional to the phase shift |Ph

− The inductor (L) and the output capacitor (C

, Q4) rectifies and interleaves the positive levels of the two secondary

3

o

– Ph

A

o

|.

B

) serve as an LP-filter for the output voltage (V

O

OUT

).

Figure 26 PWM – Variable Phase-Shift Control – Example Using Synchronous Rectification

There is a fast Current Mode Control loop, sensed by a Fast Compare VADC channel, via a stage ‘R’

acting as trans-resistance, and there is a slow Voltage Mode Control loop via another VADC channel.

The MOSFETs require some kind of isolating driver stage (e.g. opto-couplers).

Application Guide 37 V1.0, 2015-01

Page 38

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.11.2 Zero-Voltage Switching (ZVS) Control

ZVS implies nearly lossless transitions. In combination with smooth zero crossing by resonance

components, an almost ideal switching process is achievable. This effect can be made by controlling

the free-wheeling currents and using the parasitic stray reactive elements (See also Figure 27).

Instead of using a traditional, combined control of the diagonal switches, there are individual delays

implemented to focus the ZVS spots to occur in appropriate time, and to keep the free-wheeling

current polarity unchanged.

Free-wheeling Current Control by Active Clamp

When the upper (or the lower) switches are conducting simultaneously, due to the phase shift, the

transformer and the free-wheeling inductive current path is short circuited to the upper (or lower) input

voltage rail.

The time-constant (‘L/R’) almost reaches infinity with this current on-holding active clamp.

ZVS Control

During the delay, in front of each turn-on event, the switch remains off and is clamped to a zero

voltage drop by the resonance effect.

The switch is held off while the free-wheeling current circulates via a body diode and the opposite leg

switch, still on. The inductive energy has to last for this though.

Figure 27 PWM – Phase-Shift-Full-Bridge (PSFB) with Zero-Voltage Switching (ZVS)

Application Guide 38 V1.0, 2015-01

Page 39

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.12 Adding High Resolution Channel (HRC) – HRPWM

There are devices in the XMC family series offering High Resolution Channel (HRC) Generation.

The High Resolution PWM (HRPWM) can be used with the CC8 slices and the CSG (Comparator and

Slope Generator). The output pins are with or without HRPWM.

Figure 28 High Resolution Channel (HRC) Add-on Principle

Properties

Each one of the High Resolution channels is capable of addressing up to 2 complementary MOSFET

switches, and Set/Clear may be mapped to different sources.

Flexible Set / Clear Switch in Runtime

Any combination of the four CC8y slices and the three CSGs units may act as the Set/Clear source

pair, with individual event profile conditions. The set/clear setup may be changed as required during

runtime.

Insertion

The enhanced PWM resolution is performed by insertion that shortens or lengthens the original pulse

width of the CCU8 slice output pulse stepwise, in lengths of 150 ps within the LSB.

Performance example: The HRPWM offers a resolution of 10-bit up to 5 MHz PWM.

Application Guide 39 V1.0, 2015-01

Page 40

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

Output

The HRPWM path offers dynamic Dead-Time Insertion and Active Output Level Selection.

4.12.1 PWM Dead-Time Compensation

The Dead-Time parameters for rise or fall-time can be independently changed, at any time, in any

mode, from one switch cycle to another. This is useful for adapting to load variations.

The XMC devices make use of this in order to maintain an optimized efficiency.

Figure 29 Dead-Time Compensation

Updating the Dead-Time

There are two methods:

1. Linked to one of the timers

2. Linked to the Dead-Time timer overflows

Source Switching (Mixed Mode)

There is switch mode-bit, by which the source setup that can be used in switching between CCM (i.e.

only timer control) and CRM (i.e. timer plus comparator), can be exchanged on demand, by request.

Application Guide 40 V1.0, 2015-01

Page 41

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.13 Half-Bridge LLC Control using ½ CCU4

LLC Converter Power Transfer by Pulse Frequency Modulation Control (PFM)

The power transfer through an LLC converter can be controlled by frequency and/or PWM. The

operating point should focus on the inductive property slope of the gain-vs-frequency characteristic

curve, where the current phase is delayed and the gain will be reduced by increasing the frequency.

LLC Converter using a pair of Inter-connected CCU4 Slices in Single-Shot Mode

Figure 30 Half-Bridge LLC Converter – Using CCU4

50% duty-cycle and center aligned modulation (referenced to the sinusoidal voltage zero-crossings)

can be achieved by two timer-cells in equal single-shot mode, interacting by alternately starting each

other.

PWM tuning may be added onto the invoked dead-times and be controlled by the compare registers.

Note: This configuration can also be made by a single CC8y slice timer (See Figure 32).

LLC Converter Power Transfer by PWM Fine-Tuning Control

PWM duty-cycle also impacts on the power transfer through an LLC converter, since the amount of

energy is cycle wise injected into the resonant tank. This enables output level fine-tuning.

