Page 1

Please read the Important Notice and Warnings at the end of this document Rev. 1.0

www.infineon.com/embeddedpower 2018-09-25

TLE985x Evaluation Board User Manual

Figure 1 TLE985x Evaluation Board

About this document

Scope and purpose

The TLE985x Evaluation Board is designed to evaluate hardware and software functionalities of the TLE985x

device family. All pins of the chip are able to be contacted via pin headers. Further, the on-board MOSFET Hbridge can be used to evaluate DC motor applications.

This manual provides information about the board’s interconnections, jumper settings, communication and

debug interfaces. Additionally, an introduction to the software toolchain is given as well as detailed information

about the board’s design data.

Note: This evaluation board is not optimized for EMC behavior.

Intended audience

This document is for everyone who works with the TLE985x_EVB.

Page 2

TOC-1 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

Table of contents

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Preface-1

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TOC-1

1 Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2 Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3 Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

4 Communication Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 LIN and uIO for LIN BSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 UART (virtual COM port via USB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 SWD debug interface (J-Link via USB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

5 Software Toolchain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Keil µVision 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Infineon Config Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 TLE985x Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.4 Debug Connection Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6 PCB Design Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Layout Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3 Part List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .References-1

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RevisionHistory-1

Table of contents

Page 3

1-1 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

Concept

1Concept

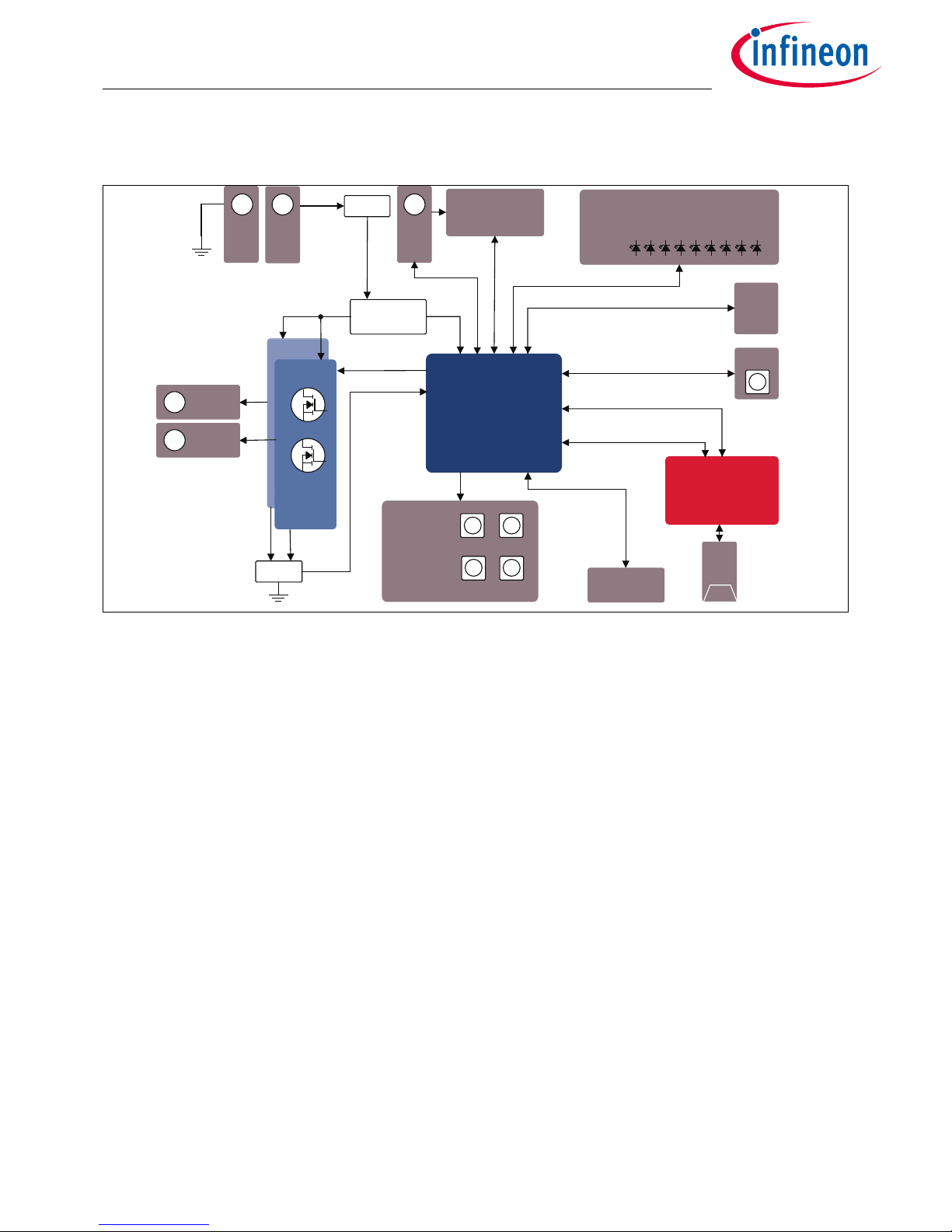

Figure 2 TLE985x Evaluation Board concept

This board is designed to provide a fast and easy start of evaluation for Infineon’s Embedded Power TLE985x

device family. Initialy, the evaluation board brings several interfaces and interconnections shown in Figure 2.

The TLE985x device is placed in the center of the PCB. A socket provides the possibility to test and evaluate all ICs

out of the TLE985x device family. Every pin of the IC is connectable via rows of pin headers. The board is protected

against reverse polarity of input voltage supply.

Two MOSFET half bridges are available to instantly drive a DC motor, which can be connected via banana jacks.

The evaluation board provides an on-board debugger. It is placed in the lower right of Figure 2. It provides a

debug connection (SWD) and a virtual COM port for serial UART communication.

The high-voltage monitor pins can be triggered with dedicated pushbuttons.

For analog input values, a potentiometer is connected to pin P2.1.

The LIN connection can be configured to master or slave mode.

Pushbuttons

for MON1-4

RESET

LEDs

LIN

TLE985x

On-board debugger

with XMC 4200

VBAT

uIO BSL

interface

SW debug

interface

GND

Rev. polarity

protection

PI-filter

SHUNT

USB

POTI

(P2.1)

