Page 1

Data Sheet v01_00

www.infineon.com 1 2020-11-02

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC

interface

Features

• Two highly accurate redundant Hall measurement channels (main and sub)

integrated on one chip.

• Developed compliant to ISO 26262 (first edition 2011) Safety Element out of

Context for safety requirements rated up to ASIL D.

• High diagnostic coverage by plausibility checking of main and sub signal on

system level.

• Fast digital SPC interface with min. 0.5µs unit time for transmission of main

and sub signals in less than 500 µs.

• Bus-capability for up to 4 sensor ICs on one data line.

• Selectable 12/14/16bit output signals, protected by CRC and rolling counter.

• Thin 8-pin SMD single sensor package.

• Operating automotive temperature range -40°C to 125°C.

• Digital temperature and stress compensation.

• Reverse-polarity and over voltage protection for VDD, GND and OUT pins.

• Main and sub channel programmable independently in EEPROM.

• Multipoint calibration up to 9 points.

• Frameholder mechanism.

• Single-wire SICI programming interface on output pin.

• 2 x 16 bit user-configurable ID in EEPROM.

PRO-SIL™ Features

• Safety Manual and Safety Analysis Summary Report.

Potential applications

• Robust replacement of potentiometers: No mechanical abrasion, resistant to humidity, temperature,

pollution, and vibration.

• Linear and angular position sensing in automotive and industrial applications with highest accuracy

requirements.

• Suited for safety applications such as pedal position, throttle position, and steering torque sensing.

Page 2

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Product validation

Qualified for automotive applications. Product validation according to AEC-Q100.

Description

The TLE4999C8 is a dual channel linear Hall sensor with a bus-capable digital Short-PWM-Code (SPC)

interface. Both channels are integrated on one die in the chip.

The highly accurate measurement channels (main and sub) can be used for a plausibility check on system

level. This enables a high diagnostic coverage.

The sensor is developed in compliance to ISO 26262 (first edition 2011), supporting safety requirements on

system level rated up to ASIL D.

Highest accuracy over a wide temperature range and lifetime is achieved by an integrated digital

temperature- and stress-compensation.

Table 1 Ordering Information

Product Name Marking Ordering Code Package

TLE4999C8 99C SP002662500 single sensor, PG-TDSO-8-1

Data Sheet 2 v01_00

2020-11-02

Page 3

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Table of Contents

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Potential applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Product validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Pin and package configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Operating range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1 Calculation of the junction temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 Electrical, magnetic and output parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8 SPC output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.1 SPC bus mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.2 SPC unit times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.3 SPC trigger pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.4 Status nibble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.5 Short serial message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.6 Temperature nibbles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.7 Rolling Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.8 CRC nibble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.9 SPC frameholder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9 Configuration and calibration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10 Package outlines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10.1 Distance of chip to package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10.2 Moisture Sensitivity Level (MSL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10.3 Package marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

