Fiber Optics

Small Form Factor

Single Mode 1300 nm 1.0625 Gbit/s Fibre Channel

1.25 Gigabit Ethernet Transceiver

2x5/2x10 Pinning with LC™ Connector

Preliminary Data

Features

• Small Form Factor transceiver

• Complies with Fibre Channel and Gigabit Ethernet

standards

• RJ-45 style LC™ connector system

• Available with or without collar

• Half the size of SC Duplex 1x9 transceiver

• Single power supply (3.3 V)

• Low power consumption, 650 mW typical

• Loss of optical signal indicator

V23818-K15-Lxx

File: 1119

• Laser disable input

• LVPECL differential inputs and outputs

• AC/AC coupling in accordance to SFF MSA or optional

DC/DC coupling version

• For distance of up to 10 km on single mode fiber

(SMF)

• Class 1 FDA and IEC laser safety compliant

• Multisource 2x5/2x10 footprint

1)

• Small size for high port density

• UL 94 V-0 certified

• Compliant with FCC (Class B) and EN 55022

• Tx and Rx power monitor on 2x10 pinning version

File: 1120

1)

Current MSA documentation can be found at www.infineon.com/fiberoptics

For ordering information see next page.

LC™ is a trademark of Lucent.

Data Sheet 1 2003-03-21

V23818-K15-Lxx

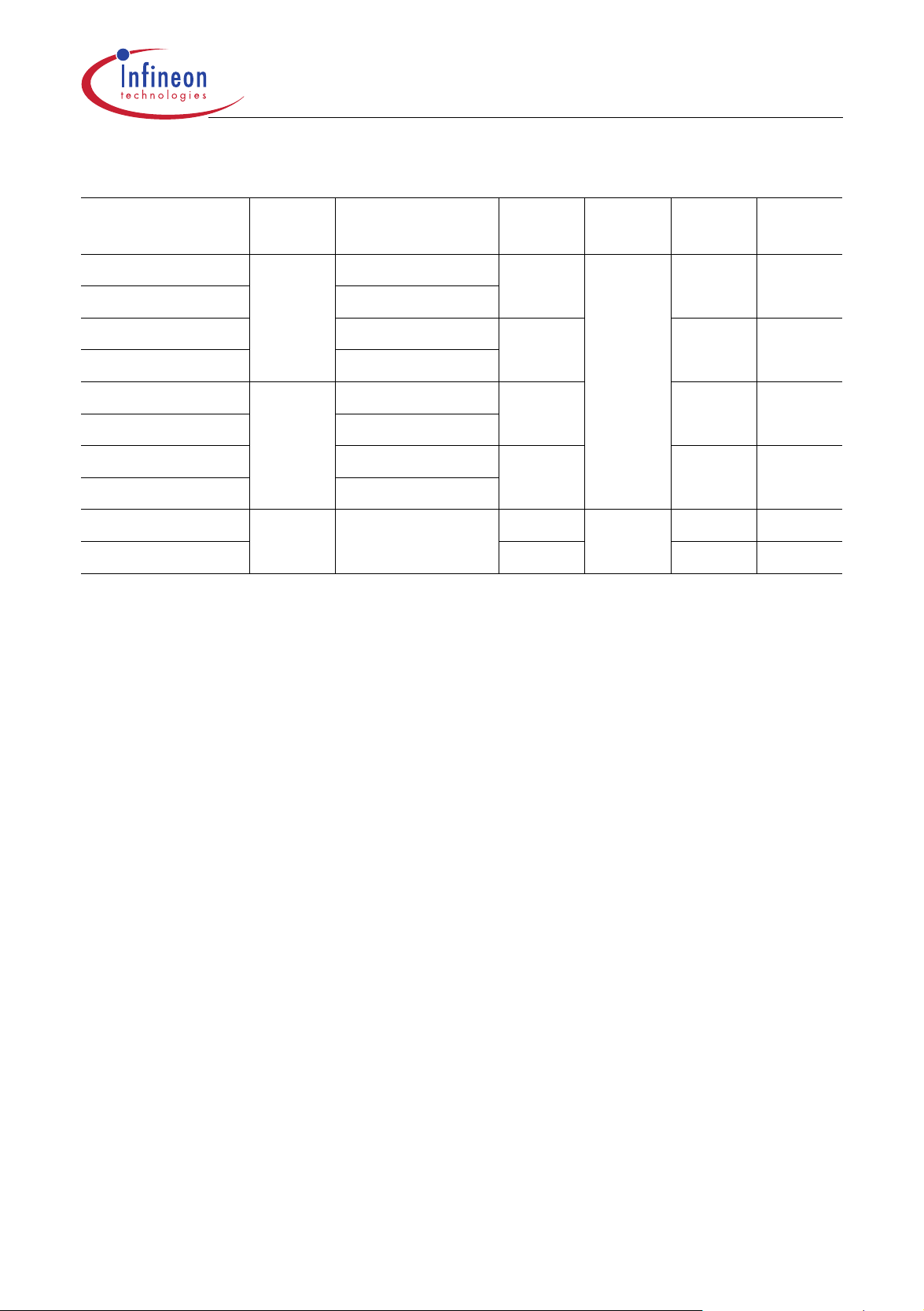

Ordering Information

Ordering Information

Part Number Pinning Temperature

Range

Signal

Detect

Collar Input Output

V23818-K15-L37 2x5 0°C to 70°C LVPECL yes DC DC

V23818-K15-L36 –40°C to 85°C

V23818-K15-L47 0°C to 70°C LVTTL AC AC

V23818-K15-L46 –40°C to 85°C

V23818-K15-L17 2x10 0°C to 70°C LVPECL DC DC

