Page 1

XC800 Family

Guide to using the DALI LightNet tool

AP08104

Application Note

V1.4, 2012-10

Microcontrollers

Page 2

Edition 2012-10

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2012 Infineon Technologies AG

All Rights Reserved.

LEGAL DISCLAIMER

THE INFORMATION GIVEN IN THIS APPLICATION NOTE IS GIVEN AS A HINT FOR THE IMPLEMENTATION

OF THE INFINEON TECHNOLOGIES COMPONENT ONLY AND SHALL NOT BE REGARDED AS ANY

DESCRIPTION OR WARRANTY OF A CERTAIN FUNCTIONALITY, CONDITION OR QUALITY OF THE

INFINEON TECHNOLOGIES COMPONENT. THE RECIPIENT OF THIS APPLICATION NOTE MUST VERIFY

ANY FUNCTION DESCRIBED HEREIN IN THE REAL APPLICATION. INFINEON TECHNOLOGIES HEREBY

DISCLAIMS ANY AND ALL WARRANTIES AND LIABILITIES OF ANY KIND (INCLUDING WITHOUT

LIMITATION WARRANTIES OF NON-INFRINGEMENT OF INTELLECTUAL PROPERTY RIGHTS OF ANY

THIRD PARTY) WITH RESPECT TO ANY AND ALL INFORMATION GIVEN IN THIS APPLICATION NOTE.

Information

For further information on technology, delivery terms and conditions and prices, please contact the nearest

Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements, components may contain dangerous substances. For information on the types in

question, please contact the nearest Infineon Technologies Office.

Infineon Technologies components may be used in life-support devices or systems only with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Page 3

Guide to using the DALI LightNet tool

We Listen to Your Comments

Is there any information in this document that you feel is wrong, unclear or missing? Your feedback will help us to

continuously improve the quality of this document. Please send your proposal (including a reference to this document) to:

mcdocu.comments@infineon.com

XC83x

Revision History: V1.4 2012-10

Previous Version(s): V1.3

Page Subjects (major changes since last revision)

– Updated DALI Control Gear Schematic Part 1; Changed R5 from 1K to 560R

Trademarks

AP08104

Application Note 3 V1.4, 2012-10

Page 4

Guide to using the DALI LightNet tool

AP08104

Table of Contents

Table of Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 AP08104 Software Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 LightNet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 DALI Control Device Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 DALI Control Gear Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5.1 Setting up the Control Device for LightNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5.2 Setting up the Control Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.3 Connecting DALI Master and Slave to the DALI Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3 LightNet Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Connecting the LightNet tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Address Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3 General Control & Status Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 Detailed Configuration Command Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5 Memory Access Control Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

APPENDIX - DALI PHY Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

APPENDIX - DALI Control Gear Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Application Note 4 V1.4, 2012-10

Page 5

Guide to using the DALI LightNet tool

Complex System : Multiple DALI systems can be connected together utilising gateways to building

management systems . Software programs offer more sophisticated programming functionality for

grouped systems , such as scenesetting , timeclock , and partition control .

Groupe d Sy stem : Brightness control within large open - plan office, lecture halls or conference

rooms . DALI can provide zoned or localised control of lighting . Control could be offered through

infra-red remote control or a software control with GUI support , or used together as an easy

configuration tool to group loads together . Offering flexibility in customised lighting .

DALI Bus

DALI Control Gear

(e.g. Lamp)

DALI Control Device(s)

(e.g. Control Panel, Remote Controller

, software control with GUI support)

DALI Control Gear

(e.g. Lamp)

Can connect up to 64

DALI Control Gear

Building

Management

System

DALI Bus

DALI Control Gear

(e.g. Lamp)

DALI Control Device(s)

(e.g. Control Panel, Remote Controller

, software control with GUI support)

DALI Control Gear

(e.g. Lamp)

Can connect up to 64

DALI Control Gear

Gateway Gateway

DALI

Systems

Gateway

DALI

Systems

Gateway

DALI

Systems

DALI Power

Supply

DALI Power

Supply

AP08104

Overview

1Overview

Digital Addressable Lighting Interface (DALI) is a communication protocol for lighting control in buildings. The

interface was first described in the IEC60929 standard for fluorescent lamp ballast, Annex E. The standard was

subsequently updated to include other lighting devices, such as LED, HID, etc., to become IEC-62386. The

complete standard for control interface of electronic control gears was published in June 2009, while the standard

for lighting control devices is scheduled to be published in 2012.

Only a pair of wires are required to form the bus for communication to all devices on a single DALI network. Each

piece of operating equiment with a DALI interface can be communicated with individually. Using a bi-directional

data exchange, a DALI controller can query and set the status of each connected lighting device. As a standalone

system, DALI can be operated with a maximum of 64 devices. Alternatively, DALI can be used as a subsystem via

DALI gateways for connection to building management systems.

Figure 1 DALI system types

Application Note 5 V1.4, 2012-10

Page 6

Guide to using the DALI LightNet tool

LightNET

DALI configuration SW

for groups and scenes

Power

Supply

USB /UART

PC Connector

XC83x

SW Stack

DAL I

PHY

XC83x

SW Stack

DALI

PHY

XC83x

SW Stack

DAL I

PHY

DAL I BUS

Easy Kit as

DALI Master Board

XC83x

DALI Slave Board

XC83x

DALI Slave Board

AP08104

Figure 2 Block Diagram for DALI Control Device and Control Gear

Overview

Infineon has developed a solution for control gears based on the published IEC standard. The DALI Software

Stack for Control Gear has been designed around the Infineon XC83x devices. ‘LightNet’ has been created to

mimic the basic functions of a lighting control device and can therefore be used to evaluate the software. This

document describes the setup of the LightNet tool.