11 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Data Sheet 3 v01_00

2020-11-02

Page 4

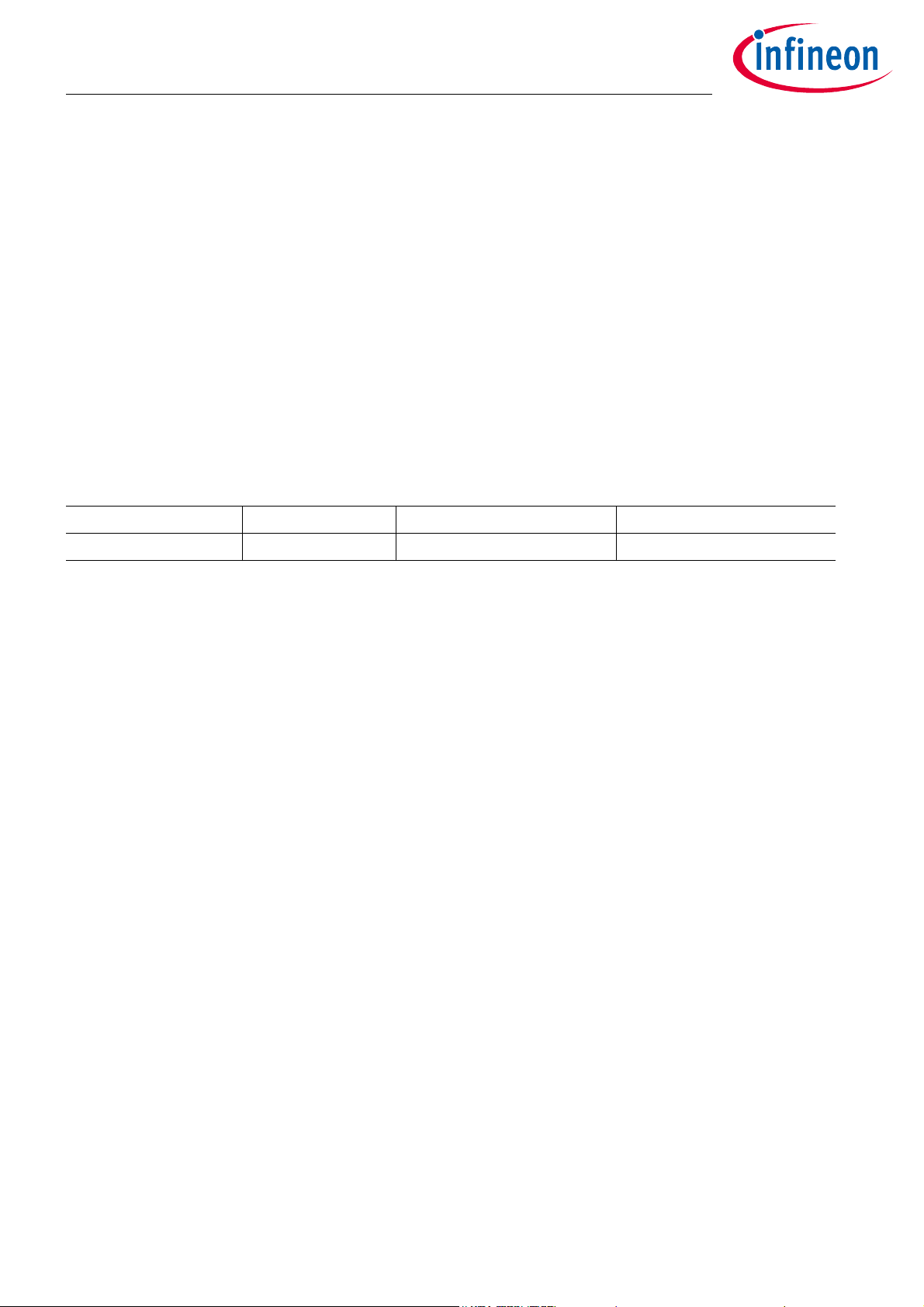

Main

Hall

Main

T-Sensing

element

ROM 1

EEPROM

SICI

OUT

CBUF

GND

Main Bias

Main Analog

Regulator

Sub Analog

Regulator

Digital

Regulator

Supply

Sub

Hall

Sub Bias

Main

S-Sensing

element

ROM 2

A

D

A

D

DSP 2

DSP 1

Su b

T-Sensing

element

Su b

S-Sensing

element

Main HADC

Sub HT S -ADC

VDD

SPC

Encoder

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Block diagram

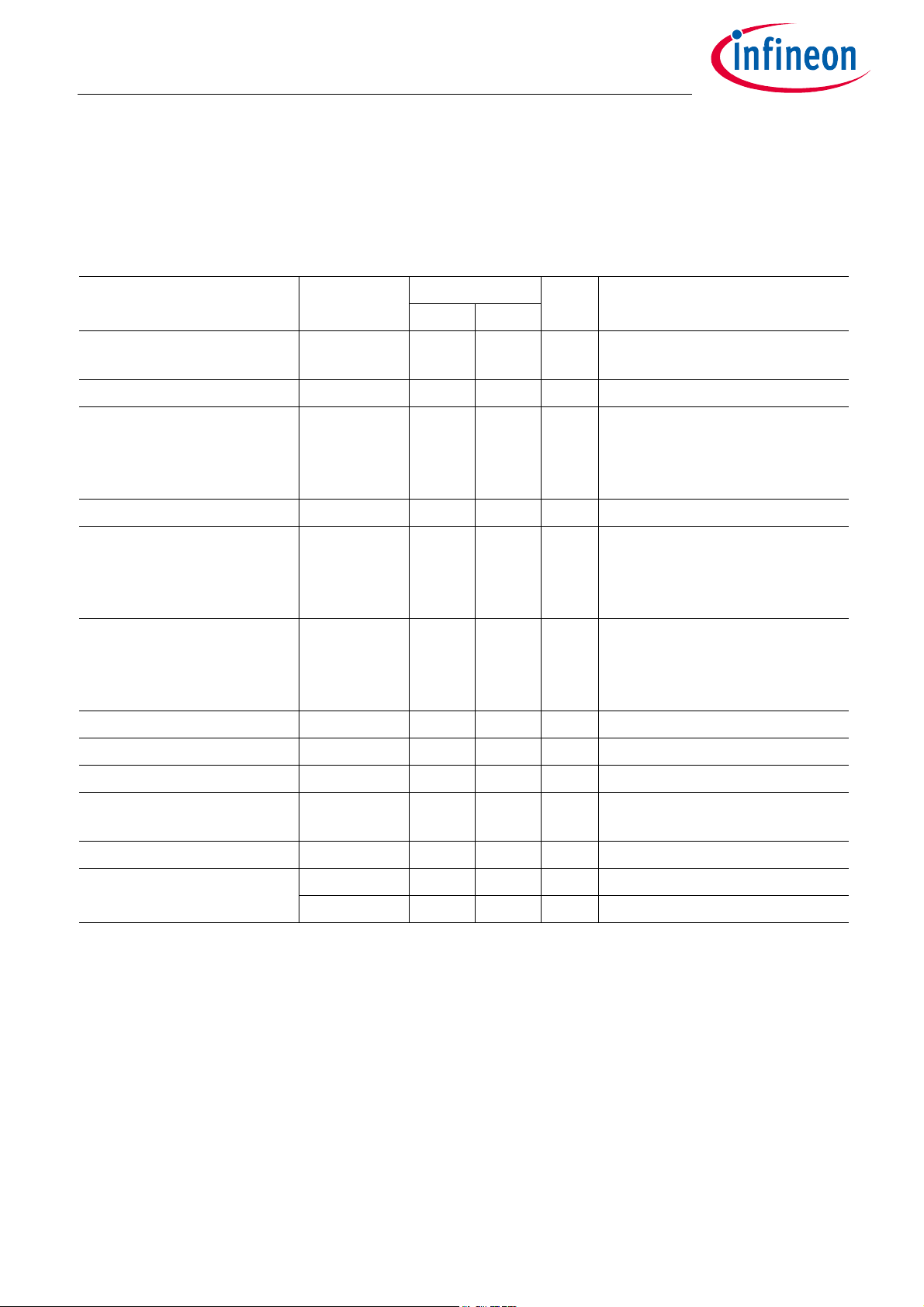

1 Block diagram

Figure 1 Block diagram

Data Sheet 4 v01_00

2020-11-02

Page 5

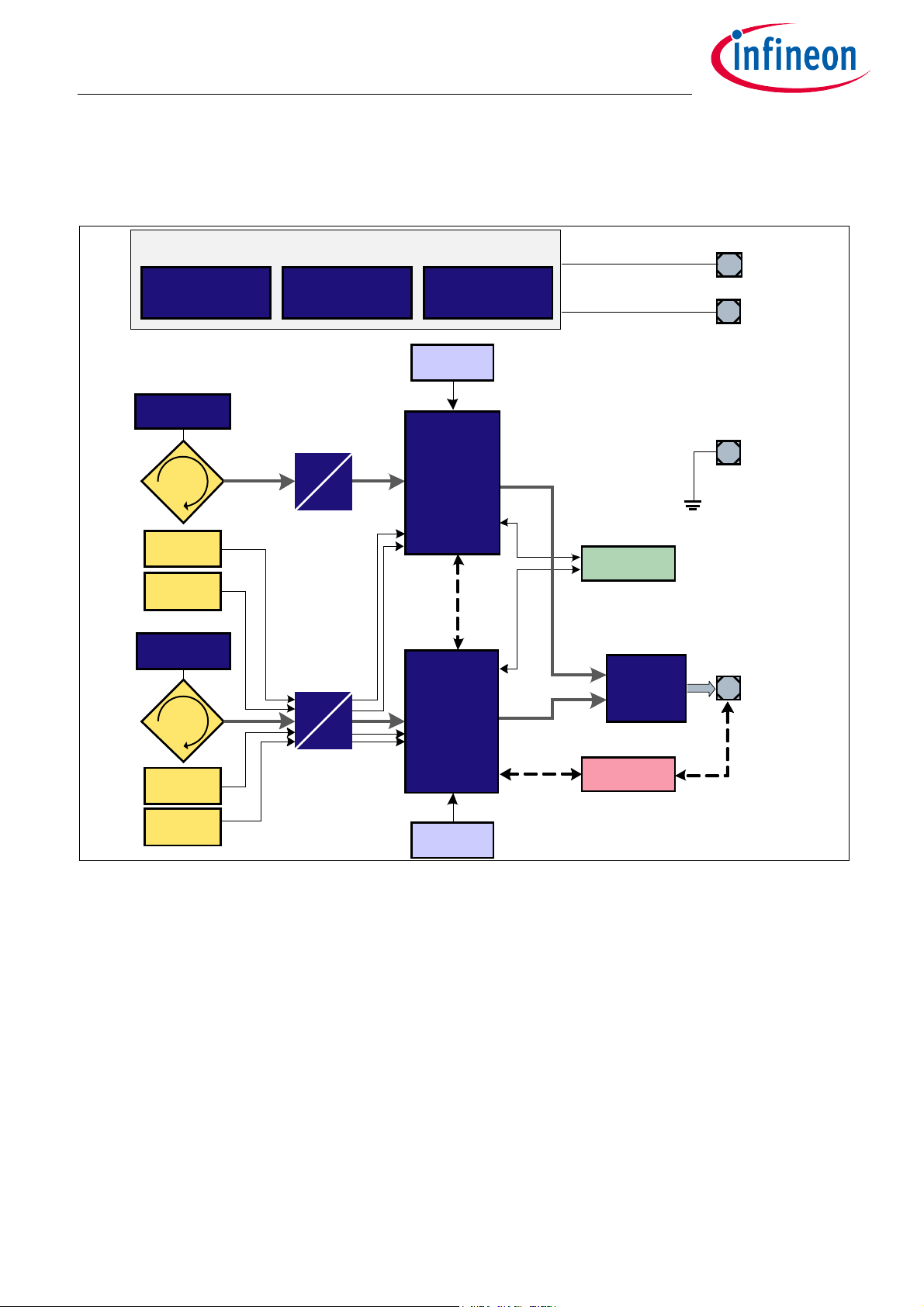

Main

Hall

Sub

Hall

Main Channel

Sub Channel

SPC

Pin 4 - OU T

Pin 3 - GN D

Pin 2 - VDD

TLE4999 C8

TLE4999C

TLE4999C8

Pin 1 - C BU F

A0.2

B0.2

Center of sensitive area

1

2

34

8

7

65

0.90

0.96

Main/Sub

Hall Probes

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Pin and package configuration

2 Pin and package configuration

Figure 2 shows the arrangement of the measurement channels of the TLE4999C8. The location of the Hall

probes in the package and the pin configuration of the TLE4999C8 are shown in Figure 3.

