Page 1

Please read the Important notice and the Safety precautions and the Warnings

www.infineon.com page 1 of 37 2020-11-03

UG-2020-31

11 kW bi-directional CLLC DC-DC converter with

1200 V and 1700 V CoolSiC™ MOSFETs

About this document

Scope and purpose

This document introduces a complete Infineon Technologies AG system solution for an 11 kW bi-directional DCDC converter. The REF-DAB11KIZSICSYS board is a DC-DC stage with a wide range output using two inductors

and two capacitors (CLLC) resonant network with bi-directional capability.This converter can operate under

high power conversion efficiency, as the symmetric CLLC resonant network has zero-voltage switching

capability for primary power switches and synchronous-rectification commutation capability for secondry-side

output rectifiers. The converter could change the power flow direction, and its maximum power conversion

efficiency was around 98% during the operation.

This document shows the board using 1200 V CoolSiC™ MOSFETs in TO247-4 package and EiceDRIVER™ 1ED

compact gate driver ICs, which leverage the advantages of SiC technology including improved efficiency, space

and weight savings, part count reduction, and enhanced system reliability.

Intended audience

This document is intended for engineers who want to use 1200 V and 1700 V CoolSiC™ MOSFETs with

EiceDRIVER™ driver ICs for bi-directional resonant topology applications such as EV-charger wall box, energy

storage systems to achieve reliable main-circuit design and increased power density.

Reference board/kit

Product(s) embedded in a PCB, with focus on specific applications and defined use cases that can include

software. PCB and auxiliary circuits are optimized for the requirements of the target application.

Note: Boards do not necessarily meet safety, EMI, quality standards (for example UL, CE) requirements.

Page 2

2 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

Important notice

Important notice

“Evaluation Boards and Reference Boards” shall mean products embedded on a printed circuit board

(PCB) for demonstration and/or evaluation purposes, which include, without limitation, demonstration,

reference and evaluation boards, kits and design (collectively referred to as “Reference Board”).

Environmental conditions have been considered in the design of the Evaluation Boards and Reference

Boards provided by Infineon Technologies. The design of the Evaluation Boards and Reference Boards

has been tested by Infineon Technologies only as described in this document. The design is not qualified

in terms of safety requirements, manufacturing and operation over the entire operating temperature

range or lifetime.

The Evaluation Boards and Reference Boards provided by Infineon Technologies are subject to functional

testing only under typical load conditions. Evaluation Boards and Reference Boards are not subject to the

same procedures as regular products regarding returned material analysis (RMA), process change

notification (PCN) and product discontinuation (PD).

Evaluation Boards and Reference Boards are not commercialized products, and are solely intended for

evaluation and testing purposes. In particular, they shall not be used for reliability testing or production.

The Evaluation Boards and Reference Boards may therefore not comply with CE or similar standards

(including but not limited to the EMC Directive 2004/EC/108 and the EMC Act) and may not fulfill other

requirements of the country in which they are operated by the customer. The customer shall ensure that

all Evaluation Boards and Reference Boards will be handled in a way which is compliant with the relevant

requirements and standards of the country in which they are operated.

The Evaluation Boards and Reference Boards as well as the information provided in this document are

addressed only to qualified and skilled technical staff, for laboratory usage, and shall be used and

managed according to the terms and conditions set forth in this document and in other related

documentation supplied with the respective Evaluation Board or Reference Board.

It is the responsibility of the customer’s technical departments to evaluate the suitability of the

Evaluation Boards and Reference Boards for the intended application, and to evaluate the completeness

and correctness of the information provided in this document with respect to such application.

The customer is obliged to ensure that the use of the Evaluation Boards and Reference Boards does not

cause any harm to persons or third party property.

The Evaluation Boards and Reference Boards and any information in this document is provided "as is"

and Infineon Technologies disclaims any warranties, express or implied, including but not limited to

warranties of non-infringement of third party rights and implied warranties of fitness for any purpose, or

for merchantability.

Infineon Technologies shall not be responsible for any damages resulting from the use of the Evaluation

Boards and Reference Boards and/or from any information provided in this document. The customer is

obliged to defend, indemnify and hold Infineon Technologies harmless from and against any claims or

damages arising out of or resulting from any use thereof.

Infineon Technologies reserves the right to modify this document and/or any information provided

herein at any time without further notice.

Page 3

3 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

Safety precautions

Safety precautions

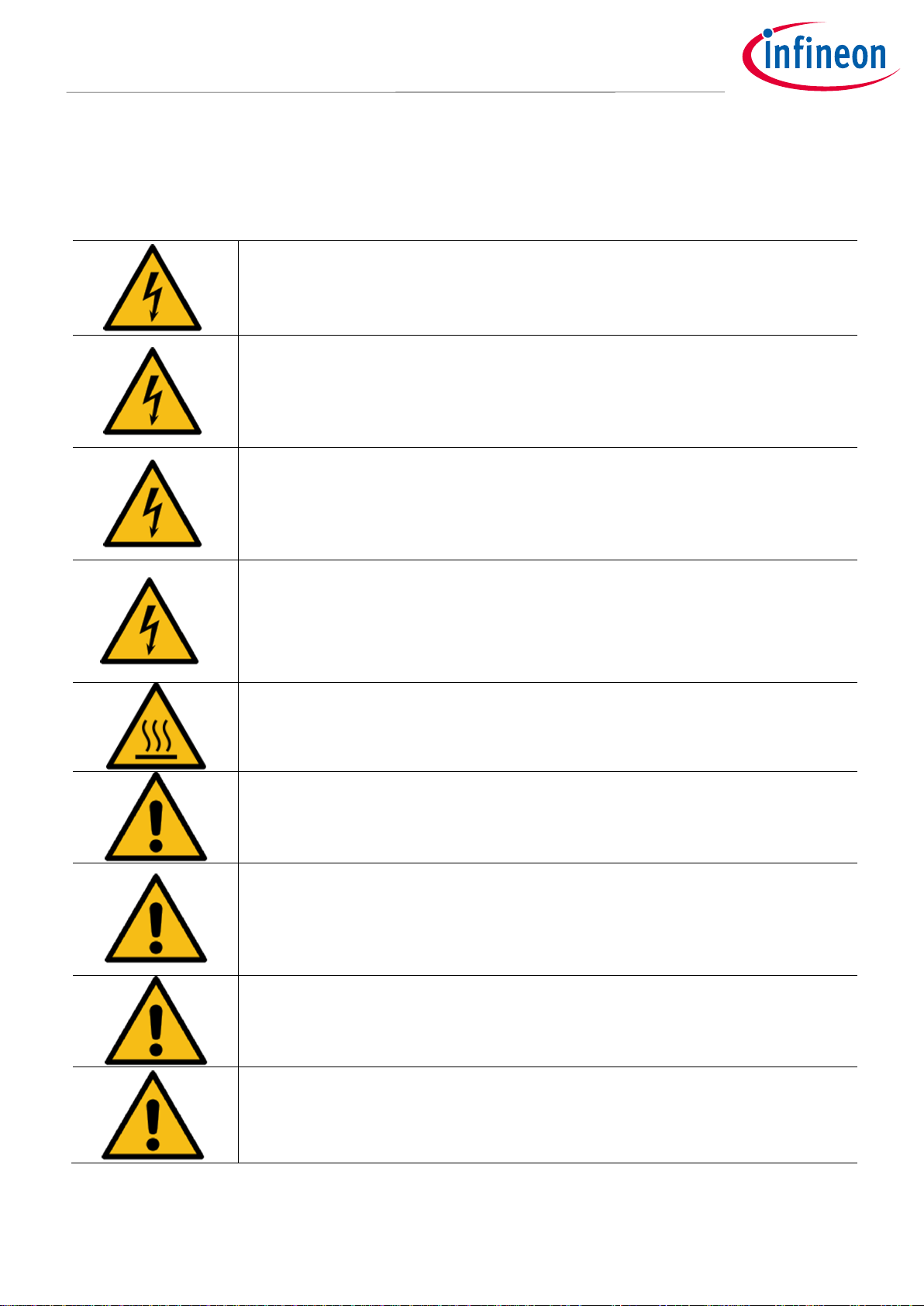

Note: Please note the following warnings regarding the hazards associated with development systems.

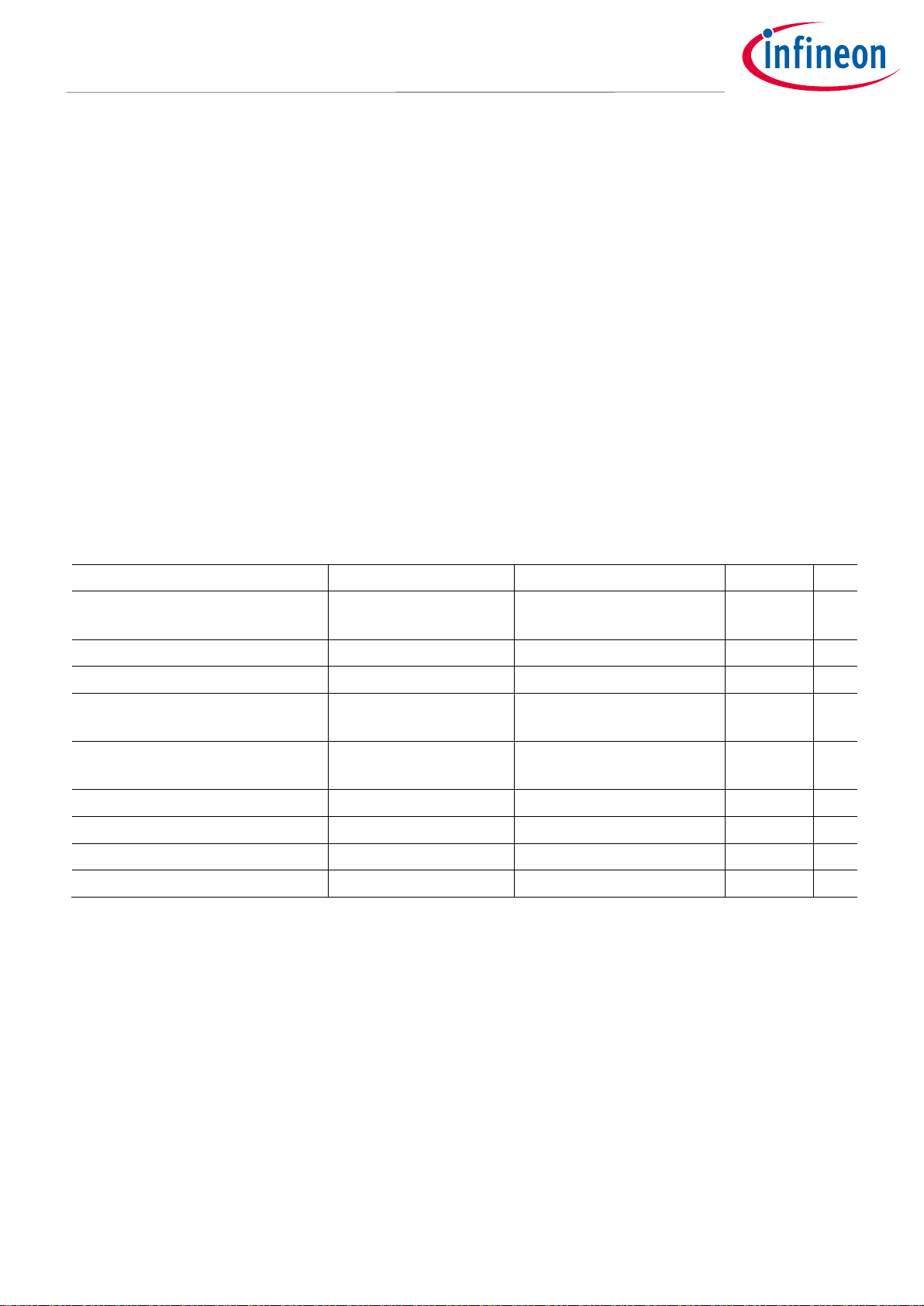

Table 1 Safety precautions

Warning: The DC link potential of this board is up to 1000 VDC. When measuring voltage

waveforms by oscilloscope, high voltage differential probes must be used. Failure to do

so may result in personal injury or death.

