Data Sheet, V1.2, March 2006

XC167CI-16F

16-Bit Single-Chip Microcontroller

with C166SV2 Core

Microcontrollers

Edition 2006-03

Published by

Infineon Technologies AG

81726 München, Germany

© Infineon Technologies AG 2006.

All Rights Reserved.

Legal Disclaimer

The information given in this document shall in no event be regarded as a guarantee of conditions or

characteristics (“Beschaffenheitsgarantie”). With respect to any examples or hints given herein, any typical values

stated herein and/or any information regarding the application of the device, Infineon Technologies hereby

disclaims any and all warranties and liabilities of any kind, including without limitation warranties of noninfringement of intellectual property rights of any third party.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Data Sheet, V1.2, March 2006

XC167CI-16F

16-Bit Single-Chip Microcontroller

with C166SV2 Core

Microcontrollers

XC167-16

Derivatives

XC167

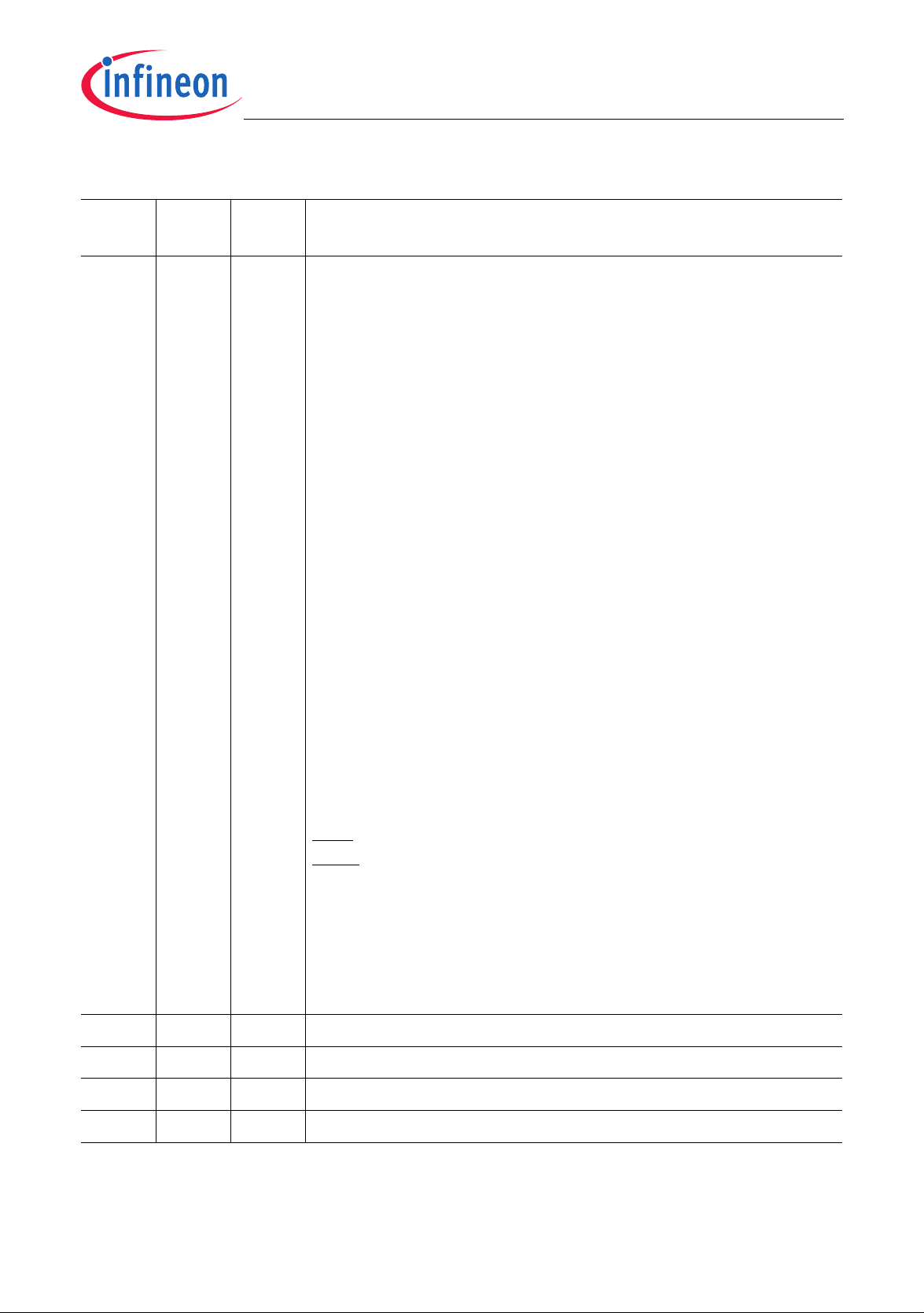

Revision History: V1.2, 2006-03

Previous Version(s):

V1.1, 2003-06

V1.0, 2002-10

Page Subjects (major changes since last revision)

all Layout of graphics and text structures has been adapted to the new

company documentation rules.

73 Minimum oscillator period corrected

77 Output delay/hold time of A23 … A16 moved from

tc

-> tc12, tc21 -> tc

11

82 Parameter tc40 corrected

85 Chapter “Package and Reliability” added.

We Listen to Your Comments

Any information within this document that you feel is wrong, unclear or missing at all?

Your feedback will help us to continuously improve the quality of this document.

Please send your proposal (including a reference to this document) to:

mcdocu.comments@infineon.com

23

Data Sheet V1.2, 2006-03

XC167-16

Derivatives

Table of Contents

Table of Contents

1 Summary of Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 General Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Pin Configuration and Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Memory Subsystem and Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2 External Bus Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3 Central Processing Unit (CPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4 Interrupt System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5 On-Chip Debug Support (OCDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.6 Capture/Compare Units (CAPCOM1/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.7 The Capture/Compare Unit CAPCOM6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.8 General Purpose Timer (GPT12E) Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.9 Real Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.10 A/D Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.11 Asynchronous/Synchronous Serial Interfaces (ASC0/ASC1) . . . . . . . . . . 45

3.12 High Speed Synchronous Serial Channels (SSC0/SSC1) . . . . . . . . . . . . 46

3.13 TwinCAN Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.14 IIC Bus Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.15 Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.16 Clock Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.17 Parallel Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.18 Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.19 Instruction Set Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4 Electrical Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.1 General Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.2 DC Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.3 Analog/Digital Converter Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.4 AC Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.4.1 Definition of Internal Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.4.2 On-chip Flash Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.4.3 External Clock Drive XTAL1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.4.4 Testing Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.4.5 External Bus Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5 Package and Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.1 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.2 Flash Memory Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Data Sheet 3 V1.2, 2006-03

XC16716-Bit Single-Chip Microcontroller with C166SV2 Core

XC166 Family

1 Summary of Features

• High Performance 16-bit CPU with 5-Stage Pipeline

– 25 ns Instruction Cycle Time at 40 MHz CPU Clock (Single-Cycle Execution)

– 1-Cycle Multiplication (16 ×16 bit), Background Division (32 / 16 bit) in 21 Cycles

– 1-Cycle Multiply-and-Accumulate (MAC) Instructions

– Enhanced Boolean Bit Manipulation Facilities

– Zero-Cycle Jump Execution

– Additional Instructions to Support HLL and Operating Systems

– Register-Based Design with Multiple Variable Register Banks

– Fast Context Switching Support with Two Additional Local Register Banks

– 16 Mbytes Total Linear Address Space for Code and Data

– 1024 Bytes On-Chip Special Function Register Area (C166 Family Compatible)

• 16-Priority-Level Interrupt System with 77 Sources, Sample-Rate down to 50 ns

• 8-Channel Interrupt-Driven Single-Cycle Data Transfer Facilities via

Peripheral Event Controller (PEC), 24-Bit Pointers Cover Total Address Space

• Clock Generation via on-chip PLL (factors 1:0.15 … 1:10), or

via Prescaler (factors 1:1 … 60:1)

• On-Chip Memory Modules

– 2 Kbytes On-Chip Dual-Port RAM (DPRAM)

– 4 Kbytes On-Chip Data SRAM (DSRAM)

– 2 Kbytes On-Chip Program/Data SRAM (PSRAM)

– 128 Kbytes On-Chip Program Memory (Flash Memory)

• On-Chip Peripheral Modules

– 16-Channel A/D Converter with Programmable Resolution (10-bit or 8-bit) and

Conversion Time (down to 2.55 µs or 2.15 µs)

– Two 16-Channel General Purpose Capture/Compare Units (32 Input/Output Pins)

– Capture/Compare Unit for flexible PWM Signal Generation (CAPCOM6)

(3/6 Capture/Compare Channels and 1 Compare Channel)

– Multi-Functional General Purpose Timer Unit with 5 Timers

– Two Synchronous/Asynchronous Serial Channels (USARTs)

– Two High-Speed-Synchronous Serial Channels

– On-Chip TwinCAN Interface (Rev. 2.0B active) with 32 Message Objects

(Full CAN/Basic CAN) on Two CAN Nodes, and Gateway Functionality

– IIC Bus Interface (10-bit addressing, 400 kbit/s) with 3 Channels (multiplexed)

– On-Chip Real Time Clock, Driven by Dedicated Oscillator

• Idle, Sleep, and Power Down Modes with Flexible Power Management

• Programmable Watchdog Timer and Oscillator Watchdog

Data Sheet 4 V1.2, 2006-03

Summary of Features

• Up to 12 Mbytes External Address Space for Code and Data

– Programmable External Bus Characteristics for Different Address Ranges

– Multiplexed or Demultiplexed External Address/Data Buses

– Selectable Address Bus Width

– 16-Bit or 8-Bit Data Bus Width

– Five Programmable Chip-Select Signals

– Hold- and Hold-Acknowledge Bus Arbitration Support

• Up to 103 General Purpose I/O Lines,

partly with Selectable Input Thresholds and Hysteresis

• On-Chip Bootstrap Loader

• Supported by a Large Range of Development Tools like C-Compilers,

Macro-Assembler Packages, Emulators, Evaluation Boards, HLL-Debuggers,

Simulators, Logic Analyzer Disassemblers, Programming Boards

• On-Chip Debug Support via JTAG Interface

• 144-Pin TQFP Package, 0.5 mm (19.7 mil) pitch

XC167-16

Derivatives

Ordering Information

The ordering code for Infineon microcontrollers provides an exact reference to the

required product. This ordering code identifies:

• the derivative itself, i.e. its function set, the temperature range, and the supply voltage

• the package and the type of delivery.

For the available ordering codes for the XC167 please refer to the “Product Catalog

Microcontrollers”, which summarizes all available microcontroller variants.

Note: The ordering codes for Mask-ROM versions are defined for each product after

verification of the respective ROM code.

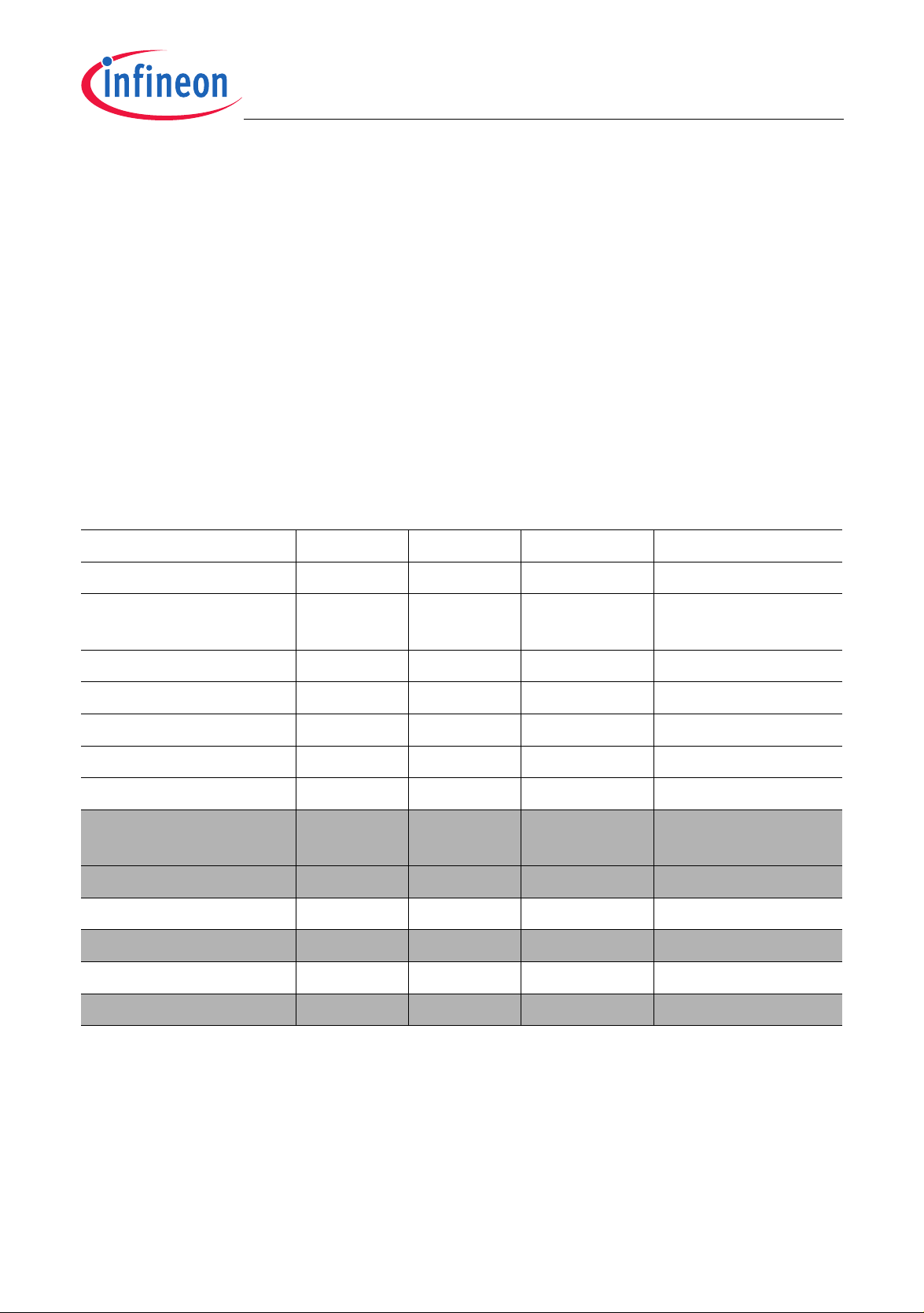

This document describes several derivatives of the XC167 group. Table 1 enumerates

these derivatives and summarizes the differences. As this document refers to all of these

derivatives, some descriptions may not apply to a specific product.

