Page 1

User’s Manual 1 Rev. 1.0

www.infineon.com/sensors 2019-03-12

TLE5014

GMR-Based Angle Sensor

User’s Manual

About this document

Scope and purpose

This document covers the TLE5014 with the different interfaces SENT, SPC, PWM and SICI. It provides further

information what should be considered using this sensor in an application and how to program it.

Intended audience

This document is aimed at experienced hardware and software engineers using the TLE5014 iGMR angle

sensor.

This documents contains information for the following devices:

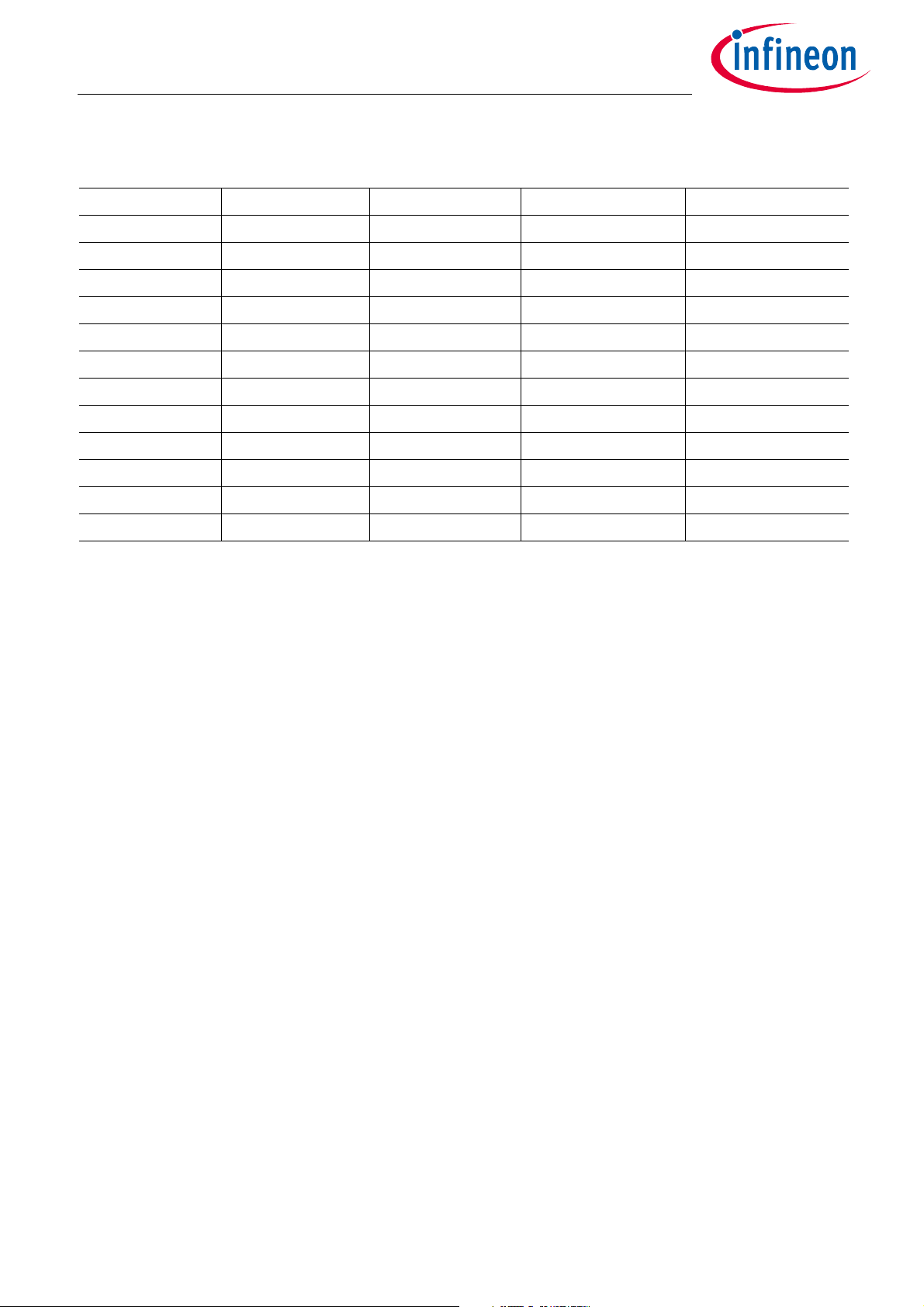

Table 1 Derivatives covered by this user manual

Product Type Marking Ordering Code Package Comment

TLE5014P16 014P SP001231814 PG-TDSO-16 PWM Interface, single die

TLE5014S16 014S SP001231818 PG-TDSO-16 SENT Interface, single die

TLE5014C16 014C SP001231806 PG-TDSO-16 SPC Interface, single die

TLE5014S16D 014SD SP001410046 PG-TDSO-16 SENT Interface, dual die

TLE5014C16D 014CD SP001410042 PG-TDSO-16 SPC Interface, dual die

TLE5014P16D 014PD SP001673472 PG-TDSO-16 PWM Interface, dual die

Page 2

TLE5014

GMR-Based Angle Sensor

Table of Contents

1 Application Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Interfaces overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 PWM Interface Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 SPC Interface Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 SENT Interface Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 EEPROM Page Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 EEPROM Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Page 0x006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Page 0x009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Page 0x00A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4 Page 0x00B - 0x00E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.5 Page 0x00F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Working Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.1 STAT Register 0x00: Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2 AVAL Register 0x02: Angle Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 ASPD Register 0x03: Angle Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4 RAW_X Register 0x06: X raw value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5 RAW_Y Register 0x07: Y raw value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6 TEMP Register 0x0A: Temperature raw value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.7 ANG_BASE register 0x14: Angle base and rotation direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 SICI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 Basic Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 SICI Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.1 Bit Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.2 Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2.3 CRC generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2.4 SICI Application Example: Reading working register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2.5 SICI Application Example: EEPROM read/write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3 SICI Programming in Bus Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7 EEPROM Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1 Writing and Reading of EEPROM Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2 Verification of EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.3 Locking of EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8 Initial Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.1 Zero Angle Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.2 Look-up Table Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.3 Customer ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9 Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1 Angle Read Out Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2 Angle Base Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.3 Look-up Table Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.4 Temperature calculation from Short Serial Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.5 Reading registers with SICI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

User’s Manual 2 Rev. 1.0

2019-03-12

Page 3

TLE5014

GMR-Based Angle Sensor

9.6 Reading EEPROM with SICI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.7 Writing EEPROM with SICI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

User’s Manual 3 Rev. 1.0

2019-03-12

Page 4

TLE5014

TLE5014

GND

µControlle r

Master

10 0nF

V

DD

V

DD

GND

IF1

IF2

IF3

IFA

IFB

IFC

V

µC

R

p

PWM

C

w

TLE5014

GND

µControlle r

Master

10 0nF

V

DD

V

DD

GND

IF1

IF2

IF3

IFA

IFB

IFC

V

µC

R

p

SP C

C

w

GMR-Based Angle Sensor

Application Circuits

1 Application Circuits

The application circuits in this chapter show the various communication possibilities of the TLE5014.

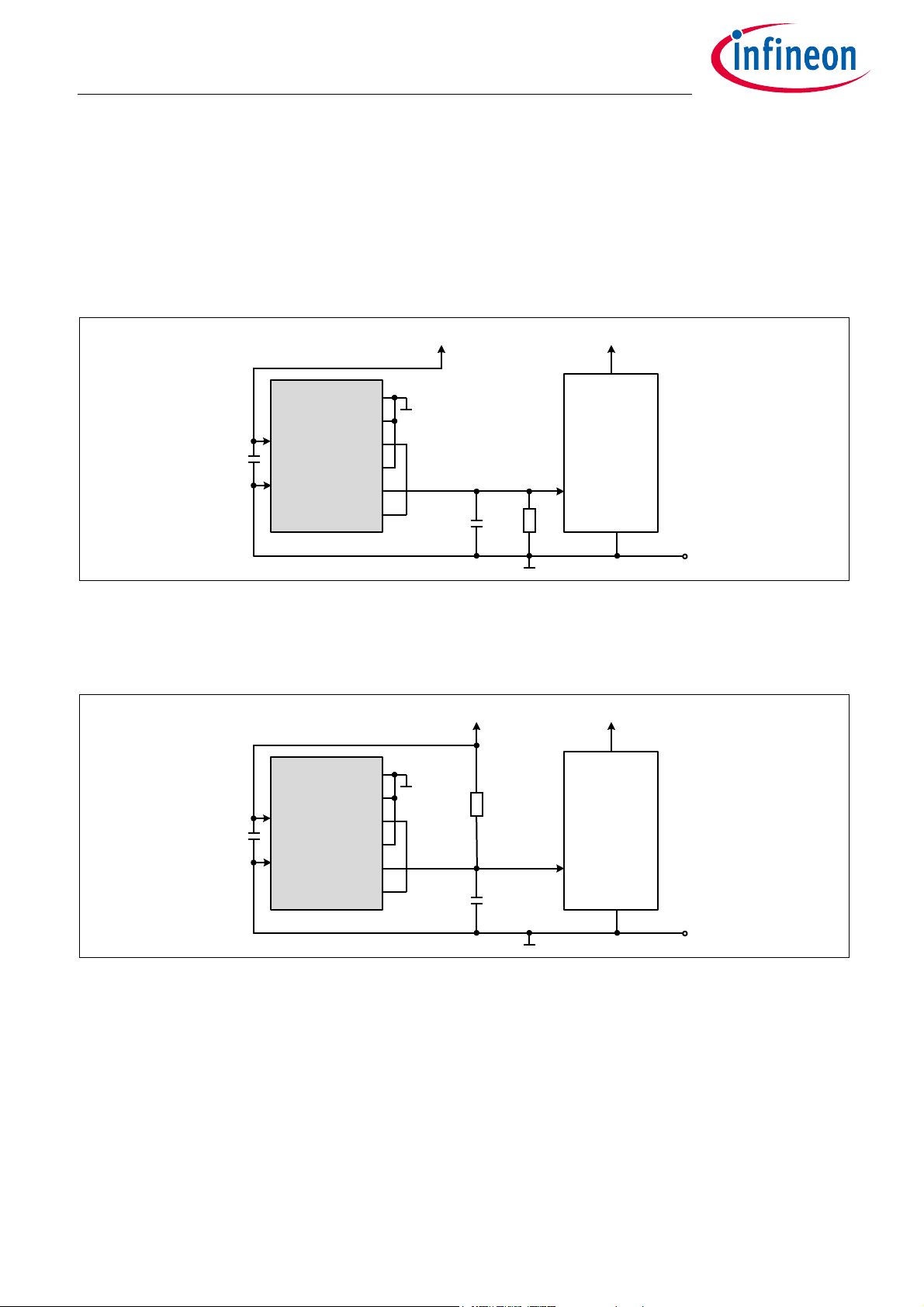

Figure 1 shows a basic application circuit of a TLE5014 with PWM interface. The pull-down resistor is required

to ensure that the sensor starts with a low level after power-on or reset (PWM starts with a rising edge). If the

sensor is configured in such a way, that the PWM starts with a falling edge, the pull-down has to be replaced

by a pull-up.

Figure 1 Application circuit for TLE5014 with PWM, sensor configured to start with a rising edge of

PWM

Figure 2 shows a basic application circuit of the TLE5014 with SPC mode.

