Page 1

TLE92104 APPKIT

About this document

Scope and purpose

This user manual is intended to help users using the TLE92104 APPKIT. This APPKIT is designed to evaluate

hardware and software functionalities of the TLE92104.

This manual provides additional information about the board's layout, jumper settings, interface and how to

use the GUI.

Intended audience

This document is for everyone who works with the TLE92104 APPKIT.

User Manual Please read the Important Notice and Warnings at the end of this document v1.0

www.infineon.com 2020-12-28

Page 2

TLE92104 APPKIT

Abbreviations

Abbreviations

CSN Chip select

CSIx Current Sense Input x

CSOx Current Sense Output

DC Direct Current or Duty Cycle

EN TLE92104 enable pin

GH1-4 Gate high-side MOSFET for half-bridge 1-4

GL1-4 Gate low-side MOSFET for half-bridge 1-4

GND Ground

GUI Graphic User Interface

MOSFET Metal-Oxide-Semiconductor Field-Effect Transistor

N.C. Not connected

OC Overcurrent

OV Overvoltage

PWM1-3 Pulse Width Modulation channel 1-3

SCLK Serial Clock

SDI Serial Data In

SDO Serial Data Out

SPI Serial Periphery Interface

TJ Junction temperature

UV Undervoltage

VBAT Battery supply voltage

VCP Charge pump voltage

VDD Logic supply voltage

VDH Voltage drain of high-side MOSFET

VS Battery supply voltage

VSP Half-bridge supply voltage

User Manual 2 v1.0

2020-12-28

Page 3

TLE92104 APPKIT

Table of contents

Table of contents

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4 Current Sense Output (CSO) jumper setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 SMD test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

6 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 TLE92104-232 pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8 APPKIT setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

8.1 Installing the GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.2 Establishing communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.3 Using the GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9 How to use the GUI (examples) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.1 Example - PWM DC motor control using half-bridge 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2 Example - Enabling Adaptive MOSFET Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9.3 Example - Setting blanking, cross-current protection and drain-source monitoring . . . . . . . . . . . .18

