Page 1

User Manual Please read the Important Notice and Warnings at the end of this document Rev. 1.0

www.infineon.com page 1 of 20 2019-04-04

TLE986x EvalBoard User Manual

About this document

Scope and purpose

This user manual is intented to help users using the TLE986x Evalboard. This Evalboard is designed to evaluate

hardware and software functionalities of the TLE986x device family.

This manual provides additional information about the board’s layout, jumper settings, interface and debug

options. It introduces the evaluation platform as well as how to write software and download it to the TLE986x.

Intended audience

This document is for everyone who works with the TLE986x Evalboard.

Page 2

User Manual 2 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

About this document

Abbreviations and definitions

Table 1 Abbreviations

Abbreviation

Definition

BLDC

Brushless direct current

BSL

Bootstrap loader

GH 1, 2

Gate high-side MOSFET for phases 1, 2

GL 1, 2

Gate low-side MOSFET for phase 1, 2

GPIO

General purpose input / output

ISP

In-system programmer

LIN

Local interconnect network

MON

Monitor

n.c.

Not connected

n/u

Not used

OP1

Negative operational amplifier input

OP2

Positive operational amplifier input

RST

Reset

SL

Source low-side MOSFETs

SWD

Arm® serial wire debug

TMS

Test mode select

UART

Universal asynchronous receiver transmitter

VAREF

Reference voltage

VBAT

Battery voltage supply

VCOM

Virtual COM-port

VCP

Voltage charge pump

VDDC

Core supply

VDDEXT

External voltage supply output

VDDP

I/O port supply

VDH

Voltage drain high-side MOSFET

VS

Battery supply input

VSD

Battery supply input for MOSFET driver

Page 3

User Manual 3 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Table of contents

Table of contents

About this document ....................................................................................................................... 1

Table of contents ............................................................................................................................ 3

1 Concept ................................................................................................................................ 4

2 Interconnects ........................................................................................................................ 5

3 Test points and LEDs ............................................................................................................... 7

4 Jumper settings ..................................................................................................................... 8

5 Communication interfaces ..................................................................................................... 10

5.1 LIN (via banana jack and uIO BSL) ........................................................................................................ 10

5.2 UART ...................................................................................................................................................... 10

5.3 Debugging .............................................................................................................................................. 10

6 Software toolchain ................................................................................................................ 11

6.1 Keil µVision 5 ......................................................................................................................................... 11

6.2 Infineon ConfigWizard ........................................................................................................................... 11

6.3 TLE986x SDK .......................................................................................................................................... 11

6.4 Debug connection setup ....................................................................................................................... 11

7 Technical data ...................................................................................................................... 13

8 Optional additional placements .............................................................................................. 14

9 Schematics and layout ........................................................................................................... 15

9.1 Schematic .............................................................................................................................................. 15

9.2 Layout .................................................................................................................................................... 18