Figure 2 Application circuit for TLE5014 with SPC, SPC address is configured to be “0” (IF1 and IF2

connected to GND)

The circuit shows the minimum external circuit which is needed to operate the SPC interface. The generation

of the trigger pulse (switch to pull the line low) is not shown. Depending on EMC requirements, additional

circuitry may be required. The value of C

and Rp are specified in the datasheet.

w

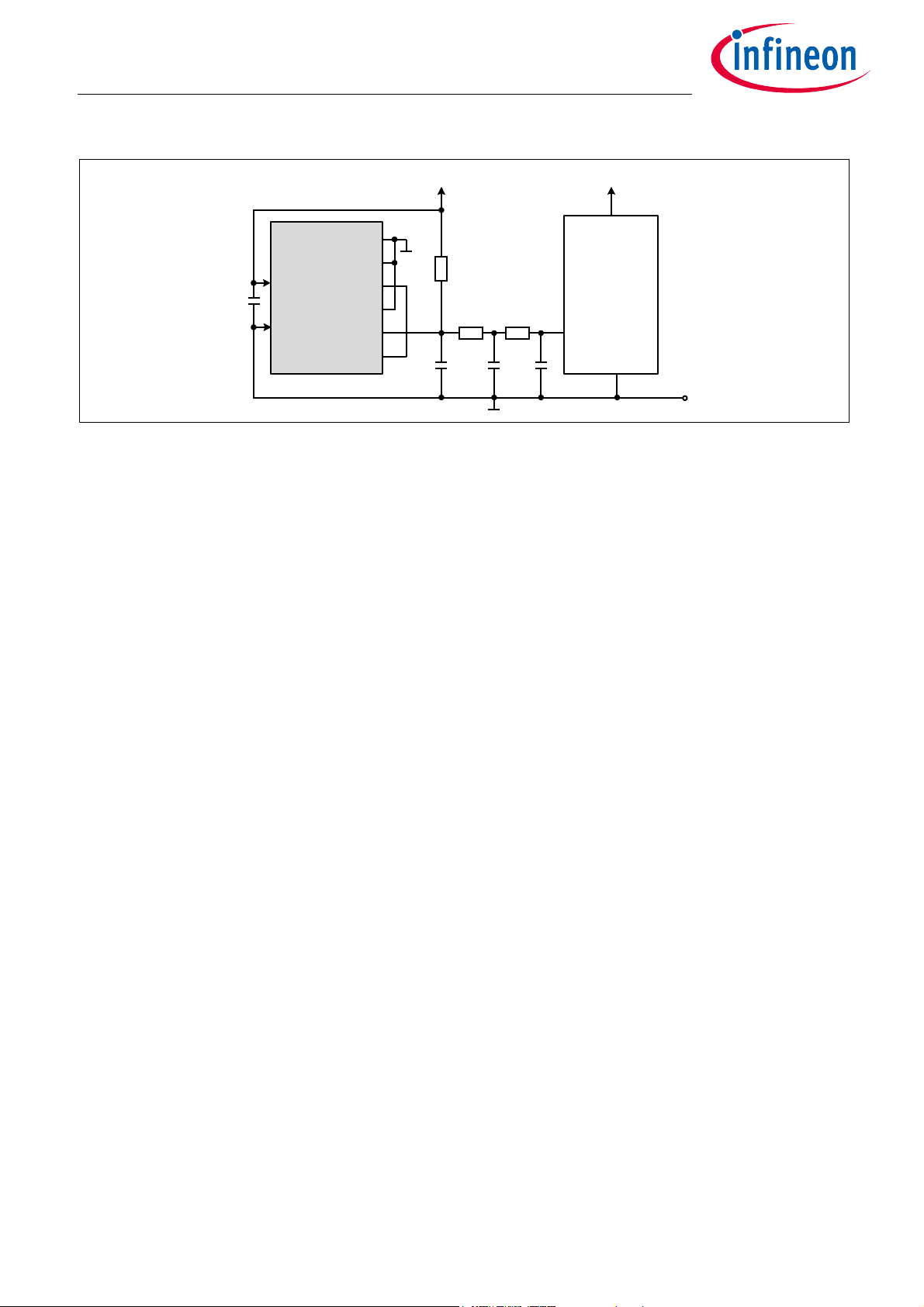

The TLE5014 can also be used with a SENT interface (Figure 3). The circuit shown is according to the SAE

J2716-2010 SENT specification.

User’s Manual 4 Rev. 1.0

2019-03-12

Page 5

TLE5014

TLE5014

GND

µControlle r

Master

10 0nF

V

DD

V

DD

GND

IF1

IF2

IF3

IFA

IFB

IFC

V

µC

10 k

56 0

10k

68 p 2 .2n 10 0p

GMR-Based Angle Sensor

Application Circuits

Figure 3 Application circuit for TLE5014 with SENT

User’s Manual 5 Rev. 1.0

2019-03-12

Page 6

TLE5014

GMR-Based Angle Sensor

Interfaces overview

2 Interfaces overview

Depending on the application, the TLE5014 is available with different interfaces:

• PWM (Pulse Width Modulation)

• SPC (Short PWM Code)

• SENT (Single Edge Nibble Transmission)

• SICI (Single-wire Interface for Calibration and Inspection; for programming purpose only)

PWM

The PWM is an unidirectional interface. Only one line is needed in which the angle value is transmitted. The

angle value corresponds to the duty cycle of the signal data. A reserved duty cycle range is implemented which

is used for indication of internal detected device errors. The data duty cycle range and the error duty cycle

range can be programmed via EEPROM setting.

SPC

The SPC is an interface based on the SENT protocol. The ECU (master µC) sends a trigger pulse which triggers

the TLE5014 to transmit the 12-bit angle value. If desired, the temperature can also be transmitted on a slow

channel (short serial message). The SPC also sends a CRC nibble and an end-pulse to terminate the

communication. One line is needed for the transmission and the pins IF1, IF2 and IFC are used to set the slave

number. Up to four slaves can be connected to one ECU; the ECU trigger pulse length will trigger the respective

sensor.

SENT

SENT is a standardized interface described in SAE J2716-2010.

SICI

A PWM based, bidirectional interface which is used for programming purpose only.

Further details on the SENT, SPC and PWM interface can be found in the data sheet of TLE5014.

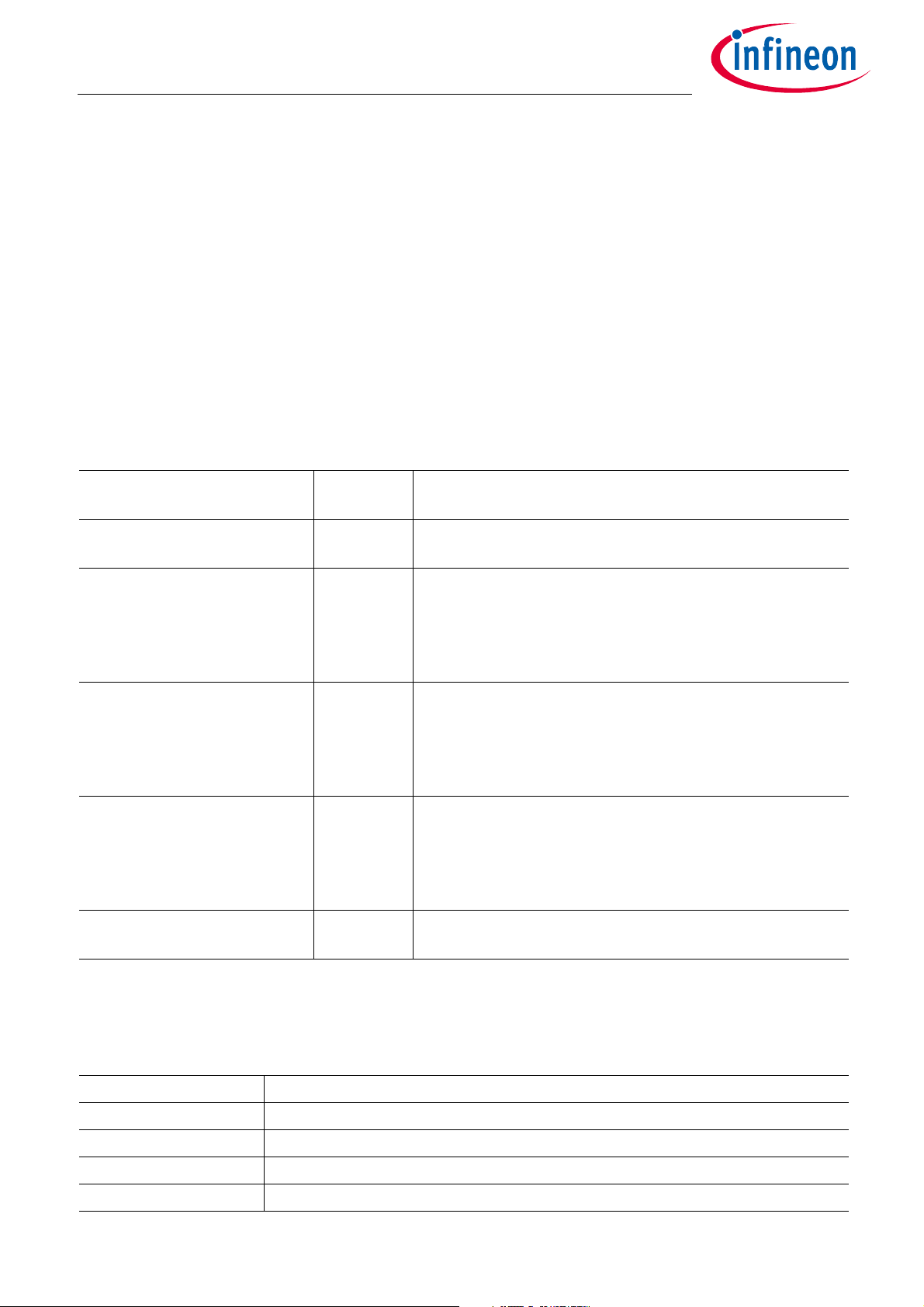

2.1 PWM Interface Configuration

The following configuration of the PWM interface is possible. Further details are in the EEPROM register

description in Chapter 4.

Table 2 PWM Interface configuration

Parameter EEPROM

Register

PWM data duty cycle range

minimum value

PWM data duty cycle range

maximum value

PWM diagnostic duty cycle low 0x0064 This value determines the duty cycle which indicates a

User’s Manual 6 Rev. 1.0

0x0060 This value determines the low value of the duty cycle for

0x0062 This value determines the high value of the duty cycle for

Description

angle transmission. It corresponds to an angle value of 0°

angle transmission. It corresponds to an angle value of

359.91°

sensor failure detected by the internal safety mechanism

2019-03-12

Page 7

TLE5014

GMR-Based Angle Sensor

Interfaces overview

Table 2 PWM Interface configuration (cont’d)

Parameter EEPROM

Description

Register

PWM diagnostic duty cycle high 0x0066 This value determines the duty cycle which indicates a

sensor reset or a sensor start-up error (BIST error)

PWM predevider for PWM period 0x0068 This value is used for PWM frequency adjustment according

to Equation (4.1)

PWM period 0x006A This value is used for PWM frequency adjustment according

to Equation (4.1)

PWM starting edge 0x00A2 This value determines the starting edge of the PWM protocol.

It can be rising or falling. In case a rising edge is selected, the

PWM protocol will start with a HIGH level. In case a falling

edge is selected, it will start with a LOW

Care has to be taken when programming the low and high diagnostic duty cycle that there is no overlap with

the programmed data duty cycle range. In such a case, diagnostic information (e.g. sensor failure) could not

be distinguished from a valid transmitted angle value. It is recommended to add a safety margin between the

diagnostic and the data duty cycle range.

2.2 SPC Interface Configuration

The following table shows the different options for SPC interface configuration. The details for the EEPROM

setting are shown in Chapter 4.3

Table 3 SPC Interface configuration

Parameter EEPROM

Description

Register

SPC low time 0x00A2 This value can be 5 UT or 3UT. With 5UT, the SPC nibble is

compliant to the SENT specification

Temperature information in SPC

protocol

0x00A2 The SPC frame can contain two additional nibbles for

transmitting the temperature information

Rolling counter 0x00A2 A 4-bit rolling counter (rolling counter nibble) can be

activated which counts the transmitted frames. This is

necessary for functional safety applications to increase the

diagnostic coverage

Rolling counter in CRC 0x00A2 The rolling counter information can be coded in the CRC of

the SPC frame instead of being transmitted as extra nibble.

In this case the rolling counter information has 2 bit only.

This feature reduces overall frame length of the SPC protocol

SPC trigger 0x00A2 Two options are available for the total trigger length. It can

be constant with a length of 90 UT or variable. The variable

trigger length is t

time t

. Both settings can be used in a bus configuration as

low

the address of the sensor is defined by the low time t

+12 UT and depends on the trigger low

low

low

only.

