Page 1

Data Sheet, V 2.10, April 2020

TLE4997E2

Programmable Linear Hall Sensor

Sensors

Never stop thinking.

Page 2

Edition 2020-04

Published by Infineon Technologies AG,

Am Campeon 1-12,

85579 Neubiberg, Germany

© Infineon Technologies AG 2020.

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as a guarantee of

characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement, regarding

circuits, descriptions and charts stated herein.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Page 3

TLE4997E2

We Listen to Your Comments

Any information within this document that you feel is wrong, unclear or missing at all?

Your feedback will help us to continuously improve the quality of this document.

Please send your proposal (including a reference to this document) to:

sensors@infineon.com

Revision History: 2020-04 V2.10

Previous Version: V 2.09, January 2018

Page Subjects (major changes since last revision)

All Updated product name to TLE4997E2

16 Table 5: removed unintended content

Page 4

TLE4997E2

Table of Contents Page

1Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Target Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Further Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Transfer Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Electrical and Magnetic Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Signal Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 Magnetic Field Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Gain Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Offset Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.4 DSP Input Low Pass Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.5 DAC Input Interpolation Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.6 Clamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Error Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.1 Voltages Outside the Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2 Open Circuit of Supply Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.3 Not Correctable EEPROM Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8 Temperature Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.1 Parameter Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.1 Calibration Data Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.2 Programming Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.3 Laboratory Evaluation Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10 Application Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

11 Package Outlines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Data Sheet 4 V 2.10, 2020-04

Page 5

TLE4997E2

List of Figure s Page

Figure 1 Pin Configuration and Hall Cell Location . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 3 Examples of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 4 Ratiometry Error Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 5 Signal Processing Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 6 DSP Input Filter (Magnitude Plot) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 7 DAC Input Filter (Magnitude Plot) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 8 Clamping Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 9 EEPROM Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 10 Application Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 11 PG-SSO-3-10 (Plastic Green Single Small Outline Package) . . . . . . . 33

Data Sheet 5 V 2.10, 2020-04

Page 6

TLE4997E2

List of Tables Page

Table 1 Pin Definitions and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2 Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 3 Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 4 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 5 Magnetic Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 6 Range Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 7 Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 8 Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 9 Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 10 Low Pass Filter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 11 Low Pass Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 12 Clamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 13 Undervoltage and Overvoltage (All values with RL ≥ 10k) . . . . . . . . . . 25

Table 14 Open Circuit (OBD Parameters) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 15 EEPROM Error Signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 16 Temperature Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 17 Calibration Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 18 Programming Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Data Sheet 6 V 2.10, 2020-04

Page 7

TLE4997E2Programmable Linear Hall Sensor

1Overview

1.1 Features

• High linear and ratiometric push-pull rail-to-rail output

signal

• 20-bit Digital Signal Processing

• Digital temperature compensation

• 12-bit overall resolution

• Operates from -40°C up to 150°C

• Low drift of output signal over temperature and lifetime

• Programmable parameters stored in EEPROM with single bit error correction:

– magnetic range and magnetic sensitivity (gain)

– zero field voltage (offset)

– bandwidth

– polarity of the output slope

– clamping option

– temperature coefficient for all common magnets

– memory lock

• Re-programmable until memory lock

• Single supply voltage 4.5 - 5.5 V (4 - 7 V in extended range)

• Operation between -200 mT and +200 mT within three ranges

• Slim 3-pin package (Green)

• Reverse polarity and overvoltage protection for all pins

• Output short circuit protection

• On-board diagnostics (wire breakage detection, undervoltage, overvoltage)

• Digital readout of internal temperature and magnetic field values in calibration mode.

• Individual programming and operation of multiple sensors with common power supply

• Two-point calibration of magnetic transfer function

• Precise calibration without iteration steps

• High immunity against mechanical stress, EMC, ESD

Type Marking Ordering Code Package

TLE4997 4997E2 SP000235288 PG-SSO-3-10

Data Sheet 7 V 2.10, 2020-04

Page 8

TLE4997E2

1

Center of

Hall Probe

23

AEP03717

0.38

±0.05

2.03

±0.1

1.625

±0.1

Hall-Probe

Branded Side

Overview

1.2 Target Applications

• Robust replacement of potentiometers

– No mechanical abrasion

– Resistant to humidity, temperature, pollution and vibration

• Linear and angular position sensing in automotive applications like pedal position,

suspension control, valve or throttle position, headlight levelling and steering angle

• High current sensing for battery management, motor control, and electronic fuse

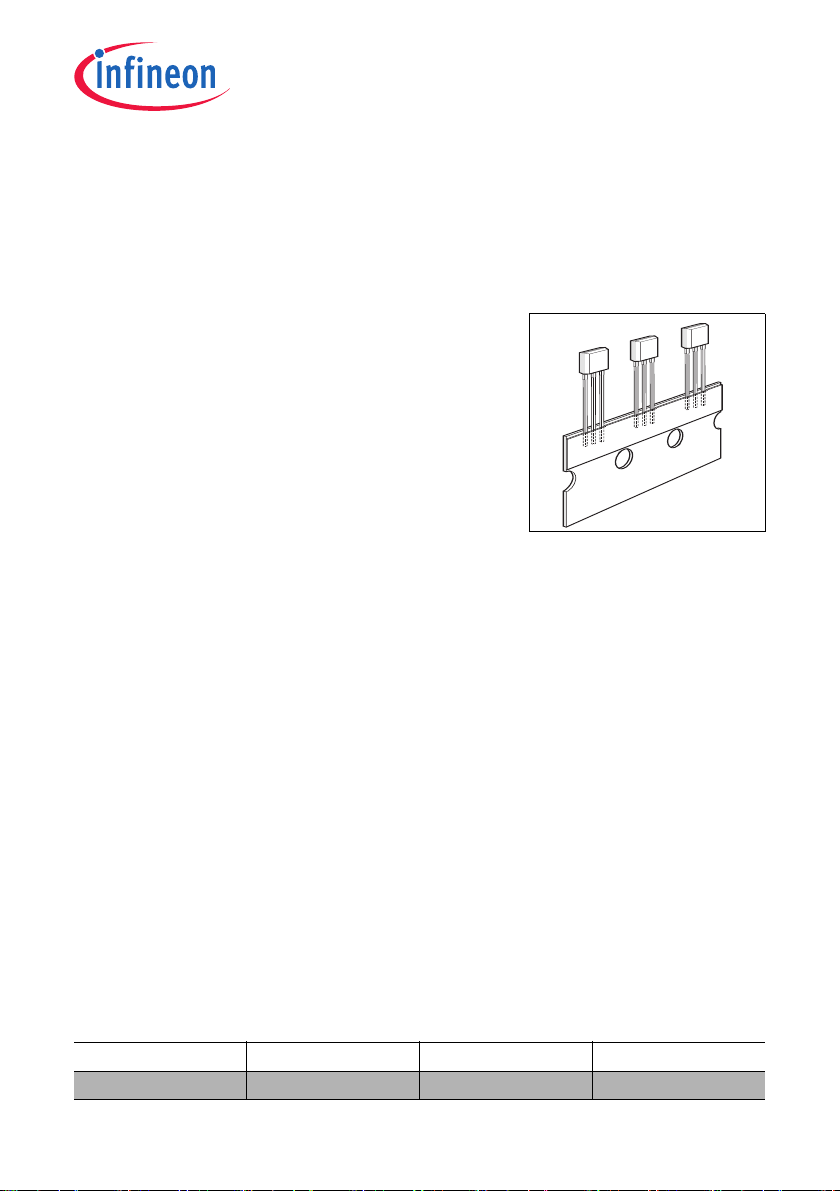

1.3 Pin Configuration

Figure 1 shows the location of the Hall element in the chip and the distance between the

Hall probe and the surface of the package.

Figure 1 Pin Configuration and Hall Cell Location

Table 1 Pin Definitions and Functions

Pin No. Symbol Function

1

2

3

Data Sheet 8 V 2.10, 2020-04

V

DD

GND

OUT

Supply voltage / programming interface

Ground

Output voltage / programming interface

Page 9

HALL

Bias

A

D

DSP

D

A

A

D

Temp.