9.4 Example - Off-state diagnostics on half-bridge 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

10 Schematics and layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

10.1 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10.2

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

User Manual 3 v1.0

2020-12-28

Page 4

TLE92104 APPKIT

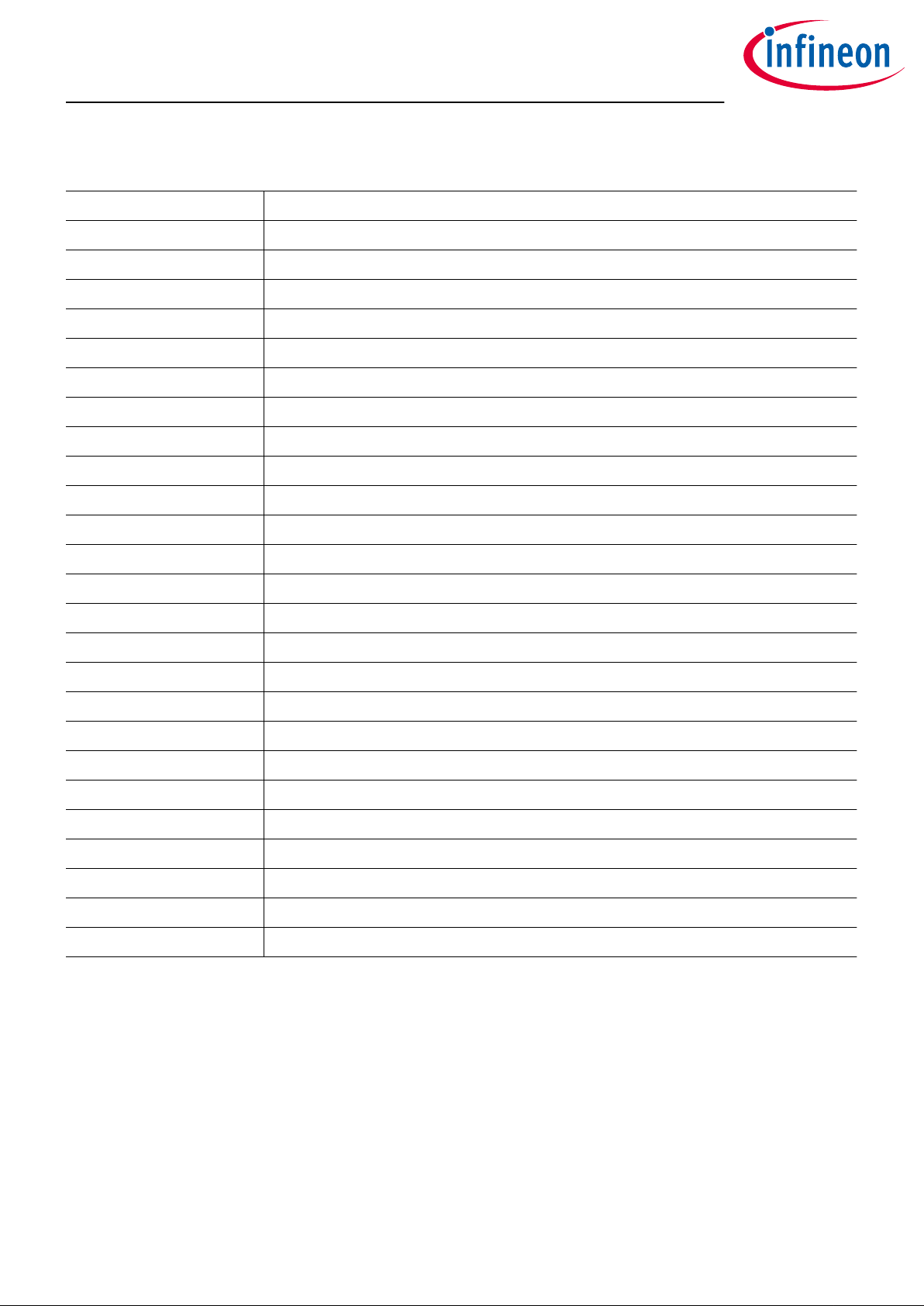

1 Concept

1

Concept

Figure 1 Block diagram

The TLE92104 APPKIT board provides a simple, easy-to-use tool to get familiar with Infineon's Multi MOSFET

Driver TLE92104-232QX (TLE92104).

It contains the TLE92104 and a typical application circuit including 4 MOSFET half-bridges to drive up to

4 DC motors. The board is ready to be connected to a vehicle level power supply and is controlled over SPI.

All pins relevant to control the device can be accessed via the dedicated 8 × 2 header using the uIO-stick by

hitex EMBEDDED TOOLS & SOLUTIONS (http://www.hitex.com/uIO).

The board is powered by the power connector and provides an active on-board reverse-polarity protection for

fastest response time in case of reverse polarity with minimal power-loss during normal operation.

The board allows control of Phase 1-4 which can be used to control up to 4 motors independently that can be

connected to OUT1-4 with the 2 screw terminal block motor connectors.

2 high-side shunts provide load current measurement and monitoring.