V23818-K15-L16 –40°C to 85°C

V23818-K15-L57 0°C to 70°C LVTTL AC AC

V23818-K15-L56 –40°C to 85°C

V23818-K15-L35 2x5 0°C to 70°C LVPECL no DC DC

V23818-K15-L45 LVTTL AC AC

Data Sheet 2 2003-03-21

V23818-K15-Lxx

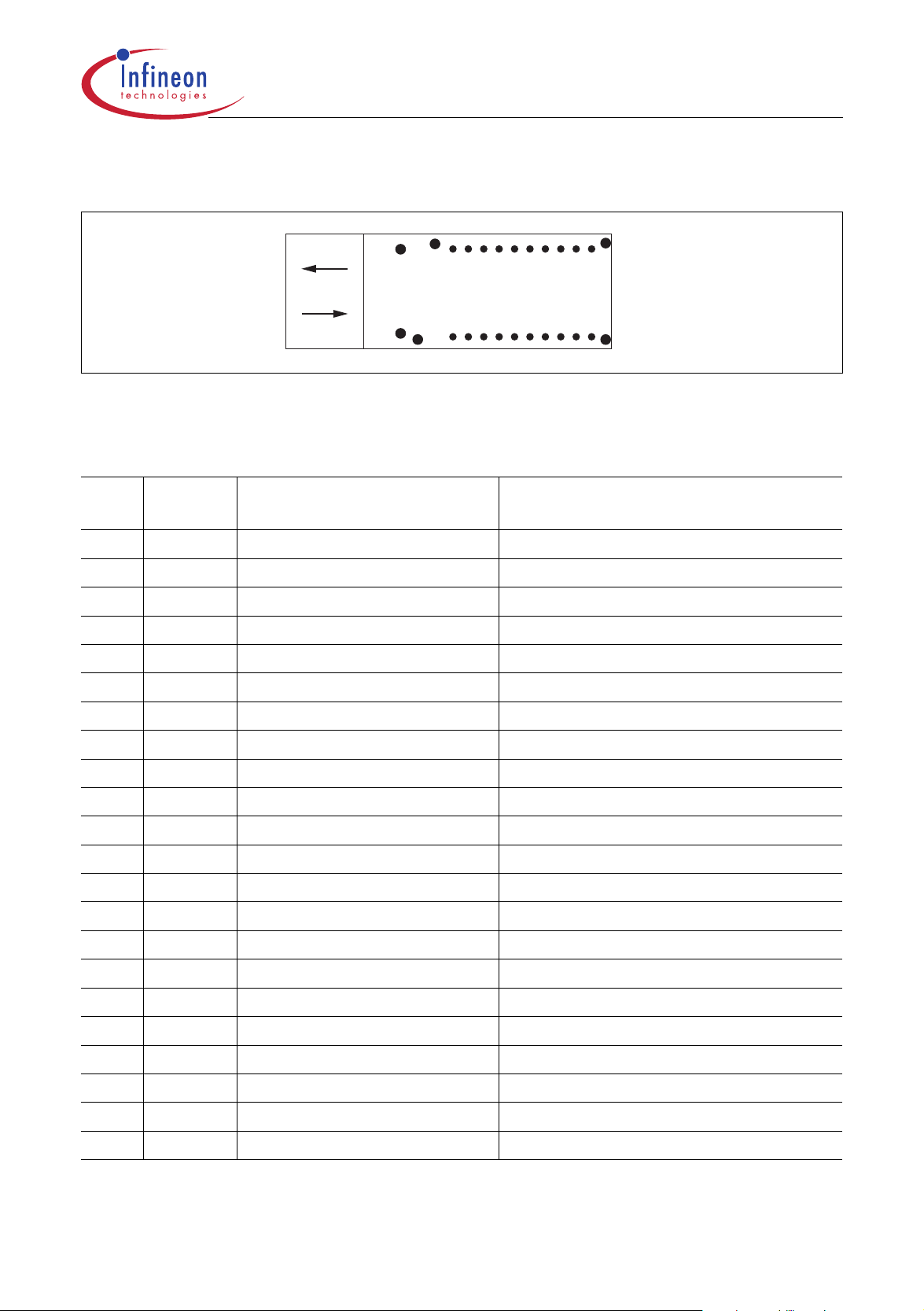

Pin Configuration

Pin Configuration

Tx

Rx

MS

MS

HL

TOP VIEW

12345

HL

1617181920

678910

HL

1112131415

HL

File: 1335

Figure 1 2x10 Pin Connect Diagram

2x10 Pin Description

Pin

Symbol Level/Logic Description

No.

1 PDBias DC current PIN photo detector bias current

2

3

V

V

EEr

EEr

Ground Receiver signal ground

Ground Receiver signal ground

4 NC Not connected

5 NC Not connected

6

7

V

V

EEr

CCr

8 SD LVTTL or LVPECL output

Ground Receiver signal ground

Power supply Receiver power supply

1)

Receiver optical input level monitor

9 RD– LVPECL output Receiver data out bar

10 RD+ LVPECL output Receiver data out

11

12

V

V

CCt

EEt

Power supply Transmitter power supply

Ground Transmitter signal ground

13 TDis LVTTL input Transmitter disable

14 TD+ LVPECL input Transmitter data in

15 TD– LVPECL input Transmitter data in bar

16

V

EEt

Ground Transmitter signal ground

17 BMon– DC voltage Laser diode bias current monitor

18 BMon+ DC voltage Laser diode bias current monitor

19 PMon– DC voltage Laser diode optical power monitor

20 PMon+ DC voltage Laser diode optical power monitor

MS Mounting studs

HL Housing leads

1)

LVPECL output active high for V23818-K15-L17/L16.

LVTTL output active high for V23818-K15-L57/L56.

