现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

Step Down Voltage-Regulator with Reset

Datasheet

1Overview

1.1 Features

• Step down converter

• Supply Over- and Under-Voltage-Lockout

• Low Output voltage tolerance

• Output Overvoltage Lockout

• Output Under-Voltage-Reset with delay

• Overtemperature Shutdown

• Wide Ambient operation range -40°C to 125°C

• Wide Supply voltage operation range

• Very low current consumption

• Very small P-DSO-8 SMD package

Type Ordering Code Package

P-DSO-8-3

TLE 6365

TLE 6365 G Q67006-A9515 P-DSO-8-3

Functional description

General

The TLE 6365 G is a power supply circuit especially designed for automotive

applications.

The device is based on Infineon’s power technology SPT

®

which allows bipolar and

CMOS control circuitry to be integrated with DMOS power devices on the same

monolithic circuitry.

The TLE 6365 G contains a buck converter and a power on reset feature to start up the

system.

The very small P-DSO-8-3 SMD package meets the application requierements.

It delivers a precise 5V fully short circuit protected output voltage.

Furthermore, the build-in features like under- and overvoltage lockout for supply- and

output-voltage and the overtemperature shutdown feature increase the reliability of the

TLE 6365 G supply system.

Data Sheet Rev. 1.7 1 2003-06-02

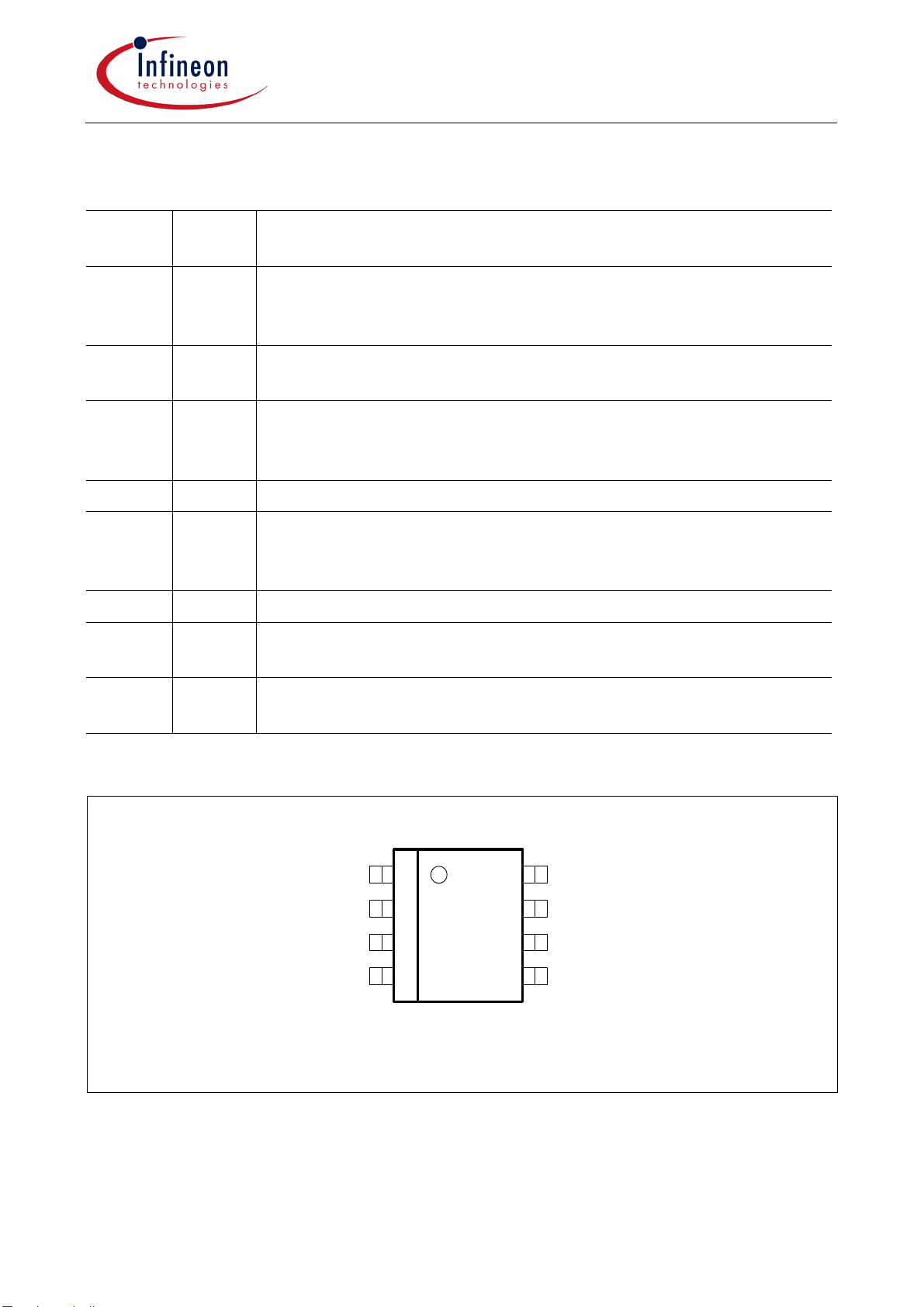

1.2 Pin Definitions and Functions

TLE 6365

Pin

Symbol Function

No

1R Reference Input; an external resistor from this pin to GND

determines the reference current and so the oscillator / switching

frequency

2RO Reset Output; open drain output from reset comparator with an

internal pull up resistor

3BUCBuck-Converter Compensation Input; output of internal error

amplifier; for loop-compensation and therefore stability connect

an external R-C-series combination to GND.

4GNDGround; analog signal ground

5 V

CC

Output Voltage Input; feedback input (with integrated resistor

devider) and logic supply input; external blocking capacitor

necessary

7BUOBuck Converter Output; source of the integrated power-DMOS

6BDSBuck Driver Supply Input; voltage to drive the buck converter

powerstage

8 V

S

Supply Voltage Input; buck converter input voltage; external

blocking capacitor necessary.

Pin Configuration

R

18

RO BUO

BUC BDS

GND

2

3

4

P-DSO-8-3

Figure 1 Pin Configuration (top view)

