Page 1

User Manual Revision 1.0

www.infineon.com 2020-12-08

DC Motor Control HAT with TLE94112ES

Complies with the Raspberry Pi HAT specification

About this document

Scope and purpose

This user manual describes the DC motor control HAT equipped with the TLE94112ES, a twelve-fold halfbridge driver with integrated power stages. This document provides detailed information on the board’s

content, layout and use. It should be used in conjunction with the TLE94112ES datasheet, which contains

full technical details on the device specification and operation.

Intended audience

Engineers, hobbyists and students who want to add a powerful motor control to their projects.

Related information

Table 1 Supplementary links and document references

Reference

Description

TLE94112ES datasheet

Product page which contains reference information for the multiple

half-bridge driver TLE94112ES

TLE941xy SPI interface

Application note for the SPI interface of the multiple half-bridge

driver family TLE941xy

DC motor HAT with TLE94112ES

Information page for DC Motor Control HAT with TLE94112ES

Library for TLE94112ES on GitHub

Software library for TLE94112ES including examples

Page 2

User Manual 2 Revision 1.0

2021-03-

Title

Title_continued

Introduction

Table of Contents

About this document ....................................................................................................................... 1

1 Introduction .................................................................................................................. 3

1.1 DC Motor Control HAT overview ............................................................................................................. 3

1.2 Key features ............................................................................................................................................. 4

1.3 Application diagram for bi-directional DC motor applications ............................................................. 5

2 DC Motor Control HAT description ................................................................................... 6

2.1 Overview .................................................................................................................................................. 6

2.2 Schematics .............................................................................................................................................. 7

2.3 Layout ...................................................................................................................................................... 8

2.4 Bill of Material of the DC Motor Control HAT .......................................................................................... 9

2.5 CS Pin Selection ..................................................................................................................................... 11

2.6 EEPROM ................................................................................................................................................. 12

2.7 Backpowering ........................................................................................................................................ 12

2.8 Stacking multiple DC Motor Control HATs ........................................................................................... 12

2.9 Pin assignment ...................................................................................................................................... 13

2.10 Pin definitions and functions ............................................................................................................... 14

3 TLE94112ES overview ................................................................................................... 15

3.1 Key features of the TLE94112ES ........................................................................................................... 15

3.2 Block diagram ........................................................................................................................................ 16

3.3 Pin assignment ...................................................................................................................................... 17

3.4 Pin definitions and functions ................................................................................................................ 18

4 Getting started ............................................................................................................. 19

5 Revision History ........................................................................................................... 20