For simplicity all versions are referred to by the term XC167 throughout this document.

Data Sheet 5 V1.2, 2006-03

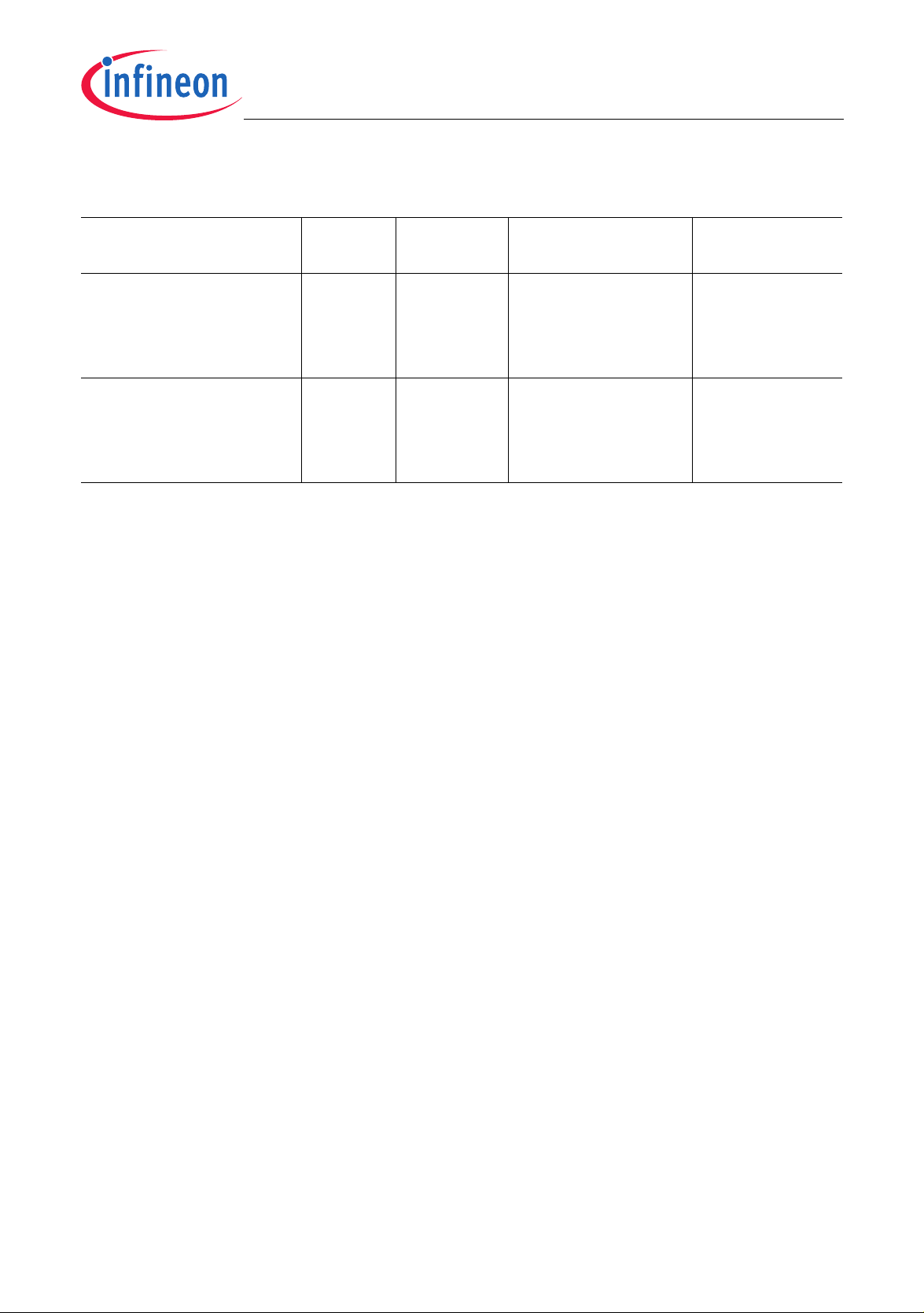

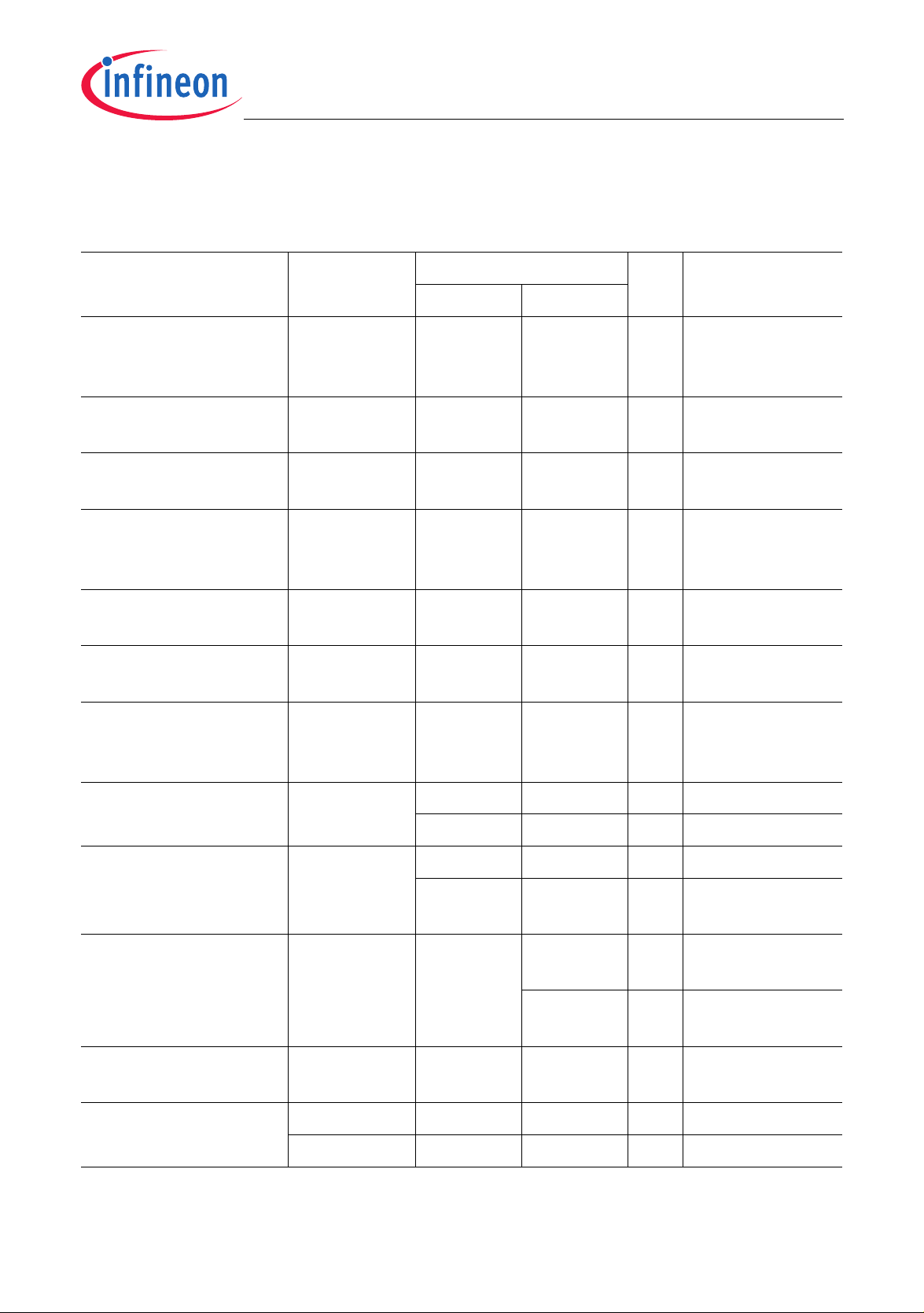

Table 1 XC167 Derivative Synopsis

Derivative

1)

Temp.

Range

Program

Memory

XC167-16

Derivatives

Summary of Features

On-Chip RAM Interfaces

SAK-XC167CI-16F40F,

SAK-XC167CI-16F20F

-40 °C to

125 °C

128 Kbytes

Flash

2 Kbytes DPRAM,

4 Kbytes DSRAM,

2 Kbytes PSRAM

SAF-XC167CI-16F40F,

SAF-XC167CI-16F20F

-40 °C to

85 °C

128 Kbytes

Flash

2 Kbytes DPRAM,

4 Kbytes DSRAM,

2 Kbytes PSRAM

1) This Data Sheet is valid for devices starting with and including design step AD.

ASC0, ASC1,

SSC0, SSC1,

CAN0, CAN1,

IIC

ASC0, ASC1,

SSC0, SSC1,

CAN0, CAN1,

IIC

Data Sheet 6 V1.2, 2006-03

XC167-16

Derivatives

General Device Information

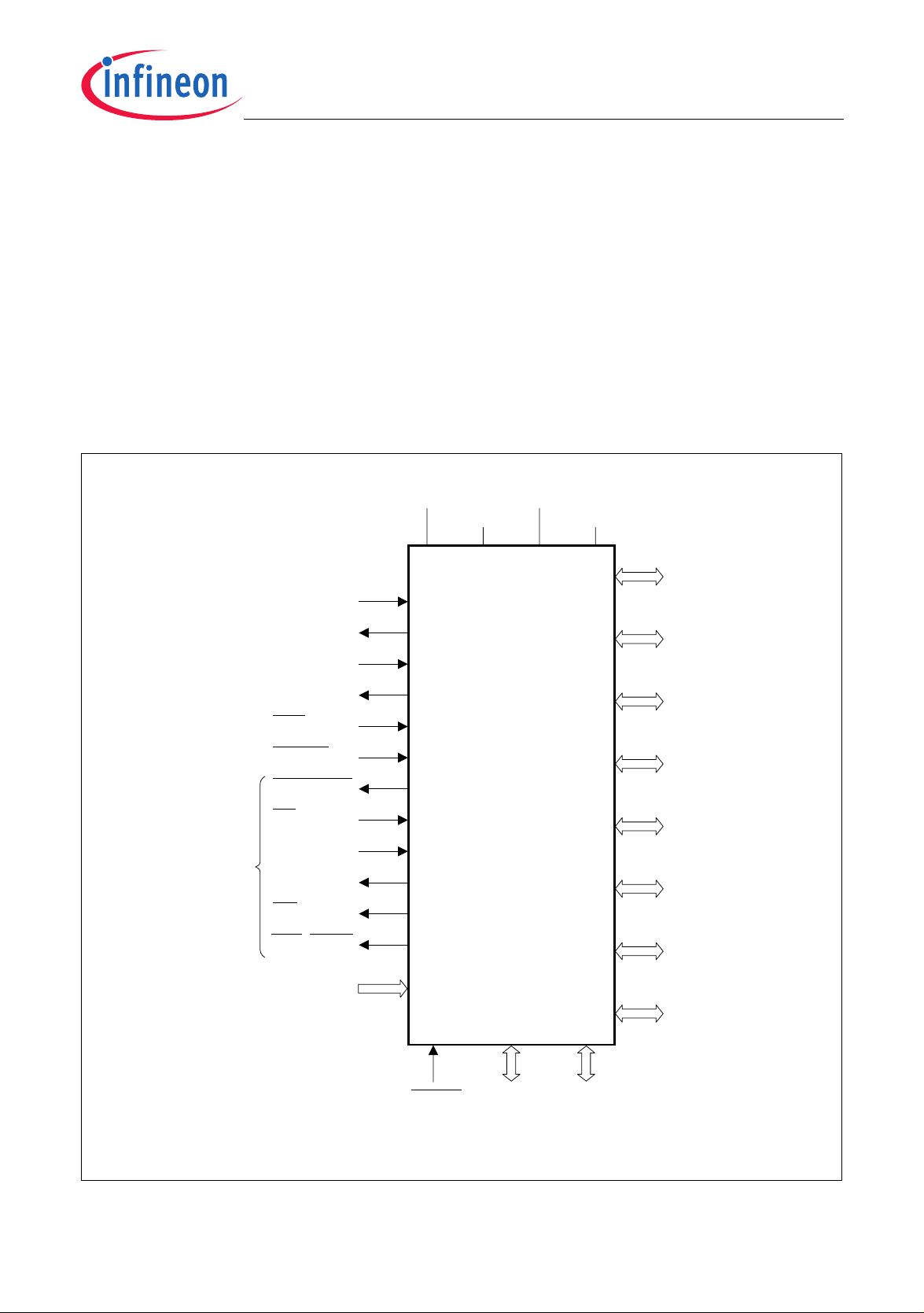

2 General Device Information

2.1 Introduction

The XC167 derivatives are high-performance members of the Infineon XC166 Family of

full featured single-chip CMOS microcontrollers. These devices extend the functionality

and performance of the C166 Family in terms of instructions (MAC unit), peripherals, and

speed. They combine high CPU performance (up to 40 million instructions per second)

with high peripheral functionality and enhanced IO-capabilities. They also provide clock

generation via PLL and various on-chip memory modules such as program Flash,

program RAM, and data RAM.