Warning: The evaluation or reference board contains DC bus capacitors which take

time to discharge after removal of the main supply. Before working on the drive

system, wait five minutes for capacitors to discharge to safe voltage levels. Failure to

do so may result in personal injury or death. Darkened display LEDs are not an

indication that capacitors have discharged to safe voltage levels.

Warning: The evaluation or reference board is connected to the grid input during

testing. Hence, high-voltage differential probes must be used when measuring voltage

waveforms by oscilloscope. Failure to do so may result in personal injury or death.

Darkened display LEDs are not an indication that capacitors have discharged to safe

voltage levels.

Warning: Remove or disconnect power from the drive before you disconnect or

reconnect wires, or perform maintenance work. Wait five minutes after removing

power to discharge the bus capacitors. Do not attempt to service the drive until the bus

capacitors have discharged to zero. Failure to do so may result in personal injury or

death.

Caution: The heat sink and device surfaces of the evaluation or reference board may

become hot during testing. Hence, necessary precautions are required while handling

the board. Failure to comply may cause injury.

Caution: Only personnel familiar with the drive, power electronics and associated

machinery should plan, install, commission and subsequently service the system.

Failure to comply may result in personal injury and/or equipment damage.

Caution: The evaluation or reference board contains parts and assemblies sensitive to

electrostatic discharge (ESD). Electrostatic control precautions are required when

installing, testing, servicing or repairing the assembly. Component damage may result

if ESD control procedures are not followed. If you are not familiar with electrostatic

control procedures, refer to the applicable ESD protection handbooks and guidelines.

Caution: A drive that is incorrectly applied or installed can lead to component damage

or reduction in product lifetime. Wiring or application errors such as undersizing the

motor, supplying an incorrect or inadequate AC supply, or excessive ambient

temperatures may result in system malfunction.

Caution: The evaluation or reference board is shipped with packing materials that

need to be removed prior to installation. Failure to remove all packing materials that

are unnecessary for system installation may result in overheating or abnormal

operating conditions.

Page 4

4 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

Table of contents

Table of contents

Contents

About this document ....................................................................................................................... 1

Important notice ............................................................................................................................ 2

Safety precautions .......................................................................................................................... 3

Table of contents ............................................................................................................................ 4

1 The board at a glance .............................................................................................................. 5

1.1 Delivery content ...................................................................................................................................... 6

1.2 Block diagram .......................................................................................................................................... 6

1.3 Main features ........................................................................................................................................... 8

1.4 Board parameters and technical data .................................................................................................... 8

2 System and functional description ........................................................................................... 9

2.1 Commissioning ........................................................................................................................................ 9

2.2 Description of the functional blocks ....................................................................................................... 9

2.2.1 Description of the functional blocks ............................................................................................... 10

2.2.2 Special operation modes ................................................................................................................. 15

2.3 Auxiliary power boards ......................................................................................................................... 17

2.3.1 The technical specification of auxiliary power boards ................................................................... 17

2.3.2 Auxiliary power board description .................................................................................................. 17

2.3.3 1700 V CoolSiC™ MOSFET overview ................................................................................................ 18

2.4 User interface ........................................................................................................................................ 19

3 System design....................................................................................................................... 22

3.1 Schematics ............................................................................................................................................ 22

3.2 Layout .................................................................................................................................................... 26

3.3 Bill of material ....................................................................................................................................... 30

4 References and appendices .................................................................................................... 35

4.1 Abbreviations and definitions ............................................................................................................... 35

4.2 References ............................................................................................................................................. 35

4.3 Additional information .......................................................................................................................... 35

Revision history ............................................................................................................................. 36

Page 5

5 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

The board at a glance

E-mobility is well on its way to revolutionizing private and public transportation, reducing air pollution and

making the earth a better place to live. Energy storage systems can also help save energy consumption by

maximizing the allocation of energy.

Infineon is proud to be a key player in this green megatrend. Being a one-stop shop for high-quality components

and solutions, the target of the REF-DAB11KIZSICSYS board is to build up a solution for bi-directional DC-DC

converters, which will enable customers to implement unique bi-directional charger designs in a very short time.

This featured 11 kW CLLC resonant DC-DC converter with bi-directional power flow capability and soft-switching

characteristics is the ideal choice for on- & off-board chargers and energy storage systems (ESS). This reference

design provides a complete and fully characterized hardware and firmware solution, and user-friendly graphical

user interface (GUI). It ensures that CoolSiC™ MOSFETs integrate with Infineon driver IC, XMC controller, flyback

controller, voltage regulator MOSFETs, current sensor, Cypress memory, and security & safty chip. It is the perfect

way to improve cost-effective power density with high reliability, and easy usage up to the next level!

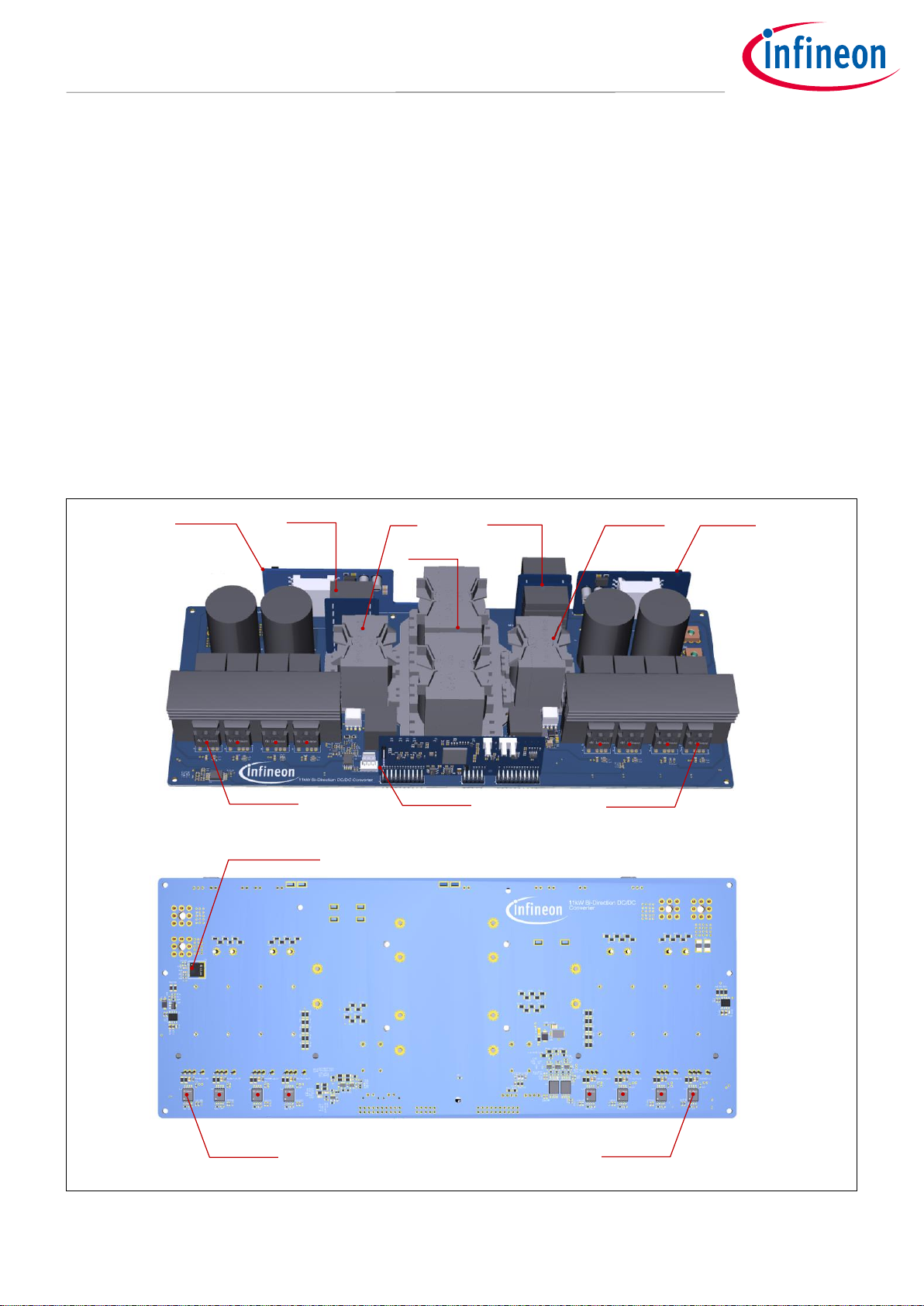

In UG-2020-31, Figure 1 shows the placement of the different components on the 11 kW bi-directional DC-DC

converter. The outer dimensions of the board, enclosed in the case, are 33.1 mm x 13.4 mm x 6 mm, which results

in a power density in the range of 4.1 W/cm³ (5.5 W/g).

Auxiliary Power Board

Auxiliary Power Board

1200 V SiC MOSFETs- IMZ120R030M1H

Controller Board

1200 V SiC MOSFETs- IMZ120R030M1H

Driver ICs-1EDC20I12AH

Driver ICs-1EDC20I12AH

Current Sensor- TLI4971

Resonant capacitor

Resonant Inductor

Resonant InductorResonant capacitor

Transformer

Page 6

6 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

The board at a glance

Figure 1 Placement of the different sections in the 11 kW bi-directional CLLC DC-DC converter with

Infineon CoolSiC™ MOSFETs.

1.1 Delivery content

The 11 kW bi-directional board is a CLLC DC-DC converter developed with Infineon power semiconductors as

well as Infineon drivers, current sensor, controllers, communication chip, security chip and memory chip. The

combination of these devices can provide customers with an optimized system solution. The Infineon devices

used in the implementation of the 11 kW bi-directional board include:

Main power board

1200 V CoolSiC

TM

MOSFETs discretes - IMZ120R030M1H

1200VSingle channel IGBT gate driver IC in wide body package -1EDC20I12AH

XENSIV™ - high-precision coreless current sensors for industrial applications- TLI4971

Auxilary power board

1700 V CoolSiC™ MOSFET discretes- IMBF170R1K0M1

PWM-QR (quasi resonant) flyback control ICs- ICE5QSAG

Controller board

32-bit XMC4000 industrial microcontroller ARM® Cortex®-M4 family- XMC4400-F100k512 BA

High speed CAN transceiver generation-TLE9251VSJ

OPTIGA™ TRUST M -SLS32AIA

Low voltage drop linear voltage regulators - IFX25001TFV33

256-Kbit (32K × 8) serial (SPI) F-RAM: FM25V02A from Cypress

More information concerning these devices is available on the Infineon website.