The advantage of the variable trigger length is that the total

frame length can be reduced

User’s Manual 7 Rev. 1.0

2019-03-12

Page 8

TLE5014

Synchronisation

Frame

Trigger Nibble

µC Acti vity

Sensor Activity

90 UT

56 UT 12 … 27 UT 12 … 27 UT 12 … 27 UT 12 … 27 UT 12 … 27 UT 12 UT

Status Nibble

Data Nibble 1 Data Nibble 3Data Nibble 2 CRC

End

pulse

12 … 27 UT

Rolling counter

GMR-Based Angle Sensor

Interfaces overview

Table 3 SPC Interface configuration (cont’d)

Parameter EEPROM

Description

Register

SPC short serial message 0x00A2 A short serial message (slow message) can be activated,

which transmits one bit of a 16 bit information in each SPC

frame and thus needs 16 SPC frames for the whole data

transmission.This transmitted information is the

programmed angle base and rotation direction, the chip

temperature and 32 bit of the customer ID.

SPC unit time (UT) 0x00A2 The SPC unit time (UT) can be selected in the range of 1.0 µs

to 3.0 us.

SPC address setting in bus mode

The address of the sensor, so that it responds to a corresponding SPC trigger pulse, has to be set in the

EEPROM. All parts delivered from Infineon have the default address of ID = 0 in the EEPROM. Please refer to

description of EEPROM register 0x00A4 in Description EEPROM Address 0x00A4 CRC_CFG for correct setting.

The address of the sensor written to the EEPROM must be identical to the address of the sensor defined via

hard-wiring of the pins IF1, IF2 and IFC. Table 4 shows how the sensor address has to be set using the pins IF1,

IF2, IFC.

Table 4 SPC Address Configuration

Address IF1 IF2

0GNDGND

1IFCGND

2GNDIFC

3IFCIFC

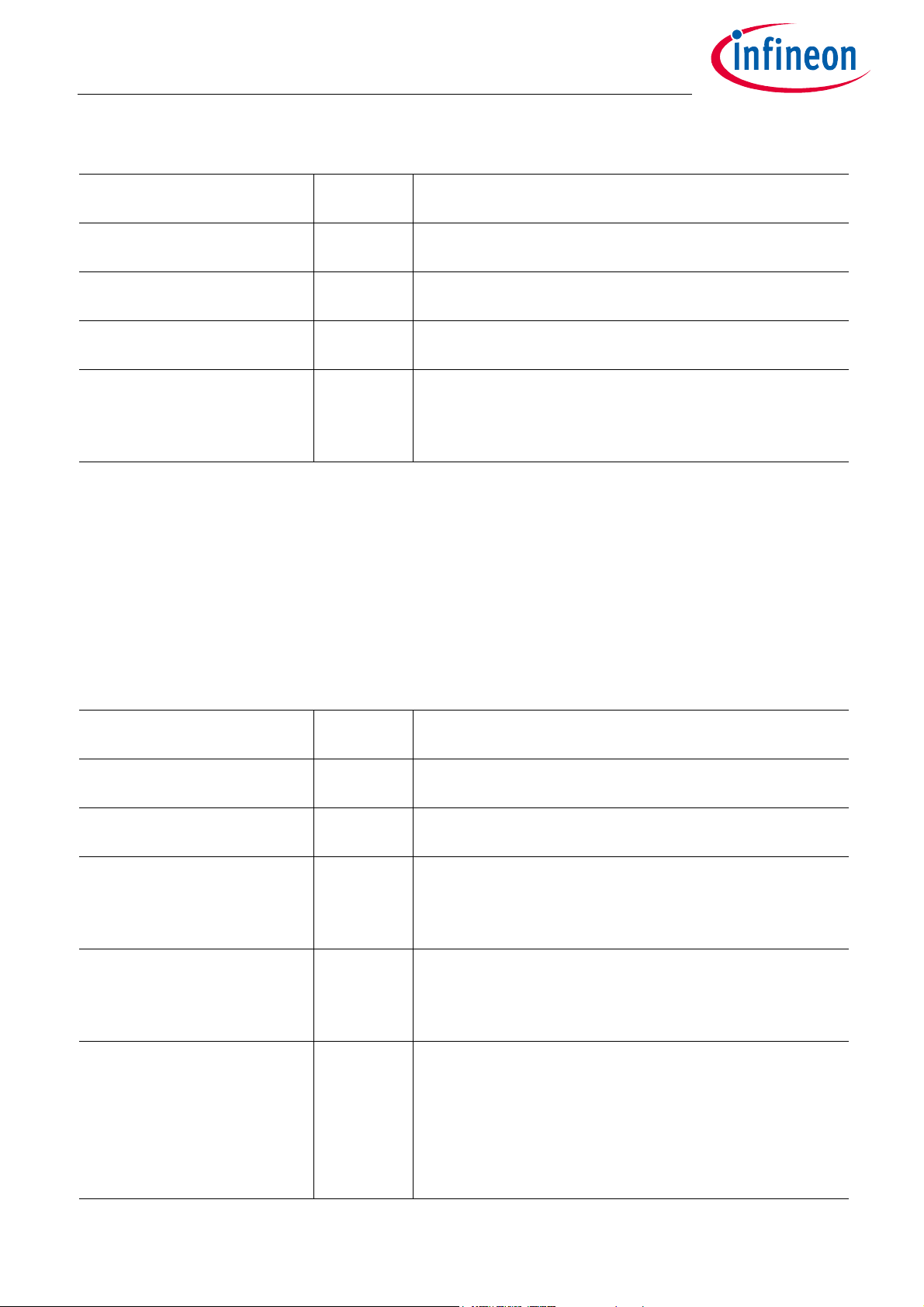

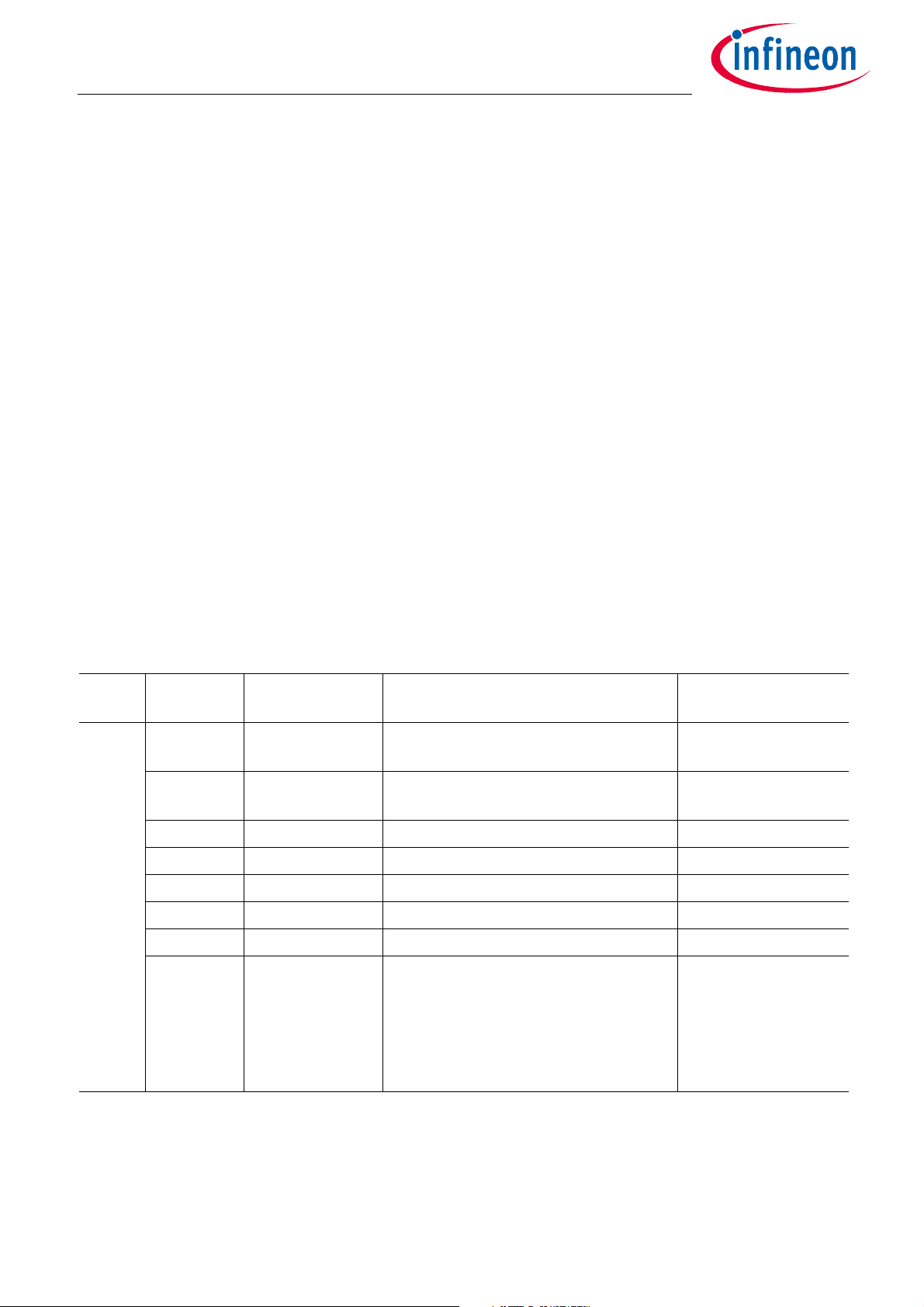

Figure 4 shows a SPC frame with constant trigger length of 90UT, a status nibble, 3 data nibbles, a rolling

counter nibble and a CRC nibble. The low time of the trigger nibble determines the address of the sensor.

Figure 4 SPC frame with constant trigger length and rolling counter enabled as additional nibble

User’s Manual 8 Rev. 1.0

2019-03-12

Page 9

TLE5014

GMR-Based Angle Sensor

Interfaces overview

SPC status nibble

The 4-bit status nibble of the SPC protocol has different content depending on SPC protocol configuration:

• No short serial message:

Table 5 SPC Status Nibble

Bit Description

0 (LSB) Sensor ID (LSB)

1Sensor ID (MSB)

2 Internal sensor failure

3 (MSB) Sensor reset or start-up (BIST) failure

• Short serial message (SSM) enabled:

Table 6 SPC Status Nibble

Bit Description

0 (LSB) Data bit of SSM

1 Start bit of SSM

2 Internal sensor failure

3 (MSB) Sensor reset or start-up (BIST) failure

In this configuration, the sensor ID is coded in the CRC and not available in the status nibble. There is also the

option, that the rolling counter is not a dedicated nibble but the information is also coded in the CRC.

Therefore, four different versions of the CRC calculation exist:

• No short serial message (SSM) and rolling counter as nibble

Input data for the CRC calculation are:

STATUS & DATA1 & DATA2 & DATA3 & ROLLING_CNT

• Short serial message (SSM) enabled and rolling counter as nibble

the CRC calculation has to include a special 4-bit “ID-nibble” and is performed with the following input

data:

STATUS & DATA1 & DATA2 & DATA3 & ROLLING_CNT & ID_NIBBLE

ID_NIBBLE = (0 0 ID(MSB) ID(LSB))

• Short serial message (SSM) is disabled and rolling counter is included in CRC (no rolling counter as nibble)

The CRC calculation has to include a special 4-bit “RC-nibble” and is performed with the following input

data:

STATUS & DATA1 & DATA2 & DATA3 & RC_NIBBLE

RC_NIBBLE = (RC(MSB) RC(LSB) 0 0)

• Short serial message (SSM) is enabled and rolling counter is included in CRC (no rolling counter as nibble)

The CRC calculation has to include a special 4-bit “RC_ID-nibble” and is performed with the following input

data:

STATUS & DATA1 & DATA2 & DATA3 & RC_ID_NIBBLE

RC_ID_NIBBLE = (RC(MSB) RC(LSB) ID(MSB) ID(LSB))

User’s Manual 9 Rev. 1.0

2019-03-12

Page 10

TLE5014

GMR-Based Angle Sensor

Interfaces overview

Table 7 Examples for ID Nibble, RC_Nibble and ID_RC_Nibble calculation

ID RC ID_Nibble RC_Nibble RC_ID_Nibble

00

B

01

B

10

B

11

B

–00

–01

–10

–11

00

B

01

B

10

B

11

B

– 0000

– 0001

– 0010

– 0011

–0000B–

–0100B–

–1000–

–1100B–

– – 0000

– – 0101

– – 1010

– – 1111

00

01

10

11

B

B

B

B

B

B

B

B

B

B

B

B

––

––

––

––

B

B

B

B

Synchronization of the Rolling Counter

The first transmitted SPC frame has a rolling counter value of 0. The next frame transmits a rolling counter

value which is incremented by 1. In case the rolling counter is coded in the CRC, it is a 2-bit value. In this

configuration, a synchronization of the counter value (sensor value and counter value in the micro controller)

is required. The following two options are possible:

• Calculate the CRC with the received sensor data and a RC_NIBBLE of RC_NIBBLE = 0000

. Repeat this until

B

the calculated CRC matches with the transmitted CRC. This frame has the rolling counter value of 0. The

next transmitted frame has the incremented counter value of 1 and so on. As the rolling counter has 2 bit

in case it is coded in the CRC, latest the fourth transmitted frame needs to have a matched CRC. If this is

not the case an error occurred.