Data Sheet 3 2003-03-21

V23818-K15-Lxx

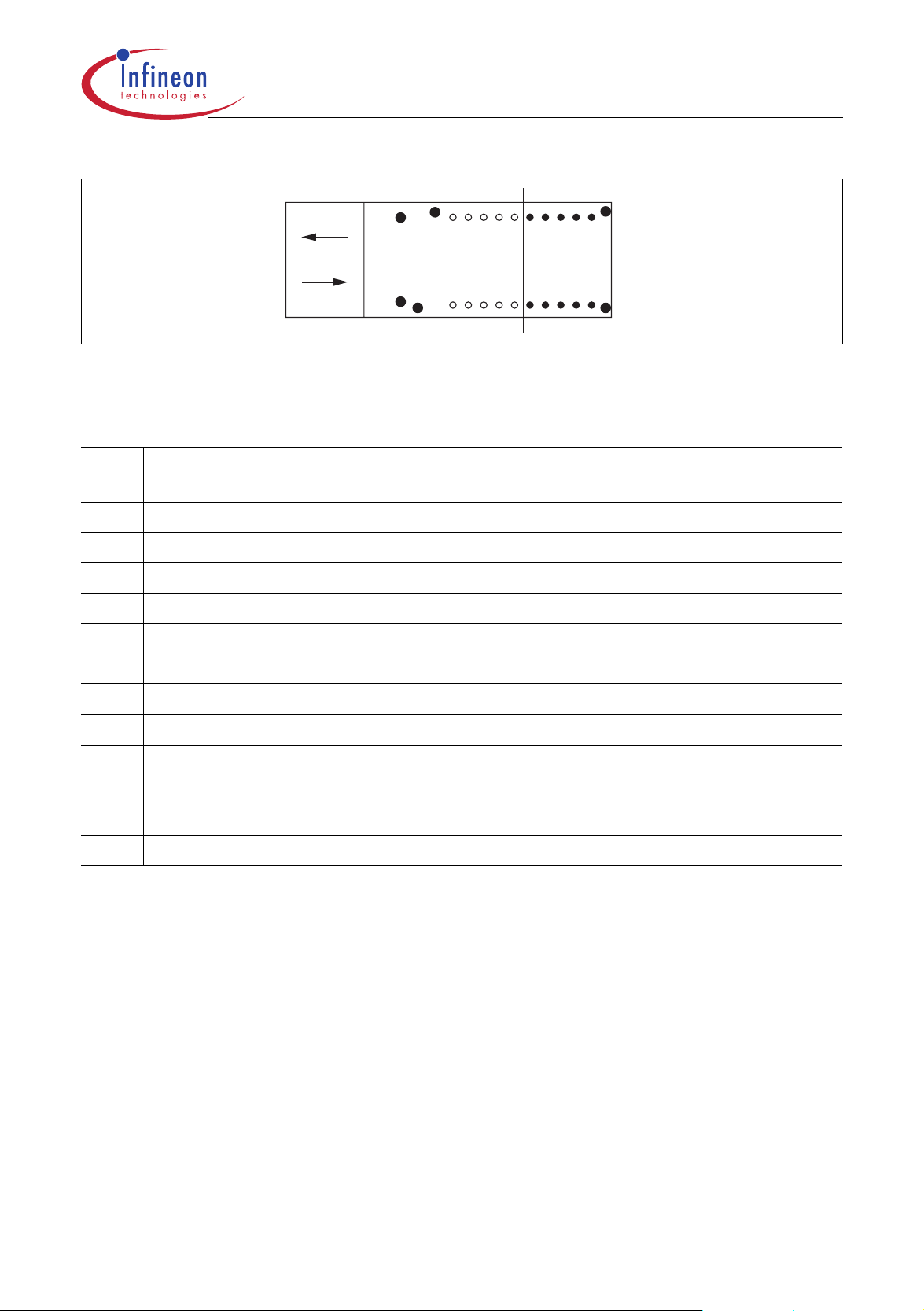

Tx

Rx

MS

MS

HL

TOP VIEW

HL

Figure 2 2x5 Pin Connect Diagram

2x5 Pin Description

Pin

Symbol Level/Logic Description

No.

1

2

V

V

EEr

CCr

Ground Receiver signal ground

Power supply Receiver power supply

3 SD LVTTL or LVPECL output

Pin Configuration

HL

678910

12345

1)

Receiver optical input level monitor

HL

File: 1331

4 RD– LVPECL output Receiver data out bar

5 RD+ LVPECL output Receiver data out

6

7

V

V

CCt

EEt

Power supply Transmitter power supply

Ground Transmitter signal ground

8 TDis LVTTL input Transmitter disable

9 TD+ LVPECL input Transmitter data in

10 TD– LVPECL input Transmitter data in bar

MS Mounting studs

HL Housing leads

1)

LVPECL output active high for V23818-K15-L37/L36/L35.

LVTTL output active high for V23818-K15-L47/L46/L45.

V

/ V

EEr

EEt

For 2x10 transceivers, connect pins 2, 3, 6, 12 and 16 to signal ground. For 2x5

transceivers, connect pins 1 and 7 to signal ground.

Data Sheet 4 2003-03-21

V23818-K15-Lxx

V

CCr

/ V

CCt

Pin Configuration

For 2x10 transceivers a 3.3 V DC power supply must be applied at pins 7 and 11. For

2x5 transceivers a 3.3 V

DC power supply must be applied at pins 2 and 6. A

recommended power supply filter network is given in the termination scheme. Locate

power supply filtering directly at the transceiver power supply pins. Proper power supply

filtering is essential for good EMI performance.

TD+ / TD–

Transmitter data LVPECL level inputs. For V23818-K15-L47/L46/L57/L56/L45

terminated and AC coupled internally. For V23818-K15-L37/L36/L17/L16/L35 use

termination and coupling as shown in the termination scheme.

RD– / RD+

Receiver data LVPECL level outputs. For V23818-K15-L47/L46/L57/L56/L45 biased and

AC coupled internally. For V23818-K15-L37/L36/L17/L16/L35 use termination and

coupling as shown in the termination scheme.

TDis

A logical LVTTL high input will disable the laser. To enable the laser, an LVTTL low input

must be applied. Leave pin unconnected if feature not required.

SD

LVTTL output for V23818-K15-L47/L46/L57/L56/L45.

LVPECL output for V23818-K15-L37/L36/L17/L16/L35.

A logical high output indicates normal optical input levels to the receiver. Low optical

input levels at the receiver result in a low output. Signal Detect can be used to determine

a definite optical link failure; break in fiber, unplugging of a connector, faulty laser source.

However it is not a detection of a bad link due to data-related errors.

MS

Mounting studs are provided for transceiver mechanical attachment to the circuit board.

They also provide an optional connection of the transceiver to the equipment chassis

ground. The holes in the circuit board must be tied to chassis ground.

HL

Housing leads are provided for additional signal grounding. The holes in the circuit board

must be included and tied to signal ground.