The following items are required for use with this application note:

• 1x XC836 Easy Kit (to serve as a DALI Control Device; KIT_XC836_EK_V1)

• 1x DALI PHY (KIT_XC822_XC836_DALI)

• 1x XC836 DALI Slave (KIT_DALI_RGB_XC836_DKV1) including DALI Control Gear Software Stack

(AP08102)

• Infineon DALI LightNet tool

Application Note 6 V1.4, 2012-10

Page 7

Guide to using the DALI LightNet tool

AP08104

Getting started

2 Getting started

This section is a guide to installing LightNet.

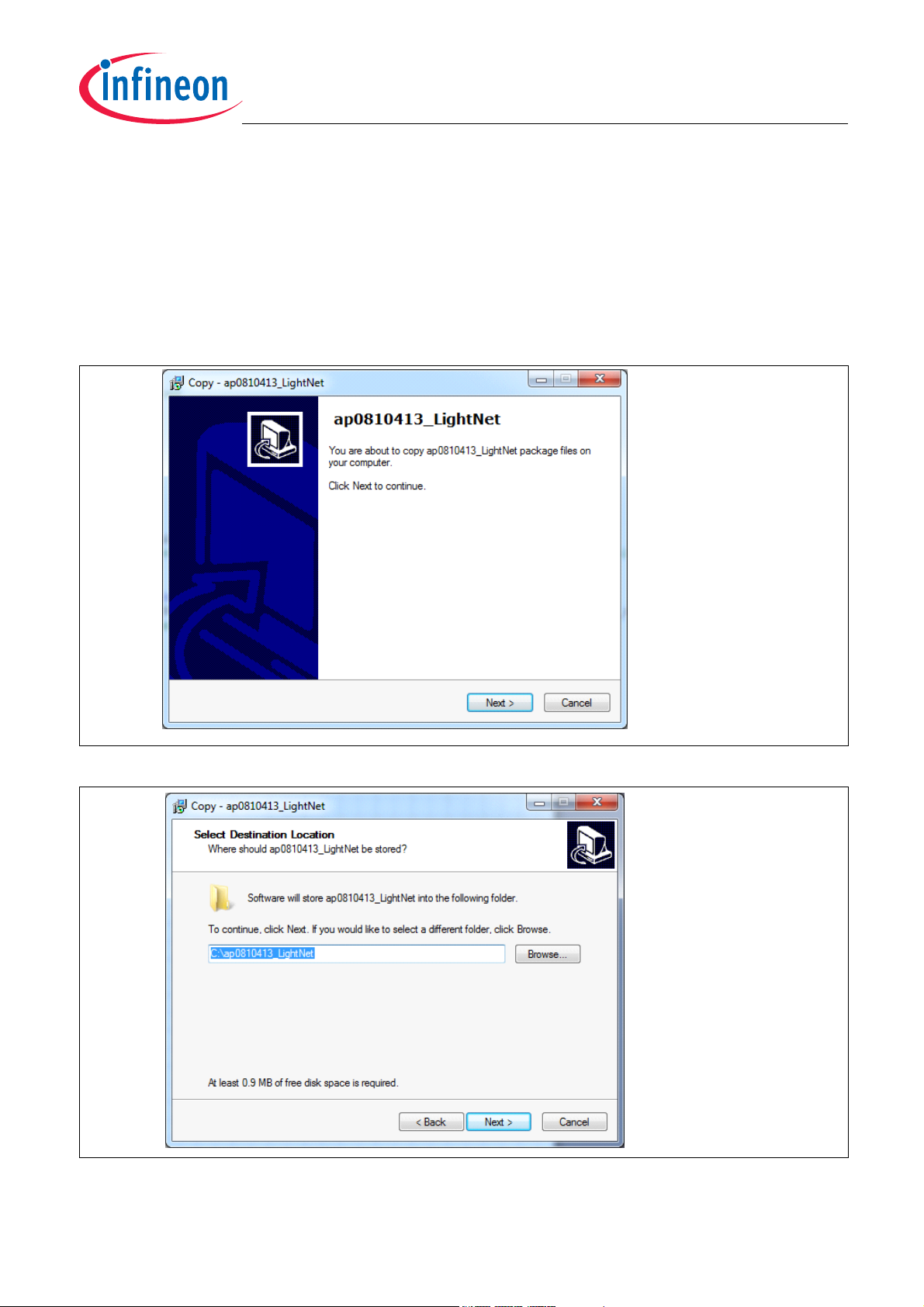

2.1 AP08104 Software Package

This software package consists of the installation package for the LightNet software running on the computer and

a DALI Software for Control Device developed to support the use of the LightNet tool.

The following figures step through the software installation on the user’s computer.

