Page 1

Application Note Please read the Important Notice and Warnings at the end of this document Revision 1.0

www.infineon.com 2016-11-01

AN_GS_201611_PL21_003

Getting Started with the XDPL8220 Reference

Board Using .dp Vision Software

XDPTMdigital power

About this document

Scope and purpose

The purpose of this document is to give a quick guide how to operate the XDPL8220 reference board of all

power classes for LED lighting applications and use the .dp Vision software to programm the operating

parameters of the digital controller XDPL8220.

Intended audience

This document is intended for anyone who wants to evaluate the XDPL8220 reference design for LED lighting.

Table of Contents

About this document....................................................................................................................... 1

Table of Contents ........................................................................................................................... 1

1 Hardware...................................................................................................................... 2

1.1 Required Hardware tools........................................................................................................................2

1.2 Hardware Connection.............................................................................................................................3

2 Software....................................................................................................................... 6

2.1 Required Software Tools.........................................................................................................................6

2.2 Software Installation............................................................................................................................... 7

3 Getting Started.............................................................................................................. 8

Revision History ............................................................................................................................13

Page 2

Application Note 2 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

1 Hardware

1.1 Required Hardware tools

The required hardware tools are listed in the following Table 1. Please order all the hardware tools under the

following links.

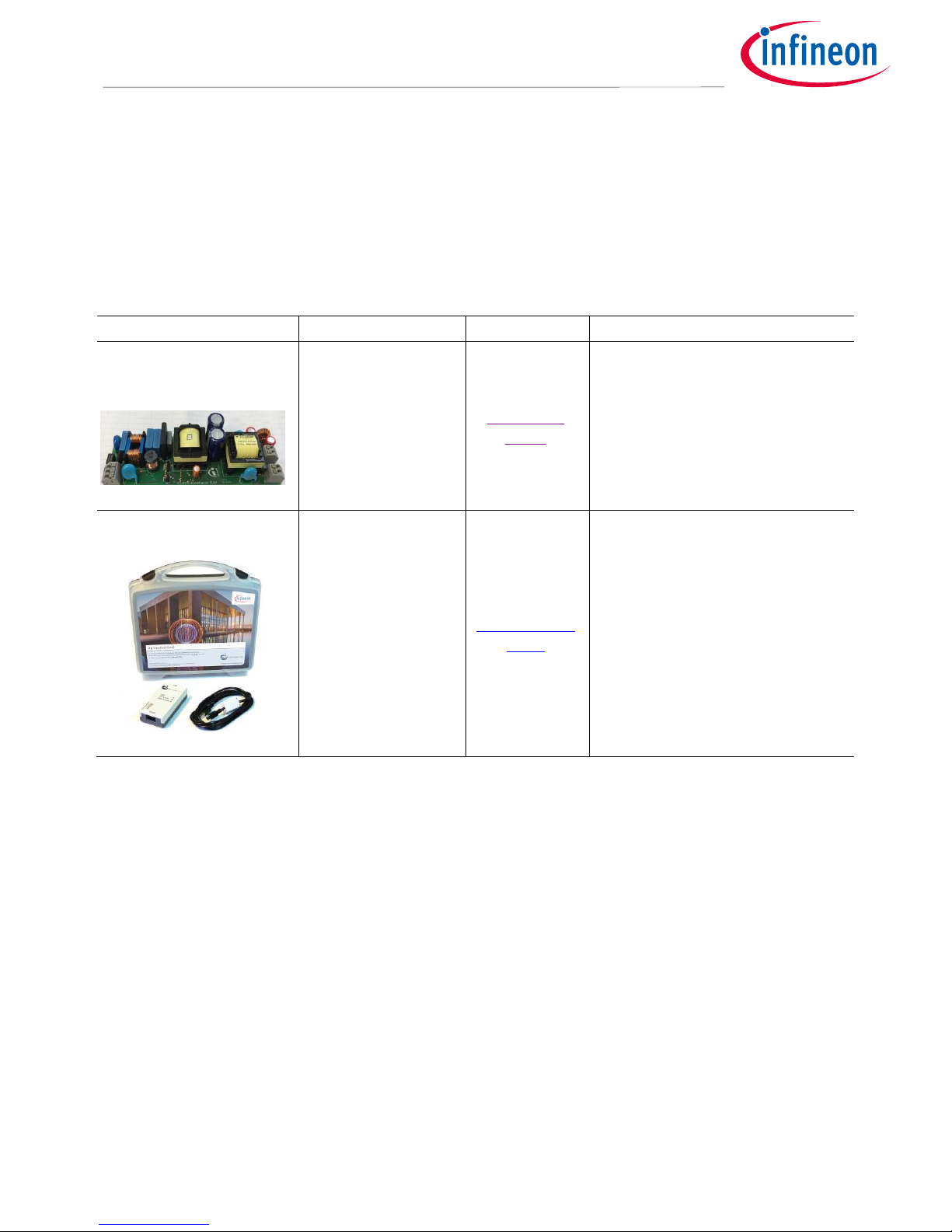

Table 1 Required Hardware Tools for Getting Started

Name Description Ordering Link Ordering Content

XDPL8220 Reference

Board

XDPL8220 reference

board for LED lighting

XDPL8220-

Demo

• XDPL8220 Reference Board

Driver for LED lighting

• Programming Cable

To connect the XDPL8220

reference board with the .dp

Interface Gen2

.dp Interface Gen2

Interface to control

XDPL8220 from

PC/Notebook

IF-BOARD.DP-

GEN2

• .dp Interface Gen2

Interface for programming the

XDPL8220 digital controller

• USB Cable

To connect the .dp Interface Gen2

with PC

Page 3

Application Note 3 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

1.2 Hardware Connection

After the required hardware tools are available, please follow the steps below to make the correct hardware

connection:

• Connect the .dp Interface Gen2 with the USB Cable to Notebook/PC

Figure 1 Connection from .dp Interface Gen2 to Notebook

Note: The detection of the .dp Interface Gen2 sometimes fails on USB3.0 ports. Therefore the use of a