Phase 2

2-phase

power

half-bridge

Phase 1

2-phase

power

half-bridge

VS

MON1

UART2 P1.0/P1.1

SWD TMS/P0.0

VDH

Gate control

CSA

VDDEXTHSP1.2

P0.5

P0.4

P0.3

P1.4

P0.2

P0.1

MON2

MON3 MON4

PHASE 2

PHASE 1

Page 4

2-1 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

Interconnections

2 Interconnections

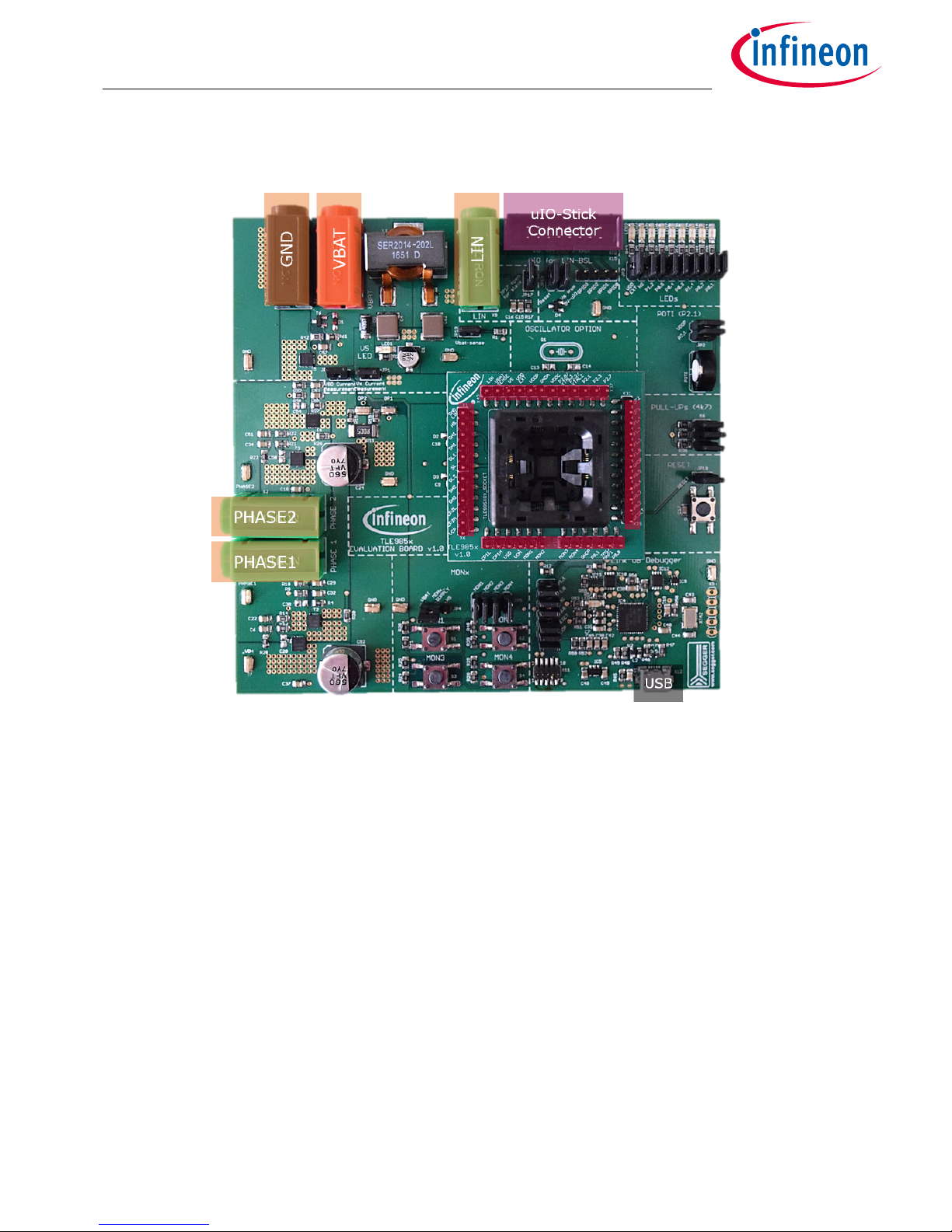

Figure 3 Interconnections

4mm laboratory connectors (orange)

Ground, supply voltage (operating voltage is documented in the datasheet) and LIN communication can be

connected via banana jacks:

GND (black), VBAT (red), LIN (green)

Two MOSFET half bridges can also be accessed with laboratory equipment:

PHASE1 and PHASE2 (green)

uIO connector (purple)

The uIO Stick can be connected at the upper right corner of the evaluation board. It provides BSL programming

via FastLIN. The connector provides a reverse-polarity protected connection between the evaluation board and

the uIO Stick. (Signals: RESET, VS, LIN)

USB (black)

An on-board debugger is implemented on the TLE985x Evaluation Board. The USB connection provides a debug

and serial interface to the PC.

Pin headers (red)

Each pin of the TLE985x is available for measurements and evaluation via pin headers.