1.2 Block diagram

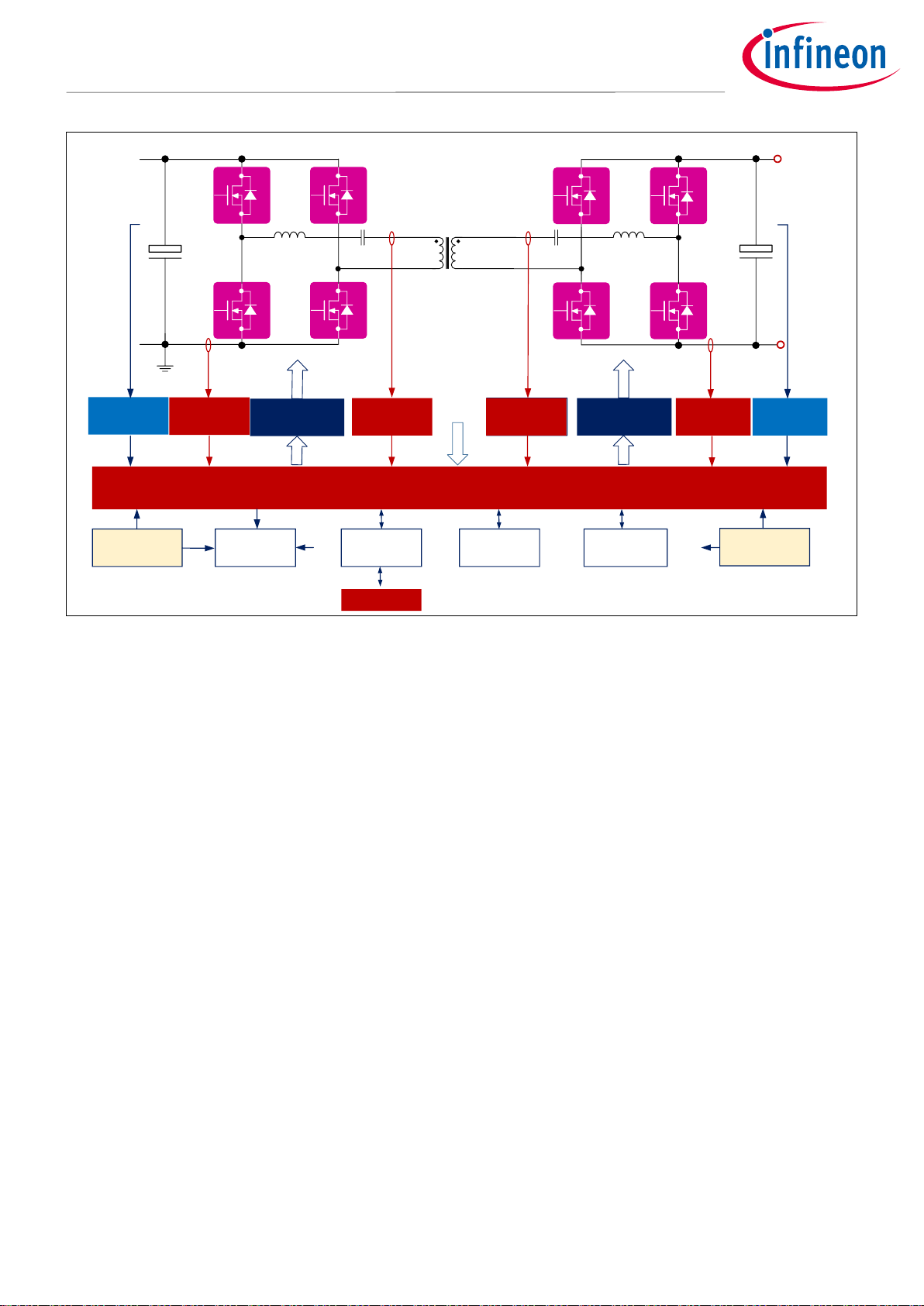

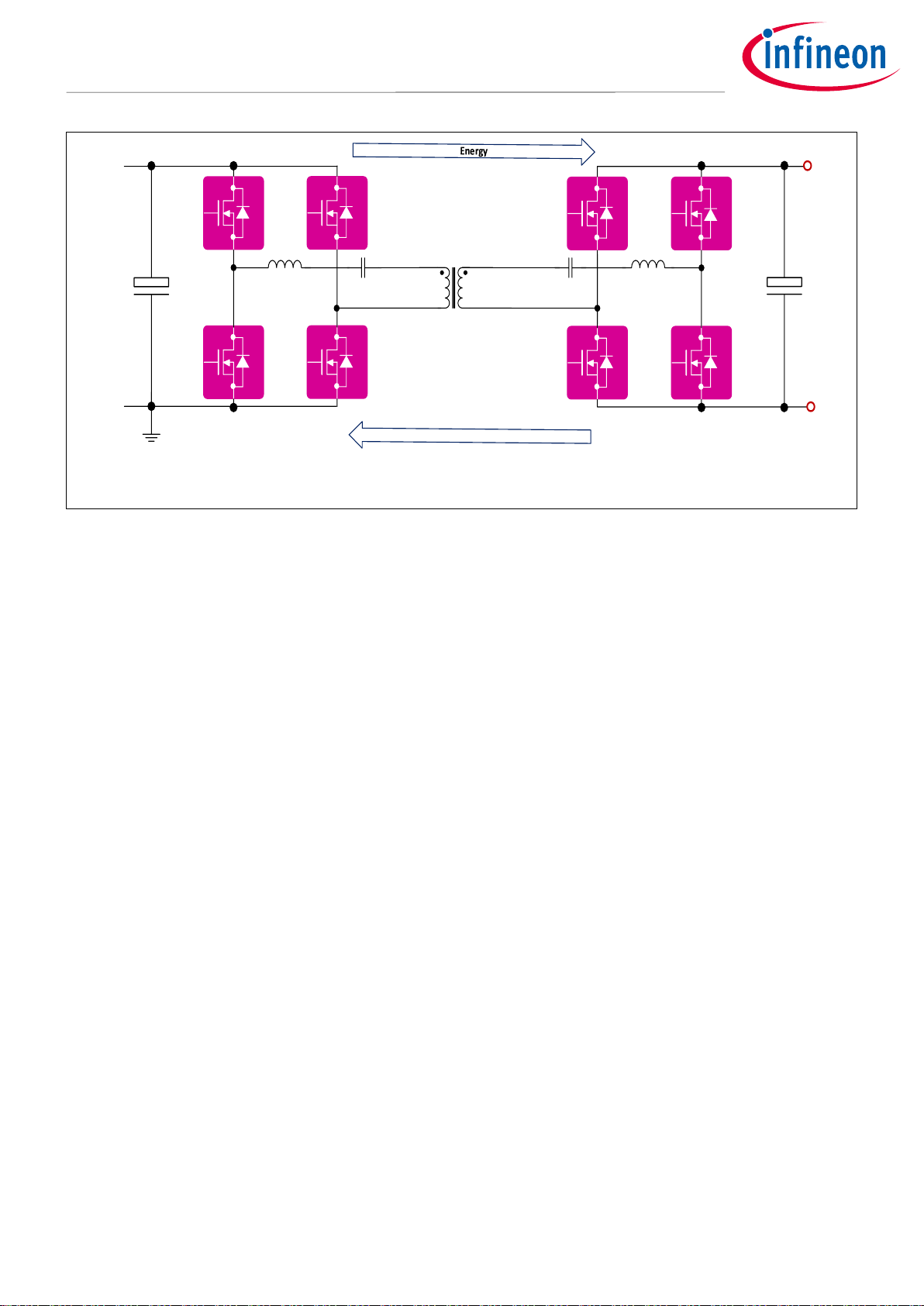

The REF-DAB11KIZSICSYS design consists of a CLLC in full-bridge configuration (Figure 2). The CLLC resonant

converter is widely used as a DC transformer to interlink the AC/DC to DC bus, because of its advantages of high

power density and the capacity of bi-directional power transfer. In both forward and reverse modes, the

resonant tank possesses almost the same operational characteristics of the conventional LLC resonant

tank.Thus the ZVS+ZCS soft switching can be achieved both in forward and reverse modes, and the switching

losses can be minimized, thereby improving charger efficiency.

This architecture showed in the block diagram contains three parts, the main power circuit, the auxiliary power

board and the control board.

Page 7

7 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

The board at a glance

Isolated gate driver

1EDC20I12AH

Isolated current

transformer

Isolated current

transformer

Isolated voltage

sensor

Isolated

voltage sensor

XMC4400 MCU Controller

Aux power

CoolSET+SIC MOS

FAN Wifi Module Cypress FeRAM OPTIGATrust X

NTC

Current sensor

isolated

Aux power

CoolSET+SIC MOS

Current sensor

TLI4971

Isolated gate driver

1EDC20I12AH

GUI

Figure 2 11 kW bi-directional CLLC DC-DC converter (REF-DAB11KIZSICSYS ) – simplified diagram

showing the Infineon semiconductors used in the system

The main power circuit includes 1200 V CoolSiCTM MOSFETs make high efficiency possible.

The auxiliary power supply uses 1700 V CoolSiCTM MOSFETs for an efficient design, as it is as small as a card.

The control is implemented in an XMC4400 Infineon microcontroller, which includes the following features:

ARM® Cortex™-M4, 120MHz, incl. single cycle DSP MAC and floating point unit (FPU)

8-channel DMA + dedicated DMAs for USB and Ethernet

USIC 4ch [Quad SPI, SCI/UART, I²C, I²S, LIN]

Supply voltage range: 3.13 - 3.63V

USB 2.0 full-speed, on-the-go

CPU frequency: 120MHz

Peripherals‘ clock: 120 [MHZ]

eFlash: 512 kB including hardware ECC

80 kB SRAM

10/100 Ethernet MAC (/w IEEE 1588)

2x CAN, 64 MO

Package: PG-LQFP-100

4x ΔΣ demodulator

Temperature range from -40° to 125°

Further details about the digital control implementation and other functionalities of CLLC in the XMC™ 4000

family can be found on the Infineon website.

Page 8

8 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

The board at a glance

1.3 Main features

A bi-directional full-bridge CLLC resonant converter using a symmetric CLLC-type resonant network

is proposed for a bi-directional power distribution system. This converter can operate under high

power conversion efficiency, as the symmetric LLC resonant network has zero-voltage switching

capability for primary power switches and sychronous rectification capability for secondary- side

rectifiers.

In addition, the proposed topology does not require any snubber circuits to reduce the voltage stress

of the switching devices because the switch voltage of the primary and secondary power stage is

confined by the input and output voltage, respectively. In addition, the power conversion efficiency

of any direction is similar. Intelligent digital-control algorithms are also proposed to regulate output

voltage, control bi-directional power conversions and to achieve synchronous rectification.

1.4 Board parameters and technical data

Table 2 shows the specifications of the board

Table 2 Parameter

Parameter

Symbol

Conditions

Value

Unit

Rated power P V

bus

=750V,

VHV=800V,Ta=250C. I

pri.

=15A

11

KW

Primay side bus voltage

V

bus

-

750

V

Secondary side bus voltage

VHV

-

550-~800

V

Primay side current

I

pri.

V

bus

=750V,

VHV=800V,Ta=250C. I

pri.

=15A

15

A

Secondary side current

I

sec.

VHV=550V,P=11KW,

Ta=250C.

20

A

Switching frequency

fs

-

40~200

Khz

Auxilary power output voltage

V

aux.

P

aux.

=32W

15/20

V

Auxilary power output power

P

aux.

V

aux.

=20V, ,Ta=250C.