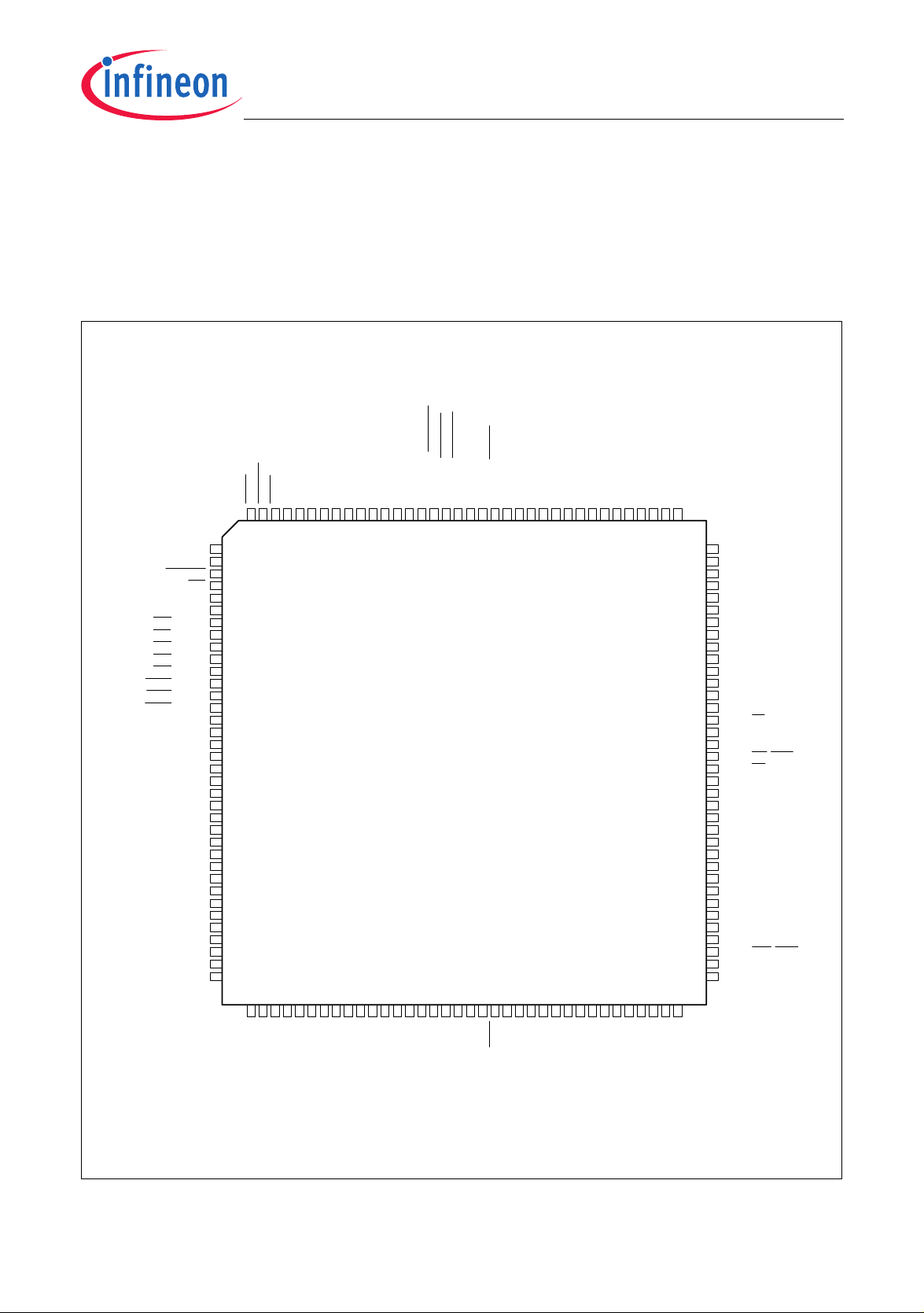

Port 20

6 bit

XTAL1

XTAL2

XTAL3

XTAL4

NMI

RSTIN

RSTOUT

EA

READY

ALE

RD

WR/WRL

Port 5

16 bit

V

AREF

V

AGND

XC167

V

DDI/P

V

SSI/P

PORT0

16 bit

PORT1

16 bit

Port 2

8 bit

Port 3

15 bit

Port 4

8 bit

Port 6

8 bit

Port 7

4 bit

Port 9

6 bit

TRST Debug

JTAG

5 bit

2 bit

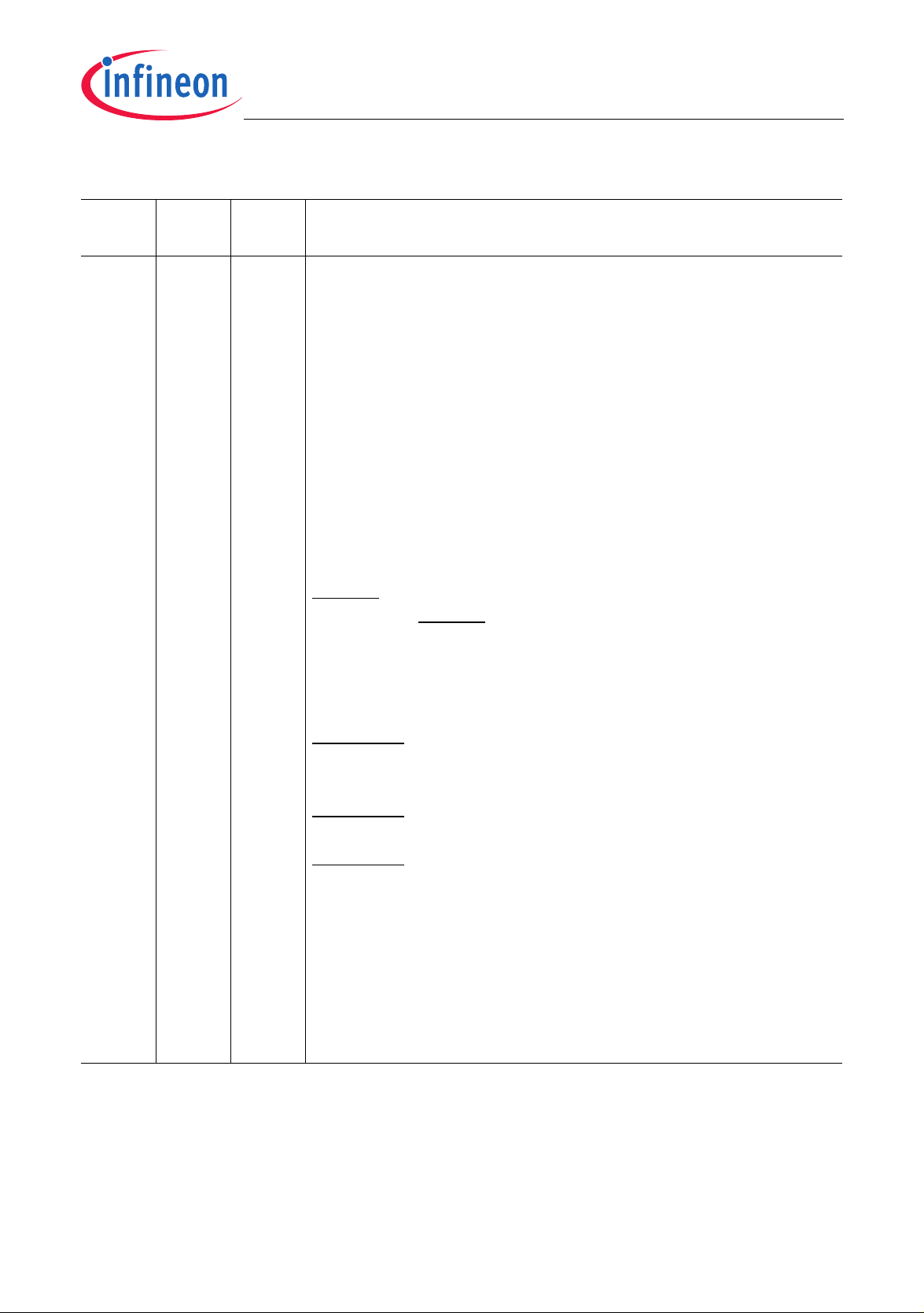

MCA05554_7

Figure 1 Logic Symbol

Data Sheet 7 V1.2, 2006-03

XC167-16

Derivatives

General Device Information

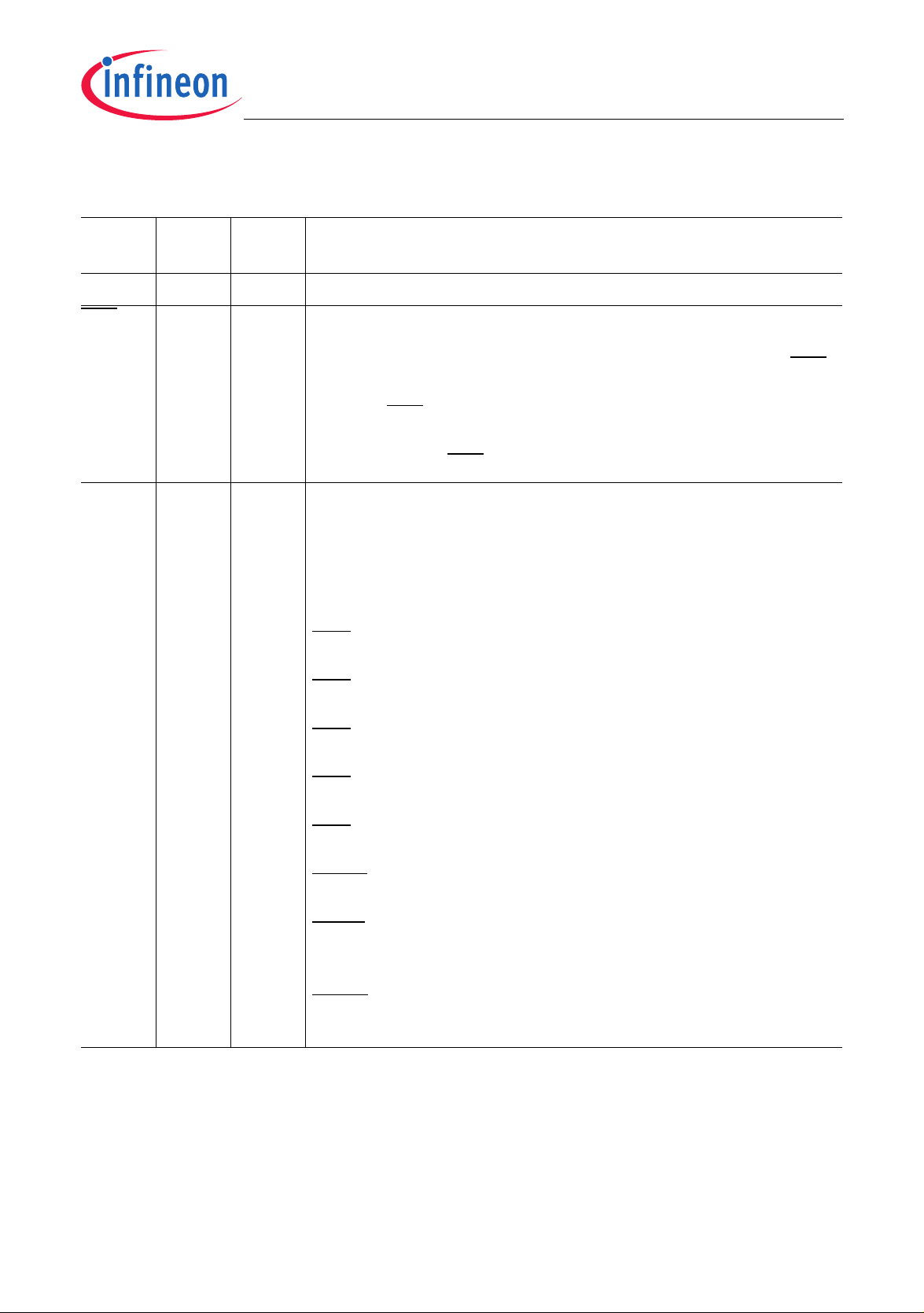

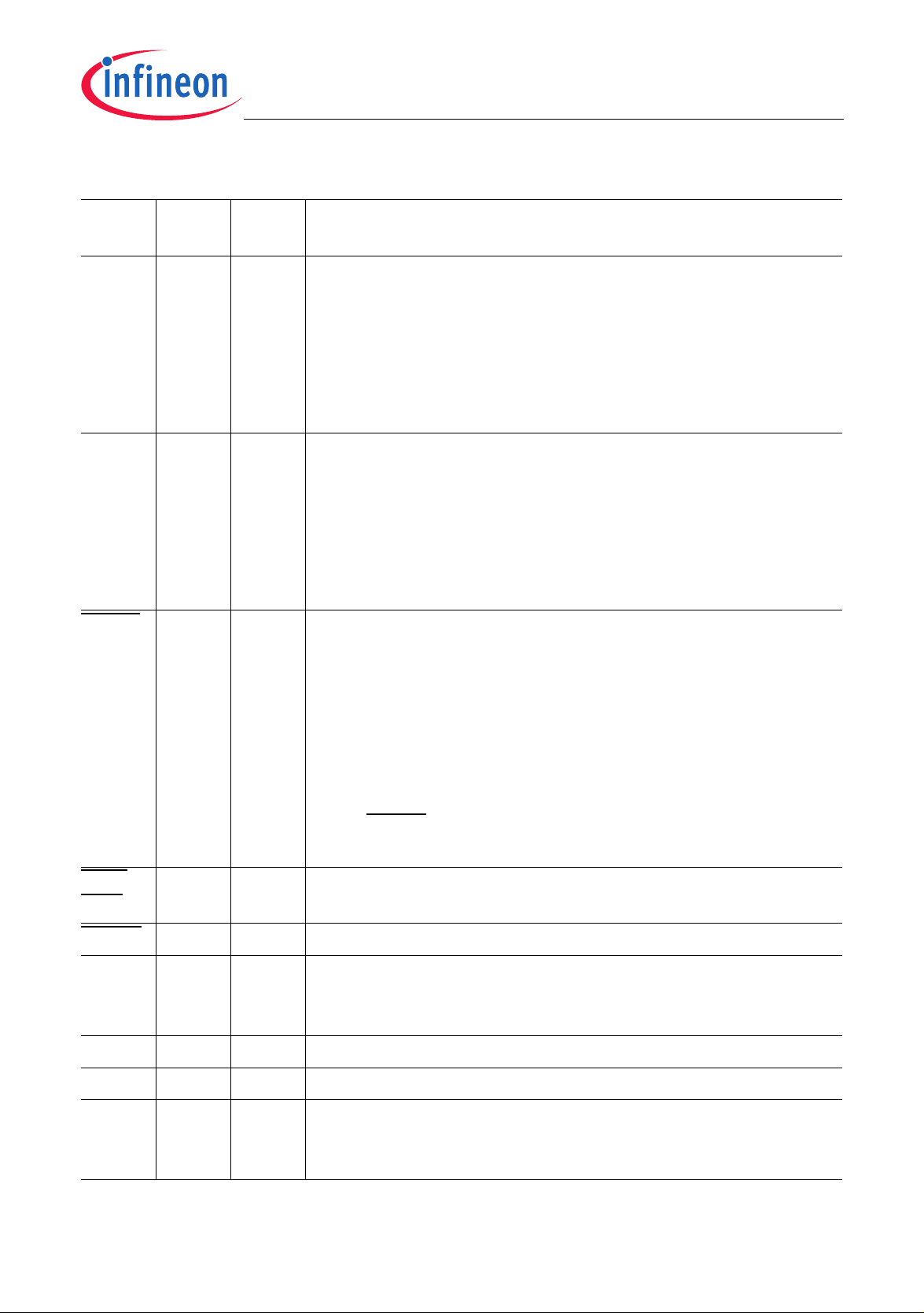

2.2 Pin Configuration and Definition

The pins of the XC167 are described in detail in Table 2, including all their alternate

functions. Figure 2 summarizes all pins in a condensed way, showing their location on

the 4 sides of the package. E*) and C*) mark pins to be used as alternate external

interrupt inputs, C*) marks pins that can have CAN interface lines assigned to them.