Data Sheet 5 2003-03-21

V23818-K15-Lxx

Pin Configuration

2x10 Transceiver Additional Functionality

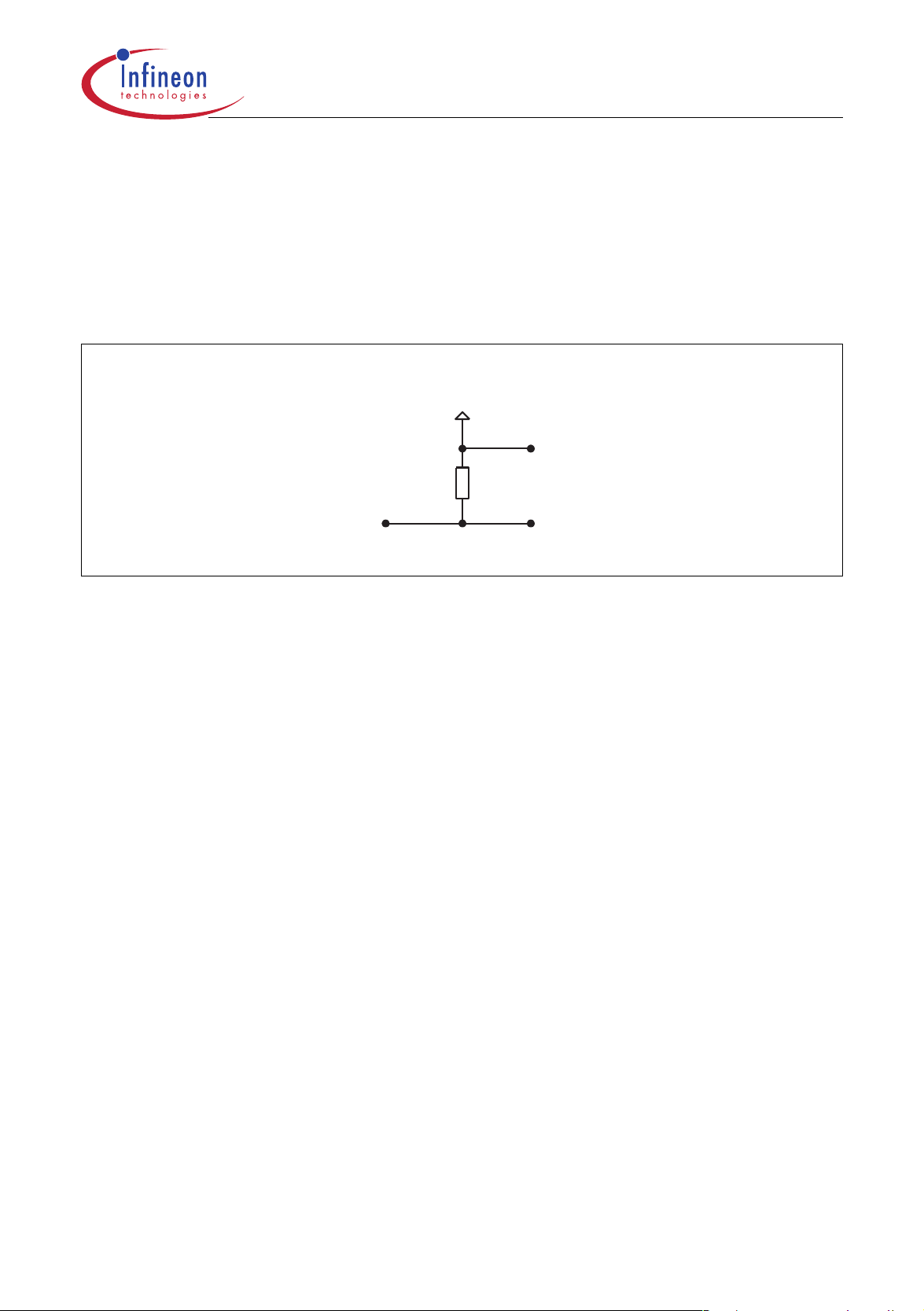

PDBias

Connect pin 1 to

V

through a bias resistor, of a value not exceeding 2 kΩ, as shown in

CC

Figure 3 to monitor PIN photo detector bias current. Leave pin floating if not used.

Typical behaviour is shown in Figure 4 and Figure 5 using a 2 kΩ load.

V

CC

≤ 2 kΩ

Pin 1

V

bias

File: 1307

Figure 3 Photo Detector Bias Interface

Data Sheet 6 2003-03-21

V23818-K15-Lxx

Pin Configuration

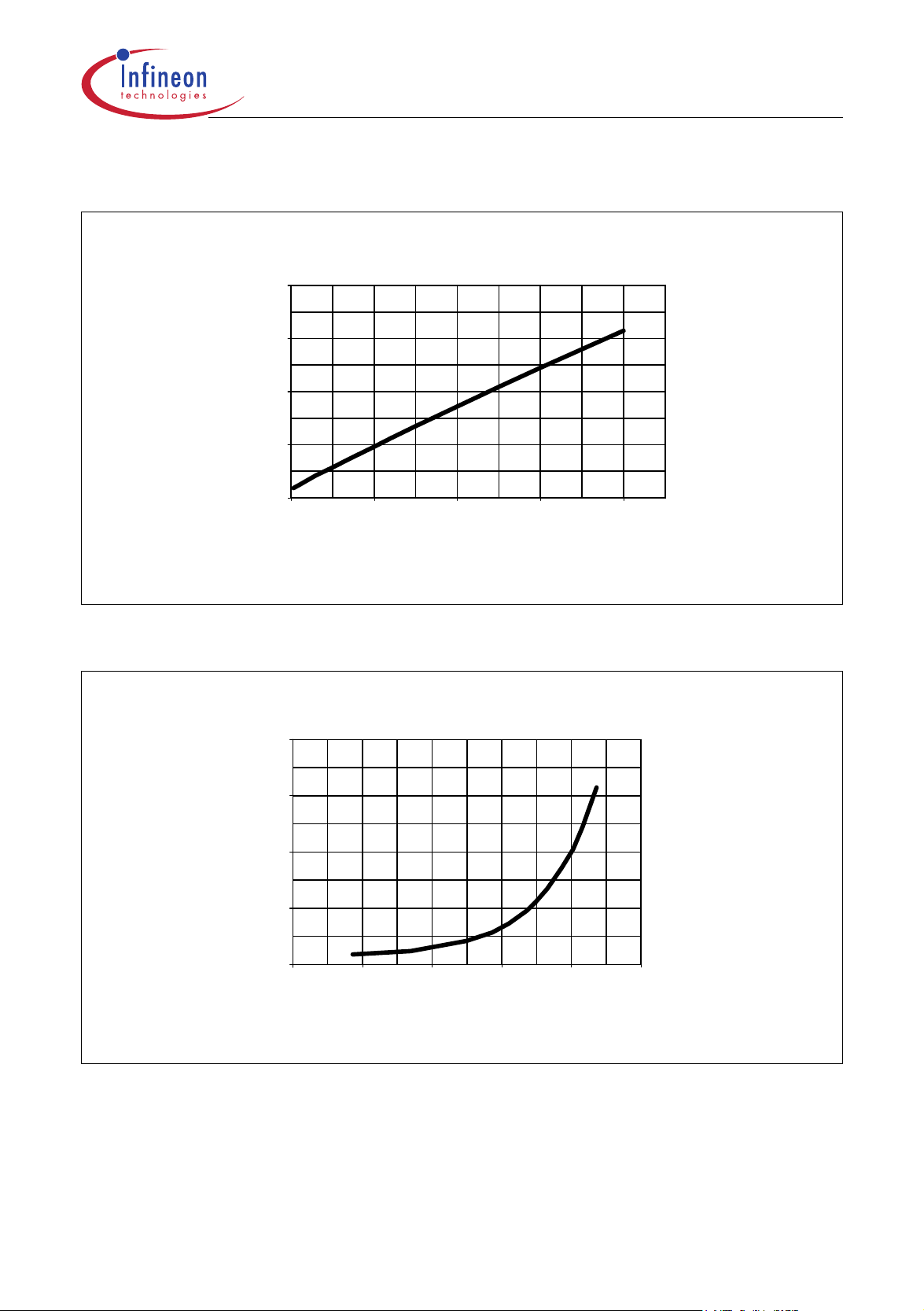

Typical Responsitivity of PIN Photo Detector Bias Current Monitor

400

300

200

100

Photo Detector Monitor Current (µA)