Figure 2 TLE4999C8 Package configuration

Table 2 TLE4999C8 Pin definitions and functions

Pin No. Symbol TLE4999C8 Function

1 CBUF Buffer capacitor pin

1)

2 VDD Supply voltage

3GND Ground

4 OUT SPC output / programming interface I/O

5 NC Not connected

6 NC Not connected

7 NC Not connected

8 NC Not connected

1) In case CBUF capacitor is not used, CBUF pin shall be left floating

Figure 3 Pin Configuration of TLE4999C8 package

Data Sheet 5 v01_00

2020-11-02

Page 6

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

General

3General

3.1 Functional description

The TLE4999C8 is a dual channel linear Hall sensor designed to meet the requirements of applications with

highly accurate and reliable magnetic field measurement. The sensor provides a digital SPC (Short PWM Code)

protocol on the OUT pin that is based on the SENT (Single Edge Nibble Transmission) standard. Configuration

parameters can be programmed after assembly of the sensor in a module in an end-of-line calibration

procedure using the serial inspection and configuration interface (SICI).

The two measurement channels have separate analog supply domains controlled by the main and sub analog

regulators. These regulators feed separate biasing units for the main and sub Hall sensor elements.

A multiplexed second analog-digital converter (Sub HTS-ADC) is used to convert analog signals from the main

and sub temperature sensors, and the sub Hall probe. The sub Hall, the temperature and the stress signals are

fed into the second digital signal processing unit (DSP2).

The DSP2 uses the signals from all stress and temperature sensing elements for plausibility and range checks

to ensure the integrity of the sensing elements and the analog signal path.

The analog signal of the main Hall probe is fed into an analog-digital converter (Main HADC), and is then

processed in a digital signal processing unit (DSP1).

Each DSP uses its corresponding Hall signal, together with compensation parameters stored in the EEPROM,

to calculate a Hall measurement value that is compensated for stress and temperature effects.

A high speed SPC protocol is generated containing the data of the two DSPs in the SPC protocol encoder and

transmitted after a SPC trigger pulse.

Data Sheet 6 v01_00

2020-11-02

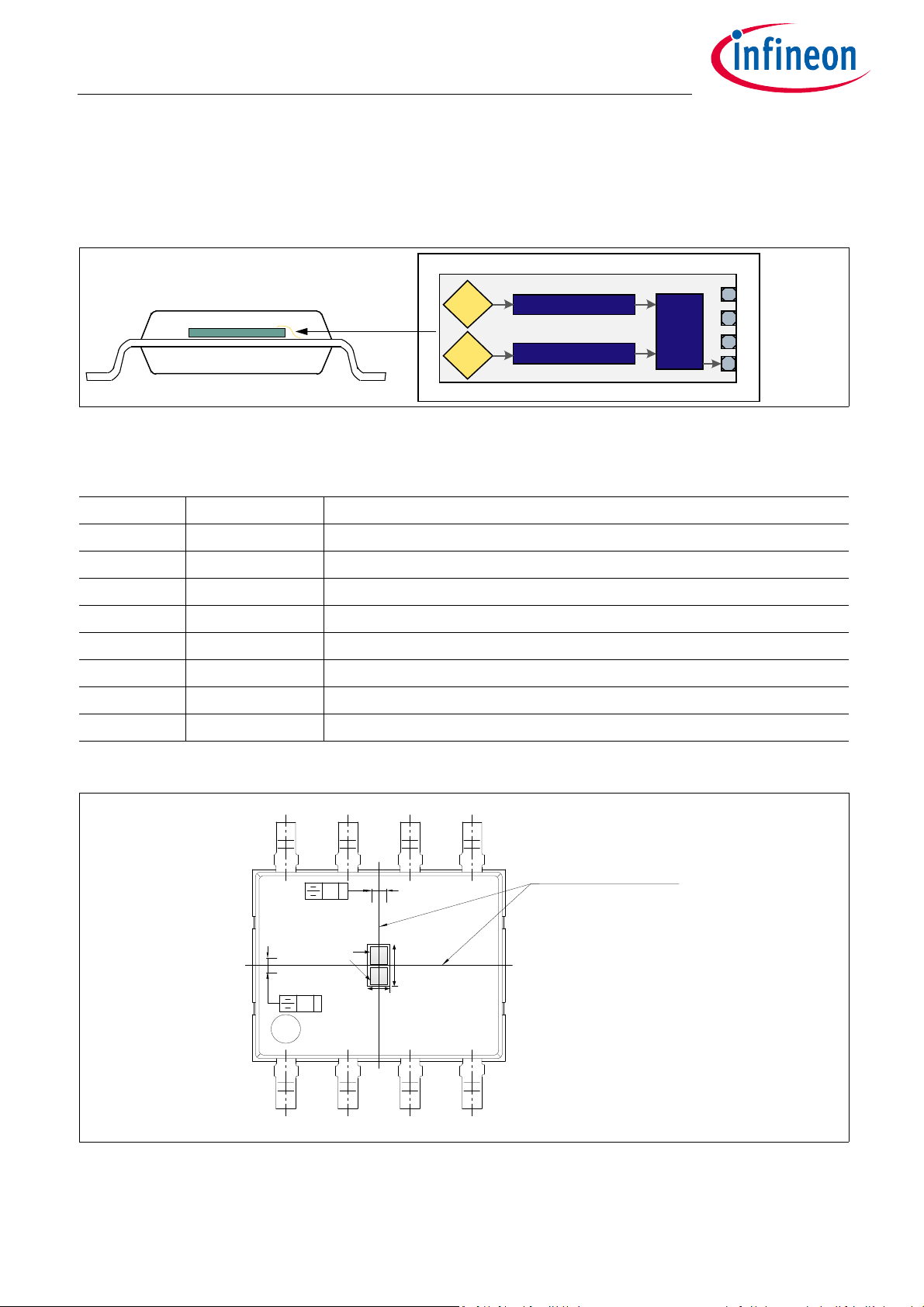

Page 7

TLE4999C

GND

SP C

µC

V

DD

GND

V

µC

V

DD_1

CS

Out

CL

V

pu ll- up_2

Rp

CBuf

TLE4999C

GND

SP C

CS

Out

CL

CBuf

V

DD

CBuf

V

DD

CBuf

V

DD_2

Rp

V

pu ll- up_1

Unit Time

0.5 - 1 µs

1.05 - 2 µs 2.05 - 3 µs

CL 1 nF 2.2 nF 3.9 nF

CS

CBuf

Pull-up

resistor

min. typ. max.

Rp

1.45 kΩ

2.2 kΩ 10 kΩ

Voltages min. typ. max.

V

DD

4.5V - 5.5V

V

pull-up

3.0V - 5.5V

100 nF

68 nF

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Application circuit

4 Application circuit

Figure 4 shows the recommended application circuit for two TLE4999C8 sensors.

Figure 4 Application circuit

Attention: The system integrator shall take in consideration that the maximum value of CL shall include

also the capacitance of the bus line.

Note: For improved EMC capability the usage of a twisted cable is recommended.

Data Sheet 7 v01_00

2020-11-02

Page 8

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Maximum ratings

5 Maximum ratings

All specifications are valid over the full temperature range and over lifetime. They refer to each of the

implemented sensors IC’s, unless otherwise noted.

Table 3 Absolute maximum ratings

Parameter Symbol Limit Values Unit Notes

Min.

Max.