User Manual 4 v1.0

2020-12-28

Page 5

TLE92104 APPKIT

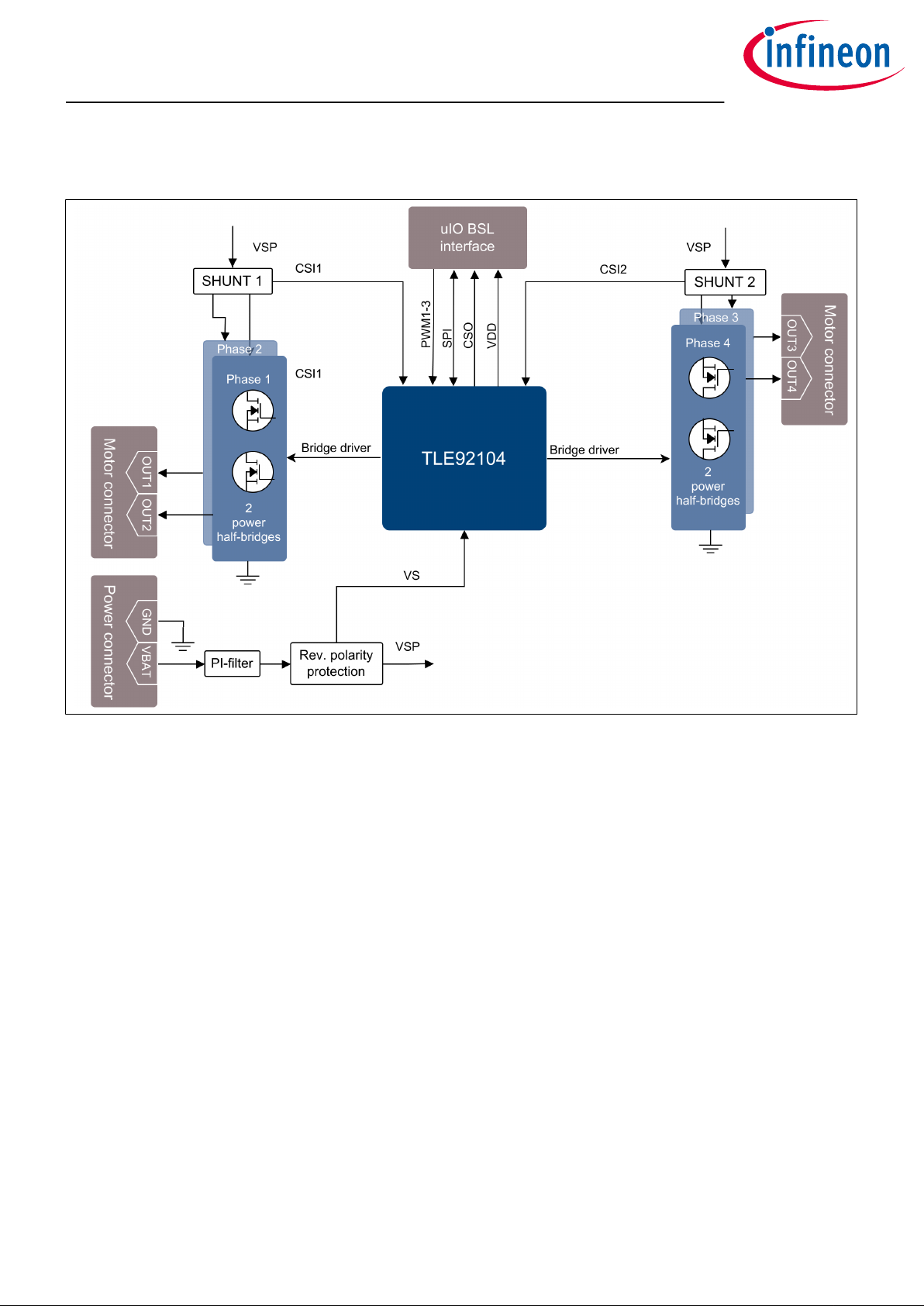

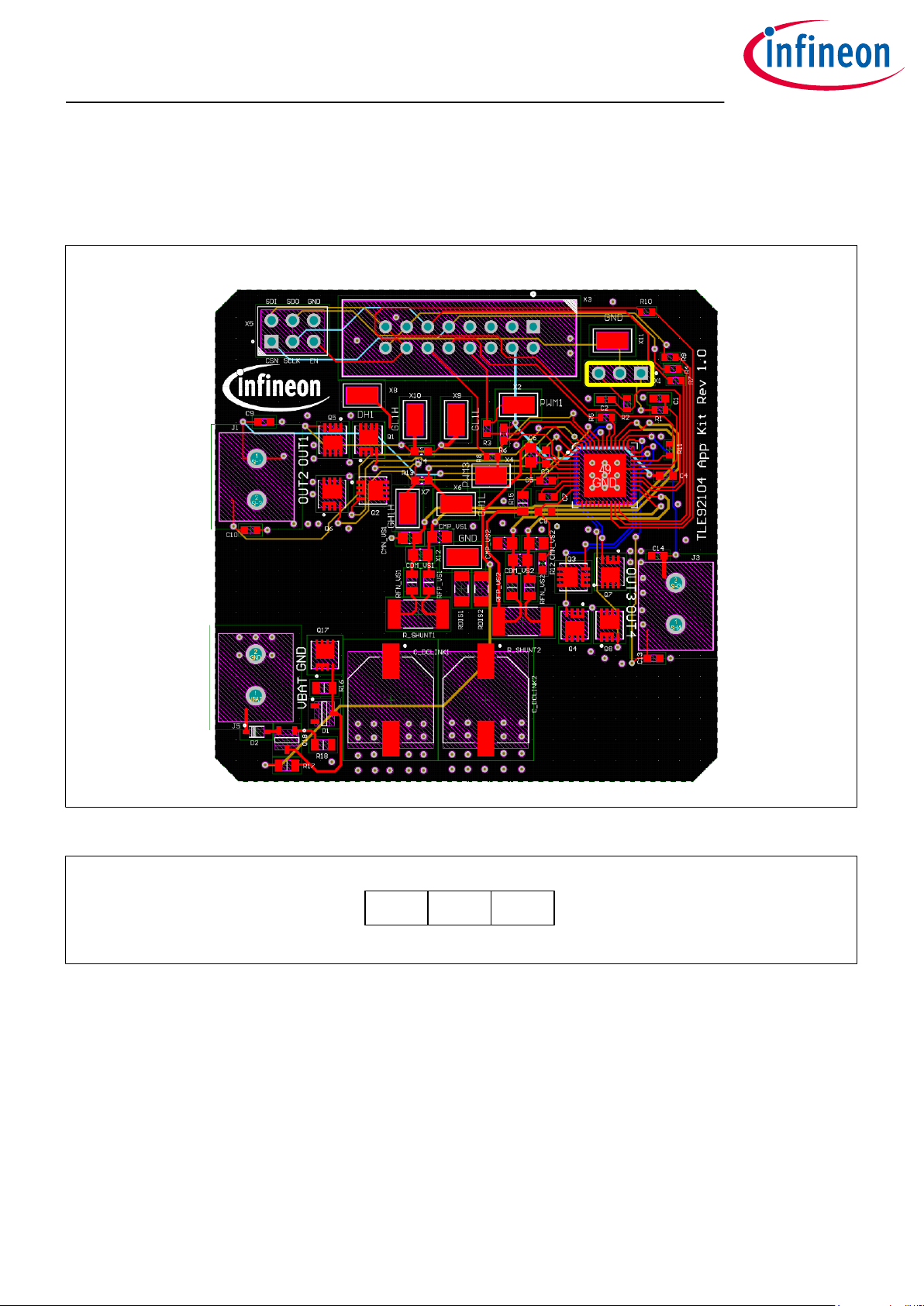

2 PCB layout

2

PCB layout

Infineon's TLE92104 is a Multi-MOSFET driver IC providing control of up to 8 n-channel MOSFETs. It supports up

to 4 half-bridges for DC motor control applications such as automotive power seat control or other multi-motor

applications (Datasheet of TLE92104-232QX).

LS1

HS1

TLE92104

LS2

HS2

HS3

LS3

HS4 LS4

Figure 2 PCB layout

HS1-4, LS1-4

Infineon's new OptiMOS™ 5 40 V product family in S3O8 package combines leading power MOSFET technology