Sense

ROM

EEPROM

Interface

enable

OUT

V

DD

GND

Supply

OBD

V

DD

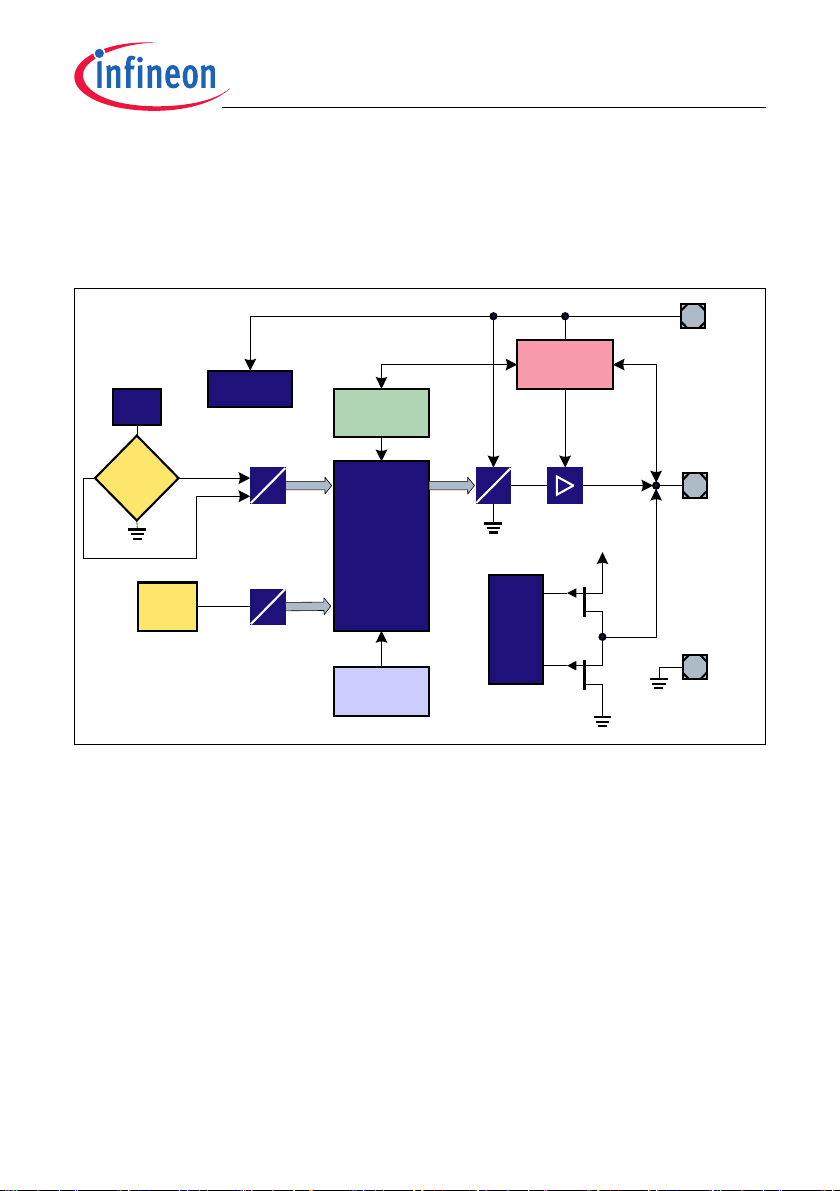

2 General

2.1 Block Diagram

Figure 2 shows a simplified block diagram.

TLE4997E2

General

Figure 2 Block Diagram

2.2 Functional Description

The linear Hall IC TLE4997E2has been designed specifically to meet the demands of

highly accurate rotation and position detection, as well as for current measurement

applications.

The sensor provides a ratiometric analog output voltage, which is ideally suited to

Analog-to-Digital (A/D) conversion with the supply voltage as a reference.

The IC is produced in BiCMOS technology with high voltage capability and also provides

reverse polarity protection.

Digital signal processing using a 16-bit DSP architecture and digital temperature

compensation guarantees excellent stability over a long period of time.

The minimum overall resolution is 12 bits. Nevertheless, some internal stages work with

resolutions up to 20 bits.

Data Sheet 9 V 2.10, 2020-04

Page 10

TLE4997E2

General

2.3 Principle of Operation

• A magnetic flux is measured by a Hall-effect cell.

• The output signal from the Hall-effect cell is converted from Analog to Digital signals.

• The chopped Hall-effect cell and continuous-time A to D conversion provide very low

and stable magnetic offset.

• A programmable Low-Pass filter reduces the noise.

• The temperature is measured and A to D converted.

• Temperature compensation is processed digitally using a second order function.

• Digital processing of output voltage is based on zero field and sensitivity value.

• The output voltage range can be clamped by digital limiters.

• The final output value is D to A converted.

• The output voltage is proportional to the supply voltage (ratiometric DAC).

V

• An On-Board-Diagnostics (OBD) circuit connects the output to

DD

or GND in case of errors.

2.4 Further Notes

Product qualification is based on “AEC Q100” (Automotive Electronics Council - Stress

test qualification for integrated circuits).

Data Sheet 10 V 2.10, 2020-04

Page 11

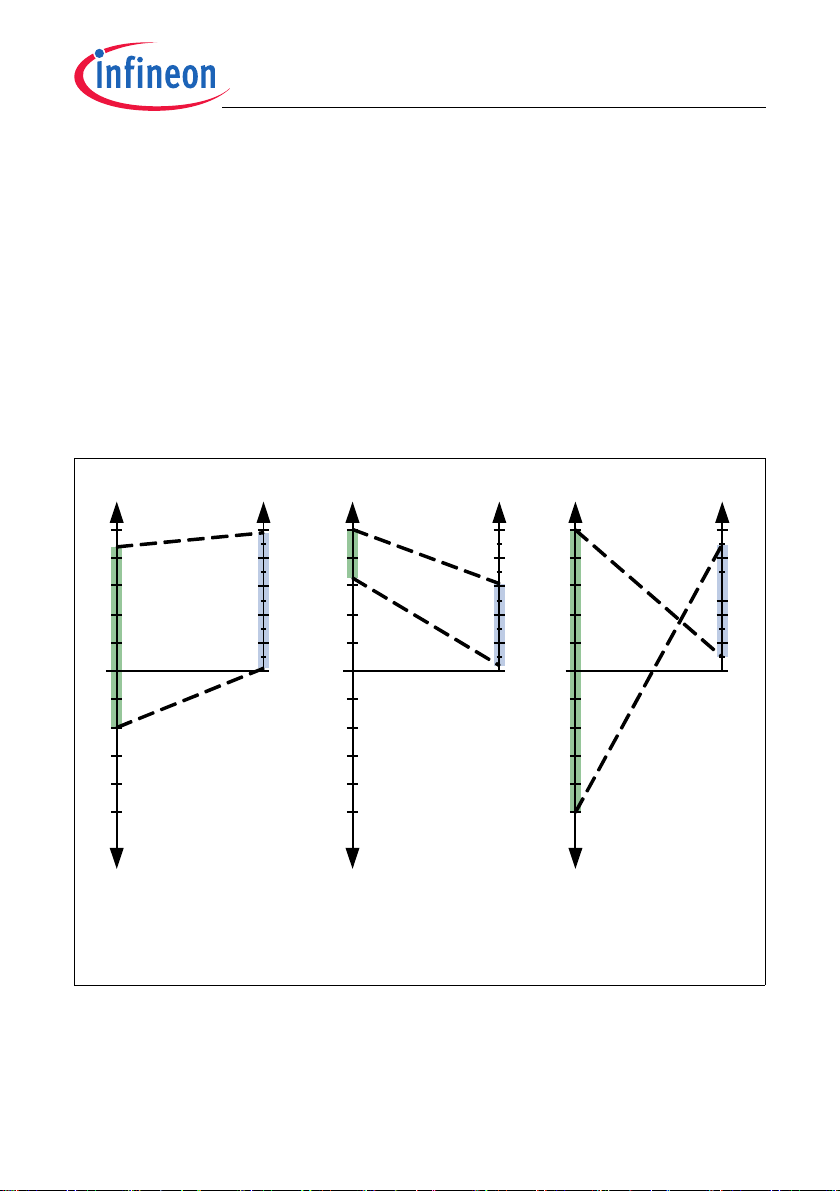

TLE4997E2

0

5

50

-50

5100

-100

5200

-200

V

OUT

(V)

V

OUT

V

OUT

00

B (mT)

V

OUT

(V)

B (mT)

V

OUT

(V)

B (mT)

000

Example 1:

- Bipolar

Example 2:

-Unipolar

-Big offset

- Outp ut for 3.3 V

Example 3:

- Bipolar

- Inverted (neg. gain)

General

2.5 Transfer Functions

The examples in Figure 3 show how easily different magnetic field ranges can be

mapped to the output voltage.