0

0 100 200 300 400

Received Optical Power (µW)

File: 1308

Figure 4 Linear Response

400

300

200

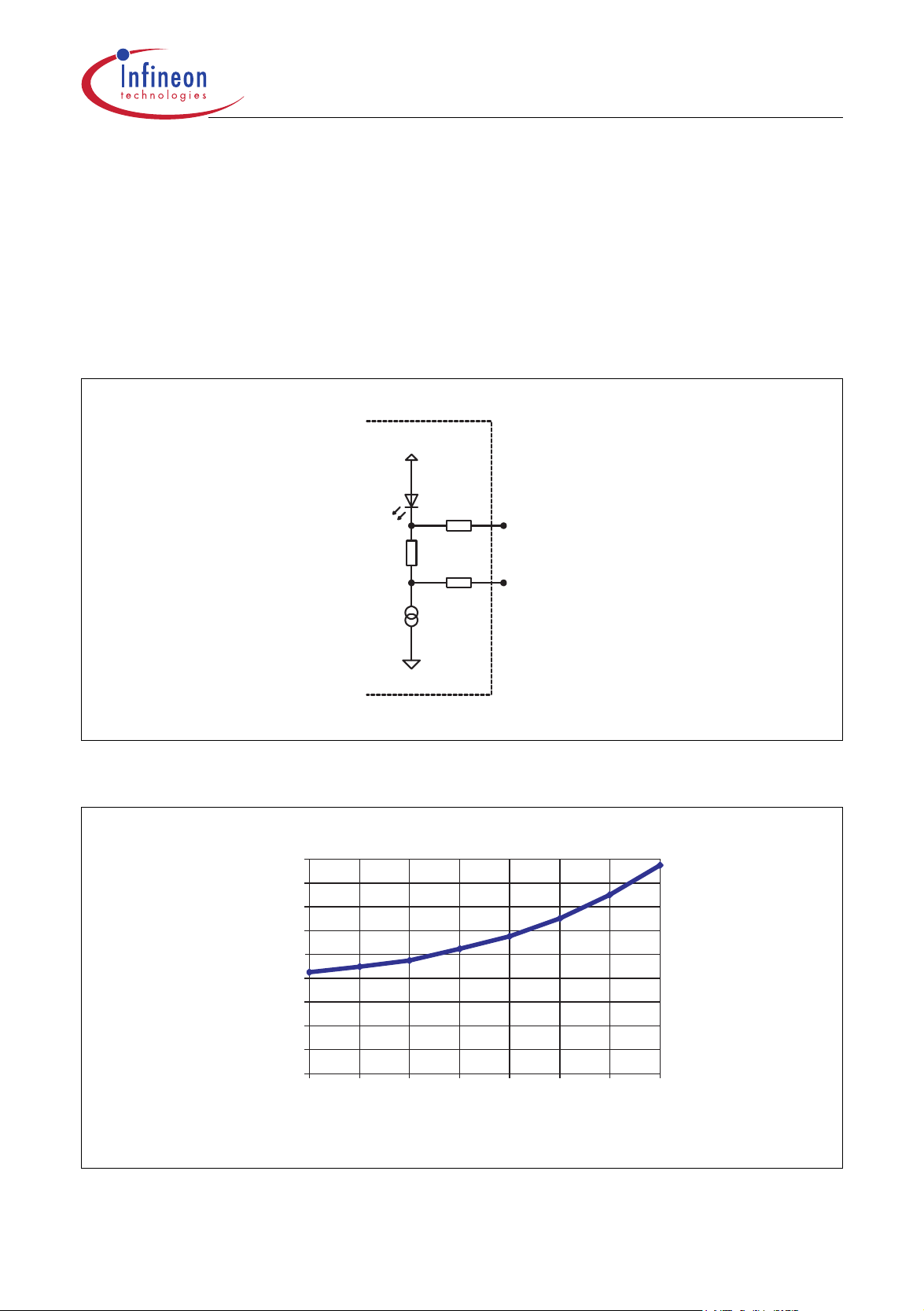

100

Photo Detector Monitor Current (µA)

0

−30 −24 −18 −12 −60

Received Optical Power (dBm)

File: 1309

Figure 5 Logarithmic Response

Data Sheet 7 2003-03-21

V23818-K15-Lxx

0

0.04

0.08

0.12

0.16

0.2

0.24

0.28

0.32

0.36

010203040506070

Temperature (˚C)

BMon Output Voltage (V)

Pin Configuration

BMon– / BMon+

The DC voltage measured across pins 17 and 18 is proportional to the laser bias current.

Use the equation:

I

bias

= V

bias

/10 Ω

Use this output to monitor laser performance and EOL conditions. A schematic and

typical behaviour are shown in Figure 6 and Figure 7.

I

@ ambient 25°C < 60 mA.

bias

Leave pins floating if function is not required.

V

CC

10 Ω

3 kΩ

3 kΩ

Pin 18

Pin 17

V

EE

Figure 6 Bias Monitor – Transceiver Internal

Figure 7 Typical Variations of Bias Monitor Voltage over Temperature

Data Sheet 8 2003-03-21

File: 1310

File: 1312

V23818-K15-Lxx

Pin Configuration

PMon– / PMon+

This output is derived from the Tx monitor diode. Output voltage is in the range of

1.2 ±0.2 V. Source resistance R

= 100 kΩ.

S

Note: This voltage level is not MSA compliant.

Data Sheet 9 2003-03-21

V23818-K15-Lxx

Description

Description

The Infineon single mode transceiver is based on and compliant to the Physical Medium

Depend (PMD) sublayer and baseband medium, type 1000-Base-LX (long wavelength)

as specified in IEEE Std 802.3 and Fibre Channel FC-PI Rev. 13 100-SM-LC-L.

The appropriate fiber optic cable is 9 µm single mode fiber with LC connector.

The Infineon single mode transceiver is a single unit comprised of a transmitter, a

receiver, and an LC receptacle. This design frees the customer from many alignment

and PC board layout concerns.

This transceiver supports the LC connectorization concept, which competes with UTP/

CAT 5 solutions. It is compatible with RJ-45 style backpanels for fiber-to-the-desktop

applications while providing the advantages of fiber optic technology. The receptacle

accepts the new LC connector. The Small Form Factor is specially developed for

distances of up to 10 km.