USB2.0 port is recommended (which can be provided by an external USB2.0 hub if the machine

offers USB3.0 ports only).

• Connect the .dp Interface Gen2 with the Programming Cable to the XDPL8220 Reference Board

Figure 2 .dp Interface Gen2 Connection

Note: Please ensure that the connector of the Programming Cable is plugged in correctly: the red wire

indicates the Pin 1 and should be connected to the Pin Vcc on the XDPL8220 Reference Board.

USB

Cable

To

Notebook

Page 4

Application Note 4 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

Figure 3 Connection from .dp Interface Gen2 to the XDPL8220 Reference Board

• Connect the XDPL8220 Reference Board to LED load

• Optional: Connect an 0-10V analog dimmer/PWM dimming signal to the XDPL8220 Reference Board

Attention: If an analog/PWM dimmer is not connected, with the default parameters (dim-to-off

disabled, dimming curve inverted) burned in XDPL8220, the reference board will output the

minimum current. For more information, please refer to the CSV file description [3].

Figure 4 Connection from the XDPL8220 Reference Board to LED Load and Dimmer

Programming

Interface

+ Vcc

UART

GND

To LED Load

Dimming

Interface

+

ە

+

ە

Page 5

Application Note 5 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

• Connect the AC/DC power supply to the XDPL8220 Reference Board

Figure 5 Connection of AC/DC Power Supply

Attention: Please note that when the AC/DC is supplied to the XDPL8220 Reference Board before the

successful connection establishment from .dp Vision to the controller XDPL8220, the board will

operate with the already burned parameters. If the AC/DC is supplied after the successful

connection from .dp Vision to XDPL8220, the board will not operate and wait for the start

command (Test Configuration Set) from .dp Vision.

N

L

PE

AC/DC Input

Page 6

Application Note 6 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

2 Software

2.1 Required Software Tools

The required software tools are listed in the following Table 2. Please download all the software tools with the

latest version.

Table 2 Required Software Tools for Getting Started

Name Description Download Link Download Content

.dp Vision

Graphic User interface

(GUI) for programming the

parameters of the digital

controller XDPL8220

.dp Vision

• .dp Vision installer (*.msi)

XDPL8220 Parameters CSV

File

XDPL8220 parameters

configuration file which is

opened by .dp Vision

all documents

are in

XDPL8220

project addon

installer

• XDPL8220 parameters

configuration file (*.csv)

• XDPL8220 image files

(*.png)

• XDPL8220 documentation

files (datasheet [1], board

description [2] , CSV file

description [3] and design

guide [4])

• XDPL8220 System

simulation & Design

Creation Tool

• .dp Interface Gen2

Firmware

XDPL8220 Image Files

Image files which explain

XDPL8220 parameters in

the .dp Vision. They are

mandotary to open the CSV

file in the .dp Vision.

XDPL8220 Documentation

Files

Datasheet [1], XDPL8220

board description [2], CSV

file description [3] and

design guide [4].

XDP8220 System simulation &

Design Creation Tool

Simulation and design tool

which helps customers to

develop their own designs

using XDPL8220

.dp Interface Gen2 Firmware

Firmware for .dp Interface

Gen2 to connect with

XDPL8220

Note: Please make sure that the latest version of all software is downloaded or .dp Vision will show error

messages.

