Page 1

Data Sheet Rev. 1.1

www.infineon.com 1 2019-04-04

TLE5014SP16 E0002

GMR-based Angle Sensor

Features

• Fast SSC interface up to 8MHz

• Giant Magneto Resistance (GMR)-based principle

• Integrated magnetic field sensing for angle measurement

• 360° angle measurement

• EEPROM for storage of configuration (e.g. zero angle) and customer

specific ID

• 15 bit representation of absolute angle value on the output

• Max. 1° angle error over lifetime and temperature range

• Developed according to ISO26262 with process complying to ASIL-D

• Internal safety mechanisms with a SPFM > 97%

• 32 point look-up table to correct for systematic angle errors (e.g. magnetic circuit)

• 112 bit customer ID (programmable)

• Automotive qualified Q100, Grade 1: -40°C to 125°C (ambient temperature)

•ESD: 4 kV (HBM) on V

• RoHS compliant and halogen free package

and 2kV (HBM) on output pins

DD

Functional Safety

Safety Manual and Safety Analysis Summary Report available on request

Product validation

Qualified for automotive applications. Product validation according to AEC-Q100.

Description

The TLE5014SP16 E0002 is an iGMR (integrated GMR) based angle sensor with a high speed serial interface

(SSC interface). It provides high accurate angular position information for various applications.

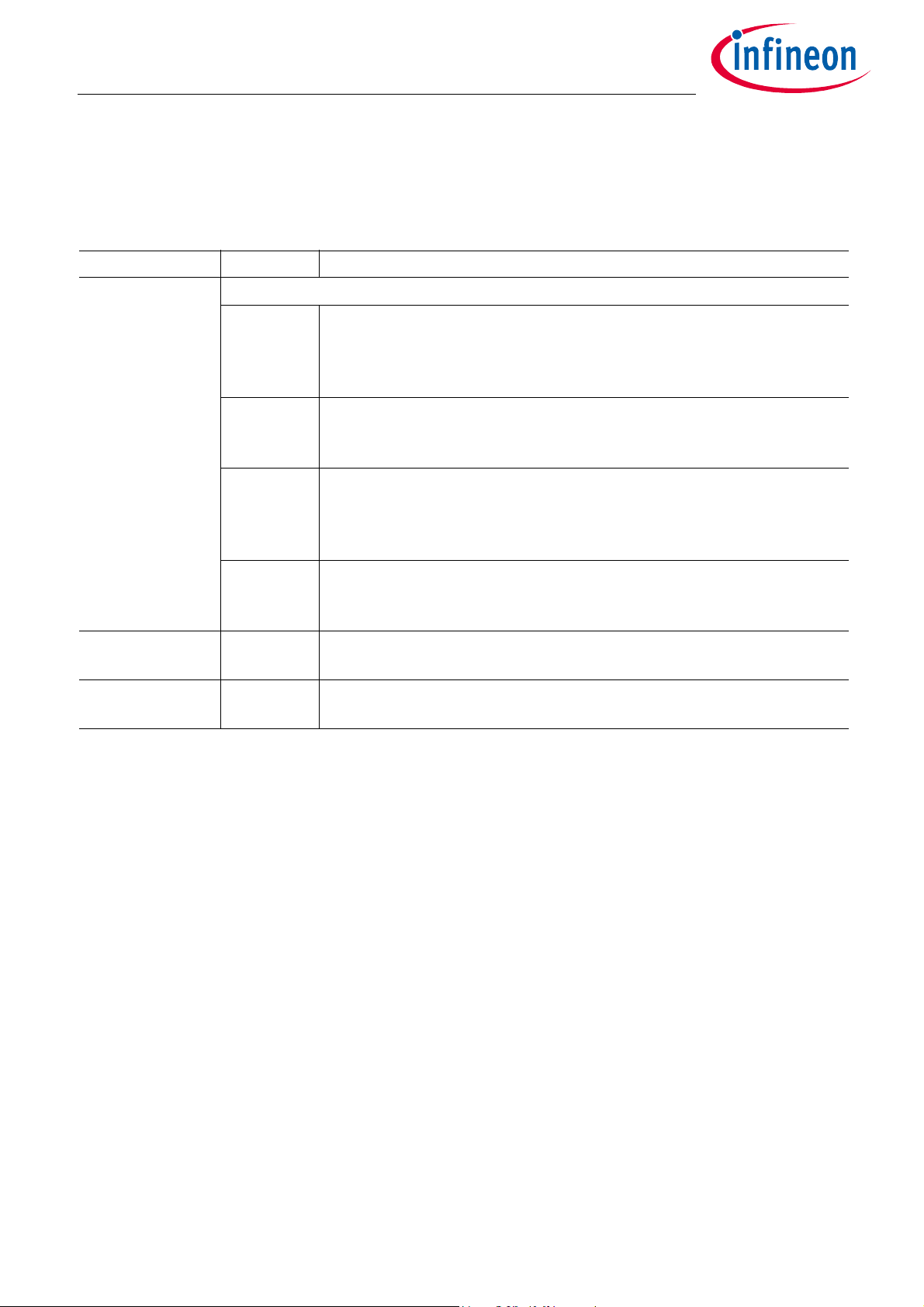

Table 1 Derivative Ordering codes

Product Type Marking Ordering Code Package Comment

TLE5014SP16 E0002 014SP02 SP004531446 PG-TDSO-16 SSC Interface, single die

Page 2

TLE5014SP16 E0002

GMR-based Angle Sensor

Table of contents

1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Functional Block Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Sensing Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Application Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3.1 Input/Output Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3.2 ESD Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.3 Angle Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 EEPROM Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5 Reset Concept and Fault Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.6 External & Internal Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.7 Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.8 Device Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Synchronous Serial Communication (SSC) interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Data transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.1 Bit Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.2 Update of update-registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.1 Command Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.2 Safety word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.3 Cyclic Redundancy Check (CRC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Package Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Package Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Package Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3 Footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.4 Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5 Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Data Sheet 2 Rev. 1.1

2019-04-04

Page 3

PMU Clock EEPROM

ADC_X Filter

ADC_Y Fil ter

GMR_X

GMR_Y

Temp. ADC_T

ISM_ALG

CORDIC

(Hardware)

SSC

Interface

ISM_SAF

CORDIC

(Software)