SSI

BRKIN

BRKOUT

RSTIN

XTAL4

XTAL3

SSIVDDI

V

XTAL1

XTAL2

V

P1H.7/A15/CC27IO

P1H.6/A14/CC26IO

P1H.5/A13/CC25IO

P1H.4/A12/CC24IO

P1H.3/A11/SCLK1/E*)

SSPVDDP

P1H.2/A10/CC6POS2/MTSR1

P1H.1/A9/CC6POS1/MRST1

P1H.0/A8/CC6POS0/CC23IO/E*)

V

P1L.7/A7/CTRAP/CC22IO

P1L.6/A6/COUT63

P1L.5/A5/COUT62

P1L.4/A4/CC62

P1L.3/A3/COUT61

P1L.2/A2/CC61

P1L.1/A1/COUT60

P1L.0/A0/CC60

P0H.7/AD15

P0H.6/AD14

P0H.5/AD13

P0H.4/AD12

P0H.3/AD11

P0H.2/AD10

N.C.

N.C.

N.C.

P20.12/RSTOUT

P6.0/CS0/CC0IO

P6.1/CS1/CC1IO

P6.2/CS2/CC2IO

P6.3/CS3/CC3IO

P6.4/CS4/CC4IO

P6.5/HOLD/CC5IO

P6.6/HLDA/CC6IO

P6.7/BREQ/CC7IO

P7.4/CC28IO/C*)

P7.5/CC29IO/C*)

P7.6/CC30IO/C*)

P7.7/CC31IO/C*)

P9.0/SDA0/CC16IO/C*)

P9.1/SCL0/CC17IO/C*)

P9.2/SDA1/CC18IO/C*)

P9.3/SCL1/CC19IO/C*)

P9.4/SDA2/CC20IO

P9.5/SCL2/CC21IO

P5.10/AN10/T6EUD

P5.11/AN11/T5EUD

N.C.

NMI

V

SSP

V

DDP

V

SSP

V

DDP

V

SSP

V

DDP

P5.0/AN0

P5.1/AN1

P5.2/AN2

P5.3/AN3

P5.4/AN4

P5.5/AN5

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

3738394041424344454647484950515253545556575859606162636465666768697071

XC167

115

114

113

112

111

110

109

N.C.

108

N.C.

107

P0H.1/AD9

106

P0H.0/AD8

105

V

104

SSP

V

103

DDP

P0L.7/AD7

102

P0L.6/AD6

101

P0L.5/AD5

100

P0L.4/AD4

99

P0L.3/AD3

98

P0L.2/AD2

97

P0L.1/AD1

96

P0L.0/AD0

95

P20.5/EA

94

P20.4/ALE

93

P20.2/READY

92

P20.1/WR/WRL

91

P20.0/RD

90

V

89

SSP

V

88

DDP

P4.7/A23/C*)

87

P4.6/A22/C*)

86

P4.5/A21/C*)

85

P4.4/A20/C*)

84

P4.3/A19

83

P4.2/A18

82

P4.1/A17

81

P4.0/A16

80

V

79

SSI

V

78

DDI

P3.15/CLKOUT/FOUT

77

P3.13/SCLK0/E*)

76

P3.12/BHE/WRH/E*)

75

TMS

74

TDO

7336

72

SSI

P5.8/AN8

P5.9/AN9

P5.6/AN6

P5.7/AN7

DDI

AREF

AGND

V

V

V

V

P5.12/AN12/T6IN

P5.13/AN13/T5IN

P5.14/AN14/T4EUD

P2.8/CC8IO/EX0IN

P5.15/AN15/T2EUD

P2.9/CC9IO/EX1IN

P2.10/CC10IO/EX2IN

P2.11/CC11IO/EX3IN

P2.12/CC12IO/EX4IN

P2.13/CC13IO/EX5IN

DDP

V

TRST

P3.5/T4IN

P3.6/T3IN

P3.2/CAPIN

P3.3/T3OUT

P2.14/CC14IO/EX6IN

P3.0/T0IN/TxD1/E*)

P3.1/T6OUT/RxD1/E*)

P2.15/CC15IO/EX7IN/T7IN

P3.7/T2IN

P3.4/T3EUD

P3.8/MRST0

P3.9/MTSR0

TDI

TCK

P3.10/TxD0/E*)

P3.11/RxD0/E*)

MCP06458

Figure 2 Pin Configuration (top view)

Data Sheet 8 V1.2, 2006-03

Table 2 Pin Definitions and Functions

XC167-16

Derivatives

General Device Information

Symbol

Pin

Num.

Input

Outp.

Function

P20.12 3 IO For details, please refer to the description of P20.

NMI

4 I Non-Maskable Interrupt Input. A high to low transition at this

pin causes the CPU to vector to the NMI trap routine. When

the PWRDN (power down) instruction is executed, the NMI

pin must be low in order to force the XC167 into power down

mode. If NMI

is high, when PWRDN is executed, the part will

continue to run in normal mode.

P6

IO

If not used, pin NMI

Port 6 is an 8-bit bidirectional I/O port. Each pin can be

should be pulled high externally.

programmed for input (output driver in high-impedance

state) or output (configurable as push/pull or open drain

driver). The input threshold of Port 6 is selectable (standard

or special).

The Port 6 pins also serve for alternate functions:

P6.0

P6.1

P6.2

P6.3

P6.4

P6.5

P6.6

7

8

9

10

11

12

13

O

IO

O

IO

O

IO

O

IO

O

IO

I

IO

I/O

CS0

Chip Select 0 Output,

CC0IO CAPCOM1: CC0 Capture Inp./Compare Output

CS1

Chip Select 1 Output,

CC1IO CAPCOM1: CC1 Capture Inp./Compare Output

CS2

Chip Select 2 Output,

CC2IO CAPCOM1: CC2 Capture Inp./Compare Output

CS3

Chip Select 3 Output,

CC3IO CAPCOM1: CC3 Capture Inp./Compare Output

CS4

Chip Select 4 Output,

CC4IO CAPCOM1: CC4 Capture Inp./Compare Output

HOLD

External Master Hold Request Input,

CC5IO CAPCOM1: CC5 Capture Inp./Compare Output

HLDA

Hold Acknowledge Output (master mode) or

Input (slave mode),

CC6IO CAPCOM1: CC6 Capture Inp./Compare Output

BREQ

Bus Request Output,

CC7IO CAPCOM1: CC7 Capture Inp./Compare Output

P6.7

14

IO

O

IO

Data Sheet 9 V1.2, 2006-03

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

Symbol

P7

P7.4

P7.5

P7.6

P7.7

Pin

Num.

15

16

17

18

Input

Outp.

IO

I/O

I

I

I/O

O

I

I/O

I

I

I/O

O

I

Function

Port 7 is a 4-bit bidirectional I/O port. Each pin can be

programmed for input (output driver in high-impedance

state) or output (configurable as push/pull or open drain

driver). The input threshold of Port 7 is selectable (standard

or special).

Port 7 pins provide inputs/outputs for CAPCOM2 and serial

interface lines.

1)

CC28IO CAPCOM2: CC28 Capture Inp./Compare Outp.,

CAN2_RxD CAN Node 2 Receive Data Input,

EX7IN Fast External Interrupt 7 Input (alternate pin B)

CC29IO CAPCOM2: CC29 Capture Inp./Compare Outp.,

CAN2_TxD CAN Node 2 Transmit Data Output,

EX6IN Fast External Interrupt 6 Input (alternate pin B)

CC30IO CAPCOM2: CC30 Capture Inp./Compare Outp.,

CAN1_RxD CAN Node 1 Receive Data Input,

EX7IN Fast External Interrupt 7 Input (alternate pin A)

CC31IO CAPCOM2: CC31 Capture Inp./Compare Outp.,

CAN1_TxD CAN Node 1 Transmit Data Output,

EX6IN Fast External Interrupt 6 Input (alternate pin A)

Data Sheet 10 V1.2, 2006-03

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

Symbol

P9

P9.0

P9.1

P9.2

P9.3

P9.4

P9.5

Pin

Num.

21

22

23

24

25

26

Input

Outp.

IO

I/O

I

I/O

I/O

O

I/O

I/O

I

I/O

I/O

O

I/O

I/O

I/O

I/O

I/O

Function

Port 9 is a 6-bit bidirectional I/O port. Each pin can be

programmed for input (output driver in high-impedance

state) or output (configurable as push/pull or open drain

driver). The input threshold of Port 9 is selectable (standard

or special).

The following Port 9 pins also serve for alternate functions:

CC16IO CAPCOM2: CC16 Capture Inp./Compare Outp.,

CAN2_RxD CAN Node 2 Receive Data Input,

SDA0 IIC Bus Data Line 0

CC17IO CAPCOM2: CC17 Capture Inp./Compare Outp.,

CAN2_TxD CAN Node 2 Transmit Data Output,

SCL0 IIC Bus Clock Line 0

CC18IO CAPCOM2: CC18 Capture Inp./Compare Outp.,

CAN1_RxD CAN Node 1 Receive Data Input,

SDA1 IIC Bus Data Line 1

CC19IO CAPCOM2: CC19 Capture Inp./Compare Outp.,

CAN1_TxD CAN Node 1 Transmit Data Output,

SCL1 IIC Bus Clock Line 1

CC20IO CAPCOM2: CC20 Capture Inp./Compare Outp.,

SDA2 IIC Bus Data Line 2

CC21IO CAPCOM2: CC21 Capture Inp./Compare Outp.,

SCL2 IIC Bus Clock Line 2

1)

Data Sheet 11 V1.2, 2006-03

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

Symbol

P5

P5.0

P5.1

P5.2

P5.3

P5.4

P5.5

P5.10

P5.11

P5.8

P5.9

P5.6

P5.7

P5.12

P5.13

P5.14

P5.15

Pin

Num.

29

30

31

32

33

34

35

36

37

38

39

40

43

44

45

46

Input

Outp.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Function

Port 5 is a 16-bit input-only port.

The pins of Port 5 also serve as analog input channels for the

A/D converter, or they serve as timer inputs:

AN0

AN1

AN2

AN3

AN4

AN5

AN10, T6EUD GPT1 Timer T4 Ext. Up/Down Ctrl. Inp.

AN11, T5EUD GPT1 Timer T2 Ext. Up/Down Ctrl. Inp

AN8

AN9

AN6

AN7

AN12, T6IN GPT2 Timer T6 Count/Gate Input

AN13, T5IN GPT2 Timer T5 Count/Gate Input

AN14, T4EUD GPT1 Timer T4 Ext. Up/Down Ctrl. Inp.

AN15, T2EUD GPT1 Timer T2 Ext. Up/Down Ctrl. Inp.

Data Sheet 12 V1.2, 2006-03

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

Symbol

P2

P2.8

P2.9

P2.10

P2.11

P2.12

P2.13

P2.14

P2.15

Pin

Num.

49

50

51

52

53

54

55

56

Input

Outp.

IO

I/O

I

I/O

I

I/O

I

I/O

I

I/O

I

I/O

I

I/O

I

I/O

I

I

Function

Port 2 is an 8-bit bidirectional I/O port. Each pin can be

programmed for input (output driver in high-impedance

state) or output (configurable as push/pull or open drain

driver). The input threshold of Port 2 is selectable (standard

or special).

The following Port 2 pins also serve for alternate functions:

CC8IO CAPCOM1: CC8 Capture Inp./Compare Output,

EX0IN Fast External Interrupt 0 Input (default pin)

CC9IO CAPCOM1: CC9 Capture Inp./Compare Output,

EX1IN Fast External Interrupt 1 Input (default pin)

CC10IO CAPCOM1: CC10 Capture Inp./Compare Outp.,

EX2IN Fast External Interrupt 2 Input (default pin)

CC11IO CAPCOM1: CC11 Capture Inp./Compare Outp.,

EX3IN Fast External Interrupt 3 Input (default pin)

CC12IO CAPCOM1: CC12 Capture Inp./Compare Outp.,

EX4IN Fast External Interrupt 4 Input (default pin)

CC13IO CAPCOM1: CC13 Capture Inp./Compare Outp.,

EX5IN Fast External Interrupt 5 Input (default pin)

CC14IO CAPCOM1: CC14 Capture Inp./Compare Outp.,

EX6IN Fast External Interrupt 6 Input (default pin)

CC15IO CAPCOM1: CC15 Capture Inp./Compare Outp.,

EX7IN Fast External Interrupt 7 Input (default pin),

T7IN CAPCOM2: Timer T7 Count Input

TRST

57 I Test-System Reset Input. A high-level at this pin activates

the XC167’s debug system.

Note: For normal system operation, pin TRST

should be

held low.

Data Sheet 13 V1.2, 2006-03

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

Symbol

P3

P3.0

P3.1

P3.2

P3.3

P3.4

P3.5

P3.6

P3.7

P3.8

P3.9

P3.10

P3.11

P3.12

P3.13

P3.15

Pin

Num.

59

60

61

62

63

64

65

66

67

68

69

70

75

76

77

Input

Outp.

IO

I

O

I

O

I/O

I

I

O

I

I

I

I

I/O

I/O

O

I

I/O

I

O

O

I

I/O

I

O

O

Function

Port 3 is a 15-bit bidirectional I/O port. Each pin can be

programmed for input (output driver in high-impedance

state) or output (configurable as push/pull or open drain

driver). The input threshold of Port 3 is selectable (standard

or special).

The following Port 3 pins also serve for alternate functions:

T0IN CAPCOM1 Timer T0 Count Input,

TxD1 ASC1 Clock/Data Output (Async./Sync),

EX1IN Fast External Interrupt 1 Input (alternate pin B)

T6OUT GPT2 Timer T6 Toggle Latch Output,

RxD1 ASC1 Data Input (Async.) or Inp./Outp. (Sync.),

EX1IN Fast External Interrupt 1 Input (alternate pin A)

CAPIN GPT2 Register CAPREL Capture Input

T3OUT GPT1 Timer T3 Toggle Latch Output

T3EUD GPT1 Timer T3 External Up/Down Control Input

T4IN GPT1 Timer T4 Count/Gate/Reload/Capture Inp

T3IN GPT1 Timer T3 Count/Gate Input

T2IN GPT1 Timer T2 Count/Gate/Reload/Capture Inp

MRST0 SSC0 Master-Receive/Slave-Transmit In/Out.