Page 4

User Manual 4 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Concept

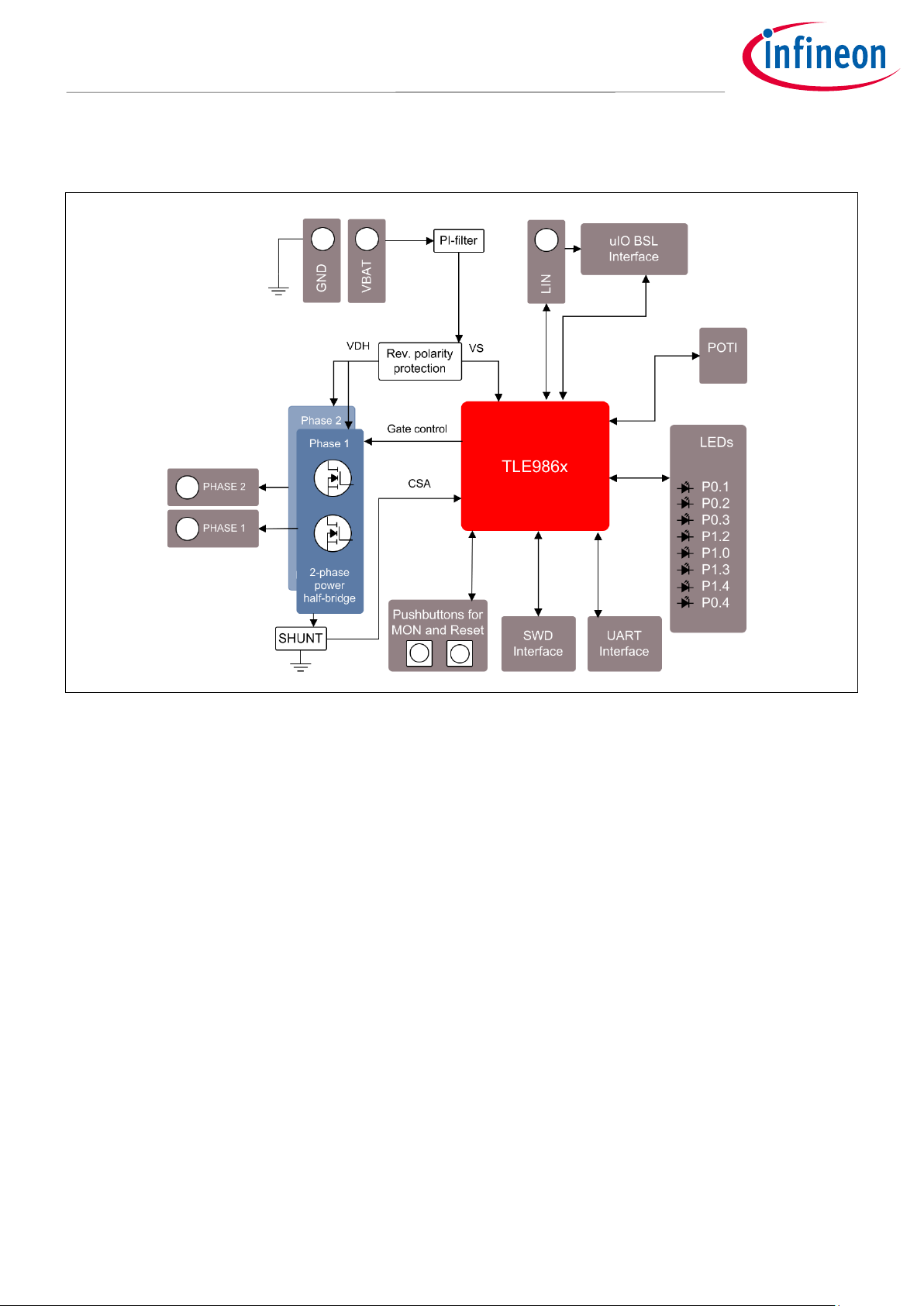

1 Concept

Figure 1 Board concept

This board is designed to provide a simple, easy-to-use tool for getting familiar with Infineon’s Embedded

Power IC TLE986x devices. A socket provides the possibility to test and evaluate all ICs of the TLE986x family.

Every pin of the IC is connectable via rows of pin headers. The board is protected against reverse polarity of

input voltage supply.

Two MOSFET half bridges are assembled on the board to drive a DC motor. The board is ready to be connected

to a car supply or similar and offers a SWD port to connect an external debugger.

The evaluation board can be operated by standard laboratory equipment as power supply and LIN

communication are working via banana jacks.

There is a battery LED that indicates that the board is connected to supply in the correct way. Otherwise

reverse polarity protection secures the board from damage by cross connection.

Page 5

User Manual 5 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Interconnects

2 Interconnects

Figure 2 Interconnects

Banana jacks for ground, supply and LIN

There are jacks in different colors for ground, supply (max. 28 V) and LIN communication via banana jack. The

following jacks are available: GND (marked purple), VBAT (marked red), motor phase 1 & 2 (marked red) and LIN

(marked green).

Banana jacks for motor connection (marked red)

The two jacks Phase1 and Phase2 provide access to the two half bridges and are intended to connect a motor.

uIO Stick connector (marked green)

This uIO bootstrap loader is a 16-pin header (2 x 8) with 2.54 mm pitch.

It is intended to connect additional hardware for bootstrap loading. This interface can be used to program the

TLE986x via LIN (see www.infineon.com/uio or www.hitex.com/uio).

