Page 1

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

About this document

Scope and purpose

This document provides product information and descriptions regarding:

• I2C Registers

• I2C Interface

• Wake Up mode

• Diagnostic and Tests

Intended audience

This document is aimed at engineers and developers of hard and soware using the sensor TLE493D-P2B6.

Usermanual Please read the Important Notice and Warnings at the end of this document Ver. 1.0

www.infineon.com 2020-12-11

Page 2

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

Table of contents

Table of contents

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1 I2C Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 Register overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 Register description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Bit types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Measurement data and registers combined in the I²C parity bit “P” . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.3 Wake Up and registers combined in the I2C parity flag “CF" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.2.4 Mode registers combined in the I²C parity flag “FF” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

1.2.5 Diagnostic, status and version registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 I²C Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.1 I²C protocol description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.2 I²C write command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.3 I²C read commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.3.1 2-byte read command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1.3.2 1-byte read command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.2 Collision avoidance and clock stretching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2.2.1 Collision avoidance (CA bit = 0B and INT bit = 0B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.2.2 Clock stretching (CA bit = 0B and INT bit = 1B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.3 Sensor reset by I²C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.4 Sensor Initialization and Readout example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2.5 Loss of VDD impact on I²C bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3 Wake Up mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.1 Wake Up activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2 Wake Up constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3 Wake Up in combination with the angular mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4 Diagnostic and tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1 Diagnostic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.1.1 Parity bits and parity flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.2 Test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.3 Power-down flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.4 Frame counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.1.5 Device address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2 Test functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2.1 Vhall/Vext test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.1.1 Test description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.1.2 Test implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Usermanual 2 Ver. 1.0

2020-12-11

Page 3

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

Table of contents

4.2.1.3 Test reference values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.2 Spintest mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.2.2.1 Test description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2.2.2 Test implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.2.2.3 Test reference values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2.3 SAT-test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2.3.1 Test description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2.3.2 Test implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4.3 Magnetic measurement implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Usermanual 3 Ver. 1.0