V

S

7

6

5

V

CC

Data Sheet Rev. 1.7 2 2003-06-02

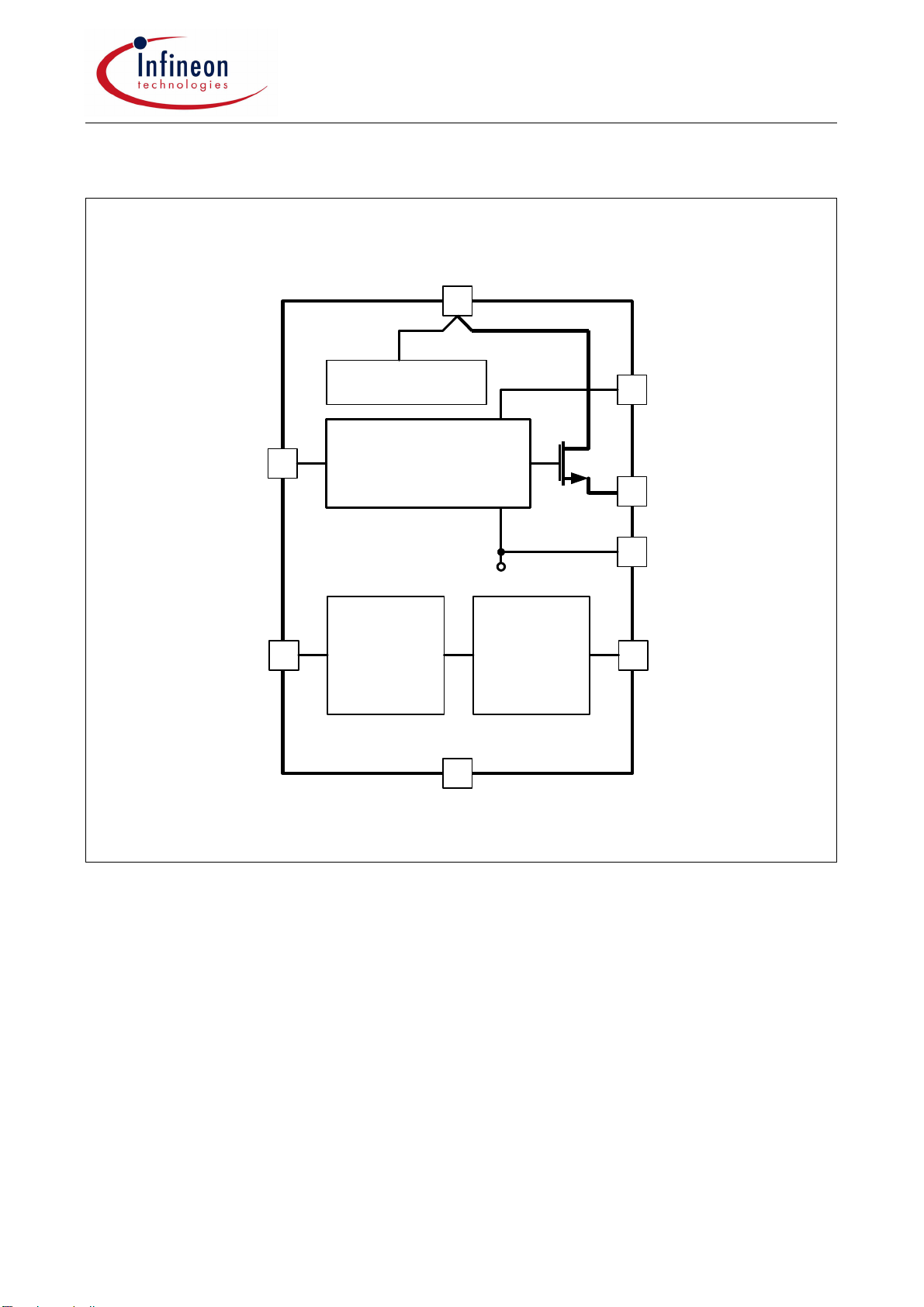

1.3 Block Diagram

TLE 6365

V

S

8

BUC

Biasing and V

3

Buck

Converter

TLE 6365 G

Reference

R

1

Current

Generator

and

Oscillator

REF

4

GND

V

internal

Undervoltage

Reset

Generator

BDS

6

BUO

7

V

CC

5

RO

2

Figure 2 Block Diagram

Data Sheet Rev. 1.7 3 2003-06-02

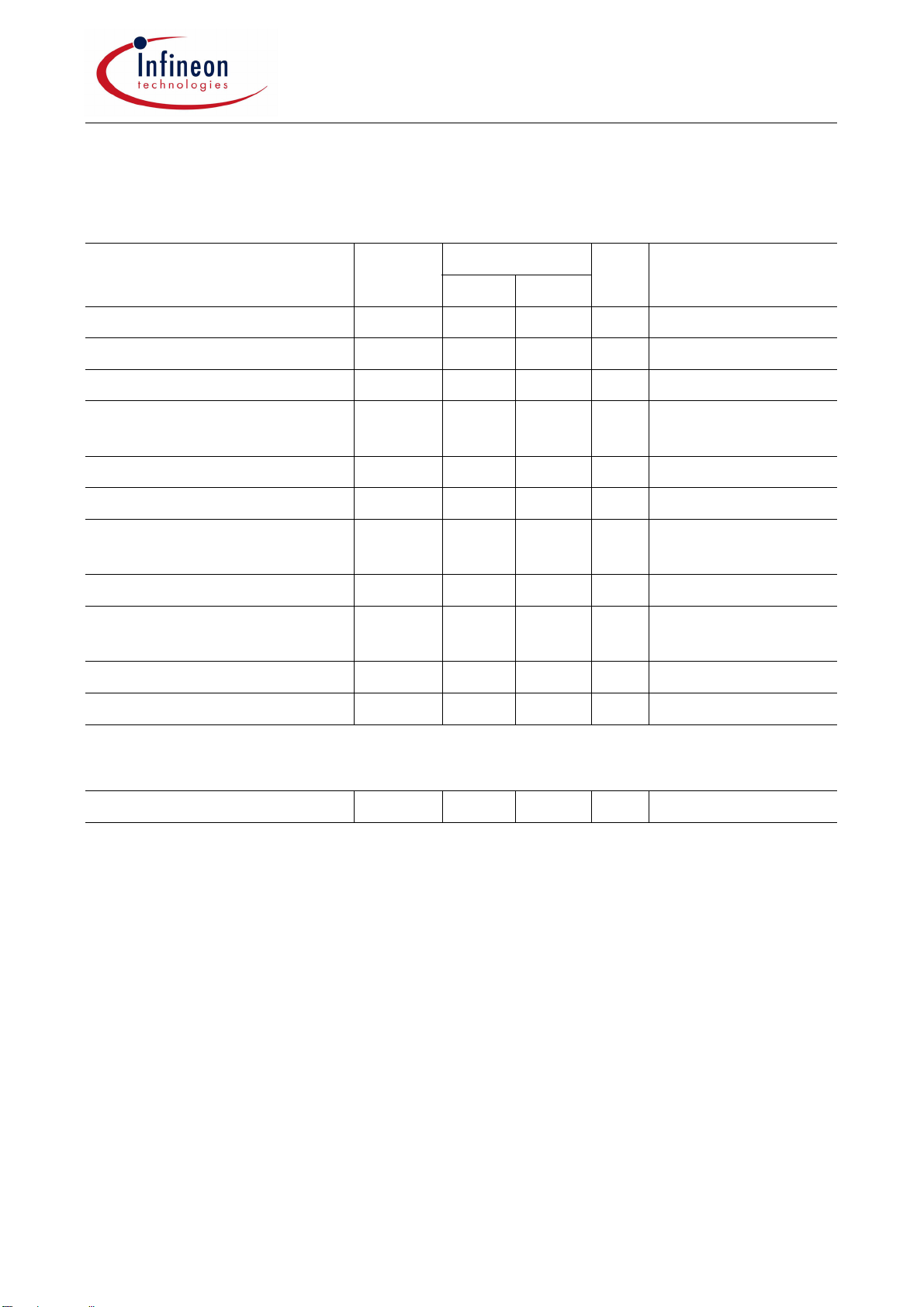

1.4 Absolute Maximum Ratings

Parameter Symbol Limit Values Unit Remarks

min. max.

Voltages

TLE 6365

Supply voltage V

Buck output voltage V

Buck driver supply voltage V

Buck compensation input

V

S

BUO

BDS

BUC

– 0.3 46 V

– 1 46 V

– 0.3 55 V

– 0.3 6.8 V

voltage

Logic supply voltage V

Reset output voltage V

Current reference voltage V

CC

RO

R

– 0.3 6.8 V

– 0.3 6.8 V

– 0.3 6.8 V

ESD-Protection (Human Body Model; R=1,5kΩ; C=100pF)

all pins to GND V

HBM

–2 2 kV

Temperatures

Junction temperature T

Storage temperature

j

T

stg

– 40 150 ° C–

– 50 150 ° C–

Note: Stresses above those listed here may cause permanent damage to the device.

Exposure to absolute maximum rating conditions for extended periods may affect

device reliability.