Interface

compare

TLE5014SP16 E0002

GMR-based Angle Sensor

Functional Description

1 Functional Description

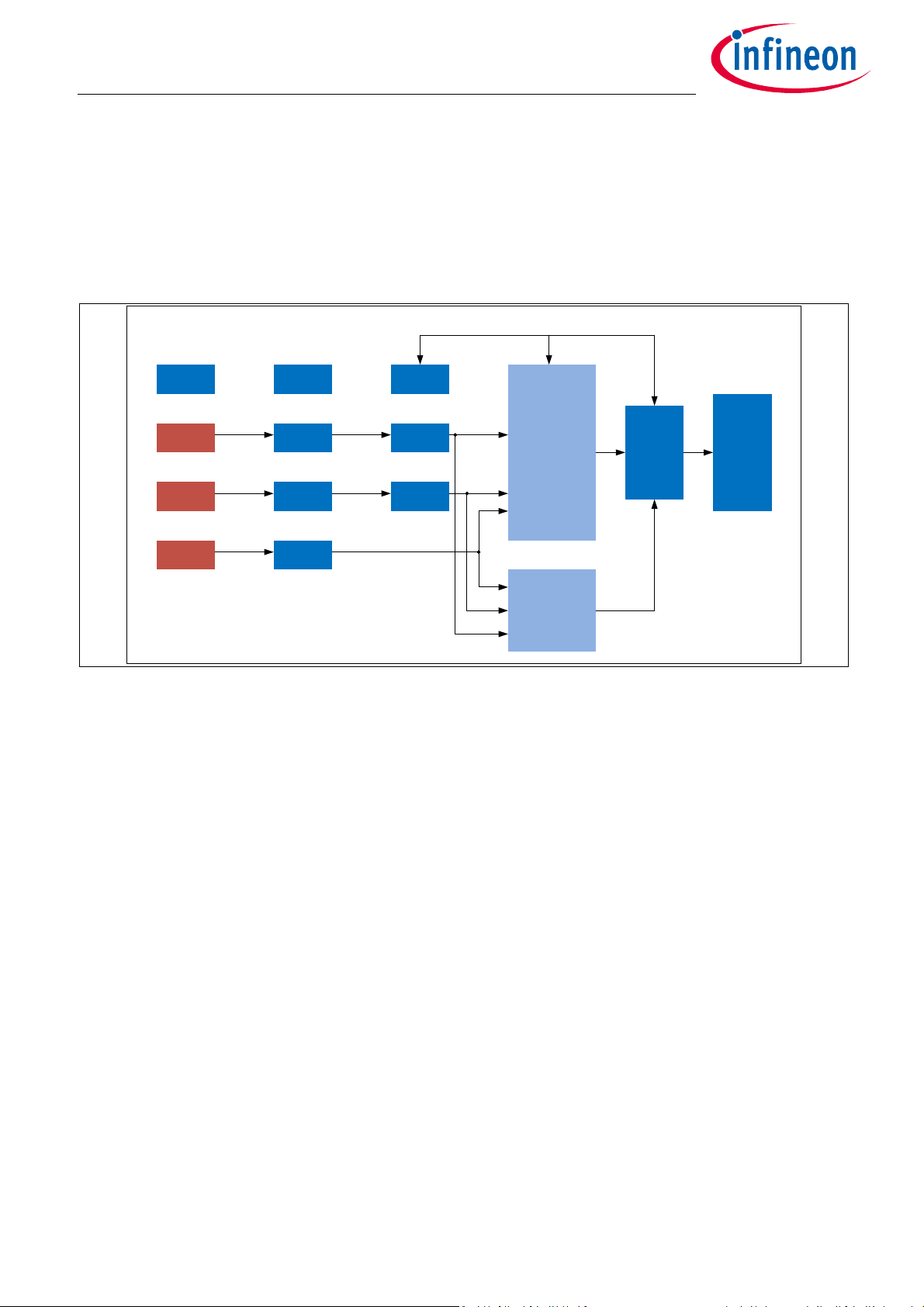

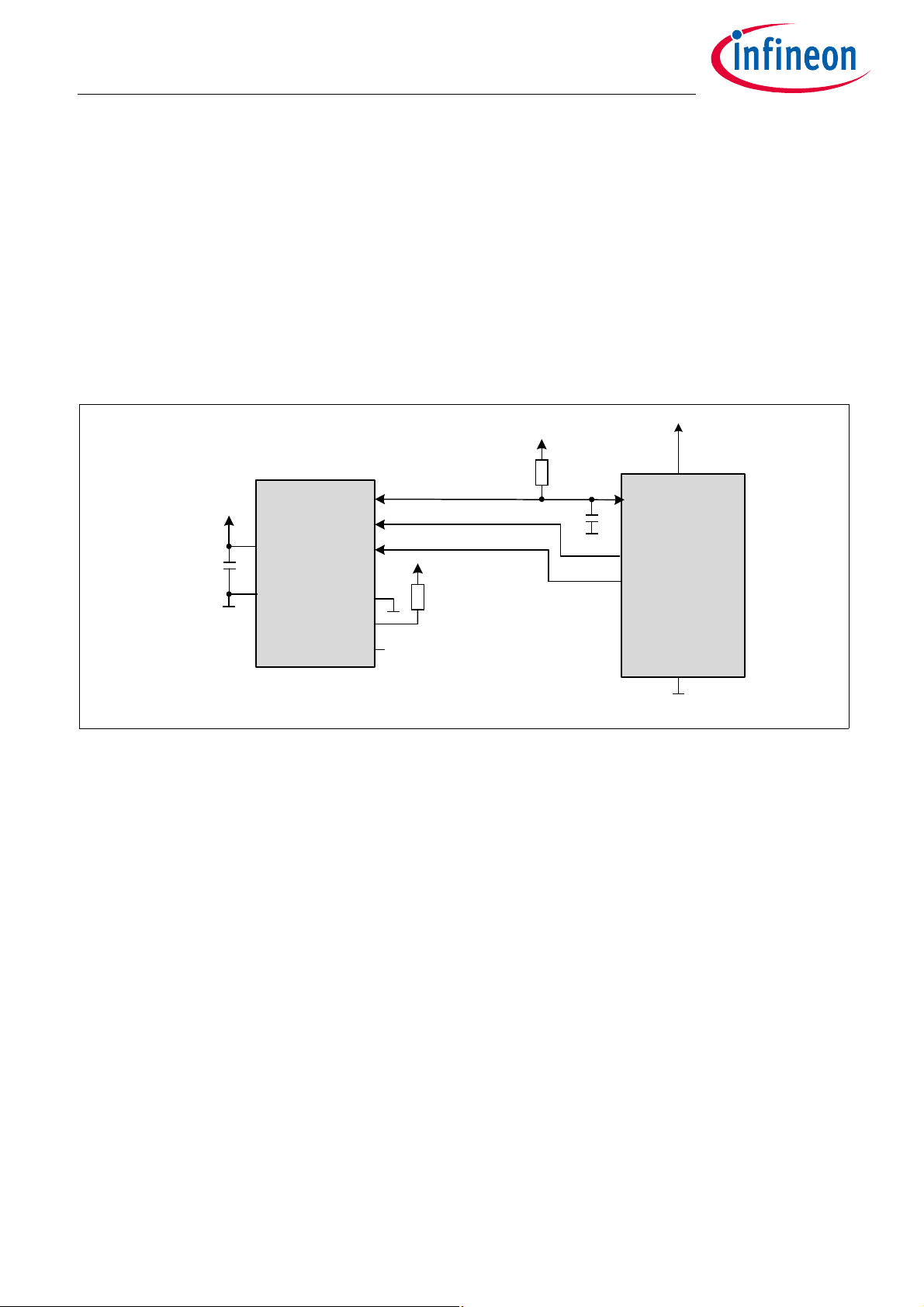

1.1 Block Diagram

Figure 1-1 TLE5014SP16 E0002 block diagram

1.2 Functional Block Description

Internal Power Supply (PMU)

The internal blocks of the TLE5014SP16 E0002 are supplied from several voltage regulators:

• GMR Voltage Regulator, VRS

• Analog Voltage Regulator, VRA

• Digital Voltage Regulator, VRD

These regulators are directly connected to the supply voltage VDD.

Oscillator and PLL (Clock)

The digital clock of the TLE5014SP16 E0002 is given by the Phase-Locked Loop (PLL), which is fed by an

internal oscillator.

SD-ADC

The Sigma-Delta Analog-Digital-Converters (SD-ADC) transform the analog GMR voltages and temperature

voltage into the digital domain.

Digital Signal Processing Unit ISM_ALG

The Digital Signal Processing Unit ISM_ALG contains the:

• Intelligent State Machine (ISM), which does error compensation of offset, offset temperature drift,

amplitude synchronicity and orthogonality of the raw signals from the GMR bridges.

• COordinate Rotation DIgital Computer (CORDIC), which contains the trigonometric function for angle

calculation

Data Sheet 3 Rev. 1.1

2019-04-04

Page 4

TLE5014SP16 E0002

GMR-based Angle Sensor

Functional Description

Digital Signal Processing Unit ISM_SAF

The Digital Signal Processing Unit ISM_SAF performs the internal safety mechanism and plausibility checks.

Furthermore, a second CORDIC algorithm is implemented in a diverse way as in the ISM_ALG. This is for cross

checking the angle calculation

Interface

The Interface block is used to generate the SSC signals

Angle Compare

This digital block compares the angle value calculated by ISM_ALG and ISM_SAF. In case they are not identical,

an error is indicated in the transmitted protocol.

EEPROM

The EEPROM contains the configuration and calibration parameters. A part of the EEPROM can be accessed by

the customer for application specific configuration of the device. Programming of the EEPROM is achieved

with the SSC interface. Programming mode can be accessed directly after power-up of the IC.