• For the first transmitted frame, calculate the four possible CRCs with the RC_NIBBLE values 0000

to 0011B.

B

The CRC which is matching the transmitted CRC has the correct rolling counter value. Use this value as

starting value which is incremented with the next received frame.

CRC calculation for SPC protocol

The checksum nibble is a 4-bit CRC of the data nibbles including the status nibble. The CRC is calculated using

a polynomial x4+x3+x2+1 with a seed value of 0101

. The remainder after the last data nibble is transmitted as

B

CRC. The CRC calculation method is based on “recommended” implementation in the SENT standard 2010.

For this “recommended” implementation, the CRC is calculated based on the input data which is then

augmented with four extra zero bits and an additional CRC calculation step.

Code example:

//Table CRC, Poly=0xD

uint8_t cr4Table[16] = {0, 13, 7, 10, 14, 3, 9, 4, 1, 12, 6, 11, 15, 2, 8, 5};

//Example:

//Status Nibble = 0x6

//Data Nibble = 0x7, 0x4, 0x8, 0x7, 0x4, 0x8

uint8_t nibble[7] = {6, 7, 4, 8, 7, 4, 8};

uint8_t nb_nibble = 0x7;

User’s Manual 10 Rev. 1.0

2019-03-12

Page 11

TLE5014

GMR-Based Angle Sensor

Interfaces overview

//Seed value = 0x5

uint8_t crc = 0x5;

for(uint8_t i=0;i<nb_nibble;i++){

crc = nibble[i] ^ cr4Table[crc];

}

//Final XOR

crc = 0x0 ^ cr4Table[crc];

2.3 SENT Interface Configuration

The following table shows the different options for SENT interface configuration.

Table 8 SENT Interface configuration

Parameter EEPROM

Register

SENT low time 0x00A2 This value can be 5 UT or 3 UT. With 5 UT, the nibble is

SENT protocol type 0x00A2 Two different SENT implementations can be configured:

Sent short serial message 0x00A2 A short serial message (slow message) can be activated

SENT error indication 0x00A2 In case of an internal chip error, the error can be indicated

Se nt u nit time (UT) 0x 00A 2 The SE NT uni t tim e (UT ) can be sel ecte d in th e ran ge of 1.5 µ s

Description

compliant to the SENT specification

Standard SENT: Status nibble, 3 x 4-bit data nibbles, CRC

nibble

Single Secure SENT: Status nibble, 3 x 4-bit data nibbles, 2x4bit rolling counter; Inverted data nibble, CRC nibble

which transmits one bit of additional information in each

SPC frame. This transmitted information is the programmed

angle base and rotation direction, the chip temperature and

32 bit of the customer ID

only in the status nibble by setting an error bit or in the status

nibble and also in the SENT data range. In this case an error

code of “4091” is sent. For this option, the data range has not

the full 12-bit resolution but only 1 … 4088 LSB

to 3.0 us

SENT Status Nibble

The 4-bit status nibble of the SENT protocol contains the following information:

Table 9 SENT Status Nibble

Bit Description

0 (LSB) error indication or start-up (BIST) error or sensor reset

1 reserved

2 short serial message bit (data bit)

3 (MSB) short serial message bit (start indication)

User’s Manual 11 Rev. 1.0

2019-03-12

Page 12

TLE5014

GMR-Based Angle Sensor

Interfaces overview

CRC calculation for SENT protocol

The checksum nibble is a 4-bit CRC of the data nibbles and does not include the status nibble (different to SPC

CRC implementation). The CRC is calculated using a polynomial x4+x3+x2+1 with a seed value of 0101

remainder after the last data nibble is transmitted as CRC. The CRC calculation method is based on

“recommended” implementation in the SENT standard 2010. For this “recommended” implementation, the

CRC is calculated based on the input data (without STATUS nibble) which is then augmented with four extra

zero bits and an additional CRC calculation step.

Code example:

//Table CRC, Poly=0xD

uint8_t cr4Table[16] = {0, 13, 7, 10, 14, 3, 9, 4, 1, 12, 6, 11, 15, 2, 8, 5};

//Example:

//Data Nibble = 0x7, 0x4, 0x8, 0x7, 0x4, 0x8

uint8_t nibble[6] = {7, 4, 8, 7, 4, 8};

uint8_t nb_nibble = 0x6;

//Seed value = 0x5

uint8_t crc = 0x5;

. The

B

for(uint8_t i=0;i<nb_nibble;i++){

crc = nibble[i] ^ cr4Table[crc];

}

//Final XOR

crc = 0x0 ^ cr4Table[crc];

User’s Manual 12 Rev. 1.0

2019-03-12

Page 13

TLE5014

GMR-Based Angle Sensor

EEPROM Page Map

3 EEPROM Page Map

The TLE5014 has an EEPROM as non-volatile memory where sensor configuration data can be stored. The

memory is organized in pages, each page contains 8 registers, each register has 16 bit. Some pages and

registers can be accessed by the user and the content can be modified thus changing chip configuration. Care

has to be taken when modifying content of the EEPROM as the device behavior can be changed and no or

wrong output data can be generated. There is no automatic restore functionality where the pre-programmed

status can be recovered.

The EEPROM content is secured by a CRC. In case any content of the EEPROM is changed, the CRC has to be

recalculated and written to the corresponding register, otherwise an error is indicated. The CRC has always be

calculated out of several pages and registers, which are indicated in the description of the corresponding CRC

(Table 10). The algorithm for the CRC calculation is described in Chapter 6.2.3.