2020-12-11

Page 4

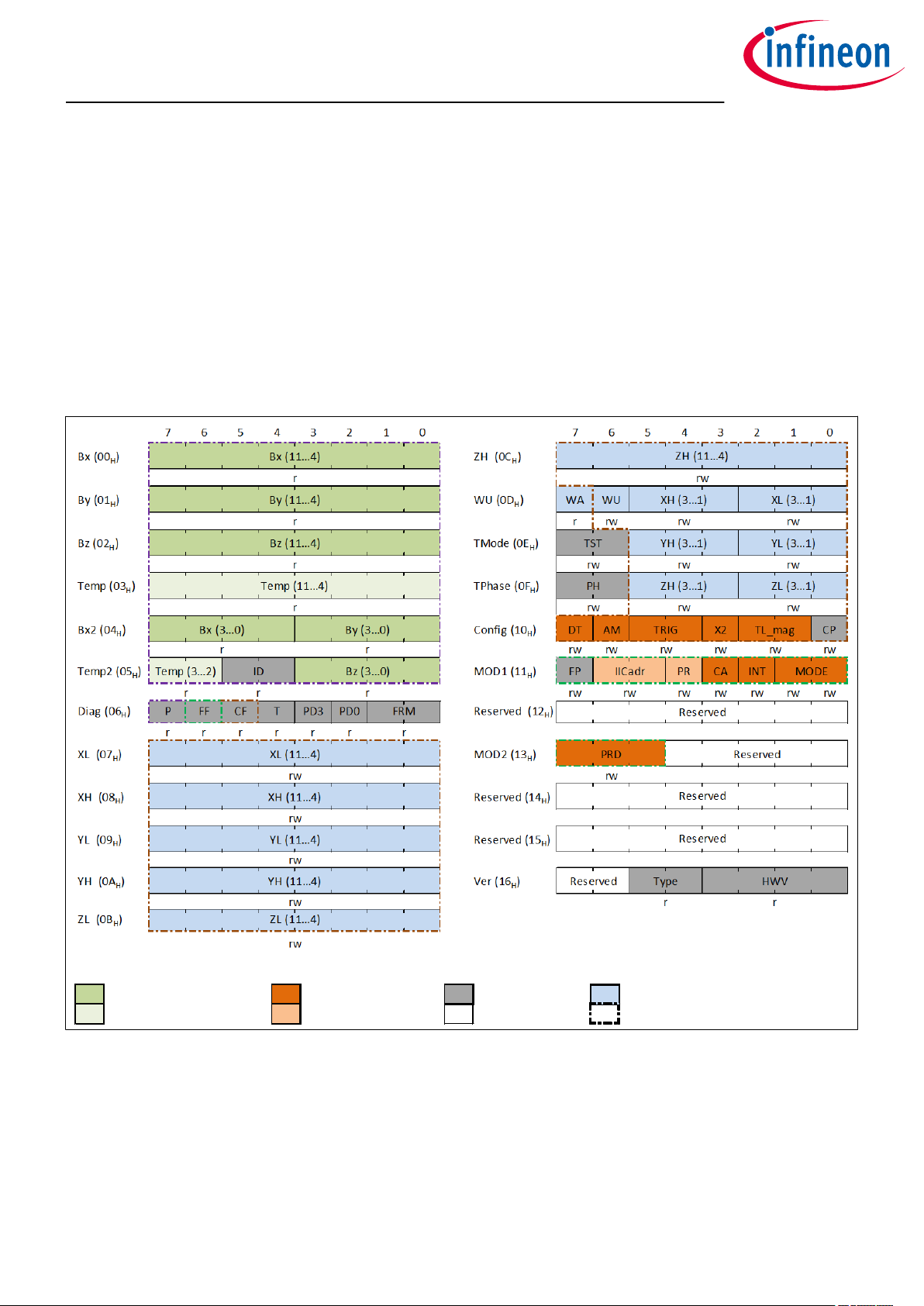

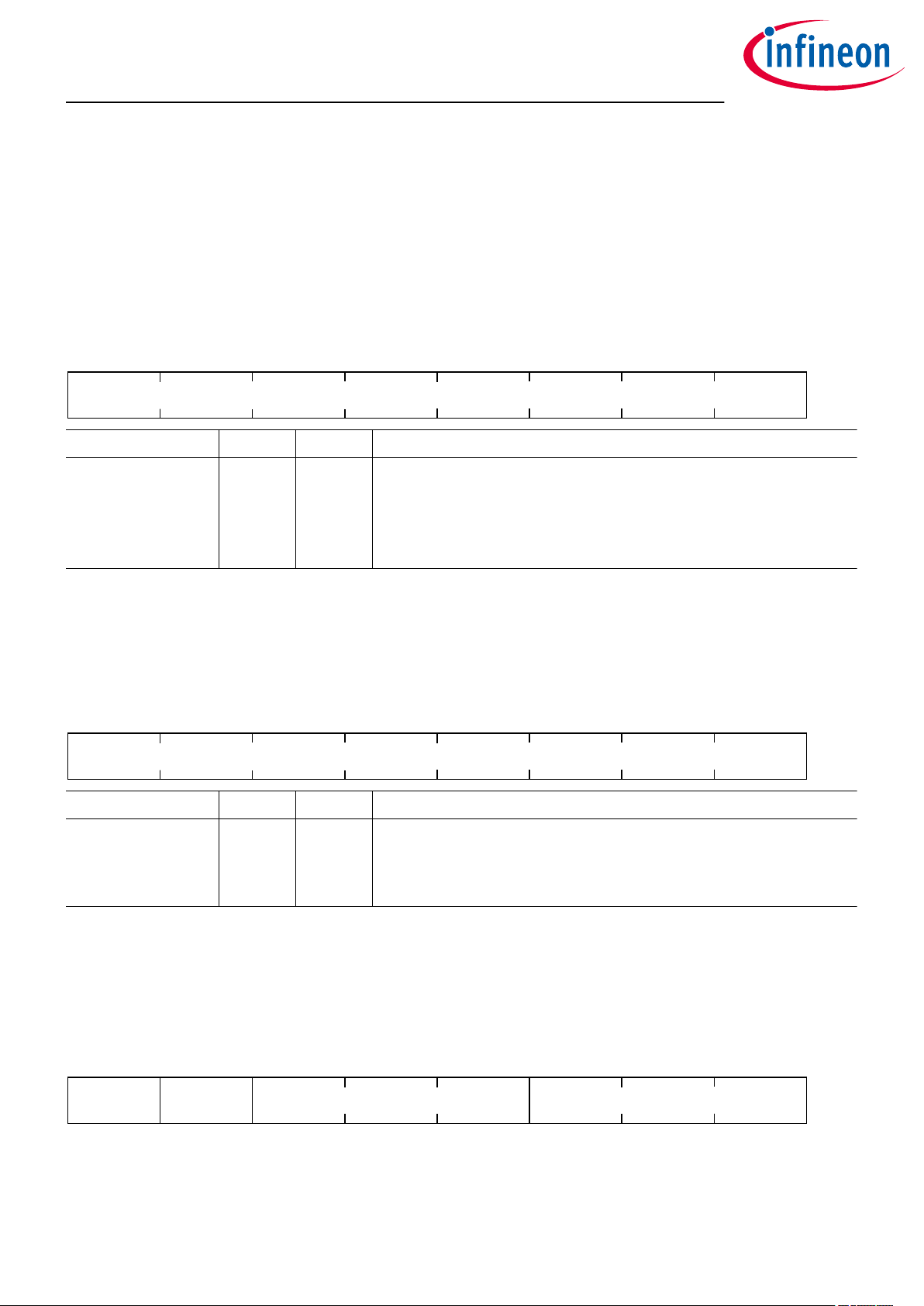

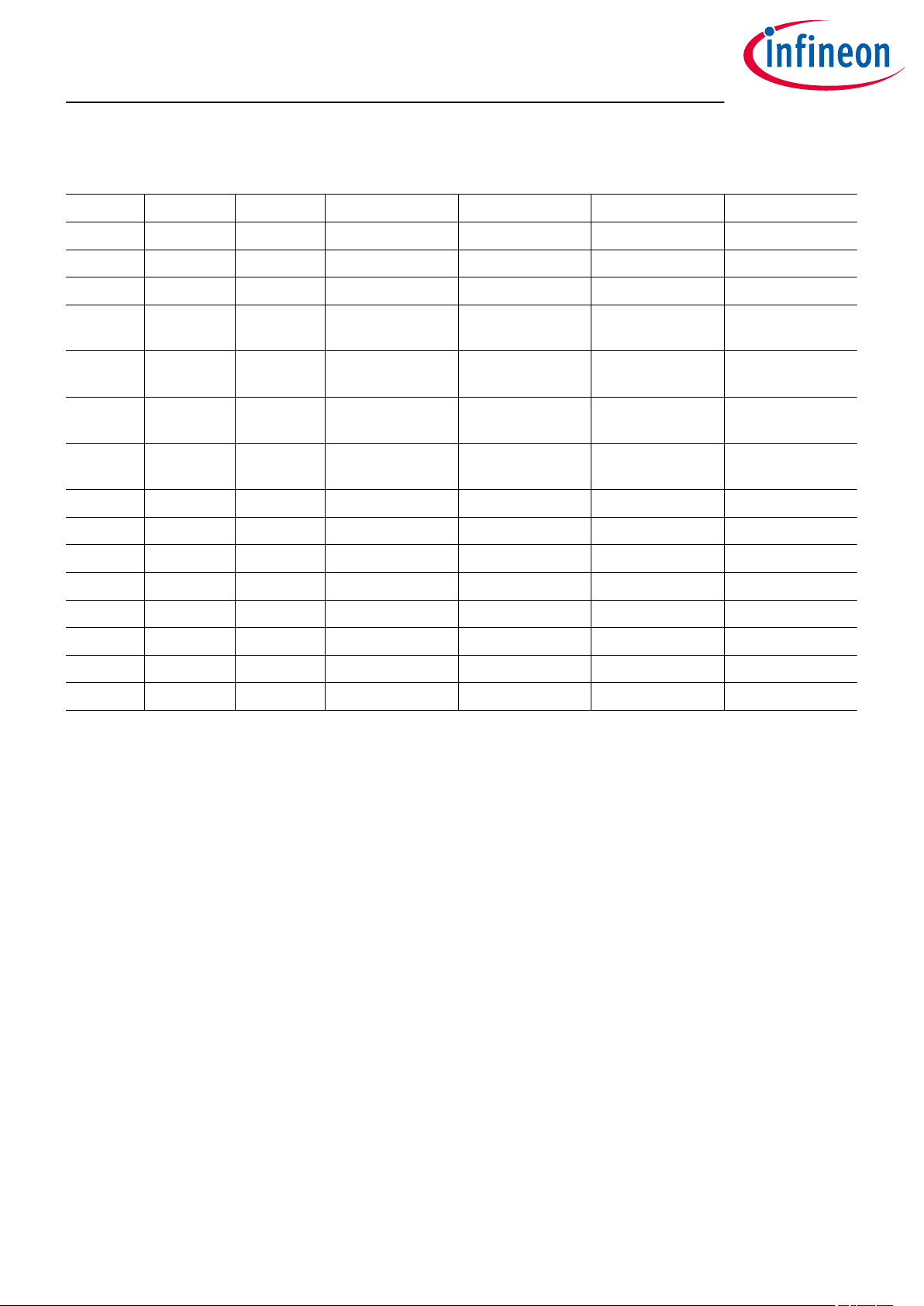

Colour legend for the Bitmap

Magnetic values Configuration Diagnosis

Wake Up

Temperature values Configuration bus Reserved bits Parity bits and related registers (colour)

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

1 I2C Register

The TLE493D-P2B6 includes several registers that can be accessed via Inter-Integrated Circuit interface (I2C) to

read data as well as to write and configure settings.

1.1 Register overview

A bitmap overview is presented in Figure 1. Basically the following sections are available:

• measurement data (green bits in registers 00H till 05H)

• sensor status and diagnostics (grey bits in registers 05H, 06H, 0EH, 0FH, 10H and 11H)

• configuration parameters such as the power mode (orange bits in registers 10H, 11H and 13H)

• Wake Up values in registers (blue bits in registers 07H till 0FH)

Figure 1 TLE493D-P2B6 Bitmap

The diagnostic register 06H contains parity information as a diagnostic mechanism. The bitmap illustrates this

and marks the relationship of the sections to this flags with dierent colored lines/frames around the bit

contents.