GND

Phase 2

Phase 1

SWD

UART-Serial

VBAT

LIN

uIO

Stick

VBAT

Page 6

User Manual 6 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Interconnects

Figure 3 Pin configuration uIO BSL

Pin header for SWD (marked blue)

There is a 10 pin header (2 x 5) with 1.27 mm pitch on the evaluation board. This interface is meant to be used

for debugging.

Figure 4 Pin configuration SWD interface

5 V 1 2

3 4

5 6

7 8

GND

GND

n.c.

SWDIO (TMS)

SWCLK (P0.0)

n.c.

n.c.

9 10DBPRE RESET

LIN

RESET

GND

VS

TXD1

RXD1

VDD5

GPIO3

1

2

3

4

5

6

7

8

9

11

10

13

14

15

16

GPIO2

GPIO1

SCS

SCLK

MISO

MOSI

AD0

GPIO0

12

Page 7

User Manual 7 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Test points and LEDs

3 Test points and LEDs

Figure 5 Test points

Several ground test points are provided.

Test point LIN_INT is used to measure the LIN voltage.

Test point VDH is used to measure the voltage on the VDH pin.

Tests points Motor 1 and Motor 2 can be used to measure the voltage at phase 1 and 2 of the motor.

There are 11 LEDs for visual validations on the board:

LED 1 to 8 can be connected to GPIOs (see Table 3).

LED 9 (Vbat LED) indicates power supply.

LED 10 (Motor Status 1) lights up if the motor is running forward.

LED 11 (Motor Status 2) lights up if the motor is running backward.

Motor

Status 1

Motor

Status 2

GND

Motor 2

VDH

Motor 1

Vbat LED

GND

GND

LIN_INT

LEDs 1-8

Page 8

User Manual 8 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Jumper settings

4 Jumper settings

Figure 6 Jumpers

Table 2 Jumpers

JP7

Close this jumper to connect MON button to MON input. Open it to disconnect MON

button from MON input.

JP8 / JP11

Open or close these jumpers to enable or disable the measurement shunt of the current

sense amplifier.

JP9

Close this jumper to connect RESET button to RESET input. Open it to disconnect RESET

button from RESET input.

JP10

Close this jumper to connect an additional 1 kΩ pull-up resistor. This is intended for LIN

master communication. Open the jumper to use the TLE986x as slave in a LIN network.

Software for LIN low level driver can be found at the homepage of IHR (www.ihr.de).

JP12

Close this jumper to enable UART communication.

JP13

This jumper is closed by default. If this jumper is left open the device is not supplied. It is

intended to open the VSD line in order to measure the current flowing into the TLE986x

device.

JP14

Open or close these jumpers to connect or disconnect the LEDs (see Table 3).

JP15

Close this jumper to enable UART communication.

+5V_AUX_SEL

JP18

JP15

JP12

JP14

JP7 JP9

JP17

JP11

JP8

JP13

JP16

JP10

Page 9

User Manual 9 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Jumper settings

JP16

This jumper is closed by default. If this jumper is left open the device is not supplied. It is

intended to open the VS line in order to measure the current flowing into the TLE986x

device.

JP17

Close this jumper to connect the motor status LEDs. Open it to disconnect the LEDs.

JP18

Close this Jumper to connect the potentiometer to P2.4. Open this jumper to disconnect

the potentiometer.

+5V_AUX_SEL

Open this jumper to disable the board’s voltage regulator.

Table 3 GPIOs’ function

P0.1

LED 1

P0.2

LED 2

P0.3

LED 3

P0.4

LED 8

P1.0

LED 5

P1.1

UART

P1.2

LED 4 / UART

P1.3

LED 6

P1.4

LED 7

Page 10

User Manual 10 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Communication interfaces

5 Communication interfaces

5.1 LIN (via banana jack and uIO BSL)

The device integrated LIN transceiver is connected to a banana jack and additionally to the uIO BSL interface.

To integrate the device in a LIN network it is sufficient to use the single wire banana interface. The BSL interface

is intended to program the device via LIN. For further information about the uIO interface see

www.infineon.com/uio or www.hitex.com/uio.

5.2 UART

A RS232 connector on the board enables a serial communication.