Junction temperature T

Non-operating temperature T

Maximum supply voltage V

Maximum voltage on OUT V

Maximum voltage on C

Buf

Maximum voltage between 2

V

V

J

NO

DD

OUT

Cbuf

Diff

pins

Voltage peaks VDD, V

OUT short circuit current

Supply current in over voltage I

Supply current in reverse

2)

I

OUT

DD, ov

I

DD, rev

voltage

OUT

-40 140 °C max. 1000h at 140°C1) (not

additive)

-40 125 °C max. 1400h (not additive)

1)

-20 20 V max. 24 h for -40°C to 30°C T

max. 10 min. for 30°C to 80°C T

max. 30 s for 80°C to 125°C T

max. 15 s above 125°C T

J

-18 19.5 V max. 40 h (not additive)

-0.3 20 V max. 24 h for -40°C to 30°C T

max. 10 min. for 30°C to 80°C T

max. 30 s for 80°C to 125°C T

max. 15 s above 125°C T

J

-20 20 V max. 24 h for -40°C to 30°C T

max. 10 min. for 30°C to 80°C T

max. 30 s for 80°C to 125°C T

max. 15 s above 125°C T

J

– 30 V for max. 50 µs

-130 130 mA max. 1 h

45 mA time limitation for VDD applies

-75 – mA time limitation for VDD applies

J

J

J

J

J

J

J

J

J

Magnetic flux density B

ESD Immunity V

1) Maximum exposure time at other junction temperatures shall be calculated using the Arrhenius-model.

2) Short to VDD or GND.

3) Human Body Model (HBM) according to ANSI/ESDA/JEDEC JS-001.

4) Charged Device Model (CDM) according to ANSI/ESDA/JEDEC JS-002.

max

HBM

V

CDM

– 1000 mT

-4 +4 kV Human Body Model

3)

-0.75 +0.75 kV Charged Device Model

4)

Note: Any stress exceeding the values listed in Table 3 may cause permanent damage to the device. The

values given are stress ratings only and functional operation of the device at these conditions is not

implied. Exposure to absolute maximum rating conditions for extended periods may affect device

reliability.

Data Sheet 8 v01_00

2020-11-02

Page 9

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Operating range

6 Operating range

The following operating conditions shall not be exceeded in order to ensure correct operation of the

TLE4999C8. All parameters specified in the following sections refer to these operating conditions.

Table 4 Operating range

Parameter Symbol

Supply voltage V

Supply voltage slew rate V

Operating junction

DD

DD,slew

T

J

temperature

Output pull-up voltage V

Pull-up resistance R

Load capacitance C

Supply capacitance C

Buffer capacitor C

pull-up

P

L

S

Buf

Min.

4.5 – 5.5 V

V

DD, pon

0.1 – 10

-40 – 140 °C max. 1000h at 140°C

3.04)/4.5

1.45 2.2 10 kΩ

1–3.9nF

– 100 – nF

–68–nF

Values

Unit Notes

Typ. Max.

–V

DD, poff

8

VExtended range

V/s

– 5.5V

1)

2)

3)

(not additive)

5)6)

7)

7)

Magnetic flux density |B| – – 50 mT Maximum measurement range

1) No magnetic performance degradation in extended range between supply under voltage release level and supply

over voltage release level.

2) The slew rate is the maximum voltage change per time and relates to the Application circuit.

3) Maximum exposure time at other junction temperatures shall be calculated using the Arrhenius-model.

4) Value valid only when the 3.3V bus capability bit is set in the EEPROM.

5) Output protocol characteristics depend on these parameters, RL must be according to max. output current. For the

maximum output pull up voltage value refer to the note on Table 3.

6) The SPC output protocol will be deactivated when permanent voltages higher then 7.5V are present at the OUT pin.

7) Pull-up resistance and load capacitance have to be chosen in accordance with configured unit time, please see

Application circuit.

6.1 Calculation of the junction temperature

The internal power dissipation P

temperature (TA).

The power multiplied by the total thermal resistance R

junction temperature. R

is the sum of the addition of the two components, Junction to Case and Case to

thJA

Ambient.

R

thJA=RthJC

TJ=TA +Δ T = R

+R

thCA

thJA

xP

TOT

= R

thJA

Example (assuming no load on V

• VDD = 5.5 V

• IDD = 14.5mA

•

Δ T= 150 [K/W] x (5.5 [V] x 0.0145 [A] + 0 [VA]) = 11.963K → 15K used for worst case scenario calculations

Data Sheet 9 v01_00

of the sensor increases the chip junction temperature above the ambient

TOT

(junction to ambient) added to TA leads to the final

thJA

x(VDD x IDD +V

):

OUT

OUT

x I

OUT

); IDD, I

> 0, if direction is into IC

OUT

2020-11-02

Page 10

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Electrical, magnetic and output parameters

7 Electrical, magnetic and output parameters

All specifications are valid over the full temperature range and over lifetime. They refer to each of the

implemented sensors IC’s, if not otherwise noted.

Table 5 Electrical characteristics

Parameter Symbol

Supply current I

Thermal resistance

Power-on time

1)

2)

Supply under voltage

DD

R

thJA

t

pon

V

DD, pon

reset/release level

Supply over voltage

V

DD, poff

reset/release level

Supply voltage reset

V

DD,pon hyst

hysteresis

Out pin over voltage

V

OUT, ov res

reset level

Out pin over voltage

V

OUT, ov res

release level

Out pin over voltage

V

OUT, ov hyst

reset hyteresis

Output saturation

V

OL

voltage

Min.

Values

Typ. Max.

Unit Notes

4 – 14.5 mA

– – 150 K/W junction to ambient

––5ms

3.1 – 4.2 V

6–7.5V

100 – 300 mV

7.5 8.25 9 V

6 6.75 7.5 V

11.52V

– – 0.1*VDD–for I

≤ 3.4mA

OUT

Output fall and rise time t

fall/trise

0.3 0.5 0.75 µs for UT = 0.5 µs and 0.75 µs

0.6 1 1.4 µs for UT = 1 µs and 1.25 µs

0.9 1.5 2.1 µs for UT = 1.5 µs

1.2 2 2.8 µs for UT = 2 µs and 2.5 µs

1.8 3 4.2 µs for UT = 3 µs

Output current I

Output leakage current I

Oscillator frequency

OUT,avg

OUT Leak

20 100 120 µA V

Δf -5 – 5 % Nominal oscillator frequency:

variation

1) Measured on 2s2p PCB board

2) Time since the sensor starts, until it is ready to respond to the first trigger pulse

5mA

pull-up

20MHz

= 5V and 0 < VDD< V

DD, pon

The following Figure 5 shows the operating area of the device, the condition for over voltage and

under voltage and the corresponding sensor reaction. The values for the over- and under voltage comparators

are the typical values from Table 5.

In the extended range, the sensor fulfills the full specification. However, voltages above the operating range

can only be applied for a limited time (see Table 3).

Data Sheet 10 v01_00

2020-11-02

Page 11

V

OUT

/ V

pull up

V

DD

4.2 6

7.5

3.1

9

No output

No output

No output

Operating

range

Extended range

Extended range

7.5

Vout

OV reset

V

DD

UV reset

V

DD

OV reset

Extended range

No output

3

1)

/ 4.5

Operating range

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Electrical, magnetic and output parameters

Figure 5 Operating area and sensor reaction for over- and under voltage.

1)

Main and Sub channels of the TLE4999C8 provide highly accurate 12/14/16bit magnetic field signals. The

output characteristics of the two channels are specified in Table 6.

Table 6 Magnetic and output characteristics of main and sub channel

Parameter Symbol

Magnetic offset drift

Magnetic initial offset B

Magnetic sensitivity drift

Output noise (RMS)

Magnetic hysteresis B

Integral non-linearity

Signal latency

1) Drift over temperature and lifetime

2) For LP-Filter setting 8

3) Range 50 mT, gain 1.0 (scales linearly with gain)

4) Defined as phase shift of 100 Hz sine signal

5) For LP-Filter setting Off

Figure 6 shows the output characteristics of the sensor’s main and sub channel in the default setting. The

output characteristics can be changed by reconfiguring the zero point, gain and clamping ranges for main and

sub channel (see Chapter 9).