Application Guide 41 V1.0, 2015-01

Page 42

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.14 Half-Bridge LLC Control - Synchronous Rectification using CCU4

A single CCU4 CAPCOM unit is capable of driving an entire LLC converter with synchronous rectifier.

Dead-time insertions are implemented in all switch commutations.

The MOSFETs in the rectifier stage offer lower voltage drop than diodes do for high currents. The

control paths to Q3,Q4 assume isolation.

Figure 31 PFM – Using Half-Bridge LLC – Synchronous Rectification

LLC Control by Matrix-Interaction Paths in the Timer Cell Pair Setup with CC40/41 and CC42/43

All four timers work in single-shot mode. The CC40/41 timer pair interacts by alternating start requests

on a period match. However the timer CC42 is acting as a slave to the timer CC40: It will start the

CC42 on a compare match. This relationship and action is the same from timer CC41 to timer CC43.

LLC Control by Frequency, Dead-Time Delays and PWM Tuning

Frequency is changed by simultaneous period register updates by hardware (via shadow transfer

requests from the software). Dead-Times are controlled individually by compare registers.

Power transfer tuning can be accomplished by add-on control of compare registers, or by shortening

the CC42/43 single-shots.

Application Guide 42 V1.0, 2015-01

Page 43

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.15 Full-Bridge LLC Control Using HRC – Synchronous Rectification

Here slices from different CAPCOM units (CCUs) interact on event control.

A CCU8 slice timer (CC80) creates Pulse-Frequency Modulation (PFM), optionally with PWM for Full-

Bridge control. CC80 is master of the synchronous rectifier (CC42/43).

Note: The slices CC42/43 in this example can be replaced by a CCU8 slice configuration.

Figure 32 Full-Bridge LLC Control w/ Synchronous Rectification – Using HRPWM

LLC Control by Frequency and Fine Tuning by HRPWM

The PFM and the PWM are simultaneously updated in the CC80-timer period and compare-registers.

Power transfer tuning is invoked by the High-Resolution Insertion (HRI) and Dead-Time Insertion

(DTI), between status-bits (CCST1/-2) and bridge inputs. Tuning is also possible with the CC42/43

periods.

Application Guide 43 V1.0, 2015-01

Page 44

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

4.16 Full-Bridge LLC Control – Synchronous Rectification Using HRC

The Full-Bridge LLC control by Pulse-Frequency-Modulated (PFM) and complementary PWM signalpairs, with individual Dead-Time Insertions, offer a tailor-made matrix of variables for an LLC

converter, including a phase adjustable synchronous rectification for alignment to the sinusoidal

current phase.

Figure 33 PWM – Full-Bridge LLC Control – Phase-Adjusted High-Resolution Rectification

Adjusting the Synchronous Rectification Phase Compliantly to the Sinusoidal Current Phase

The synchronously running timers (CC80 and CC81) may be phase-adjusted, on-the fly, in order to be

mapped optimally to the voltage switching phase and the current phase respectively. This will focus

the rectifier operation for the best efficiency, combined with the high-resolution insertion by the HRC.

Application Guide 44 V1.0, 2015-01

Page 45

Introduction to Digital Power Conversion

XMC4000/1000 Family

PWM Generation

Synchronous Rectification Phase-Shift by Using the Timer-Load Input Function

This alternative, to phase-shift a PWM, is useful here. The CC81 timer-load input function needs to be

mapped in the interconnection matrix to be requested on every CC80 One-Match event. The

CC81CR2 register is chosen as a timer load source, acting as a type of “mailbox” for every new

phase-shift (Ref.: CC8yTC.TLS register).

The phase-shift procedure, after the interconnectivity for the timer-load function is setup, is as follows:

Each new phase-shift value must be written into the CC81CR2 register (This can be done at any

time).

On every CC80 One-Match event (at valley point), the CC81 timer will be loaded with this value.

Synchronous Rectification Control with High Resolution PWM (HRPWM)

The CC81CR1 register is used in compare mode to generate the PWM stream that Set/Clear triggers

the HRCy channel to output synchronous rectification control of the MOSFET-stage (Q3 , Q4).

Application Guide 45 V1.0, 2015-01

Page 46

Introduction to Digital Power Conversion

XMC4000/1000 Family

Sensing

5 Sensing

The XMC analog input signal sensing front-end, with dedicated features for switch-mode power

control applications, covers:

VADC channels

Analog Voltage / Current measurements

Fast Compare mode features, using result compare registers and sticky Fast Compare Result

(FCR) Flags

Limit Checking / Out-of-Range Comparators (indicating Outside or Inside Valid-Band, with

Boundary Flags (BFL)

ACMP / CSG (Analog Comparator / Comparator and Slope Generator) with embedded 10-bit DAC

DSD ADC (Delta-Sigma De-modulator, Analog-to-Digital Converter)

Uses

Sensing is essential for the closed loop control of the converter transfer functions.

In the closed loop there are reference inputs values, by which the loop control gain forces error

deviations towards zero.