The module is designed for low cost LAN and WAN applications. It can be used as the

network end device interface in mainframes, workstations, servers, and storage devices,

and in a broad range of network devices such as bridges, routers, hubs, and local and

wide area switches.

This transceiver operates at 1.0625 and 1.25 Gbit/s from a single power supply. The full

differential data inputs and outputs are LVPECL compatible.

Functional Description of SFF Transceiver

This transceiver is designed to transmit serial data via single mode fiber.

BMon

-

BMon+

Automatic

TDis

TD

TD+

PMon

PMon+

RD

RD+

SD

Shut-Down

3k3k3k

-

-

-

Laser

Driver

Power

Control

Receiver

200

10

3k

Tx

Coupling Unit

e/o

Laser

o/e

Monitor

Rx

Coupling Unit

o/e

Single

Mode

Fiber

PDBias

File: 1357

Figure 8 Functional Diagram 2x10 Pin Rows

Data Sheet 10 2003-03-21

V23818-K15-Lxx

Automatic

TDis

TD−

TD+

RD−

RD+

SD

Shut-Down

Laser

Driver

Power

Control

Limiting

Amp

Tx

Coupling Unit

Rx

Coupling Unit

TIA

e/o

Laser

o/e

Monitor

o/e

Single

Mode

Fiber

Description

File: 1351

Figure 9 Functional Diagram 2x5 Pin Rows

The receiver component converts the optical serial data into an electrical data (RD+ and

RD–). The Signal Detect output (SD) shows whether an optical signal is present.

The transmitter part converts electrical LVPECL compatible serial data (TD+ and TD–)

into optical serial data.

The module has an integrated shutdown function that switches the laser off in the event

of an internal failure.

Reset is only possible if the power is turned off, and then on again. (

V

).

TH

V

switched below

CCt

The transmitter contains a laser driver circuit that drives the modulation and bias current

of the laser diode. The currents are controlled by a power control circuit to guarantee

constant output power of the laser over temperature and aging. The power control uses

the output of the monitor PIN diode (mechanically built into the laser coupling unit) as a

controlling signal, to prevent the laser power from exceeding the operating limits.

Data Sheet 11 2003-03-21

V23818-K15-Lxx

Regulatory Compliance

Feature Standard Comments

ESD:

Electrostatic Discharge to

the Electrical Pins

Immunity:

Against Electrostatic

Discharge (ESD) to the

Duplex LC Receptacle

Immunity:

Against Radio Frequency

Electromagnetic Field

EIA/JESD22-A114-B

(MIL-STD 883D

Method 3015.7)

EN 61000-4-2

IEC 61000-4-2

EN 61000-4-3

IEC 61000-4-3

Class 1C

Discharges ranging from ±2 kV to

±15 kV on the receptacle cause no

damage to transceiver (under

recommended conditions).

With a field strength of 3 V/m, noise

frequency ranges from 10 MHz to

2 GHz. No effect on transceiver

performance between the

specification limits.

Emission:

Electromagnetic

Interference (EMI)

FCC 47 CFR Part 15,

Class B

EN 55022 Class B

Noise frequency range:

30 MHz to 18 GHz

CISPR 22

Description

(13.97)

*) min. pitch between SFF transceiver according to MSA.

Dimensions in (mm) inches File: 1501

*)

.550

Figure 10 Transceiver Pitch

Data Sheet 12 2003-03-21

V23818-K15-Lxx

Technical Data

Technical Data

Absolute Maximum Ratings

Parameter Symbol Limit Values Unit

min. max.

Package Power Dissipation 0.95 W

Supply Voltage

Data Input Levels

Differential Data Input Voltage Swing

V

CC–VEE

V

+0.5 VEE–0.5 V

CC

V

pk-pk 5 V

ID

4V

Storage Ambient Temperature –40 85 °C

Hand Lead Soldering Temp/Time 260/10 °C/s

Wave Soldering Temp/Time 260/10 °C/s

Aqueous Wash Pressure < 110 psi

Exceeding any one of these values may destroy the device immediately.

Data Sheet 13 2003-03-21

V23818-K15-Lxx

Technical Data

Recommended Operating Conditions

Parameter Symbol Limit Values Unit

min. typ. max.

Ambient Temperature

Ambient Temperature

Power Supply Voltage

1), 3)

2), 3)

T

AMB

V

CC–VEE

–40 85 °C

070

3.14 3.3 3.46 V

Transmitter

Data Input High Voltage DC/DC

Differential Data Input Voltage

V

IH–VCC

V

pk-pk 500 3200 mV

ID

–1165 –880 mV

Swing AC/AC

Data Input Low Voltage DC/DC V

Data Input Rise/Fall Time

Supply Current Tx

t

I

IL–VCC

i

CCt

–1810 –1475 mV

120 ps

140 mA

Receiver

Input Center Wavelength λ

Supply Current Rx

1)

For V23818-K15-L36/L46/L16/L56.

2)

For V23818-K15-L37/L47/L17/L57/L35/L45.

3)

Ambient operating temperature requires a 2 ms–1 airflow over the device.

I

Rx

CCr

1260 1580 nm

130 mA

The electro-optical characteristics described in the following tables are valid only for use

under the recommended operating conditions.

Data Sheet 14 2003-03-21

V23818-K15-Lxx

Technical Data

Transmitter Electro-Optical Characteristics

Parameter Symbol Limit Values Unit

min. typ. max.

Output Power (Average)

1)

Center Wavelength λ

P

O

C

–9.5 –3 dBm

1270 1355 nm

Spectral Width (RMS) σ 4nm

Extinction Ratio (Dynamic) ER 9 dB

Reset Threshold for

Power on Delay

2)

V

CCt

2)

V

t

DEL

TH

2.7 V

30 ms

Total Tx Jitter TJ 53 130 ps

T

Assert Voltage LVTTL V

Dis

T

Deassert Voltage LVTTL V

Dis

T

Assert Time

Dis

T

Deassert Time

Dis

1)

Into single mode fiber, 9 µm diameter

2)

Laser power is shut down if power supply is below VTH and switched on if power supply is above VTH after t

3)

T

assertion to laser shutdown.

Dis

4)

T

reassertion to laser startup.

Dis

3)

4)

t

ASS

t

DAS

TDH

TDL

2V

0.8 V

0.4 1 ms

0.06 10 µs

.

RES

Receiver Electro-Optical Characteristics

Parameter Symbol Limit Values Unit

min. typ. max.