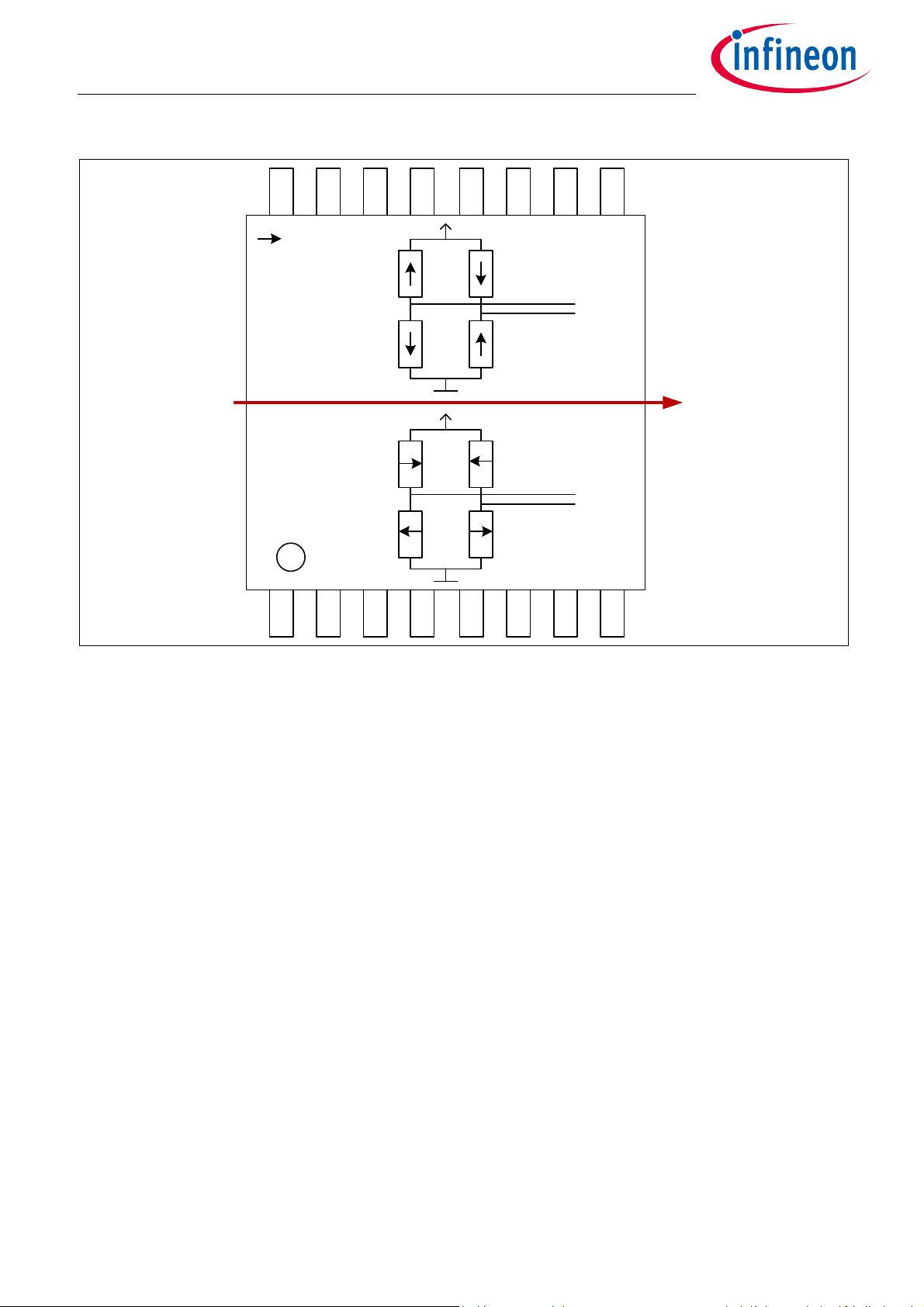

1.3 Sensing Principle

The Giant Magneto Resistance (GMR) sensor is implemented using vertical integration. This means that the

GMR-sensitive areas are integrated above the logic part of the TLE5014SP16 E0002 device. These GMR

elements change their resistance depending on the direction of the magnetic field.

Four individual GMR elements are connected to one Wheatstone sensor bridge. These GMR elements sense

one of two components of the applied magnetic field:

•X component, V

•Y component, V

With this full-bridge structure the maximum GMR signal is available and temperature effects cancel out each

other.

(cosine) or the

x

(sine)

y

Data Sheet 4 Rev. 1.1

2019-04-04

Page 5

0°

10111213141516

1

9

87654321

Reference Direction:

Resist anc e low when

external magnetic field is

in this direction

Y

X

TLE5014SP16 E0002

GMR-based Angle Sensor

Functional Description

Figure 1-2 Sensitive bridges of the GMR sensor (not to scale)

In Figure 1-2 the arrows in the resistors represent the magnetic direction which is fixed in the reference layer.

If the external magnetic field is parallel to the direction of the Reference Layer, the resistance is minimal. If

they are anti-parallel, resistance is maximal.

The output signal of each bridge is only unambiguous over 180° between two maxima. Therefore two bridges

are oriented orthogonally to each other to measure 360°.

With the trigonometric function ARCTAN2, the true 360° angle value is calculated out of the raw X and Y signals

from the sensor bridges.

Data Sheet 5 Rev. 1.1

2019-04-04

Page 6

10111213141516

1

9

87654321

Center of

Sensitive area

TLE5014SP16 E0002

GMR-based Angle Sensor

Functional Description

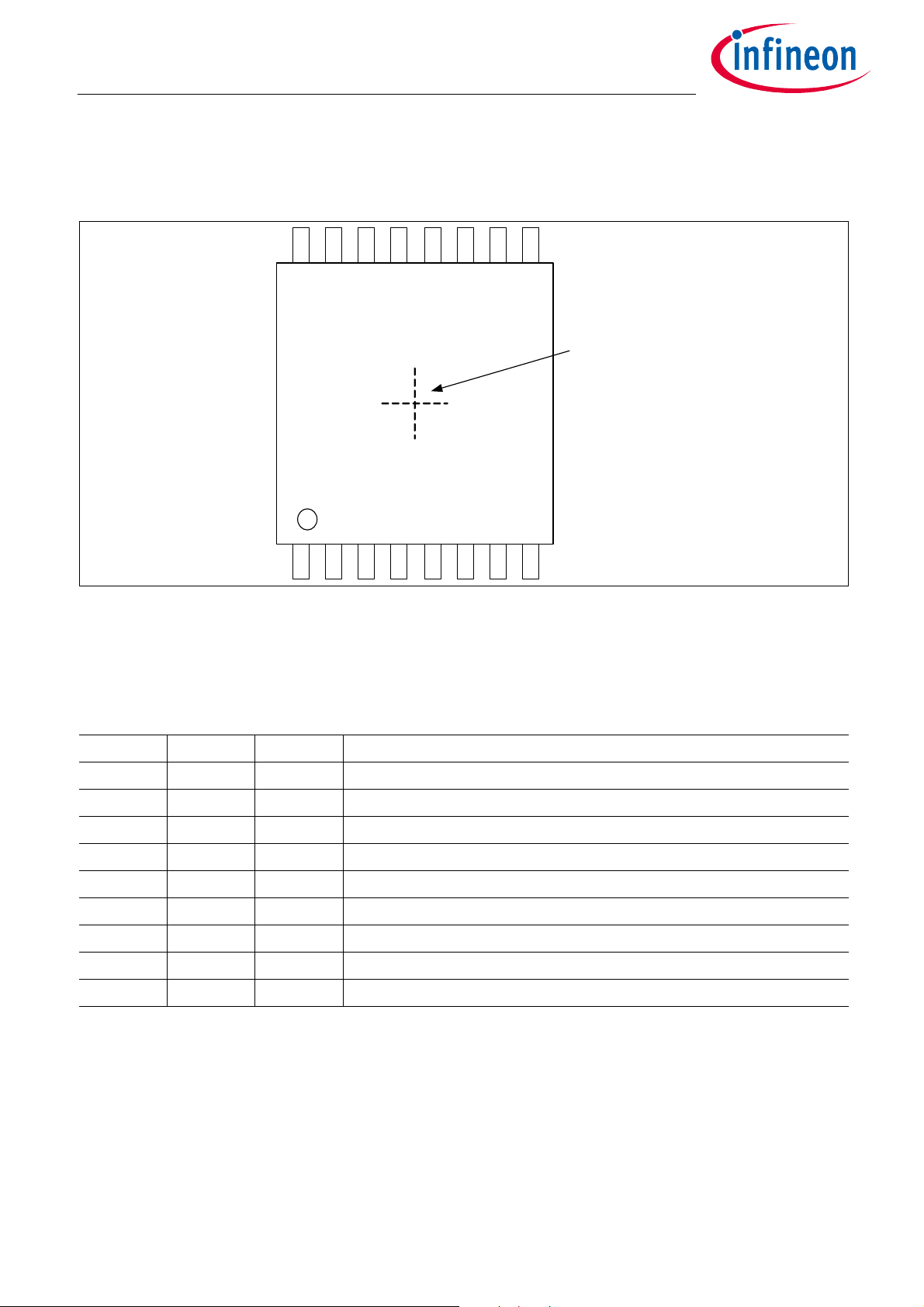

1.4 Pin Configuration

Figure 1-3 Pin configuration (top view)

1.5 Pin Description

The following Table 1-1 describes the pin-out of the chip.