Figure 3 Copying ap08104

Figure 4 Selecting destination location

Application Note 7 V1.4, 2012-10

Page 8

Guide to using the DALI LightNet tool

AP08104

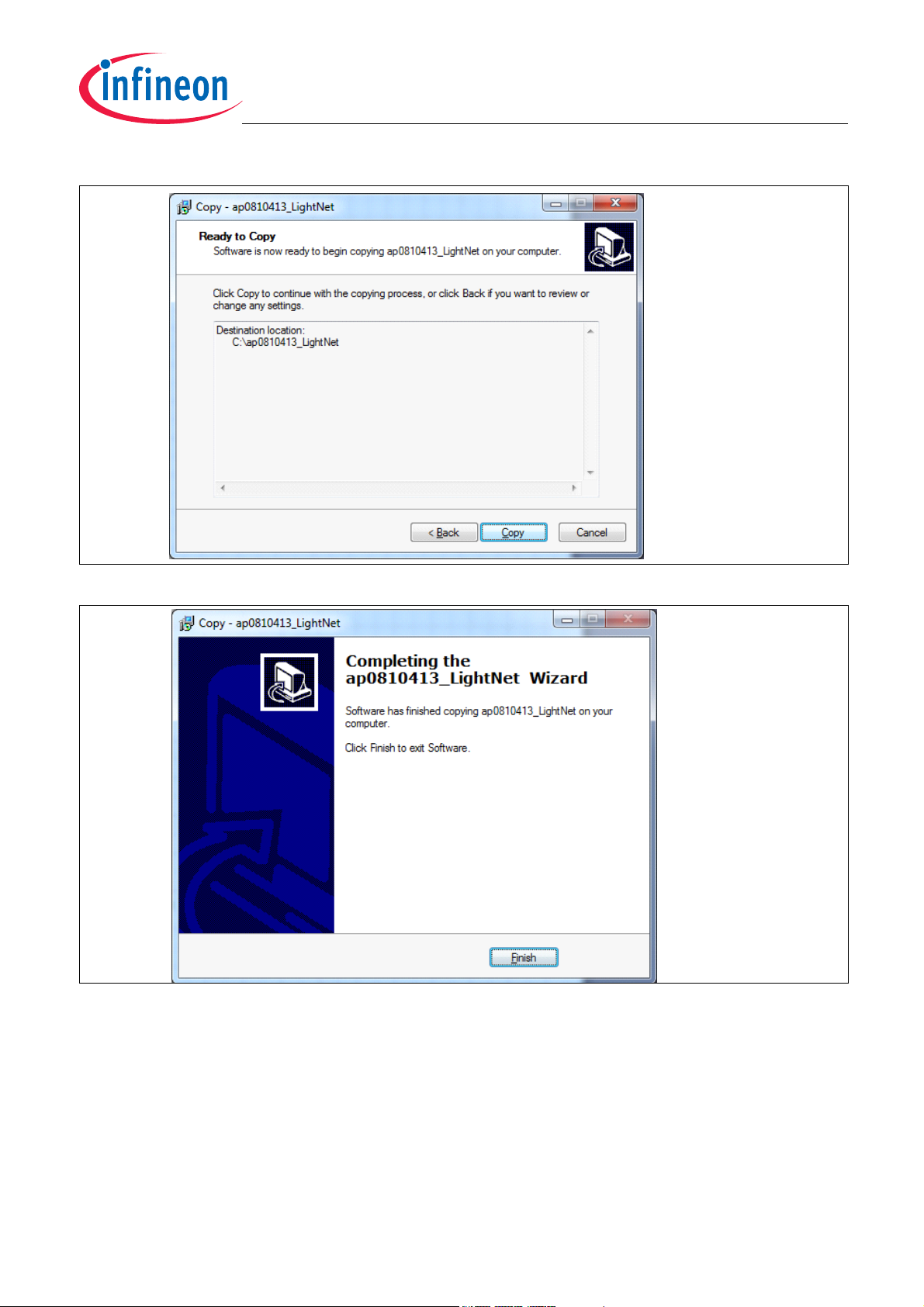

Figure 5 Start the copy process

Getting started

Figure 6 Copy completed

2.2 LightNet Installation

The LightNet software is designed to provide the control device the facility to send basic DALI commands to the

connected control gear. Installation is only to be performed once, using the file: LightNet_setup_V1_3.exe.