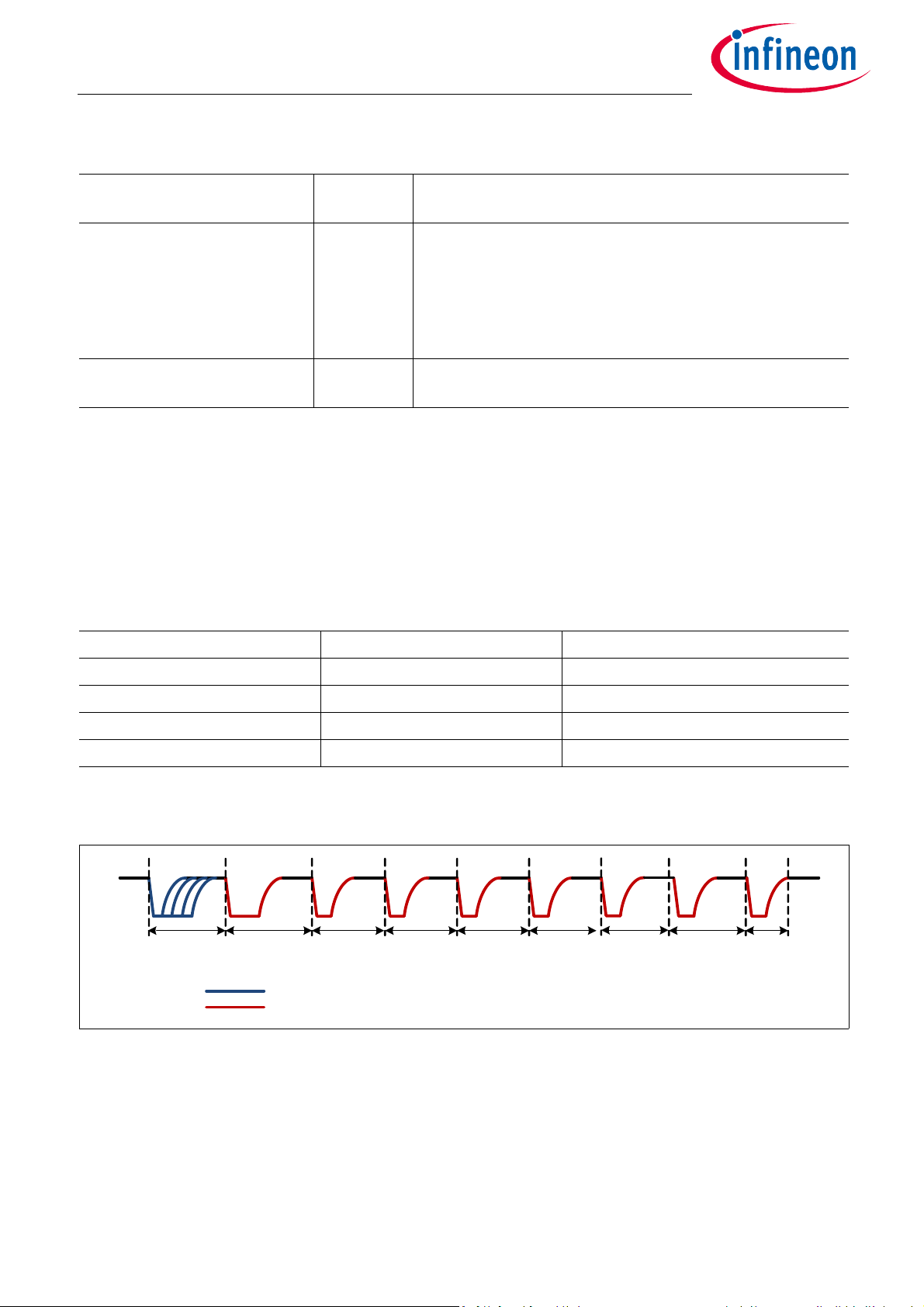

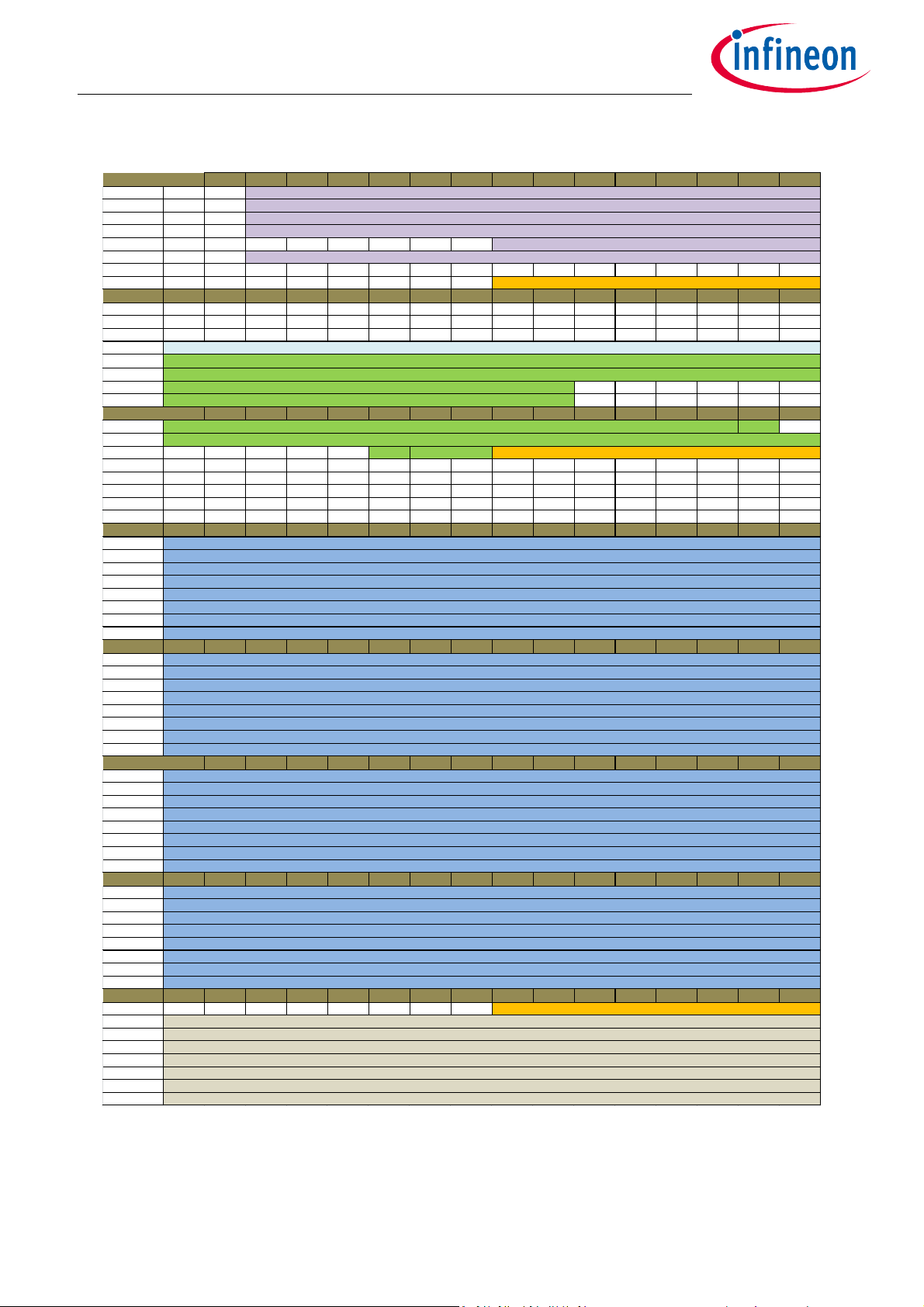

The following Table 10 shows the pages and EEPROM registers of each page and their function. A detailed

description of the EEPROM registers and the possible settings can be found in Chapter 4.

The startup value of each configuration register of the TLE5014 is stored in a corresponding EEPROM register,

which can be modified by the user. Table 10 lists the allocation of the user-configurable EEPROM pages.

Care shall be taken when the EEPROM configuration is changed, as not all possible configurations are released

by Infineon. This means, that they can be used for testing purpose but not necessarily for production. All

released configurations can be found in the TLE5014 datasheet.

Table 10 EEPROM page map

Page EEPROM

Register

0x006 0x0060 OUT_LIM_MIN PWM data duty cycle range minimum

0x0062 OUT_LIM_MAX PWM data duty cycle range maximum

0x0064 OUT_STAT_L PWM diagnostic duty cycle low

0x0066 OUT_STAT_H PWM diagnostic duty cycle high

0x0068 TMR_PREDIV PWM predevider for PWM period

0x006A TMR_PERIOD PWM period

0x006C – Reserved

0x006E CRC_EEP CRC has to be calculated with following

Name Description Default value of Reg.

value

value

values: page 0x002 & 0x003 & 0x004 &

0x005 & register 0x0060 & 0x0062 &

0x0064 & 0x0066 & 0x0068 & 0x006A &

0x006C & first byte of 0x006E (bit [15:8] &

0xFF00)

User’s Manual 13 Rev. 1.0

2019-03-12

Page 14

TLE5014

GMR-Based Angle Sensor

EEPROM Page Map

Table 10 EEPROM page map (cont’d)

Page EEPROM

Register

0x009 0x0090 – Reserved

0x0092 – Reserved

0x0094 – Reserved

0x0096 ACSTAT Activation of internal safety mechanism

0x0098 MOD1 3 V/5 V, pad configuration, LUT options

0x009A MOD2 Lock function for register PWI_MD_USR

0x009C IF123_CFG Pin configuration of pin IF1, IF2, IF3

0x009E IFABC_CFG Pin configuration of pin IFA, IFB, IFC

0x00A 0x00A0 ANG_BASE Angle base & rotation direction

0x00A2 PWI_MD_USR Interface configuration

0x00A4 CRC_CFG Configuration CRC and SPC address;

Name Description Default value of Reg.

CRC has to be calculated with following

values: registers 0x0096 & 0x0098 &

0x009A & 0x009C & 0x009E & 0x00A0 &

0x00A2 & first byte of 0x00A4 (bit [15:8] &

0xFF00)

0x00A6 – Reserved

0x00A8 – Reserved

0x00AA – Reserved

0x0AC – Reserved

0x00AE – Reserved

0x00B 0x00B0 LUT_0 Look-up table value for 0°

0x00B2 LUT_1 Look-up table value for 11.25°

0x00B4 LUT_2 Look-up table value for 22.50°

0x00B6 LUT_3 Look-up table value for 33.75°

0x00B8 LUT_4 Look-up table value for 45.00°

0x00BA LUT_5 Look-up table value for 56.25°

0x00BC LUT_6 Look-up table value for 67.50°

0x00BE LUT_7 Look-up table value for 78.75°

0x00C 0x00C0 LUT_8 Look-up table value for 90.00°

0x00C2 LUT_9 Look-up table value for 101.25°

0x00C4 LUT_10 Look-up table value for 112.50°

0x00C6 LUT_11 Look-up table value for 123.75°

0x00C8 LUT_12 Look-up table value for 135.00°

0x00CA LUT_13 Look-up table value for 146.25°

0x00CC LUT_14 Look-up table value for 157.50°

0x00CE LUT_15 Look-up table value for 168.75°

User’s Manual 14 Rev. 1.0

2019-03-12

Page 15

TLE5014

GMR-Based Angle Sensor

EEPROM Page Map

Table 10 EEPROM page map (cont’d)

Page EEPROM

Register

0x00D 0x00D0 LUT_16 Look-up table value for 180.00°

0x00D2 LUT_17 Look-up table value for 191.25°

0x00D4 LUT_18 Look-up table value for 202.50°

0x00D6 LUT_19 Look-up table value for 213.75°

0x00D8 LUT_20 Look-up table value for 225.00°

0x00DA LUT_21 Look-up table value for 236.25°

0x00DC LUT_22 Look-up table value for 247.50°

0x00DE LUT_23 Look-up table value for 258.75°

0x00E 0x00E0 LUT_24 Look-up table value for 270.00°

0x00E2 LUT_25 Look-up table value for 281.25°

0x00E4 LUT_26 Look-up table value for 292.50°

0x00E6 LUT_27 Look-up table value for 303.75°

0x00E8 LUT_28 Look-up table value for 315.00°

0x00EA LUT_29 Look-up table value for 326.25°

0x00EC LUT_30 Look-up table value for 337.50°

Name Description Default value of Reg.

0x00EE LUT_31 Look-up table value for 348.75°

0x00F 0x00F0 [7:0] CRC_LUT 8-bit CRC for Look-up table; CRC has to

be calculated with following values:

page 0x00B & 0x00C & 0x00D & 0x00E &

first byte of register 0x00F0 (bits [15:8] &

0xFF00)

0x00F2 CUST_ID_0 16-bit of customer ID, will be

transmitted via short serial message

0x00F4 CUST_ID_1 16-bit of customer ID, will be

transmitted via short serial message

0x00F6 CUST_ID_2 16-bit of customer ID

0x00F8 CUST_ID_3 16-bit of customer ID

0x00FA CUST_ID_4 16-bit of customer ID

0x00FC CUST_ID_5 16-bit of customer ID

0x00FE CUST_ID_6 16-bit of customer ID

User’s Manual 15 Rev. 1.0

2019-03-12

Page 16

TLE5014

Page 0x006 1514131211109876543210

0x0060 - -

0x0062 - -

0x0064 - -

0x0066 - -

0x0068 - - ------

0x006A - -

0x006C - - -------------

0x006E - - ------

Page 0x009

0x0090 - - --------------

0x0092 - - --------------

0x0094 - - --------------

0x0096

0x0098

0x009A

0x009C ------

0x009E ------

Page 0x00A

0x00A0 ANG_DIR -

0x00A2

0x00A4 -----AS_NR

0x00A6 - - --------------

0x00A8 - - --------------

0x00AA - - --------------

0x00AC - - --------------

0x00AE - - --------------

Page 0x00B

0x00B0

0x00B2

0x00B4

0x00B6

0x00B8

0x00BA

0x00BC

0x00BE

Page 0x00C

0x00C0

0x00C2

0x00C4

0x00C6

0x00C8

0x00CA

0x00CC

0x00CE

Page 0x00D

0x00D0

0x00D2

0x00D4

0x00D6

0x00D8

0x00DA

0x00DC

0x00DE

Page 0x00E

0x00E0

0x00E2

0x00E4

0x00E6

0x00E8

0x00EA

0x00EC

0x00EE

Page 0x00F

0x00F0 --------

0x00F2

0x00F4

0x00F6

0x00F8

0x00FA

0x00FC

0x00FE

CUST_ID_2

CUST_ID_3

CUST_ID_4

CUST_ID_5

CUST_ID_6

CUST_ID_0

CUST_ID_1

LUT_22

LUT_23

LUT_24

LUT_25

LUT_26

LUT_27

CRC_LUT

LUT_28

LUT_29

LUT_30

LUT_31

LUT_21

LUT_10

LUT_11

LUT_12

LUT_13

LUT_14

LUT_15

LUT_16

LUT_17

LUT_18

LUT_19

LUT_20

LUT_8

LUT_9

LUT_3

LUT_4

LUT_5

LUT_6

LUT_7

TMR_PERIOD

CRC_EEP

LUT_0

LUT_1

LUT_2

ANG_BASE

ACSTAT

MOD1

MOD2

IF123_CFG

IFABC_C FG

PWI_MOD

S_NR_EEP CRC_CFG

OUT_LIM_MIN

OUT_LIM_MAX

OUT_STAT_L

OUT_STAT_H

TMR_PREDIV

GMR-Based Angle Sensor

EEPROM Page Map

Figure 5 TLE5014 EEPROM bitmap

User’s Manual 16 Rev. 1.0

2019-03-12

Page 17

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

4 EEPROM Register Description

This chapter describes the EEPROM registers which can be accessed via SICI in the EEPROM programming

mode. Further registers needed for EEPROM programming are described in Chapter 7.1.

Care shall be taken that there is no unintended modification of bits. When modifying registers, reserved bits

have to be read and written back with the same value.

4.1 Page 0x006

The page 0x06 is used for the configuration of the PWM protocol. It is only relevant in case PWM is selected as

interface in the register PWI_MD_USR (0x00A2). The following tables EEPROM Register Address 0x0060

OUT_LIM_MIN to EEPROM Register Address 0x006E CRC_EEP show the details.