Page 3

User Manual 3 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

1 Introduction

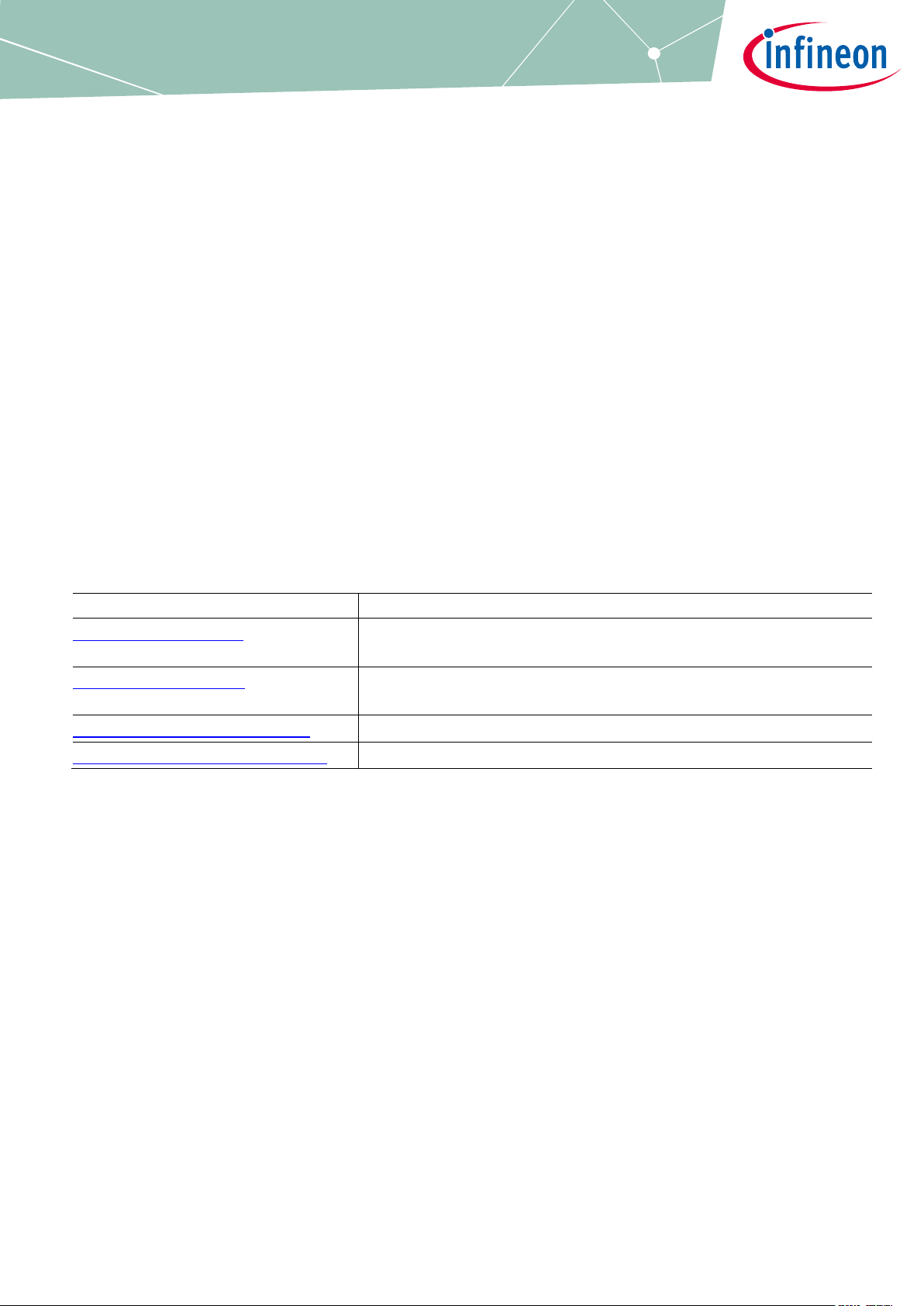

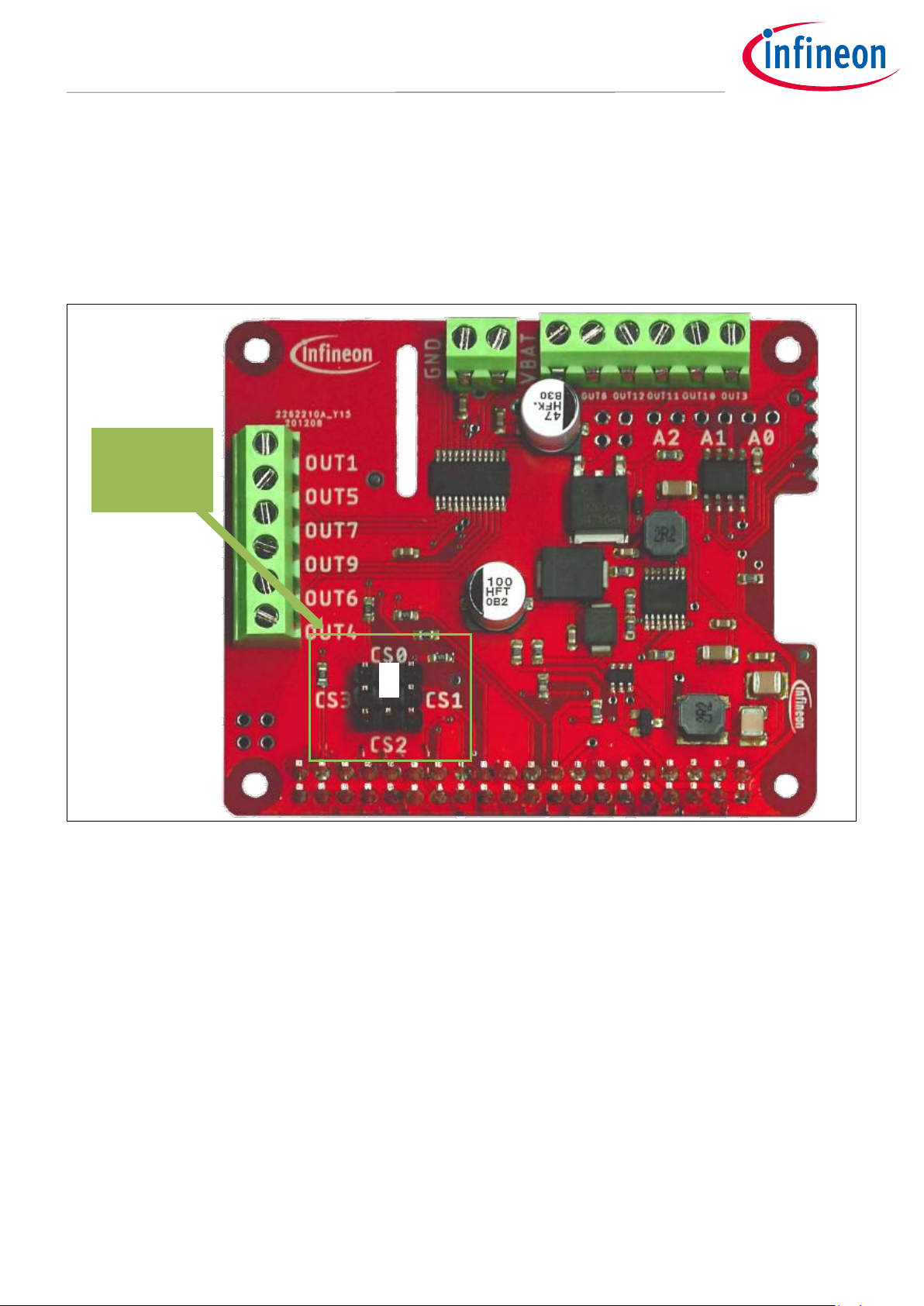

1.1 DC Motor Control HAT overview

The DC Motor Control HAT with TLE94112ES makes it easy to control up to six independent or eleven

cascaded bidirectional DC motors.

The HAT can be controlled by a compatible Raspberry Pi via the SPI interface of the TLE94112ES.

The board features an Infineon TLE94112ES, a twelve-fold half-bridge driver with integrated MOSFETs.

Each half-bridge can drive peak currents up to 0.9 A and DC current in the range of 200 mA to 500 mA,

depending on the application conditions and the number of activated outputs.

The DC Motor Control HAT has an active reverse polarity protection with the p-channel MOSFET

IPD50P04P4L-11.

The HAT can power the Raspberry Pi using Infineon’s OPTIREG™ DC/DC converter TLS4125D0EPV50.

The DC Motor Control HAT can be easily connected to a Raspberry Pi via its 40-pin header.