Table 1-1 Pin description TLE5014SP16

Pin Symbol In/Out Function

1 IF1 I/O DATA (MOSI/MISO)

2 IF2 I SCK (SSC clock)

3 IF3 I CSQ (chip select)

4 VDD – Supply voltage, positive

5 GND – Supply voltage, ground

6 IFA – Connect to GND

7 IFB – Connect via pull-up to V

8 IFC – Keep open

9-16 - – n.c.

DD

Data Sheet 6 Rev. 1.1

2019-04-04

Page 7

µController

Master

TLE501 4

GND

10 0nF

V

DD

GND

IF1

IF2

IF3

IFA

IFB

IFC

V

µC

2.2k

50k

C

D

R

PU

R

P1

SC K

MOSI/MISO

CSQ

GND

C

L

V

DD

V

DD

V

DD

TLE5014SP16 E0002

GMR-based Angle Sensor

Application Circuits

2 Application Circuits

The application circuit in this chapter shows the communication possibilities of the TLE5014SP16 E0002. To

improve robustness against electro-magnetic disturbances, a capacitor of 100nF on the supply is

recommended. This capacitor shall be placed as close as possible to the corresponding sensor pins. The load

capacitor C

but the driver is switched off once reaching the HIGH state. Therefore, a pull-up resistor is recommended to

maintain a stable HIGH level.

In case of a high speed communication, an additional serial resistor in the range of 140Ω can be implemented

in the DATA, SCK and CSQ line to avoid reflections and enhance communication reliability. In this case the user

is responsible to verify that the intended communication speed can be reached in his specific setup.

shall not exceed the specified value (Table 3-5). The DATA line is actively driven to HIGH and LOW

L

Figure 2-1 Application circuit for TLE5014SP16 E0002 with SSC interface, microcontroller switches pin

between MISO and MOSI

Data Sheet 7 Rev. 1.1

2019-04-04

Page 8

TLE5014SP16 E0002

GMR-based Angle Sensor

Specification

3 Specification

3.1 Absolute Maximum Ratings

Stresses above the max. values listed here may cause permanent damage to the device. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability. Maximum ratings are absolute

ratings; exceeding only one of these values may cause irreversible damage to the device.

Table 3-1 Maximum Ratings for Voltages and Output Current

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

Absolute maximum supply

voltage

Voltage Peaks V

Absolute maximum voltage

V

DD

DD

V

IF

-18 26 V for 40h, no damage of device;

-18V means V

< GND

DD

30 V for 50µs, no current limitation

-0.3 6 V no damage of device

for pin IF1, IF2, IF3

Absolute maximum voltage

V

IO

for pin IFB

Voltage Peaks (for pin IFB) V

IO

Table 3-2 Maximum Temperature and Magnetic Field

-18 19.5 V for 40h; no damage of device,

-18V means V

< GND

DD

30 V for 50µs, no current limitation

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

Maximum ambient

T

A

-40 125 °C Q100, Grade 1

temperature

Maximum allowed magnetic

B 200 mT max 5 min @ T

= 25°C

A

field

Maximum allowed magnetic

B 150 mT max 5 h @ T

= 25°C

A

field

Storage & Shipment

1) 2)

T

storage

5 40 °C for dry packed devices,

Relative humidity < 90%,

storage time < 3a

1) Air-conditioning of ware houses, distribution centres etc. is not necessary, if the combination of the specified limits

of 75% R.H. and 40 °C will not be exceeded during storage for more than 10 events per year, irrespective of the

duration per event, and one of the specified limits (75 % R.H. or 40 °C) will not be exceeded for longer than 30 days

per year

2) See Infineon Application Note: “Storage of Products Supplied by Infineon Technologies”

Table 3-3 Mission Profile

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

Mission Profile T

Data Sheet 8 Rev. 1.1

A,max

125 °C for 2000h

2019-04-04

Page 9

TLE5014SP16 E0002

GMR-based Angle Sensor

Specification

Table 3-4 Lifetime & Ignition Cycles

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

Operating life time t

op_life

15.000 h see Table 3-3 for mission

profile

Total life time t

Ignition cycles N

1) The lifetime shall be considered as an anticipation with regard to the product that shall not extend the warranty

period

tot_life

ignition

19 a additional 2a storage time

200.000 during operating lifetime t

The device qualification is done according to AEC Q100 Grade 1 for ambient temperature range -40°C < T

1)

op_life

<

A

125°C

3.2 Operating Range

The following operating conditions must not be exceeded in order to ensure correct operation of the angle

sensor. All parameters specified in the following sections refer to these operating conditions, unless otherwise

noted. Table 3-5 is valid for -40°C < T

Table 3-5 Operating Range

Parameter Symbol Values Unit Note / Test Condition

Operating supply voltage V

Supply Voltage Slew Rate V

Operating ambient

T

temperature

< 125°C unless otherwise noted.

A

Min. Typ. Max.

DD

DD_slew

A

3.0 5.5 V -

0.1 10

-40 125 °C -

8

V/s -

Angle speed n 30000 rpm -

Capacitive output load on

C

L

––50pF

SSC interface (DATA pin)

Magnetic Field Range

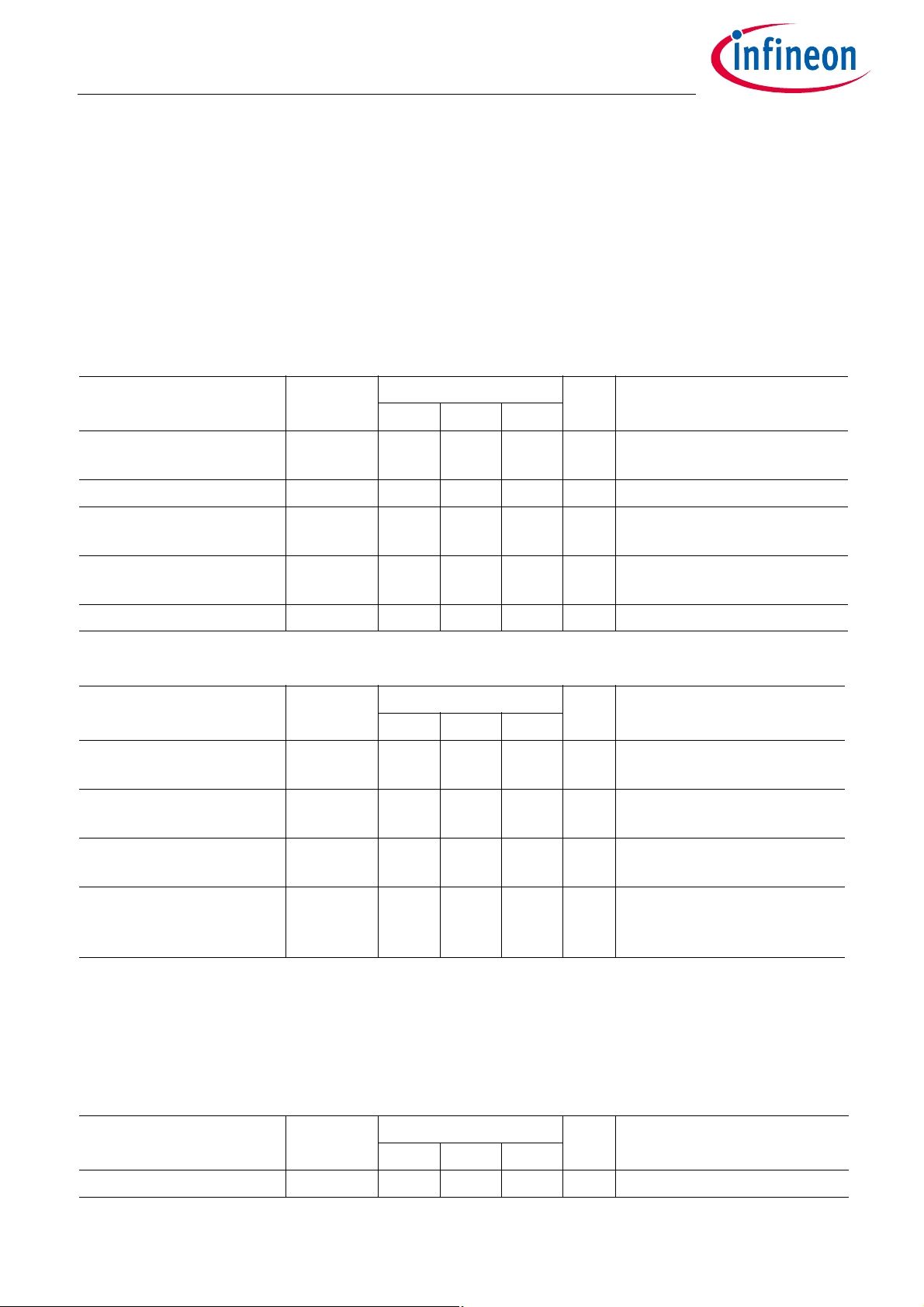

The operating range of the magnetic field describes the field values where the performance of the sensor,

especially the accuracy, is as specified in Table 3-11 and Table 3-12. This value is valid for a NdFeB magnet

with a Tc of -1300ppm/K. In case a different magnet is used, the individual Tc of this magnet has to be

considered and ensured that the limits are not exceeded. The allowed magnetic field range is given in