Usermanual 4 Ver. 1.0

2020-12-11

Page 5

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

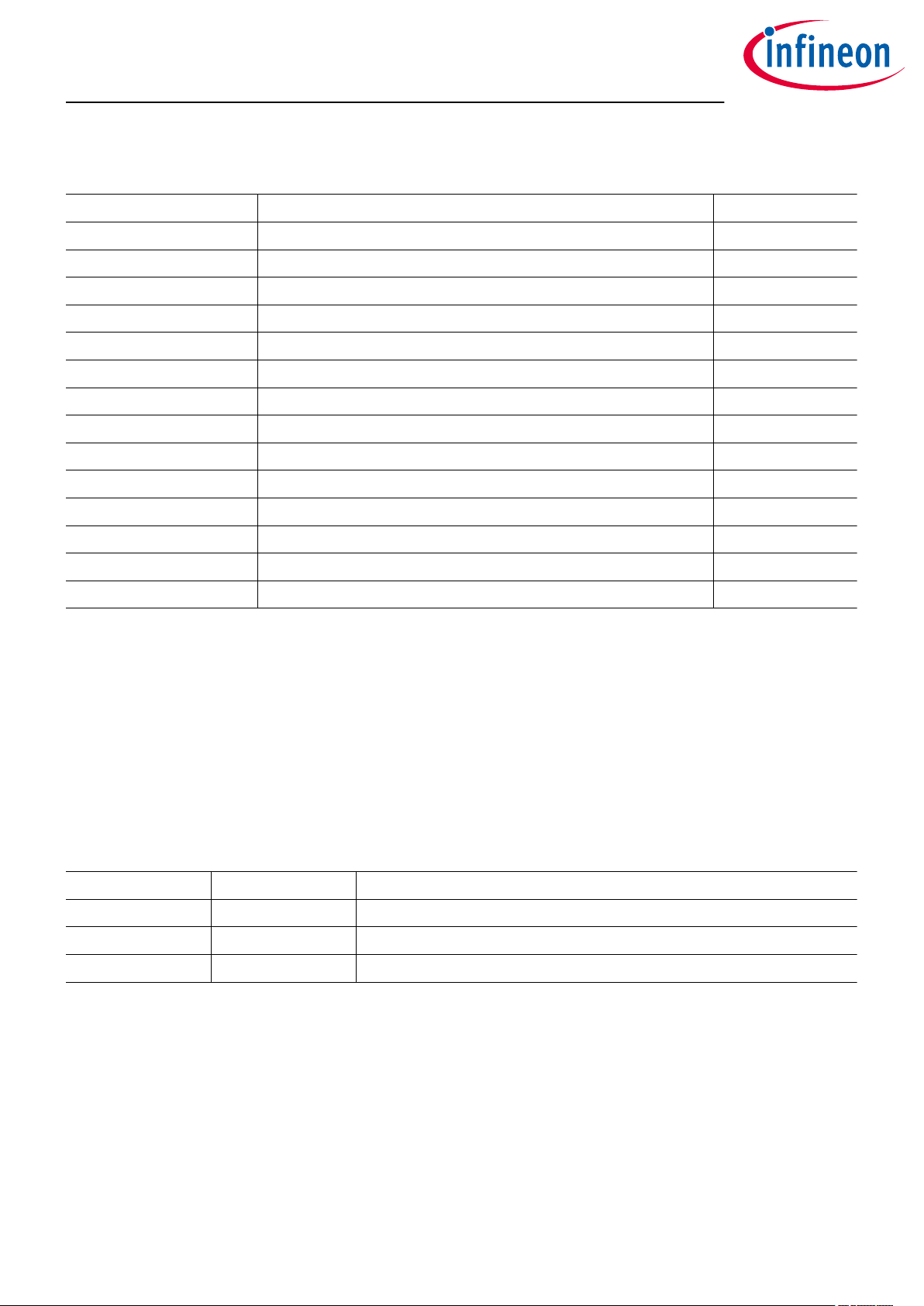

Table 1 Register overview

Register name Register long name Address

Bx, By and Bz Magnetic values MSBs 00H, 01H, 02

Temp Temperature value MSBs 03

Bx2 Magnetic values LSBs 04

Temp2 Temperature and magnetic LSBs and device address 05

Diag Sensor diagnostic and status register 06

H

H

H

H

XL, YL and ZL Wake Up lower threshold MSBs 07H, 09H, 0B

XH, YH and ZH Wake Up upper threshold MSBs 08H, 0AH, 0C

WU Wake Up enable and X thresholds LSBs 0D

TMode Test Mode and Wake Up Y thresholds LSBs 0E

TPhase Test Phase and Wake Up Z thresholds LSBs 0F

Config Configuration register 10

MOD1 Power mode, interrupt, address, parity 11

MOD2 Low Power Mode update rate 13

Ver Version register 16

H

H

H

H

H

H

H

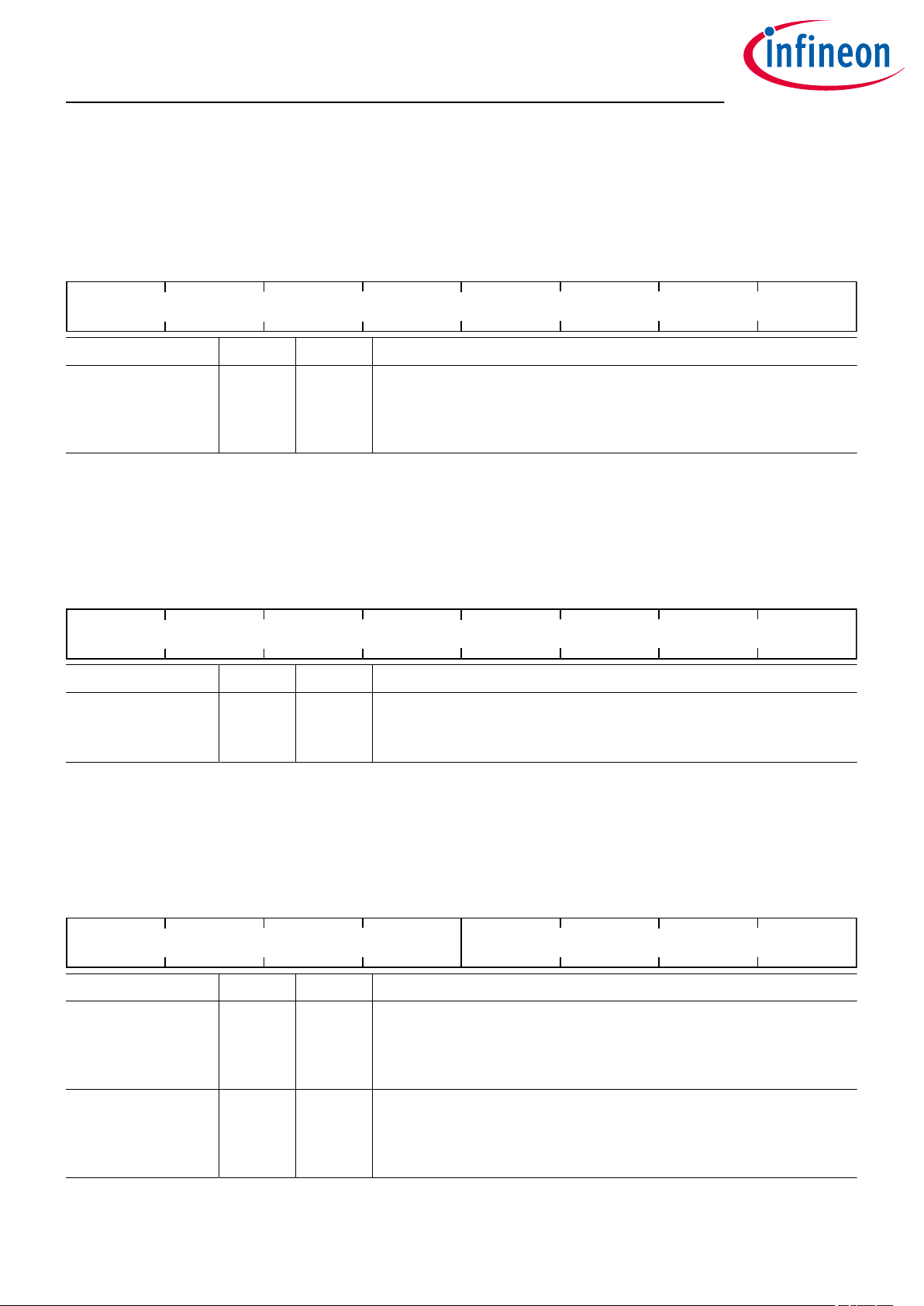

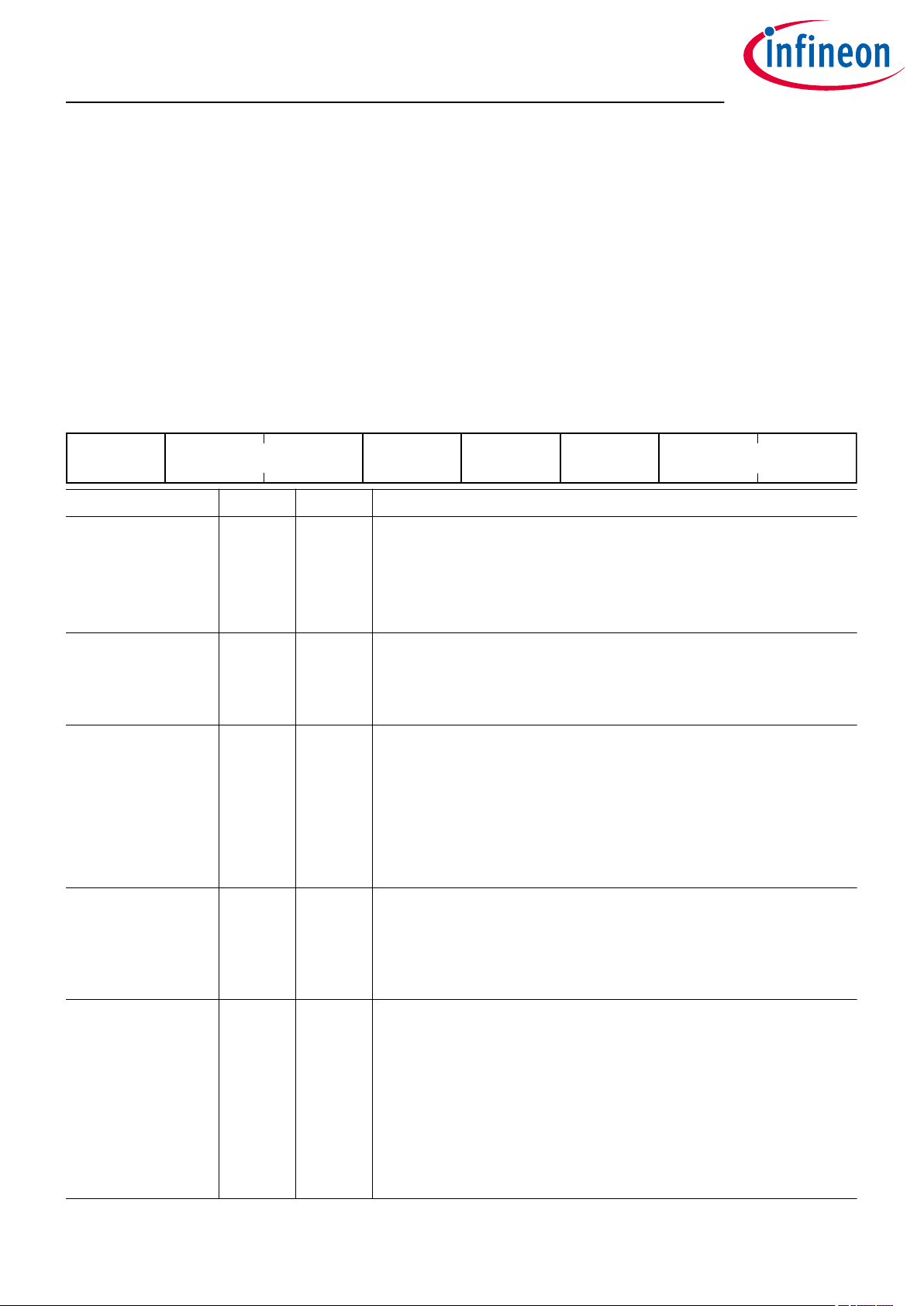

1.2 Register description

H

H

H

The I2C registers can be read or written at any time. It is recommended to read measurement data in a

synchronized fashion, i.e. aer an interrupt pulse (/INT). This avoids reading inconsistent sensor or diagnostic

data, especially in fast mode. Additionally, several flags can be checked to ensure the register values are

consistent and the ADC was not running at the time of readout.

1.2.1 Bit types

The TLE493D-P2B6 contains read bits, write bits and reserved bits.

Table 2 Bit types

Abbreviation Function Description

r Read Read-only bits

rw Read Write Readable and writable bit

Reserved Bits that must keep the default values (read prior to write required)

1.2.2 Measurement data and registers combined in the I²C parity bit “P”

The I2C communication of the registers in this chapter is protected with the parity bit “P”, described in the Diag

register with the address 06H. See also Figure 1 - parity bits and related registers.

To make sure all data is consistent, the registers from 00H to 06H should be read with the same I2C command.

Otherwise, the sampled data (X, Y, Z, Temperature) may correspond to dierent conversion cycles.

Usermanual 5 Ver. 1.0

2020-12-11

Page 6

7

0

Bx, By and Bz (11...4)

7

0

Temp (11...4)

7

0

Bx (3...0)

By (3...0)

4 3

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

Magnetic values MSBs

Register names Address Reset Value

Bx, By and Bz 00H, 01H, 02

H

80

Field Bits Type Description

Bx, By and Bz 7:0 r Bx, By and Bz values

Signed value as two’s complement from the HALL probes in the

x, y and z-direction of the magnetic field. Contains the eight Most

Significant Bits. If Bz is deactivated the Bz value is the reset value.

Back to TLE493D-P2B6 Bitmap.

Temperature value MSBs

Register name Address Reset Value

Temp 03

H

80

Field Bits Type Description

H

H

Temp 7:0 r Temperature value

Signed value as two’s complement. If the temperature

measurement is deactivated, the Temp value is the reset value.