32

W

Board net weight

W

Without encloser

2

Kg

Page 9

9 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

2 System and functional description

2.1 Commissioning

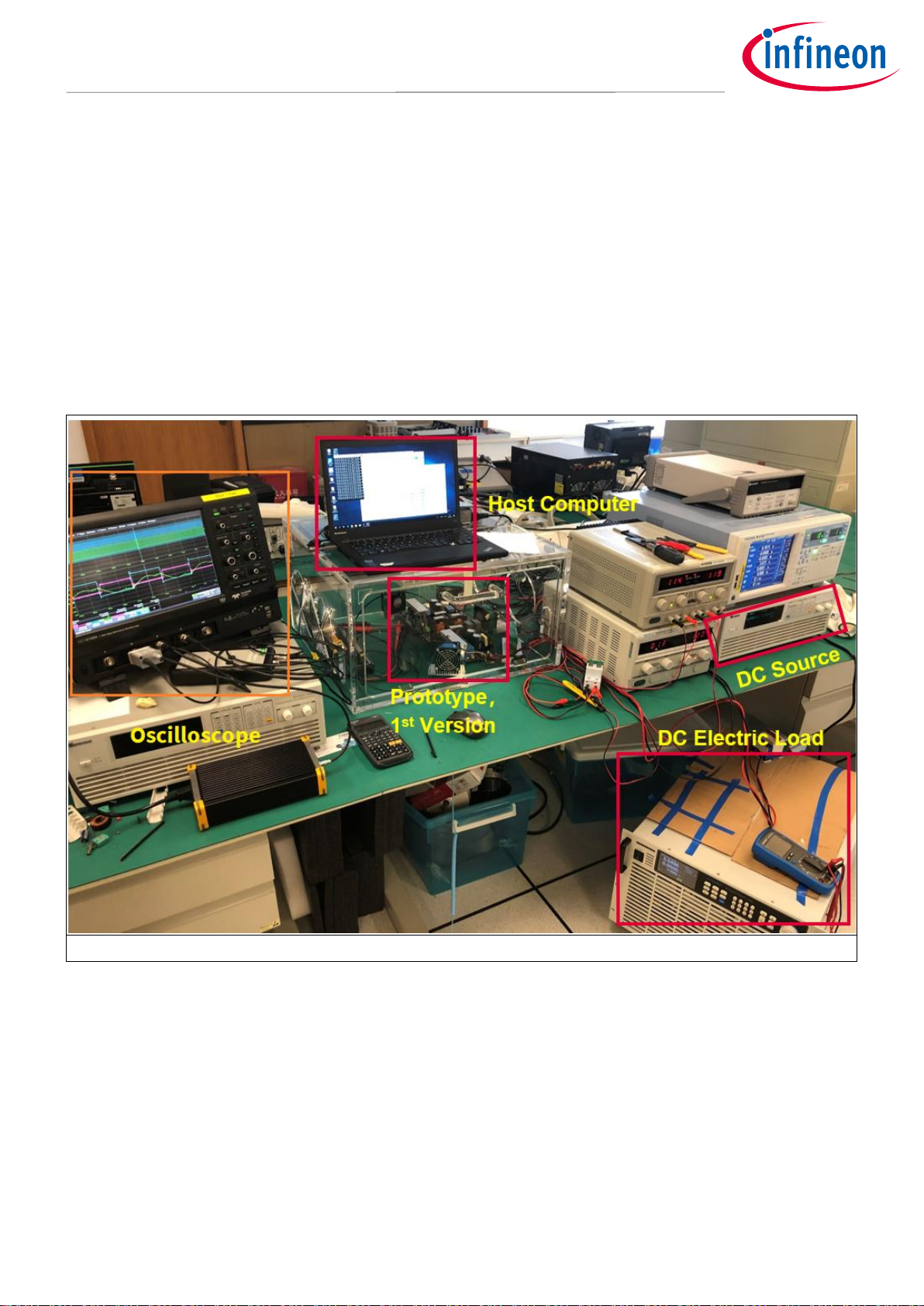

This chapter presents the set-up on how to evaluate the performance and behavior of the 11 kW bi-directional

DC-DC converter using CoolSiC™ MOSFETs.

DC source provides the power to the converter prototype

Secondary side of converter prototype connect with the DC electric load

The host computer controls the start and stop of the prototype and sets the working parameters

through GUI

Observe the corresponding waveforms with an oscilloscope

Figure 3 11 kW bi-directional CLLC DC-DC converter measuring environment

2.2 Description of the functional blocks

The 11 kW bi-directional CLLC DC-DC converter can operate as an isolated buck or as an isolated boost

converter, with the power flowing from the bus side to the isolated HV side or vice versa.

For validation of the buck mode, the suggested set-up includes:

Bus supply capable of 700 V~800 V and at least 11 kW (when testing up to full load)

HV electronic load (500 V to 800 V), in constant current mode, capable of at least 11 kW (when testing up to full

load). Nominal input voltage of the converter is 750 V. The converter works as indicated in Figure 4.

Page 10

10 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

Bus

HV

36uH 132nF 22uH216nF

20:16,Lm=160uH

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

Figure 4 Buck mode recommended validation set-up

For validation of the boost mode, the suggested set-up is exactly the same as for the buck mode, except for

thing: the output voltage parameter must be changed in the GUI window.

2.2.1 Description of the functional blocks

The output gain function of CLLC topology is generally analyzed by the fundamental wave-analysis method.

Based on this analysis method, the parameters of the key resonant components in the current design are

shown in the Figure 4:

By using this parameter, the resonance parameter Q of the primary and secondary transformers is consistent,

and the natural resonance frequency is 73 kHz. In the design, we chose a switching frequency of the topology in

the range of 40 kHz to 200 KHz.

The structure of CLLC topology on the primary side and the secondary side is the same. On the contrary, the

fundamental wave-analysis method is also valid. The relationship between the output/input gain and the

switching frequency of the circuit is shown in Error! Reference source not found.(reverse energy

transmission):

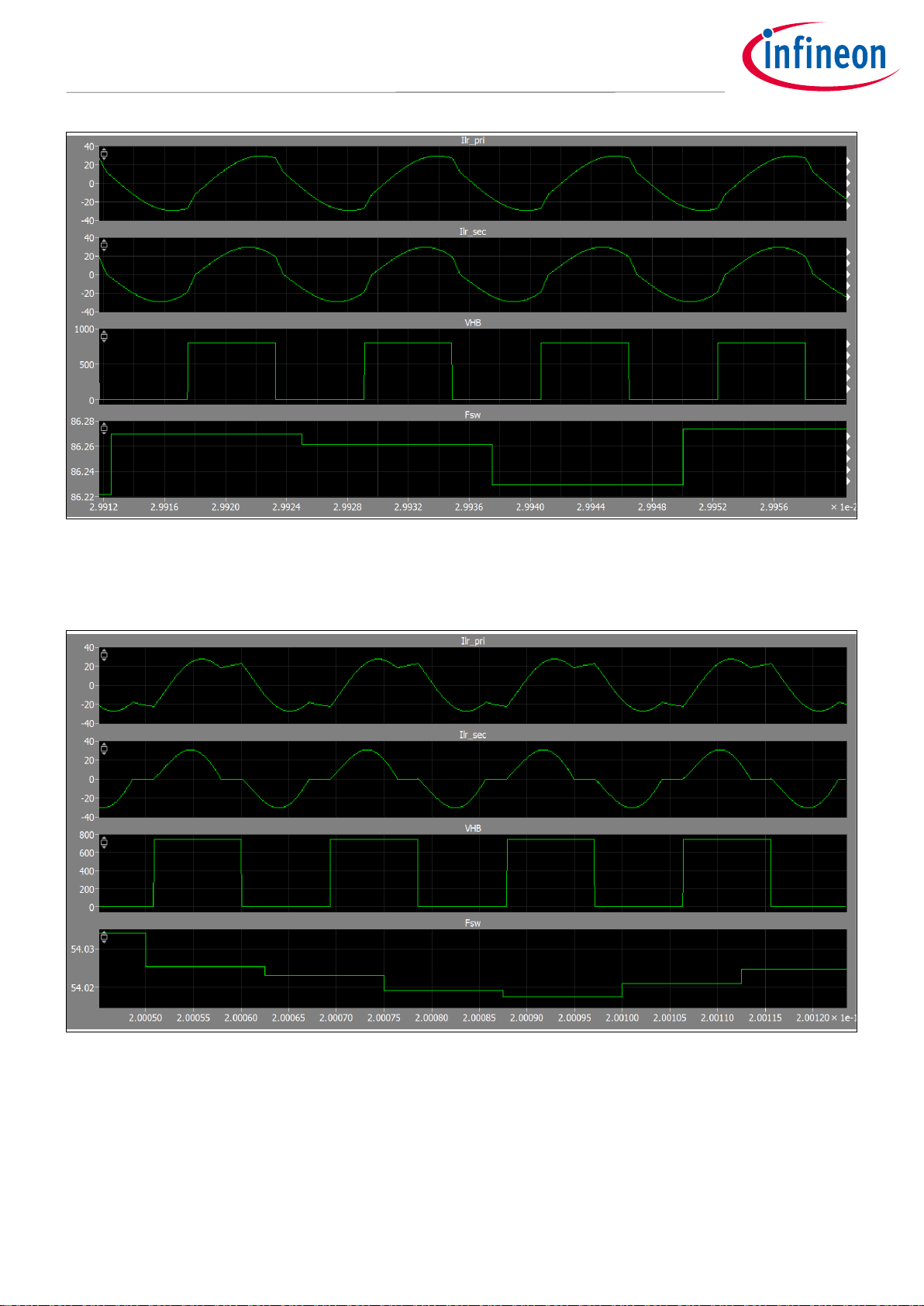

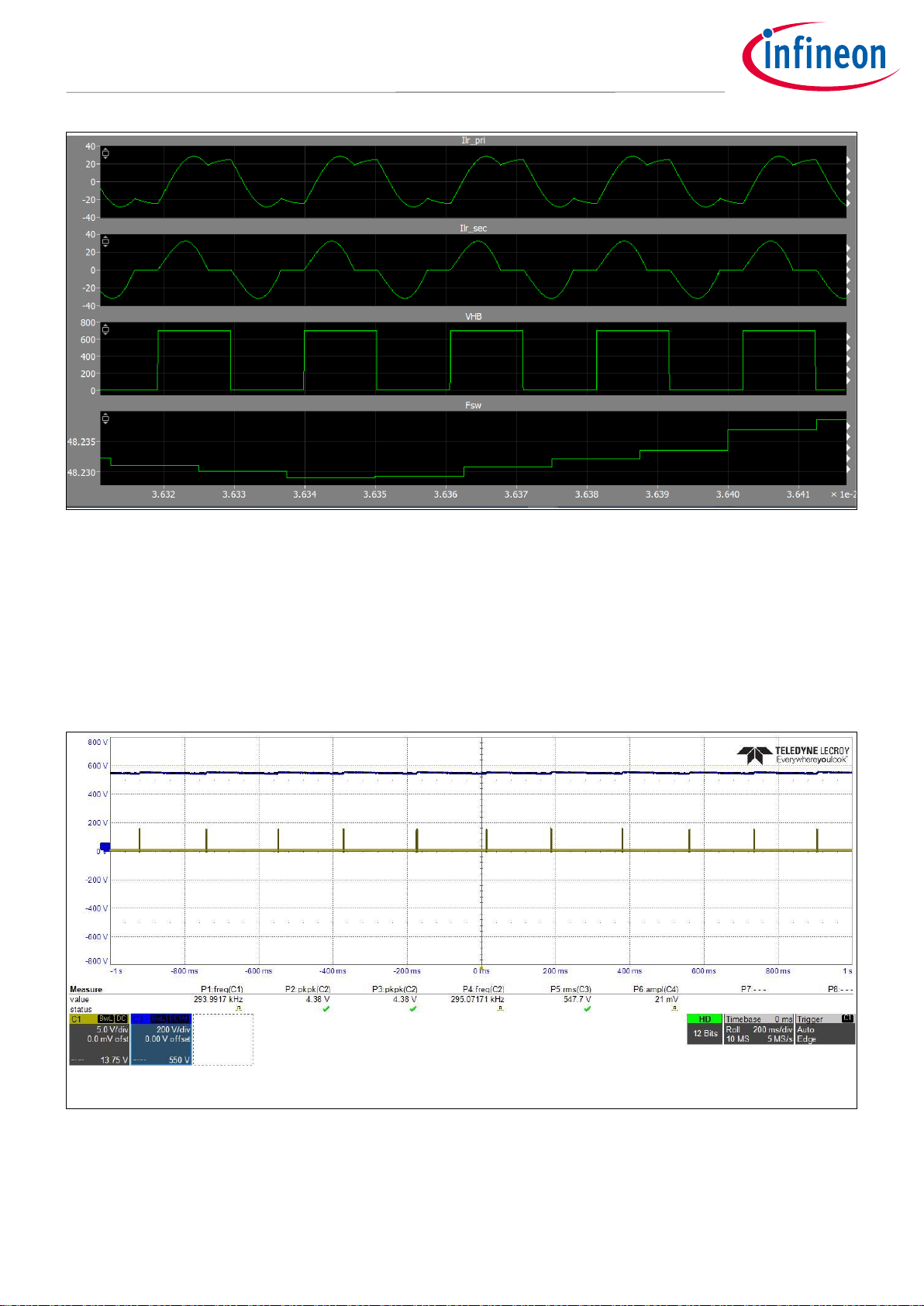

The current of the primary/secondary resonant cavity and the Vds waveform of the SiC MOSFET in the steady

state can be obtained as follows with the help of PLECS simulation software for verification:

Buck mode (forward-energy transmission), input voltage 800 V, and output voltage 550 V with load 27.5 Ω. At

this time, the CLLC topology switching frequency is 86.2 KHz:

Ilr_pri is the primary side resonant tank current.