Figure 3-1.

Table 3-6 Magnetic Field Range

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

Angle measurement field

range @ 25°C

B25 80mTT

= 25°C, valid for NdFeB

A

magnet

The below figure Figure 3-1 shows the magnetic field range which shall not be exceeded during operation at

the respective ambient temperature. The temperature dependency of the magnetic field is based on a NdFeB

magnet with Tc = -1300ppm/K.

Data Sheet 9 Rev. 1.1

2019-04-04

Page 10

20

30

40

50

60

70

80

90

100

-50 -30 -10 10 30 50 70 90 110 130 150

magnetic field (mT)

Temperature (°C)

TLE5014SP16 E0002

GMR-based Angle Sensor

Specification

Figure 3-1 Allowed magnetic field range within operating ambient temperature range.

It is also possible to widen the magnetic field range for higher temperatures. In that case, additional angle

errors have to be considered.

Data Sheet 10 Rev. 1.1

2019-04-04

Page 11

TLE5014SP16 E0002

GMR-based Angle Sensor

Specification

3.3 Electrical Characteristics

3.3.1 Input/Output Characteristics

The indicated parameters apply to the full operating range, unless otherwise specified. The typical values

correspond to a supply voltage V

All other values correspond to -40°C < T

Table 3-7 Electrical Characteristics

Parameter Symbol Values Unit Note / Test Condition

= 5.0V and an ambient temperature TA = 25°C, unless individually specified.

DD

< 125°C.

A

Min. Typ. Max.

Operating Supply Current I

Time between supply voltage

t

DD

Pon

12 15 mA -

7ms

reaches reset value and valid

angle value is available on the

output (without interface

delay

Overvoltage detection on V

DDVOV

– 6.5 7.0 V In an overvoltage condition

the output switches to tristate

Undervoltage detection on V

DDVUV

Internal clock tolerance Δf

clock

2.3 2.5 2.7 V In an undervoltage condition

the sensor performs a reset

-5 5 % including temperature and

lifetime

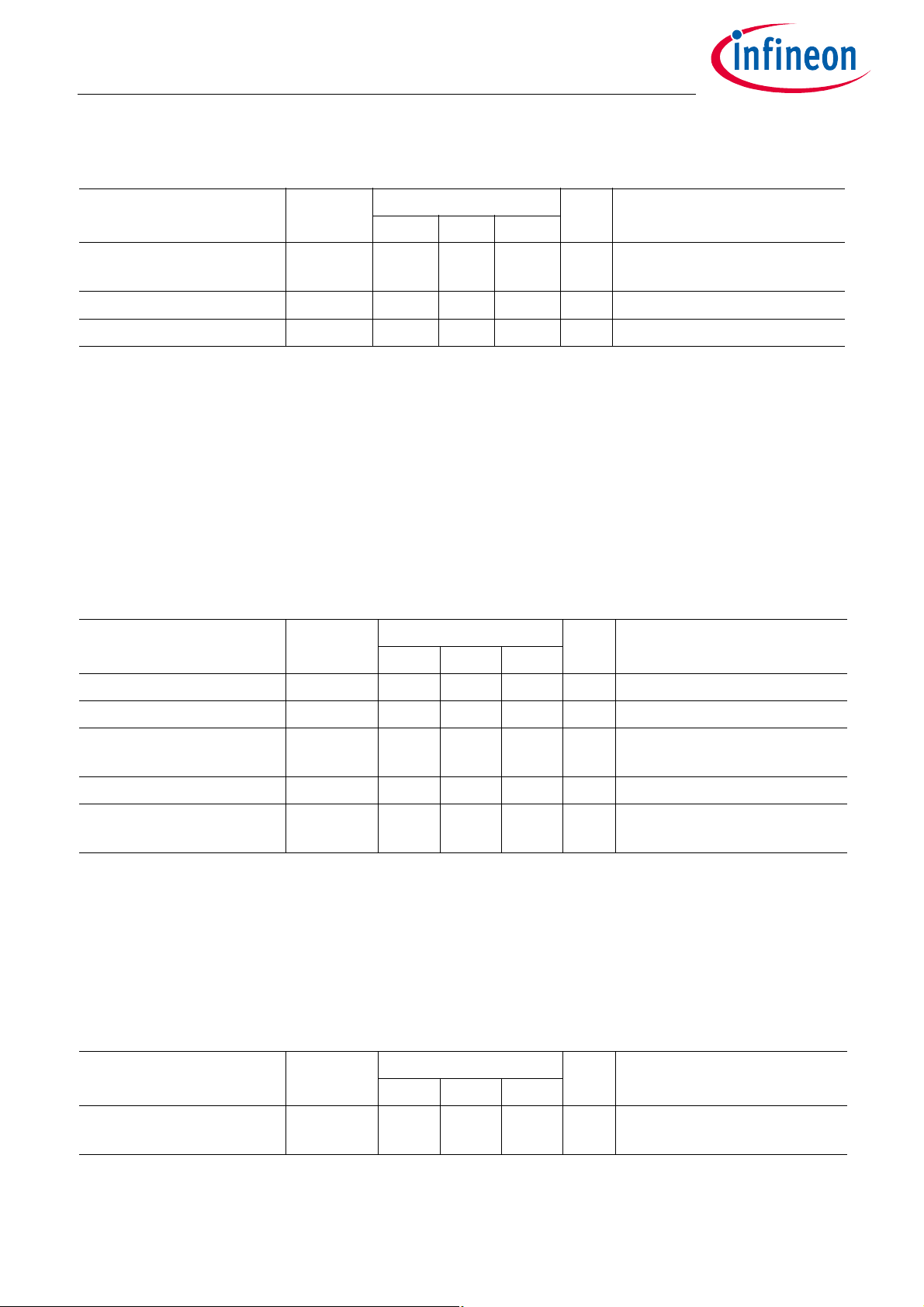

The following Figure 3-2 shows the operating area of the device, the condition for overvoltage and

undervoltage and the corresponding sensor reaction. The values for the over- and undervoltage comparators

are the typical values from Table 3-7.

In the extended range, the sensor fulfills the full specification. However, voltages above the operating range

can only be applied for a limited time (see Table 3-1).

Data Sheet 11 Rev. 1.1

2019-04-04

Page 12

V_out

VDD

3.0 5.5

6.5

2.5

5.7

7.0

8.0

No output

Sensor

reset

No output

No output

Operating

range

Extended range

Extended range

V

OUT

t

V

DD

V

OH

V

OL

TLE5014SP16 E0002

GMR-based Angle Sensor

Specification

Figure 3-2 Operating area and sensor reaction for over- and undervoltage.

Table 3-8 Output driver

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

Output low level

Output high level

1) In case several sensors are connected in a bus mode, the output levels may be influenced and out of specification in

case a malfunction of one of the sensors on the bus occurs (e.g. one sensors has loss of V

1)

1)

V

OL

V

OH

0.7*V

DD

0.3*V

DD

DD

).