Back to TLE493D-P2B6 Bitmap.

Magnetic values LSBs

Register name Address Reset Value

Bx2 04

H

00

Field Bits Type Description

Bx 7:4 r Bx value

Signed value as two’s complement from the HALL probes in the xdirection of the magnetic field. Contains the four Least Significant

Bits.

By 3:0 r By value

Signed value as two’s complement from the HALL probes in the ydirection of the magnetic field. Contains the four Least Significant

Bits.

H

Back to TLE493D-P2B6 Bitmap.

Usermanual 6 Ver. 1.0

2020-12-11

Page 7

7

0

Bz (3...0)

4 3

Temp (3...2)

ID

6

5

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

Temperature and magnetic LSBs and device address

Register name Address Reset Value

Temp2 05

H

Field Bits Type Description

Temp 7:6 r Temperature value

Signed value as two’s complement. If the temperature

measurement is deactivated, the Temp value is the reset value.

ID 5:4 r ID

Readback of the sensor ID, from IICadr . µC shall verify the address

sent by the sensor. See Table 4 .

Bz 3:0 r Bz value

Signed value as two’s complement from the HALL probes in the zdirection of the magnetic field. Contains the four Least Significant

Bits. If Bz is deactivated the Bz value is 0H.

(Product Type A0) 00

(Product Type A1) 10

(Product Type A2) 20

(Product Type A3) 30

H

H

H

H

Back to TLE493D-P2B6 Bitmap.

Usermanual 7 Ver. 1.0

2020-12-11

Page 8

7

0

XL, YL and ZL (11...4)

7

0

XH, YH and ZH (11...4)

7

0

6

5 3

2

XL (3...1)XH (3...1)WUWA

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

1.2.3 Wake Up and registers combined in the I2C parity flag “CF"

The I2C communication of the registers in this chapter is protected by the parity bit CF, which is described in the

Diag register with the address 06H. See also Figure 1 - parity bits and related registers.

Wake Up lower threshold MSBs

Register names Address Reset Value

XL, YL and ZL 07H 09H 0B

H

80

Field Bits Type Description

XL, YL and ZL 7:0 rw Wake Up lower threshold

Defines the lower threshold MSBs of the magnetic field in the x, y

and z-direction at or below which the sensor enables the /INT, if

INT bit = 0B.

See Equation 2.

Back to TLE493D-P2B6 Bitmap.

Wake Up upper threshold MSBs

Register names Address Reset Value

XH, YH and ZH 08H 0AH 0C

H

7F

H

H

Field Bits Type Description

XH, YH and ZH 7:0 rw Wake Up upper threshold

Defines the upper threshold MSBs of the magnetic field in the x,

y and z direction at or above which the sensor enables the /INT, if

INT bit = 0B. See Equation 2.

Back to TLE493D-P2B6 Bitmap.

Wake Up enable and X thresholds LSBs

Register name Address Reset Value

WU 0D

Usermanual 8 Ver. 1.0

H

2020-12-11

38

H

Page 9

7

0

6

5 3

2

YL (3...1)YH (3...1)TST

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

Field Bits Type Description

WA 7 r Wake Up mode active

Flag that reports whether the Wake Up mode is disabled or

enabled.