Page 5

3-1 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

Jumper Settings

3 Jumper Settings

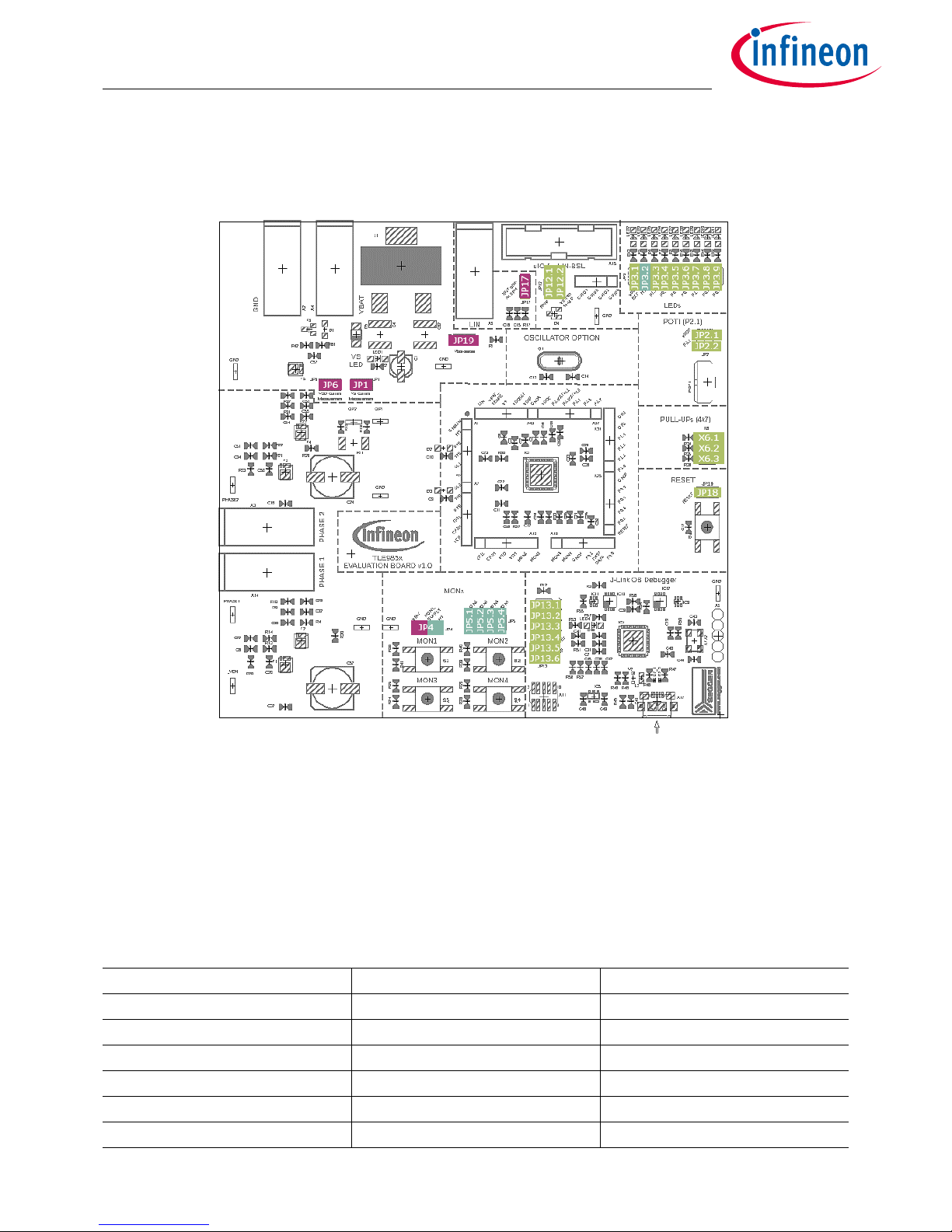

Figure 4 Jumper settings

Figure 4 shows the jumper positions on the Evaluation Board. The colors give an information about the voltage,

which can appear at the jumper pins as follows:

• Green-marked jumpers are related to the 5-V domain (voltage range 0 V ... VDDP/VDDEXT).

• Blue-marked jumpers are related to high-voltage inputs or outputs of the TLE985x.

• Purple-marked jumpers are connected to the supply voltage of the evaluation board.

Table 1 shows which jumper is connected to which pins and peripherals of the TLE985x.