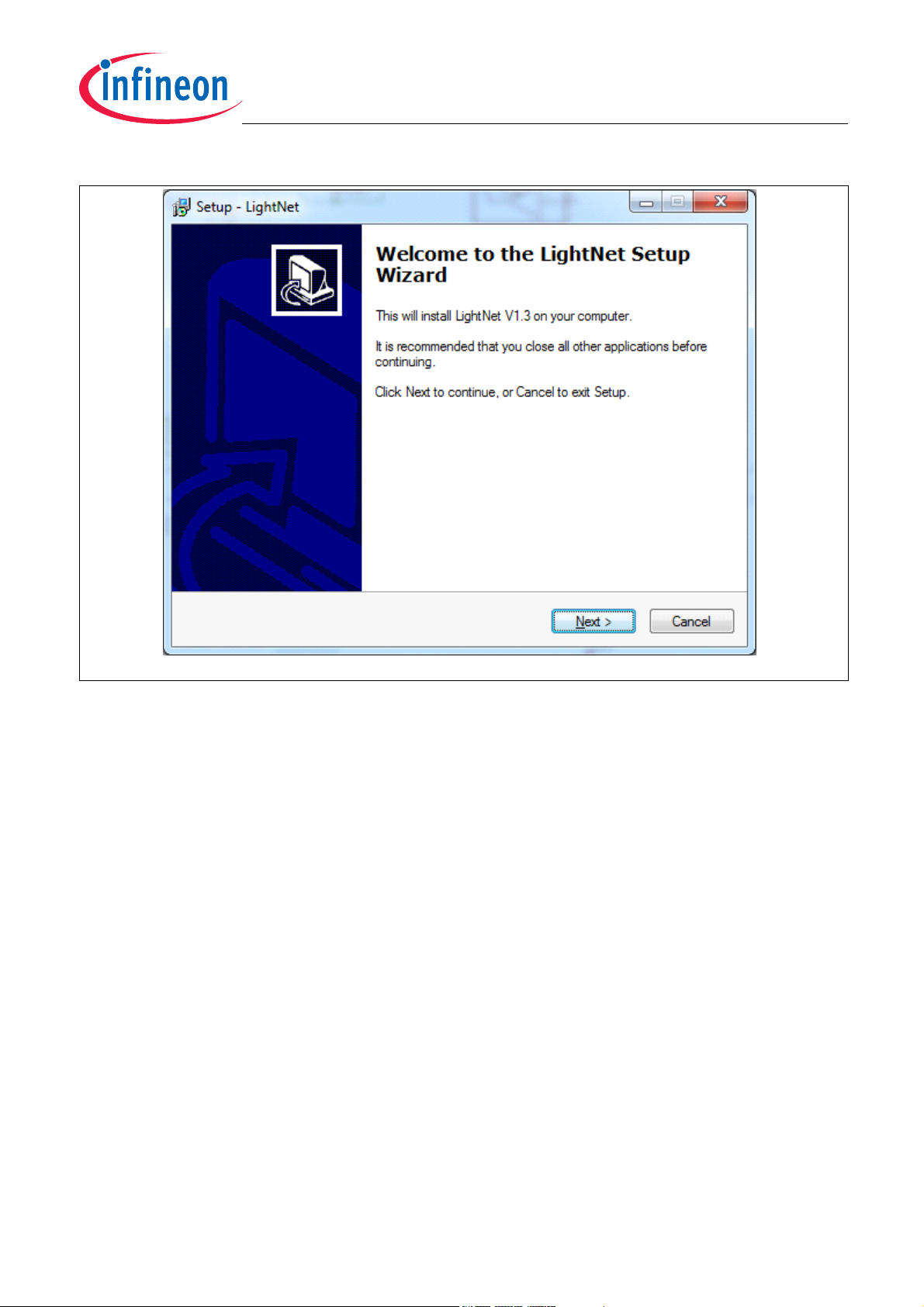

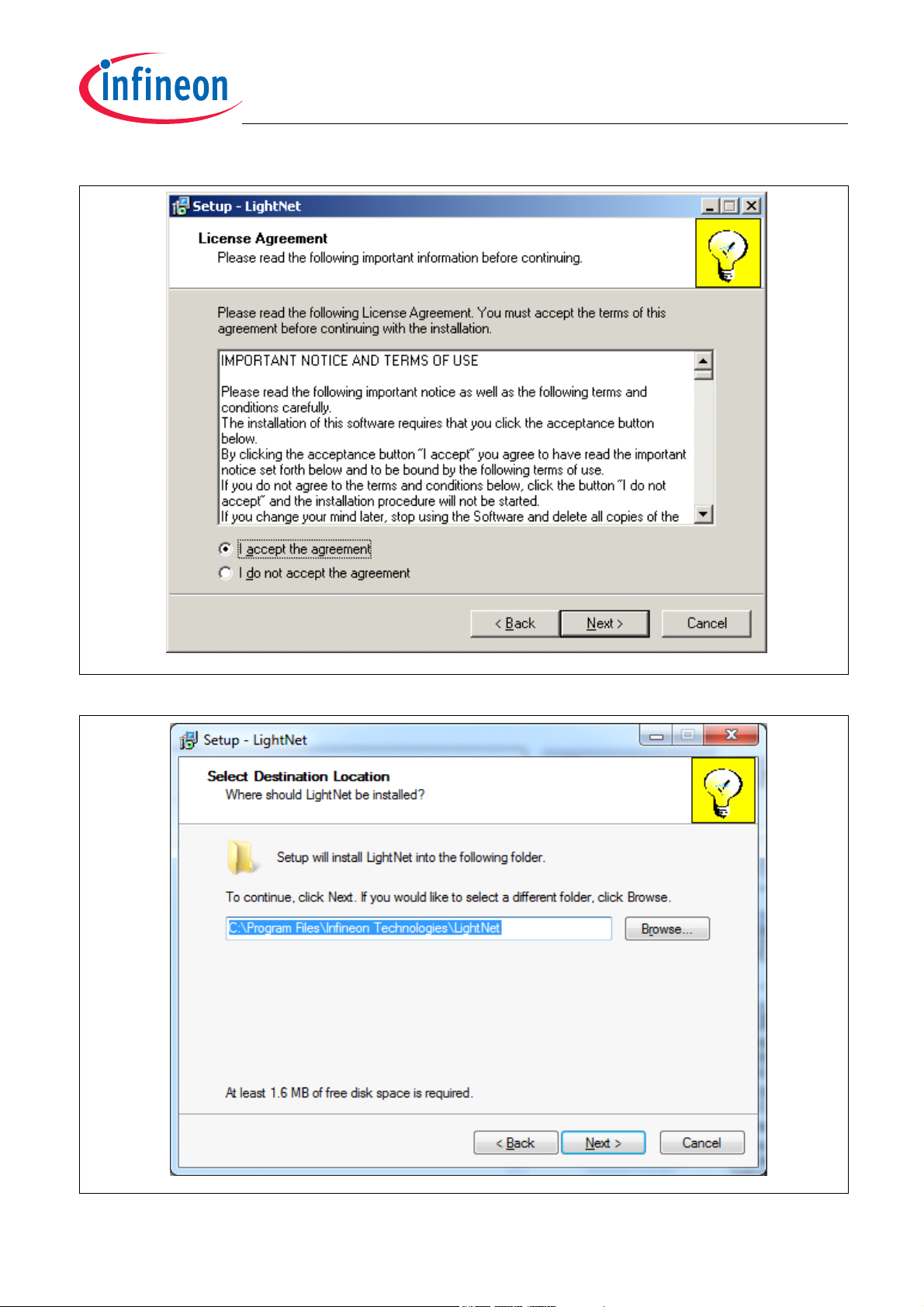

The following figures step through the LightNet tool installation process.

Application Note 8 V1.4, 2012-10

Page 9

Guide to using the DALI LightNet tool

AP08104

Getting started

Figure 7 LightNet tool installation window

Application Note 9 V1.4, 2012-10

Page 10

Guide to using the DALI LightNet tool

AP08104

Getting started

Figure 8 LightNet tool license agreement

Figure 9 LightNet tool destination location selection

Application Note 10 V1.4, 2012-10

Page 11

Guide to using the DALI LightNet tool

AP08104

Getting started

Figure 10 LightNet tool installation start

Figure 11 LightNet tool setup completed

Application Note 11 V1.4, 2012-10

Page 12

Guide to using the DALI LightNet tool

AP08104

Getting started

Figure 12 Screenshots of LightNet tool

Application Note 12 V1.4, 2012-10

Page 13

Guide to using the DALI LightNet tool

DALI Slave Board

(Control Gear)

Comprising of:

- KIT_DALI_RGB_XC836_DKV1

DALI Master Board

(Control Device)

Comprising of:

- KIT_XC836_EK_V1

- KIT_XC822_XC836_DALI

DALI Powe r Supply

15V supply with 100Ω resisto rs

to power up the DALI bus line

PC Connection

via USB /UART

Control using:

- LightNET Softwar e

to PC

AP08104

Getting started

2.3 DALI Control Device Software

The DALI Software for Control Device has been developed to support the use of the LightNet tool and can work

on XC836 Easy Kit boards. This software must be downloaded to the XC836 Easy Kit board prior to calling the

LightNet tool. (File: AP0810413_LightNet_XC800Master_code.exe) In addition to control via LightNet, touch pad

control is available.

2.4 DALI Control Gear Software

The DALI Software for Control Gear has been developed on the XC83x devices to support the features specified

in the International Standard IEC-62386 / Part 102 for control gears. This software includes application code for

driving an LED module, supplied with the XC836 DALI Control Gear (KIT_DALI_RGB_XC836_DKV1). Through a

control device, the LightNet software allows DALI commands to be issued to control the brightness of the LED

module attached to the control gear. This software must be downloaded to the XC836 DALI Control Kit. For further