EEPROM Register Address 0x0060 OUT_LIM_MIN

1514131211109876543210

OUT_LIM_MIN

Field Bits Type Description

OUT_LIM_MIN 13:0

Minimum value of data duty cycle range; 0% … 100% mapped to

0 … 16383

EEPROM Register Address 0x0062 OUT_LIM_MAX

1514131211109876543210

OUT_LIM_MAX

Field Bits Type Description

OUT_LIM_MAX 13:0

Maximum value of data duty cycle range; 0% … 100% mapped to

0 … 16383

EEPROM Register Address 0x0064 OUT_STAT_L

1514131211109876543210

OUT_STAT_L

User’s Manual 17 Rev. 1.0

2019-03-12

Page 18

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

Field Bits Type Description

OUT_STAT_L 13:0

Low value of diagnostic duty cycle; 0% … 100% mapped to 0 … 16383

EEPROM Register Address 0x0066 OUT_STAT_H

1514131211109876543210

OUT_STAT_H

Field Bits Type Description

OUT_STAT_H 13:0

High value of diagnostic duty cycle; 0% … 100% mapped to 0 … 16383

EEPROM Register Address 0x0068 TMR_PREDIV

1514131211109876543210

TMR_PREDIV

Field Bits Type Description

TMR_PREDIV 7:0

For calculation of PWM frequency according to Equation (4.1)

EEPROM Register Address 0x006A TMR_PERIOD

1514131211109876543210

TMR_PERIOD

Field Bits Type Description

TMR_PERIOD 13:0

For calculation of PWM frequency according to Equation (4.1)

EEPROM Register Address 0x006E CRC_EEP

1514131211109876543210

CRC_EEP

User’s Manual 18 Rev. 1.0

2019-03-12

Page 19

TLE5014

fHz[]

40000000

1 TMR_PREDIV+()TMR_PERIOD()

----------------------------------------------------------------------------------------------

=

GMR-Based Angle Sensor

EEPROM Register Description

Field Bits Type Description

CRC_EEP 7:0

CRC has to be calculated with following values: page 0x002 & 0x003 &

0x004 & 0x005 & register 0x0060 & 0x0062 & 0x0064 & 0x0066 & 0x0068

& 0x006A & 0x006C & first byte of 0x006E (bit [15:8])

The PWM frequency of the PWM output can be programmed with the two parameters TMR_PREDIV and

TMR_PERIOD according to the following Equation (4.1):

(4.1)

Example:

For TMR_PREDIV = 12, TMR_Period = 15384, the PWM frequency calculates to f = 200 Hz.

4.2 Page 0x009

Care has be taken that there is no unintended modification of bits. When modifying registers, reserved bits

have to be read and written back with the same value.

Description EEPROM Register Address 0x0098 MOD1

1514131211109876543210

RST_3_5CLK_SELFIR_M

D

LUT_MD IFMD_ABC

Field Bits Type Description

RST_3_5 13

0:

Reset comparator set to < 3.0 V

B

1:

Reset comparator set to < 4.2 V

B

CLK_SEL 12

For test purpose only

IFMD_

123

FIR_MD 11

Internal update rate of angle calculation:

0:

25.6 µs

B

51.2 µs

1:

B

LUT_MD 9:8

Look-up table (LUT) configuration:

LUT disabled

00:

B

01:

LUT range = 360° (angle steps = 11.25°)

B

LUT range = 180° (angle steps = 5.625°)

10:

B

11:

LUT range = 90° (angle steps = 2.813°)

B

User’s Manual 19 Rev. 1.0

2019-03-12

Page 20

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

Field Bits Type Description

IFMD_ABC 5:4

For test purpose only

IFMD_123 0

For test purpose only

Description EEPROM Register Address 0x009A MOD2

1514131211109876543210

MOD2

Field Bits Type Description

MOD2 15:0

Lock register for 0x00A2. The bits in this registers are connected with a

logical AND function with the corresponding bit in 0x00A2. This means

that a “0” in a bit of register 0x009A prohibits to set a “1” in the

corresponding bit of 0x00A2. Note: The bit will show as “1” in 0x00A2

but has no effect

Description EEPROM Register Address 0x009C IF123_CFG

1514131211109876543210

PAD_

OV_O

FF

PAD_S

PIKE

IF3_ODIF3_CFGIF2_ODIF2_CFGIF1_ODIF1_C

FG

Field Bits Type Description

PAD_OV_OFF 15

Enable/disable overvoltage functionality. Output deactivated in case

of overvoltage on V

Overvoltage functionality enabled

0:

B

1:

Overvoltage functionality disabled

B

DD

:

PAD_SPIKE 14

Activate spike filter for input stage:

0:

Spike filter disabled

B

Spike filter enabled

1:

B

IF3_OD 11

IF3 open drain enable:

Disable (Push-Pull)

0:

B

1:

Enable (Open Drain)

B

User’s Manual 20 Rev. 1.0

2019-03-12

Page 21

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

Field Bits Type Description

IF3_CFG 10

For test purpose only

IF2_OD 9

IF2 open drain enable:

0:

Disable (Push-Pull)

B

Enable (Open Drain)

1:

B

IF2_CFG 8

For test purpose only

IF1_OD 7

IF1 open drain enable:

Disable (Push-Pull)

0:

B

1:

Enable (Open Drain)

B

IF1_CFG 6

For test purpose only

Description EEPROM Register Address 0x009E IFABC_CFG

1514131211109876543210

IFB_SLP

IFC_ODIFC_CFGIFB_ODIFB_CFGIFA_ODIFA_C

FG

Field Bits Type Description

IFB_SLP 15:14

Slope control of output signal:

00:

2µs

B

01:

4µs

B

10:

6µs

B

Tristate

11:

B

IFC_OD 11

IFC open drain enable:

Disable (Push-Pull)

0:

B

1:

Enable (Open Drain)

B

IFC_CFG 10

For test purpose only

IFB_OD 9

IFB open drain enable:

0:

Disable (Push-Pull)

B

1:

Enable (Open Drain with edges control)

B

IFB_CFG 8

For test purpose only

User’s Manual 21 Rev. 1.0

2019-03-12

Page 22

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

Field Bits Type Description

IFA_OD 7

IFA open drain enable:

0:

Disable (Push-Pull)

B

Enable (Open Drain)

1:

B

IFA_CFG 6

For test purpose only

4.3 Page 0x00A

Care has be taken that there is no unintended modification of bits. When modifying registers, reserved bits

have to be read and written back with the same value.

Description EEPROM Address 0x00A0 ANG_BASE

1514131211109876543210

ANG_BASE

Field Bits Type Description

ANG_BASE 15:2

Signed 14 bit value:

0° = 0x0000

-180.000° = 0x2000

+179.978° = 0x1FFF

+0.02197° = 0x001

ANG_DIR 1

Direction of magnet rotation:

0:

ccw

B

1:

cw

B

Reserved 0

0:

Reserved bit, shall not be changed

B

Description EEPROM Address 0x00A2 PWI_MD_USR

ANG_

DIR

Reser

ved

1514131211109876543210

EDGE

SENT/

SPC_L

T_5_3

SPC_T

EMP

SPC_R

CNIB

SPC_R

CCRC

SPC_T

PWI_MODE

User’s Manual 22 Rev. 1.0

PWM_

RIG

SENT_

PROM

O

SENT_

ERR_S

IG

SENT_

PAPU

SENT/

SPC_P

WI_SS

M

SENT/SPC_UT

2019-03-12

Page 23

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

Field Bits Type Description

PWI_MODE 15:13

Interface selection (Only available for Product Type: TLE5014F16D):

100:

PWM

B

SENT

010:

B

001:

SPC

B

PWM _EDGE 12

PWM starting edge:

0:

Rising edge

B

Falling edge

1:

B

SENT/SPC_LT_

5_3

SPC_TEMP 10

SPC_RCNIB 9

SPC_RCCRC 8

SPC_TRIG 7

SENT_PROMO 6

11

SENT/SPC low time:

5UT

0:

B

1:

3UT

B

Temperature information in SPC protocol:

0:

No temperature nibble

B

1:

Two temperature nibbles

B

Rolling counter:

0:

Rolling counter nibble enabled

B

No rolling counter nibble

1:

B

Rolling counter in CRC:

No rolling counter in CRC

0:

B

1:

Rolling counter in CRC

B

SPC bus mode:

0:

90 UT constant trigger length

B

1:

Variable trigger length

B

SENT protocol type:

0:

Single secure sensor (with rolling counter and inverted data

B

nibble)

1:

Standard SENT (without rolling counter and inverted data

B

nibble)

SENT_ERR_SIG 5

SENT error indication:

Error code “4091” in data range

0:

B

1:

Error indication in status nibble only

B

SENT_PAPU 4

Pause pulse activation:

0:

No pause pulse

B

1:

Pause pulse activated

B

User’s Manual 23 Rev. 1.0

2019-03-12

Page 24

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

Field Bits Type Description

SENT/SPC_PWI

_SSM

3

SENT/SPC short serial message:

0:

No short serial message

B

Short serial message activated

1:

B

SENT/SPC_UT 2:0

SENT/SPC unit time setting:

3µs

000:

B

001:

2.5 µs

B

2.0 µs

010:

B

011:

1.5 µs

B

100:

1.0 µs

B

Description EEPROM Address 0x00A4 CRC_CFG

1514131211109876543210

AS_N

S_NR_EEP CRC_CFG

R

Field Bits Type Description

AS_NR 10

0:

Address configuration for SICI as defined in bits S_NR_EEP

B

Address configuration for SICI as defined by hard wiring of pins

1:

B

Note: This bit shall be set to “1”, otherwise no programming in bus

S_NR_EEP 9:8

Address coding of SPC slave:

00:

ID = 0

B

01:

ID = 1

B

ID = 2

10:

B

11:

ID = 3

B

CRC_CFG 7:0

Configuration CRC and SPC address; CRC has to be calculated with

following values: registers 0x0096 & 0x0098 & 0x009A & 0x009C &

0x009E & 0x00A0 & 0x00A2 & first byte of 0x00A4 (bit [15:8])

4.4 Page 0x00B - 0x00E

Look-up table, see Table 10.

mode is possible. SPC protocol is always using the values

from bits S_NR_EEP

4.5 Page 0x00F

In EEPROM register 0x00F0 the 8-bit CRC for the look-up table is stored.

User’s Manual 24 Rev. 1.0

2019-03-12

Page 25

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

Description EEPROM Address 0x00F0 CRC_LUT

1514131211109876543210

CRC_LUT

Field Bits Type Description

CRC_LUT 7:0

8-bit CRC has to be calculated with following values:

Page 0x00B & 0x00C & 0x00D & 0x00E & first byte of 0x00F0 (bits [15:8])

In the EEPROM registers 0x00F2 to 0x00FE the customer ID is stored. In total it is 16 x 7 = 112 bit.

The first 32 bits (EEPROM address 0x00F2 and 0x00F4) are transmitted in the short serial message.

User’s Manual 25 Rev. 1.0

2019-03-12

Page 26

TLE5014

GMR-Based Angle Sensor

Working Register Description

5 Working Register Description

This chapter describes the working registers which can be read with the SICI interface. These registers are

updated with the time t

5.1 STAT Register 0x00: Status

This register provides detailed information on sensor status and internal sensor errors.

Register Address 0x00: STAT (Status)

1514131211109876543210

, which is approximately 25 µs.

update

Read Command: 0xC001

RD_ST RES S_IF S_VEC RES RES S_EEP S_CRC

uuuu uuuuuuuuuu

S_PROGS_BISTS_ADC

T

S_ADC S_VR S_WD

S_PLA

USI

S_RST

Field Bits Type Description

RD_ST 15 u

Read bit that indicates that the bits in the STAT-line are updated since

the last readout

RES 14 u

Reserved

S_IF 13 u

Bit is set when a interface issue happened

S_VEC 12 u

Bit indicates when the vector length of the actual angle_vector

exceeds the defined limits

RES 11

Reserved

RES 10

Reserved

S_EEP 9u

Bit indicates whenever the EEPROM initiates an error

S_CRC 8u

Bit is set whenever one of the bit error detection functions is alarming

S_PROG 7u

Bit indicates a DSP error

S_BIST 6u

Bit is set whenever one of the startup-BIST is failing. (BIST: Built in self

test)

S_ADCT 5u

Bit is set when the temperature is out of limits or the temperature

delta check is failing

S_ADC 4u

Bit is set when the ADC_raw_max or ADC_raw_delta check fails or the

filter-scheduling check is alarming

User’s Manual 26 Rev. 1.0

2019-03-12

Page 27

TLE5014

GMR-Based Angle Sensor

Working Register Description

Field Bits Type Description

S_VR 3u

Bit is a combination of several voltage checks

S_WD 2u

Bit is set when the last reset happened due to a watchdog event

S_PLAUSI 1u

Bit is set when the redundant angle calculation is failing the limits

S_RST 0u

Reset occurred

5.2 AVAL Register 0x02: Angle Value

The current angle value can be read via SICI interface in register AVAL at address 0x02. It is updated approx.

every 25 µs, which is the time needed for sampling and calculating a new angle value. It is a signed 15-bit value

(see Description Register Address 0x02 AVAL).