Table 1 Jumper list

Jumper number Signal name Description and board connection

JP1 VS VS current measurement

JP2.1 VDDP Potentiometer supply

JP2.2 P2.1 Potentiometer connected to P2.1

JP3.1 VDDEXT LED2

JP3.2 HS LED3

JP3.3 P1.2 LED5

Page 6

3-2 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

Jumper Settings

JP3.4 P0.5 LED6

JP3.5 P0.4 LED7

JP3.6 P0.3 LED8

JP3.7 P1.4 LED9

JP3.8 P0.2 LED10

JP3.9 P0.1 LED11

JP4 VBAT/HS Supply selection for MONx switches

JP5.1 MON1 Pushbutton S1 (MON1)

JP5.2 MON2 Pushbutton S2 (MON2)

JP5.3 MON3 Pushbutton S3 (MON3)

JP5.4 MON4 Pushbutton S4 (MON4)

JP6 VSD VSD current measurement

JP12.1 RESET Reset connection from uIO Stick

JP12.2 VS Supply connection from uIO Stick

JP13.1 P1.1 Disconnect UART/Debugger

JP13.2 P1.0 Disconnect UART/Debugger

JP13.3 TMS Disconnect UART/Debugger

JP13.4 P0.0 Disconnect UART/Debugger

JP13.5 RESET Disconnect UART/Debugger

JP13.6 VDDP Disconnect UART/Debugger

JP17 LIN LIN master/slave configuration

JP18 RESET Pushbutton S6 (RESET)

JP19 VBAT VBAT_SENSE

X6.1 VDDEXT Pull-up for wire connection

X6.2 VDDEXT Pull-up for wire connection

X6.3 VDDEXT Pull-up for wire connection

Table 1 Jumper list

Jumper number Signal name Description and board connection

Page 7

4-1 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

Communication Interfaces

4 Communication Interfaces

4.1 LIN and uIO for LIN BSL

The device-integrated LIN transceiver is connected to a banana jack and additionally to the uIO BSL interface. To

integrate the device in a LIN network it is sufficient to use the single wire banana interface. The BSL interface is

intended to program the device via LIN. For further information about the uIO interface seewww.hitex.com/uio.

4.2 UART (virtual COM port via USB)

A virtual COM port provided by the Segger driver enables a PC-to-board communication via UART. The UART2

module of TLE985x uses the pins P1.0 (transmit) and P1.1 (receive). Those are connected to the XMC4200, which

emulates Rx and Tx on PC side with the Segger firmware. Although they can be disconnected physically,

bidirectional level shifters ensure that the XMC pins are hi-Z in the case the virtual COM port is not used. By

connecting the evaluation board to the PC a virtual COM port gets emulated by the Segger driver automatically.

The port will show up in the Microsoft® Windows® device manager.

Figure 5 UART and Debugging

Note: Only one of the interfaces USB or SWD can be used at one time. While using the SWD interface the XMC

is hold in reset. It therefore eliminates debugging or UART via USB while a debugger is connected with

the SWD interface.

4.3 SWD debug interface (J-Link via USB)

For serial wire debug (SWD) the TLE985x uses the pins TMS (data) and P0.0 (clock). Level shifters between

XMC4200 and TLE985x allow using P0.0, while it is not used for debugging.

The Segger J-Link module on board allows serial wire debugging via USB.

It is also possible to use an alternative debugger instead of the on-board Segger debugger, e.g. Keil ULINK2. For

this the signals are routed through the 10 pin header SWD interface between the XMC4200 and the TLE985x. The

pin configuration makes sure that the XMC is hold in reset while another debugger is physically connected at X15.

The virtual COM port will be disabled, while the external ISP is connected.

Page 8

5-1 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

Software Toolchain

5 Software Toolchain

5.1 Keil µVision 5

The recommended Integrated Software Developement Environment is Keil® µVision5®.

Infineon’s Embedded Power family is suported. For more information about the Toolchain go to: www.keil.com

5.2 Infineon Config Wizard

In addition to the IDE, Infineon® provides the ConfigWizard. The tool is designed for code configuration, in

combination with the IDE. Infineons Config Wizard can be downloaded via:

www.infineon.com/embeddedpower

5.3 TLE985x Installation

All embedded Power products can be installed to Keil® µVision5® via “Pack Installer”. Browsing to the Infineon

chapter in “All Devices” will lead to the “TLE98xx Series”. The “.pack” file comes with several code examples, to

provide an easy start up and speed up software developement.