If 0B the Wake Up mode is disabled.

If 1B the Wake Up mode is enabled.

This bit can be checked if the Wake Up function is disabled or

enabled. As long as the WA bit = 0B, the /INT will be asserted

according Table 5.

WU 6 rw Enables Wake Up mode

If 0B the Wake Up mode will be disabled.

If 1B the Wake Up mode will be enabled.

The following conditions must be fulfilled:

• Test modes must be disabled (T bit = 0B)

• CP parity bit (register 10H) must be odd

• Configuration parity must be flagged (CF bit = 1B)

Interrupts /INT will be sent when the measurement data is ≥ upper

or ≤ lower Wake Up threshold.

XH 5:3 rw Wake Up X upper threshold

Defines the upper threshold LSBs of the magnetic field in the

x-direction at or above the sensor enables the /INT, if INT bit = 0B.

See Equation 2.

XL 2:0 rw Wake Up X lower threshold

Defines the lower threshold LSBs of the magnetic field density in

the x-direction at or below the sensor enables the /INT, if INT bit =

0B. See Equation 2.

Back to TLE493D-P2B6 Bitmap.

Test Mode and Wake Up Y thresholds LSBs

Register name Address Reset Value

TMode 0E

H

Field Bits Type Description

TST 7:6 rw Test mode

Dierent test modes can be enabled, see Table 3:

If 00B no test active (normal sensor operation and T bit = 0B). In the

following test modes the T bit = 1B and the test result overwrites

the measurement data register:

If 01B Vhall/Vext test starts: measure the Hall bias voltage on all

Hall plates and VDD.

If 10B Spintest starts: the PH bits select the channel to diagnose

with the Spin-switch and Hall-oset test.

If 11B SAT test starts: a test of the whole digital path, generates

patterns, defined by the PH bits during conversion.

Usermanual 9 Ver. 1.0

2020-12-11

38

H

Page 10

7

0

6

5 3

2

ZL (3...1)ZH (3...1)PH

7

0

CP

6

5

4

3

2

1

TL_magX2AMDT TRIG

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

Field Bits Type Description

YH 5:3 rw Wake Up Y upper threshold

Defines the upper threshold LSBs of the magnetic field in the

y-direction at or above which the sensor enables the /INT, if INT bit

= 0B.

See Equation 2.

YL 2:0 rw Wake Up Y lower threshold

Defines the lower threshold LSBs of the magnetic field density in

the y-direction at or below which the sensor enables the /INT, if INT

bit = 0B. See Equation 2.

Back to TLE493D-P2B6 Bitmap.

Test Phase and Wake Up Z thresholds LSBs

Register name Address Reset Value

TPhase 0F

H

Field Bits Type Description

PH 7:6 rw Test phase selection

In the Spintest these bits define the channel. In the digital test,

specific patterns are defined. See Test phase selection Table 3.

The PH bits have no eect in the voltage measurement test (Vext)

and in normal operating mode TST bit=00B and T bit=0B).

See Equation 2.

ZH 5:3 rw Wake Up Z upper threshold

Defines the upper threshold LSBs of the magnetic field in the

z-direction at or above which the sensor enables the /INT, if INT bit

= 0B.

See Equation 2.

ZL 2:0 rw Wake Up Z lower threshold

Defines the lower threshold LSBs of the magnetic field density in

the z-direction at or below which the sensor enables the /INT, if INT

bit = 0B. See Equation 2.

38

H

Back to TLE493D-P2B6 Bitmap.

Configuration register

Register names Address Reset Value

Config 10

Usermanual 10 Ver. 1.0

H

2020-12-11

01

H

Page 11

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

Field Bits Type Description

DT 7 rw Disable Temperature

If 0B temperature measurement is enabled.

If 1B temperature measurement is disabled. This means the Bx, By

and Bz channels are measured. The Temp channel is disabled and

contains the reset value until a new conversion with Temp is done.

AM 6 rw X/Y Angular Measurement

If 0B the Bz measurement is enabled.

If 1B and DT bit = 1B: the Bz measurement is disabled. This means

the Bx and By channel is measured. The channels Bz and Temp

contain the reset values until a new conversion with Bz and Temp

is done

If 1B and DT bit = 0B: must not be used.

TRIG 5:4 rw Trigger options

If PR bit = 1B (1-byte read protocol), the TRIG bits define the trigger

mode of the device:

If 00B no ADC trigger on read

If 01B ADC trigger on read before first MSB.

If 1xB ADC trigger on read aer register 05H.

If PR bit = 0B these bits have no eect.

X2 3 rw Short range sensitivity

When this bit is set, the sensitivity of the Bx, By, and Bz ADCconversion is doubled by a longer ADC integration time. The Temp

result will not change, neither in sensitivity nor conversion time.

See Table 3.

TL_mag 2:1 rw Magnetic temperature compensation

There are two bits for setting the sensitivity over temperature of

the sensor to compensate a magnet temperature coeicient.

If 00B → TC0 (no compensation)

If 01B → TC

If 10B → TC

If 11B → TC

1

2

3

CP 0 rw Wake Up and configuration parity

The registers 07H through 10H (including 10H) without WA TST and

PH bit are odd parity protected with this bit. On startup or reset,

this parity is false and the CF bit in the status register 06H is

cleared. Thus the CP bit has to be corrected once aer startup or a

reset.

If this parity bit is incorrect during a write cycle, the Wake Up is

disabled.