Ilr_sec is the secondary side resonant tank current.

VHB is the V

ds

voltage of Q2 (The position of SiC MOSFETs Q1~Q8 can be seen in Figure 4.).

Fsw is the switching frequency.

Page 11

11 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

Figure 5 Simulation result of CLLC buck mode

Forward-energy transmission, input voltage 750 V, output voltage 750 V, load 51.1 Ohm. The switching

frequency of CLLC topology is 54.0 KHz at this condition, the simulation wavefrom can be seen in Figure 6.

Figure 6 Simulation result of CLLC

Boost mode (forward-energy transmission), input voltage 700 V, output voltage 800 V, load 58.1 Ohm. At this

time, the CLLC topology switching frequency is around 48.2 KHz:

Page 12

12 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

Figure 7 Simulation result of CLLC boost mode

In the case of no load or light load, the CLLC topology must work in frequency-modulation mode (PFM),

otherwise the power devices in the circuit may work at a very high switching frequency. Due to the existence of

parasitic parameters, the output voltage cannot be reduced to the target value under the circumstances of

continuous wave mode. The topology will work in this mode:

Channel 1 is the controller board ouput pulse-width modulation (PWM) signal.

Channel 2 is the output voltage.

Figure 8 Test result of light load

In the “burst” state, the output voltage waveform is as follows when a sudden load is added:

Channel 3 is the output voltage.

Page 13

13 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

Channel 4 is the load current.

Figure 9 Test result of added sudden load

At this time, there is an obvious overshoot of resonant cavity current according to Figure 10. If the peak value is

more than 40 A, it will trigger the overcurrent protection:

Channel 2 is the gate PWM signal of Q2.

Channel 3 is the V

ds

voltage of Q2.

Channel 4 is the primary side resonant tank current.

Figure 10 Test result of added sudden load

Page 14

14 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

Steady state, the Vgs/Vds voltage waveform of SiC MOSFET and current waveform in the resonation tank can be

seen in Figure 11.

Figure 11 Test waveform when the load is 10KW

For more expanded waveform details, please see Figure 12 below.

Figure 12 Details of V

gs/Vds

In Figure 13, the output voltage ripple is around 16.5 V; here we have considered the peak-to-peak value.

Channel 1 is the controller output PWM signal.

Channel 2 is the output voltage, here we consider the peak-to-peak value.

Page 15

15 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

Figure 13 Output voltage ripple

2.2.2 Special operation modes

The CLLC circuit used CoolSiCTM MOSFETs in the primary and secondary sides, so under normal work conditions

when one side of the transformer is in the switching state, the other side works in the diode rectification mode.

As known, MOSFET body diodes have considerable conduction voltage drops. Fortunately, the channel of the

MOSFET has reverse-conduction capability with a much smaller conducting voltage drop than its body diode.

Therefore it is necessary to adopt the synchronous rectification method to reduce the conduction loss on the

rectifier side, and improve the conversion efficiency.

Here explain a basic principle of the synchronous rectification scheme:

Under normal circumstances, dedicated synchronous rectifier drive controllers are widely used to detect the Vds

of the rectifier tube, and to control the gate drive in time. However, we cannot use this method in bi-directional

Page 16

16 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

DC/DC converters. In this board, we adopted another low-cost method to achieve synchronous rectification

control:

By sampling the current on the secondary side of the transformer through the current transformer CT,

and converting the periodic positive and negative current sampling signal into a DC current via the

rectifier circuit, then sending it to the non-inverting input of the comparator;

The comparator compares the rectified current sampling signal with a fixed threshold V

ref

, which is set

to be slightly more than 0;

The output inversion signal of the comparator and the primary pulse-width modulation (PWM) signal

are subjected to the AND operation and then sent to the corresponding rectifier drive circuit as the

drive signal. This process can also be completed by the MCU.

Below is the implementation block diagram of the synchronous rectification function:

Gate

Driver

&

Gate

Driver

V

rec

V

ref

V

comp.out

V

gs

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

Figure 14 Synchronous rectification function

With this method, it is easy to achieve synchronous rectification. At present, the AND operation between the flip

signal output by the comparator and the primary PWM signal is carried out inside the MCU. The MCU recognizes

that the comparator outputs a high level, and triggers an external interrupt, which is combined with the current

cycle of the PWM wave-sending sequence in the interrupt service routine. The corresponding synchronous

rectification drive is issued, but there is a certain delay in the actual measurement software processing. The

actual measurement current delay is about 1 s, and software optimization is required to reduce this delay

time.

Channel 1 is the V

ref

.

Channel 2 is output signal of the comparator.

Channel 3 is secondary side gate PWM signal.

Channel 4 is primary side gate PWM signal.

Page 17

17 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

Figure 15 Synchronous rectification gate signal

2.3 Auxiliary power boards

2.3.1 The technical specification of auxiliary power boards

The reference board is intended to support customers designing an auxiliary power supply for three-phase

converters using the Infineon 1700 V CoolSiC™ MOSFET. Potential applications include solar inverters, energy

storage, EV chargers, UPS and motor drives. Table 2 lists the key board specifications.

Table 3 Technical specifications

Input voltage

300 VDC to 900 VDC

Output power

32 W

Topology

Single-ended flyback

Output voltage

15V

20 V

Tolerance 2%

2%

Output current 2 A

2 A

Frequency

65~130 kHz, QR mode

Derating of switches VDS

85% (1450 V)

Efficiency at full load

>85%

2.3.2 Auxiliary power board description

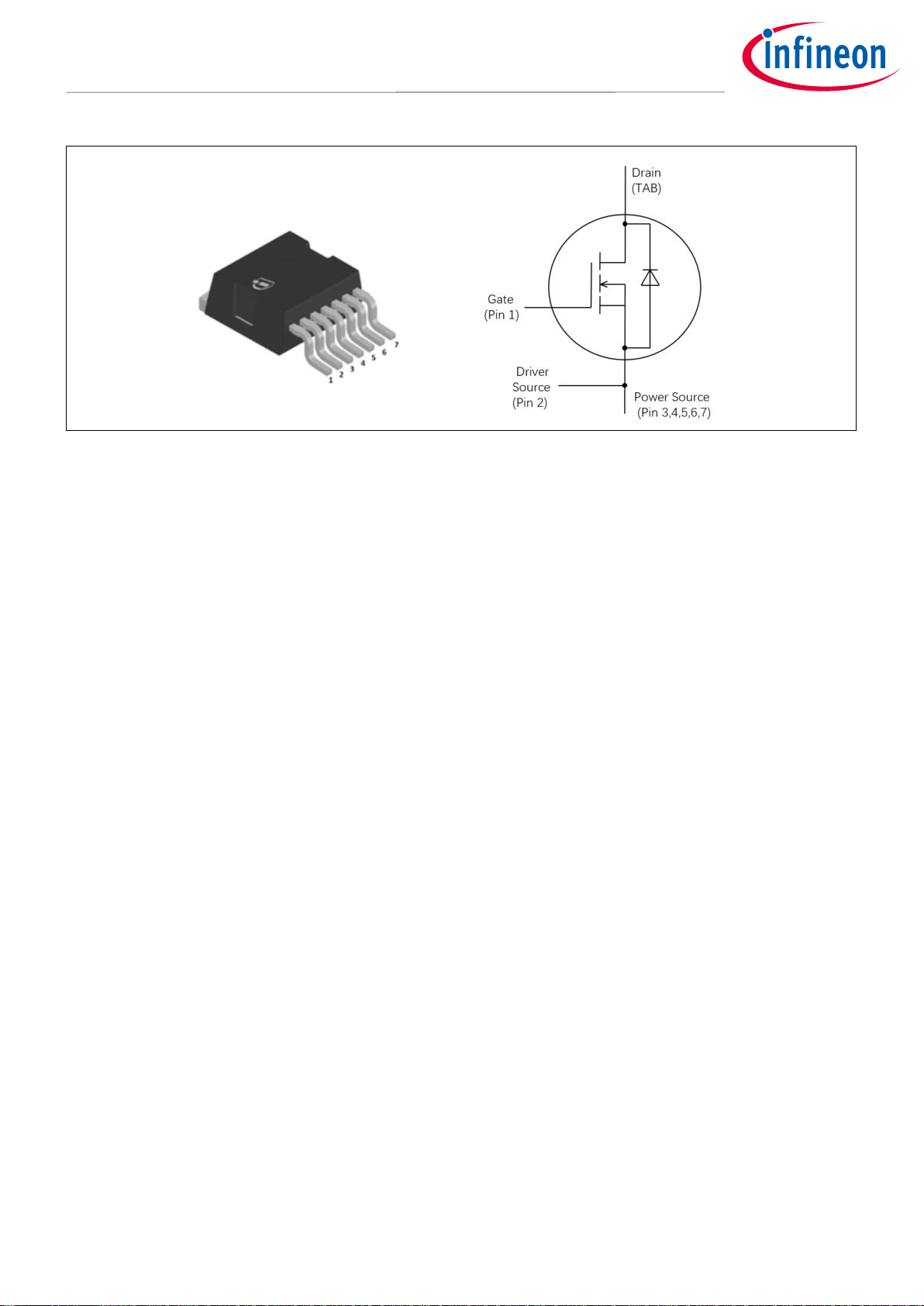

The auxiliary power boards was developed using the 1700 V CoolSiC™ MOSFET in a single-ended flyback topology

to provide auxiliary power for these DC-DC converters.

The board has 20V outputs with up to 32 W output power working in a wide input voltage range from 200 VDC to

850 VDC. Its potential applications are any power electronic system having a high input voltage DC link.

This user guide contains an overview of the reference board’s operation, product information and technical

details with measurement results. The board uses 1700 V CoolSiC™ MOSFET in a TO-263 7L surface-mounted

Page 18

18 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

device (SMD) package as the main switch, which is well suited for high input voltage DC link, with single-ended

flyback topology. With low R

DS(on)

, high efficiency and low device temperature rise can be achieved with this

board.

The controller works in quasi-resonant mode to help reduce EMI noise. This information can help customers

during their design-in phase, and for re-use of the reference design board for their own specific requirements.

Figure 16 Pictures of auxiliary power board

2.3.3 1700 V CoolSiC™ MOSFET overview

The auxiliary power board was developed using the 1700 V CoolSiC™ MOSFET in a single-ended flyback topology

to provide auxiliary power for this DC-DC. The 1700 V CoolSiC™ MOSFET from Infineon is an excellent choice for

high input voltage DC link systems like those found in auxiliary power supplies for three-phase converters. The

TO-263 7L surface-mounted device (SMD) package is an optimized package for up to 1700 V high voltage power

device. There is a creepage distance of about 7 mm width between drain and source, so safety standards are

easily met. The separate driver source pin is helpful in reducing parasitic inductance of the gate loop to prevent

gate-ringing effects.