5.4 Debug Connection Setup

For a proper Flash and Debug Connection, Install V5.10 (or newer) from:

www.segger.com/jlink-software.html

Keil® µVision5® has to be configured in the IDE Menu “Options for Target”. After connecting the USB-cable and

power up the Evalboard, go to the “Debug” register-card and choose “J-LINK / J-TRACE Cortex” and press

”Settings”.

Figure 6 Debug and Flash Configuration

If the board has been connected successfully, the ARM IDCODE will be visible in the SW Device Window.

If connection fails, “Connect & Reset Options” and “Port” window has to be checked.

Page 9

6-1 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

PCB Design Data

6 PCB Design Data

This Chapter contains schematic and layout data.

6.1 Schematic

Figure 7 TLE985x Circuit and peripheral components

Note: This is a very simplified example of an application circuit and bill of material. The function must be

verified in the application.

Page 10

6-2 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

PCB Design Data

Figure 8 On-board debug cicuit

Note: This is a very simplified example of an application circuit and bill of material. The function must be

verified in the application.

Page 11

6-3 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

PCB Design Data

6.2 Layout Data

Figure 9 Parts placement

Note: This is a very simplified example of an application circuit and bill of material. The function must be

verified in the application.

Page 12

6-4 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

PCB Design Data

Figure 10 Full layout

Note: This is a very simplified example of an application circuit and bill of material. The function must be

verified in the application.