Sensitivity (Average Power)

Saturation (Average Power)

Min. Optical Modulation

Amplitude

2)

Signal Detect Assert Level

Signal Detect Deassert Level

Signal Detect Hysteresis

Signal Detect Assert Time

Signal Detect Deassert Time

Receiver 3 dB Cut off

Frequency

2)

1)

P

P

IN

SAT

–20 dBm

–3 dBm

OMA 15 µW

3)

3)

2), 4)

4)

P

P

P

–P

t

ASS

t

DAS

SDA

SDD

SDA

SDD

–20 dBm

–37 dBm

3dB

0.1 ms

0.35 ms

1.5 GHz

Data Sheet 15 2003-03-21

V23818-K15-Lxx

Technical Data

Receiver Electro-Optical Characteristics (cont’d)

Parameter Symbol Limit Values Unit

min. typ. max.

Receiver 10 dB Cut off

Frequency

Output Voltage

Output Voltage

2)

5)

5)

Differential Data Output Voltage

Swing

5)

Signal Detect Output High

Voltage LVPECL

6), 7)

Signal Detect Output Low

Voltage LVPECL

6), 7)

Signal Detect Output High

Voltage LVTTL

6), 8)

V

OH–VCC

V

OL–VCC

V

pk-pk 1000 2000 mV

OD

V

SDH–VEEVCC

V

SDL–VEEVCC

V

SDH

–1110 –650 mV

–1800 –1300 mV

–

1200

–

1900

2.4 V

3GHz

V

CC

mV

–820

V

CC

–

1580

mV

Signal Detect Output Low

Voltage LVTTL

Rx-Monitor

1)

Minimum average optical power at which the BER is less than 1x10

2)

Fibre Channel PI Standard.

3)

An increase in optical power above the specified level will cause the Signal Detect to switch from a low state

to a high state (high active output).

4)

A decrease in optical power below the specified level will cause the Signal Detect to switch from a high state

to a low state.

5)

Load is 100 Ω differential.

6)

Internal load is 510 Ω to GND, no external load necessary. Signal Detect is a high active output. High level

means signal is present, low level means loss of signal.

7)

For V23818-K15-L37/L36/L17/L16/L35.

8)

For V23818-K15-L47/L46/L57/L56/L45.

9)

Monitor current needs to be sunk to VCC.

10)

Only available on 2x10 transceivers: V23818-K15-L17/L16/L57/L56.

6), 8)

9), 10)

V

SDL

Rx-Mon 0.5 1 A/W

–10

. Measured with a 2

0.5 V

7

–1 NRZ PRBS.

Data Sheet 16 2003-03-21

V23818-K15-Lxx

Eye Safety

Eye Safety

This laser based single mode transceiver is a Class 1 product.

It complies with IEC 60825-1 and FDA 21 CFR 1040.10 and 1040.11.

To meet laser safety requirements the transceiver shall be operated within the Absolute

Maximum Ratings.

Attention: All adjustments have been made at the factory prior to shipment of the

devices. No maintenance or alteration to the device is required.

Tampering with or modifying the performance of the device will result

in voided product warranty.

Note: Failure to adhere to the above restrictions could result in a modification that is

considered an act of “manufacturing”, and will require, under law, recertification of

the modified product with the U.S. Food and Drug Administration (ref. 21 CFR

1040.10 (i)).

Laser Data

Wavelength 1300 nm

Total output power

< 2 mW

(as defined by IEC: 7 mm aperture at 14 mm distance)

Total output power

< 180 µW

(as defined by FDA: 7 mm aperture at 20 cm distance)

Beam divergence 6°

FDA

Complies with 21 CFR

1040.10 and 1040.11

Class 1 Laser Product

IEC

Figure 11 Required Labels

Indication of

laser aperture

and beam

Tx

Rx

20 19 18 17 16 15 14 13 12 11

Top view

12345678910

File: 1401

File: 1334

Figure 12 Laser Emission

Data Sheet 17 2003-03-21

V23818-K15-Lxx

EMI-Recommendations

EMI-Recommendations

To avoid electromagnetic radiation exceeding the required limits please take note of the

following recommendations.

When Gigabit switching components are found on a PCB (multiplexers, clock recoveries

etc.) any opening of the chassis may produce radiation also at chassis slots other than

that of the device itself. Thus every mechanical opening or aperture should be as small

as possible.

On the board itself every data connection should be an impedance matched line (e.g.

strip line, coplanar strip line). Data, Datanot should be routed symmetrically, vias should

be avoided. A terminating resistor of 100 Ω should be placed at the end of each matched

line. An alternative termination can be provided with a 50 Ω resistor at each (D, Dn). In

DC coupled systems a thevenin equivalent 50 Ω resistance can be achieved as follows:

for 3.3 V: 125 Ω to

V

and 82 Ω to VEE, for 5 V: 82 Ω to VCC and 125 Ω to VEE at Data

CC

and Datanot. Please consider whether there is an internal termination inside an IC or a

transceiver.

In certain cases signal GND is the most harmful source of radiation. Connecting chassis

GND and signal GND at the plate/bezel/chassis rear e.g. by means of a fiber optic

transceiver may result in a large amount of radiation. Even a capacitive coupling

between signal GND and chassis may be harmful if it is too close to an opening or an

aperture.

If a separation of signal GND and chassis GND is not planned, it is strongly

recommended to provide a proper contact between signal GND and chassis GND at

every location where possible. This concept is designed to avoid hotspots. Hotspots are

places of highest radiation which could be generated if only a few connections between

signal and chassis GND exist. Compensation currents would concentrate at these

connections, causing radiation.

By use of Gigabit switching components in a design, the return path of the RF current

must also be considered. Thus a split GND plane of Tx and Rx portion may result in

severe EMI problems.

A recommendation is to connect the housing leads to signal GND. However, in certain

applications it may improve EMI performance by connecting them to chassis GND.

The cutout should be sized so that all contact springs make good contact with the face

plate.

Please consider that the PCB may behave like a waveguide. With an ε

of 4, the

r

wavelength of the harmonics inside the PCB will be half of that in free space. In this

scenario even the smallest PCBs may have unexpected resonances.

Data Sheet 18 2003-03-21

V23818-K15-Lxx

Recommended Termination Schemes

2x10 DC/DC Transceiver

PMon+

PMon−

BMon−

BMon+

18

1720 19

12,16

V

EEt

14

TD+

Laser

Driver

SFF Transceiver

PreAmp

Limiting

Amplifier

100 Ω

Signal

Detect

RD−

RD+

TD−

TDis

V

CCt

V

CCr

SD

RD−

RD+

V

EEr

15

13

11

7

8

1

9

10

2,3,6

C8

C9

Recommended Termination Schemes

TDis

C1

C2

PDBias

R2

R3

SD

VCC SerDes

C6

C7

L1

V

CC

3.3 V

L2

C3

C4

C5

R4

C10

R5

R1

V

CC

SerDat Out

SerDat Out −

Serializer/

Deserializer

SerDat In −

SerDat In +

+

ECL/

PECL

Driver

Receiver

PLL etc.