MTSR0 SSC0 Master-Transmit/Slave-Receive Out/In.

TxD0 ASC0 Clock/Data Output (Async./Sync.),

EX2IN Fast External Interrupt 2 Input (alternate pin B)

RxD0 ASC0 Data Input (Async.) or Inp./Outp. (Sync.),

EX2IN Fast External Interrupt 2 Input (alternate pin A)

BHE

WRH

External Memory High Byte Enable Signal,

External Memory High Byte Write Strobe,

EX3IN Fast External Interrupt 3 Input (alternate pin B)

SCLK0 SSC0 Master Clock Output/Slave Clock Input.,

EX3IN Fast External Interrupt 3 Input (alternate pin A)

CLKOUT Master Clock Output,

FOUT Programmable Frequency Output

TCK 71 I Debug System: JTAG Clock Input

TDI 72 I Debug System: JTAG Data In

TDO 73 O Debug System: JTAG Data Out

TMS 74 I Debug System: JTAG Test Mode Selection

Data Sheet 14 V1.2, 2006-03

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

Symbol

P4

P4.0

P4.1

P4.2

P4.3

P4.4

P4.5

P4.6

P4.7

Pin

Num.

80

81

82

83

84

85

86

87

Input

Outp.

IO

O

O

O

O

O

I

I

O

I

I

O

O

I

O

I

O

I

Function

Port 4 is an 8-bit bidirectional I/O port. Each pin can be

programmed for input (output driver in high-impedance

state) or output (configurable as push/pull or open drain

driver). The input threshold of Port 4 is selectable (standard

or special).

Port 4 can be used to output the segment address lines, the

optional chip select lines, and for serial interface lines:

1)

A16 Least Significant Segment Address Line

A17 Segment Address Line

A18 Segment Address Line

A19 Segment Address Line

A20 Segment Address Line,

CAN2_RxD CAN Node 2 Receive Data Input,

EX5IN Fast External Interrupt 5 Input (alternate pin B)

A21 Segment Address Line,

CAN1_RxD CAN Node 1 Receive Data Input,

EX4IN Fast External Interrupt 4 Input (alternate pin B)

A22 Segment Address Line,

CAN1_TxD CAN Node 1 Transmit Data Output,

EX5IN Fast External Interrupt 5 Input (alternate pin A)

A23 Most Significant Segment Address Line,

CAN1_RxD CAN Node 1 Receive Data Input,

CAN2_TxD CAN Node 2 Transmit Data Output,

EX4IN Fast External Interrupt 4 Input (alternate pin A)

Data Sheet 15 V1.2, 2006-03

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

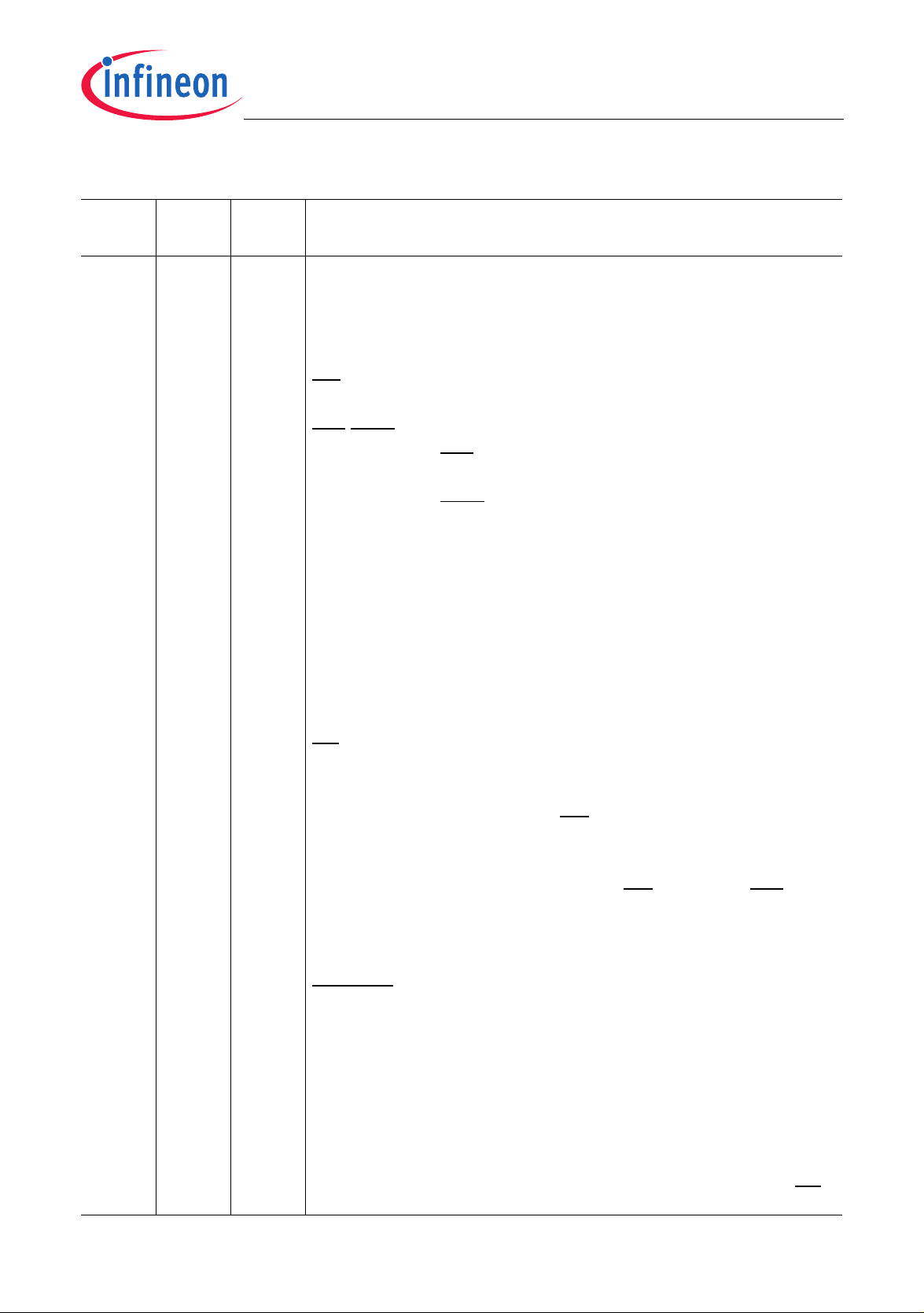

Symbol

P20

P20.0

P20.1

P20.2

P20.4

P20.5

P20.12

Pin

Num.

90

91

92

93

94

3

Input

Outp.

IO

O

O

I

O

I

O

Function

Port 20 is a 6-bit bidirectional I/O port. Each pin can be

programmed for input (output driver in high-impedance

state) or output. The input threshold of Port 20 is selectable

(standard or special).

The following Port 20 pins also serve for alternate functions:

RD

External Memory Read Strobe, activated for

every external instruction or data read access.

WR

/WRL External Memory Write Strobe.

In WR

-mode this pin is activated for every

external data write access.

In WRL

-mode this pin is activated for low byte

data write accesses on a 16-bit bus, and for

every data write access on an 8-bit bus.

READY READY Input. When the READY function is

enabled, memory cycle time waitstates can be

forced via this pin during an external access.

ALE Address Latch Enable Output.

Can be used for latching the address into

external memory or an address latch in the

multiplexed bus modes.

EA

External Access Enable pin.

A low-level at this pin during and after Reset

forces the XC167 to latch the configuration from

PORT0 and pin RD

, and to begin instruction

execution out of external memory.

A high-level forces the XC167 to latch the

configuration from pins RD

, ALE, and WR, and

to begin instruction execution out of the internal

program memory. “ROMless” versions must

have this pin tied to ‘0’.

RSTOUT

Internal Reset Indication Output.

Is activated asynchronously with an external

hardware reset. It may also be activated

(selectable) synchronously with an internal

software or watchdog reset.

Is deactivated upon the execution of the EINIT

instruction, optionally at the end of reset, or at

any time (before EINIT) via user software.

Note: Port 20 pins may input configuration values (see EA

Data Sheet 16 V1.2, 2006-03

).

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

Symbol

PORT0

P0L.0 P0L.7,

P0H.0,

P0H.1,

P0H.2 P0H.7

Pin

Num.

95 102,

105,

106,

111 116

Input

Function

Outp.

IO PORT0 consists of the two 8-bit bidirectional I/O ports P0L

and P0H. Each pin can be programmed for input (output

driver in high-impedance state) or output.

In case of an external bus configuration, PORT0 serves as

the address (A) and address/data (AD) bus in multiplexed

bus modes and as the data (D) bus in demultiplexed bus

modes.

Demultiplexed bus modes:

8-bit data bus: P0H = I/O, P0L = D7 - D0

16-bit data bus: P0H = D15 - D8, P0L = D7 - D0

Multiplexed bus modes:

8-bit data bus: P0H = A15 - A8, P0L = AD7 - AD0

16-bit data bus: P0H = AD15 - AD8, P0L = AD7 - AD0

Note: At the end of an external reset (EA

= 0) PORT0 also

may input configuration values.

Data Sheet 17 V1.2, 2006-03

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

Symbol

PORT1

P1L.0

P1L.1

P1L.2

P1L.3

P1L.4

P1L.5

P1L.6

P1L.7

P1H.0

P1H.1

P1H.2

P1H.3

P1H.4

P1H.5

P1H.6

P1H.7

Pin

Num.

117

118

119

120

121

122

123

124

127

128

129

130

131

132

133

134

Input

Outp.

IO

I/O

O

I/O

O

I/O

O

O

I

I/O

I

I

I/O

I

I/O

I

I/O

I/O

I

I/O

I/O

I/O

I/O

Function

PORT1 consists of the two 8-bit bidirectional I/O ports P1L

and P1H. Each pin can be programmed for input (output

driver in high-impedance state) or output.

PORT1 is used as the 16-bit address bus (A) in

demultiplexed bus modes (also after switching from a

demultiplexed to a multiplexed bus mode).

The following PORT1 pins also serve for alt. functions:

CC60 CAPCOM6: Input / Output of Channel 0

COUT60 CAPCOM6: Output of Channel 0

CC61 CAPCOM6: Input / Output of Channel 1

COUT61 CAPCOM6: Output of Channel 1

CC62 CAPCOM6: Input / Output of Channel 2

COUT62 CAPCOM6: Output of Channel 2

COUT63 Output of 10-bit Compare Channel

CTRAP

CAPCOM2: CC22 Capture Inp./Compare Outp.

CTRAP

is an input pin with an internal pull-up

resistor. A low level on this pin switches the

CAPCOM6 compare outputs to the logic level

defined by software (if enabled).

CC22IO CAPCOM2: CC22 Capture Inp./Compare Outp.

CC6POS0

CAPCOM6: Position 0 Input,

EX0IN Fast External Interrupt 0 Input (alternate pin B),

CC23IO CAPCOM2: CC23 Capture Inp./Compare Outp.

CC6POS1

CAPCOM6: Position 1 Input,

MRST1 SSC1 Master-Receive/Slave-Transmit In/Out.

CC6POS2

CAPCOM6: Position 2 Input,

MTSR1 SSC1 Master-Transmit/Slave-Receive Out/Inp.

SCLK1 SSC1 Master Clock Output / Slave Clock Input,

EX0IN Fast External Interrupt 0 Input (alternate pin A)

CC24IO CAPCOM2: CC24 Capture Inp./Compare Outp.

CC25IO CAPCOM2: CC25 Capture Inp./Compare Outp.

CC26IO CAPCOM2: CC26 Capture Inp./Compare Outp.

CC27IO CAPCOM2: CC27 Capture Inp./Compare Outp.

Data Sheet 18 V1.2, 2006-03

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

Symbol

XTAL2

XTAL1

XTAL3

XTAL4

RSTIN

Pin

Num.

137

138

Input

Outp.

O

I

Function

XTAL2: Output of the main oscillator amplifier circuit

XTAL1: Input to the main oscillator amplifier and input to

the internal clock generator

To clock the device from an external source, drive XTAL1,

while leaving XTAL2 unconnected. Minimum and maximum

high/low and rise/fall times specified in the AC

Characteristics must be observed.

140

141

I

O

XTAL3: Input to the auxiliary (32-kHz) oscillator amplifier

XTAL4: Output of the auxiliary (32-kHz) oscillator

amplifier circuit

To clock the device from an external source, drive XTAL3,

while leaving XTAL4 unconnected. Minimum and maximum

high/low and rise/fall times specified in the AC

Characteristics must be observed.

142 I Reset Input with Schmitt-Trigger characteristics. A low-level

at this pin while the oscillator is running resets the XC167.

A spike filter suppresses input pulses < 10 ns. Input pulses

> 100 ns safely pass the filter. The minimum duration for a

safe recognition should be 100 ns + 2 CPU clock cycles.

BRK

143 O Debug System: Break Out

OUT

BRKIN

144 I Debug System: Break In

NC 1, 2,

107 110

V

V

V

AREF

AGND

DDI

41 – Reference voltage for the A/D converter.

42 – Reference ground for the A/D converter.

48, 78,

135

Note: The reset duration must be sufficient to let the

hardware configuration signals settle.

External circuitry must guarantee low-level at the

RSTIN

pin at least until both power supply voltages

have reached the operating range.

– No connection.

It is recommended not to connect these pins to the PCB.

– Digital Core Supply Voltage (On-Chip Modules):

+2.5 V during normal operation and idle mode.

Please refer to the Operating Conditions.

Data Sheet 19 V1.2, 2006-03

Table 2 Pin Definitions and Functions (cont’d)

XC167-16

Derivatives

General Device Information

Symbol

V

DDP

Pin

Num.

6, 20,

28, 58,

88,

Input

Function

Outp.

– Digital Pad Supply Voltage (Pin Output Drivers):

+5 V during normal operation and idle mode.

Please refer to the Operating Conditions.

103,

125

V

V

SSI

SSP

47, 79,

136,

139

5, 19,

27, 89,

– Digital Ground

Connect decoupling capacitors to adjacent

as close as possible to the pins.

All

V

pins must be connected to the ground-line or ground-

–

SS

plane.

104,

126

1) The CAN interface lines are assigned to ports P4, P7, and P9 under software control.

V

DD/VSS

pin pairs

Data Sheet 20 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

3 Functional Description

The architecture of the XC167 combines advantages of RISC, CISC, and DSP

processors with an advanced peripheral subsystem in a very well-balanced way. In

addition, the on-chip memory blocks allow the design of compact systems-on-silicon with

maximum performance (computing, control, communication).