Description Register Address 0x02 AVAL

Read command: 0x8021

1514131211109876543210

RD_AV AVAL

Field Bits Type Description

RD_AV 15

Read bit that indicates that the bits in the AVAL register are updated

since last readout by interface

AVAL 14:0

Signed 15-bit internal angle value:

0° = 0x0000

-180° = 0x4000

179.99° = 0x3FFF

5.3 ASPD Register 0x03: Angle Speed

This register provides the actual angle speed.

Register Address 0x03: Angle speed

Read command: 0xC031

1514131211109876543210

RD_AS

PD

uu

User’s Manual 27 Rev. 1.0

RES ASPD

2019-03-12

Page 28

TLE5014

speed ° s⁄[]

360°

65536

---------------

ASPD digits[]×

t

update s[]

----------------------------------------------------------

=

GMR-Based Angle Sensor

Working Register Description

Field Bits Type Description

RD_ASPD 15 u Read angle speed

Read bit that indicates that the bits in the ASPD-register are updated

since last readout by interface

RES 14:12

Reserved

ASPD 11:0 u Angle speed

Calculated angle speed signed 12-bit value

5.4 RAW_X Register 0x06: X raw value

This register provides the x-raw value (cosine value).

Register Address 0x06: X raw value

Read command: 0xC061

1514131211109876543210

RAW_X

u

Field Bits Type Description

RAW_X 15:0 u

Unsigned 16-bit value of X-raw

5.5 RAW_Y Register 0x07: Y raw value

This register provides the y-raw value (sine value).

Register Address 0x07: Y raw value

Read command: 0x8071

1514131211109876543210

RAW_Y

u

Field Bits Type Description

RAW_Y 15:0 u

Unsigned 16-bit value of Y-raw

User’s Manual 28 Rev. 1.0

2019-03-12

Page 29

TLE5014

GMR-Based Angle Sensor

Working Register Description

5.6 TEMP Register 0x0A: Temperature raw value

This register provides the actual raw temperature value. To calculate the actual temperature, the temperature

offset has to be determined. This is done by reading the register once at a known temperature (e.g. 25°C) This

value is then TEMPER_25 and the offset corrected temperature can be calculated using the formula below.

Register Address 0x0A: temperature raw value

Read command: 0xC0A1

1514131211109876543210

TEMP_VALUE

rrr

Field Bits Type Description

TEMP_VALUE 15:6 r Temperature value

10-bit temperature value, not offset corrected

T [°C] = (TEMP_VALUE-TEMPER_25) / 1.3815 [LSB/°C] + 25°C

TEMPER_25: TEMP_VALUE @25°C

In case the offset correction is not done at 25°C but at a different

temperature, the formula has to be modified accordingly.

RD_SM 5rRead state machine

Bit is set when new value is available since state machine has read

last one

RD_INT 4rRead interface

Bit is set when new value is available since interface has read last one

RES 3:0

Reserved

RD_SMRD_IN

T

RES

5.7 ANG_BASE register 0x14: Angle base and rotation direction

This register contains the angle base. The output angle is referring to this angle base value.

Register Address 0x14: angle base and rotation direction

Read command: 0xC141

1514131211109876543210

ANG_BASE

ww

User’s Manual 29 Rev. 1.0

ANG_

DIR

2019-03-12

RES

Page 30

TLE5014

GMR-Based Angle Sensor

Working Register Description

Field Bits Type Description

ANG_BASE 15:2 w Angle base

signed 14 bit zero angle value.

Output angle is referring to this angle base

0x0000 = 0°,

0x2000 = -180°,

0x1FFF = +179,978°,

0x001 = 0,02197°

ANG_DIR 1wDirection of the angle rotation

0 = clockwise

1 = counter clockwise

RES 0

Reserved

User’s Manual 30 Rev. 1.0

2019-03-12

Page 31

TLE5014

GMR-Based Angle Sensor

SICI

6SICI

6.1 Basic Functionality

The SICI interface (SICI: Single-Wire Interface for Calibration and Inspection) is a one-wire programming

interface that allows read and write access to the working registers and EEPROM registers of the sensor. It is

bidirectional for every transferred bit, meaning that for every single bit sent by the master one bit is

immediately sent back from the slave. The speed of the interface is automatically determined from the length

of the first bit sent by the master.

The one-wire interface enables a robust data transmission at a speed of up to 240 kbit/s. It is a voltage

interface based on a bit-wise pulse-width-modulation (PWM) principle and requires an open-drain driver on

micro controller side. Regardless of the interface configuration of the TLE5014, the SICI interface is always

available on the IFB pin during the startup time.

In order to use the SICI interface, sensor and micro controller have to use an open drain output, so they can

actively pull a “low” level. The communication line has to be connected to V

1.5-2 kΩ. Higher values for the pull-up resistor may lead to problems to achieve the necessary speed of the

communication.

by a pull-up resistor of approx.

DD

6.2 SICI Data Transfer

The communication via the SICI interface is based on transmitting a single bit to the sensor and immediately

receiving a bit. These bits form a 16-bit word. It makes the interface bit-synchronous, robust and very flexible

in timing. Bidirectional data transmission can thus be realized using only a single wire without a trimmed

oscillator on sensor or master side. To enhance the robustness of the interface, the sensor repeats the 16-bit

command word sent by the master in order to have a confirmation of the correct understanding of the

message, and transmits a safety word after each communication. Additionally, a time-out feature is

implemented: If during a communication the sensor does not receive a bit from the master within a certain

time span (see Table 11, Interface reset time), the interface is reset and a new command can be sent.

6.2.1 Bit Encoding

For the SICI interface, bits are encoded as the difference in duration of consecutive “low” and “high” levels. To

transmit a bit to the sensor, the master sends one single low/high PWM signal with a period T, then pulls the

line to “low” again for a short time T

“low” and “high” time:

• to transmit a “0” to the sensor, the master pulls the line “low” for a short time T

for a long time T - T

(typically T1=0.3*T)

1

• to transmit a “1” to the sensor, the master pulls the line “low” for a long time T

for a short time T - T

(typically T2=0.7*T)

2

The sensor recognizes the total bit-time interval T as the duration between two consecutive falling edges from

the master. This encoding scheme is illustrated in Figure 6.

. The logic value of the bit is then encoded as the difference between

3

, then releases it to “high”

1

, then releases it to “high”

2

User’s Manual 31 Rev. 1.0

2019-03-12

Page 32

TLE5014

T

0:

1:

T

1

T

2

ΔT = T – 2*T

1

ΔT = 2*T2-T

ΔT

master pulls low

line is released

0

1

GND

V

DD

T

3

1

0

Δ T

Master checks

resp onse here

Master pulls low

Sensor pulls low

Line is released

V

DD

GND

GMR-Based Angle Sensor

SICI

Figure 6 Timing description of master bit

After receiving a bit from the master, the sensor answers by transmitting one bit:

• the sensor transmits a “1” by pulling the SICI-line “low” for the time difference ∆T between “high” and

“low” level given by the received PWM signal (i.e. if a “0” was transmitted by the master, ∆T = T -2*T

whereas if a “1” was transmitted by the master, ∆T =2*T

• the sensor transmits a “0” by keeping the line “high”

To read the bit transmitted by the sensor, the master has to check the level of the line after T

pulse) but before time ∆T has expired (recommended 80% of ∆T, see Figure 7).

2

- T)

(master low

3

,

1

Figure 7 Timing description of response bit from sensor

After receiving the response bit from the sensor, the master can pause for a time T

next bit. T

interface is reset. Figure 8 shows an example communication between master and sensor.

User’s Manual 32 Rev. 1.0

has to be shorter than the time-out limit (see Table 11, interface reset time), otherwise the

4

before transmitting the

4

2019-03-12

Page 33

TLE5014

master pulls low

line is released

sensor pulls low

T

1

T

2

T

3

ΔT T

4

T ΔT

0 from maste r 1 from sensor

1 from maste r

0 from sensor

GND

V

DD

GMR-Based Angle Sensor

SICI

Figure 8 SICI communication example

The transmission rate of the interface is determined by the width T of the PWM signal sent by the master. A

maximum transmission speed of 240 kbit/s can be reached for T = 2 µs. Lowering the transmission rate

generally increases the robustness of the communication in distorted environments and/or with high

capacitive loads on the line. The optimum communication speed thus depends on the application circuitry.

The timing specification of the SICI interface is given in Table 11.

Table 11 SICI interface timing and level specification

Parameter Symbol Values Unit Note or Test Condition

Min. Typ. Max.

Master PWM period T 2

1)

– 980 µs Determines interface

transmission rate

Master low time to transmit “0” T

Master low time to transmit “1” T

Time difference between master

low and high level

Master low pulse after PWM bit T

Master pause time after sensor

1

2

0.2*T – 0.33*T µs

0.66*T –0.8*T µs

∆T 0.33*T –0.6*T µs ∆T = T - 2 * T1 ; for “0”

3

T

4

0.4 – 0.25*T µs

0.75*T – 810 µs

2)

2)

∆T = 2 * T

2)3)

2)3)

- T; for “1”

2

bit response

Interface reset time T

Input signal low level V

Input signal high level V

Output signal low level V

SICI line pull-up resistor R

Wait time between transmitted

Res

low,in

high,in

low,in

pu

t

delay

– 820 1640 µs

––0.3*V

DD

0.7*VDD–– V

––0.9V

1–– kΩ

1–– µs

16-bit words

1) Achievable transmission rate (minimum master PWM period) depends on parasitic capacities in external circuitry.

2) Verified by design/characterization.

3) Rise/fall times due to parasitic capacitances on the line have to be added.

4) Max. time for reset calculated for worst case interruption of SICI transmission

2)4)

2)

V

2)

2)

2)

User’s Manual 33 Rev. 1.0

2)

2)

2019-03-12

Page 34

TLE5014

a) Read:

Masters sends :

Sensor responds :

Command

repeat Command

0x0000

Data Word 1

0x0000

Data Word n

0x0000

Safety Word

t

delay

t

dela y

t

delay

b) Wri te :

Masters sends :

Sensor responds :

Command

repeat Command

Data Word 1

repeat Data Word 1

Data Word n

repeat Data Word n

0x0000

Safety Word

t

delay

t

delay

t

dela y

t

t

GMR-Based Angle Sensor

SICI

To enter the programming mode of TLE5014 some dedicated commands have to be sent within the start-up

time of the sensor (see Chapter 6.2.4).Thus, not all possible settings of the SICI timing parameters (e.g. T, T1,

T2, …) can be used with TLE5014. An example setting of the timing parameters for SICI interface, which allows

to send all necessary SICI commands within the start-up time, is shown in Table 12.

Table 12 Example of SICI timing parameters

Parameter Symbol Value Unit Remarks

Master PWM period T 21.1 µs

Master low time to transmit “0” T

Master low time to transmit “1” T

Time difference between master low

and high level

Master low pulse after PWM bit T

Master pause time after sensor bit

1

2

∆T 7.9 µs ∆T = T - 2 * T

3

T

4

6.6 µs

14.5 µs

3.5 µs

25 µs

∆T = 2 * T

; for “0”

1

- T; for “1”

2

response

6.2.2 Communication Protocol

The master transmits a 16-bit command word to read or write registers, then sends or receives a number of

data words and then receives a safety word from the sensor. Each transmission starts with the mostsignificant-bit (MSB). The register map is shown in Chapter 3. Table 13 shows the structure of the command

word.

Figure 9 SICI data transfer for read command (a) and write command (b)

User’s Manual 34 Rev. 1.0

2019-03-12

Page 35

TLE5014

GMR-Based Angle Sensor

SICI

Table 13 Structure of the Command Word

Name Bits Description

RW [15] Read - Write

0: Write

1: Read

PRTY [14] Command Parity

Odd parity of all command word bits. Number of “1”s including parity has

to be odd

CMD [13] Command Mode

0: ADDR field is interpreted as register address to be read/written

ACCESS [12..11] Access mode to registers

READ:

00

: Direct readout

B

01

: Update all registers and then readout

B

1x

: Readout only updated registers

B

WRITE:

00

: Direct write

B

10

: Reset active bits (ones in written data)

B

:Set active bits (ones in written data)

11

B

ADDR [10..4] 7 bit address

LEN [3..0] 4 bit length; number of data words to read/write

If a read command is transmitted, the master has to send a 16-bit sequence of 0’s for every requested word to

be read. The sensor then responds to each “0” from the master with a bit from the register word to be read,

starting with the MSB. If a write command is transmitted, the sensor repeats every single bit of the data words.