• Polarity Mode:

– Unipolar: Only North- or South-oriented magnetic fields are measured.

– Bipolar: Magnetic fields can be measured in both orientations.

The limit points must not be symmetric to the zero field point.

• Inversion: The gain values can be set positive or negative.

Figure 3 Examples of Operation

Note: Due to the ratiometry, voltage drops at the V

line are imaged in the output

DD

signal.

Data Sheet 11 V 2.10, 2020-04

Page 12

TLE4997E2

Maximum Ratings

3 Maximum Ratings

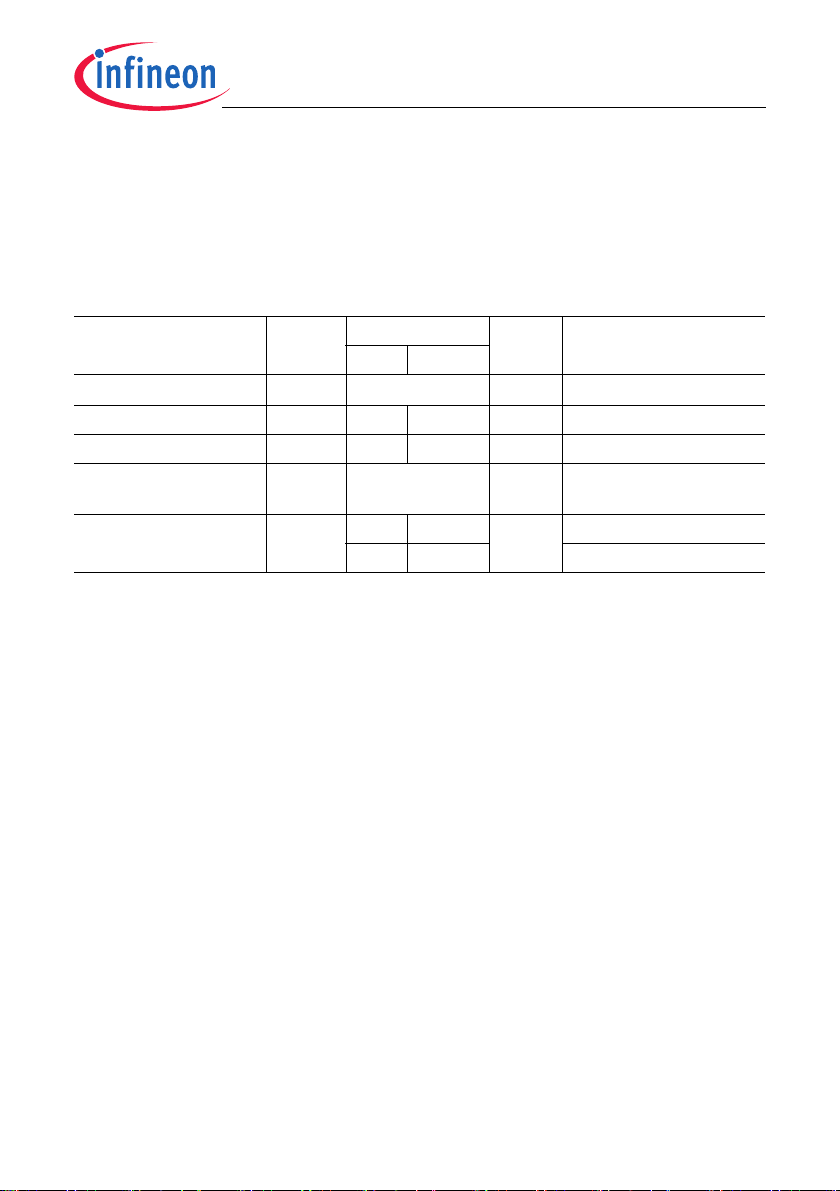

Table 2 Absolute Maximum Ratings

Parameter Symbol Limit Values Unit Notes

min. max.

SS

T

ST

T

J

V

DD

)

I

DDov

Storage temperature

Junction temperature

Voltage on VDD pins with

respect to ground (

V

Supply current

@ overvoltage

Supply current

I

DDrev

@ reverse voltage

Voltage on output pin with

V

OUTov

respect to ground (VSS)

Magnetic field B

ESD protection

1)

For limited time only. Depends on customer temperature lifetime cycles. Please ask for support by Infineon.

2)

max 24 h @ -50°C ≤ Ta< 30°C

max 10 min. @ 30°C ≤

max 30 sec. @ 80°C ≤

max 15 sec. @ 125°C ≤

3)

max. 24 h @ TJ< 80°C.

4)

Guaranteed by laboratory characterization, tested at ±18V.

5)

Max. 1 ms @ TJ< 30°C; -8.5 V for 100 h @ TJ< 80°C.

6)

100 pF and 1.5 kΩ

T

T

< 80°C

a

< 125°C

a

T

≤ 150°C.

a

V

MAX

ESD

-40 150 °C

R

THja

1)

≤ 150 K/W

-40 170 °C For 96h

-20

2)

20

3)

4)

V

-52mA

- 75 - mA

-16

5)

16

3)

V R

≤ 150 K/W

THja

may be > V

V

out

- unlimited T

- 4.0 kV According HBM

JESD22-A114-B

DD

6)

Note: Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in

the operational sections of this specification is not implied. Furthermore, only

single error cases are assumed. More than one stress/error case may also

damage the device.

Exposure to absolute maximum rating conditions for extended periods may affect

V

device reliability. During absolute maximum rating overload conditions (

> V

IN

DD

or VIN< VSS) the voltage on VDD pins with respect to ground (VSS) must not

exceed the values defined by the absolute maximum ratings.

Data Sheet 12 V 2.10, 2020-04

Page 13

TLE4997E2

Operating Range

4 Operating Range

The following operating conditions must not be exceeded in order to ensure correct

operation of the TLE4997E2. All parameters specified in the following sections of this

document refer to these operating conditions, unless otherwise indicated.

Table 3 Operating Range

Parameter Symbol Limit Values Unit Notes

min. max.

Supply voltage

Output current I

Load resistance R

Load capacitance C

Junction temperature

Useful lifetime

1)

For reduced output accuracy.

2)

For V

within the range of 5% ... 95% of VDD.

OUT

3)

R

≤ 150 K/W.

THja

4)

For reduced magnetic accuracy.

5)

Not additive.

V

DD

OUT

L

L

3)

T

J

t

Live

4.5 5.5 V

4 7 V Extended range

-1 1 mA

10

10

-

kΩ Pull-down to GND

-

2)

Pull-up to V

DD

0210nF

-40 125

150

°C For 5000h

For 1000h

4) 5)

- 16 years

1)

Note: Keeping signal levels within the limits specified in this table ensures operation

without overload conditions.