with 3.3 × 3.3 mm2 leadless power package for very compact and robust automotive system solutions

(Datasheet of IPZ40N04S5-3R1).

Reverse polarity protection

The active reverse polarity protection is based on the design documented in the "Reverse Polarity Protection

for Embedded Power ICs" Application Note (Z864338247).

User Manual 5 v1.0

2020-12-28

protection

Reverse polarity

Page 6

TLE92104 APPKIT

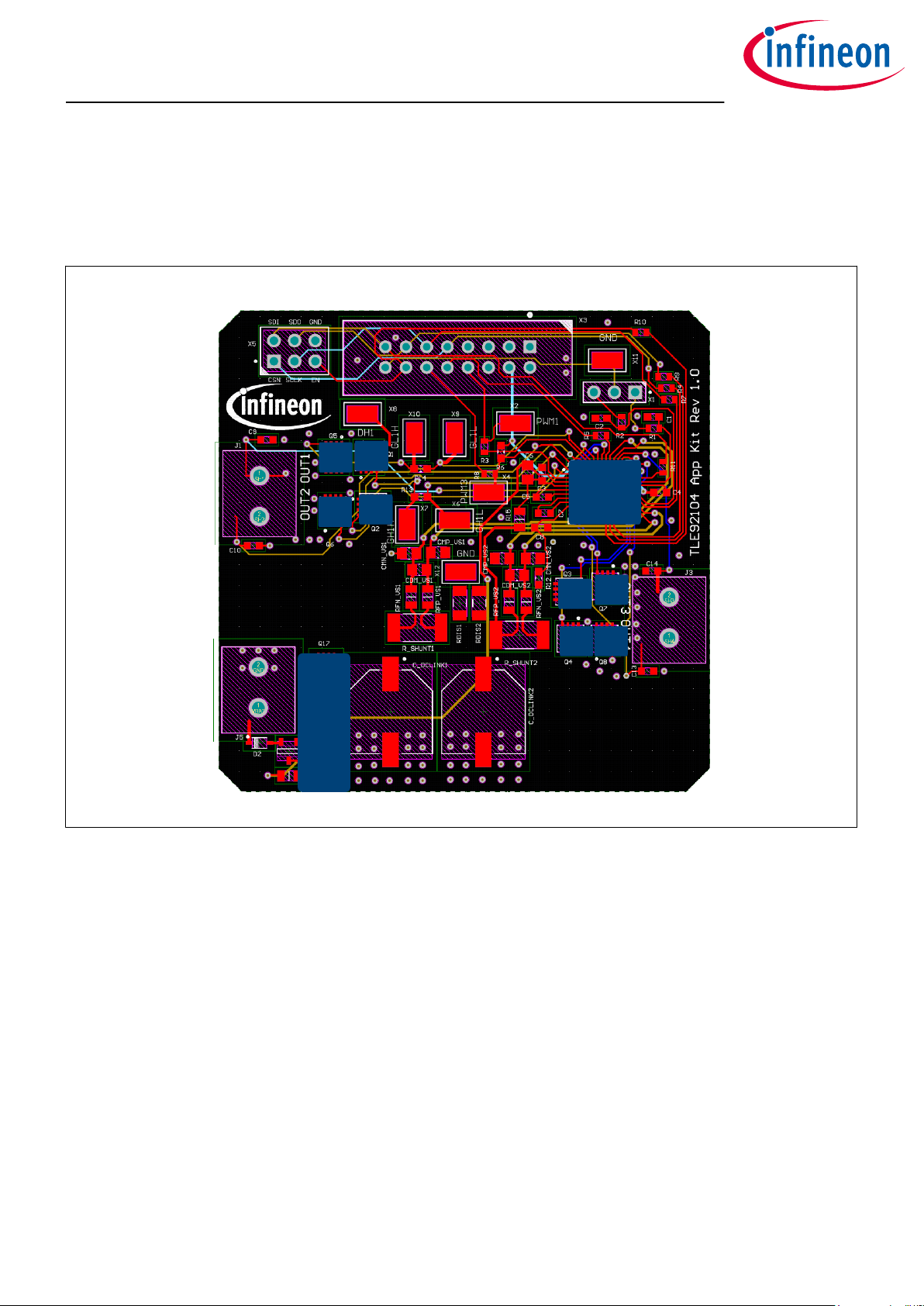

3 Connections

3

Connections

Several external connections are available on the TLE92104 APPKIT.