Figure 1 DC Motor Control HAT with TLE94112ES

TLE94112ES

EEPROM

TLS4125D0EP V50

OUT2

OUT8

OUT12 OUT11

OUT10

OUT3

OUT1

OUT5

OUT7

OUT9

OUT6

OUT4

VBAT

GND

Page 4

User Manual 4 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

1.2 Key features

The DC Motor Control HAT has the following features:

Can be controlled by compatible Raspberry Pis:

o 1 Mod. A+, 1 Mod. B+, 2 Mod. B, 2 Mod. B v1.2, 3 Mod. A+, 3 Mod. B, 3 Mod. B+, 4 Mod. B

o Zero, Zero W

Brushed DC Motor Control up to 0.9 A peak

o 5.5 – 18 V normal operating input voltage

o 18 – 20 V extended operating input voltage

Control of:

o Six independent bidirectional DC motors

o Eleven cascaded bidirectional DC motors

SPI interface for high configurability and detailed diagnosis

Protections:

o Overtemperature

o Overcurrent

o Undervoltage

o Overvoltage

Detailed diagnosis per MOSFET:

o Individual open load detection

o Individual overcurrent detection

Paralleling outputs for higher current capability (up to 3.6 A)

Motor speed control by PWM

o Three independent PWM generators

o PWM frequency: 80 Hz, 100 Hz or 200 Hz

o 8-bit resolution, 0.5% duty cycle steps

o Active freewheeling for lower power dissipation

Multiple HATs can be stacked to control an increased number of motors

Reverse polarity protection with IPD50P04P4L-11

Powering of Raspberry Pi with up to 2.5A with TLS4125D0EPV50

EEPROM containing HAT information

Page 5

User Manual 5 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

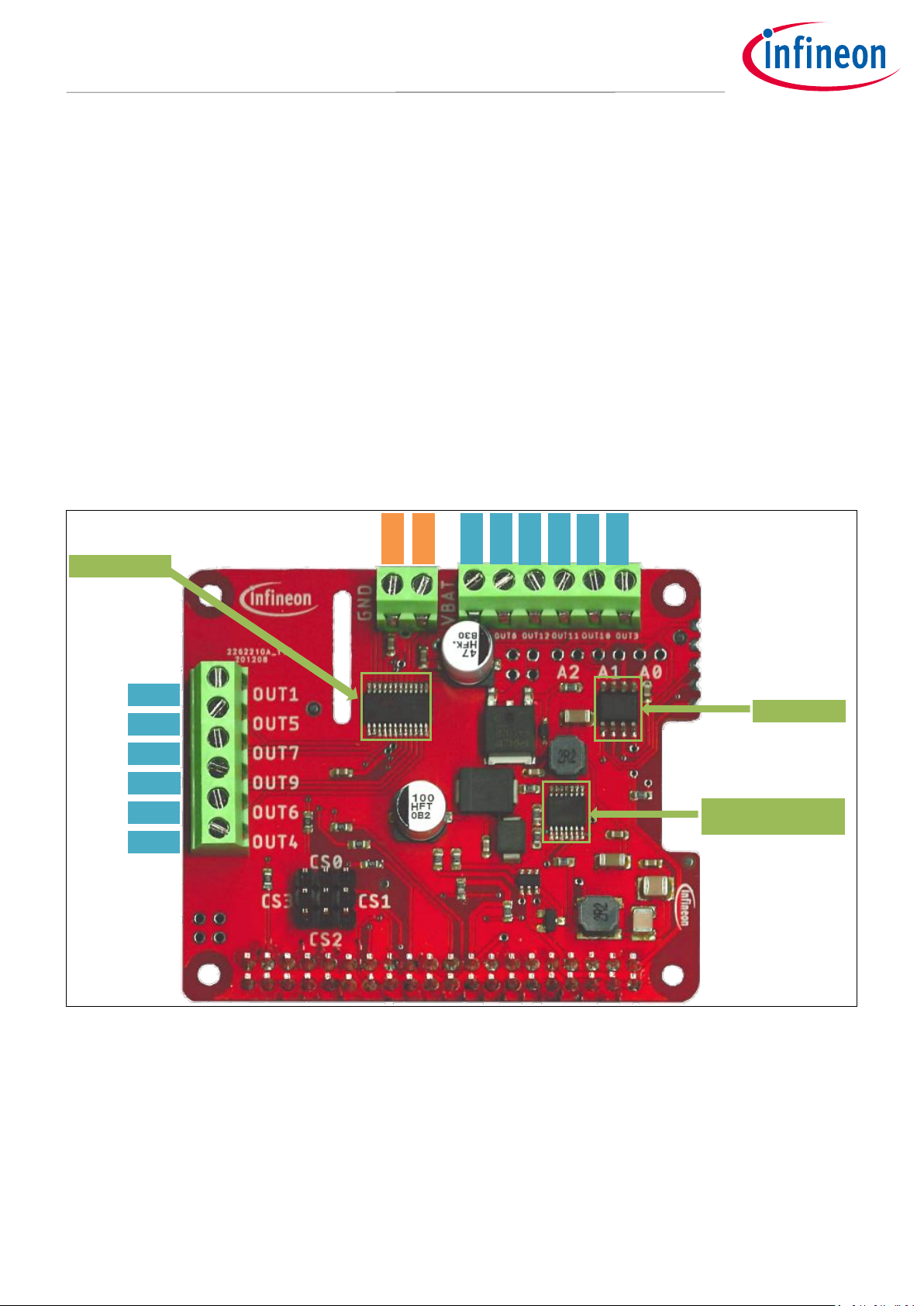

1.3 Application diagram for bi-directional DC motor applications

Figure 2 Simplified application diagram with TLE94112ES driving DC motors

Refer to the TLE94112ES datasheet for more information.