Page 13

6-5 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

PCB Design Data

6.3 Part List

Table 2 Evaluation board part list

Part Number Value Package

C1 22µF/50V CAP-MASTER 153CLV-0505

C11, C27 220nF 0805

C13, C14 18pF 0805

C15 2.2nF 0805

C16 220pF 0805

C2, C60 330nF 0805

C20, C30, C50, C54 33pF 0805

C21, C23, C25, C35, C58 6.8nF 0805

C22, C32, C51, C55 4.7nF 0805

C24, C52 560µF/35V 153CLV-1014

C3, C7, C18, C19, C28, C36, C37, C38,

C39, C40, C41, C42, C45, C49, C57,

C59, C61

100nF 0805

C31 4.7µF 0805

C4, C62 10µF/50V C2220K

C43, C44 12pF 0805

C46 10µF 0805

C48 22µF/6.3V 0805

C5, C12 1µF 0805

C56 470nF 0805

C6, C8, C29, C34, C47, C53 10nF 0805

C9, C10, C17, C26, C33 1nF 0805

D1, D2, D3 BAS3010B-03W SOD323-W

D4 BAS116 SOT23

D5 SM4007 DO-214AC

D7_1, D7_3 ESD8V0L1B-02EL TSLP-2

GND, GND_1, GND_2, GND_3,

GND_5, GND_6, GND_7, OP1, OP2,

PH1, PH2, VDH

Testpoint TP_SMD

IC1 TLE985xQX VQFN48

IC10, IC12 SN74LVC2T45DCT R-PDSO-G8

IC4 XMC4200 QFN48

IC5 IFX54211 MBV33 SCT595

IC9, IC11 SN74LVC1T45DCK R-PDSO-G6

JP1, JP6, JP17, JP18, JP19 Pin header 1x2 1X02

JP13 Pin header 2x6 2X06

JP2, JP12 Pin header 2x2 2X02

Page 14

6-6 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

PCB Design Data

JP3 Pin header 2x9 2X09

JP4 Pin header 1x3 1X03

JP5 Pin header 2x4 2X04

L1 2.2µH SER2014

L2 BLM18PG600 L1608

LED1, LED2, LED4 LED red 1206

LED3, LED5, LED6, LED7, LED8, LED9,

LED10, LED11

LED green 1206

POTI 10K PT-10S

Q1 HC49/S

R1, R42 3K3 0805

R10, R20, R23, R32, R37 2R 0805

R11 5m 2512

R15, R19 12R 0805

R17, R24, R28, R33, R40, R41 1K 0805

R2, R5 2K7 0805

R25, R29, R38, R39 3K9 0805

R3, R12, R49, R51, R54, R55, R56, R61 10K 0805

R34, R35, R36, R48, R57 4K7 0805

R4, R13, R21, R27 100K 0805

R45 1M 0805

R46, R47 22R 0805

R50 150R 0805

R52, R58 5K1 0805

R53 680R 0805

R6, R7, R8, R16, R18, R43, R44, R59 1K5 0805

R60 160R 0805

R9, R14, R22, R26, R30, R31 10R 0805

S1, S2, S3, S4, S6 Button SK_SMD

T1, T2, T3, T4, T5 IPZ40N04S5-3R1 PG-TSDSON-8

T6 BC817 SOT23-BEC

V2 BAT60 SOD323-R

X1, X7, X13, X19, X25, X31, X37, X43 Pin header 1x6 1X06

X11 FTSH105-01-L-DV FTSH105_SMD

X12 ZX62-AB-5PA MICRO-USB

X15 Pin header 2x8 PAK100/2500-16

X16 Pin header 1x4 1X04

X2 black 4mm Banana

Table 2 Evaluation board part list

Part Number Value Package

Page 15

6-7 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

PCB Design Data

X3, X9, X14 green 4mm Banana

X4 red 4mm Banana

X5 Pin header 1x5 1X05

X6 Pin header 2x3 2X03

XTA2 12MHz HC5032

Table 2 Evaluation board part list

Part Number Value Package

Page 16

References-1 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

References

References

[1] www.infineon.com/embeddedpower

Page 17

RevisionHistory-1 Rev. 1.0

2018-09-25

User Manual

TLE985x Evaluation Board