Figure 3-3 Output level high / low

Output Delay Time and Jitter

Data Sheet 12 Rev. 1.1

2019-04-04

Page 13

α

1

α

2

calculate α

1

calculate α2calculate α

3

X1; Y

1

X2; Y

2

X3; Y

3

X4; Y

4

α

1

α

3

α

2

α

4

t

ad el

t

de ljittde ljit

t

up dat e

t

angle

sin/cos raw

values filtering

angle

calculation

angle val ue

register

TLE5014SP16 E0002

GMR-based Angle Sensor

Specification

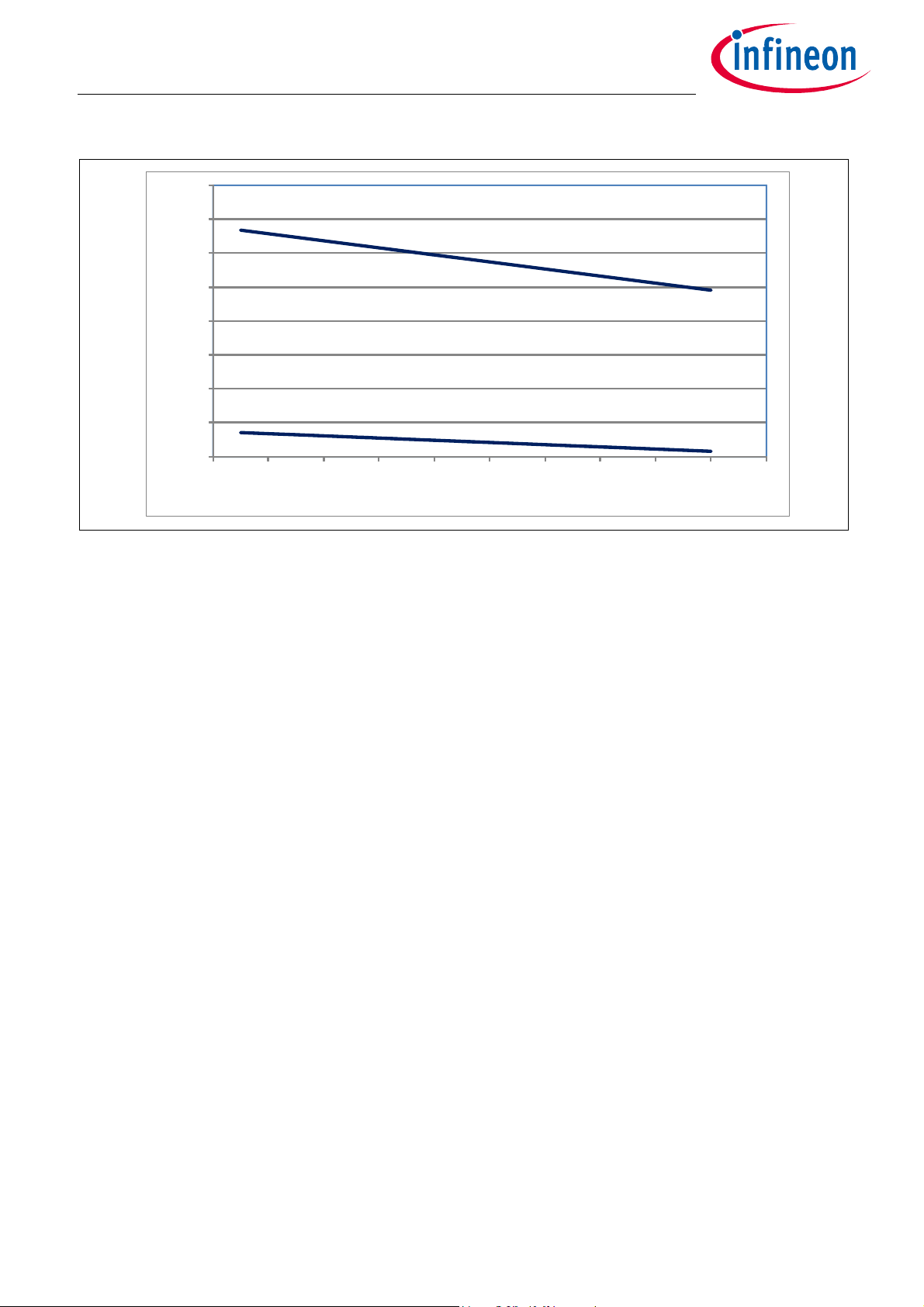

Due to the internal signal sampling and signal conditioning, there will be a delay of the provided angle value

at the output. The definition of this delay is described in below Figure 3-4

Table 3-9 Signal delay and delay time jitter

Parameter Symbol Values Unit Note /

Min. Typ. Max.

Test Condition

Delay time between real angle

and angle value available at the

AVAL register

Variation of delay time t

adel

t

adel

t

deljit

60.8 64 67.2 µs Min/max values

include clock

tolerance

+/-12.0 +/-12.8 +/-14.0 µs Min/max values

include clock

tolerance

Angle update rate

t

update

(new angle value is provided in

the AVAL register)

The sensor calculates a new angle value every t

24.3 25.6 27.0 µs Min/max values

include clock

tolerance

. The delay time (latency) of the angle value is determined

update

by the time needed for the sampling of the sin/cos raw signals and angle calculation. The calculated angle is

then transferred into the corresponding SSC register. This register is updated every t

. As the reading of

update

the angle value with the SSC interface is asynchronous to the internal angle update rate, a jitter on the delay

time of the angle value is introduced in the range of t

deljit

= +/- t

/2. Figure 3-4 shows this relation.

update

Figure 3-4 Definition of update rate t

Data Sheet 13 Rev. 1.1

, delay time t

update

and jitter of delay time t

adel

deljit

2019-04-04

Page 14

TLE5014SP16 E0002

GMR-based Angle Sensor

Specification

3.3.2 ESD Protection

Table 3-10 ESD Voltage

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

Electro-Static-Discharge

voltage (HBM), according to

ANSI/ESDA/JEDEC JS-001

Electro-Static-Discharge

voltage (HBM), according to

ANSI/ESDA/JEDEC JS-001

Electro-Static-Discharge

voltage (CDM), according to

JESD22-C101

V

V

V

HBM

HBM

CDM

±4 kV HBM contact discharge

for pins VDD, GND, IFB

±2 kV HBM contact discharge

for pins IF1, IF2, IF3, IFA, IFC

±0.5 kV for all pins except corner pins

±0.75 kV for corner pins only

Data Sheet 14 Rev. 1.1

2019-04-04

Page 15

TLE5014SP16 E0002

GMR-based Angle Sensor

Specification

3.3.3 Angle Performance

After internal angle calculation, the sensor has a remaining error, as shown in Table 3-11 for an ambient

temperature range up to 85°C and a reduced magnetic field range and in Table 3-12 for the ambient

temperature range up to 125°C and full magnetic operating range. The error value refers to B

The overall angle error represents the relative angle error. This error describes the deviation from the

reference line after zero-angle definition. It is valid for a static magnetic field.

If the magnetic field is rotating during the measurement, an additional propagation error is caused by the

angle delay time (see Table 3-9).

= 0mT.

Z

Table 3-11 Angle Error for -40°C < T

< 85°C and magnetic field range 33mT < B < 50mT

A

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

Accuracy

1)

over temperature

A

Err,T

0.8 ° 0h2), over temperature

w/o look-up table

Accuracy1) over temperature

and lifetime,

A

Err,s

0.9 ° lifetime stress:

T

=85°C/1000h/50mT

A

w/o look-up table

1)3)

Accuracy

over

temperature and lifetime,

with look-up table

Hysteresis

1) Hysteresis and noise are included in the angle accuracy specification

2) “0h” is the condition when the part leaves the production at Infineon

3) Verified by characterization

4) Hysteresis is the maximum difference of the angle value for forward and backward rotation

4)

Table 3-12 Angle Error for -40°C < T

A

Err,sLUT

A

Hyst

< 125°C

A

0.65 ° lifetime stress:

T

=85°C/1000h/50mT

A

with look-up table correction

0.1 0.16 ° value includes quantization

error

Parameter Symbol Values Unit Note / Test Condition

Min. Typ. Max.