details, please refer to AP08102 DALI Control Gear Software Stack.

2.5 Hardware Setup

The LightNet tool acts as the software for the DALI Control Device, used with the XC836 Easy Kit.

The following sections describe how to setup the LightNet tool to evaluate the DALI protocol.

Figure 13 Hardware Setup for Infineon Control Device and Control Gear

2.5.1 Setting up the Control Device for LightNet

The XC836 Easy Kit board can be used as the LightNet DALI Control Device, with the following steps:

1. Connect and download the generated hexfile (File:Lightnet_XC800Master.hex) from Section 2.3 into the

XC836 Easy Kit board using XC800 FLOAD in DAVEBENCH

Application Note 13 V1.4, 2012-10

TM

or KEIL UVision4.

Page 14

Guide to using the DALI LightNet tool

Connec t to PC for

LightNET control

V_SEL

5V

3.3V

VIN

This is a default setting

where VDDP is supplied

by 5Vdc from USB port

Displays the command selected.

- PC control: Displays 8888

- Touch Pad Control: Displays commands

Displays connected devices

- ALL: Broa dcast comm and

- D1: Short Address #0

- D2: Short Address #1

- D3: Short Address #2

Touch pads for

command selection

Control modes s upported :

- LightNET via PC

- Touch Pad control

CO M_ SE L

P2.0

P1.5

RX

TX

GND VCC

X1

DALI BUS

Connec t t o DA LI B us

x2

DALI PHY

DALI PHY

(KIT_XC822 _XC836_DALI )

DALI PHY is attached onto (H2 and H1) headers on the XC836 Easy Kit

Connections for the DALI PHY Board

H2 H1

AP08104

Getting started

Note:To ensure the success of the following procedures, please ensure that the device is co nfigured to User Mode

Diagnostic and COM_SEL settings is set to USB.

Figure 14 Overview for DALI Master (Control Device)

Figure 15 DALI PHY connection for XC836 Easy Kit

Application Note 14 V1.4, 2012-10

Page 15

Guide to using the DALI LightNet tool

1

[ALL]

2

[UP]

3

[SCEN E0 ]

4

[DEVICE 1]

5

[DOW N]6[SCEN E1 ]

7

[DEVICE 2]

8

[ON]

9

[SCEN E2 ]

*

[DEVICE 3]

0

[OFF]

#

[SCEN E3 ]

Sends Broadcast Address

Sends Short Addres s 0

Sends Short Addres s 1

Sends Short Addres s 2

Increase brightness

Dec rease brigntness

Turns on connected device

Turn of f connect ed dev ice

Goto Scene 0

Goto Scene 1

Goto Scene 2

Goto Scene 3

Upon powering up, default control mode using touch pad control is entered.