Usermanual 11 Ver. 1.0

2020-12-11

Page 12

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

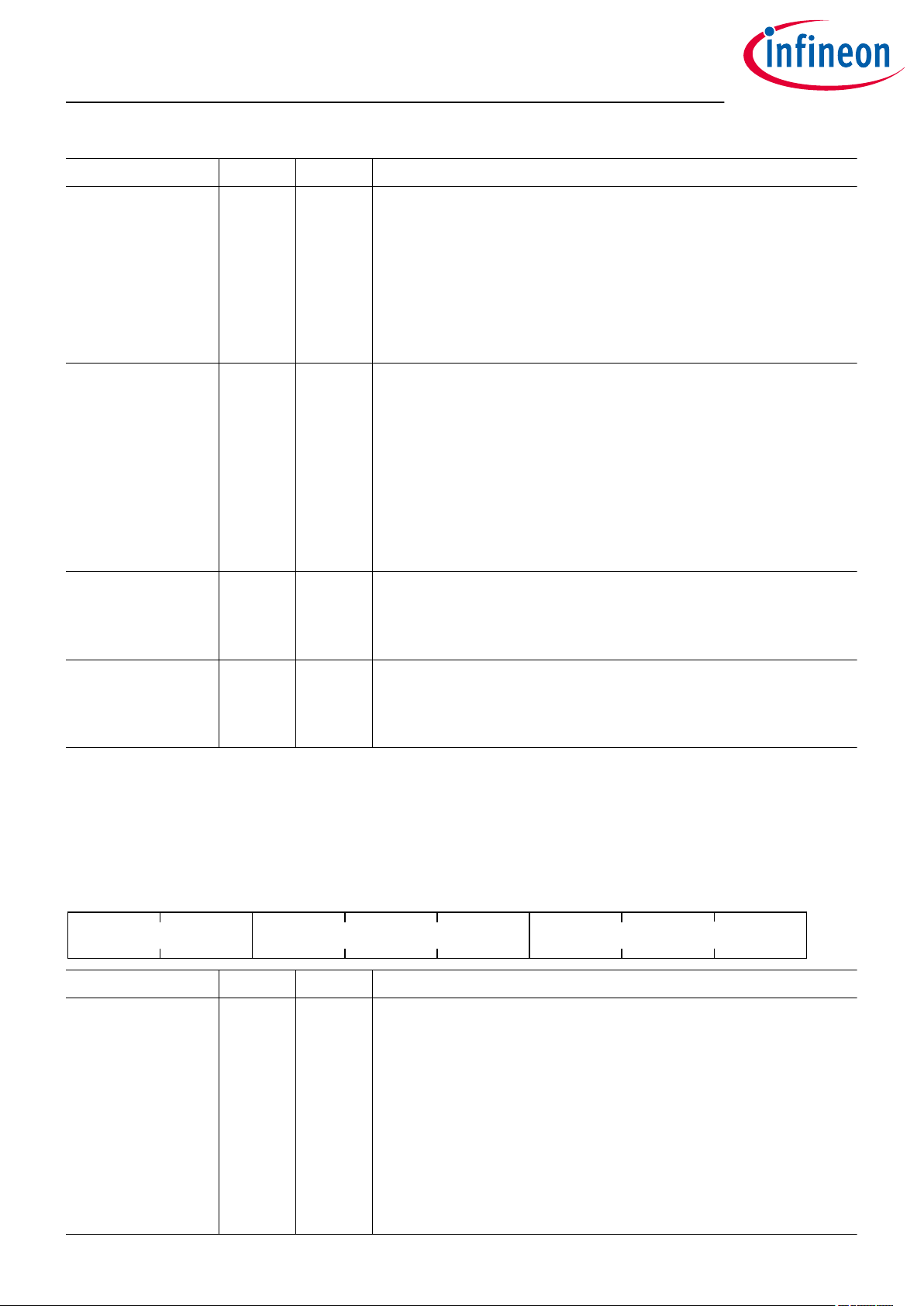

Table 3 Test mode interaction of TST, PH and X2 bits

TST bits PH bits X2 bit Bx (11...0) By (11...0) Bz (11...0) T (11...2)

00

00

01

10

10

10

10

11

11

11

11

11

11

11

11

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

don´t care 0

don´t care 1

B

B

don´t care don´t care Vhall X Vhall Y Vhall Z Voltage V

00

01

10

11

00

01

10

11

00

01

10

11

B

B

B

B

B

B

B

B

B

B

B

B

don´t care Spintest-Bx,

don´t care Spintest-By,

don´t care Spintest-Bz,

don´t care Spintest-T,

0

B

0

B

0

B

0

B

1

B

1

B

1

B

1

B

Bx full-range By full-range Bz full-range T full-range

Bx short-range By short-range Bz short-range T full-range

DD

spin-0 disabled

spin-0 disabled

spin-0 disabled

setting1

7F9

H

806

H

7FF

H

800

H

7FF

H

800

H

7FF

H

800

H

Spintest-Bx,

spin-1 disabled

Spintest-By,

spin-1 disabled

Spintest-Bz,

spin-1 disabled

Spintest-T,

setting2

806

H

7F9

H

800

H

7FF

H

800

H

7FF

H

800

H

7FF

H

Spintest-Bx,

spin-2 disabled

Spintest By,

spin-2 disabled

Spintest-Bz,

spin-2 disabled

Spintest-T,

setting2

7FF

H

800

H

7F9

H

806

H

7FF

H

800

H

7FF

H

800

H

Spintest-Bx,

spin-3 disabled

Spintest By,

spin-3 disabled

Spintest-Bz,

spin-3 disabled

Spintest-T,

setting1

200

H

1FF

H

201

H

1FE

H

200

H

1FF

H

201

H

1FE

H

Back to TLE493D-P2B6 Bitmap.

Usermanual 12 Ver. 1.0

2020-12-11

Page 13

7

0

FP

6 3 2 1

PR INT MODE

5 4

IICadr CA

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

1.2.4 Mode registers combined in the I²C parity flag “FF”

The I²C communication of the registers in this chapter is protected with the parity bit “FF”, described in the Diag

register with the address 06H. See also Figure 1 - parity bits and related registers.

Power mode, interrupt, address, parity

Register name Address Reset Value

MOD1 11

H

Field Bits Type Description

FP 7 rw Fuse parity

The registers 11H and 13H (bits 7:5) are odd parity protected with

this bit.

If this parity bit is incorrect please see FF bit.

To exit this state a sensor reset is necessary.

IICadr 6:5 rw I²C address

Bits can be set to 00B, 01B, 10B or 11B to define the slave address in

bus configuration.

See Table 4 and data sheet.

PR 4 rw I²C 1-byte or 2-byte read protocol

If 0B this is the 2-byte read protocol:

<start> <I²Cadr.> <reg.adr.> <data of reg.adr.> <data of reg.adr.+1>

…. <stop>

If 1B this is the 1-byte read protocol:

<start> <I²Cadr.> <data of reg.00H> <data of reg.01H> …. <stop>

See I²C read commands

(Product Type A0) 80

(Product Type A1) 20

(Product Type A2) 40

(Product Type A3) E0

H

H

H

H

CA 3 rw Collision avoidance

Clock stretching only in master-controlled and low-power mode,

not in fast mode.

The CA bit interacts with the INT bit, see Table 5 and Collision

avoidance and clock stretching.

INT 2 rw Interrupt enabled

If 1B /INT disabled

If 0B /INT enabled: Aer a completed measurement and ADC-

conversion, an /INT pulse will be generated.

For bus configurations /INT timing constraints between I²C data

transfers and interrupt pulses must be monitored and aligned.

Enabled Wake Up mode or Collision avoidance (CA bit = 0B and

INT bit = 0B) may suppress the /INT pulse.

The INT bit interacts with the CA bit, see Table 5 .

Usermanual 13 Ver. 1.0

2020-12-11

Page 14

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

Field Bits Type Description

MODE 1:0 rw Power mode

If 00B Low Power Mode:

Cyclic measurements and ADC-conversions with a update rate,

defined in the PRD registers. “No ADC trigger” must be used, see

Table 6 and TRIG.

If 01B Master Controlled Mode (Power Down mode):

Measurement triggering depends on the PR bit and is possible with

I²C sub address byte (see Table 6) or TRIG bits.

If 10B is reserved and must not be used.

If 11B Fast Mode:

The measurements and ADC-conversions are running

continuously. It is recommended to set INT = 0B and use a I²C clock

speed ≥ 800 kHz.

Back to TLE493D-P2B6 Bitmap.

Table 4 Device address overview

The addresses are selected to ensure a minimum Hamming distance of 4 between them.

Product

Type

Default address

write

A0 6A

A1 44

A2 F0

A3 88

1)

Default address

read

H

H

H

H

6B

45

F1

89

H

H

H

H

1)

IICadr (bit-6) IICadr (bit-5) ID (bit-5) ID (bit-4)

0

B

0

B

1

B

1

B

0

B

1

B

0

B

1

B

0

B

0

B

1

B

1

B

Table 5 /INT (interrupt), collision avoidance and clock stretching configuration

CA INT Configuration

0

B

0

B

/INT and collision avoidance enabled

Clock stretching disabled

0

B

1

B

/INT and collision avoidance disabled

Clock stretching enabled

This configuration must not be used:

• in fast mode

• with the “read” trigger-bits (7:5) = 010B or 011B (see Table 6)

• with the trigger option TRIG bit = 01B.

0

B

1

B

0

B

1

B

1

B

0

B

/INT enabled and collision avoidance disabled

Clock stretching disabled

1

B

1

B

/INT and collision avoidance disabled

Clock stretching disabled

1

See data sheet ordering information

Usermanual 14 Ver. 1.0

2020-12-11

Page 15

7

0

PRD

Reserved

4

5

7

0

FRM

6

5

4

3

2

1

PD0PD3TCFFFP

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

Low Power Mode update rate

Register name Address Reset Value

MOD2 13

H

Field Bits Type Description

PRD 7:5 rw Update rate settings

If 000B typ. update frequency f

If 001B typ. update frequency f

If 010B typ. update frequency f

If 011B typ. update frequency f

If 100B typ. update frequency f

If 101B typ. update frequency f

If 110B typ. update frequency f

If 111B typ. update frequency f

Reserved 4:0 rw Factory settings

Do not modify, read before write required.

Back to TLE493D-P2B6 Bitmap.

1.2.5 Diagnostic, status and version registers

Update

Update

Update

Update

Update

Update

Update

Update

≈ 770 Hz.