Accuracy

w/o look-up table

Accuracy1) over temperature

and lifetime,

1)

over temperature

A

A

Err,T

Err,s

0.8 ° 0h2), over temperature

B = 33mT to 80mT

3)

1.0 ° 33mT…80mT3)

lifetime stress: T

=125°C/2000h

A

w/o look-up table

1)4)

Accuracy

over

temperature and lifetime,

with look-up table

Hysteresis

5)

A

Err,sLUT

A

Hyst

0.85 ° B = 33mT to 80mT3),

lifetime stress: T

=125°C/2000h

A

with look-up table correction

0.1 0.16 ° B = 33mT to 80mT6), value

includes quantization error

1) Hysteresis and noise are included in the angle accuracy specification

2) “0h” is the condition when the part leaves the production at Infineon

3) For the magnetic field range of 25mT < B < 33mT, 0.2° have to be added to the max. angle accuracy

4) Verified by characterization

5) Hysteresis is the maximum difference of the angle value for forward and backward rotation

Data Sheet 15 Rev. 1.1

2019-04-04

Page 16

TLE5014SP16 E0002

GMR-based Angle Sensor

Specification

6) For the magnetic field range of 25mT < B < 33mT, 0.1° have to be added to the max. hysteresis A

Hyst

3.4 EEPROM Memory

The sensor includes a non-volatile memory (NVM) where calibration data and sensor configuration data are

stored. The customer has access to a part of this memory for storage of application specific data (e.g. look-up

table & customer ID)

The time for programming the customer relevant part of the NVM as well as maximum cycles of programming

and data retention is given in Table 3-13

Table 3-13 EEPROM

Parameter Symbol Values Unit Note /

Test Condition

lifetime and 2a

storage

table,

configuration,

customer ID;

with 100kbit/s

Number of possible NVM

programming cycles

NVM data retention t

Time for programming of

whole NVM (customer

relevant part)

n

Prog

retention

t

Prog

Min. Typ. Max.

100 -

- 21 a includes 19a

0.5 s incl. look-up

Number

3.5 Reset Concept and Fault Monitoring

Some internal and external faults of the device can trigger a reset. During this reset, all output pins are highohmic to avoid any disturbance of other sensors which may be connected together in a bus mode. A reset is

indicated as soon as the sensor is back at operational mode either by a status bit.

3.6 External & Internal Faults

In case of an occurrence of external or internal faults, as for example overvoltage or undervoltage, the sensor

reacts in a way that these faults are indicated to the customer.

The error signaling (safe state) is defined as:

• indication of an error (e.g. status bit)

• detectable wrong output (e.g. CRC failure)

• no output

All errors are indicated as long as they persist, but at least once. After disappearance of the error, the error

indication is also cleared. The error is signaled and communicated to the ECU latest after 5ms from occurrence

of the fault. To achieve this, it has to be ensured that the protocol transmission time is not exceeding 1ms.

Otherwise, the fault tolerant time interval is increased above 5ms.

Overvoltage, undervoltage

It is ensured, that the sensor provides a valid output value as long as the voltage is within the operating range

or no under- or overvoltage is indicated. At occurrence of an undervoltage, the sensor performs a reset. The

implemented undervoltage comparator at V

detects an undervoltage at ~2.5V (typ. value). At occurrence of

DD

Data Sheet 16 Rev. 1.1

2019-04-04

Page 17

TLE5014SP16 E0002

GMR-based Angle Sensor

Specification

an overvoltage, the sensor output goes to tristate and no protocol is transmitted. The implemented

overvoltage comparator at V

Open and Shorts

detects an overvoltage at ~6.5V (typ. value).

DD

All pins of the device withstand a short to ground (GND) and a short to V

range). In case of an open V

which is considered as a safe state.

It is also ensured that a short between two neighboring pins leads to a detectable wrong output signal.

Communication Failures

An external fault can happen where an ongoing communication is interrupted before it is finished correctly. In

such an event, no sensor malfunction or dead-lock will occur.

connection or an open GND the sensor provides a detectable wrong signal,

DD

(as long as VDD is within the operating

DD

3.7 Power Dissipation

Following table describes the calculated power dissipation for the different application cases within the

operating range defined in Table 3-5. It is a worst case assumption with the maximum values within the

operating range.

Table 3-14 Power Dissipation

Scenario Configuration V

1 SSC 3.3 15 ~0 49.5

2 SSC 5.5 15 ~0 82.8

(V) IDD (mA) V

DD

(V) I

OUT

(mA) P (mW)

OUT

3.8 Device Programming

It is possible to do the programming of the EEPROM with the SSC interface. The programming mode can be

accessed directly after start-up of the IC by sending the appropriate command.

Following parameters can be programmed and stored in the EEPROM:

• Zero angle (angle base)

• Rotation direction (clock wise or counter clock wise)

• Look-up table (32 points)

• Customer ID (112bit individual data)

To align the angle output of the sensor with the application specific required zero angle direction this value

can be programmed. All further output angles are in reference to this zero angle.

Look-Up Table

To increase the accuracy of the provided angle value, a look-up table is implemented which allows to

compensate for external angle errors which may be introduced for example by the magnetic circuit. Alignment

tolerances (eccentricity or tilt) may lead to a non-linearity of the output signal which can be compensated

using the implemented look-up table. This look-up table has 32 equidistant points over 360° angle range with

a linear interpolation between the 32 defined values

Further details for programming and configuration of the device can be found in the corresponding user

manual of the TLE5014.

Data Sheet 17 Rev. 1.1

2019-04-04

Page 18

SCK

DATA 811 10 9MSB 14 13 12

CSQ

SSC Tran sfer

LSB3217 6 5 4

Com mand W ord

Data Wor d (s )

SSC -Mas ter is dri ving D AT A

SSC -Slav e is dri ving D AT A

LSB1

RW ADDR LENCMD

MSB

t

wr_delay

PRT Y ACCESS

TLE5014SP16 E0002

GMR-based Angle Sensor

Synchronous Serial Communication (SSC) interface

4 Synchronous Serial Communication (SSC) interface

The SSC interface is a half-duplex communication protocol. The communication is always initiated by the

microcontroller by sending a command to the TLE5014SP16 E0002. The command can be either a Read access

(Figure 4-3) or a Write access (Figure 4-4). According to the command, the microcontroller can either send a

data word to the TLE5014SP16 E0002 (Write access) or receive data word from the TLE5014SP16 E0002 (Read

access). At the end of the communication the TLE5014SP16 E0002 sends a safety word.

The 3-pin SSC Interface is composed of:

• DATA: Bidirectional data line. Data bits are sent synchronously with the clock line.

• SCK: Unidirectional clock line. Generated by the microcontroller, TLE5014SP16 E0002 is always a slave.

• CSQ: Chip select, active low. Asserted by the microcontroller to select a slave.

4.1 Data transmission

The data communication via SSC interface has the following characteristic:

• The SSC Interface is word-aligned. All functions are activated after each transmitted word.

• The microcontroller selects a TLE5014SP16 E0002 by asserting the CSQ to low. A “high” condition on the

negated Chip Select pin (CSQ) of the selected TLE5014SP16 E0002 interrupts the transfer immediately. The

CRC calculator is automatically reset.

• Data is put on the data line with the rising edge on SCK and read with the falling edge on SCK. Similar to a

SPI configuration with CPOL=0 and CPHA=1.

• After changing the data direction, a delay (t

transfer. This is necessary for internal register access.

) has to be considered before continuing the data

wr_delay

• After sending the Safety Word the transfer ends. To start another data transfer, the CSQ has to be

deselected once for t

CSoff

.

• The SSC is default Push-Pull. The Push-Pull driver is only active, if the TLE5014SP16 E0002 has to send data,

otherwise the Push-Pull is disabled for receiving data from the microcontroller.

Figure 4-1 SSC data transmission

4.1.1 Bit Numbering

The SSC communication is using the convention: Most Significant Bit (MSB) first. Figure 4-1 shows the

Command Word and the beginning of the Data Word to demonstrate the bit numbering.

4.1.2 Update of update-registers

At a rising edge of CSQ without a preceding data transfert (no SCK pulse), the content of all registers which

have an update buffer is saved into the buffer. The content of the update buffer can be read by sending a read

Data Sheet 18 Rev. 1.1

2019-04-04

Page 19

SCK

DATA

CSQ

LSB LSBMSB

Com mand Wor d Data Wor d (s )Update -Signal

Update -Event

SSC -Master is drivi ng DAT A

SSC -Slave is driving DAT A

t

CSupdate

TLE5014SP16 E0002

GMR-based Angle Sensor

Synchronous Serial Communication (SSC) interface

command for the desired register and setting the ACCESS bits of the Command Word to 11

This feature allows to take a snapshot of all necessary system parameters at the same time.