The LED display shows 8888 whenever LightNet is used.

METHOD 2: TOUCH PAD Control

METHOD 1: PC Control via LightNet

LightNet functions are described in this document

AP08104

Getting started

Figure 16 DALI Control using PC and Touch Pad description

2. The DALI Control Device is now ready to be connected to the DALI bus.

3. User can control the DALI network using LightNet (via PC) and through the Touch Pad available on the XC836

Easy Kit.

2.5.2 Setting up the Control Gear

The DALI Control Gear can be setup with the following steps:

1. Connect the DAP MiniWiggler to the DALI Control Gear as shown in Figure 17. Download the hexfile

(File:AP08102_v1_2_Slave.hex) from Section 2.4 into the DALI Slave Board using XC800 FLOAD in

DAVEBENCH

2. The DALI Control Gear is now ready to be connected to the DALI bus.

TM

or KEIL UVision4.

Application Note 15 V1.4, 2012-10

Page 16

Guide to using the DALI LightNet tool

KIT_DAP_MINWIGGLER_USB

KIT_DALI_RGB_XC836_DKV1

3

4 2

3 2 1

1 2

X2

SPD

GNDVCC

X3

GNDVCC

(KIT_DALI_RGB_XC836_DKV1)

KIT_DAP_MINIWIGGLER_USB

PC

5V Supply

Connections for programming the DALI

Control Gear using a DAP MINIWI GGLER

Power Conn

(Connector X 3)

Programming Pin

(Connector X 2)

X2

X3

AP08104

Getting started

Figure 17 Programming the Control Gear using DAP miniWiggler

Application Note 16 V1.4, 2012-10

Page 17

Guide to using the DALI LightNet tool

DALI Control Gear

(K IT_DALI_RGB_XC836_ D KV1)

DALI

PHY

X1

Connect to

DALI BUS

DALI BUS Connector

(C onnector X1)

2

1

X1

(KIT_DALI_RGB_XC836_DKV1)

DALI BUS

DALI PHY

AP08104

Getting started

Figure 18 Connecting the DALI Control Gear

2.5.3 Connecting DALI Master and Slave to the DALI Bus

The DALI network can be setup with the following steps:

1. To supply power for the DALI bus, connect 100Ω resistors in series to each terminal of a power supply unit

supplying 15VDC. This supplies the DALI bus for the DALI network devices.

2. Connect the DALI Control Device (Master) and Control Gear (Slave) to the DALI bus. This completes the DALI

setup to control the devices using LightNet!

Application Note 17 V1.4, 2012-10

Page 18

Guide to using the DALI LightNet tool

POWER SUPPLY UNIT

+15V GND

100 Ω

100 Ω

DALI BUS

POWER SUPPLY

UNIT

+15V GND

100Ω

100Ω

DALI BUS

DALI C ontrol

Device

DALI Control

Device

DALI Slave Board

(Control Gear )

Comprising of:

- KIT_DALI_RGB_XC836_DKV1

DALI Master Board

(Control Device)

Compr isi ng of:

-KIT_XC836_EK_V1

- KIT_XC822_XC836_DALI

DALI Power Supply

15V supply with 100Ω re sisto rs

to power up the DALI bus line

PC Connection

via USB/UART

Control using:

- LightNET Software

to PC

AP08104

Figure 19 Adding 100Ω resistors to Power Supply

Getting started

Figure 20 DALI Network Hardware connection

Application Note 18 V1.4, 2012-10

Page 19

Guide to using the DALI LightNet tool

“RED” indicates that

board is not connected.

Clicking on “Connect”

initiates connection to

LightNet tool

“GREEN” indicates that

board is connected.

Clicking on “Disconnect”

initiates disconnection

from LightNet tool

Broadcast Address:

Fixed address of 0xFF is

sent with commands.

Group Address:

Group setting needs to be

added by user. Supports

range from 00 to 15.

Short Address:

User selectable short

address range from 00 to

63.

NOTE:

1, Steps to adding group address

and programming of short address

can be found in Detailed

Configuration tab.

2. This selection allows user

commands to be addressed with

the various supported address

types listed.

AP08104

LightNet Tool

3 LightNet Tool

This chapter describes how the LightNet software is organised.

3.1 Connecting the LightNet tool

Once the recommended hardware setup has been completed, LightNet can be used. Figure 21 shows how to

connect to the LightNet tool.

Note:The LightNet tool cannot be activated if the reco mmended setup ha s not been compl eted as described; i.e.

the XC836 Easy Kit is not connected, or the BMI is incorrectly selected.

Figure 21 Connecting the Board

3.2 Address Selection

LightNet supports 3 types of DALI addressing:

• Broadcast

• Short Address

• Group Address

The user decides the type of addressing to be sent with each command by selecting from the available options.

For Group Address, the user is required to add the group address to the detailed configuration settings tab, as

shown in Chapter 3.4.

Figure 22 Address Selection

Application Note 19 V1.4, 2012-10

Page 20

Guide to using the DALI LightNet tool

Send Direct ARC:

Sends Direct ARC level command to device. User entry for

desired ARC level to be sent

Steps to send direct ARC commands

:

1. Enter user desired ARC level.

2. Click on “Send Direct ARC” to send command to device.

Down:

Dim down 200ms using the

selected Fade Rate. No change if

power level is already at

Minimum.