The on-chip memory blocks (program code-memory and SRAM, dual-port RAM, data

SRAM) and the set of generic peripherals are connected to the CPU via separate buses.

Another bus, the LXBus, connects additional on-chip resources as well as external

resources (see Figure 3).

This bus structure enhances the overall system performance by enabling the concurrent

operation of several subsystems of the XC167.

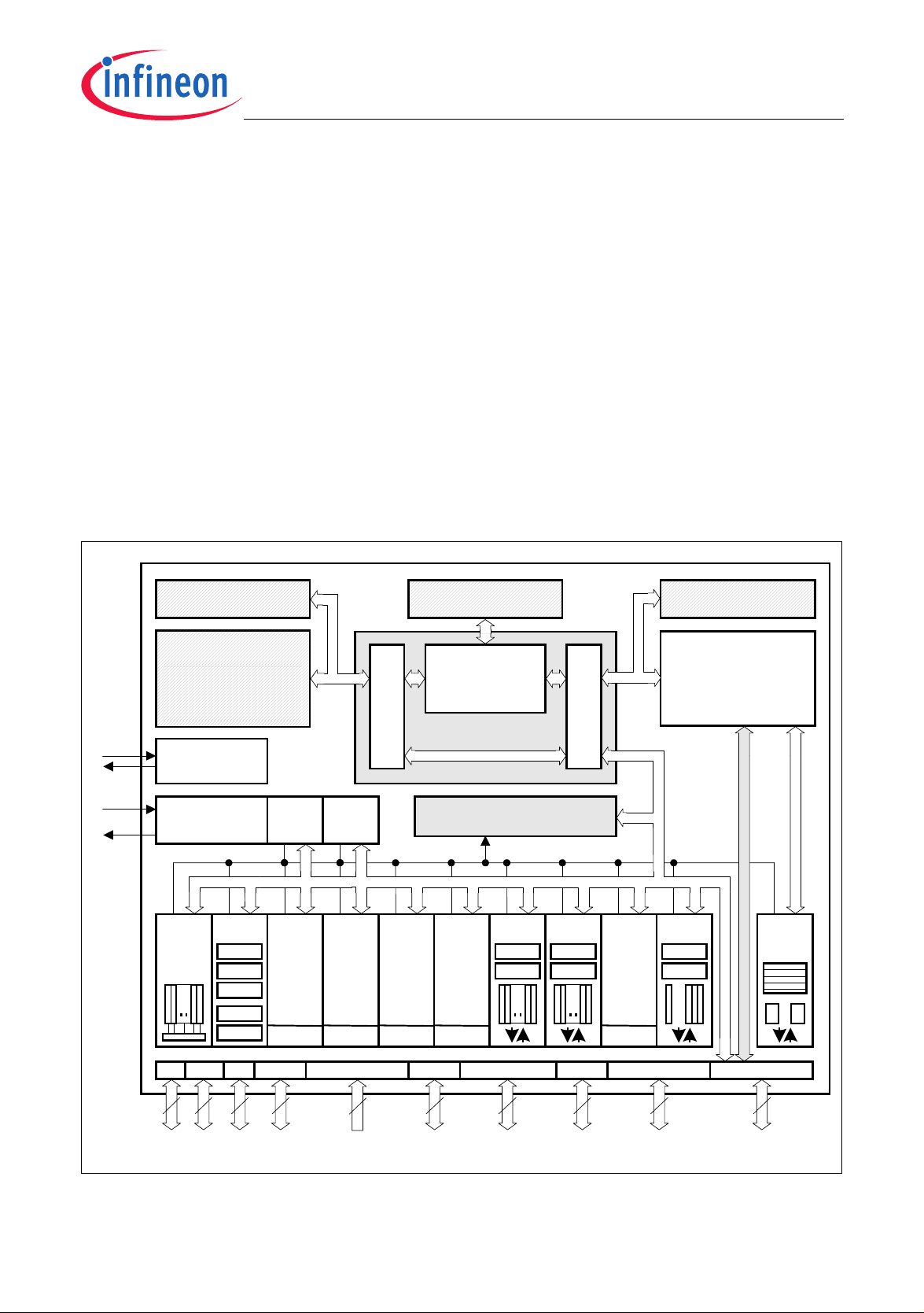

The following block diagram gives an overview of the different on-chip components and

of the advanced, high bandwidth internal bus structure of the XC167.

XTAL

PSRAM DPRAM DSRAM

ProgMem

Flash

128 KBytes

PMU

CPU

DMU

C166SV2-Core

OCDS

Debug Support

Osc / PLL

Clock Generation

ADC

8/10-Bit

Channels

GPT

16

T2

T3

T4

T5

T6

RTC WDT

ASC0

(USAR T)

BRGen

ASC1

(USART)

BRGen

SSC0

(SPI)

BRGen

Interrupt & PEC

SSC1

(SPI)

BRGen

CC1

T0

T1

Interrupt Bus

Peripheral Data Bus

CC2

T7

T8

BRGen

IIC

CC6

EBC

XBUS Control

External Bus

Control

T12

T13

Twin

CAN

A B

P 20

4

66

Port 5

16

PORT1 PORT0Port 2Port 3Port 4Port 6P 7Port 9

81588

16

16

MCB04323_x7.vsd

Figure 3 Block Diagram

Data Sheet 21 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

3.1 Memory Subsystem and Organization

The memory space of the XC167 is configured in a Von Neumann architecture, which

means that all internal and external resources, such as code memory, data memory,

registers and I/O ports, are organized within the same linear address space. This

common memory space includes 16 Mbytes and is arranged as 256 segments of

64 Kbytes each, where each segment consists of four data pages of 16 Kbytes each.

The entire memory space can be accessed bytewise or wordwise. Portions of the

on-chip DPRAM and the register spaces (E/SFR) have additionally been made directly

bitaddressable.

The internal data memory areas and the Special Function Register areas (SFR and

ESFR) are mapped into segment 0, the system segment.

The Program Management Unit (PMU) handles all code fetches and, therefore, controls

accesses to the program memories, such as Flash memory and PSRAM.

The Data Management Unit (DMU) handles all data transfers and, therefore, controls

accesses to the DSRAM and the on-chip peripherals.

Both units (PMU and DMU) are connected via the high-speed system bus to exchange

data. This is required if operands are read from program memory, code or data is written

to the PSRAM, code is fetched from external memory, or data is read from or written to

external resources, including peripherals on the LXBus (such as TwinCAN). The system

bus allows concurrent two-way communication for maximum transfer performance.

128 Kbytes of on-chip Flash memory store code or constant data. The on-chip Flash

memory is organized as four 8-Kbyte sectors, one 32-Kbyte sector, and one 64-Kbyte

sector. Each sector can be separately write protected

1)

, erased and programmed (in

blocks of 128 Bytes). The complete Flash area can be read-protected. A password

sequence temporarily unlocks protected areas. The Flash module combines very fast

64-bit one-cycle read accesses with protected and efficient writing algorithms for

programming and erasing. Thus, program execution out of the internal Flash results in

maximum performance. Dynamic error correction provides extremely high read data

security for all read accesses.

For timing characteristics, please refer to Section 4.4.2.

2 Kbytes of on-chip Program SRAM (PSRAM) are provided to store user code or data.

The PSRAM is accessed via the PMU and is therefore optimized for code fetches.

4 Kbytes of on-chip Data SRAM (DSRAM) are provided as a storage for general user

data. The DSRAM is accessed via the DMU and is therefore optimized for data

accesses.

2 Kbytes of on-chip Dual-Port RAM (DPRAM) are provided as a storage for user

defined variables, for the system stack, and general purpose register banks. A register

bank can consist of up to 16 wordwide (R0 to R15) and/or bytewide (RL0, RH0, …, RL7,

1) Each two 8-Kbyte sectors are combined for write-protection purposes.

Data Sheet 22 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

RH7) so-called General Purpose Registers (GPRs).

The upper 256 bytes of the DPRAM are directly bitaddressable. When used by a GPR,

any location in the DPRAM is bitaddressable.

1024 bytes (2 × 512 bytes) of the address space are reserved for the Special Function

Register areas (SFR space and ESFR space). SFRs are wordwide registers which are

used for controlling and monitoring functions of the different on-chip units. Unused SFR

addresses are reserved for future members of the XC166 Family. Therefore, they should

either not be accessed, or written with zeros, to ensure upward compatibility.

In order to meet the needs of designs where more memory is required than is provided

on chip, up to 12 Mbytes (approximately, see Table 3) of external RAM and/or ROM can

be connected to the microcontroller. The External Bus Interface also provides access to

external peripherals.

Table 3 XC167 Memory Map

1)

Address Area Start Loc. End Loc. Area Size

Flash register space FF’F000

Reserved (Access trap) F8’0000

Reserved for PSRAM E0’0800

Program SRAM E0’0000

Reserved for pr. mem. C2’0000

Program Flash C0’0000

Reserved BF’0000

External memory area 40’0000

External IO area

4)

20’0800

TwinCAN registers 20’0000

External memory area 01’0000

H

H

H

H

H

H

H

H

H

H

H

FF’FFFF

FF’EFFF

F7’FFFF

E0’07FF

DF’FFFF

C1’FFFF

BF’FFFF

BE’FFFF

3F’FFFF

20’07FF

1F’FFFF

4 Kbytes

H

< 0.5 Mbytes Minus Flash

H

< 1.5 Mbytes Minus PSRAM

H

2 Kbytes Maximum

H

< 2 Mbytes Minus Flash

H

128 Kbytes –

H

64 Kbytes –

H

< 8 Mbytes Minus reserved

H

< 2 Mbytes Minus TwinCAN

H

2 Kbytes –

H

< 2 Mbytes Minus segment 0

H

2)

Notes

3)

registers

segment

Data RAMs and SFRs 00’8000

External memory area 00’0000

1) Accesses to the shaded areas generate external bus accesses.

2) The areas marked with “<” are slightly smaller than indicated, see column “Notes”.

3) Not defined register locations return a trap code.

4) Several pipeline optimizations are not active within the external IO area. This is necessary to control external

peripherals properly.

Data Sheet 23 V1.2, 2006-03

H

H

00’FFFF

00’7FFF

32 Kbytes Partly used

H

32 Kbytes –

H

XC167-16

Derivatives

Functional Description

3.2 External Bus Controller

All of the external memory accesses are performed by a particular on-chip External Bus

Controller (EBC). It can be programmed either to Single Chip Mode when no external

memory is required, or to one of four different external memory access modes

are as follows:

• 16 … 24-bit Addresses, 16-bit Data, Demultiplexed

• 16 … 24-bit Addresses, 16-bit Data, Multiplexed

• 16 … 24-bit Addresses, 8-bit Data, Multiplexed

• 16 … 24-bit Addresses, 8-bit Data, Demultiplexed

In the demultiplexed bus modes, addresses are output on PORT1 and data is

input/output on PORT0 or P0L, respectively. In the multiplexed bus modes both

addresses and data use PORT0 for input/output. The high order address (segment) lines

use Port 4. The number of active segment address lines is selectable, restricting the

external address space to 8 Mbytes … 64 Kbytes. This is required when interface lines

are assigned to Port 4.

1)

, which

Up to 5 external CS

signals (4 windows plus default) can be generated in order to save

external glue logic. External modules can directly be connected to the common

address/data bus and their individual select lines.

Access to very slow memories or modules with varying access times is supported via a

particular ‘Ready’ function. The active level of the control input signal is selectable.

A HOLD

/HLDA protocol is available for bus arbitration and allows the sharing of external

resources with other bus masters. The bus arbitration is enabled by software. After

enabling, pins P6.7 … P6.5 (BREQ

EBC. In Master Mode (default after reset) the HLDA

HLDA

is switched to input. This allows the direct connection of the slave controller to

, HLDA, HOLD) are automatically controlled by the

pin is an output. In Slave Mode pin

another master controller without glue logic.

Important timing characteristics of the external bus interface have been made

programmable (via registers TCONCSx/FCONCSx) to allow the user the adaption of a

wide range of different types of memories and external peripherals.

In addition, up to 4 independent address windows may be defined (via registers

ADDRSELx) which control the access to different resources with different bus

characteristics. These address windows are arranged hierarchically where window 4

overrides window 3, and window 2 overrides window 1. All accesses to locations not

covered by these 4 address windows are controlled by TCONCS0/FCONCS0. The

currently active window can generate a chip select signal.

The external bus timing is related to the rising edge of the reference clock output

CLKOUT. The external bus protocol is compatible with that of the standard C166 Family.

1) Bus modes are switched dynamically if several address windows with different mode settings are used.

Data Sheet 24 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

The EBC also controls accesses to resources connected to the on-chip LXBus. The

LXBus is an internal representation of the external bus and allows accessing integrated

peripherals and modules in the same way as external components.

The TwinCAN module is connected and accessed via the LXBus.