After the transmission of the data words, the master has to send another 16-bit sequence of 0’s, and the sensor

responds to each “0” with one bit of the safety word, starting with the MSB. Between each transmitted word,

there has to be a delay t

to allow the sensor to process the data. Figure 9 illustrates the sequence of

delay

command, data and safety words for read/write access.

A safety word is sent at the end of each communication. The structure of the safety word is shown in Table 14.

An internally detected sensor fault is indicated in the safety word.

It is recommended to read the status register STAT (Chapter 5.1) in this case to get further information of the

error. Reading of the STAT register causes a reset of the error bit in the safety word. If the status register is not

read, the error indication will persist in the safety word, even when the error is no longer existing

User’s Manual 35 Rev. 1.0

2019-03-12

Page 36

TLE5014

xor

X7 X6 X5 X4 X3 X2

xor

X0

xor

xor

Input

Serial

CRC

output

&

TX_CRC

1111 1 1 1

1

X1

parallel

Remainder

GMR-Based Angle Sensor

SICI

Table 14 Structure of the Safety Word

Name Bits Description

STAT Chip and Interface Status

[15] Indication of Chip-Reset or watchdog was activated

0: Reset occurred or watchdog was activated

1: No reset

[14] System Error (e.g. Overvoltage; Undervoltage; GND- off; CRC)

0: Error occurred

1: No error

[13] Interface Access Error (access to wrong address; wrong lock, wrong parity)

0: Error occurred

1: No error

[12] Valid Angle Value (no ADC error, no internal plausibility check error)

0: Angle value invalid

1: Angle value valid

RESP [11..8] Sensor Number Response Indicator

The sensor number bit is pulled low and the other bits are high.

CRC [7..0] Cyclic Redundancy Check (CRC) includes command word, data words,

STAT & RESP

6.2.3 CRC generation

The TLE5014 uses a cyclic redundancy check (CRC) to confirm the correct processing of read and write

commands via the safety word, and to monitor the integrity of configuration registers and EEPROM pages. The

CRC is generated according to the J1850 Bus-Specification:

• Every new transfer resets the CRC generation

• Every Byte of a transfer will be taken into account to generate the CRC (also the sent command(s))

• Generator-Polynomial: X8+X4+X3+X2+1; for the CRC generation the fast-CRC generation circuit is used (see

Figure 10)

• The remainder of the fast CRC circuit is initially set to ’11111111

• Remainder is inverted before transmission

’

B

Figure 10 Fast CRC polynomial division circuit

6.2.4 SICI Application Example: Reading working register

Sensor and micro controller must use an open-drain output, so they can actively pull only a 0 Volt level; the

5 Volt level is achieved by an external pull-up resistor.

User’s Manual 36 Rev. 1.0

2019-03-12

Page 37

TLE5014

GMR-Based Angle Sensor

SICI

In the application, the chip will switch into SENT/SPC/PWM mode (depending on pre programmed

configuration) after startup. Therefore the SICI can only be entered during startup and internal settings have

to be modified to keep the SICI in case it shall be used for programming purpose.

The following sequence has to be performed to read a register (angle value register AVAL 0x02 in this example):

Power on the sensor, wait at least 10 µs to allow the internal voltages to stabilize:

• Set the KEEP_IF bit to ensure the SICI is not disabled after startup:

– WRITE-CMD to 0x6C: 0x06C1

– DATA: 0x4000 (keep SICI after startup)

–Read Safety word

• Wait until startup is finished; refer to the TLE5014 data sheet for power-on time specification

• The 15-bit angle value can be read to get data for the angle base or look-up table programming:

– READ-CMD to 0x02: 0x8021

– Read DATA (send 0x0000)

–Read Safety word

6.2.5 SICI Application Example: EEPROM read/write

Sensor and micro controller must use an open-drain output, so they can actively pull only a 0 V level; the 5 V

level is achieved by an external pull-up resistor.

In the application, the chip will switch into SENT/SPC/PWM mode (depending on pre programmed

configuration) after startup. Therefore the SICI can only be entered during startup and internal settings have

to be modified to keep the SICI in case it shall be used for programming purpose.

The following sequence has to be performed to allow an EEPROM read/write via SICI:

• Power on the sensor, wait at least 10 µs to allow the internal voltages to stabilize

• Write unlock word 0x4711 to 0x77 to enable access to the registers:

– WRITE-CMD to 0x77: 0x0771

– DATA: 0x4711 (unlock)

–Read Safety word

• Set the KEEP_IF bit to ensure the SICI is not disabled after startup:

– WRITE-CMD to 0x6C: 0x06C1

– DATA: 0x4000 (keep SICI after startup)

–Read Safety word

• Wait until startup is finished; refer to the TLE5014 data sheet for power-on time specification

• For reading or writing EEPROM content, the internal controller has to be switched off:

– WRITE-CMD to 0x6C: 0x06C1

– DATA: 0xC000 (switch off DSP)

–Read Safety word

• Now the EEPROM-reading / writing can be entered (see Chapter 7)

• After writing/reading the EEPROM, send a write command to the ACSTAT register (address 0x01) with data

word 0x0001 to trigger a chip reset:

– WRITE-CMD to 0x01: 0x4011

– DATA: 0x0001 (chip reset)

User’s Manual 37 Rev. 1.0

2019-03-12

Page 38

TLE5014

GMR-Based Angle Sensor

SICI

6.3 SICI Programming in Bus Mode

In case several sensors (up to 4) are connected in a bus mode with the SPC interface, the EEPROM read/write

via SICI has to be performed in the bus mode configuration. For this purpose, to each individual sensor an

address has to be assigned which is done by the external wiring of the pins IF1, IF2 and IFC on the PCB as

described in the data sheet and in Table 4 of this document.

To address the individual sensors with SICI, one of the following ID_WORD has to be sent according to the

hard-wired sensor ID:

ID=0: ID_WORD = 0x05AC

ID=1: ID_WORD = 0x05A9

ID=2: ID_WORD = 0x05A6

ID=3: ID_WORD = 0x05A3

The following sequence has to be performed to allow an EEPROM read/write via SICI in bus mode. The

commands in blue have to be added to the command sequence described in Chapter 6.2.4 for

reading/writing in bus mode and contain the ID_WORD for sensor addressing: Power on the sensor, wait at

least 10 µs to allow the internal voltages to stabilize:

• Write unlock word 0x4711 to 0x77 to enable access to the registers:

– WRITE-CMD to 0x77: 0x0771

– DATA: 0x4711 (unlock)

–Read Safety word

• Set the KEEP_IF bit to ensure the SICI is not disabled after startup:

– WRITE-CMD to 0x6C: 0x06C1

– DATA: 0x4000 (keep SICI after startup)

–Read Safety word

• Write sensor ID to SICI-DISABLE register at 0x7A:

– WRITE-CMD to 0x7A: 0x47A1

– DATA: ID_WORD

–Read Safety word

• Wait until startup is finished; refer to the TLE5014 data sheet for power-on time specification

• For the programming, the internal controller has to be switched off:

– WRITE-CMD to 0x6C: 0x06C1

– DATA: 0xC000

–Read Safety word

• Now the EEPROM-reading / writing can be entered (see Chapter 7)

• After writing/reading the EEPROM, send a write command to the ACSTAT register (address 0x01) with data

word 0x0001 to trigger a chip reset:

– WRITE-CMD to 0x01: 0x4011

– DATA: 0x0001 (chip reset)

User’s Manual 38 Rev. 1.0

2019-03-12

Page 39

TLE5014

GMR-Based Angle Sensor

EEPROM Programming

7 EEPROM Programming

The EEPROM of the TLE5014 consists of user accessible and locked pages with eight 16-bit data words each.

To access a page of the EEPROM, the page is mapped onto a range of registers, which can then be read or

written via the SICI interface.

7.1 Writing and Reading of EEPROM Pages

To read or write data form the EEPROM, the desired page has first to be mapped to working registers EEP_0 to

EEP_7 (address 0x60 to 0x67) by writing the desired page number (0..15) to the EEP_PAGE register (address

0x68, see Table 13). The content of the EEPROM page can then be read from registers EEP_0 to EEP_7.

Before EEPROM content can be read or written, the steps describes in Chapter 6.2.5 have to be performed.

Programming the EEPROM is done by sending the following command sequence (example for EEPROM page

0x009):

• Map the desired EEPROM page to the registers EEP_0 to EEP_7 (0x60 to 0x67) by writing the page number

into the EEP_PAGE register 0x68 (example for EEPROM page 0x006):

– WRITE-CMD to 0x68: 0x4681

– DATA: 0x0009 (maps EEPROM page 0x009 to working registers 0x60 … 0x67)

• Read the content of the desired EEPROM page by sending a read command to registers EEP_0 to EEP_7,

then change the desired bits and write the content back to registers EEP_0 to EEP_7:

– READ-CMD to 0x60: 0xC601 (reads working register 0x60 = EEP_0)

– DATA: content of working register 0x60 (corresponds to EEPROM register 0x0090

–…

– READ-CMD to 0x67: 0x8671 (reads working register 0x67 = EEP_7)

– DATA: content of working register 0x67 (corresponds to EEPROM register 0x009E)

• To change EEPROM content, first overwrite register EEP_0 to EEP_7 (0x60 to 0x67) with the desired

content:

– WRITE-CMD to 0x60: 0x0601

– DATA: 0xFFFF (example for writing 0xFFFF in EEPROM register 0x0090)

–…

• To program the data from registers EEP_0 to EEP_7 back into the EEPROM page, the following commands

have to be sent:

– WRITE-CMD to 0x68: 0x4681

– DATA: 0x03FF

– WRITE-CMD to 0x67: 0x4671 (program with automatic verification)

– DATA: 0x0009

• After writing/reading the EEPROM, send a write command to the ACSTAT register (address 0x01) with data

word 0x0001 to trigger a chip reset:

– WRITE-CMD to 0x01: 0x4011

– DATA: 0x0001 (chip reset)

The EEPROM data is protected by checksums. When changes are made to one or more EEPROM registers, the

respective checksum has to be recalculated and written into the corresponding register. Therefore, the

complete register range which is covered by the checksum has to be read, and the checksum calculation has

to be performed as described in Chapter 2.3. The addresses of the checksum registers and the register range

covered by each checksum are listed in Table 10.

User’s Manual 39 Rev. 1.0

2019-03-12

Page 40

TLE5014

GMR-Based Angle Sensor

EEPROM Programming

Changing the configuration of the TLE5014 without updating the corresponding checksum results in a CRC

error, which is indicated.

EEPROM Timing

Table 11 gives the timing specification for reading and programming the EEPROM.

Table 15 EEPROM timing specification

Parameter Symbol Values Unit Note or Test Condition

Min. Typ. Max.

Read time per word t

Write time

Erase time

Program time

2)

2)

2)

Startup time after reset t

1) Verified by design/characterization.

2) Times are identical, independent of the number of words that are written, erased, or programmed at a time.

read_ac

t

write

t

erase

t

program

startup

– – 150 ns

4.0 5.0 6.0 ms

4.0 5.0 6.0 ms

8.0 10.0 12.0 ms

46 57 68 µs

1)

2)

2)

2)

2)

7.2 Verification of EEPROM

To verify if the programing of the EEPROM page was successful, the respective EEPROM page should be read

again and verified if the content matches with the intended content.

In addition, there is a register at address 0x69, which indicates the status after the EEPROM burning.

EEPROM writing verification, address 0x69

1514131211109876543210

RES VER_RESULT RES

Field Bits Type Description

RES 15:4

Reserved

VER_RESULT 3:2

Indicates result of verification:

00:

No verification error occurred

B

One single bit verification error occurred

01:

B

10:

More than one single bit verification error occurred

B

11:

Al least one multi-bit verification error occurred

B

RES 1:0

Reserved

7.3 Locking of EEPROM

After programming the EEPROM, the content can be locked. In this case, no second programming is possible.