5.1 Analog Signal Sensing

5.1.1 Level Crossing Detection, Fast Compare mode

A VADC channel, in Fast Compare mode, may generate an interaction request via the associated

FCR flag on level crossing detection events, caused by the sensed signal. A reference result register

and two hysteresis boundary registers (0/1), define the level crossing range.

Typical Fast Compare mode use cases

Over Voltage Protection (OVP)

Over Current Protection (OCP)

Application Guide 46 V1.0, 2015-01

Page 47

Introduction to Digital Power Conversion

XMC4000/1000 Family

Sensing

Figure 34 VADC Channel in Fast Compare Mode

Fast Compare Result

The outcome from a Fast Compare event is an affected Fast Compare Result flag (FCR) associated

to the VADC channel.

The FCR flag is sticky; i.e. it keeps its status until the result reference level has been crossed again,

and untill te Outside-Band has been detected on the opposite side of the hysteresis range.

Fast Compare Performance

When using a VADC channel in Fast Compare mode for analog threshold sensing, the input voltage

is directly compared with a digital value in the result register, resulting in a single bit (above/below

comparison level).

This method is not as fast as using an analog comparator (ACMP or CSG), but would be suitable for

Low-end solutions.

Fast ADC Compare Properties

Conversion rate is 150ns.

Resolution is 10-bit.

5.1.2 PWM with Fast Compare mode Hysteretic Switching

The on/off sequences in a switch-mode power converter can be influenced by sensing the inductor

currents that ramp-up or down, according to the commutation of the switches.

In this example, an FCR influences PWM by ‘set/clear’ on ‘Out-of-Band’ crossing events.

Application Guide 47 V1.0, 2015-01

Page 48

Introduction to Digital Power Conversion

XMC4000/1000 Family

Sensing

Figure 35 Peak & Zero-Crossing Detection (PCC & ZCD) in Fast Compare Mode

5.1.3 Peak Control Using Fast Compare mode

This type of sensing is called Peak-Detection; i.e. the detection event occurs when the analog signal

has ramped-up to and crosses a defined level.

In this example,

the lower boundary(1) defines Hysteresis

the Reference is set to Peak-Detection level

the upper boundary(0) is set to the Peak-Detection level

Figure 36 Sensing for Peak Control by Boundary Flag

Application Guide 48 V1.0, 2015-01

Page 49

Introduction to Digital Power Conversion

XMC4000/1000 Family

Sensing

5.1.4 ZCD Control Using Fast Compare mode

This type of sensing is called Valley-Detection (the opposite of Peak-Detection).

In this example, the selected Valley-Detection level is Zero.

To utilize the hysteresis effectively, map:

Hysteresis to the upper boundary(0)

Reference to the lower boundary(1) close to 0(ε).

Figure 37 Sensing for ZCD Control by Boundary Flag

Note: In practical terms, the value of ‘ε’ is imagined as a very small value to cover a contingent offset

in the analog input signal, so that the lower boundary(1) detection conditions are realistic.

Application Guide 49 V1.0, 2015-01

Page 50

Introduction to Digital Power Conversion

XMC4000/1000 Family

Sensing

5.2 Over Voltage and Over Current Protection (OVP / OCP)

Limit Checking Input Signals

The Valid Band for Limit-Checking an analog input signal, has a freely programmable position and

size within the entire result range. The settings should be mapped in two boundary registers(0/1).

Out-of-Range will set a BFL, if the corresponding activation / enable flags (BFLA / BFLE) are set.

Figure 38 Out-Of-Range Comparator – Limit Checking

CCU Trap on Out-of-Range Detection (BFL) – Requires ERU

If activated (by the BFLA), the Boundary Flag (BFL) may issue a CCU Trap, if enabled.

Application Guide 50 V1.0, 2015-01

Page 51

Introduction to Digital Power Conversion

XMC4000/1000 Family

Modulation

6 Modulation

The modulation task is to maintain the steady state duty-cycle-to-output-voltage transfer function of a

sense-modulate-drive control loop in a switch-mode power converter.

Each modulation mode (course of action) meets certain required properties and frequency response

of the converter transfer function.

Modulation Mode

The following are the basic modulation modes, with various steady state duty-cycle-to-output transfer

function properties, and frequency response characteristics, which are often used in combinations to

add performance:

Voltage Control (VC) Error signal feedback High accuracy, lower cost Slow w/ CPU

Average Current Control (ACC) Error signal feedback Mid accuracy, higher cost Slow w/ CPU

Peak Current Control (PCC) Inherent feedback Low accuracy, higher cost Fast w/o CPU

Zero Crossing Detection (ZCD) Inherent feed-back Low accuracy, higher cost Fast w/o CPU

Voltage Control

Voltage Mode Control implies that the actual output voltage deviation from the desired output voltage

(i.e. an error voltage feedback) controls the voltage applied across the inductor.

Advantages

− Low noise sensitivity

− Low cost

− High resolution

− Easy feedback design

Disadvantages

− Slow response to input/output condition changes