Data Sheet 25 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

3.3 Central Processing Unit (CPU)

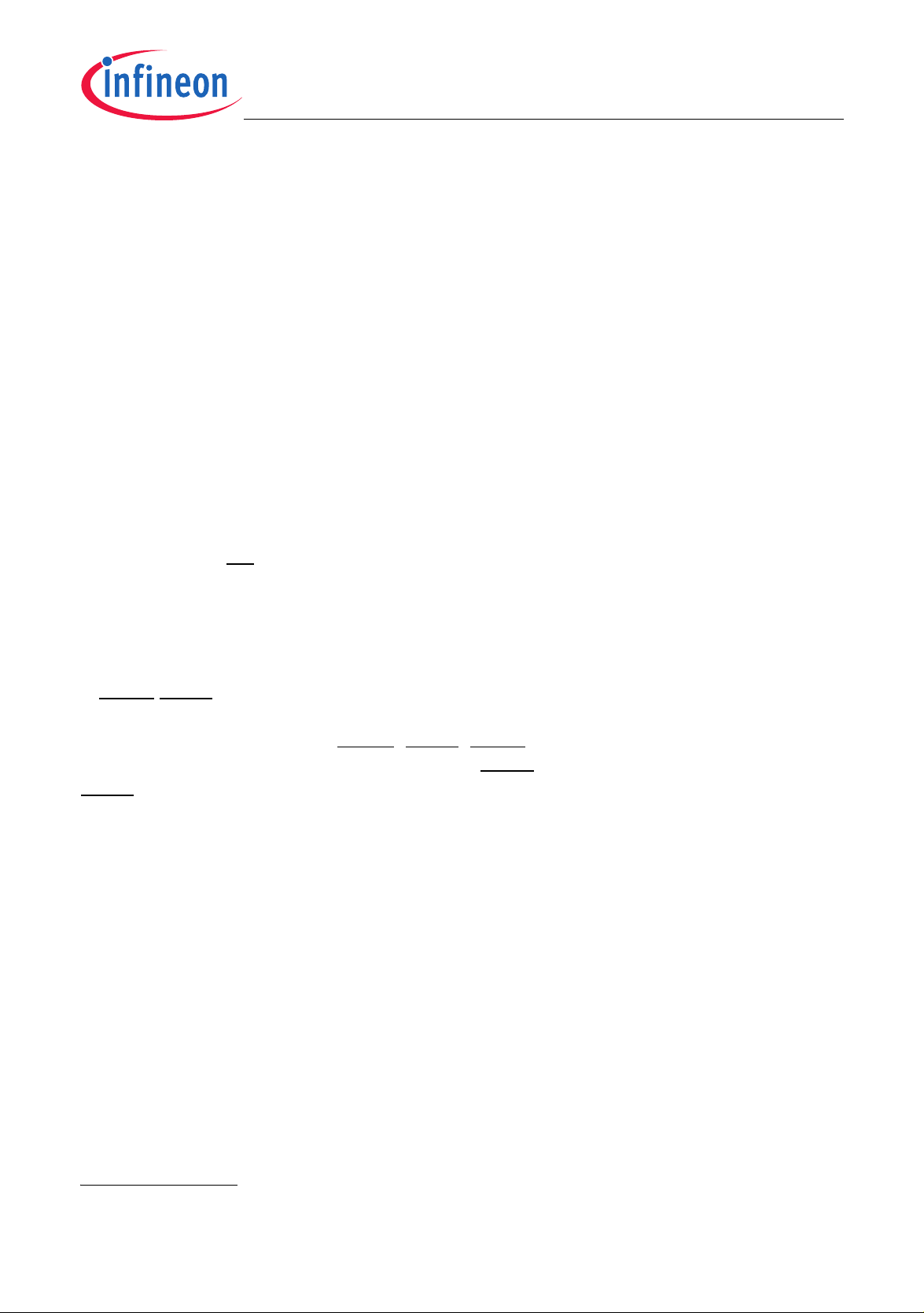

The main core of the CPU consists of a 5-stage execution pipeline with a 2-stage

instruction-fetch pipeline, a 16-bit arithmetic and logic unit (ALU), a 32-bit/40-bit multiply

and accumulate unit (MAC), a register-file providing three register banks, and dedicated

SFRs. The ALU features a multiply and divide unit, a bit-mask generator, and a barrel

shifter.

CPU

Prefetch

Branch

Multiply

Unit

Unit

FIFO

IDX0

IDX1

QX0

QX1

+/-

Unit

+/-

CSP IP

CPUCON1

CPUCON2

Return

Stack

QR0

QR1

+/-

MRW

MCW

MSW

IFU

DPP0

DPP1

DPP2

DPP3

Division Unit

M ultip ly U n it

MDC

PSW

VECSEG

TFR

Injection/

Exception

Handler

SPSEG

SP

STKOV

STKUN

Bit-Mask-Gen.

Barrel-Shifter

+/-

ADU

PMU

2-Stage

5-Stage

R15

R14

GPRs

GPRs

RF

Prefetch

Pipeline

Pipeline

CP

R15

R15

R14

R14

GPRs

R1

R1

R0

R1

R0

R0

PSRAM

Flash/ROM

DPRAM

IPIP

R15

R14

GPRs

R1

R0

MAC

MAH

MAL

MDH

ZEROS

MDL

ONES

ALU

Buffer

DMU

WB

DSRAM

EBC

Peripherals

mca04917_x.vsd

Figure 4 CPU Block Diagram

Based on these hardware provisions, most of the XC167’s instructions can be executed

in just one machine cycle which requires 25 ns at 40 MHz CPU clock. For example, shift

Data Sheet 26 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

and rotate instructions are always processed during one machine cycle independent of

the number of bits to be shifted. Also multiplication and most MAC instructions execute

in one single cycle. All multiple-cycle instructions have been optimized so that they can

be executed very fast as well: for example, a division algorithm is performed in 18 to 21

CPU cycles, depending on the data and division type. Four cycles are always visible, the

rest runs in the background. Another pipeline optimization, the branch target prediction,

allows eliminating the execution time of branch instructions if the prediction was correct.

The CPU has a register context consisting of up to three register banks with 16 wordwide

GPRs each at its disposal. The global register bank is physically allocated within the onchip DPRAM area. A Context Pointer (CP) register determines the base address of the

active global register bank to be accessed by the CPU at any time. The number of

register banks is only restricted by the available internal RAM space. For easy parameter

passing, a register bank may overlap others.

A system stack of up to 32 Kwords is provided as a storage for temporary data. The

system stack can be allocated to any location within the address space (preferably in the

on-chip RAM area), and it is accessed by the CPU via the stack pointer (SP) register.

Two separate SFRs, STKOV and STKUN, are implicitly compared against the stack

pointer value upon each stack access for the detection of a stack overflow or underflow.

The high performance offered by the hardware implementation of the CPU can efficiently

be utilized by a programmer via the highly efficient XC167 instruction set which includes

the following instruction classes:

• Standard Arithmetic Instructions

• DSP-Oriented Arithmetic Instructions

• Logical Instructions

• Boolean Bit Manipulation Instructions

• Compare and Loop Control Instructions

• Shift and Rotate Instructions

• Prioritize Instruction

• Data Movement Instructions

• System Stack Instructions

• Jump and Call Instructions

• Return Instructions

• System Control Instructions

• Miscellaneous Instructions

The basic instruction length is either 2 or 4 bytes. Possible operand types are bits, bytes

and words. A variety of direct, indirect or immediate addressing modes are provided to

specify the required operands.

Data Sheet 27 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

3.4 Interrupt System

With an interrupt response time of typically 8 CPU clocks (in case of internal program

execution), the XC167 is capable of reacting very fast to the occurrence of nondeterministic events.

The architecture of the XC167 supports several mechanisms for fast and flexible

response to service requests that can be generated from various sources internal or

external to the microcontroller. Any of these interrupt requests can be programmed to

being serviced by the Interrupt Controller or by the Peripheral Event Controller (PEC).

In contrast to a standard interrupt service where the current program execution is

suspended and a branch to the interrupt vector table is performed, just one cycle is

‘stolen’ from the current CPU activity to perform a PEC service. A PEC service implies a

single byte or word data transfer between any two memory locations with an additional

increment of either the PEC source, or the destination pointer, or both. An individual PEC

transfer counter is implicitly decremented for each PEC service except when performing

in the continuous transfer mode. When this counter reaches zero, a standard interrupt is

performed to the corresponding source related vector location. PEC services are very

well suited, for example, for supporting the transmission or reception of blocks of data.

The XC167 has 8 PEC channels each of which offers such fast interrupt-driven data

transfer capabilities.

A separate control register which contains an interrupt request flag, an interrupt enable

flag and an interrupt priority bitfield exists for each of the possible interrupt nodes. Via its

related register, each node can be programmed to one of sixteen interrupt priority levels.

Once having been accepted by the CPU, an interrupt service can only be interrupted by

a higher prioritized service request. For the standard interrupt processing, each of the

possible interrupt nodes has a dedicated vector location.

Fast external interrupt inputs are provided to service external interrupts with high

precision requirements. These fast interrupt inputs feature programmable edge

detection (rising edge, falling edge, or both edges).

Software interrupts are supported by means of the ‘TRAP’ instruction in combination with

an individual trap (interrupt) number.

Table 4 shows all of the possible XC167 interrupt sources and the corresponding

hardware-related interrupt flags, vectors, vector locations and trap (interrupt) numbers.

Note: Interrupt nodes which are not assigned to peripherals (unassigned nodes), may

be used to generate software controlled interrupt requests by setting the

respective interrupt request bit (xIR).

Data Sheet 28 V1.2, 2006-03

Table 4 XC167 Interrupt Nodes

XC167-16

Derivatives

Functional Description

Source of Interrupt or PEC

Service Request

Control

Register

Vector

Location

CAPCOM Register 0 CC1_CC0IC xx’0040

CAPCOM Register 1 CC1_CC1IC xx’0044

CAPCOM Register 2 CC1_CC2IC xx’0048

CAPCOM Register 3 CC1_CC3IC xx’004C

CAPCOM Register 4 CC1_CC4IC xx’0050

CAPCOM Register 5 CC1_CC5IC xx’0054

CAPCOM Register 6 CC1_CC6IC xx’0058

CAPCOM Register 7 CC1_CC7IC xx’005C

CAPCOM Register 8 CC1_CC8IC xx’0060

CAPCOM Register 9 CC1_CC9IC xx’0064

CAPCOM Register 10 CC1_CC10IC xx’0068

CAPCOM Register 11 CC1_CC11IC xx’006C

CAPCOM Register 12 CC1_CC12IC xx’0070

Trap

1)

H

H

H

H

H

H

H

H

H

H

H

H

H

Number

10H / 16

11H / 17

12H / 18

13H / 19

14H / 20

15H / 21

16H / 22

17H / 23

18H / 24

19H / 25

1AH / 26

1BH / 27

1CH / 28

D

D

D

D

D

D

D

D

D

D

D

D

D

CAPCOM Register 13 CC1_CC13IC xx’0074

CAPCOM Register 14 CC1_CC14IC xx’0078

CAPCOM Register 15 CC1_CC15IC xx’007C

CAPCOM Register 16 CC2_CC16IC xx’00C0

CAPCOM Register 17 CC2_CC17IC xx’00C4

CAPCOM Register 18 CC2_CC18IC xx’00C8

CAPCOM Register 19 CC2_CC19IC xx’00CC

CAPCOM Register 20 CC2_CC20IC xx’00D0

CAPCOM Register 21 CC2_CC21IC xx’00D4

CAPCOM Register 22 CC2_CC22IC xx’00D8

CAPCOM Register 23 CC2_CC23IC xx’00DC

CAPCOM Register 24 CC2_CC24IC xx’00E0

CAPCOM Register 25 CC2_CC25IC xx’00E4

CAPCOM Register 26 CC2_CC26IC xx’00E8

CAPCOM Register 27 CC2_CC27IC xx’00EC

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

1DH / 29

1EH / 30

1FH / 31

30H / 48

31H / 49

32H / 50

33H / 51

34H / 52

35H / 53

36H / 54

37H / 55

38H / 56

39H / 57

3AH / 58

3BH / 59

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

CAPCOM Register 28 CC2_CC28IC xx’00F0

H

3CH / 60

D

Data Sheet 29 V1.2, 2006-03

Table 4 XC167 Interrupt Nodes (cont’d)

XC167-16

Derivatives

Functional Description

Source of Interrupt or PEC

Service Request

Control

Register

Vector

Location

CAPCOM Register 29 CC2_CC29IC xx’0110

CAPCOM Register 30 CC2_CC30IC xx’0114

CAPCOM Register 31 CC2_CC31IC xx’0118

CAPCOM Timer 0 CC1_T0IC xx’0080

CAPCOM Timer 1 CC1_T1IC xx’0084

CAPCOM Timer 7 CC2_T7IC xx’00F4

CAPCOM Timer 8 CC2_T8IC xx’00F8

GPT1 Timer 2 GPT12E_T2IC xx’0088

GPT1 Timer 3 GPT12E_T3IC xx’008C

GPT1 Timer 4 GPT12E_T4IC xx’0090

GPT2 Timer 5 GPT12E_T5IC xx’0094

GPT2 Timer 6 GPT12E_T6IC xx’0098

GPT2 CAPREL Register GPT12E_CRIC xx’009C

Trap

1)

H

H

H

H

H

H

H

H

H

H

H

H

H

Number

44H / 68

45H / 69

46H / 70

20H / 32

21H / 33

3DH / 61

3EH / 62

22H / 34

23H / 35

24H / 36

25H / 37

26H / 38

27H / 39

D

D

D

D

D

D

D

D

D

D

D

D

D

A/D Conversion Complete ADC_CIC xx’00A0

A/D Overrun Error ADC_EIC xx’00A4

ASC0 Transmit ASC0_TIC xx’00A8

ASC0 Transmit Buffer ASC0_TBIC xx’011C

ASC0 Receive ASC0_RIC xx’00AC

ASC0 Error ASC0_EIC xx’00B0

ASC0 Autobaud ASC0_ABIC xx’017C

SSC0 Transmit SSC0_TIC xx’00B4

SSC0 Receive SSC0_RIC xx’00B8

SSC0 Error SSC0_EIC xx’00BC

IIC Data Transfer Event IIC_DTIC xx’0100

IIC Protocol Event IIC_PEIC xx’0104

PLL/OWD PLLIC xx’010C

ASC1 Transmit ASC1_TIC xx’0120

ASC1 Transmit Buffer ASC1_TBIC xx’0178

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

28H / 40

29H / 41

2AH / 42

47H / 71

2BH / 43

2CH / 44

5FH / 95

2DH / 45

2EH / 46

2FH / 47

40H / 64

41H / 65

43H / 67

48H / 72

5EH / 94

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

ASC1 Receive ASC1_RIC xx’0124

ASC1 Error ASC1_EIC xx’0128

H

H

49H / 73

4AH / 74

D

D

Data Sheet 30 V1.2, 2006-03

Table 4 XC167 Interrupt Nodes (cont’d)

XC167-16

Derivatives

Functional Description

Source of Interrupt or PEC

Service Request

Control

Register

Vector

Location

ASC1 Autobaud ASC1_ABIC xx’0108

End of PEC Subchannel EOPIC xx’0130

CAPCOM6 Timer T12 CCU6_T12IC xx’0134

CAPCOM6 Timer T13 CCU6_T13IC xx’0138

CAPCOM6 Emergency CCU6_EIC xx’013C

CAPCOM6 CCU6_IC xx’0140

SSC1 Transmit SSC1_TIC xx’0144

SSC1 Receive SSC1_RIC xx’0148

SSC1 Error SSC1_EIC xx’014C

CAN0 CAN_0IC xx’0150

CAN1 CAN_1IC xx’0154

CAN2 CAN_2IC xx’0158

CAN3 CAN_3IC xx’015C

Trap

1)

H

H

H

H

H

H

H

H

H

H

H

H

H

Number

42H / 66

4CH / 76

4DH / 77

4EH / 78

4FH / 79

50H / 80

51H / 81

52H / 82

53H / 83

54H / 84

55H / 85

56H / 86

57H / 87

D

D

D

D

D

D

D

D

D

D

D

D

D

CAN4 CAN_4IC xx’0164

CAN5 CAN_5IC xx’0168

CAN6 CAN_6IC xx’016C

CAN7 CAN_7IC xx’0170

RTC RTC_IC xx’0174

Unassigned node – xx’012C

Unassigned node – xx’00FC

Unassigned node – xx’0160

1) Register VECSEG defines the segment where the vector table is located to.