SPI

header

uIO-stick

interface

OUT 1

OUT 2

OUT 3

OUT 4

Ground

VBAT

Figure 3 Connections

uIO-stick interface

The uIO-stick interface can be used to establish communication with the TLE92104 for programming of the SFRs

and motor control. Setting up the interface can be found in APPKIT setup. The pinout is shown in Figure 4.

SDI SDO SCLK CSN N.C. N.C. N.C. NC.

15 13 11 9 7 5 3 1

16 14 12 10 8 6 4 2

CSOx EN PWM3 PWM2 PWM1 N.C. VDD GND

Figure 4 Pin configuration of uIO-stick

User Manual 6 v1.0

2020-12-28

Page 7

TLE92104 APPKIT

3 Connections

Motor connectors

The screw terminal blocks can be used to connect DC motors in multiple topologies, some examples are shown

in Figure 5.

M

Out 1

Out 2

Out 3

M

VS

Out 4

M

Figure 5 Motor connectors and topologies

Power connector

The screw terminal blocks are used to connect the supply voltage to VBAT and ground to GND.

Figure 6 Power connector

SPI header

The 3 × 2 header can be used for SPI debugging. The pinout is shown in Figure 7.

SDI SDO GND

2 4 6

1 3 5

CSN SCLK EN

Figure 7 SPI header pinout

User Manual 7 v1.0

2020-12-28

Page 8

TLE92104 APPKIT

4 Current Sense Output (CSO) jumper setting

4

Current Sense Output (CSO) jumper setting

The Current Sense Output jumper selects which IC current sense output is connected to the uIO interface. The

signal is routed to the uIO-stick interface pin 16. The pinout is shown in Figure 9.

CSO selection jumper

Figure 8 Current Sense Output selection jumper

CSO2 CSOx CSO1

Figure 9 CSO selection jumper pinout

User Manual 8 v1.0

2020-12-28

Page 9

TLE92104 APPKIT

5 SMD test points

5

SMD test points

The TLE92104 APPKIT provides 9 SMD test points for evaluation and testing.

GND

DH

GL1

GH1

PWM 1

PWM 3

GND

Figure 10 SMD test points

The TLE92104 APPKIT includes test points for:

• 2× GND

• 1× VDH

• 2× GL1

• 2× GH1

• 1× PWM1

• 1× PWM3

User Manual 9 v1.0

2020-12-28

Page 10

TLE92104 APPKIT

6 Bill of material

6

Bill of material

Table 1 Bill of material

Designator Value

C1, C2 100 pF

C3, C4, C8 100 nF

C5, C7 220 nF

C6 470 nF

C9, C10, C13, C14 22 nF

C_DCLINK1, C_DCLINK2 560 uF

CDM_VS1, CDM_VS2 1.50 nF

CMN_VS1, CMN_VS2, CMP_VS1, CMP_VS2 22 nF

D1 BZX84C16LT1G

D2 BAS21

J1, J3, J5 20020316-G021B01LF

Q1, Q2, Q3, Q4, Q5, Q6, Q7, Q8 IPZ40N04S5-3R1

Q17 BCR141

Q18 IPZ40N04S5L-2R8

R1, R2, R3, R4, R5, R7, R8, R9, R10, R11 1 kR

R6 47 kR

R12 2 R

R13, R14 10 R

R15 2.20 R

R16 100 kR

R17 4.7 kR

R18 47 kR

R_SHUNT1, R_SHUNT2 5 mR

RDIS1, RDIS2 15 kR

RFN_VS1, RFN_VS2, RFP_VS1, RFP_VS2 4.70 R

U1 TLE92104-233QX

X1 Header 3

X2, X4, X6, X7, X8, X9, X10, X11, X12 connector_1_f

X3 Header 8X2

X5 Header 3X2A

User Manual 10 v1.0

2020-12-28

Page 11

TLE92104 APPKIT

7 TLE92104-232 pinout

7

TLE92104-232 pinout

The TLE92104 comes in a space saving 7 × 7 mm2 VQFN 48 pin package and is AEQ-Q100 qualified up to a

junction temperature TJ of 150°C.