Using Infineon’s 1700 V CoolSiC™ MOSFET can simplify the current auxiliary power supply designs by developing

a single-ended flyback reference design board. For a low-power auxiliary power supply, a flyback is the most

common topology due to its simple design. However, the flyback topology requires a switching device with a

high-blocking voltage. Currently, silicon MOSFETs only have a blocking voltage of up to 1500 V that leaves low

design margins, which affects the reliability of the power supply at a given input voltage DC link of 1000 VDC.

Moreover, most 1500 V silicon MOSFETs have very large on-state resistance (R

DS(on)

), which will lead to higher

losses, and thus lower system efficiency.

Page 19

19 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

Figure 17 1700 V CoolSiC™ MOSFET IMBF170R1K0M1

The ICE5QSAG gate drive output stage has a 0.9 A source capability, and output voltage up to 13 V, so the SiC

MOSFET can be driven directly, which simplifies the driver circuit design.

The auxiliary power board was developed using the 1700 V CoolSiC™ MOSFET in a single-ended flyback

topology to provide auxiliary power for this DC-DC. The 1700 V CoolSiC™ MOSFET from Infineon is an excellent

choice for high input voltage DC link.

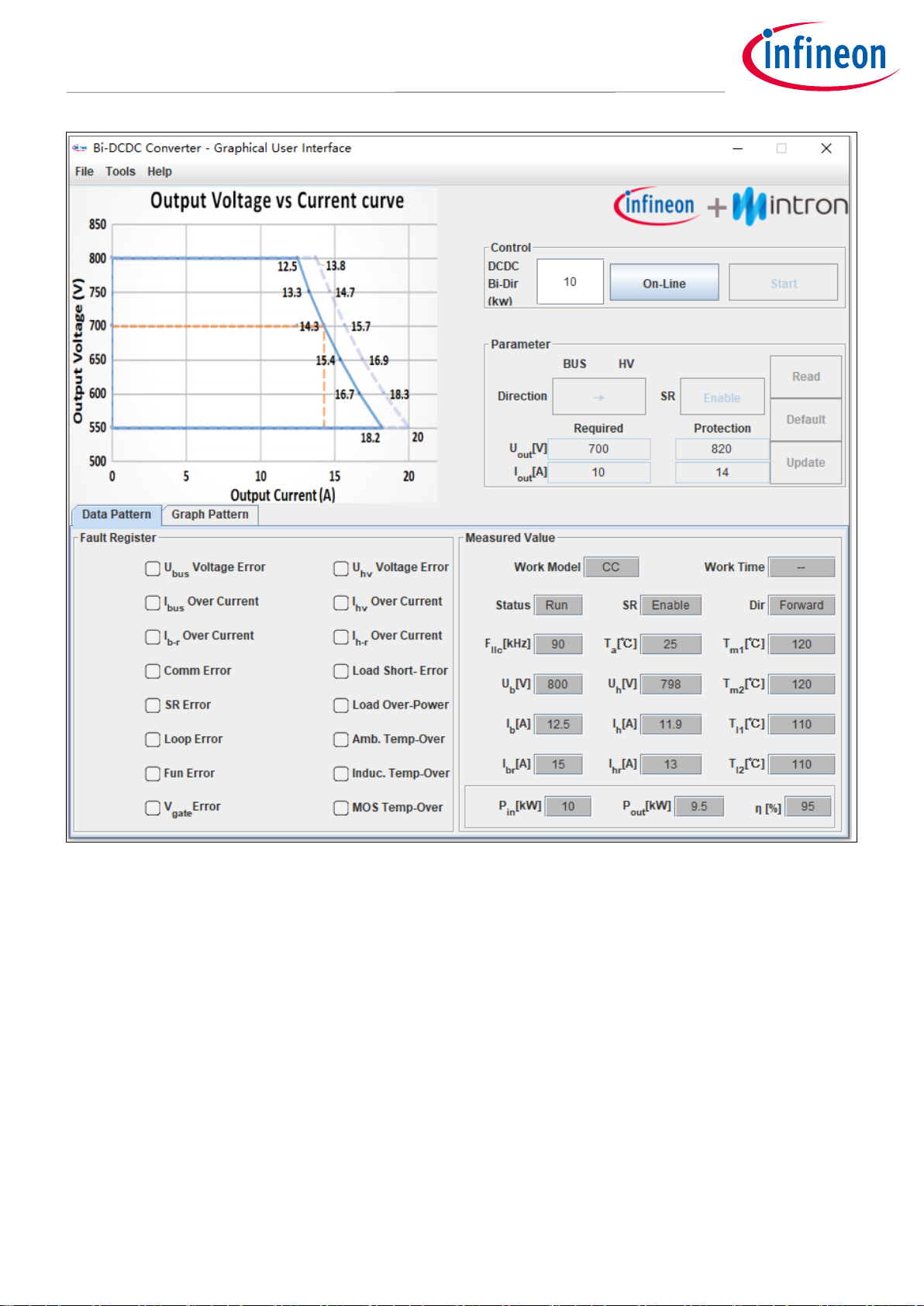

2.4 User interface

The 11 kW bi-directional DC-DC converter includes Wi-Fi wireless communication and the

corresponding protocol, allowing the converter system to implement the following functions through

the GUI interface of the computer:

System parameter setting (output direction, synchronous rectification function, output

voltage/current, voltage/current protection)

Working status control (connection, start/stop)

Running status display (measured value)

Abnormal status monitoring (fault register)

Abnormal analysis data reading (tools)

The signal chain between the GUI control interface and the converter system is the computer GUI

interface -> PC Wi-Fi connection -> DC-DC converter system.

The corresponding human-machine interface realizes corresponding functions through the

combination of graphics + data + buttons. The detailed interface is shown in the figure below:

Page 20

20 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

Figure 18 Graphical user interface (GUI)

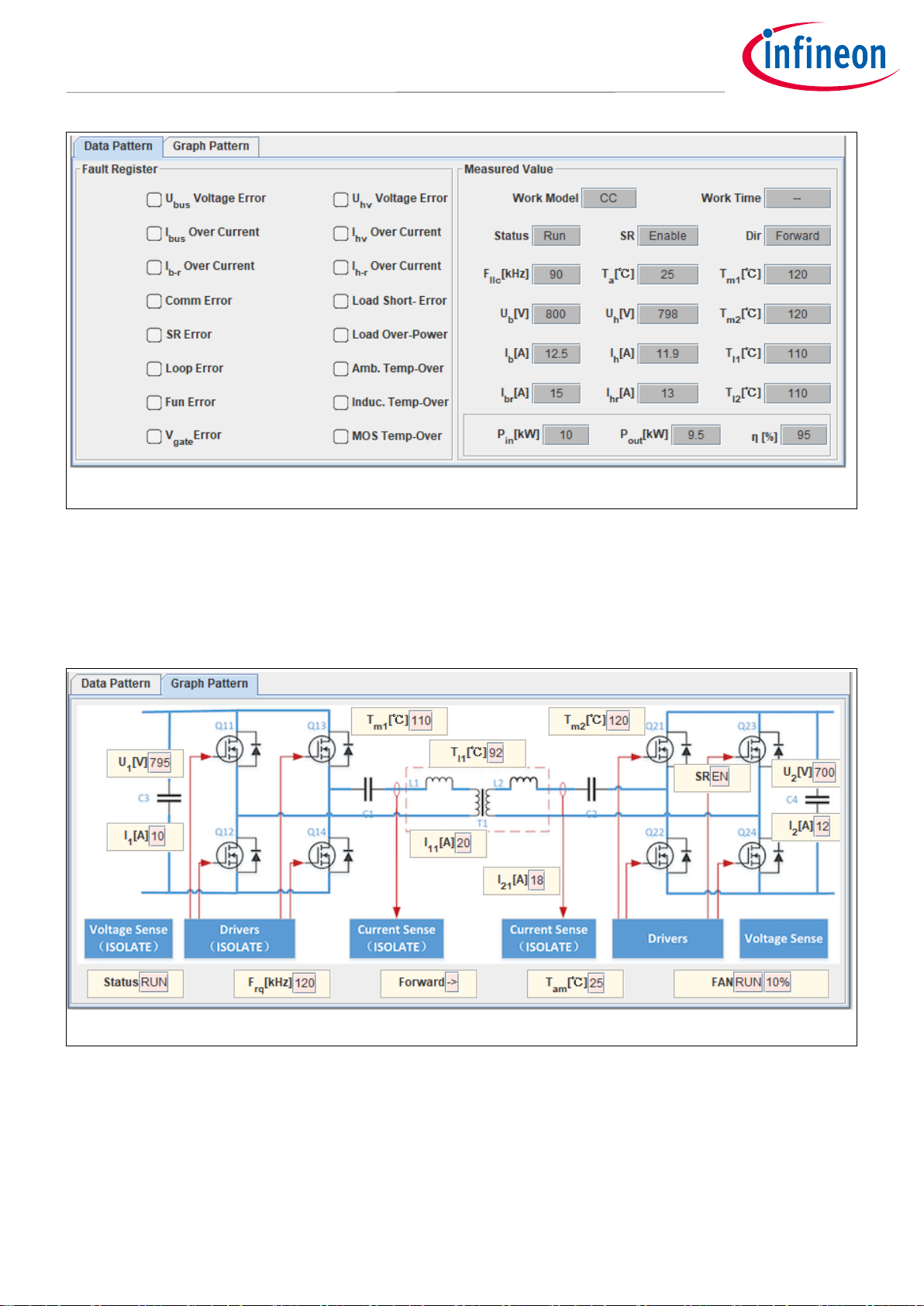

There are two ways for the GUI to display real-time data:

Data dattern: Data parameter interface displays:

Working status, operating voltage/current, resonance parameters, temperature of key

components, abnormal status monitoring and display.

Page 21

21 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System and functional description

Figure 19 Data pattern in GUI user

Graph Pattern:Graphical parameter interface displays:

Relevant real-time operating data of components in the corresponding position of topology of

the system.