5.3 Debugging

Debugging is possible via the SWD interface; the signals are routed through the 10 pin header SWD interface

(see Figure 4).

Page 11

User Manual 11 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Software toolchain

6 Software toolchain

6.1 Keil µVision 5

The recommended Integrated Software Development Environment is Keil® µVision5®.

Infineon’s Embedded Power family is supported. For more information about the installation process, go to

www.keil.com.

6.2 Infineon ConfigWizard

In addition to the IDE, Infineon provides ConfigWizard. The tool is designed for code configuration, in

combination with the IDE. Infineon ConfigWizard can be downloaded via the Infineon Toolbox. The Infineon

Toolbox is a central place to download and update all your Infineon tools. It can be downloaded from

www.infineon.com/toolbox.

6.3 TLE986x SDK

All Embedded Power products can be installed to Keil® µVision5® via “Pack Installer”. Browsing to the Infineon

chapter in “All Devices” will lead to the “TLE98xx Series”. The “.pack” file comes with several code examples, to

provide an easy start up and speed up software development.

6.4 Debug connection setup

For a proper Flash and Debug Connection, install V5.10 (or newer) from: www.segger.com/jlink-

software.html. Keil® µVision5® has to be configured in the IDE Menu “Options for Target”. After connecting the

USB-cable and power up the EvalBoard, go to the “Debug” register-card, choose “J-LINK / J-TRACE Cortex” and

press “Settings”.

Page 12

User Manual 12 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Software toolchain

Figure 7 Debug and flash configuration

If the board is connected successfully, the Arm® IDCODE will be visible in the SW Device Window. If connection

fails, “Connect & Reset Options” and “Port” window has to be checked.

Page 13

User Manual 13 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Technical data

7 Technical data

Table 4 Technical data

Voltage supply:

max. 28 V

Motor current:

max. 20 A

Pin ports:

5 V

Page 14

User Manual 14 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Optional additional placements

8 Optional additional placements

Figure 8 Additional placements’ positions

Values for these optional additional placements have to be determined depending on application.

Table 5 Additional placements

Component

Description

Value

Q1

External oscillator

/

C_DG_H1(NB)

Gate drain capacitor high-side MOSFET phase 1

33 - 330 pF

C_DG_L1(NB)

Gate drain capacitor low-side MOSFET phase 1

33 - 330 pF

C_DG_H2(NB)

Gate drain capacitor high-side MOSFET phase 2

33 - 330 pF

C_DG_L2(NB)

Gate drain capacitor low-side MOSFET phase2

33 - 330 pF

Q1

C DG L2(NB) C DG H2(NB)

C DG L1(NB)

C DG H1(NB)

Page 15

User Manual 15 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Schematics and layout

9 Schematics and layout

9.1 Schematic

Figure 9 Schematics: Sheet 1

Page 16

User Manual 16 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Schematics and layout

Figure 10 Schematics: Sheet 2

Page 17

User Manual 17 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Schematics and layout

Figure 11 Schematics: Sheet 3

Page 18

User Manual 18 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Schematics and layout

9.2 Layout

Figure 12 Top layer

Page 19

User Manual 19 of 20 Rev. 1.0

2019-04-04

TLE986x EvalBoard User Manual

Schematics and layout

Figure 13 Bottom layer

Page 20

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2019-04-04

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2019 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

IMPORTANT NOTICE

The information given in this document shall in no

event be regarded as a guarantee of conditions or

characteristics (“Beschaffenheitsgarantie”).

With respect to any examples, hints or any typical

values stated herein and/or any information

regarding the application of the product, Infineon

Technologies hereby disclaims any and all

warranties and liabilities of any kind, including

without limitation warranties of non-infringement

of intellectual property rights of any third party.

In addition, any information given in this document

is subject to customer’s compliance with its

obligations stated in this document and any

applicable legal requirements, norms and

standards concerning customer’s products and any

use of the product of Infineon Technologies in

customer’s applications.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments

to evaluate the suitability of the product for the

intended application and the completeness of the

product information given in this document with

respect to such application.

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may

contain dangerous substances. For information on

the types in question please contact your nearest

Infineon Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of

the product or any consequences of the use thereof

can reasonably be expected to result in personal

injury.

Loading...

Loading...