OFF:

Tur ns off device.

Step Down & OFF:

Tur ns off device if curr ent state

is minimum level. Otherwise,

set power level 1 step lo wer

immediately without fading.

ON & Step Up:

Turns on device if current state

is OFF. Otherwise, set power

level 1 step higher immediately

without fading.

Ma ximu m:

Sets device to M aximu m level

without fading. Turns on

device, if current state is OFF.

Up :

Dim up 200ms using the

selected Fade Rate. No change

if power level is already at

Maximum.

Step Up:

Set power level 1 step higher

immediately without fading.

Step Do wn:

Set power level 1 step lower

immediately without fading.

Minimum:

Sets device to M inimum level

without fading. Turns on

device, if current state is OFF.

Control Gear:

Indicates if connected

control gear is functional.

Status: OK or NO

Fade Running?:

Status: YES or NO

Get Stat us:

Click on this to obtain

current device status

Lamp Failure:

Indicates if connected lamp

has failure.

Status: YES or NO

Lamp Arc Power:

Indicates power status.

Status: ON or OFF

Limit Error?

Indicates if last requested

arc power level is between

MIN and MAX LEVEL or

OFF

Status is YES or NO

Actual Level:

Indicates current power level

of connect device

Device Type:

Indicates which device is

connected.

0: Fluorescent lamps

6: LED modules

Reset State?:

Indicates if device is in

re set state.

Status: YES or NO

Missing Short Addr.?:

Indicates if device has

short address missing.

Status: YES or NO

Power Failu re?

Indicates if power failure has

occurred. If no failure, it

means that a " RESET" or an

arc power control command

has been received since last

power-on.

Status is YES or NO

Fade Time:

Range: 0 to 15

Fade Rate:

Range : 1 to 15

AP08104

3.3 General Control & Status Tab

This section describes the general device control and status functions.

LightNet Tool

Figure 23 Light Control

Figure 24 Device Status

Application Note 20 V1.4, 2012-10

Page 21

Guide to using the DALI LightNet tool

Go To Scene:

Click button to jump

to the selected

Scene .

Scenes:

Supports 16 scenes.

User to select desired

scene to enter.

Scene # / Level:

Selects the scene for selected device to be

set or removed. To set the scene level, user

can enter desired scene level in the level

field provided.

Steps to Set / Remove

Scene info:

1. Select the desired scene from the drop

down list provided.

2. Enter the desired level in the Level field .

Skip this step if intention is to remove

scene.

3. Click on the radio button for the desired

action. (Set / Remove)

Time / Rate:

Selects the device fade time / rate.

Fade Time Range: 0 to 15

Fade Rate Range: 1 to 15

Steps to select Fade Control Settings:

1. Select from drop down list. Once

setting, new setting takes effect.

Power Control Settings:

Sets the desired power setting for

selected device. Supports following

sett ing:

- Maximum level

- Minimum level

- System Failure level

- Power ON level.

Steps to Set

power settings:

1. Select the type of power setting to be

changed.

2. Enter the desired level in the Level

field.

3. Click on the Set to activate setting.

4. The new settings will only be

programmed to the flash upon “OFF”

selection in the Lights Control tab.

Device Enable Type:

Set the device enable type.

Supported types: 0 and 6.

Steps to enable type settings:

1. Select from drop down list. Once setting,

new setting takes effect .

Reset:

Reset selected device

to reset condition.

Program Short Addr:

Programs user selected short address to

connected device.

Range: 0 to 63

Steps to Program

Short Address:

1. Select from drop down list desired

short address.

2. Click on Program button, Once

completed, new setting takes effect.

Group #:

Selects group for selected device to join or

remove.

Steps to Join / Remove

group:

1. Select the desired group from the drop

down list provided.

2. Click on the radio button for the desired

action. (Join / Remove)

AP08104

Figure 25 Go to scenes

3.4 Detailed Configuration Command Tab

This section describes the options in the configuration settings.

LightNet Tool

Figure 26 Configuration Settings

Application Note 21 V1.4, 2012-10

Page 22

Guide to using the DALI LightNet tool

Scenes :

Indicates the power level

information from Scene 0

to 15

Group :

Indicates the group(s) that

selected device belongs

to.

Versio ni ng :

Indicates the version number

Physical Min. Level :

Indicates the physical minimum

level of the selected device .

Maximum Level :

Indicates the maximum level of

the selected device .

Mi n imu m L e vel :

Indicates the minimum level of

the selected device .

Power ON Level :

Indicates the power on level

when turn on of the selected

device.

System Failure Level :

Indicates the system failure level

of the selected device.

Refresh! :

Click on this to refresh

data in window

AP08104

LightNet Tool

Figure 27 Device Information

Application Note 22 V1.4, 2012-10

Page 23

Guide to using the DALI LightNet tool

Factory Settings Description

Describes the memory settings

supported for Bank 0 and 1

Retrieve Factory Settings

This option retrieves the memory bank contents settings.

Note: This operation takes a few seconds to complete.

Memory Bank Window

This shows the contents of the memory bank s.

Select the required memory contents for read or write

.

Clic king this window opens up the Memory Access

Input Dialog.

Memory bank Selection

Selects Memory Bank 0 or 1.