≈ 97 Hz.

≈ 24 Hz.

≈ 12 Hz.

≈ 6 Hz.

≈ 3 Hz.

≈ 0.4 Hz.

≈ 0.05 Hz.

(bits 7:5) 000

B

The device provides diagnostic and status information in register 06H and version information in register 16H.

Sensor diagnostic and status register

Register name Address Reset Value

Diag 06

H

60

Field Bits Type Description

P 7 r Bus parity

This bit adds up to an odd parity of the registers 00H through

05H (including 05H), described in Measurement data and registers

combined in the I²C parity bit “P”.

The parity bit is generated during the I²C readout. The address

byte, register byte and acknowledge bits are not included in the

parity sum.

If the parity calculated by the microcontroller aer I²C reads is

incorrect, these values must be treated as invalid.

H

Usermanual 15 Ver. 1.0

2020-12-11

Page 16

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

Field Bits Type Description

FF 6 r Fuse parity flag

Provides a flag from the internal fuse parity check of registers 11

to 15H. This parity check includes the FP bit.

If 1B parity is OK.

If 0B the parity is not correct. The sensor must be considered

defective and must no longer be used. A sensor with an invalid fuse

parity disconnects its SDA. It will automatically go to low-power

mode and only uses the /INT signal to communicate the error

(collision avoidance is enabled).

CF 5 r Wake Up and configuration parity flag

Provides a flag from the internal configuration and Wake Up parity

check of registers 07H through 10H (including 10H) without WA TST

and PH bit. This parity check includes the CP bit.

If 1B parity is OK.

If 0B parity is not OK, or aer startup or aer reset the CP bit is

false to indicate a reset of all registers. Thus the CP bit has to be

corrected once aer startup or a reset.

H

T 4 r Test mode

If 1B test mode is enabled. Data in registers 00H till 05H are either

test results or - aer a “ADC restart” - invalid measurement data.

If 0B test mode is disabled, valid measurement data available.

PD3 3 r Power-down flag 3

If 1B ADC-conversion of Temp is completed and valid measurement

data can be read out. Thus it must be 1B at readout.

If 0B ADC-conversion of Temp is running and read measurement

data are invalid. Any readout with PD3 bit = 0B should be

considered invalid.

At startup, this is 0B until one ADC conversion has been performed.

The value then changes to 1B.

PD0 2 r Power-down flag 0

If 1B the ADC conversion of Bx is completed and valid measurement

data can be read out. Thus it must be 1B at readout.

If 0B the ADC conversion of Bx is running and read measurement

data are invalid. Any readout with PD0 bit = 0B should be

considered invalid.

At startup, this is 0B until one ADC conversion has been performed.

The value then changes to 1B.

FRM 1:0 r Frame counter

Increments at every updated ADC-conversion, once a X/Y/Z/T or

X/Y/Z or X/Y conversion is completed and the new measurement

data have been stored in the registers 00H till 05H.

The microcontroller shall check if bits change in consecutive

conversion runs.

Back to TLE493D-P2B6 Bitmap.

Usermanual 16 Ver. 1.0

2020-12-11

Page 17

7

0

Reserved

HWV

4 3

TYPE

6

5

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

1 I2C Register

Version register

Register name Address Reset Value

Ver 16

H

Field Bits Type Description

Reserved 7:6 r Factory settings

TYPE 5:4 r Chip feature

If 00B, 10B or 01B: device with Wake Up feature.

HWV 3:0 r Hardware revision

If 9H it is the B21 design step.

Back to TLE493D-P2B6 Bitmap.

C9H, D9H or E9

H

Usermanual 17 Ver. 1.0

2020-12-11

Page 18

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

2 I²C Interface

The TLE493D-P2B6 uses Inter-Integrated Circuit (I²C) as the communication interface with the microcontroller.

The I²C interface has three main functions:

• Sensor configuration

• Transmit measurement data

• Interrupt handling

This sensor provides two I²C read protocols:

• 16-bit read frame (µC is driving data), so called 2-byte read command.

• 8-bit read frame (µC is driving data), so called 1-byte read command.

2.1 I²C protocol description

The TLE493D-P2B6 provides one I²C write protocol, based on 2 bytes and two I²C read protocols. Default is the

2-byte read protocol. With the PR bit it can be selected, if the 1-byte read protocol or the 2-byte read protocol is

used.

2.1.1 General description

• The interface conforms to the I2C fast mode specification (400kBit/sec max.), but can be driven faster

according to the data sheet.

• The TLE493D-P2B6 does not support “repeated starts”. Each addressing requires a start condition.

• The interface can be accessed in any power mode.

• The data transmission order is Most Significant Bit (MSB) first, Least Significant Bit (LSB) last.

• A I²C communication is always initiated with a start condition and concluded with a stop condition by the

master (microcontroller). During a start or stop condition the SCL line must stay “high” and the SDA line

must change its state: SDA line falling = start condition and SDA line rising = stop condition.

• Bit transfer occur when the SCL line is “high”.

• Each byte is followed by one ACK bit. The ACK bit is always generated by the recipient of each data byte.

- If no error occurs during the data transfer, the ACK bit will be set to “low”.

- If an error occurs during the data transfer, the ACK bit will be set to “high”.

- If the communication is finished (before the Stop condition), the ACK bit must be set to “high”.

2.1.2 I²C write command

Write I²C communication description:

• The purpose of the sensor address is to identify the sensor with which communication should occur. The

sensor address byte is required independently of the number of sensors connected to the microcontroller.

• The register address identifies the register in the bitmap (according to Figure 1) with which the first data

byte will be written.

• Data bytes are transmitted as long as the SCL line generates pulses. Each additional data byte increments

the register address until the stop condition occurs.

• Bytes transmitted beyond the register address frame are ignored and the corresponding ACK bit is sent

“high”, indicating an error.

The I2C write communication frame consists of:

• The start condition.

• The sensor address, according to Table 4.

• Write command bit = “low” (read = “high”).

Usermanual 18 Ver. 1.0

2020-12-11

Page 19

SCL

SDA

I2C master is driving data (µC) I2C slave is driving data (sensor)

ACK ACK ACKWrite dataSensor address

Register

address

Trigger

bits

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

• Acknowledge ACK.

• Trigger bits, according to Table 6.

• The register address, according to Figure 1.

• Acknowledge ACK.

• Writing of one or several bytes to the sensor, each byte followed by an acknowledge ACK.

• The stop condition.

Figure 2 General I²C write frame format: Write data from microcontroller to sensor

Trigger bits in the I²C protocol

The trigger bits are used in Power Down Mode. The Power Down Mode is used in the Master Controlled Mode,

when no measurement is running. Thus the trigger bits are relevant for the Master Controlled Mode as well.

For a more silent measurement environment it is recommended to separate the measurement and the

communication as much as possible, by using the trigger bits = 001B or trigger bits = 100B and communicate

between two measurements with reduced overlap of measurement and communication.