Data Sheet Rev. 1.7 4 2003-06-02

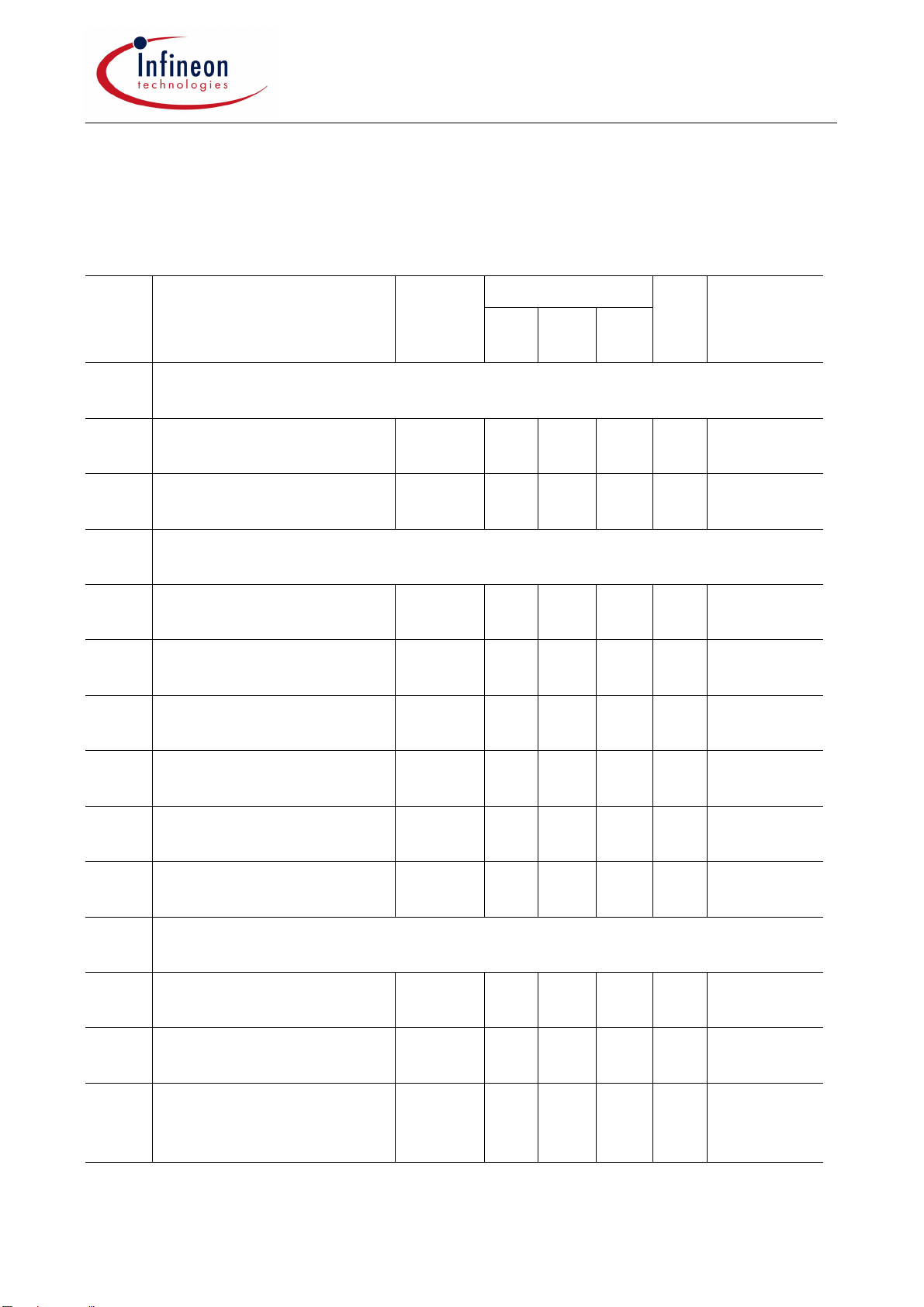

1.5 Operating Range

Parameter Symbol Limit Values Unit Remarks

min. max.

TLE 6365

Supply voltage V

Supply voltage V

Supply voltage V

Supply voltage V

Buck output voltage V

Buck driver supply voltage V

Buck compensation input

V

voltage

Logic supply voltage V

Reset output voltage V

Current reference voltage V

Junction temperature

T

Thermal Resistance

S

S

S

S

BUO

BDS

BUC

CC

RO

CREF

j

– 0.3 40 V

535VV

4.5 36 V V

increasing

S

decreasing

S

– 0.3 4.5 V Buck-Converter

OFF

– 0.6 40 V

– 0.3 50 V

03.0V

4.0 6.2 V

– 0.3 V

CC

V

+0.3

01.23V

– 40 150 ° C

Junction ambient R

Data Sheet Rev. 1.7 5 2003-06-02

thj-a

180 K/W –

TLE 6365

1.6 Electrical Characteristics

V

8V<

all voltages with respect to ground; positive current defined flowing into the pin; unless otherwise specified

No. Parameter Symbol Limit Values Unit Test

1.6.1 Current Consumption

< 35V; 4.75V< VCC<5.25V; - 40°C< Tj<150°C; RR=47kΩ;

S

min. typ. max

.

Condition

1.6.1.1 Current consumption;

I

S

see applicatiopn circuit

1.6.1.2 Current consumption;

I

S

see applicatiopn circuit

1.6.2 Under- and Over-Voltage Lockout at

1.6.2.1 UV ON voltage;

V

SUVON

buck conv. ON

1.6.2.2 UV OFF voltage;

V

SUVOFF

buck conv. OFF

1.6.2.3 UV Hysteresis voltage V

1.6.2.4 OV OFF voltage;

SUVHY

V

SOVOFF

buck conv. OFF

1.6.2.5 OV ON voltage;

V

SOVON

buck conv. ON

1.6.2.6 OV Hysteresis voltage V

SUVHY

1.5 4 mA ICC=0mA

510mAICC=400mA

V

S

4.0 4.5 5.0 V V

S

increasing;