Figure 11 TLE92104 pinout

User Manual 11 v1.0

2020-12-28

Page 12

TLE92104 APPKIT

8 APPKIT setup

8

APPKIT setup

The APPKIT can be controlled with the uIO-stick which provides an interface between the PC GUI and the

APPKIT's uIO connector is able to translate message between the APPKIT and the GUI available for PC.

8.1 Installing the GUI

The GUI is installed the Infineon Toolbox following the steps below:

1. Go to: www.infineon.com/toolbox.

2. Follow the instructions provided on the toolbox installation webpage. Also see the “Download Getting

Started Infineon Toolbox Guide” link for additional user information.

3. Launch the Infineon Toolbox on your PC:

4. Select Manage Tools.

5. Search and install the tool: Config Wizard for Multi MOSFET Driver.

6.

Start the

Config Wizard for Multi MOSFET Driver

.

7. Click on TLE92104 APPKIT.

8.2 Establishing communication

To establish communication between the GUI and the TLE92104 APPKIT you must:

• Connect the TLE92104 Appkit to a power-supply.

• Connect the uIO-stick to the TLE92104 APPKIT.

• Connect the uIO-stick to a USB port of your PC.

• Turn on the power supply.

• Start the GUI.

Note: The GUI requires the uIO-sticks'-firmware to be of version 2.21 or above.

The GUI can be used to update the uIO-stick firmware to the latest version:

1. Open the GUI.

2. Click Extras.

3. Click Update uIO ….

4. A window will pop up, click Yes.

5. Select uIO_v221.hex or above.

6. Click Open.

Note: It is recommended to remove and reinsert the uIO-stick to reboot the uIO hardware.

User Manual 12 v1.0

2020-12-28

Page 13

TLE92104 APPKIT

8 APPKIT setup

8.3

Using the GUI

The GUI consists of three panels/tabs:

•

Motor Control

• Detailed Settings

• PWM and Diagnostic

Figure 12 TLE92104 APPKIT GUI

Additionally the status of the USB connection, bridge driver and diagnostic read is shown on the top of the

display:

Everything is up and running.

There seems to be a problem.

The GUI provides buttons to Clear Diagnosis, to Clear Status Registers and to RESET the device.

Motor Control

In this panel it is possible to:

• Configure the PWM channels 1-3 with 0-100% DC and up to 25 kHz which are generated by the uIO-stick.

• Map the PWM to half-bridges 1-4.

• Set the HB state in either cascade or H bridge configuration.

• Select and disable the CSAs and see the current VCSOx output.

• See the General Status register and Global Status byte.

• Perform off-state diagnosis.

User Manual 13 v1.0

2020-12-28

Page 14

TLE92104 APPKIT

8 APPKIT setup

Detailed Settings

In this panel it is possible to:

• Enable and configure the charge pump and set OV and UV thresholds.

• Configure passive mode settings.

• Configure the CSAs and enable OC shutdown.

• Configure gate driver timings (cross-current-protection and blank time), hold and static currents.

• Configure DS overvoltage.

• Map gate drive timings and static currents to half-bridge.

PWM and Diagnostic

In this panel it is possible to:

• Enable adaptive MOSFET control, set filter, enable generator mode detection or deep adaption.

• Set dis/charge currents for active and free-wheeling MOSFET, configure adaptive currents, set target turn-

on delay and pre dis/charge time for PWM channel 1-3.

• Read PWM switching characteristics.

• Check Global Status Byte, General Status register, PWM mapping error and drain-source overvoltage.

User Manual 14 v1.0

2020-12-28

Page 15

TLE92104 APPKIT

9 How to use the GUI (examples)

9

How to use the GUI (examples)

9.1 Example - PWM DC motor control using half-bridge 1 and 2

In this example a DC motor will be controlled by half-bridge 1 and 2. The half-bridge 1 output will be configured

for 20 kHz PWM with 50% DC and the load current can be monitored using CSA1.

Setup

Before you configure the GUI you will need to:

• Connect a DC motor to OUT1 and OUT2.

• Establish communication between the Appkit and the GUI as described in Establishing communication.

Configure the GUI

3

4

2

1

Figure 13 Control your first DC motor

To start the motor you will need to:

1. Set PWM 1 to 20 kHz and 50% DC (default values).

2. Map PWM 1 to HB1.

3. CSA1/2 are on and CSA 1 is selected by default. The PCB on-board jumper should connect CSO1 and

CSO1/2 as described in Current Sense Output (CSO) jumper setting. For correct current sensing the

value of RSHUNT should be set to 5 mΩ to match the PCB hardware.

4. Set Motor 1 to HS1/LS2 on.

The motor should start running with 20 kHz HS PWM at 50%.

The output of CSO1 can be seen in the CSA window (3).