Value valid only when the 3.3V bus capability bit is set in the EEPROM.

Values

4)5)

1)

1)

2)3)

3)

Min.

ΔB

ΔB

OS_Main

OS_Sub

OS

-100 – 100 µT Main channel offset drift

-200 – 200 µT Sub channel offset drift

-300 – 300 µT at 0 h, 25 °C

ΔS -2.0 – 2.0 %

OUT

OUT

Hys

Noise_Main

Noise_Sub

––1LSB12Main channel noise

––4LSB12Sub channel noise

––40µT

INL -4 – 4 LSB

t

latency

– – 200 µs not including interface

Typ. Max.

Unit Notes

12

transmission time

Data Sheet 11 v01_00

2020-11-02

Page 12

Magnetic Flux B [mT]

Sensor Signal [LSB

12

]

-50 500

2048

0

4095

Main clamping

Sub clamping

4095

205

Branded Side

N

S

Main Channel

Sub Channel

3890

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Electrical, magnetic and output parameters

Figure 6 Output characteristic

Data Sheet 12 v01_00

2020-11-02

Page 13

Sub Hall data (12 bi t)

Sync Fr ameTrigger Pulse

µC Activity

Sensor Ac tivity

13 UT / 90 UT

56 UT 12 … 27 UT 12 … 27 UT 12 … 27 UT 12 … 27 UT

12 UT

Status Nibble

Data Nibble 1

Data Nibble 3

Data N ibble 2

End

Pulse

12 … 27 UT 12 … 27 UT 12 … 27 UT

Data Nibble 4 Data Nibble 6

Data N ibble 5

CRC Nibble

12 … 27 UT

Main H all data (12 bi t)

Nibble Encoding: (12 + x) * UT

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

SPC output

8 SPC output

The TLE4999C8 features a fast SPC (Short PWM Code) protocol, which is based on the SENT standard (Single

Edge Nibble Transmission) defined by SAE J2716. As opposed to SENT, which implies a continuous

transmission of data, the SPC protocol transmits data only after receiving a specific trigger pulse from the

micro controller. The required length of the trigger pulse depends if the sensor is configured in synchronous

mode or in bus mode. In case of bus mode the trigger pulse depends on the sensor number, which is

configurable. Thereby, SPC allows the operation of up to four sensors on one bus line.

For the SPC interface the push pull setting with controlled slopes is used (the push-pull mode is only active

during the slope controlled mode). In this configuration, the TLE4999C8 has controlled rising and falling

slopes. Between the slope controlled transitions the HIGH level is maintained by the external pull-up resistor.

Once the SPC protocol telegram is sent, the TLE4999C8 goes in to receiving mode (OUT Pin in Tri-sate mode)

and waits until a valid trigger signal is received.

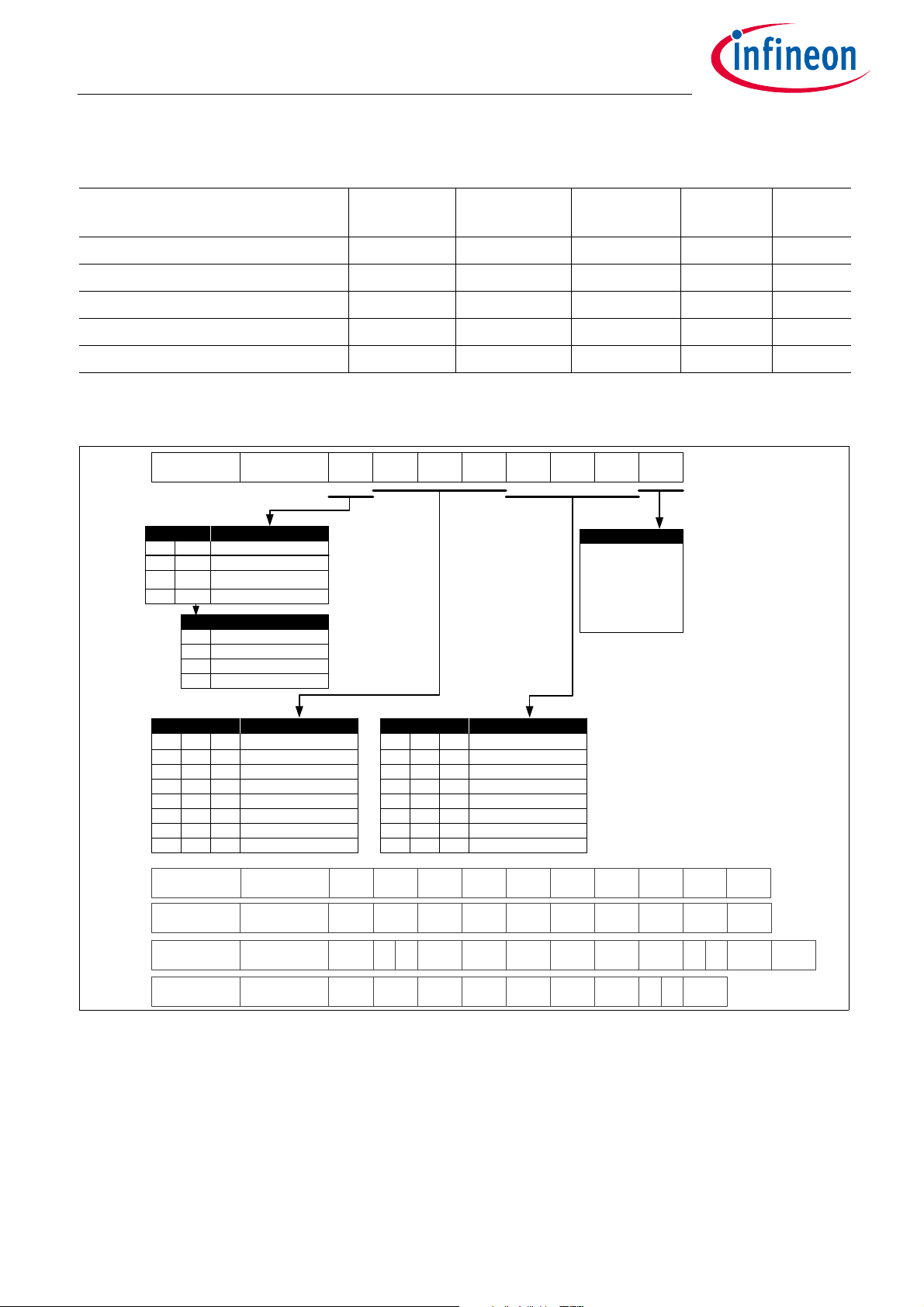

Figure 7 SPC default protocol example

As in the SENT protocol, the time between two consecutive falling edges defines the value of a 4-bit nibble,

thus representing numbers between 0 and 15. The transmission time therefore depends on the transmitted

data values. All values are multiples of a unit time frame (see Table 8). A SPC frame consists of the following

nibbles (see Table 7):

• A trigger pulse by the master, which initiates the data transmission.

• A synchronization period of 56 UT.

• A st atus nibble of 12-27 UT, contai ning over volta ge/ error signaling and short serial message (SSM) data or

the sensor ID.

• Between 3 and 4 data nibbles of 12-27 UT each (number is programmable), representing the Main Hall

value

• Between 3 and 4 data nibbles of 12-27 UT each (number is programmable), representing the Sub Hall

value.

• Optional 2 temperature nibbles of 12-27 UT each (programmable).

• Optional 2 /4 bit rolling counter of 12-27 UT (programmable).

• One or two checksum (CRC) nibbles of 12-27 UT each (programmable).

• An end pulse of 12 UT to terminate the SPC frame transmission.

The sensor is available for the next sample after the falling edge of the end pulse. The sensor’s sampling

time is at the beginning of the synchronization period, i.e. when a correct trigger is received.