Data Sheet 13 V 2.10, 2020-04

Page 14

TLE4997E2

Electrical and Magnetic Parameters

5 Electrical and Magnetic Parameters

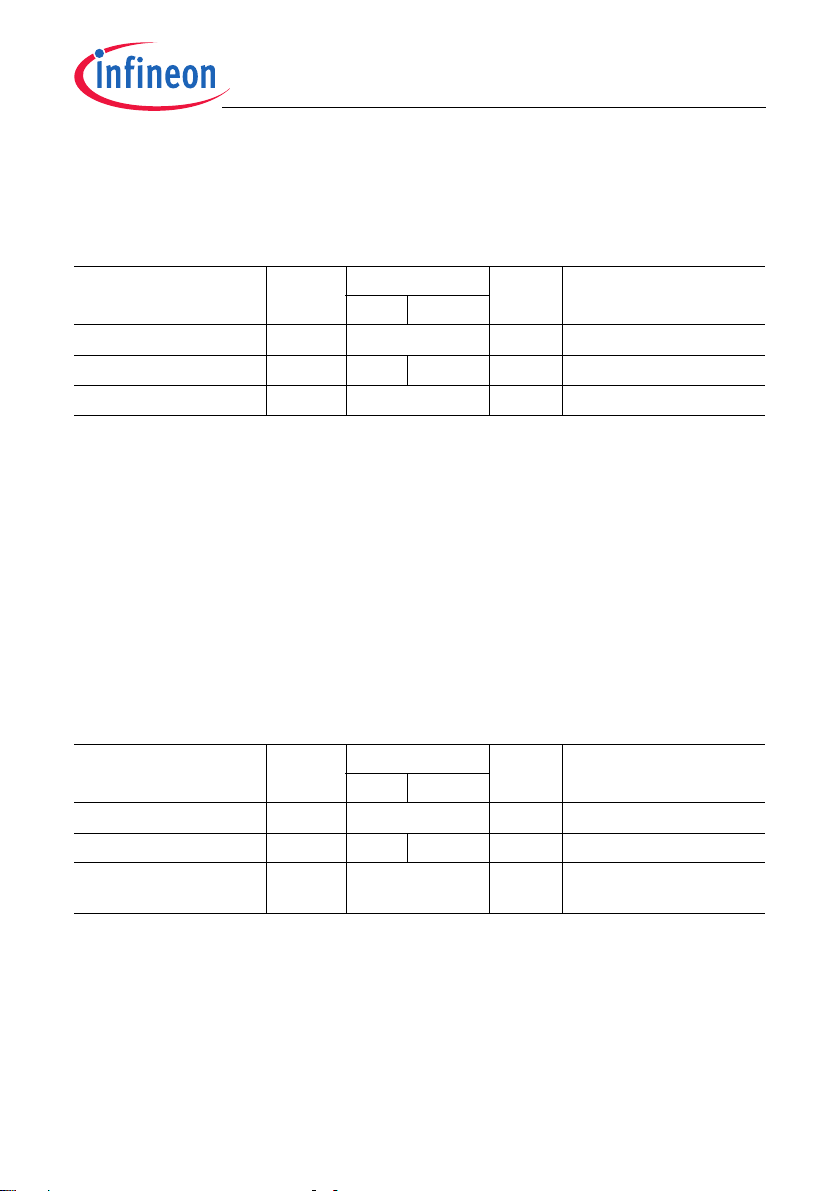

Table 4 Electrical Characteristics

Parameter Symbol Limit Values Unit Notes

min. typ. max.

Output voltage range

Supply current

Output current @ OUT

V

OUT

I

DD

I

OUTsh

shorted to supply lines

Zero field voltage

Zero field voltage drift

Ratiometry error E

Thermal resistance R

Power on time

Power On Reset level V

Output DAC quantization

V

ZERO

Δ

V

RAT

thJA

R

thJC

t

Pon

DDpon

Δ

V

Output DAC resolution - 12 bit

Output DAC bandwidth

Output noise V

Differential non-linearity

Signal delay

1)

Also in extended VDD range. For V

2)

Programmable in steps of 1.22 mV ( @ VDD=5V).

3)

For Sensitivity S ≤ 25 mV/mT. For higher sensitivities the magnetic offset drift is dominant. This means that for

the precalibrated (typical) 60mV/mT sensitivity the typical output drift might be given due to the allowed

magnetic offset tolerence up to ±0.4mT x 60 mV/mT = ±24 mV.

4)

For 4.5 V≤V

5)

For the maximum error in the extended voltage range, see “Ratiometry” on Page 15.

6)

More information, see “DAC Input Interpolation Filter” on Page 22.

7)

100 mT range, sensitivity 60 mV/mT, LP-filter 244 Hz, 160 Hz external RC low pass filter as application circuit.

8)

’5% exceeded’ means that 5 of 100 continuously measured V

9)

A sinusoidal magnetic field is applied, V

≤5.5 V and within nominal V

DD

f

DAC

noise

DNL

t

DS

5

-9594% of

6

V

37.510mA

For TA ≤ 120°C

For TA> 120°C

DD

1)

-30 - 30 mA For operating supply

voltage range only

-100 - 100 % Of V

-10 - 10 mV In lifetime

ZERO

DD

-10 - 10 mV Error band ov. temp.

-0.25 - +0.25 % Of V

DD

- - 219 K/W Junction to air

- - 47 K/W Junction to case

--110ms

Δ

V

OUT

Δ

V

OUT

2-4 V

OUT

1.22 mV @ VDD=5V

- 3.2 - kHz Interpolation filter

- - 4.68 mVpp5% exceeded

-1 - 1 LSB Of output DAC

- - 250 µs @ 100 Hz

within the range of 5%... 95% of VDD, I

OUT

range; see “Ratiometry” on Page 15 for details on E

OUT

samples are out of limit.

OUT

shows amplitude of 20% of VDD, no LP filter is selected.

OUT

OUT

= 0mA.

2)

3)

4)5)

≤ ±5% of V

≤ ±1% of V

7)8)

9)

6)

RAT

3)

DD

DD

.

Data Sheet 14 V 2.10, 2020-04

Page 15

TLE4997E2

E

RAT

V

OUTVDD

()

V

DD

-------------------------------

V

OUT

5V()

5V

---------------------------

–

èø

ç÷

æö

= 100× %

E

RAT

%

0

V

DD

V

4567

0.25

0.5

0.75

1

-0.25

-0.5

-0.75

-1

Electrical and Magnetic Parameters

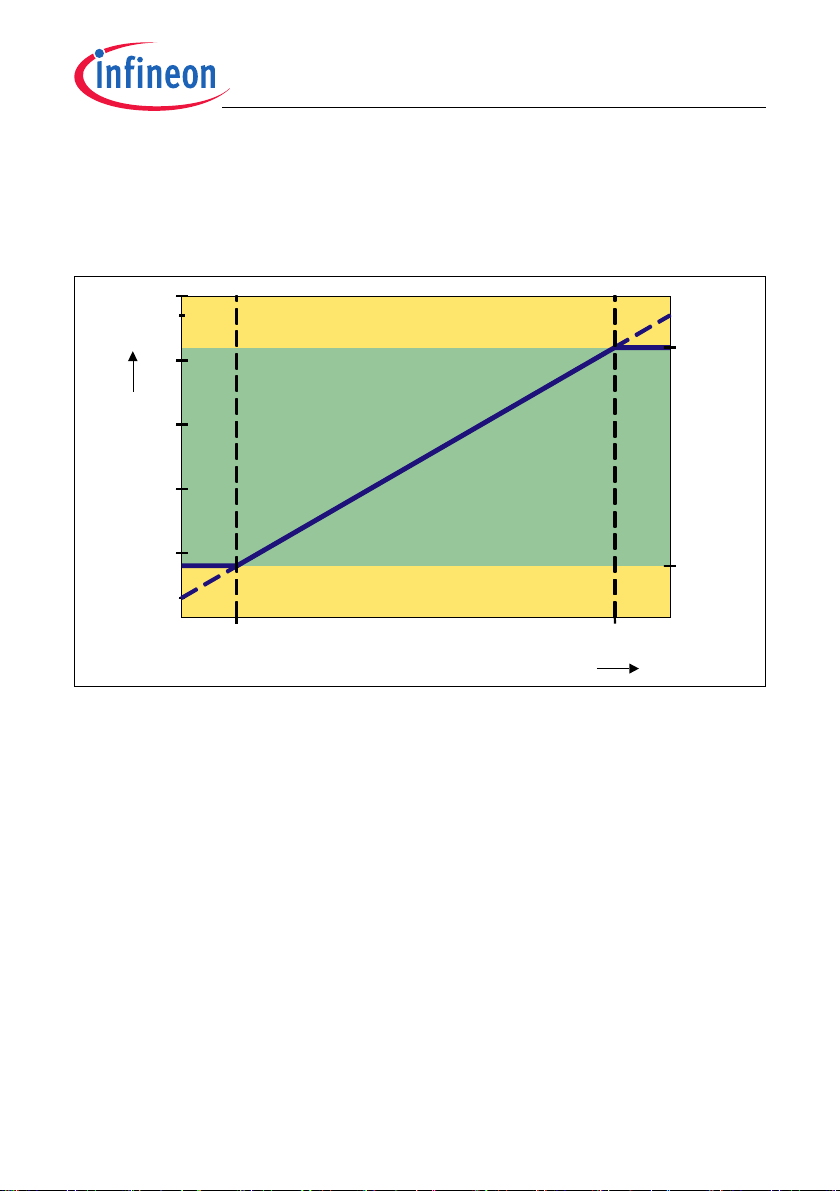

Ratiometry

The linear Hall sensor works like a potentiometer. The output voltage is proportional to

the supply voltage. The division factor depends on the magnetic field strength. This

behavior is called “ratiometric”’.

V

The supply voltage

microcontroller. In this case, variations of VDD are compensated.