Page 7

Application Note 7 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

2.2 Software Installation

After the required software tools are downloaded, please follow the steps below to make the correct software

installation.

• Install first the .dp Vision software.

• After the .dp Vision is successfully installed, please install the project addon.

• After the .dp Vision and project addon are successfully installed, four sub folders are created under the “.dp

Vision” folder as shown in the following Figure 6:

Figure 6 Four Sub-folders Under .dp Vision

Note: Please use the shortcut generated on the desktop to access to these folders quickly!

• In the “Documents” folder you will find all the related documentation like datasheet, board description, CSV

file description and Design guide.

Attention: Please make sure that before getting started to operate the XDPL8220 reference board,

read the “XDPL8220 Board Description” thoroughly. A wrong operation of the reference board

could be dangerous to health and even to life!

• In the “DpIfGen2_FW” folder, the firmware of the interface board .dp Interface Gen2 is stored.

Attention: Please make sure that the firmware version of the interface board for XDPL8220 has

always a format of “dpIfGen2_Rev2-x-x.hex”. If the firmware version has a format of

“dpIfGen2_Rev1-x-x.hex” (f.g. for XDPL8105), please update if first or it will show error

message when connecting to XDPL8220.

• In the “Images” folder, the images related to the XDPL8220 parameters CSV file are stored.

Attention: Please make sure that the all necessary images are stored in this folder. If any image is

missing, the CSV file will not be opened by the .dp Vision and an error message will show.

• In the “Parameters” folder, the XDPL8220 parameters CSV file is stored.

Page 8

Application Note 8 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

3 Getting Started

After the correct hardware connection and software installation, please follow the steps below to get started

with the operation of the XDPL8220 reference board and parameterization.

• Start the .dp Vision program by clicking the shortcut “.dp Vision” on the desktop as the following Figure 7

shows.

Figure 7 Starting .dp Vision

Attention: During the program startup, if the system shows there is a newer version of .dp Vision,

please kindly follow the procedures and update it accordingly.

• Open the XDPL8220 parameters configuration file (*.csv) in the folder …\Infineon Technologies AG\.dp

vision\Parameters as shown in the following

Figure 8 Open the CSV File

Select XDPL8220

configuration CSV file to

open

Page 9

Application Note 9 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

• After opening the parameter csv file, a list of XDPL8220 configurable parameters will shown (see the box on

the left in Figure 9). These values can be then modified by users and will turn blue.

Attention: .dpVision will check the plausibility of the parameters values which are input by the user.

If any value violates the limits, the value will turn red and an error message will appear in the

message bar as shown in Figure 9. The limits may also be dependent on other user inputs.

Users are not allowed to save, test or burn the configuration if there is error detected.

Figure 9 Changing Parameter Values in .dp Vision

There are 2 options available to configure the IC based on the parameter values in .dp Vision.

• Burn Configuration

As the XDPL8220 chip on the 50W reference design PCB was already permanently burned with a first full set of

parameters in its one time programmable (OTP) memory space, any parameter value change using this option

is considered as parameter patching. The OTP memory space which is dedicated for patching or burning the

parameter value change has a memory size of 274 words.

Each time when the burn configuration function is executed, it will detect if there is parameter value difference

between the saved configuration file and the target XDPL8220. If there is difference detected, each burn

configuration will consume minimum 3 words depends on how many parameters need to be patched.

However, the process will be aborted if it consumes more memory space than what is remaining in the target

IC. As a result, the user will have to replace the target IC with a new XDPL8220 chip, in order to burn the

configuration.

Table 3 below shows the recommended procedures of using burn configuration function in .dp Vision to patch

the parameter into the OTP memory.

List of configurable

parameters

Message Bar

Page 10

Application Note 10 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

Table 3 Burn Configuration procedures

Step Instruction

I Open configuration file (see example in Figure 9)

II If necessary, change any parameter value then press [File] >> [Save] or [File] >> [Save as], to save

the configuration file. Otherwise, proceed to step III

III Ensure that the primary supply voltage (e.g AC input) to the board is switched off or

disconnected and the hardware connection for configuration is ok based on Figure 2 and Figure

3

IV

Press to supply power and establish connection to the target XDPL8220. After this step,

XDPL8220 will be in configuration mode and the device status should change to .

V

Press to burn configuration into target XDPL8220

After this step, you should see a pop-up window, which is similar to one of these below.

VI Press “Proceed” or “Yes” to burn the configuration

After this step, you should see a pop up window which shows the burning is successful.

VII Press “OK” on the pop up window then disconnect the programming cable from board

connector and test the application, if needed.