Page 6

User Manual 6 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

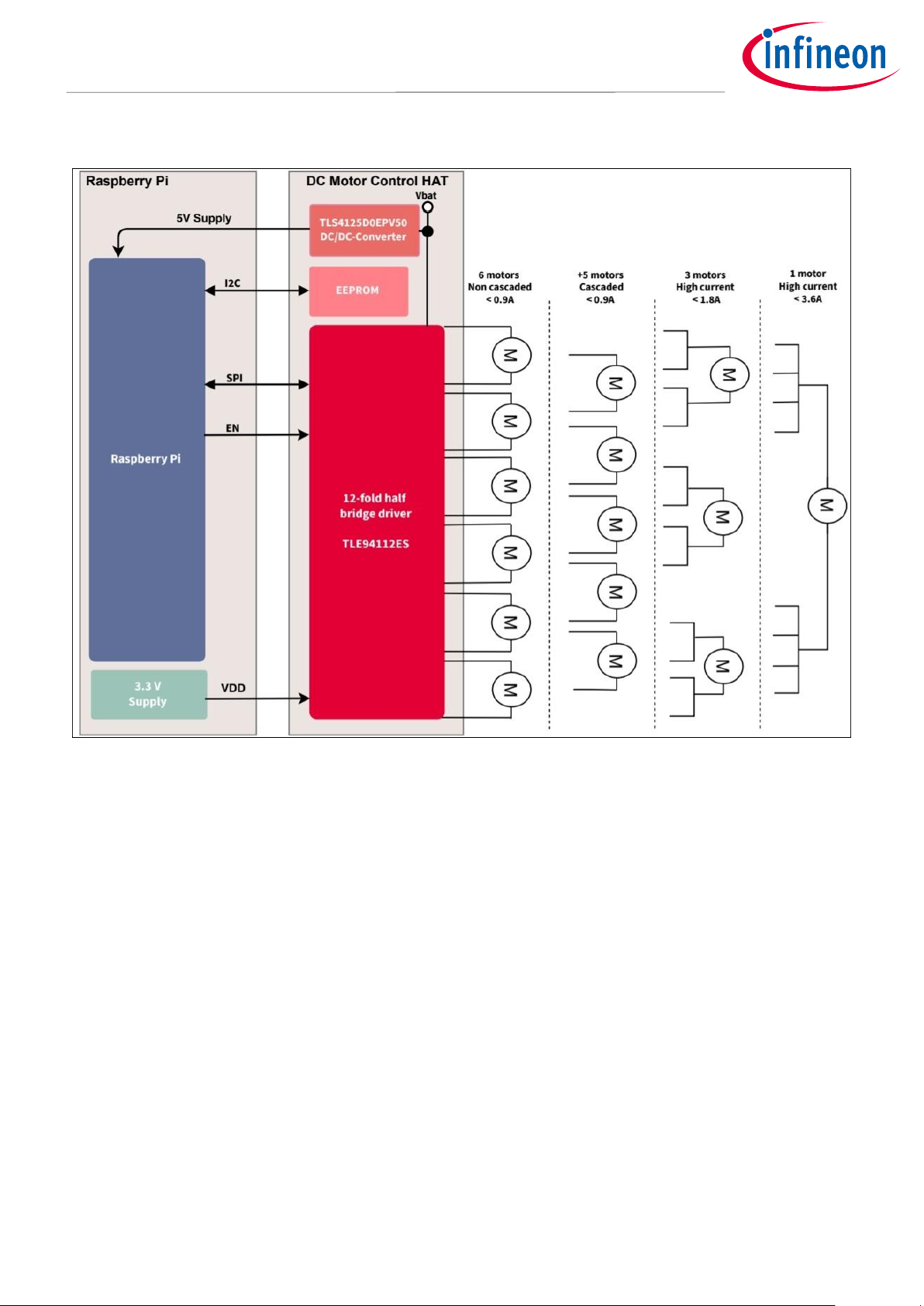

2 DC Motor Control HAT description

For a safe and optimized motor control design, some discrete components are needed.

Figure 4, Figure , Figure and Figure 7 show the schematics and the corresponding layout of the DC Motor

Control Shield with TLE94112ES.

2.1 Overview

Figure 3 DC Motor Control HAT connectors

TLE94112ES

The input of the TLE is connected to different capacitors. C11 is there to smooth VCC, the input voltage, C13 to

smooth VDD, the 3.3V supply, so glitches do not influence the functionality of the motor driver. C14 and C12 are

included to stabilize the input voltage.

TLS4125

The DC/DC converter, the TLS4125D0EPV50 is connected to multiple capacitors and inductors on the input and

the output side of the chip. C_IN compensates possible drops in the supply voltage. C56 is there to smooth the

input voltage, so glitches cannot disturb the functionality of the converter. L_IN combined with C52, C53, C54

and C55 create an EMI filter. This filter protects the TLS against electromagnetic interference. At the output of

the chip L_OUT with C58 and C59 are there to support the voltage conversion and C57 is responsible for

stabilizing the output voltage.