The ratiometry error is defined as follows:

The ratiometry error band displays as a “Butterfly Curve”.

should be used as the reference for the A/D Converter of the

DD

Figure 4 Ratiometry Error Band

Note: Take care of possible voltage drops on the VDD and V

result. Ideally, both values are acquired and their ratio is calculated to gain the

highest accuracy. This method should be used especially during calibration.

Data Sheet 15 V 2.10, 2020-04

line degrading the

OUT

Page 16

Electrical and Magnetic Parameters

Calculation of the Junction Temperature

The total power dissipation P

temperature. The power multiplied with the total thermal resistance R

Ambient) leads to the final junction temperature. R

values of the two components

R

thJA

T

= TA +

J

Δ

T = R

= R

thJA

thJC

Δ

T

xP

+ R

TOT

thCA

=R

thJA

of the chip increases its temperature above the ambient

TOT

is the sum of the addition of the

thJA

thJA

Junction to Case and Case to Ambient.

x(VDDx IDD+ V

OUT

x I

OUT

) I

, I

> 0, if direction is into IC

DD

OUT

Example (assuming no noticeable load on Vout):

–

V

= 5 V

DD

– I

= 10 mA

DD

Δ

T = 219 [K/W] x (5 [V] x 0.01 [A] + 0 [VA]) = 11 K

–

For moulded sensors, the calculation with R

is more adequate.

thJC

Magnetic Parameters

Table 5 Magnetic Characteristics

Parameter Symbol Limit Values Unit Notes

min. typ. max.

Sensitivity

Magnetic field range

Integral nonlinearity

Magnetic offset B

S

MFR

INL

OS

Magnetic offset drift ΔB

1)

Programmable in steps of 0.024%, @ V

2)

This range is also used for temperature and offset pre-calibration of the IC.

3)

Depending on the Offset and Gain settings, the output may saturate at lower fields.

4)

INL = V

V

5)

In operating temperature range and over lifetime.

6)

For Sensitivity S > 25 mV / mT. For lower sensitivities, the zero field voltage drift is dominant.

7)

Measured at ± 100 mT range.

- V

out,lse

with V

out

) for TJ≤ 120°C and (6% of VDD)<V

DD

= least square error fit of V

out,lse

± 12.5 - ± 300 mV/mT1)

± 50 ± 100

2)

± 200 mT Programmable

-15 - 15 mV = ± 0.3% of V

-400 - 400 μT

- 5 - 5 μT / °C Error band

OS

= 5 V and TJ=25°C

DD

. Valid in the range (5% of VDD)<V

< (94% of VDD) for 120°C < TJ ≤ 150°C

OUT

out

5) 6) 7)

TLE4997E2

(Junction to

3)

4)

DD

7)

< (95% of

OUT

Data Sheet 16 V 2.10, 2020-04

Page 17

D

A

A

D

X

Stored in

EEPROM

Memory

X

-T

0

+

TC

1

X

A

D

Temperature

Compensation

Hall

Sensor

Temperature

Sensor

Limiter

(Clamp)

out

1

X

Range LP

LP

DAC

+

Offset

Gain

X

TC

2

+

6 Signal Processing

The flow diagram in Figure 5 shows the data processing algorithm.

TLE4997E2

Signal Processing

Figure 5 Signal Processing Flow

Magnetic Field Path

• The analog output signal of the chopped Hall cell is converted in the continuous-time

A/D Converter. The range of the chopped A/D Converter can bet set in several steps

(see Table 6). This assures a suitable level for the A/D Converter.

• After the A/D conversion, a digital low pass filter reduces the bandwidth (Table 10).

• A multiplier amplifies the value according to the gain setting (see Table 8) plus

temperature compensation.

• The offset value is added (see Table 9).

• A limiter reduces the resulting signal to 12 bits and feeds the D/A converter.

Temperature Compensation

(Details are listed in Chapter 8)

• The output signal of the temperature cell is also A/D converted.

• The temperature is normalized by subtraction of the T

• The linear path is multiplied with the TC

Data Sheet 17 V 2.10, 2020-04

quadratic function).

value.

1

value (zero point of the

0

Page 18

TLE4997E2

Signal Processing

• In the quadratic path, the difference temperature is squared and multiplied with the

TC2 value.

• Both path outputs are added together to the gain value from the EEPROM.

6.1 Magnetic Field Ranges

The working range of the magnetic field defines the input range of the A/D Converter. It

is always symmetric to the zero field point. Any two points in the magnetic range can be

selected to be the end points of the output curve. The output voltage represents the

range between the two points.

In the case of fields higher than the range values, the output signal may be distorted.

The range must be set before the calibration of offset and gain.

Table 6 Range Setting

Range Range in mT Parameter R

Low ± 50 3

Mid ± 100 1

High ± 200 0

Table 7 Range

Parameter Symbol Limit Values Unit Notes

min. max.

Register size

1)

Ranges do not have a guaranteed absolute accuracy. The temperature pre-calibration is performed in the mid

range (100 mT).

Data Sheet 18 V 2.10, 2020-04

R

2bit

1)

Page 19

TLE4997E2

Gain

G 16384–()

4096

------------------------------

=

V

OS

OS 16384–()

4096

---------------------------------

V

DD

×=

Signal Processing

6.2 Gain Setting

The sensitivity is defined by the range and the gain setting. The output of the A/D

Converter is multiplied with the gain value.

Table 8 Gain

Parameter Symbol Limit Values Unit Notes

min. max.

Register size

Gain range

G

Gain

Gain quantization steps ΔGain 244.14 ppm Corresponds to 1/4096

1)

For gain values between - 0.5 and + 0.5, the numeric accuracy decreases.

To obtain a flatter output curve, it is recommended to select a higher range setting.

2)

A gain value of +1.0 corresponds to a typical 40 mV/mT sensitivity (100 mT range, not guaranteed). Infineon

pre-calibrates the samples to 60mV/mT (100mT range) in the final test, but does not guarantee the accuracy

of this calibration. It is crucial to do a final calibration of each IC within the application using the Gain/V

The gain value can be calculated by

:

15 bit Unsigned integer value

- 4.0 3.9998 -

1)2)

OS

value.

6.3 Offset Setting

The offset voltage corresponds to an output voltage with zero field at the sensor.

Table 9 Offset

Parameter Symbol Limit Values Unit Notes

min. max.

Register size

Offset range

Offset quantization

OS

V

ΔV

OS

OS

steps

1)

Infineon pre-calibrates the samples at zero field to 50% of VDD (100mT range) in the final test, but does not

guarantee the accuracy of this calibration. It is crucial to do a final calibration of each IC within the application

using the Gain/V

OS

value.

The offset value can be calculated by:

Data Sheet 19 V 2.10, 2020-04

15 bit Unsigned integer value

-400 399 % V

DD

1)

1.22 mV @ VDD=5V

generally V

DD

/ 4095

Page 20

TLE4997E2

Signal Processing

6.4 DSP Input Low Pass Filter

A digital Low Pass Filter is placed between the Hall A/D Converter and the DSP to

reduce the noise level. The Low Pass filter has a constant DC amplification of 0 dB (this

is exactly a gain of 1), which means that its setting has no influence on the internal Hall

A/D Converter value.

The bandwidth can be set in 8 steps.

Table 10 Low Pass Filter Setting

Parameter LP Cutoff frequency in Hz (at 3dB attenuation)

078

1244

2421

3615

4826

51060

61320

7 off

1)

As this is a digital filter running with an RC-based oscillator, the cutoff frequency may vary within ±25%.

2)

The output low pass-interpolation filter behavior remains as main component in the signal path.

2)

1)

Table 11 Low Pass Filter

Parameter Symbol Limit Values Unit Notes

min. max.

Register size

Corner frequency

LP

Δ

f -25 +25 %

3bit

variation

Note: In Low Pass filter setting 7 (filter off), the output noise increases. Because of

higher DSP load, the current consumption also rises slightly.