Add ress (Hex)

Displays the address of the user selected

memory cell from the Memory Bank Window.

Con tent (Hex)

User entered content for the selec ted memory cell.

This operation is supported for memory bank 1

when memory bank 1 lock byte is “55h” in

accordance with IEC62386

Read Button

Executes the read command

Write ButtonSelection

Executes the write memory

command

AP08104

3.5 Memory Access Control Tab

This section describes the options for memory access feature.

LightNet Tool

Figure 28 Memory Bank Window

Figure 29 Memory Input Dialog

Application Note 23 V1.4, 2012-10

Page 24

Guide to using the DALI LightNet tool

AP08104

Summary

4Summary

Infineon’s LightNet tool models the function of a lighting control device, controlling DALI control gears. This

document demonstrates how easy the tool is to use, to evaluate a DALI system.

5 References

[1] IEC 62386 Digital addressable lighting interface; Part 101: General requirements - System (Edition 1.0, 2009-

06)

[2] IEC 62386 Digital addressable lighting interface; Part 102: General requirements - Control gear (Edition 1.0,

2009-06)

[3] AP08102 DALI Control Gear Software Stack

[4] XC82x User Manual 1.1 Hardware Manual Easy Kit XC822-TSSOP16 board V1.0

[5] XC83x User Manual 1.0 Hardware Manual Easy Kit XC836-TSSOP board V1.0

Application Note 24 V1.4, 2012-10

Page 25

Guide to using the DALI LightNet tool

Connect to MCU

IFX DALI PHY BOARD CONNECTORS

Connect to DALI BUS

DALI PHY

Note:

IFX DALI PH Y Board connectors ensure

usage c onfigurability .

Depending on DALI Control Gear

Softw are stac k set tings, the DALI_TX/_R X

pins can be c onnected v ia jumpers to the

corresponding pins on the Eas y Kit

connec tors .

AP08104

APPENDIX - DALI PHY Board

Infineon DALI PHY circuit construction to support device evaluation within a typical DALI network, using the XC836

Easy Kit board. This following figure shows the schematic for a DALI PHY circuit construction that can be used

with the XC822 Easy Kit board.

Note:The DALI PHY board design supports a DALI bus level from 14.5V to 22.5V. The values of R1 and R4 can

be adjusted to support a wider DALI bus voltage range if required.

References

Figure 30 DALI PHY Board Schematics

Application Note 25 V1.4, 2012-10

Page 26

Guide to using the DALI LightNet tool

AP08104

Figure 31 Infineon DALI PHY Board and Layout

References

Table 1 Bill of Material for DALI PHY Circuit

Item Reference Value Device Package Description

1 B1 MB2S MB2S SOIC-4 Bridge Rectifier

2 C1 1u / 25V C-EUC1210 C1210 Capacitor

3 D2 BAS16 DIODE-SOD323-R SOD323-R Diode

4 D3 BZX384-2V7 DIODE-SOD323-R SOD323-R Diode

5 IC1 SFH6156-2 SFH6156 SFH 5.3 kV TRIOS High Reliability

Optocoupler

6 IC2 SFH6156-2 SFH6156 SFH 5.3 kV TRIOS High Reliability

Optocouplerstor

7 Q1 BC817-25W BC817-

25WSMD323

8 R1 10R R-EU-R0603 R0603 Resistor

9 R2 0R R-EU-R0603 R0603 Resistor

10 R3 0R R-EU-R0603 R0603 Resistor

11 R4 11k R-EU-R0603 R0603 Resistor

12 R5 324R R-EU-R0603 R0603 Resistor

13 R6 4R7 R-EU-R0603 R0603 Resistor

14 R7 1k21 R-EU-R0603 R0603 Resistor

15 R8 3k16 R-EU-R0603 R0603 Resistor

16 X1A MKDSN1,5/2-

5,08

17 X1B 2x1 PINHD-1X2 1X02 Pin Header

18 X2 4x1 PINHD-1X4 1X04 Pin Header

MKDSN1,5/2-5,08 MKDSN1,5/

SOT323 NPN Transistor

MKDSN 1,5/2-5,08 Printklemme

2-5,08

Application Note 26 V1.4, 2012-10

Page 27

Guide to using the DALI LightNet tool

AP08104

Table 1 Bill of Material for DALI PHY Circuit

Item Reference Value Device Package Description

19 H1 SAMTEC SSQ-1-

14-03-S-S

20 H2 SAMTEC SSQ-1-

14-03-S-S

PINHD-1X14 1X14 Pin Header

PINHD-1X14 1X14 Pin Header

References

Application Note 27 V1.4, 2012-10

Page 28

Guide to using the DALI LightNet tool

AP08104

APPENDIX - DALI Control Gear Board

Schematic for KIT_DALI_RGB_XC836_DKV1

References

Figure 32 Control Gear Board Schematics - Part 1

Application Note 28 V1.4, 2012-10

Page 29

Guide to using the DALI LightNet tool

AP08104

References

Figure 33 Control Gear Board Schematics - Part 2

Application Note 29 V1.4, 2012-10

Page 30

Guide to using the DALI LightNet tool

X1

BACKFRONT

DALI Control Gear

(KIT_DALI_RGB_XC836_DKV1)

AP08104

References

Figure 34 Control Gear Board Layout

Application Note 30 V1.4, 2012-10

Page 31

www.infineon.com

Published by Infineon Technologies AG

Loading...

Loading...