OUT2

OUT8

OUT12

OUT11

OUT10

OUT3

OUT1

OUT5

OUT7

OUT9

OUT6

OUT4

VBAT

GND

Page 7

User Manual 7 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

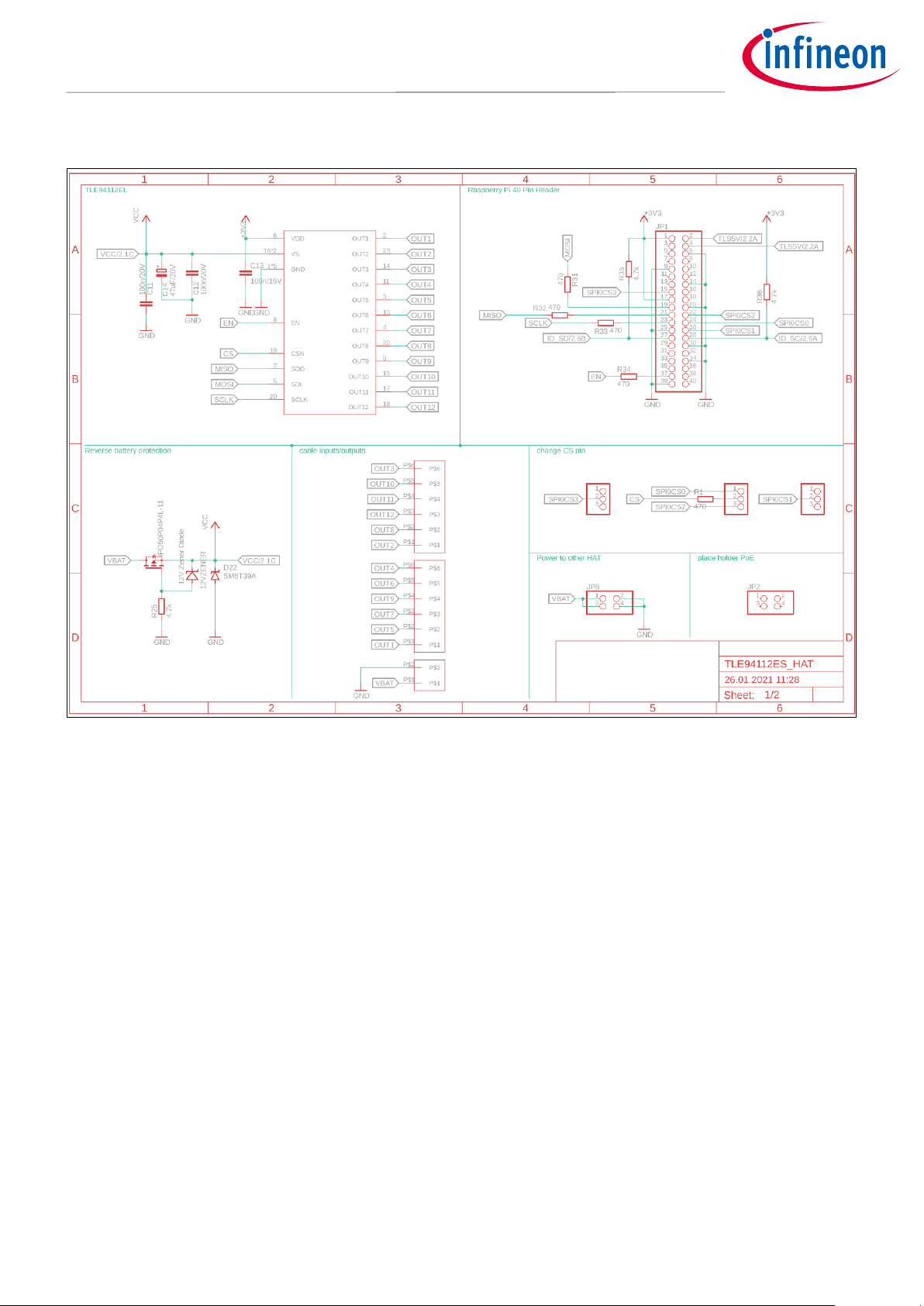

2.2 Schematics

Figure 4 Schematic Motor Control HAT for Raspberry Pi with TLE94112ES (1/2)

Page 8

User Manual 8 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

Figure 5 Schematic DC Motor Control HAT for Raspberry Pi with TLE94112ES (2/2)

2.3 Layout

Figure 6 and Figure 7 show the layout of the DC Motor Control HAT with TLE94112ES.