Data Sheet 20 V 2.10, 2020-04

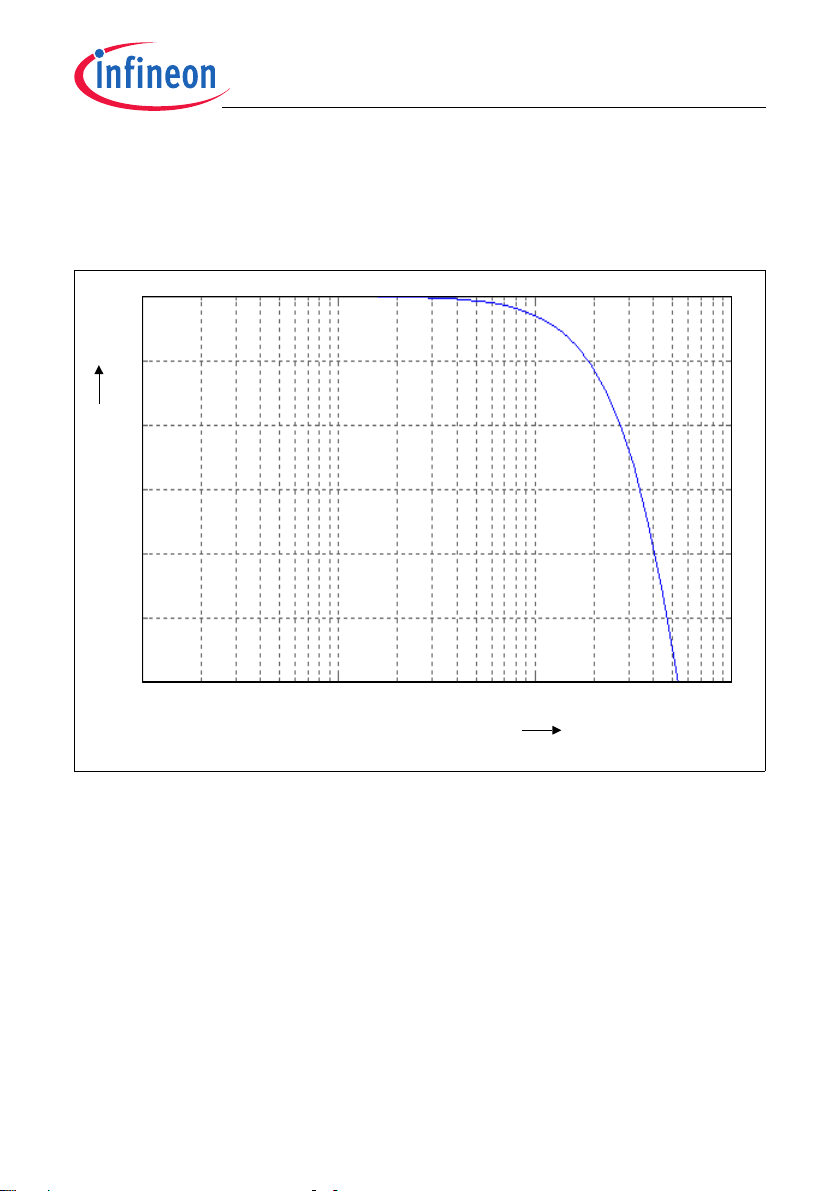

Page 21

TLE4997E2

10

1

10

2

10

3

0

-6

-5

-4

-3

-2

-1

Magnitude (dB)

Frequency (Hz)

Signal Processing

Figure 6 shows the characteristic of the filter as a magnitude plot (the highest setting is

marked). The “off” position would be a flat 0 dB line. In this case, the output decimation

filter limits the bandwidth of the sensor. The update rate after the Low Pass filter is

16 kHz.

Figure 6 DSP Input Filter (Magnitude Plot)

Data Sheet 21 V 2.10, 2020-04

Page 22

TLE4997E2

10

1

10

2

10

3

0

-6

-5

-4

-3

-2

-1

Magnitude (dB)

Frequency (Hz)

10

4

Signal Processing

6.5 DAC Input Interpolation Filter

An interpolation filter is placed between the DSP and the output DAC. It cannot be

switched off. This filter limits the frequency behavior of the complete system if the DSP

input filter is disabled. The update rate after the interpolation filter is 256 kHz.

Figure 7 DAC Input Filter (Magnitude Plot)

Note: As this is a digital filter running with an RC-based oscillator, the cutoff frequency

may vary within ±25%.

Data Sheet 22 V 2.10, 2020-04

Page 23

TLE4997E2

V

CLL

CL

4096

------------

V

DD

×=

V

CLH

CH

4096

------------

V

DD

×=

Signal Processing

6.6 Clamping

The clamping function is useful for splitting the output voltage into the operating range

and error ranges. If the magnetic field is outside the selected measurement range, the

V

output voltage

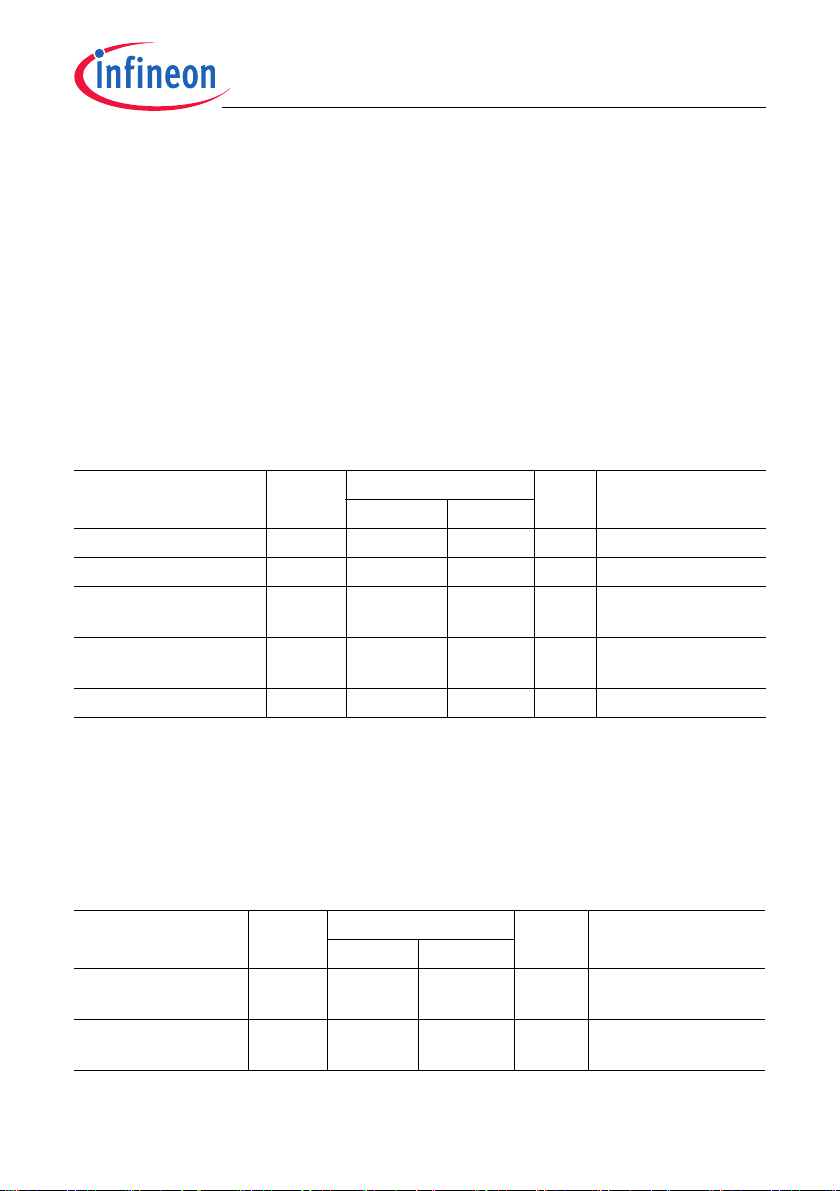

Table 12 Clamping

Parameter Symbol Limit Values Unit Notes

Register size

Clamping voltage low

Clamping voltage high V

Clamping quantization

steps

Clamping voltage drift

1)

If clamping is set, it must be within the allowed output voltage range to be effective.

2)

Valid in the range (5% of VDD)<V

and (6% of

V

is limited to the clamping values.

out

min. max.

CL,CH

DD

V

CLL

CLH

Δ

V

Δ

V

)<V

< (94% of VDD) for 120°C < TJ ≤ 150°C

OUT

0 99.98 % V

0 99.98 % V

CLQ

-15 15 mV in lifetime

CL

-15 15 over temperature

< (95% of VDD) for TJ≤ 120°C

OUT

2 x 12 bit

1)

DD

1)

DD

1.22 mV @ VDD=5V

2)

2)

The clamping values are calculated by:

Clamping low voltage:

Clamping high voltage:

Note: For an exact setup, the register value may be re-adjusted due to the actual output

voltage in the clamping condition. The output voltage range itself has electrical

limits. See the Electrical Characteristics of

Data Sheet 23 V 2.10, 2020-04

V

.

out

Page 24

TLE4997E2

0

1

B

min

B (mT)

B

max

V

out

(V)

5

2

4

3

Error range

Error range

Operating range

V

CLH

V

CLL

Signal Processing

Figure 8 shows an example in which the magnetic field range between B

is mapped to voltages between 0.8 V and 4.2 V.