Figure 4-2 Update of update-registers

The types of functions used in the registers are listed here:

Table 4-1 Bit types

Abbreviation Function Description

R Read Read-only registers

.

B

W Write Read and write registers

U Update Update buffer for this bit is present. If an update is issued and the Update-

Register Access bits (ACCESS in Command Word) are set, the immediate

values are stored in this update buffer simultaneously. This enables a

snapshot of all necessary system parameters at the same time

Data Sheet 19 Rev. 1.1

2019-04-04

Page 20

COMMAND READ Data

SAFETY-WORD

SSC-Master is driving DATA

SSC-Slave is driving DATA

t

wr_delay

COMMAND WRITE Data

SAFETY-WORD

SSC-Master is driving DATA

SSC-Slave is driving DATA

t

wr_delay

TLE5014SP16 E0002

GMR-based Angle Sensor

Synchronous Serial Communication (SSC) interface

4.2 Data transfer

The SSC data transfer is word aligned. The following transfer words are possible:

• Command word (to access and change operating modes of the TLE5014SP16 E0002)

• Data words (any data transferred in any direction)

• Safety word (confirms the data transfer and provide status information)

Figure 4-3 SSC data transfer (data read example)

Figure 4-4 SSC data transfer (data write example)

4.2.1 Command Word

The TLE5014SP is controlled by a command word. It is sent first at every data transmission.The structure of

the command word is shown in Table 4-2.

Table 4-2 Structure of the command word

Name Bits Description

RW [15] Read - Write

0: Write

1: Read

PRTY [14] Command parity

Odd parity of all Command-Word-bits. Number of “1”s has to be odd

CMD [13] Set to 0

ACCESS [12:11] Access mode to registers

ADDR [10:4] 7-bit Address

LEN [3:0] Set to 1

Data Sheet 20 Rev. 1.1

00

11

B

: Direct access

B

: Update register; read-access

B

B

2019-04-04

Page 21

TLE5014SP16 E0002

GMR-based Angle Sensor

Synchronous Serial Communication (SSC) interface

4.2.2 Safety word

The safety word contains following bits:

Table 4-3 Structure of the safety word

Name Bits Description

STAT Chip and Interface Status.

[15] Indication of chip reset (undervoltage, watchdog)

(resets after readout via SSC)

0: Reset occurred

1: No reset

[14] System Error (e.g. Overvoltage; Undervoltage; V

0: Error occurred

1: No error

[13] Interface Access Error (access to wrong address; wrong lock, wrong parity,

wrong access)

0: Error occurred

1: No error

[12] Angle Value error (ADC , vectorlength or redundant angle calculation error)

0: Angle value invalid

1: Angle value valid

RESP [11:8] Sensor Number Response Indicator

The sensor no. bit is pulled low and the other bits are high

CRC [7:0] Cyclic Redundancy Check (CRC) includes Command Word, Data-words,

STAT and RESP

-, GND- off; ROM)

DD

Data Sheet 21 Rev. 1.1

2019-04-04

Page 22

xor

X7 X6 X5 X4 X3 X2

xor

X0

xor

xor

Input

Serial

CRC

output

&

TX_CRC

1111 1 1 1

1

X1

parallel

Remainder

TLE5014SP16 E0002

GMR-based Angle Sensor

Synchronous Serial Communication (SSC) interface

4.2.3 Cyclic Redundancy Check (CRC)

• This CRC is according to the J1850 Bus-Specification.

• Every new transfer resets the CRC generation.

• Every Byte of a transfer will be taken into account to generate the CRC (also the sent command(s)).

• Generator-Polynomial: X

(see Figure 4-5).

• The remainder of the fast CRC circuit is initial set to 11111111

• Remainder is inverted before transmission.

8+X4+X3+X2

+1, but for the CRC generation the fast-CRC generation circuit is used

.

B

Figure 4-5 Fast CRC polynomial division circuit

Two code examples to compute the CRC are provided. The first implementation is based on a two loops

implentation. This implementation is recommended if the memory space is critical in the application. The

second implementation replaces the inner loop by a look-up-table. It requires more memory space but the

computation time is lower.

Data Sheet 22 Rev. 1.1

2019-04-04

Page 23

z

Tilt angle

Reference plane

y

x

Rotational

displacement

Package

Chip

x

Die pad

Chip

TLE5014SP16 E0002

GMR-based Angle Sensor

Package Information

5 Package Information

The device is qualified with a MSL level of 3. It is halogen free, lead free and RoHS compliant.

5.1 Package Parameters

Table 5-1 Package Parameters

Parameter Symbol Limit Values Unit Notes

Min. Typ. Max.

Thermal resistance R

R

R

thJA

thJC

thJL

Moisture Sensitively Level MSL 3 260°C

150 K/W Junction to air

45 K/W Junction to case

70 K/W Junction to lead

2)

1)

Lead Frame Cu

Plating Sn 100% > 7 μm

1) according to Jedec JESD51-7

2) suitable for reflow soldering with soldering profiles according to JEDEC J-STD-020E (December 2014)

Table 5-2 Position of the die in the package

Parameter Symbol Limit Values Unit Notes

Min. Typ. Max.

Tilt 3 ° in respect to the z-axis and

reference plane (see

Figure 5-1),

Rotational displacement 3 ° in respect to the reference

axis (see Figure 5-1)

Placement tolerance in

100 µm in x and y direction

package

Figure 5-1 Tolerance of the die in the package

The active area of the GMR sensing element is 360µm x 470µm.

It has to be ensured that a magnet is used which has sufficient size to provide a homogeneous magnetic field

over the total sensing element area. For a practical application design this means that the magnet has to be

Data Sheet 23 Rev. 1.1

2019-04-04

Page 24

TLE5014SP16 E0002

GMR-based Angle Sensor

Package Information

large enough to ensure that the non-homogeneity of the magnetic field in this area (plus relevant positioning

tolerances) is negligible. In case the magnet diameter is too small or there is a misalignment of the magnet to

the sensor, an additional angle error may occur which has to be taken into account by the user.

Data Sheet 24 Rev. 1.1

2019-04-04

Page 25

TLE5014SP16 E0002

GMR-based Angle Sensor

Package Information

5.2 Package Outline

Figure 5-2 PG-TDSO-16 package dimension

Figure 5-3 Position of sensing element

Data Sheet 25 Rev. 1.1

2019-04-04

Page 26

TLE5014SP16 E0002

GMR-based Angle Sensor

Package Information

5.3 Footprint

Figure 5-4 Footprint of PG TDSO-16

5.4 Packing

Figure 5-5 Tape and Reel

Data Sheet 26 Rev. 1.1

2019-04-04

Page 27

TLE5014SP16 E0002

GMR-based Angle Sensor

Package Information

5.5 Marking

Position Marking Description

1st Line Gxxxx G: green, 4-digit date code: YYWW

e.g. “1801”: 1

2nd Line xxxxxxxx Interface type and version

3rd Line xxx Lot code

st

week in 2018

Figure 5-6 Marking of PG-TDSO-16

Data Sheet 27 Rev. 1.1

2019-04-04

Page 28

TLE5014SP16 E0002

GMR-based Angle Sensor

Revision history

6 Revision history

Revision Date Changes

1.0 2019-01-17 Initial creation.

1.1 2019-04-04 Remove Register chapter

Data Sheet 28 Rev. 1.1

2019-04-04

Page 29

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

IMPORTANT NOTICE

Edition 2019-04-04

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2019 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about any

aspect of this document?

Email: erratum@infineon.com

Document reference

The information given in this document shall in no

event be regarded as a guarantee of conditions or

characteristics ("Beschaffenheitsgarantie").

With respect to any examples, hints or any typical

values stated herein and/or any information regarding

the application of the product, Infineon Technologies

hereby disclaims any and all warranties and liabilities

of any kind, including without limitation warranties of

non-infringement of intellectual property rights of any

third party.

In addition, any information given in this document is

subject to customer's compliance with its obligations

stated in this document and any applicable legal

requirements, norms and standards concerning

customer's products and any use of the product of

Infineon Technologies in customer's applications.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer's technical departments to

evaluate the suitability of the product for the intended

application and the completeness of the product

information given in this document with respect to

such application.

For further information on technology, delivery terms

and conditions and prices, please contact the nearest

Infineon Technologies Office (www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon Technologies,

Infineon Technologies’ products may not be used in

any applications where a failure of the product or any

consequences of the use thereof can reasonably be

expected to result in personal injury.

Loading...

Loading...