Figure 6 DC Motor Control HAT – Bottom and top layers

Page 9

User Manual 9 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

Figure 7 DC Motor Control HAT for Raspberry Pi with TLE94112ES – Layout

2.4 Bill of Material of the DC Motor Control HAT

Qty

Value

Device

Package

Parts

Description

3

PINHD-1X3

1X03

U$7, U$17,

U$19

PIN HEADER

1

PINHD-1X5

1X05

JP4

PIN HEADER

2

PINHD-2X2

2X02

JP2, JP8

PIN HEADER

1

PINHD-2X20

2X20

JP1

PIN HEADER

1

SJ

SJ

SJ1

SMD solder

JUMPER

1

100k

R-EU_R0603

R0603

R53

RESISTOR,

European symbol

1

100k/1%

R-EU_R0603

R0603

R5

RESISTOR,

European symbol

3

100n/16V

C-EUC0603

C0603

C1, C13,

C57

CAPACITOR,

European symbol

5

100n/20V

C-EUC0603

C0603

C11, C12,

C53, C55,

C56

CAPACITOR,

European symbol

Page 10

User Manual 10 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

1

100u/20V

CPOL-EUD

PANASONIC_D

CIN1

POLARIZED

CAPACITOR,

European symbol

2

10k

R-EU_R0603

R0603

R3, R52

RESISTOR,

European symbol

1

10u/20V

C-EUC1206

C1206

C54

CAPACITOR,

European symbol

1

12VZENER

12VZENER

SOD323_ST

D21 1

1k6/1%

R-EU_R0603

R0603

R6

RESISTOR,

European symbol

2

22u/16V

C-EUC1210K

C1210K

C58, C59

CAPACITOR,

European symbol

1

2PIN-WTBCONNECTO

R

2PIN-WTB-CONNECTOR

2PIN-WTBCONNECTOR

U$8 4

4.7k

R-EU_R0603

R0603

R2, R25,

R35, R36

RESISTOR,

European symbol

1

4.7u/20V

C-EUC1206

C1206

C52

CAPACITOR,

European symbol

5

470

R-EU_R0603

R0603

R1, R31,

R32, R33,

R34

RESISTOR,

European symbol

1

47k

R-EU_R0603

R0603

R4

RESISTOR,

European symbol

1

47uF/20V

CPOL-EUD

PANASONIC_D

C14

POLARIZED

CAPACITOR,

European symbol

2

6PIN-WTBCONNECTO

R

6PIN-WTB-CONNECTOR

6PIN-WTBCONNECTOR

U$10,

WTB1 1

CAT24C32

CAT24C32

SOIC8

U$2 1

IPD50P04P4

L-11

IPD50P04P4L-11

PG-TO252-3-313

U$6 1

MBRS320T3

G - 20V

PEAK

ON_SEMICONDUCTOR_MBRS3200T3

GON_SEMICONDUCTOR_MBRS3200T

3G_0_0

ON_SEMICONDUC

TOR_MBRS3200T3

G_0

D51

ONSC-D-K1A2-2_A

1

DMG2305U

X

DMG2305UX

SOT23

U$9 1

DMMT5401

DMMT5401

SOT26

U$11 1

SM6T39A

SUPPRESSOR-SMBJ

SMBJ

D22

Suppressor diode

1

TLE94112ES

TLE94112ES

SSOP24

U$1 1

TLS4125D0

EPV50

TLS4125D0EPV50

TSDSO-14

U$3 2

TYS50402R

2N-10

TYS50402R2N-10

5040

U$4, U$5

Figure 8 DC Motor Control HAT with TLE94112ES – Bill of Material (BOM)

Page 11

User Manual 11 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

2.5 CS Pin Selection

The GPIO 8 (CS0) of the Raspberry Pi is used by default to control the CS (Chip Select) input of the

TLE94112ES (Figure 9).

Alternatively, GPIO 7 (CS1), GPIO 22 (CS2) or GPIO 25 (CS3) of the Raspberry Pi can be used instead to

stack multiple HATs (refer to section 2.8). In this case, the jumper on the Pinheader can be changed to the

matching CS pin (Figure ).

Figure 9 Control of CSN of TLE94112ES by GPIO 8 (CS0)

GPIO 8

controls CS

input of the

TLE94112ES

Page 12

User Manual 12 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

Figure 10 Control of CS of TLE94112ES by GPIO 7 (CS1)

2.6 EEPROM

The DC Motor Control HAT also contains an Electrically Erasable Programmable Read-Only Memory

(EEPROM). It allows the Raspberry Pi firmware to automatically load the necessary drivers for the HAT.

The CAT24C32 communicates via I2C on ID_SD (GPIO 27) and ID_SC (GPIO 28) with the Raspberry Pi.

If another HAT with an EEPROM is used concurrently with the DC Motor Control HAT, the address of the

EEPROM can be adjusted by closing the solder bridge marked with A+1. If the pin is left open, the I2C

address is 0x50 and if the bridge is closed it is 0x51.

2.7 Back-Powering

This HAT is able to supply the Raspberry Pi (up to 12.5 W) via its input voltage. The input voltage

(recommended 12V) is converted to 5V and maximum 2.5A by the DC/DC converter TLS4125D0EPV50 from

Infineon. The output of the chip is connected to the 5V pins of the Raspberry Pi. Consequently the power

supply unit of the Raspberry Pi is not necessarily needed. In case the Raspberry Pi is powered separately,

the TLS is protected against voltage collision by a p-channel MOSFET and a transistor array.

2.8 Stacking multiple DC Motor Control HATs

It is possible to stack multiple DC Motor Control HATs to increase the number of controlled motors.

In this configuration, the CS input of each TLE94112ES must be controlled individually by different

microcontroller GPIOs:

- The TLE94112ES of one DC Motor Control HAT is controlled by GPIO 8 (default setting, Figure ).

GPIO 7

controls CS

input of the

TLE94112ES

Page 13

User Manual 13 Revision 1.0

2021-03-

DC Motor HAT with TLE94112ES

For Raspberry Pi

- The TLE94112ES of the other DC Motor Control HAT is controlled by GPIO 7 (Figure ).

The combination with different HATs is possible in general, but compatibility depends on pin usage and

bus addresses and cannot be guaranteed for every HAT.

2.9 Pin assignment

To use the DC Motor Control HAT, the necessary control signals can be applied directly at the Raspberry

Pi connectors.

Figure shows the pinout/connectors of the DC Motor Control HAT with TLE94112ES.

Figure 13 Connectors of DC Motor Control HAT

Page 14

User Manual 14 Revision 1.0

2021-03-

DC Motor Shield with TLE94112EL

For Raspberry Pi

2.10 Pin definitions and functions

Pin

I/O 1

Function

GND

-

GND

Common 0V reference for all components on the DC Motor Control HAT.

VBAT

-

Battery supply (5.5 – 18V normal, 18-20V extended)

Connected to the battery voltage of the HAT

VDD - Logic supply (3.3V from Raspberry Pi)

VCC - Supply for Backpowering (5V for Raspberry)

SCLK

I

Serial Clock Input 2

MOSI

I

Master Output Slave Input 2

MISO

O

Master Input Slave Output 2

CS0 I Chip Select 0

2, Error! Bookmark not defined.

CS1 I Chip Select 1

2, Error! Bookmark not defined.

CS2 I Chip Select 2

2, Error! Bookmark not defined.

CS3

I

Chip Select 3

2, Error! Bookmark not defined.

EN

I

Enable Input

Connected to GPIO 26 of the Raspberry Pi. When set to low device goes in sleep

mode with low current consumption.

OUT1-12

O

Connectors for outputs of the half-bridges 1-12

ID_SD

I

Connected to the EEPROM

ID_SC

I

Connected to the EEPROM

1

With respect to the TLE94112ES

2

Connected to the SPI interface of the Raspberry Pi

3

Refer to chapter 2.5

Page 15

User Manual 15 Revision 1.0

2021-03-

DC Motor Shield with TLE94112EL

For Raspberry Pi

3 TLE94112ES overview

The TLE94112ES is a protected twelve-fold half-bridge driver designed especially for automotive motion

control applications such as heating, ventilation and air conditioning (HVAC) flap DC motor control. It is part of

a larger family offering half-bridge drivers from three outputs to twelve outputs with direct interface or SPI

interface.