Figure 20 Graph pattern in GUI user

Page 22

22 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

3 System design

3.1 Schematics

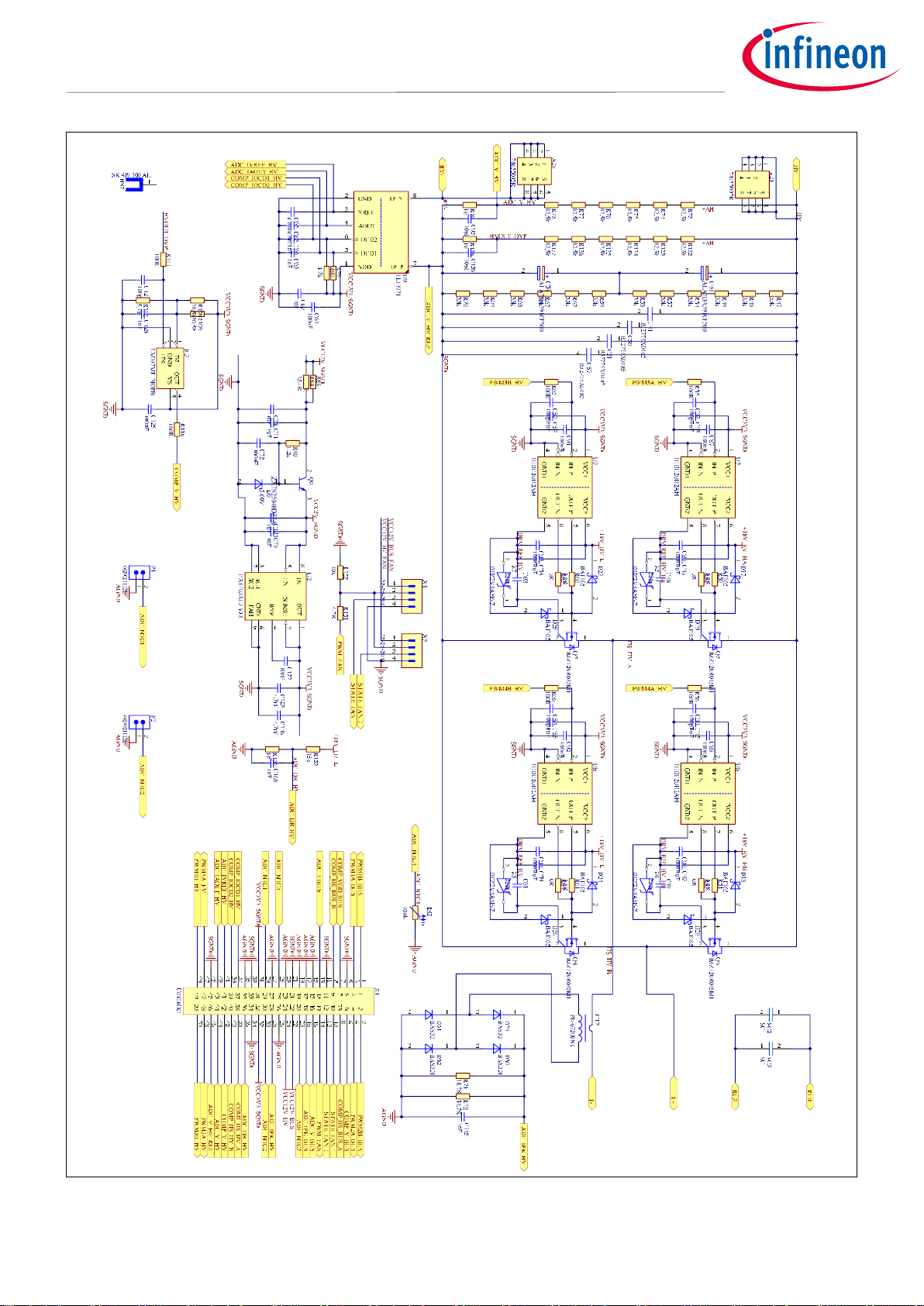

Figure 21 Main board primary side schematic

Page 23

23 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

Figure 22 Main board secondary side schematic

Page 24

24 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

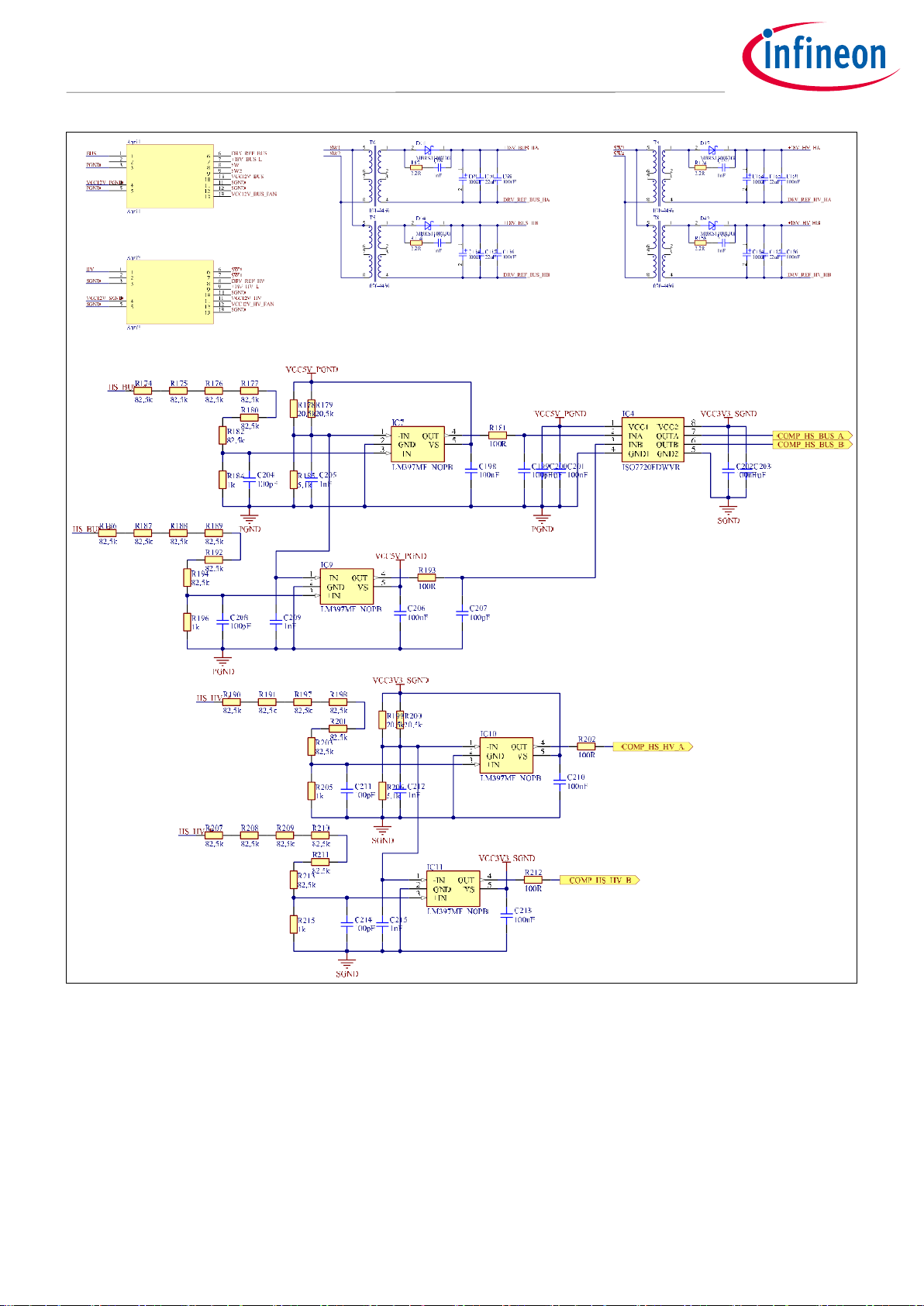

Figure 23 32 W auxiliary power supply schematic.

Page 25

25 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

Figure 24 Sensor circuit schematic

Page 26

26 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

3.2 Layout

2111

13

14

16

17

18

19

20

1 1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

13 12

1011 89 67 3 1245

1110987654321

1312

12

1 2

1 2

16

15

2

1

8

12

11

7

9

10

14

13

4

3

5

6

12

2

1

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

5030

29

28

27

26

25

24

23

22

211

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

12

1 2

1 2

2 1

1

2

1

2

1

2

2 1

1

2

12

1

2

1

2

1

2

12

1

2

1 2

3 4

1 2

3 4

1

2

3

4 5

6

7

8

1234

5 6 7 8

123

4 5

MH2MH1

12

MH2MH1

12

8765

1234

8765

1234

2

1

2

12

1

2

1

2

1

2

1

2

1

21

21

2

1

2

1

21

2

1

2

1

2

1 2

1

2

1

2

1

21

21

2 1

2

1

2 1

321 4 321 4321 4 321 4

321 4

321 4

321 4

321 4

21

2

1

21

1 2

21

21

21

2 1

2

1

2

1

2

1

2

1

1 2

1 2

1 2

1

2

1 2

2 1

12 2 1

4 3 2 1 4 3 2 1

2

1

2 1

1 2

2

1

1

2

1

2

4 3 2 1

5 6 7 8

8765

1234

2

1

1

2

2

1

1 2

21

1

2

2

1

1 2

21

1

2

1

2

1

2

1

2

Figure 25 Layer 1

Page 27

27 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

2111

13

14

16

17

18

19

20

1 1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

13 12

1011 89 67 3 1245

1110987654321

1312

12

1 2

1 2

16

15

2

1

8

12

11

7

9

10

14

13

4

3

5

6

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

5030

29

28

27

26

25

24

23

22

211

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2 1

1

2

1

2

1

2

2 1

1

2

12

1

2

1

2

1

2

12

1

2

1 2

3 4

1 2

3 4

MH2MH1

12

MH2MH1

12

321 4 321 4321 4 321 4

321 4

321 4

321 4

321 4

4 3 2 1 4 3 2 1

Figure 26 Layer 2

Page 28

28 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

2111

13

14

16

17

18

19

20

1 1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

13 12

1011 89 67 3 1245

1110987654321

1312

12

1 2

1 2

16

15

2

1

8

12

11

7

9

10

14

13

4

3

5

6

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

5030

29

28

27

26

25

24

23

22

211

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2 1

1

2

1

2

1

2

2 1

1

2

12

1

2

1

2

1

2

12

1

2

1 2

3 4

1 2

3 4

MH2MH1

12

MH2MH1

12

321 4 321 4321 4 321 4

321 4

321 4

321 4

321 4

4 3 2 1 4 3 2 1

Figure 27 Layer 3

Page 29

29 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

2111

13

14

16

17

18

19

20

3

1

2

2

1

2

1

1

2

1

2

1

2

2

1

2

1

2 1

2 1

1

2

2

1

2 1

2

1

1 2

1 1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

9

8 7

6

543

2

1

13 12

1011 89 67 3 1245

1110987654321

1312

12

1 2

1 2

16

15

2

1

8

12

11

7

9

10

14

13

4

3

5

6

1 2

2 1

21

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

5030

29

28

27

26

25

24

23

22

211

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

12

21

12

21

1 2

1 2

1 2

1 2

2

1

1 2

2 1

12

21

21

21

1 2

1 2

1 2

1 2

5 4

321

5 4

321

1

2

12

1

2

1

2

1 2

1

2

21

12

21

1 2

12

12

12

12

21

12

2 1

1 2

12

12

12

12

1 2 3

45

1 2 3

45

1 2 3 4

5678

2 1

21

2 1

2

1

2 1

21

21

21

2

1

2

1

21

2

1

2 1

1

2

1

2

1

2

2 1

1

2

12

1

2

1

2

1

2

12

1

2

1 2

3 4

1 2

3 4

1 2 3 4

5678

1 2 3

45

MH2MH1

12

MH2MH1

12

21

2

1

21

2

1

2

1

21

2

1

21

2

1

2

1

2

1

2

1

21

2

1

2

1

2

1

2

1

21

2

1

21

2

1

2

1

2

1

21

2

1

21

2

1

2

1

2

1

2 1

2 1

2

1

2 1

2 1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

1 2

1

2

1

2

1

2

21

2 1

2 1

9

8765

4 3 2 1

321 4 321 4321 4 321 4

321 4

321 4

321 4

321 4

1 2

1 2

1 2

2

1

2

1

1

2

1

2

1 2

2 1 2 1

1 2

1 21 2

2

1

2

1

1 2

1

2

1

2

2 1 2 1

1 2

1 2

1 2

1 2

1

2

2

1

2

1

1

2

2

1

2

1

2

1

2

121

21

1 2

1 2

1 2

2

1

2

1

1

2

1

2

1 2

2 1

2 1

1 2

1 21 2

2

1

2

1

1 2

1

2

1

2

2 1

2 1

1 2

1 2

1 2

1 2

1

2

1

2

1

2

1

2

1

2

2

1

12

1

2

1

2

1

2

1

2

1

2

2 1

2

1

2

1

2

1

2

1

1 2

2

1

2 1

21

212 1

21

1234

5 6 7 8

1234

5 6 7 8

1234

5 6 7 8

1234

5 6 7 8

1234

5 6 7 8

1234

5 6 7 8

1234

5 6 7 8

1234

5 6 7 8

1

6

4 3 2 1 4 3 2 1

2

1

2

1

2

1

1

2

1 2

12

1234

5 6 7 8

9

5 4

321

2

1

2

1

1 2

12

2 1

1

2

21

1

2

2

1

1

2

2

1

2

1

Figure 28 Layer 4

Page 30

30 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

3.3 Bill of material

The complete bill of material is available on the download section of the Infineon homepage. A log-in is

required to download this material.