User Manual 15 v1.0

2020-12-28

Page 16

TLE92104 APPKIT

9 How to use the GUI (examples)

The load current can be calculated accordingly:

I

Load

=

V

CSOx

− V

REF

R

SHUNT

× GAIN

Table 2 CSA V

REF

Unidirectional mode Bidirectional mode

VREF VDD/5 VDD/2

Table 3 CSA GAIN

GENCTRL1.CSAGx GAIN

b00 10

b01 20

b10 40

b11 80

The VCSO output depends on the CSA configuration (Uni- or Bidirectional) and the Gain setting. The CSA can

be configured as follows:

1. Go to Detailed Settings.

2. Set CSA Level, Gain, Unidirectional Threshold, Bidirectional Threshold and Overcurrent Filter

(overcurrent detection filter time). (See datasheet for overcurrent monitoring and protection details).

1

2

Figure 14 Configure CSA and overcurrent detection

User Manual 16 v1.0

2020-12-28

Page 17

TLE92104 APPKIT

9 How to use the GUI (examples)

9.2

Example - Enabling Adaptive MOSFET Control

One of the main features of the TLE92104 is Adaptive MOSFET Control. It can easily be configured as shown

below. See the datasheet for a detailed description of operation and configuration options.

1. Go to PWM and Diagnostic.

2. Configure Adaptive Gate Control settings. Here features like deep adaption or generator mode

detection can be enabled.

3. Set the desired turn-on/off delay and MOSFET gate drive characteristics.

1

2

3

Figure 15 Enable Adaptive MOSFET Control

User Manual 17 v1.0

2020-12-28

Page 18

TLE92104 APPKIT

9 How to use the GUI (examples)

9.3 Example - Setting blanking, cross-current protection and drain-

source monitoring

The TLE92014 has several active protection features cross-current protection and VDS overvoltage protection.

1. Go to Detailed Settings.

2. Configure Active CCP and FW CCP and make sure it is mapped to the correct half-bridge.

3. Configure Active Blank Time and FW Blank Time and make sure it is mapped to the correct half-bridge.

4. Configure Drain-source Monitoring Filter Time and set the Drain-source Overvoltage Threshold for

the addressed half-bridge.

1

2

4

2

2

4

2

3

3

4

Figure 16 TCCP, TBLANK and VDS monitoring

User Manual 18 v1.0

2020-12-28

Page 19

TLE92104 APPKIT

9 How to use the GUI (examples)

9.4

Example - Off-state diagnostics on half-bridge 1 and 2

Off-state diagnostics can be used to detect short to battery/ground or open wire without activating the motor.

Note: The Drain-Source Overvoltage threshold (as shown in Example - Setting blanking, cross-current

protection and drain-source monitoring.) for the addressed half-bridge must be set to 2.0 V for

proper detection.

1. Go to Motor Control.

2. Set Motor 1 to High Imped.

3. Enable pull-down current sources for HB1 and HB2

Refer to the Off-state diagnostics Application Note for a detailed description of diagnosis operation.