Revision History

Revision History

Revision History

Page or Item Subjects (major changes since previous revision)

Rev. 1.0 Initial version

Page 18

Trademarks of Infineon Technologies AG

µHVIC™, µIPM™, µPFC™, AU-ConvertIR™, AURIX™, C166™, CanPAK™, CIPOS™, CIPURSE™, CoolDP™, CoolGaN™, COOLiR™, CoolMOS™, CoolSET™, CoolSiC™,

DAVE™, DI-POL™, DirectFET™, DrBlade™, EasyPIM™, EconoBRIDGE™, EconoDUAL™, EconoPACK™, EconoPIM™, EiceDRIVER™, eupec™, FCOS™, GaNpowIR™,

HEXFET™, HITFET™, HybridPACK™, iMOTION™, IRAM™, ISOFACE™, IsoPACK™, LEDrivIR™, LITIX™, MIPAQ™, ModSTACK™, my-d™, NovalithIC™, OPTIGA™,

OptiMOS™, ORIGA™, PowIRaudio™, PowIRStage™, PrimePACK™, PrimeSTACK™, PROFET™, PRO-SIL™, RASIC™, REAL3™, SmartLEWIS™, SOLID FLASH™,

SPOC™, StrongIRFET™, SupIRBuck™, TEMPFET™, TRENCHSTOP™, TriCore™, UHVIC™, XHP™, XMC™.

Trademarks updated November 2015

Other Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2018-09-25

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2018 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about any

aspect of this document?

Email: erratum@infineon.com

Document reference

Doc_Number

IMPORTANT NOTICE

The information given in this document shall in no

event be regarded as a guarantee of conditions or

characteristics ("Beschaffenheitsgarantie").

With respect to any examples, hints or any typical

values stated herein and/or any information regarding

the application of the product, Infineon Technologies

hereby disclaims any and all warranties and liabilities

of any kind, including without limitation warranties of

non-infringement of intellectual property rights of any

third party.

In addition, any information given in this document is

subject to customer's compliance with its obligations

stated in this document and any applicable legal

requirements, norms and standards concerning

customer's products and any use of the product of

Infineon Technologies in customer's applications.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer's technical departments to

evaluate the suitability of the product for the intended

application and the completeness of the product

information given in this document with respect to

such application.

For further information on technology, delivery terms

and conditions and prices, please contact the nearest

Infineon Technologies Office (www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types in

question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon Technologies,

Infineon Technologies’ products may not be used in

any applications where a failure of the product or any

consequences of the use thereof can reasonably be

expected to result in personal injury.

Please read the Important Notice and Warnings at the end of this document

Loading...

Loading...