Table 4 BOM of the most important/critical parts of the reference board

Comment

Description

Designator

Footprint

LibRef

Quantity

ALA7DA391CF500

Capacitor Polarised

C1, C17, C40,

C56

CAPPRD1000W210D3050H520

0

ALA7DA391CF500

4

B32774X0405

Capacitor

C2, C11, C12,

C18, C41, C50,

C51, C57

B32774X0405

B32774X0405

8

100pF

Surface Mount

Multilayer Ceramic

Chip Capacitor

C3, C5, C13,

C15, C25, C30,

C37, C42, C44,

C52, C54, C127,

C152, C153,

C157, C199,

C204, C207,

C208, C211,

C214, C244

CAPC1608X87N

245892

22

1uF

Surface Mount

Multilayer Ceramic

Chip Capacitor

(SMD MLCC)

C4, C6, C14,

C16, C24, C26,

C31, C34, C36,

C38, C43, C45,

C53, C55, C67,

C71, C74, C75,

C76, C124,

C151, C200,

C203

CAPC1608X87N

308640

23

1uF

Chip Monolithic

Ceramic Capacitor

C7, C8, C19,

C20, C46, C47,

C58, C59

CAPC2013X135N

310545

8

220nF

Multilayer Ceramic

Capacitor

C9, C10, C21,

C22, C48, C49,

C60, C61

CAPC2013X140N-1

491974

8

100nF

Surface Mount

Multilayer Ceramic

Chip Capacitor

C23, C27, C28,

C32, C33, C35,

C39, C64, C72,

C73, C80, C81,

C82, C83, C84,

C85, C86, C87,

C88, C89, C90,

C91, C92, C93,

C94, C98, C125,

C136, C169,

C186, C198,

C201, C202,

C206, C210,

C213, C242

CAPC1608X87N

251891

37

1nF

Surface Mount

Multilayer Ceramic

Chip Capacitor

C29, C63, C66,

C128, C145,

C158, C168,

C205, C209,

C212, C215,

C245, C246

CAPC1608X87N

246012, 239242

13

Page 31

31 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

6.8nF

Chip Monolithic

Ceramic Capacitor

C62, C65

CAPC1608X90N

267248

2

1nF

SMD Comm C0G,

Ceramic Capacitor

C68, C133,

C162, C183

CAPC3216X88N

489640

4

100uF

Polymer Surface

Mount Chip

Capacitor Molded

Case, High

Performance Type

C69, C134,

C164, C184

CAPMP7343X310N-1

595120

4

22uF

Ceramic Chip

Capacitor, SMD,

MLCC,

Temperature

Stable

C70, C135,

C165, C185

CAPC3225X280N-2

308600

4

10pF

Capacitor, SMD,

MLCC, High

Temperature,

Ultra-Stable,

Automotive Grade

C95, C156

CAPC2013X88N

523442

2

10nF

Surface Mount

Multilayer Ceramic

Chip Capacitor

C122, C150

CAPC1608X09N

244517

2

4.7uF

High Value

Multilayer Ceramic

Capacitors (High

dielectric type)

C123, C126,

C146, C149

CAPC2113X140N

479052

4

PE-67200NL

Connector

CT1, CT2

PE67200NL

PE-67200NL

2

BAT165

Medium Power AF

Schottky Diode

D1, D2, D3, D4,

D7, D8, D9, D10,

D17, D18, D19,

D20, D23, D24,

D25, D26

SOD2513X110N

420071

16

5.60V

1.5 Watt Plastic

Surface Mount

Zener Voltage

Regulator

D5

DIOM5226X220N

513956

1

BAS321

General Purpose

Diode

D13, D14, D15,

D16, D29, D30,

D31, D32

SOD2513X110N-1

393569

8

MBRS1100T3G

Schottky Power

Rectifier

D21, D34, D37,

D43

DIOM5436X247N

519286

4

IFX1763XEJV50

Wide Input Range

Low Noise 500mA

5V LDO

G1

SOIC127P600X170-9N

424464

1

IFX1763XEJ V33

Wide Input Range

Low Noise 500mA

LDO

G2

SOIC127P600X170-9N

428662

1

SK 489 100 AL

Extruded Heatsink

for Lock-in

Retaining Spring,

PCB mounting,

100mm L X

29.44mm W X

45mm H, Raw

degreased

aluminum

HS1, HS2

HS SK 489 100

416826

2

AMC1302QDWVRQ

1

Integrated Circuit

IC1

SOIC127P1150X280-8N

AMC1302QDWVRQ

1

1

Page 32

32 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

AMC1311QDWVQ1

Integrated Circuit

IC2

SOIC127P1150X280-8N

AMC1311QDWVQ1

1

LM397MF_NOPB

Integrated Circuit

IC3, IC6, IC7,

IC8, IC9, IC10,

IC11

SOT95P280X145-5N

LM397MF_NOPB

7

ISO7720FDWVR

Integrated Circuit

IC4, IC5

SOIC127P1150X280-8N

ISO7720FDWVR

2

66200211122

THT Male Header

WR-MPC3,

Vertical, Single

Row, pitch 3 mm, 2

pins

P1, P2

66200211122

66200211122

2

IMZ120R045M1

CoolSiC 1200 V SiC

Trench MOSFET

Q1, Q2, Q3, Q4,

Q5, Q6, Q7, Q8

INF-PG-TO247-4

498554

8

ZXTN25040DZTA

40V, SOT89, NPN

medium power

transistor, PD =

2.4W

Q9

SOT89

527905

1

33k

Standard Thick

Film Chip Resistor

R1, R2, R3, R8,

R11, R12, R13,

R16, R21, R22,

R23, R24, R47,

R48, R49, R54,

R57, R58, R59,

R62, R67, R68,

R69, R70

RESC3216X60N

354467

24

1.8R

General Purpose

Chip Resistor

R4, R5, R14,

R15, R50, R51,

R60, R61

RESC3116X65N

329186

8

0R

Standard Thick

Film Chip Resistor

R6, R7, R17,

R18, R52, R53,

R63, R64

RESC3216X60N

351892

8

100R

General Purpose

Chip Resistor

R9, R10, R19,

R20, R29, R31,

R38, R39, R44,

R55, R56, R65,

R66, R110,

R111, R147,

R181, R193,

R202, R212,

R217

RESC1608X55N-1

327766

21

3mR

High Power

Current Sense Chip

Resistor

R25, R28

RESC6432X90N

516046

2

22R

Standard Thick

Film Chip Resistor

R26, R27

RESC2113X50N

348647

2

1k

General Purpose

Chip Resistor

R30, R155, R218

RESC1608X55N-1

327826

3

110k

Standard Thick

Film Chip Resistor

R32, R33, R34,

R35, R36, R37

RESC3216X60N

354772

6

1.2k

General Purpose

Chip Resistor

R40

RESC1608X55N-1

327831

1

51.1R

Standard Thick

Film Chip Resistor

R41

RESC3216X60N

352877

1

57.6R

Standard Thick

Film Chip Resistor

R42, R43

RESC3216X60N

352907

2

1k

Thick Film Chip

Resistor

Automotive Grade

R45, R149,

R184, R196,

R205, R215

RESC2013X60N

331288

6

Page 33

33 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

1k

Standard Thick

Film Chip Resistor

R46, R138

RESC3216X60N

353612

2

14.7R

Standard Thick

Film Chip Resistor

R71, R72

RESC2113X50N

348552

2

82.5k

Standard Thick

Film Chip Resistor

R73, R74, R75,

R76, R77, R78,

R132, R133,

R134, R135,

R136, R137,

R139, R140,

R141, R142,

R145, R146,

R174, R175,

R176, R177,

R180, R182,

R186, R187,

R188, R189,

R190, R191,

R192, R194,

R197, R198,

R201, R203,

R207, R208,

R209, R210,

R211, R213

RESC3216X60N

354707

42

4.7k

General Purpose

Chip Resistor

R79, R80

RESC1608X55N-1

327866

2

100k

Multilayer NTC

Thermistor

R81, R82

RESC1608X90N

494379

2

15.4R

Standard Thick

Film Chip Resistor

R83, R84

RESC3216X60N

352567

2

2.2R

Standard Thick

Film Chip Resistor

R87, R114,

R124, R158

RESC3216X60N

352082

4

15k

Standard Thick

Film Chip Resistor

R107, R153,

R216

RESC1609X50N

346262

3

20.5k

Standard Thick

Film Chip Resistor

R108, R109,

R143, R144,

R178, R179,

R199, R200

RESC1609X50N

346337

8

5.1k

Standard Thick

Film Chip Resistor

R112, R150,

R185, R206

RESC1609X50N

346002

4

4.7R

Standard Thick

Film Chip Resistor

R151

RESC2113X50N

348277

1

10k

General Purpose

Chip Resistor

R152

RESC2013X60N

328501

1

SC SC1, SC2, SC3

PCBComponent_1 - duplicate1

SC 3 TRANS

T1

PCBComponent_1

TRANS

1

070-4436

Transformer 8Terminal EXT,

SMD, Horizontal,

EP Style Bobbins,

EP7

T4, T5, T6, T8

EP7_4436

EP7, 070-4436

4

1EDC20I12AH

Single channel

IGBT gate driver IC

Up to 10 A typical

peak current , ±2.0

A Output current

configuration

U1, U2, U3, U4,

U5, U6, U7, U8

SOIC127P1030X265-8N-V

583333

8

Page 34

34 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

System design

TLI4971

High Precision

Coreless Current

Sensor

U9

INF-PG-TISON-8

431513

1

Controller

X1

PCBComponent_1 - duplicate3

Controller

1

74655095R

Connector

X3, X10, X21,

X26

74655095R

74655095R

4

22-29-2041

KK 254 Wire-toBoard Header,

Vertical, with

Friction Lock, 4

Pins

X4, X5

CON-M-THT-22-29-2041

383946

2

DDZ2V4ASF-7

Zener Diode

Z1, Z2, Z3, Z4,

Z5, Z6, Z7, Z8

SODFL2512X75N

DDZ2V4ASF-7

8

Page 35

35 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

References and appendices

4.1 Abbreviations and definitions

Table 5 Abbreviations

Abbreviation

Meaning

CE

Conformité Européenne

EMI

Electromagnetic interference

UL

Underwriters Laboratories

4.2 References

[1] “800 W ZVS phase-shift full-bridge evaluation board. Using 600 V CoolMOS™ CFD7 and digital control by

XMC4200”, AN_201709_PL52_027

[2] “1400 W ZVS phase-shift full-bridge evaluation board. Using 600 V CoolMOS™ CFD7 and digital control by

XMC4200”, AN_201711_PL52_003

[3] Jared Huntington, “6 W bias supply. Using the new 800 V CoolMOS™ P7, ICE5QSAG QR flyback controller,

and snubberless flyback for improved auxiliary power-supply efficiency and form factor”,

AN_201709_PL52_030

[4] Design of CLLC Resonant Converters for the Hybrid AC/DC Microgrid Applications

[5] IMBF170R1K0M1 datasheet, 1700 V CoolSiC™ MOSFET

[6] UCC28600 datasheet, 8-Pin Quasi-Resonant flyback Green-Mode Controller

[7] Gate resistor for power devices, Infineon Technologies, application note AN2015-06

4.3 Additional information

This user guide describes the first design version. In case of any future design changes, this document will be

updated accordingly.

Board hardware will available in ISAR from February 2021 onwards.

Page 36

36 of 37

2020-11-03

11 kW bi-directional CLLC DC-DC converter with 1200V and 1700V CoolSiC™

MOSFETs

Revision history

Revision history

Document

version

Date of release

Description of changes

1.0

2020-11-03

First version

Page 37

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2020-11-03

UG-2020-31

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2021 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of the

product or any consequences of the use thereof can

reasonably be expected to result in personal injury.

Loading...

Loading...