The half bridge drivers are designed to drive DC motor loads in sequential or parallel operation. Operation

modes forward, reverse, brake and high impedance are controlled from a 16-bit SPI interface. It offers diagnosis

features such as short circuit, open load, power supply failure and overtemperature detection.

In combination with its low quiescent current, this device is attractive among others for automotive

applications. The small fine pitch exposed pad package, PG-TSDSO-24, provides a good thermal performance

and reduces PCB-board space and costs.

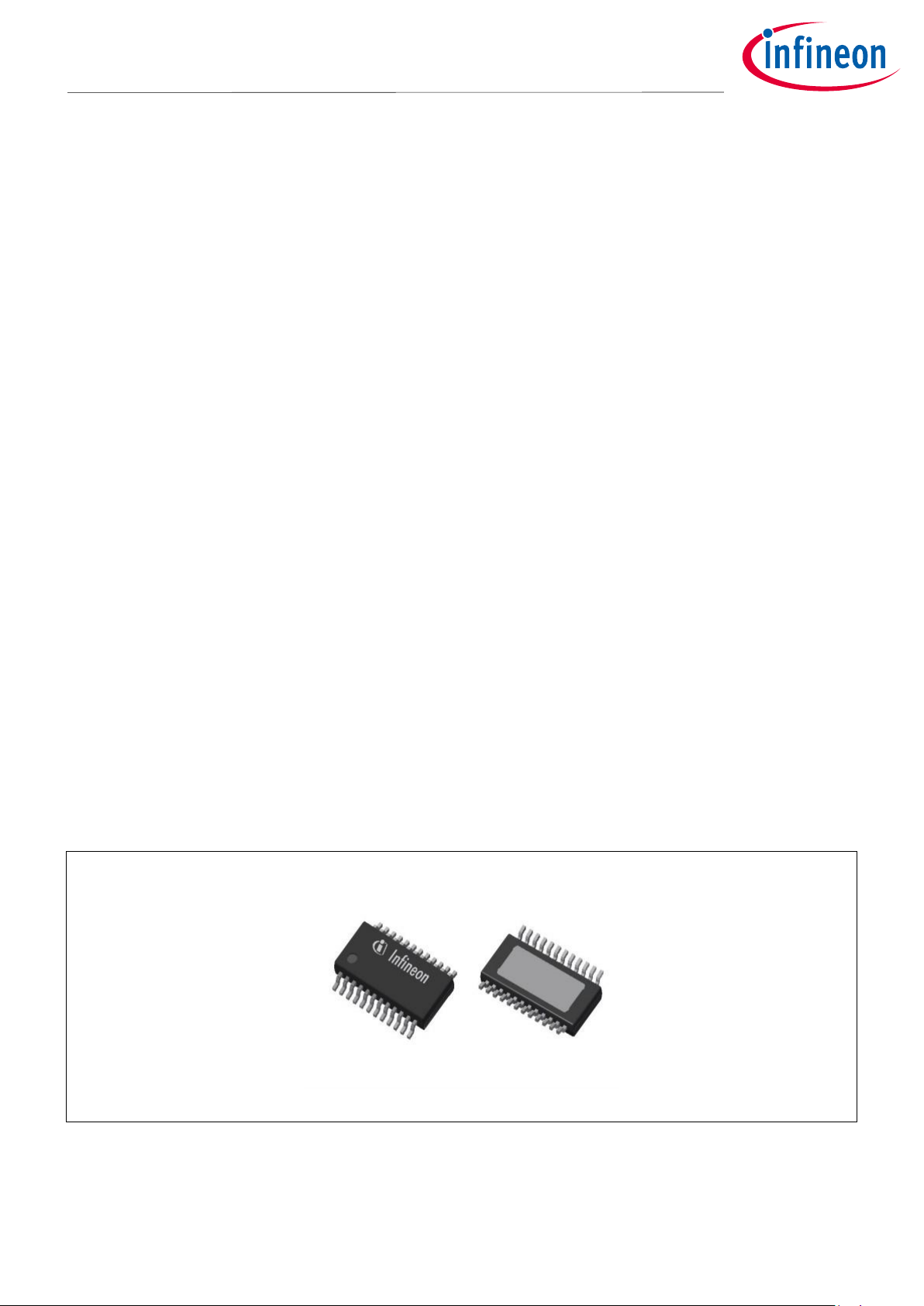

3.1 Key features of the TLE94112ES

Twelve half-bridge power outputs

Optimized EMC behavior

Very low power consumption in sleep mode

3.3V / 5V compatible inputs with hysteresis

All outputs with overload and short circuit protection

Independently diagnosable outputs (overcurrent, open load)

Open load diagnostics in ON-state for all high-side and low-side

Outputs with selectable open load thresholds (HS1, HS2)

16-bit Standard SPI interface with daisy chain and in-frame response capability for control and diagnosis

Fast diagnosis with the global error flag

PWM capable outputs for frequencies 80Hz, 100Hz and 200Hz with 8-bit duty cycle resolution

Overtemperature pre-warning and protection

Over- and Undervoltage lockout

Cross-current protection

AEC-100 Qualified

Figure 14 PG-TSDSO-24 Package

Page 16

User Manual 16 Revision 1.0

2021-03-

DC Motor Shield with TLE94112EL

For Raspberry Pi

3.2 Block diagram

Figure 15 Block diagram TLE94112ES

SCLK

EN

CSN

SDI

SDO

BIAS &

MONITOR

UNDERVOLTAGE &

OVERVOLTAGE

MONITOR

VDD

ERROR

DETECTION

VS1

CHARGE

PUMP

open load

detection

current

control

high-side

driver

low-side

driver

short to

battery

detection

temp

sensor

current

control

short to

battery

detection

high-side

driver

low-side

driver

short to

battery

detection

temp

sensor

open load

detection

current

control

short to

battery

detection

high-side

driver

low-side

driver

short to

battery

detection

temp

sensor

open load

detection

current

control

short to

battery

detection

high-side

driver

low-side

driver

short to

battery

detection

temp

sensor

current

control

short to

battery

detection

OUT 7

OUT 5

OUT 3

OUT 1

open load

detection

current

control

short to

battery

detection

low-side

driver

short to

battery

detection

temp

sensor

open load

detection

current

control

short to

battery

detection

high-side

driver

low-side

driver

short to

battery

detection

temp

sensor

current

control

short to

battery

detection

high-side

driver

low-side

driver

short to

battery

detection

temp

sensor

current

control

short to

battery

detection

high-side

driver

low-side

driver

short to

battery

detection

temp

sensor

current

control

short to

battery

detection

temp

sensor

High-side

driver

Low-side

driver

Power driver

Temp.