3.5 4.0 4.5 V V

S

decreasing

0.2 0.5 1.0 V HY = ON OFF

34 37 40 V V

S

increasing

30 33 36 V V

S

decreasing

1.5 4 10 V HY = OFF ON

1.6.3 Over-Voltage Lockout at

1.6.3.1 OV OFF voltage;

buck conv. OFF

1.6.3.2 OV ON voltage;

buck conv. ON

1.6.3.3 OV Hysteresis voltage V

V

CC

V

CCOVOFF

V

CCOVON

CCOVHY

5.5 6.0 6.5 V V

CC

increasing

5.25 5.75 6.25 V V

CC

decreasing

0.10 0.25 0.50 V HY = OFF ON

Data Sheet Rev. 1.7 6 2003-06-02

TLE 6365

1.6 Electrical Characteristics (cont’d)

V

8V<

all voltages with respect to ground; positive current defined flowing into the pin; unless otherwise specified

No. Parameter Symbol Limit Values Unit Test

< 35V; 4.75V< VCC<5.25V; - 40°C< Tj<150°C; RR=47kΩ;

S

min. typ. max

.

Condition

1.6.4 Buck-Converter; BUO, BDS, BUC and V

1.6.4.1 Logic supply voltage V

1.6.4.2 Efficiency; see. appl. circuit

1.6.4.3 Power-Stage ON

η

R

CC

BUON

4.9 5.1 V

resistance

1.6.4.4 Power-Stage ON

R

BUON

resistance

1.6.4.5 Buck overcurrent threshold I

1.6.4.6 Input current on pin V

CC

1.6.4.7 Buck Gate supply voltage;

V

=VS - V

BGS

BDS

BUOC

I

CC

V

BGS

0.7 0.9 1.2 A

57.210V

CC

1mA < ICC<

400mA;

see. appl.

circuit

85 % I

CC

400mA;

V

0.38 0.5 Ω Tj=25°C;

I

BUO

1.0 Ω I

BUO

500 µA VCC=5V

=

= 14V

S

= 0.6A

= 0.6A

1.6.5 Reference Input ; R

(Oscillator; Timebase for Buck-Converter and Reset)

1.6.5.1 Voltage on pin R

1.6.5.2 Oscillator frequency

1.6.5.3 Oscillator frequency

1.6.5.4 Cycle time for reset timing

Data Sheet Rev. 1.7 7 2003-06-02

V

f

OSC

f

OSC

t

CYL

R

1.4 V RR = 100kΩ

85 95 105 kHz Tj = 25°C

75 115 kHz

1mst

CYL

f

OSC

= 100 /

TLE 6365

1.6 Electrical Characteristics (cont’d)

8V<

V

< 35V; 4.75V< VCC<5.25V; - 40°C< Tj<150°C; RR=47kΩ;

S

all voltages with respect to ground; positive current defined flowing into the pin; unless otherwise specified

No. Parameter Symbol Limit Values Unit Test

min. typ. max

.

1.6.6 Reset Generator; RO

Condition

1.6.6.1 Reset threshold;

V

decreasing

CC

V

1.6.6.2 Reset low voltage V

1.6.6.3 Reset low voltage V

1.6.6.4 Reset high voltage V

1.6.6.5 Reset pull up curent I

1.6.6.6 Reset Reaction time

t

RT

ROL

ROL

ROH

RO

RR

4.50 4.65 4.75 V VRO H to L

or L to H

transition;

V

remains

RO

low down to

V

>1V

CC

-0.20.4VI

-0.20.4VI

=1mA;

ROL

2.5V < V

< V

RT

=0.2mA

ROL

CC

;

V

CC

-0.1

V

CC

+0.1

1V < V

V

RT

VI

ROH

<

CC

= 0mA

240 µΑ 0V < VRO<

4V

10 40 90 µs V

CC

< V

RT

1.6.6.7 Power-up reset delay time t

RD

128 t

CYL

VCC ≥ 4.8 V

1.6.7 Thermal Shutdown (Boost and Buck-Converter OFF)

1.6.7.1 Thermal shutdown junction

T

jSD

150 175 200 ° C

temperature

1.6.7.2 Thermal switch-on junction

T

jSO

120 170 °C

temperature

1.6.7.3 Temperature hysteresis ∆

Data Sheet Rev. 1.7 8 2003-06-02

T 30 K

TLE 6365

2 Circuit Description

Below some important sections of the TLE 6365 are described in more detail.

Power On Reset

In order to avoid any system failure, a sequence of several conditions has to be passed.