1

2

3

Figure 17 Off-state diagnostics

User Manual 19 v1.0

2020-12-28

Page 20

TLE92104 APPKIT

10 Schematics and layout

10

Schematics and layout

10.1 Schematics

Figure 18 Schematic page 1

User Manual 20 v1.0

2020-12-28

Page 21

TLE92104 APPKIT

10 Schematics and layout

Figure 19 Schematic page 2

User Manual 21 v1.0

2020-12-28

Page 22

TLE92104 APPKIT

10 Schematics and layout

Figure 20 Schematic page 3

User Manual 22 v1.0

2020-12-28

Page 23

TLE92104 APPKIT

10 Schematics and layout

Figure 21 Schematic page 4

User Manual 23 v1.0

2020-12-28

Page 24

TLE92104 APPKIT

10 Schematics and layout

Figure 22 Schematic page 5

User Manual 24 v1.0

2020-12-28

Page 25

TLE92104 APPKIT

10 Schematics and layout

Figure 23 Schematic page 6

User Manual 25 v1.0

2020-12-28

Page 26

TLE92104 APPKIT

10 Schematics and layout

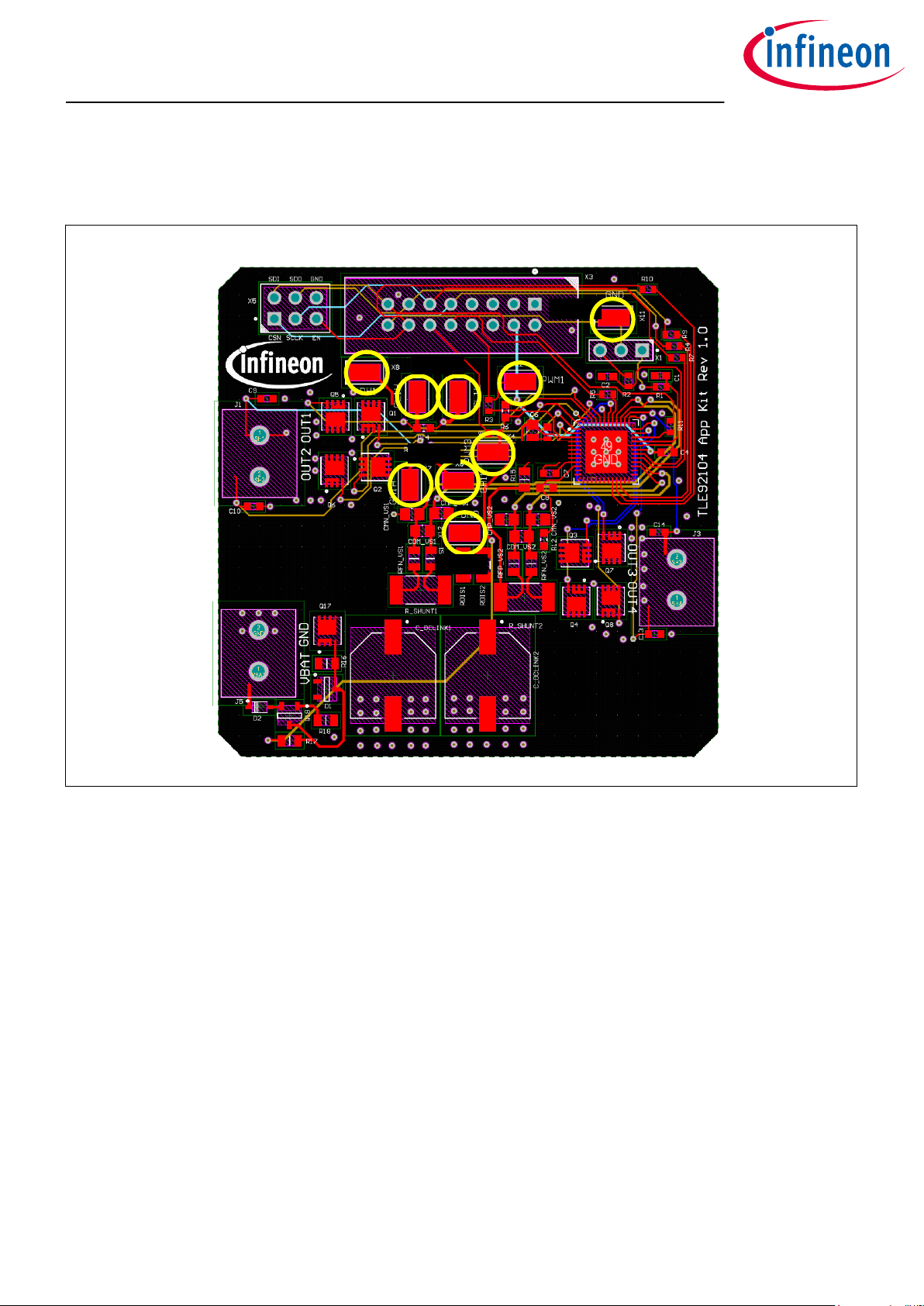

10.2

Layout

Figure 24 Top layer

Figure 25 Layer 2

User Manual 26 v1.0

2020-12-28

Page 27

TLE92104 APPKIT

10 Schematics and layout

Figure 26 Layer 3

Figure 27 Bottom layer

User Manual 27 v1.0

2020-12-28

Page 28

TLE92104 APPKIT

11 Revision history

11 Revision history

Revision Date Changes

v1.0 2020-12-28 Initial creation.

User Manual 28 v1.0

2020-12-28

Page 29

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2020-12-28

Published by

Infineon Technologies AG

81726 Munich, Germany

©

2020 Infineon Technologies AG

All Rights Reserved.

Do you have a question about any

aspect of this document?

Email: erratum@infineon.com

Document reference IFX-

nyd1600680666936

IMPORTANT NOTICE

The information given in this document shall in no

event be regarded as a guarantee of conditions or

characteristics (“Beschaffenheitsgarantie”).

With respect to any examples, hints or any typical

values stated herein and/or any information regarding

the application of the product, Infineon Technologies

hereby disclaims any and all warranties and liabilities

of any kind, including without limitation warranties of

non-infringement of intellectual property rights of any

third party.

In addition, any information given in this document is

subject to customer’s compliance with its obligations

stated in this document and any applicable legal

requirements, norms and standards concerning

customer’s products and any use of the product of

Infineon Technologies in customer’s applications.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments to

evaluate the suitability of the product for the intended

application and the completeness of the product

information given in this document with respect to such

application.

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon Technologies,

Infineon Technologies’ products may not be used in

any applications where a failure of the product or

any consequences of the use thereof can reasonably

be expected to result in personal injury.

Loading...

Loading...