Data Sheet 13 v01_00

2020-11-02

Page 14

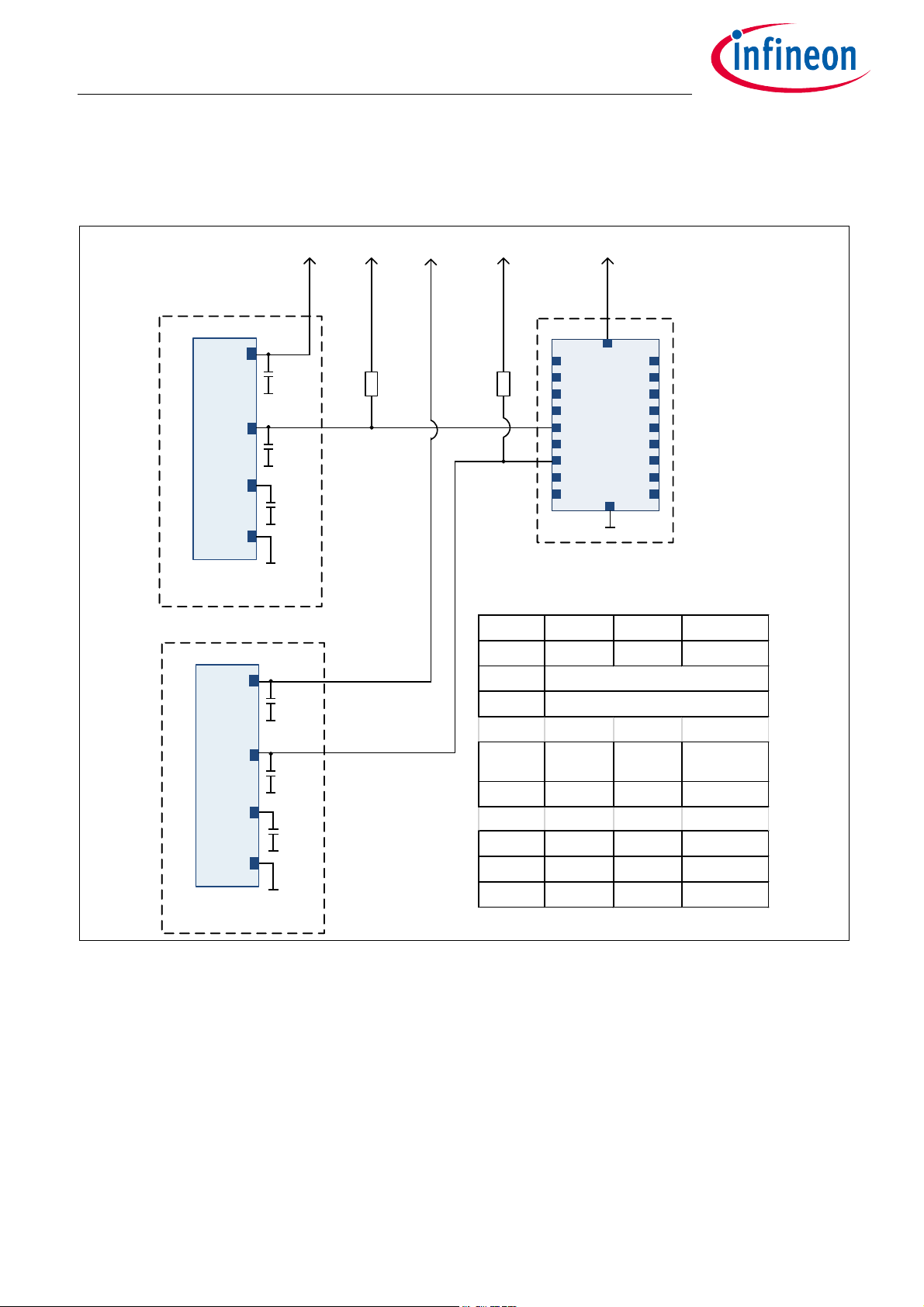

11111111 1110 4094

11111111 1101 4093

:: : :

00000000 0010 2

00000000 0001 1

00000000 0000 0

11111111

M1 M2 M3 S3 S2 S1

bits description

MSBs LSBs stat us informatio n

10

SSM/ID

01

00

startup/internal error main

internal error sub/return from

overvoltage

normal operation

bits

M3

1111

M2M1

description

Main Hall value (12 bit)

4095

SYNC ST ATUS CRC

description

CRC calculation

for all nibbles

seed value: 0101

polynomial: X

4+X3 +X2

+1

SSM/ID

SSM/ID

TRIGGER

11111111 1110 4094

11111111 1101 4093

:: : :

00000000 0010 2

00000000 0001 1

00000000 0000 0

11111111

bits

S3

1111

S2S1

description

Sub Hall value (12 bit)

4095

Frame

A

bits description

11

01

00

SSM or ID #3

SSM or ID #0

SSM or ID #1

10 SSM or ID #2

TRIGGER

Frame

B

S2M1 S1 CRC

S2TRIGGER

Frame

D

S4

CRC CRCS1

TRIGGER

Frame

E

M1

CR

C

TRIGGER

Frame

C

M1 T1 CRCT2

CRCRC

SYNC

SYNC

SYNC

SYNC

STATUS

STATUS

STATUS

STATUS

RC

1

M1

M2

M2

M2

M2

M3

M3

M3

M3

M4

S3

M4

S3

S4

S2

RC

2

S2

S3

S1

S3

S1

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

SPC output

Table 7 Frame selection

Frame Type Parameter F Data nibbles Temperature

nibbles

Rolling

Counter

CRC bits

12 bit Main Hall, 12 Bit Sub Hall A (default) 6 nibbles – – 4 bits

16 bit Main Hall, 16 Bit Sub Hall B 8 nibbles – – 4 bits

12 bit Main Hall, 12 bit Sub Hall C 6 nibbles 2 nibbles – 4 bits

14 bit Main Hall, 14 bit Sub Hall D 7 nibbles – 2 x 2 bits

12 bit Main Hall, 12 Bit Sub Hall E 6 nibbles – 2 bits

1) Rolling counters combined with data nibbles, see Figure 8

2) Rolling counter combined with CRC nibble, see Figure 8

1)

8 bits

2)

6 bits

Figure 8 Content of the SPC protocol

8.1 SPC bus mode

When the sensor is used in a bus mode with other sensors on a common SPC line, individual addresses have

to be assigned to each sensor for identification. For the operation of the sensor in a SPC bus mode, it is strongly

recommended that the sensor ID is written into the EEPROM of the sensor, as all sensors are pre configured

with the default value “ID = 0” (see the TLE4999C User Manual for further details).

A corresponding trigger nibble from the micro controller can therefore address each sensor individually.

Data Sheet 14 v01_00

2020-11-02

Page 15

SPC

V

th, falling

t

mlow

t

mtr

V

th, rising

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

SPC output

The trigger nibble low time is shown in Table 10. Each low time corresponds to an individual sensor address.

The total length of the trigger nibble can be selected to be constant at 90 UT (constant trigger length) or

variable according to Table 9(variable trigger length).

8.2 SPC unit times

Table 8 Programmable unit times

Parameter Symbol Values Unit Note or Test Condition

SPC unit time

1) Default setting is 3 μs nominal SPC unit time.

8.3 SPC trigger pulse

A SPC transmission is initiated by a trigger pulse from the ECU on the OUT pin. To detect a low-level on the

OUT pin, the voltage has to be below the threshold V

released as soon as V

The master low time t

mode switched off, the total trigger time t

transmission time for configurations where only one sensor IC is connected to the SPC line.

With bus mode switched on, it is possible to use up to four SPC sensors on one data line. The total trigger time

in bus mode is longer, and can be selected between a constant trigger or a variable trigger.