Bitfield VECSC in register CPUCON1 defines the distance between two adjacent vectors. This table

represents the default setting, with a distance of 4 (two words) between two vectors.

H

H

H

H

H

H

H

H

59H / 89

5AH / 90

5BH / 91

5CH / 92

5DH / 93

4BH / 75

3FH / 63

58H / 88

D

D

D

D

D

D

D

D

Data Sheet 31 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

The XC167 also provides an excellent mechanism to identify and to process exceptions

or error conditions that arise during run-time, so-called ‘Hardware Traps’. Hardware

traps cause immediate non-maskable system reaction which is similar to a standard

interrupt service (branching to a dedicated vector table location). The occurrence of a

hardware trap is additionally signified by an individual bit in the trap flag register (TFR).

Except when another higher prioritized trap service is in progress, a hardware trap will

interrupt any actual program execution. In turn, hardware trap services can normally not

be interrupted by standard or PEC interrupts.

Table 5 shows all of the possible exceptions or error conditions that can arise during run-

time:

Table 5 Hardware Trap Summary

Exception Condition Trap

Flag

Reset Functions:

–

• Hardware Reset

• Software Reset

• Watchdog Timer

Overflow

Class A Hardware Traps:

• Non-Maskable Interrupt

• Stack Overflow

• Stack Underflow

• Software Break

NMI

STKOF

STKUF

SOFTBRK

Class B Hardware Traps:

• Undefined Opcode

• PMI Access Error

• Protected Instruction

UNDOPC

PACER

PRTFLT

Fault

• Illegal Word Operand

ILLOPA

Access

Trap

Vector

RESET

RESET

RESET

NMITRAP

STOTRAP

STUTRAP

SBRKTRAP

BTRAP

BTRAP

BTRAP

BTRAP

Vector

Location

xx’0000

xx’0000

xx’0000

xx’0008

xx’0010

xx’0018

xx’0020

xx’0028

xx’0028

xx’0028

xx’0028

H

H

H

H

H

H

H

H

H

H

H

Trap

1)

Number

00

00

00

02

04

06

08

0A

0A

0A

0A

Trap

Priority

H

H

H

H

H

H

H

H

H

H

H

III

III

III

II

II

II

II

I

I

I

I

Reserved – – [2C

Software Traps

–– Any

• TRAP Instruction

- 3CH][0BH -

H

[xx’0000

xx’01FC

–

0F

]

H

Any

[00

-

H

]

H

7F

-

H

]

H

Current

CPU

Priority

in steps of

4

H

1) Register VECSEG defines the segment where the vector table is located to.

Data Sheet 32 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

3.5 On-Chip Debug Support (OCDS)

The On-Chip Debug Support system provides a broad range of debug and emulation

features built into the XC167. The user software running on the XC167 can thus be

debugged within the target system environment.

The OCDS is controlled by an external debugging device via the debug interface,

consisting of the IEEE-1149-conforming JTAG port and a break interface. The debugger

controls the OCDS via a set of dedicated registers accessible via the JTAG interface.

Additionally, the OCDS system can be controlled by the CPU, e.g. by a monitor program.

An injection interface allows the execution of OCDS-generated instructions by the CPU.

Multiple breakpoints can be triggered by on-chip hardware, by software, or by an

external trigger input. Single stepping is supported as well as the injection of arbitrary

instructions and read/write access to the complete internal address space. A breakpoint

trigger can be answered with a CPU-halt, a monitor call, a data transfer, or/and the

activation of an external signal.

Tracing data can be obtained via the JTAG interface or via the external bus interface for

increased performance.

The debug interface uses a set of 6 interface signals (4 JTAG lines, 2 break lines) to

communicate with external circuitry. These interface signals use dedicated pins.

Complete system emulation is supported by the New Emulation Technology (NET)

interface.

Data Sheet 33 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

3.6 Capture/Compare Units (CAPCOM1/2)

The CAPCOM units support generation and control of timing sequences on up to

32 channels with a maximum resolution of 1 system clock cycle (8 cycles in staggered

mode). The CAPCOM units are typically used to handle high speed I/O tasks such as

pulse and waveform generation, pulse width modulation (PMW), Digital to Analog (D/A)

conversion, software timing, or time recording relative to external events.

Four 16-bit timers (T0/T1, T7/T8) with reload registers provide two independent time

bases for each capture/compare register array.

The input clock for the timers is programmable to several prescaled values of the internal

system clock, or may be derived from an overflow/underflow of timer T6 in module GPT2.

This provides a wide range of variation for the timer period and resolution and allows

precise adjustments to the application specific requirements. In addition, external count

inputs for CAPCOM timers T0 and T7 allow event scheduling for the capture/compare

registers relative to external events.

Both of the two capture/compare register arrays contain 16 dual purpose

capture/compare registers, each of which may be individually allocated to either

CAPCOM timer T0 or T1 (T7 or T8, respectively), and programmed for capture or

compare function.

All registers of each module have each one port pin associated with it which serves as

an input pin for triggering the capture function, or as an output pin to indicate the

occurrence of a compare event.

Table 6 Compare Modes (CAPCOM1/2)

Compare Modes Function

Mode 0 Interrupt-only compare mode;

several compare interrupts per timer period are possible

Mode 1 Pin toggles on each compare match;

several compare events per timer period are possible

Mode 2 Interrupt-only compare mode;

only one compare interrupt per timer period is generated

Mode 3 Pin set ‘1’ on match; pin reset ‘0’ on compare timer overflow;

only one compare event per timer period is generated

Double Register

Mode

Single Event Mode Generates single edges or pulses;

Data Sheet 34 V1.2, 2006-03

Two registers operate on one pin;

pin toggles on each compare match;

several compare events per timer period are possible

can be used with any compare mode

XC167-16

Derivatives

Functional Description

When a capture/compare register has been selected for capture mode, the current

contents of the allocated timer will be latched (‘captured’) into the capture/compare

register in response to an external event at the port pin which is associated with this

register. In addition, a specific interrupt request for this capture/compare register is

generated. Either a positive, a negative, or both a positive and a negative external signal

transition at the pin can be selected as the triggering event.

The contents of all registers which have been selected for one of the five compare modes

are continuously compared with the contents of the allocated timers.

When a match occurs between the timer value and the value in a capture/compare

register, specific actions will be taken based on the selected compare mode.

Data Sheet 35 V1.2, 2006-03

f

f

Reload Reg.

T0REL/T7REL

XC167-16

Derivatives

Functional Description

CC

T0IN/T7IN

T6OUF

CCxIO

CCxIO

T0/T7

Input

Control

Mode

Control

(Capture

or

Compare)

Timer T0/T7

Sixteen

16-bit

Capture/

Compare

Registers

T0IRQ,

T7IRQ

CCxIRQ

CCxIRQ

CCxIO

CC

T6OUF

T1/T8

Input

Control

Timer T1/T8

CCxIRQ

T1IRQ,

T8IRQ

Reload Reg.

T1REL/T8REL

CAPCOM1 provides channels x = 0 … 15,

CAPCOM2 provides channels x = 16 … 31.

(see signals CCxIO and CCxIRQ)

MCB05569

Figure 5 CAPCOM1/2 Unit Block Diagram

Data Sheet 36 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

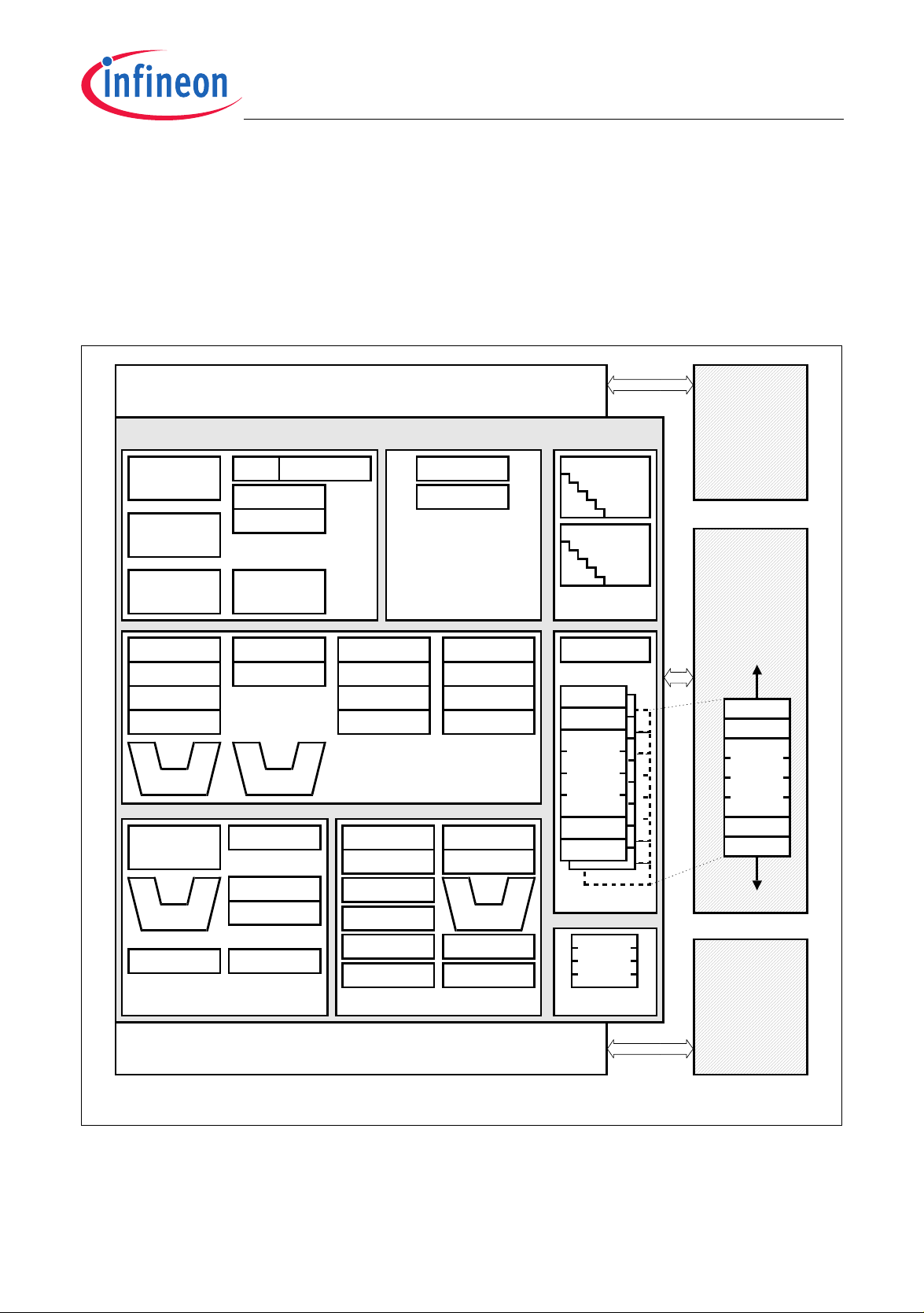

3.7 The Capture/Compare Unit CAPCOM6

The CAPCOM6 unit supports generation and control of timing sequences on up to three

16-bit capture/compare channels plus one independent 10-bit compare channel.

In compare mode the CAPCOM6 unit provides two output signals per channel which

have inverted polarity and non-overlapping pulse transitions (deadtime control). The

compare channel can generate a single PWM output signal and is further used to

modulate the capture/compare output signals.

In capture mode the contents of compare timer T12 is stored in the capture registers

upon a signal transition at pins CCx.

Compare timers T12 (16-bit) and T13 (10-bit) are free running timers which are clocked

by the prescaled system clock.

f

f

CPU

CPU

Period Register

T12P

Offset Register

T12OF

Compare

Timer T12

Prescaler

Prescaler

16-bit

Control Register

CTCON

Compare

Timer T13

10-bit

Period Register

T13P

Mode

Select Register

CC6MSEL

CC Channel 0

CC60

CC Channel 1

Control

CC61

CC Channel 2

CC62

Compare Register

CMP13

Trap Register

Port

Control

Logic

Block

Commutation

Control

CC6MCON.H

CTRAP

CC60

COUT60

CC61

COUT61

CC62

COUT62

COUT63

CC6POS0

CC6POS1

CC6POS2

The timer registers (T12, T13) are not directly accessible.

The period and offset registers are loading a value into the timer registers.

MCB04109

Figure 6 CAPCOM6 Block Diagram

For motor control applications both subunits may generate versatile multichannel PWM

signals which are basically either controlled by compare timer T12 or by a typical hall

sensor pattern at the interrupt inputs (block commutation).

Data Sheet 37 V1.2, 2006-03

XC167-16

Derivatives

Functional Description

3.8 General Purpose Timer (GPT12E) Unit

The GPT12E unit represents a very flexible multifunctional timer/counter structure which

may be used for many different time related tasks such as event timing and counting,

pulse width and duty cycle measurements, pulse generation, or pulse multiplication.

The GPT12E unit incorporates five 16-bit timers which are organized in two separate

modules, GPT1 and GPT2. Each timer in each module may operate independently in a

number of different modes, or may be concatenated with another timer of the same

module.

Each of the three timers T2, T3, T4 of module GPT1 can be configured individually for

one of four basic modes of operation, which are Timer, Gated Timer, Counter, and

Incremental Interface Mode. In Timer Mode, the input clock for a timer is derived from

the system clock, divided by a programmable prescaler, while Counter Mode allows a

timer to be clocked in reference to external events.

Pulse width or duty cycle measurement is supported in Gated Timer Mode, where the

operation of a timer is controlled by the ‘gate’ level on an external input pin. For these

purposes, each timer has one associated port pin (TxIN) which serves as gate or clock

input. The maximum resolution of the timers in module GPT1 is 4 system clock cycles.

The count direction (up/down) for each timer is programmable by software or may

additionally be altered dynamically by an external signal on a port pin (TxEUD) to

facilitate e.g. position tracking.

In Incremental Interface Mode the GPT1 timers (T2, T3, T4) can be directly connected

to the incremental position sensor signals A and B via their respective inputs TxIN and

TxEUD. Direction and count signals are internally derived from these two input signals,

so the contents of the respective timer Tx corresponds to the sensor position. The third