V

In case of

pin RO to reset an external microcontroller. When the level of

threshold

before switching to HIGH. If VCC drops below the reset threshold VRT for a time extending

the reset reaction time

period

t

RD

“glitches” on the

power down (VCC < VRT for t > tRR) a logic LOW signal is generated at the

CC

V

reaches the reset

CC

V

, the signal at RO remains LOW for the Power-up reset delay time t

RT

t

, the reset circuit is activated and a power down sequence of

RR

RD

is initiated. The reset reaction time tRR avoids wrong triggering caused by short

V

-line.

CC

< t

V

CC

RO

V

PG

V

RT

H

L

typ.4,70V

typ.4,65V

1V

invalid

ON DelayStart Up

t

RD

RR

t

RR

< t

RD

ON Delay

started stopped

Power Sart-Up Normal NormalFailed N Failed

Figure 3 Reset Function

ON Delay

t

invalidinvalid

t

RD

t

Data Sheet Rev. 1.7 9 2003-06-02

TLE 6365

Buck Converter

A stabilized logic supply voltage (typ. 5 V) for general purpose is realized in the system

L

by a buck converter. An external buck-inductance

DMOS power transistor with the programmed frequency (pin R).

The buck converter uses the temperature compensated bandgap reference voltage

(typ. 2.8 V) for its regulation loop.

This reference voltage is connected to the non-inverting input of the error amplifier and

an internal voltage divider supplies the inverting input. Therefore the output voltage

is fixed due to the internal resistor ratio to typ. 5.0 V.

The output of the error amplifier goes to the inverting input of the PWM comparator as

well as to the buck compensation output BUC.

When the error amplifier output voltage exceeds the sawtooth voltage the output power

MOS-transistor is switched on. So the duration of the output transistor conduction phase

depends on the

V

level. A logic signal PWM with variable pulse width is generated.

CC

is PWM switched by a high side

BU

V

CC

+

OV

H when

COMP

OV at V

>175°C

j

ClockRamp

CC

L when

Overcurrent

Output Stage OFF when H

ERROR-FF

R

&

S

&

-

V

thOV

1,2V

GND

H when

Error-Signal

-

<

PWM

Error-Ramp

COMP

+

L when

T

t

t

t

r

r

f

Q

OFF when H

Q

H when UV

at V

BUC

Pin 3

V

Pin 5

Pin 1

V

CC

R

VCC3

39R7

R

VCC4

R

Prot1

200

Ω

-

Error

CC

V

CC

R

VCC1

22R

R

VCC2

28R

GND

V

max

R

V

min

AMP

+

V

REF

2,8V

GND

Oscillator Schmitt-trigger 1

t

t

t

f

r

r

10R3

GND

Error-Ramp

V

high

V

low

t

t

Figure 4 Buck Converter Block Diagram

BOOST

NOR1

NOR 1

>1

UV

COMP

-

+

GND

NAND 2

&

COMP

H=

ON

OC

Gate

Driver

-

+

Gate

Driver

Supply

V

thOC

18mV

L when

PWM-FFError-Signal

&

&

Q

Q

Overcurrent

H=

OFF

INV

1

V

thUV

4V

R

S

R

Sense

18m

Ω

Power

D-MOS

V

Pin 8

BDS

Pin 6

BUO

Pin 7

S

External loop compensation is required for converter stability, and is formed by

connecting a compensation resistor-capacitor series-network (

R

BUC

, C

) between pin

BUC

BUC and GND.

Data Sheet Rev. 1.7 10 2003-06-02

TLE 6365

In the case of overload or short-circuit at VCC (the output current exceeds the buck

overcurrent threshold

overcurrent comparator immediately.

I

) the DMOS output transistor is switched off by the

BUOC

In order to protect the

V

input as well as the external load against catastrophic failures,

CC

an overvoltage protection is provided which switches off the output transistor as soon as

the voltage at pin

V

CCOVOFF

= typ. 6.0 V.

V

exceeds the internal fixed overvoltage threshold

CC

Also a battery undervoltage protection is implemented in the TLE 6365 to avoid wrong

operation of the following supplied devices, the typical threshold when decreasing the

battery voltage is at

V

SUVOFF

=typ. 4.0V.