sensor

Power stage

LOGIC CONTROL

& LATCH

SPI INTERFACE

12-Fold Half Bridge Driver

SPI Interface

Open load

detection

Overload

detection

Overtemp.

detection

Open load

detection

Overload

detection

Overtemp.

detection

PWM

GENERATOR

GND

GND

OUT 2

OUT 4

OUT 6

OUT 12

OUT 10

OUT 8

OUT 9

OUT 11

GND GND

VS2

Page 17

User Manual 17 Revision 1.0

2021-03-

DC Motor Shield with TLE94112EL

For Raspberry Pi

3.3 Pin assignment

Figure 16 Pin assignment TLE94112ES (top view)

GND

OUT 2

OUT 8

VS2

SCLK

CSN

OUT 12

SDO

EN

OUT 9

OUT 6

OUT 4

GND

GND

OUT 1

OUT 5

OUT 7

SDI

VDD

OUT 11

VS1

OUT 10

OUT 3

GND

18

17

16

15

14

13

24

23

22

21

20

19

1

2

3

4

5

6

7

8

9

10

11

12

Page 18

User Manual 18 Revision 1.0

2021-03-

DC Motor Shield with TLE94112EL

For Raspberry Pi

3.4 Pin definitions and functions

Pin

Symbol

Function

1

GND

Ground. All ground pins should be externally connected together.

2

OUT 1

Power half-bridge 1

3

OUT 5

Power half-bridge 5

4

OUT 7

Power half-bridge 7

5

SDI

Serial data input with internal pull down

6

VDD

Logic supply voltage

7

SDO

Serial data output

8

EN

Enable with internal pull-down; Places device in standby mode by pulling the

EN line Low

9

OUT 9

Power half-bridge 9

10

OUT 6

Power half-bridge 6

11

OUT 4

Power half-bridge 4

12

GND

Ground. All ground pins should be externally connected together.

13

GND

Ground. All ground pins should be externally connected together.

14

OUT 3

Power half-bridge 3

15

OUT 10

Power half-bridge 10

16

VS1

Main supply voltage for power half bridges. VS1 should be externally connected to

VS2.

17

OUT11

Power half-bridge 11

18

OUT12

Power half-bridge 12

19

CSN

Chip select Not input with internal pull up

20

SCLK

Serial clock input with internal pull down

21

VS2

Main supply voltage for power half bridges. VS1 should be externally connected to

VS1.

22

OUT 8

Power half-bridge 8

23

OUT 2

Power half-bridge 2

24

GND

Ground. All ground pins should be externally connected together.

EDP

-

Exposed Die Pad; For cooling purpose only - not usable as electrical ground.

Electrical ground must be provided by pins 1, 12, 13, 24

Page 19

User Manual 19 Revision 1.0

2021-03-

DC Motor Shield with TLE94112EL

For Raspberry Pi

4 Getting started

For a quick and easy set up check out the Quick Start Guide available on the website and on

github.com/Infineon/multi-half-bridge.

Page 20

User Manual 20 Revision 1.0

2021-03-

DC Motor Shield with TLE94112EL

For Raspberry Pi

5 Revision History

Major changes since the last revision

Page or Reference

Description of change

V1.0, 2021-03-10

First release

Page 21

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2021 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

IMPORTANT NOTICE

The information contained in this application note is

given as a hint for the implementation of the product

only and shall in no event be regarded as a

description or warranty of a certain functionality,

condition or quality of the product. Before

implementation of the product, the recipient of this

application note must verify any function and other

technical information given herein in the real

application. Infineon Technologies hereby disclaims

any and all warranties and liabilities of any kind

(including without limitation warranties of noninfringement of intellectual property rights of any

third party) with respect to any and all information

given in this application note.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments

to evaluate the suitability of the product for the

intended application and the completeness of the

product information given in this document with

respect to such application.

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of the

product or any consequences of the use thereof can

reasonably be expected to result in personal injury.

Trademarks of Infineon Technologies AG

AURIX™, C166™, CanPAK™, CIPOS™, CoolGaN™, CoolMOS™, CoolSET™, CoolSiC™, CORECONTROL™, CROSSAVE™, DAVE™, DI-POL™, DrBlade™, EasyPIM™,

EconoBRIDGE™, EconoDUAL™, EconoPACK™, EconoPIM™, EiceDRIVER™, eupec™, FCOS™, HITFET™, HybridPACK™, Infineon™, ISOFACE™, IsoPACK™,

i-Wafer™, MIPAQ™, ModSTACK™, my-d™, NovalithIC™, OmniTune™, OPTIGA™, OptiMOS™, ORIGA™, POWERCODE™, PRIMARION™, PrimePACK™,

PrimeSTACK™, PROFET™, PRO-SIL™, RASIC™, REAL3™, ReverSave™, SatRIC™, SIEGET™, SIPMOS™, SmartLEWIS™, SOLID FLASH™, SPOC™, TEMPFET™,

thinQ!™, TRENCHSTOP™, TriCore™.

Trademarks updated August 2015

Other Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2017-02-13

AppNote Number

Loading...

Loading...