If it is not necessary to signal errors, the maximum output voltage range between 0.3 V

and 4.7 V can be used.

min

and B

max

Figure 8 Clamping Example

Note: The high value must be above the low value.

If V

is set to a higher value than V

CLL

lead to a constant output voltage independent of the magnetic field strength.

CLH

, the V

value is dominating. This would

CLH

Data Sheet 24 V 2.10, 2020-04

Page 25

TLE4997E2

Error Detection

7 Error Detection

Different error cases can be detected by the On-Board-Diagnostics (OBD) and reported

to the microcontroller. The OBD is useful only when the clamping function is enabled. It

is important to set the clamping threshold values inside the error voltage values shown

in Table 13 and Table 14 to ensure that it is possible to distinguish between correct

output voltages and error signals.

7.1 Voltages Outside the Operating Range

The output signals error conditions, if VDD lies

• inside the ratings specified in Table 2 "Absolute Maximum Ratings" on Page 12

• outside the range specified in Table 3 "Operating Range" on Page 13.

Table 13 Undervoltage and Overvoltage (All values with RL ≥ 10k)

Parameter Symbol Limit Values Unit Notes

min. max.

Undervoltage threshold

Overvoltage threshold

Output voltage

@ undervoltage

Output voltage

@ overvoltage

Supply current

1)

For overvoltage and reverse voltage, see Table 2 "Absolute Maximum Ratings" on Page 12.

1)

V

DDuv

V

DDov

V

OUTuv

V

OUTov

I

DDuv

34V

78.3V

0.95 x VDD-V3V ≤ VDD≤ V

0.97 x VDD-VV

DDov

DDuv

< VDD≤ 16 V

- 10 mA @ undervoltage

7.2 Open Circuit of Supply Lines

In the case of interrupted supply lines, the data acquisition device can alert the user. If

two sensors are placed in parallel, the output of the remaining working sensor may be

still used for an emergency operation.

Table 14 Open Circuit (OBD Parameters)

Parameter Symbol Limit Values Unit Notes

min. max.

Output voltage

@ open V

DD

line

Output voltage

@ open

1)

Data Sheet 25 V 2.10, 2020-04

GND line

With VDD= 5 V and R

V

V

OUT

OUT

00.18

4.82

4.8

≥ 10 kΩ pull-down or RL≥ 20 kΩ pull-up.

L

1)

VT

0.2

5VT

≤120°C

J

120°C < TJ ≤ 150°C

≤120°C

J

120°C < TJ ≤ 150°C

Page 26

TLE4997E2

Error Detection

7.3 Not Correctable EEPROM Errors

The parity method is able to correct one single bit in one EEPROM line. One other single

bit error in another line can also be detected. As this situation is not correctable, this

V

status is signalled at the output pin by clamping the output value to

Table 15 EEPROM Error Signalling

Parameter Symbol Limit Values Unit Notes

min. max.

Output voltage @

V

OUT

0.97 x V

DDVDD

V

EEPROM error

DD

.

Data Sheet 26 V 2.10, 2020-04

Page 27

TLE4997E2

S

TC

T() 1 TC

1

TT

0

–()× TC

2

TT

0

–()

2

×++=

Temperature Compensation

8 Temperature Compensation

The magnetic field strength of a magnet depends on the temperature. This material

constant is specific to different magnet types. Therefore, the TLE4997E2 offers a second

order temperature compensation polynomial, by which the Hall signal output is multiplied

in the DSP. There are three parameters for the compensation:

• Reference temperature T

• A linear part (1st order) TC

• A quadratic part (2nd order) TC

The following formula describes the sensitivity dependent on the temperature in relation

to the sensitivity at the reference temperature T0:

For more information, see also the signal processing flow in Figure 5.

The full temperature compensation of the complete system is done in two steps:

1. Pre-calibration in the Infineon final test.

The parameters TC1, TC2, T0 are set to maximally flat temperature characteristics

regarding the Hall probe and internal analog processing parts.

2. Overall System calibration.

The typical coefficients TC1, TC2, T0 of the magnetic circuitry are programmed. This

can be done deterministically, as the algorithm of the DSP is fully reproducible. The

final settings of the TC1, TC2, T0 values are relative to the pre-calibrated values.

Table 16 Temperature Compensation

Parameter Symbol Limit Values Unit Notes

Register size

st

order coefficient TC

1

TC

1

Quantization steps of TC

Register size

nd

order coefficient TC

2

TC

2

Quantization steps of TC

Register size

T

0

Reference temperature

Quantization steps of

1)

Full adjustable range: -2441 to +5355 ppm/°C, can be only used after confirmation by Infineon

2)

Full adjustable range: -15 to +15 ppm/°C², can be only used after confirmation by Infineon

3)

A quantization step of 1°C is handled by algorithm (See Application Note).

0

1

2

min. max.

TL

TC

1

Δ

TC

1

TQ

TC

2

Δ

TC

2

TR

T

0

T

Δ

T

0

- 9 bit Unsigned integer values

-1000 2500 ppm/ °C1)

1

1

15.26 ppm/ °C

- 8 bit Unsigned integer values

- 4 4 ppm/ °C²2)

2

2

0.119 ppm/ °C²

- 3 bit Unsigned integer values

-48 64 °C

0

16 °C

3)

Data Sheet 27 V 2.10, 2020-04

Page 28

TC

1

TL 160–

65536

----------------------

1000000×=

TC

2

TQ 128–

8388608

-----------------------

1000000×=

T

0

16T R 48–=

V

OUT

B

IN

B

FSR

-------------

S

TC

× S

TCHall

× S

o

V

DD

××

èø

ç÷

æö

V

OS

+=

S

TC

TJT0–()S

TCHall

TJ()× 1≈

B

IN

T()

B

IN

T0()

--------------------

S

TCnew

T() S

TCHall

T()×× STCT() S

TCHall

T()× 1≈≈

B

IN

T()

B

IN

T0()

--------------------

S

TCnew

T()× STCT()≈

8.1 Parameter Calculation

The parameters TC1, TC2 and T0 may be calculated by:

TLE4997E2

Temperature Compensation

Now the output V

for a given field BIN at a specific temperature can be roughly

OUT

calculated by:

is the full range magnetic field. It is dependent on the range setting (e.g 100 mT).

B

FSR

S

is the nominal sensitivity of the Hall probe times the Gain factor set in the EEPROM.

o

STC is the temperature-dependent sensitivity factor calculated by the DSP.

S

is the temperature behavior of the Hall probe.

TCHall

The pre-calibration at Infineon is performed such that the following condition is met:

Within the application, an additional factor BIN(T) / BIN(T0) will be given due to the

magnetic system. STC needs now to be modified to S

so that the following condition

TCnew

is satisfied:

S

Therefore, the new sensitivity parameters

pre-calibrated setup S

using the relation:

TC

can be calculated from the

TCnew

Data Sheet 28 V 2.10, 2020-04

Page 29

TLE4997E2

Calibration

9Calibration

A special hardware interface to an external computing system and measurement

equipment is required for calibration of the sensor. All calibration and setup bits can be

written into a random access memory (RAM). This allows the EEPROM to remain

untouched during the entire calibration process. Therefore, this temporary setup (using

the RAM only) does not stress the EEPROM—and even allows a pre-verification

setup before programming—as the number of EEPROM programming cycles is limited

to provide a high data endurance.

The digital signal processing is completely deterministic. This allows a two point

calibration in one step without iterations. The two magnetic fields (here described as two

“positions” of an external magnetic circuitry) need to be applied only once. Furthermore,

a complete setup and calibration procedure can be performed requiring only one

EEPROM programming cycle at the end

2)

.

After setting up the temperature coefficients, the calibrated Hall A/D Converter values of

both positions need to be read and the sensor output signals (using a DAC test mode)

need to be acquired for the corresponding end points. Using this data, the signal

processing parameters can be immediately calculated with a program running on the

external computing system.