Data Sheet Rev. 1.7 11 2003-06-02

V

O

and

V

Error

V

V

TLE 6365

Error Voltage

max

min

OCLK

H

L

PWM

H

L

I

BUO

I

BUOC

I

DBU

V

BUO

V

S

V

CC

t

t

t

t

t

t

Overcurrent Threshold Exceeded

Controlled by theLoad-Current Increasing with Time;

Overcurrent CompControlled by the Error Amp

AED02673

Figure 5 Most Important Waveforms of the Buck Converter Circuit

Data Sheet Rev. 1.7 12 2003-06-02

3 Application circui

t

D

1

TLE 6365

V

Batt

C

L

10uF 220nF

ZD

36V

1

Biasing and V

R

CO

47k

C

CO

470nF

R

R

100k

BUC

3

TLE 6365 G

R

1

Buck

Converter

Reference

Current

Generator

and

Oscillator

V

8

REF

C

S

S

V

internal

Undervoltage

Reset

Generator

BDS

6

C

BOT

10nF

L

BUO

7

D

BU

V

CC

5

RO

2

BU

220uH

C

BU1

100uF

C

BU2

220nF

V

CC

Reset

output

Device Type

D

1

D

BU

L

BU

L

BU

B82476-A1224-M Epcos 220µH; 0.8A; 0.53

DO3316P-224 Coilcraft 220µH; 0.8A; 0.61

Figure 6 Application Circuit

4

GND

BAW78C

SS14 Schottky; 100V; 1A-

Supplier Remarks

200V; 1A; SOT89Infineon

Ω

Ω

Data Sheet Rev. 1.7 13 2003-06-02

TLE 6365

4 Diagrams: Oscillator and Boost/Buck-Converter Performance

In the following the behaviour of the Boost/Buck-converter and the oscillator is shown.

Efficiency Buck vs.

Boost Voltage

95

%

η

90

85

80

75

70

65

5

15 25 V 30

V

I

CC

Load

AED03017

= 5 V

= 120 mA

80 mA

40 mA

V

Oscillator Frequency Deviation vs.

Junction Temperature

OSC

AED03016

T

j

10

kHz

∆f

OSC

5

Referred to f

T

= 25 ˚C

at

j

0

-5

-10

-15

-50 -25 0 25 50 75 100 ˚C 150

S

Feedback Voltage vs.

Junction Temperature

5.15

V

V

CC

5.10

5.05

I

= 400 mA

BUO

5.00

4.95

4.90

4.85

4.80

-50-250 255075100 °C 150

Buck Overcurrent Threshold vs.

Junction Temperature

1.4

A

I

OC

1.3

1.2

1.1

(Buck-Converter)

1

I

BUOC

0.9

0.8

-50

-25 0 25 50 75 100 ˚C 150

T

j

AED03018

T

j

Data Sheet Rev. 1.7 14 2003-06-02

TLE 6365

Current Consumption vs.

Junction Temperature

3

mA

I

Boost

2.5

Boost ON

Buck ON

2

I

I

1.5

1

0.5

-50 -25 0 25 50 75 100 ˚C 150

BO boost

= 0 mA

CC

= 0 mA

AED02940

T

j

Oscillator Frequency vs.

Resistor between R and GNDr

1000

kHz

f

OSC

500

200

T

= 25 ˚C@

j

100

50

20

10

5

10 20 50 100 200 k 1000

AED02982

Ω

R

R

Efficiency Buck vs.

Load

90

%

η

85

RT, HT

80

75

70

65

50 150 250mA

CT

AED02942

I

LOAD

Buck ON Resistance vs.

Junction Temperature

1000

R

ON

m

Ω

800

700

600

500

400

R

@ I

300

200

100

0

-50 -25 0 25 50 75 100 °C 150

BUON

= 600 mA

BUO

T

j

Data Sheet Rev. 1.7 15 2003-06-02

5 Package Outlines

TLE 6365

Edition 6.99

Data Sheet Rev. 1.7 16 2003-06-02

TLE 6365

Published by Infineon Technologies AG i. Gr.,

Bereichs Kommunikation, St.-Martin-Strasse 53

D-81541 München

© Infineon Technologies AG1999

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as warranted characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement, regarding circuits, descriptions and

charts stated herein.

Infineon Technologiesis an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest Infineon Technologies Office

in Germany or our Infineon Technologies Representatives worldwide (see address list).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in question please contact

your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure of that life-support device or system, or to affect

the safety or effectiveness of that device or system. Life support devices or systems are intended to be implanted in the human body, or to

support and/or maintain and sustain and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other

persons may be endangered.

Data Sheet Rev. 1.7 17 2003-06-02

Loading...

Loading...