• Test Configuration

This function will download the parameter values from the list in .dp Vision into the XDPL8220 RAM memory

space and it will then be followed by an automatic IC startup for application testing with the new configuration.

Unlike using the burn configuration, parameters configuration with this option is not permanent because the

loaded RAM content will be lost once the IC supply voltage is turned off or the IC restarts due to certain

protection. The advantage of using this option is it does not consume OTP memory space, thus there is no limit

on the amount of parameter value changes.

OR

Page 11

Application Note 11 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

Table 4 below shows the recommended procedures of using test configuration function in .dp Vision to load

the new parameter values in the RAM and test the application with the new configuration.

Table 4 Test Configuration procedures

Step Instruction

I Open configuration file and change parameter value (see example in Figure 9)

II Ensure that the primary supply voltage (e.g AC input) to the board is switched off and the

hardware connection for configuration is ok based on Figure 2 and Figure 3.

III

Press to supply power and establish connection to the target XDPL8220. After this step,

XDPL8220 will be in configuration mode and the device status should change to .

IV Ensure LED output is connected to the board and switch on AC input (e.g. 230VAC).

After this step, the board does not startup because XDPL8220 is still in configuration mode.

V

Press to test configuration with target XDPL8220

After this step, the IC will automatically start up with the new configuration and you should see

a pop up window like below:

VI Press “OK” on the pop up window.

VII Repeat the steps to test another configuration change. Otherwise, turn off the AC input and

disconnect the programming cable from board connector.

Note: If there is any error encountered in between step I to VII, please kindly refer to the message bar of

.dp Vision for the error message. For more details, please kindly refer to the .dp Vision user manual

[5].

Page 12

Application Note 12 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

[1] XDPL8220 Target Data Sheet

[2] XDPL8220 U50W Reference Board Description

[3] XDPL8220 50W CSV File Description

[4] XDPL8220 Design Guide

[5] .dp Interface Gen2 User Manual

Page 13

Application Note 13 Revision 1.0

2016-11-01

Getting Started with the XDPL8220 Reference Board Using .dp Vision Software

Revision History

Major changes since the last revision

Page or Reference Description of change

All First Release

Page 14

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2017 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

IMPORTANT NOTICE

The information contained in this application note

is given as a hint for the implementation of the

product only and shall in no event be regarded as a

description or warranty of a certain functionality,

condition or quality of the product. Before

implementation of the product, the recipient of this

application note must verify any function and other

technical information given herein in the real

application. Infineon Technologies hereby

disclaims any and all warranties and liabilities of

any kind (including without limitation warranties of

non-infringement of intellectual property rights of

any third party) with respect to any and all

information given in this application note.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments

to evaluate the suitability of the product for the

intended application and the completeness of the

product information given in this document with

respect to such application.

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may

contain dangerous substances. For information on

the types in question please contact your nearest

Infineon Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of

the product or any consequences of the use thereof

can reasonably be expected to result in personal

injury.

Trademarks of Infineon Technologies AG

µHVICҹ, µIPMҹ, µPFCҹ, AU-

ConvertIRҹ, AURIXҹ, C166ҹ, CanPAKҹ, CIPOSҹ, CIPURSEҹ, CoolDPҹ, CoolGaNҹ, COOLiRҹ, CoolMOSҹ, CoolSETҹ, CoolSiCҹ,

DAVEҹ, DI-POLҹ, DirectFETҹ, DrBladeҹ, EasyPIMҹ, EconoBRIDGEҹ, EconoDUALҹ, EconoPACKҹ, EconoPIMҹ, EiceDRIVERҹ, eupecҹ, F

COSҹ, GaNpowIRҹ,

HEXFETҹ, HITFETҹ, HybridPACKҹ, iMOTIONҹ, IRAMҹ, ISOFACEҹ, IsoPACKҹ, LEDrivIRҹ, LITIXҹ, MIPAQҹ, ModSTACKҹ, my-

dҹ, NovalithICҹ, OPTIGAҹ,

OptiMOSҹ, ORIGAҹ, PowIRaudioҹ, PowIRStageҹ, PrimePACKҹ, PrimeSTACKҹ, PROFETҹ, PRO-SILҹ, RASICҹ, REAL3ҹ,

SmartLEWISҹ, SOLID FLASHҹ,

SPOCҹ, StrongIRFETҹ, SupIRBuckҹ, TEMPFETҹ, TRENCHSTOPҹ, TriCoreҹ, UHVICҹ, XHPҹ, XMCҹ

Trademarks updated November 2015

Other Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2016-11-01<yyyy-mm-dd>

AN_GS_201611_PL21_003

Loading...

Loading...