C1/2/3

C4/5/6/7

C8/9/10

L1/2

R1

= 4.7 ... 10 µF

= 100 nF

= Design criterion is the resonance frequency only. The self resonant frequency of the

capacitor must be in the vicinity of the nominal data rate. Short traces are mandatory.

*)

= 1 ... 4.7 µH

= 100 Ω (depending on SerDes chip used, ensure proper 50 Ω termination to V

EE

or

100 Ω differential is provided. Check for termination inside of SerDes chip).

R2/3

R4/5

= 150 Ω

= Biasing (depends on SerDes chip).

Place R1/4/5 close to SerDes chip.

Place R2/3 close to Infineon transceiver.

*)

The inductors may be replaced by appropriate Ferrite beads.

File: 1390

Figure 13

Data Sheet 19 2003-03-21

V23818-K15-Lxx

2x10 AC/AC Transceiver

PMon+

PMon−

BMon−

BMon+

20 18

1719

PreAmp

Laser

Driver

SFF Transceiver

100 Ω

Limiting

Amplifier

Signal

Detect

V

TD+

TD−

TDis

V

CCt

V

CCr

SD

RD−

RD+

V

EEt

EEt

12,16

14

15

13

11

7

8

1

9

10

2,3,6

C4

C5

Recommended Termination Schemes

VCC SerDes

V

CC

SerDat Out +

SerDat Out −

TDis

C1

C2

PDBias

SD

L1

V

CC

3.3 V

L2

C3

C6

R1

R5

R3

R6

Serializer/

Deserializer

R2

SerDat In −

SerDat In +

R4

ECL/

PECL

Driver

Receiver

PLL etc.

C1/2/3

C4/5/6

L1/2

R1/2/3/4

= 4.7 ... 10 µF

= Design criterion is the resonance frequency only. The self resonant frequency of the

capacitor must be in the vicinity of the nominal data rate. Short traces are mandatory.

*)

= 1 ... 4.7 µH

= Depends on SerDes chip used, ensure proper 50 Ω termination to V

differential is provided. Check for termination inside of SerDes chip.

R5/6

= Biasing (depends on SerDes chip).

Place R1/2/3/4/5/6 close to SerDes chip.

*)

The inductors may be replaced by appropriate Ferrite beads.

Figure 14

or 100 Ω

EE

File: 1391

Data Sheet 20 2003-03-21

V23818-K15-Lxx

2x5 DC/DC Transceiver

Laser

Driver

SFF Transceiver

PreAmp

Limiting

Amplifier

100 Ω

Signal

Detect

RD−

RD+

V

TD+

TD−

TDis

V

V

CCr

SD

RD−

RD+

EEt

CCt

Recommended Termination Schemes

V

CC

3.3 V

C3

VCC SerDes

C6

C7

C10

R4

R5

R1

V

CC

SerDat Out

SerDat Out −

Serializer/

Deserializer

SerDat In −

SerDat In +

+

ECL/

PECL

Driver

Receiver

PLL etc.

7

9

C8

10

8

6

2

3

4

5

C9

TDis

C1

C2

L1

L2

SD

C4

C5

1

V

EEr

C1/2/3

C4/5/6/7

C8/9/10

L1/2

R1

= 4.7 ... 10 µF

= 100 nF

= Design criterion is the resonance frequency only. The self resonant frequency of the

capacitor must be in the vicinity of the nominal data rate. Short traces are mandatory.

*)

= 1 ... 4.7 µH

= 100 Ω (depending on SerDes chip used, ensure proper 50 Ω termination to V

100 Ω differential is provided. Check for termination inside of SerDes chip).

R2/3

R4/5

= 150 Ω

= Biasing for outputs depending on Serializer.

Place R1/4/5 close to SerDes chip.

Place R2/3 close to Infineon transceiver.

*)

The inductors may be replaced by appropriate Ferrite beads.

Figure 15

R2

R3

EE

or

File: 1392

Data Sheet 21 2003-03-21

V23818-K15-Lxx

2x5 AC/AC Transceiver

Laser

Driver

SFF Transceiver

PreAmp

Limiting

Amplifier

100 Ω

Signal

Detect

RD−

RD+

V

EEt

TD+

TD−

TDis

V

CCt

V

CCr

SD

RD−

RD+

Recommended Termination Schemes

VCC SerDes

7

9

C4

10

8

TDis

6

C1

2

C2

3

4

C5

5

SD

L1

V

CC

3.3 V

L2

C3

C6

R5

R1

R6

R2

V

CC

SerDat Out

SerDat Out −

Serializer/

Deserializer

SerDat In −

SerDat In +

+

ECL/

PECL

Driver

Receiver

PLL etc.

1

V

EEr

C1/2/3

C4/5/6

L1/2

R1/2/3/4

R5/6

= 4.7 ... 10 µF

= Design criterion is the resonance frequency only. The self resonant frequency of the

capacitor must be in the vicinity of the nominal data rate. Short traces are mandatory.

*)

= 1 ... 4.7 µH

= Depends on SerDes chip used, ensure proper 50 Ω termination to V

differential is provided. Check for termination inside of SerDes chip.

= Biasing (depends on SerDes chip).

Place R1/2/3/4/5/6 close to SerDes chip.

*)

The inductors may be replaced by appropriate Ferrite beads.

Figure 16

R3

R4

or 100 Ω

EE

File: 1393

Data Sheet 22 2003-03-21

V23818-K15-Lxx

Package Outlines

Package Outlines

a) recommended bezel position

Drawing shown is 2x10 pinning with collar

Dimensions in mm [inches] File: 1213

Figure 17

Data Sheet 23 2003-03-21

V23818-K15-Lxx

Revision History: 2003-03-21 DS2

Previous Version: 2003-03-05

Page Subjects (major changes since last revision)

15 Table "Transmitter Electro-Optical Characteristics" changed

For questions on technology, delivery and prices please contact the Infineon

Technologies Offices in Germany or the Infineon Technologies Companies and

Representatives worldwide: see our webpage at http://www.infineon.com.

Edition 2003-03-21

Published by Infineon Technologies AG,

St.-Martin-Strasse 53,

D-81541 München, Germany

© Infineon Technologies AG 2003.

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as warranted

characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement, regarding

circuits, descriptions and charts stated herein.

Infineon Technologies is an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office in Germany or our Infineon Technologies Representatives worldwide.

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life-support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Loading...

Loading...