The master low time t

addressing requires all sensors on the bus to be programmed with the same nominal SPC unit time.

1)

UT 0.5, 0.75, 1.0, 1.25, 1.5, 2.0, 2.5, 3.0 μs Clkunit=20MHz

. The sensor detects that the OUT line has been

th, falling

is crossed. Table 9 and Figure 9 show the timing specification for the trigger pulse.

th, rising

as well as the total trigger time t

mlow

is shortest. This leads to a significantly shorter overall protocol

mtr

is used to identify the sensor ID of the addressed sensor IC, see Table 10. A proper

mlow

are different for SPC bus mode on or off. With bus

mtr

Figure 9 SPC master pulse timing

Table 9 SPC master pulse parameters

Parameter Symbol Values Unit Note or Test Condition

Falling edge threshold V

Rising edge threshold V

Data Sheet 15 v01_00

thf

thr

Min. Typ. Max.

–35 –% of

V

DD

–50 –% of

V

DD

1)2)

1)2)

2020-11-02

Page 16

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

SPC output

Table 9 SPC master pulse parameters (cont’d)

Parameter Symbol Values Unit Note or Test Condition

Min. Typ. Max.

Total trigger time t

mtr

–13 –UTBus mode off

– 90 – UT Bus mode on, with

constant trigger length

3)

2)

–t

1) Not subject to production test - verified by design/characterization

2) Unit is % of nominal VDD (4.5V - 5.5V)

3) Trigger time in the sensor is fixed to the number of unit times specified in the “typ.” column, but the effective trigger

time varies due to the sensor’s oscillator variation

mlow,min

+ 12– UT Bus mode on, with

variable trigger length

2)

The below Table 10 shows the trigger time window to which the sensor responds:

Table 10 Sensor SPC trigger parameters

Parameter Symbol Values Unit Note or Test Condition

Min. Typ. Max.

Master nibble low time t

Master nibble low time t

Master nibble low time t

Master nibble low time t

Master nibble low time t

1) The combination of CL and pull-up resistor Rp may prevent use of some master nibble low times due to increased

output rise time. Infineon recommends that for fast unit times (<=1.0us) the sensor is used in bus mode (with variable

trigger option) with ID0 instead of bus mode off.

mlow

mlow

mlow

mlow

mlow

2 – 7 UT Bus mode off

8 – 15 UT Bus mode on, ID = 0

16 – 28 UT Bus mode on, ID = 1

29 – 49 UT Bus mode on, ID = 2

50 – 82 UT Bus mode on, ID = 3

1)

The below Table 11 shows the trigger time window to be programmed in the ECU:

Table 11 ECU SPC trigger parameters

Parameter Symbol Values Unit Note or Test Condition

Min. Typ. Max.

Master nibble low time t

Master nibble low time t

Master nibble low time t

Master nibble low time t

Master nibble low time t

1) The combination of CL and pull-up resistor Rp may prevent use of some master nibble low times due to increased

output rise time. Infineon recommends that for fast unit times (<=1.0us) the sensor is used in bus mode (with variable

trigger option) with ID0 instead of bus mode off.

mlow

mlow

mlow

mlow

mlow

2 – 4 UT Bus mode off

9 – 12 UT Bus mode on, ID = 0

19 – 23 UT Bus mode on, ID = 1

35.5 – 40.5 UT Bus mode on, ID = 2

61.5 – 67.5 UT Bus mode on, ID = 3

1)

Attention: For detailed description of the master nibble low times, please consult the application note for

the TLE4999C, “Master nibble low time parameter and related tolerances”.

Data Sheet 16 v01_00

2020-11-02

Page 17

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

SPC output

8.4 Status nibble

The status nibble consists of 4 bits. The first two bits are status bits to monitor the internal status of the sensor

whereas the last two bits can represent a short serial message (see Chapter 8.5) or the sensor ID. Table 12

shows the usage of the status bits.

The status nibble, which is sent with each SPC data frame, provides an error indication. In case the sensor

detects an error or an over voltage condition, the corresponding error bit in the status nibble is set. As long

as the error or over voltage condition is present the error bit is set and the sensor output is disabled. After

returning from the over voltage condition the corresponding error bit is set in the first transmitted frame in the

status nibble.

Table 12 Structure of SPC status nibble

Bits Description

[0] LSB

[1]

[2]

[3] MSB

Short Serial Message bit (data) or bus mode ID LSB

Short Serial Message bit (start indication) or bus mode ID MSB

Return from over voltage condition/ internal error sub channel

Startup/ internal error main channel

8.5 Short serial message

The short serial message is an additional option which can be enabled or disabled. The short serial message

provides additional information in a slow channel transmitting an 8 bit temperature value of the main hall and

32 bit sensor ID (16 bits from main channel ID1 and 16 bits from sub channel ID2).

In each SPC frame, one bit of information is transmitted. The start of the short serial message is indicated by

a “1” in bit [1] of the status nibble. For the next 15 SPC frames, this bit will contain a “0”. The Information is

transmitted in blocks of 16 bit with 1 bit per SPC frame in bit [0] of the status nibble.

4 bit message ID

8 bit data

4bit CRC (calculated from message ID and data bits)

The message ID is used for identification of the type of data received. All data are transmitted in the bit [0] of

the status nibble in the order MSB to LSB.

The transmitted information is as follows:

Message -ID 0: 8 bit temperature value starting with MSB

Message -ID 1: 8 bit of sensor ID1 (starting with MSB)

Message -ID 2: 8 bit of sensor ID1 (starting with MSB-8)

Message -ID 3: 8 bit of sensor ID2 (starting with MSB)

Message -ID 4: 8 bit of sensor ID2 (starting with MSB-8)

Note: For further details please see the TLE4999C User Manual.

Data Sheet 17 v01_00

2020-11-02

Page 18

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

SPC output

8.6 Temperature nibbles

The temperature is coded as an 8 bit value. The value is transferred in unsigned integer format and

corresponds to the range between -55 °C and +200 °C, so a transferred value of 55 corresponds to 0 °C. The

temperature is additional information and although it is not calibrated, may be used for a plausibility check,

for example. Table 13 shows the mapping between junction temperature and the transmitted value in the

SPC frame.

Table 13 Mapping of Temperature Value

Junction Temperature Typ. Decimal Value from Sensor Note

- 55 °C 0 Theoretical lower limit

0°C 55 –

25 °C 80 –

200 °C 255 Theoretical upper limit

1) Theoretical range of temperature values, not operating temperature range.

1)

1)

8.7 Rolling Counter

The rolling counter is an additional option for a safety check implementation. Therefore the counter counts

the number of transmitted frames with rollover back to 0 and increments with each message. The ECU can use

this data for verification that no frame is missed or that no frame is sent repeatedly from the sensor.

There are two selectable protocols that include the rolling counter (see Figure 8), on frame D a 2 bit rolling

counter is included in the first main data nibble and another 2 bit rolling counter in the first sub data nibble.

On frame E a 2 bit rolling counter is included in the CRC nibble, further details can be found in Chapter 8.8.

There are frames without rolling counter bits, but to meet the safety requirements and target ASIL level of the

application, it is recommended to use this function.

8.8 CRC nibble

The CRC checksum can be used to check the validity of the decoded data. In the checksum included is the

status nibble and the data nibbles. It is calculated using a polynomial(x

The remainder after the last data nibble is transmitted as CRC.

To allow enhanced checksum for higher diagnostic coverage also 6 and 8 bit checksum are available to secure

the data transmission (see Table 7).

The 6 bit checksum is calculated using a polynomial (x

checksum is calculated using a polynomial (x

The calculation scheme of the CRC is described in detail in the TLE4999C User Manual.

8

+ x5+ x3 + x2 + x + 1) with a seed value of 01010101B.

6

+ x + 1) with a seed value of 010101B and the 8 bit

4

+ x3 + x2 + 1) with a seed value of 0101B.