Note: The calibration and programming process must be performed only at the

start of life of the device.

Table 17 Calibration Characteristics

Parameter Symbol Limit Values Unit Notes

min. max.

Temperature of sensor at

t

CAL

10 30 °C

2 point calibration and

programming

2 point calibration

accuracy

1)

1)

Setup and validation performed at start of life.

Δ

V

Δ

V

-10 10 mV Position 1

CAL1

-10 10 mV Position 2

CAL2

1)

of the

Note: Depending on the application and external instrumentation setup, the accuracy of

the 2 point calibration can be improved.

1)

This feature is not required for a deterministic two-point setup to fulfill the specification.

2)

Details and basic algorithms for this step are available on request.

Data Sheet 29 V 2.10, 2020-04

Page 30

TLE4997E2

User-Calibration Bits

Pre-Calibration Bits

Column Parity Bi ts

RowA Parity Bits

Calibration

9.1 Calibration Data Memory

When the MEMLOCK bits are programmed (two redundant bits), the memory contents

are frozen and may no longer be changed. Furthermore, the programming interface is

locked out and the chip remains in Application Mode only. This prevents accidental

programming due to environmental influences.

Figure 9 EEPROM Map

A matrix parity architecture allows the automatic correction of any single bit error. Each

row is protected by a row parity bit. The sum of bits set including this bit must be an odd

number (ODD PARITY). Each column is additionally protected by a column parity bit.

The sum of all the bits in the even positions (0, 2, etc.) of all lines must be an even

number (EVEN PARITY); the sum of all the bits in the odd positions (1,3, etc.) must be

an odd number (ODD PARITY). This mechanism of different parity calculations protects

against many block errors (such as erasing a full line or even the entire EEPROM).

When modifying the application bits (such as Gain, Offset, TC, etc.) the parity bits must

be updated. For the column bits, the pre-calibration area must be also read out and

considered for correct parity generation.

Note: A specific programming algorithm must be followed to ensure the data retention.

A separate detailed programming specification is available on request.

Data Sheet 30 V 2.10, 2020-04

Page 31

TLE4997E2

Calibration

Table 18 Programming Characteristics

Parameter Symbol Limit Values Unit Notes

min. max.

Number of EEPROM

programming cycles

Ambient temperature at

N

T

PRG

PRG

- 10 Cycles

1)

10 30 °C

Programming allowed

only at start of lifetime

programming

Programming time

Calibration memory

Error correction

1)

1 cycle is the simultaneous change of ≥ 1bit.

2)

Depending on clock frequency at VDD, write pulse 10ms ±1%, erase pulse 80ms ±1%.

t

PRG

-

-

100 - ms For complete memory

135 Bit All active EEPROM bits

25 Bit All parity EEPROM bits

2)

9.2 Programming Interface

The supply pin and the output pin are used as two-wire interface to transmit the

EEPROM data to and from the sensor.

This allows

• communication with high data reliability

• bus-type connection of several sensors

In many applications, two sensors are used to measure the same parameter. This

redundancy allows the operation to continue in an emergency mode. If both sensors use

the same power supply lines, they can be programmed together in parallel.

The data transfer protocol and programming is described in a separate document

(TLE4997 Programming Guide).

9.3 Laboratory Evaluation Programmer

For the programming of evaluation samples and QA (quality assurance) samples a

programming equipment is available on request.

Data Sheet 31 V 2.10, 2020-04

Page 32

Application Circuit

optional

Volt age Tr acker

e.g .

TLE4250

Ref

ADC

ref

ADC

in1

ADC

in2

ADC

GND

47nF

10k

100 nF10k100 nF47nF

47nF

10k

100 nF10k100 nF47nF

µC

TLE

4997

out

V

DD

GND

TLE

4997

out

V

DD

GND

10 Application Circuit

Figure 10 shows the connection of multiple sensors to a microcontroller.

TLE4997E2

Figure 10 Application Circuit

Note: For calibration and programming, the interface must be connected directly to the

output pin.

The given application circuit must be regarded as only an example. It needs to be

adapted according to the requirements of the specific application.

Data Sheet 32 V 2.10, 2020-04

Page 33

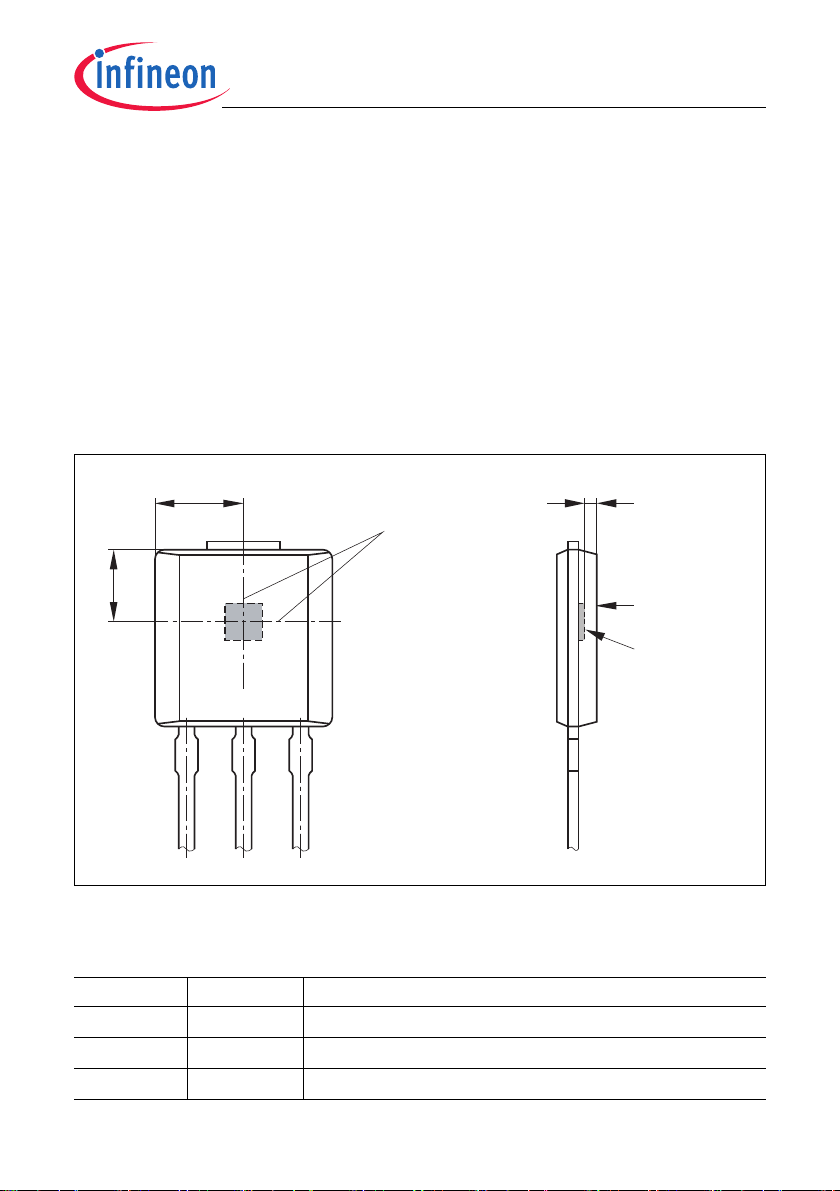

1) No solder function area

Molded body dimensions do not unclude plastic or metal protrusion of 0.15 max per side

±0.3

12.7

±0.4

6.35

12.7

±1

Total tolerance at 19 pitches ±1

±0.3

4

19

±0.5

9

-0.50

+0.75

33 MAX.

(Useable

Length)

(10)

±0.5

18

A

±0.5

6

1

-1

-0.15

0.25

±0.1

0.39

Ta pe

Adhesive

Ta pe

(0.25)

1

±0.2

1)

0.1 MAX.

0.5

0.5

±0.05

±0.1

0.42

3x

1.5

±0.05

4.06

4.05

±0.05

2 x 1.27 = 2.54

A

2

±0.05

1.5

0.36

±0.05

0.82

±0.05

P-PG-SSO-3-10-PO V02

45˚

5˚

123

B

B

C2

C

11 Package Outlines

TLE4997E2

Package Outlines

Figure 11 PG-SSO-3-10 (Plastic Green Single Small Outline Package)

Data Sheet 33 V 2.10, 2020-04

Page 34

www.infineon.com

Published by Infineon Technologies AG

Loading...

Loading...