8.9 SPC frameholder

The frameholder functionality allows the user to operate multiple sensors in a bus configuration with

synchronized sampling of the measurement value. This is achieved by having (apart from the SPC Bus ID) a

separate frameholder ID for each chip on the bus which is used as a common signal trigger.

For further information please see TLE4999C User Manual.

Data Sheet 18 v01_00

2020-11-02

Page 19

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Configuration and calibration parameters

9 Configuration and calibration parameters

To perform the EEPROM programming with application and customer specific data the Serial Inspection and

Configuration Interface (SICI) is used. The single wire interface uses the same pin as the SPC output for

communication.

The TLE4999C8 has several configurable parameters which are stored in the EEPROM. These parameters affect

the internal data processing and the output protocol. Table 14 gives an overview of the magnetic

measurement parameters, which can be configured separately for main and sub channel. Table 15 shows the

SPC interface parameters.

Table 14 TLE4999C8 Magnetic measurement parameters for main and sub Channel

Parameter Setting range Note

Magnetic range ±50 mT (default)

±25 mT

Gain -7.59...7.59

Gain value of +1.0 corresponds to typical 36.875

LSB

/mT sensitivity in 50mT range, with ±5%

12

clamping,(73.75 LSB

/mT in 25mT range, with

12

±5% clamping).

Zero point 0 LSB

... 65535 LSB

16

1)

16

The user zero point setting is independently

configurable for main and sub channels with 12,

14 or 16 bit granularity.

Clamping low level 0 LSB

... 65535 LSB

16

Clamping high level 0 LSB16 ... 65535 LSB

Default setting: 32768 LSB

1)

16

1)

16

Output clamping settings, see Figure 6.

Default setting:

CL: 205 LSB

CH: 3890 LSB

16

16

.

16

Multi point linearization 0 ... 9 point 9 user selectable linearization points

configurable in the EEPROM. The user can select

the concentration either at the corners or

around the middle point. For further details

please see the TLE4999C User Manual.

Low-pass filter

2)

0: Off

3)

Low pass filter cut-off (-3 dB) frequency.

1: 80Hz

2: 160 Hz

3: 200 Hz

4: 240 Hz

5: 320 Hz

6: 400 Hz

7: 470 Hz

8: 500 Hz (default)

9: 650 Hz

10: 870 Hz

11: 980 Hz

12: 1070 Hz

13: 1270 Hz

14: 1380 Hz

15: 1530 Hz

Data Sheet 19 v01_00

2020-11-02

Page 20

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Configuration and calibration parameters

Table 14 TLE4999C8 Magnetic measurement parameters for main and sub Channel

Parameter Setting range Note

st

order temperature

1

coefficient TC

nd

order temperature

2

coefficient TC

4)

1

4)

2

Reference Temperature

T

0

1) The internal value is always 16 bit, in case the 12 or 14 bit setting range is used, the output will be clamped

accordingly.

2) Subject to oscillator variation ±5%.

3) Set programmable low pass filter off, inherent filter of ADC stays on.

4) Adjusting the temperature coefficients (TC1 & TC2) can lead to a slight increase of the ADC noise level.

-2400 ppm/°C ... 5400 ppm/°C Second order user configurable temperature

compensation.

-30 ppm/°C2 ... 30 ppm/°C

2

0°C ... 127°C

Table 15 TLE4999C8 SPC Interface parameters

Parameter Setting range Note

SPC protocol frames 2x 12 bit Hall + 4 bit CRC (default)

see Table 7

2x 16 bit Hall +4 bit CRC

2x 12 bit Hall + 8 bit temperature + 4 bit CRC

2x 14 bit Hall + 2x 2 bit RC + 8 bit CRC

2x 12 bit Hall + 2 bit RC + 6 bit CRC

SPC unit time

1)

0.5 µs ... 3.0 µs See chapter Chapter 8.2

SPC bus mode On

See chapter Chapter 8.1

Off (default)

SPC bus pull-up voltage 3.3V/5V Default 5V

SPC ID 0 ... 3 Default ID0

SPC variable trigger On

Off (default)

SPC frameholder

address

1) Subject to oscillator variation ±5%.

2) The SPC frameholder is deactivated in case the frameholder address is equal to the SPC address.

2)

0 ... 3 Default ID0

Data Sheet 20 v01_00

2020-11-02

Page 21

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Package outlines

10 Package outlines

Figure 10 PG-TDSO (Plastic Green Thin Dual Small Outline), package dimensions

10.1 Distance of chip to package

Figure 11 shows the distance of the chip surface to the TLE4999C8 surface.

Figure 11 Distance of chip surface to package surface

10.2 Moisture Sensitivity Level (MSL)

The TLE4999C8 fulfills the MSL level 3 according to IPC/JEDEC J-STD-033B.1.

Data Sheet 21 v01_00

2020-11-02

Page 22

For further information on alternative packages, please visit our website:

http://www.infineon.com/packages.

Dimensions in mm

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Package outlines

10.3 Package marking

Figure 12 PG-TDSO (Plastic Green Thin Dual Small Outline), package marking

Data Sheet 22 v01_00

2020-11-02

Page 23

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Package outlines

Green Product (RoHS compliant)

To meet the world-wide customer requirements for environmentally friendly products, and to be compliant

with government regulations the device is available as a green product. Green products are RoHS Compliant

(i.e Pb free finish on leads and suitable for Pb free soldering according to IPC/JEDEC J-STD-020).

Data Sheet 23 v01_00

2020-11-02

Page 24

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Terminology

A

ADC Analog to digital converter

B

BIST Built-in self-test

C

CBUF Buffer capacitor

CRC Cyclic redundancy check

D

DSP Digital Signal Processing unit

E

ECC Error correction code to protect EEPROM content

EEPROM

(abbrev. EEP)

G

GND Ground - ground line of sensor

H

HADC Hall analog to digital converter

Electrically erasable and programmable read only memory - programmable memory for

sensor calibration and configuration data

HTS-ADC Hall, temperature, stress analog to digital converter

I

ID Identification

L

LP-Filter Low pass filter

LSB Least significant bit

M

MSB Most significant bit

MVS Margin voltage selector

O

OUT Digital output pin of the sensor

P

PWM Pulse Width Modulation

R

RMS Root mean square

ROM Read only memory

S

SICI Serial Inspection and Configuration Interface - Programming interface of the TLE4999C8

SPC Short PWM Code

Data Sheet 24 v01_00

2020-11-02

Page 25

TLE4999C8

Programmable dual channel linear Hall sensor with fast SPC interface

Revision History

11 Revision History

Revision Date Changes

01.00 2020-11-02 Initial release

Data Sheet 25 v01_00

2020-11-02

Page 26

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

IMPORTANT NOTICE

Edition 2020-11-02

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2020 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about any

aspect of this document?

Email: erratum@infineon.com

Document reference

The information given in this document shall in no

event be regarded as a guarantee of conditions or

characteristics ("Beschaffenheitsgarantie").

With respect to any examples, hints or any typical

values stated herein and/or any information regarding

the application of the product, Infineon Technologies

hereby disclaims any and all warranties and liabilities

of any kind, including without limitation warranties of

non-infringement of intellectual property rights of any

third party.

In addition, any information given in this document is

subject to customer's compliance with its obligations

stated in this document and any applicable legal

requirements, norms and standards concerning

customer's products and any use of the product of

Infineon Technologies in customer's applications.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer's technical departments to

evaluate the suitability of the product for the intended

application and the completeness of the product

information given in this document with respect to

such application.

For further information on technology, delivery terms

and conditions and prices, please contact the nearest

Infineon Technologies Office (www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon Technologies,

Infineon Technologies’ products may not be used in

any applications where a failure of the product or any

consequences of the use thereof can reasonably be

expected to result in personal injury.

Loading...

Loading...