Table 6 I2C trigger bits

Read/Write

Trigger-bit 7 Trigger-bit 6 Trigger-bit 5 Trigger command

command

0

B

0

B

0

B

0

B

0

B

0

B

0

B

0

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

B

0

B

0

B

0

B

0

B

1

B

1

B

1

B

1

B

0

B

0

B

0

B

0

B

1

B

1

B

1

B

1

B

0

B

0

B

1

B

1

B

0

B

0

B

1

B

1

B

0

B

0

B

1

B

1

B

0

B

0

B

1

B

1

B

0

B

1

B

0

B

1

B

0

B

1

B

0

B

1

B

0

B

1

B

0

B

1

B

0

B

1

B

0

B

1

B

no ADC trigger

ADC trigger aer write frame is finished, Figure 4

no ADC trigger

ADC trigger aer write frame is finished, Figure 4

no ADC trigger

ADC trigger aer write frame is finished, Figure 4

no ADC trigger

must not be used

no ADC trigger

no ADC trigger

ADC trigger before first MSB, Figure 3

ADC trigger before first MSB, Figure 3

ADC trigger aer register 05H, Figure 5

ADC trigger aer register 05H, Figure 5

ADC trigger aer register 05H, Figure 5

must not be used

Usermanual 19 Ver. 1.0

2020-12-11

Page 20

SCL

SDA

I2C master is driving data (µC) I2C slave is driving data (sensor)

ACK

Read data

Sensor address

Register

address

ADC

ACK ACK

ADC conversion

SCL

SDA

I2C master is driving data (µC) I2C slave is driving data (sensor)

ACK

Write data

Sensor address

Register

address

ADC

ACK ACK

ADC conversion

SCL

SDA

I2C master is driving data (µC) I2C slave is driving data (sensor)

ACK

Read data

Sensor address

Register

address

ADC

ACK ACK

ADC conversion

ACK

Read data 06

H

Read data 05

H

ACK

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

Figure 3 ADC trigger before sending first MSB of data registers, I²C trigger bits 010

Figure 4 ADC trigger aer write frame is finished, I²C trigger bits 001

B

B

Figure 5 ADC trigger aer register 05H, I²C trigger bits 100

Usermanual 20 Ver. 1.0

B

2020-12-11

Page 21

0 1 1 0 1 0 1 0 0 0 0 0 1 0 0 0 1 0 x 0 0 0 0 1 0 1 0

SCL

SDA

I2C master is driving data (µC) I2C slave is driving data (sensor)

ACK ACK ACK

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

Example I²C write communication

An example of a write communication is provided in Figure 6.

In this example the sensor with the address 6AH / 6BH (see Table 4) should be configured for:

• Master Controlled Mode

• /INT disabled

• Clock stretching enabled

• No trigger of a measurement

• Other settings should be kept as is

Implementation:

• The microcontroller generates a start condition

• Configuration changes can only be performed with a write command. The address for write operation of

this sensor is 6AH = 01101010

• If the sensor detects no error, the ACK = 0B is transmitted back to the microcontroller

• No measurement is performed if the trigger bits = 000

• The register to change the required settings is 11H according the bitmap Figure 1 = 10001

• If the sensor detects no error, the ACK = 0B is transmitted back to the microcontroller

• The parity bit “FP” is the odd parity of the registers 11H and 13H (bits 7:5), see FP register, thus it is not

possible to quantify it in this example

• The sensor address should not be changed, i.e. the sensor address 6AH / 6BH should be kept. Thus the

IICadr bits = 00B, see IICadr registers

• The 2-byte protocol should be kept as is. Thus the PR bit = 0

• In order to enable clock stretching and disable /INT the CA bit must be set to 0B and the INT bit must be set

to 1B (see Table 5)

• To use the Master Controlled Mode the MODE bits must be set to 01

• If the sensor detects no error the ACK = 0B is transmitted back to the microcontroller

• The microcontroller generates the stop condition

B

B

B

B

B

Figure 6 Example I²C frame format 2-byte: Write data from microcontroller to sensor

Usermanual 21 Ver. 1.0

2020-12-11

Page 22

SCL

SDA

I2C master is driving data (µC) I2C slave is driving data (sensor)

ACK ACK

ACK

Register

address

Read dataSensor address

Trigger

bits

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

2.1.3 I²C read commands

Read I²C communication description:

• The purpose of the sensor address is to identify the sensor with which communication should occur. The

sensor address byte is required independently of the number of sensors connected to the microcontroller.

• Only available in the 2-byte read command: The register address identifies the register in the bitmap

(according Figure 1) from which the first data byte will be read. In the 1-byte read command the read out

starts always at the register address 00H.

• As many data bytes will be transferred as long as pulses are generated by the SCL line. Each additional data

byte increments the register address. Until the stop condition occurs.

• If bytes are read beyond the register address frame the sensor keeps the SDA = 1B.

• If the microcontroller reads data and does not acknowledge the sensor data (ACK = 1B) the sensor keeps the

SDA = 1B until the next stop condition.

2.1.3.1 2-byte read command

The I²C read communication frame consists of:

• The start condition

• The sensor address, according to Table 4

• Read command bit = “high” (write = “low”)

• Acknowledge ACK

• Trigger bits, according to Table 6

• The register address, according to Figure 1

• Acknowledge ACK

• Reading of one or several bytes from the sensor, each byte followed by an acknowledge ACK

• The stop condition

Figure 7 General I²C frame format 2-byte: Read data from sensor to microcontroller

2.1.3.2 1-byte read command

The 1-byte read mode can be entered, by configuring the PR bit with an write communication. For example with

the write cycle:

• start condition

• 6AH (sensor address)

• 11H (register address)

• XXX1 XXXXB (PR bit = 1B)

• stop condition

Usermanual 22 Ver. 1.0

2020-12-11

Page 23

SCL

SDA

I2C master is driving data (µC) I2C slave is driving data (sensor)

ACK

ACKRead dataSensor address

1 1 1 1 0 0 0 1 0 0 1

SCL

SDA

I2C master is driving data (µC) I2C slave is driving data (sensor)

ACK ACK NACK

0

ACKRead data reg. 00

H

Read data reg. 06

H

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

The I²C communication frame consists of:

• The start condition

• The sensor address, according to Table 4

• Read command bit = “high” (write = “low”)

• Acknowledge ACK

• Reading of one or several bytes from the sensor, each byte followed by an acknowledge ACK

• The stop condition

Figure 8 General I²C frame format 1-byte: Read data from sensor to microcontroller

Example I²C 1-byte read communication

An example of a read communication is provided in Figure 9.

In this example, the sensor with the address F0H / F1H (see Table 4) should read out the measurement values,

registers 00H - 05H and the diagnostic register 06H:

Implementation:

• The microcontroller generates a start condition

• The address for read operation of this sensor is F1H = 11110001B. This address value must be transmitted by

the microcontroller to the sensor

• If the sensor detects no error, the ACK = 0B is transmitted back to the microcontroller

• The microcontroller must go on clocking the SCL line

• The sensor transmits 8 data bits of register 00H to the microcontroller

• If the microcontroller detects no error the ACK = 0B is transmitted back to the sensor

• The microcontroller must go on clocking the SCL line

• The sensor transmits 8 data bits of register 01H to the microcontroller

• ...

• Aer transmitting the register 06H the microcontroller transmits a NACK

• The microcontroller generates the stop condition

Figure 9 Example I²C frame format 1-byte: Read data from sensor to microcontroller

Usermanual 23 Ver. 1.0

2020-12-11

Page 24

1 1 1 1 0 0 0 1

SCL

SDA

I2C master is driving data (µC) I2C slave is driving data (sensor)

ADC

conversion

Bz T

0

ACK Read data reg. 00

H

/INT

Corrupt data

1 1 1 1 0 0 0 1

SCL

SDA

I2C master is driving data (µC) I2C slave is driving data (sensor)

ADC

conversion

Bz T

0 0 1

ACK ACK NACK

0

ACK

Read data reg. 00

H

Read data reg. 06

H

/INT

omitted

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

2.2 Collision avoidance and clock stretching

Using the configuration bits CA and INT, collision avoidance and clock stretching can be configured, see. An

overview is given in Table 5. An example without collision avoidance and clock stretching is shown in Figure 10.

In this example:

• The sensor interrupt disturbs the I²C clock, causing an additional SCL pulse which shis the data read out

by one bit

• The data read out starts when the ADC conversion is running

Figure 10 Example without collision avoidance CA bit =1B and INT bit = 0

B

2.2.1 Collision avoidance (CA bit = 0B and INT bit = 0B)

In a bus configuration combined with an activated interrupt signal /INT it must be assured, that during any

communication no interrupt /INT occurs. With collision avoidance enabled, the sensor monitors for any start/

stop condition, even if it does not detect a valid bus address. The interrupt signal /INT is omitted whenever

a start condition is detected, as shown in Figure 11, in contrast to Figure 10. Only aer a stop condition is

detected, the interrupt signal /INT is generated by the sensor.

It is strongly recommended to use the collision avoidance feature whenever the interrupt signal /INT is used.

Figure 11 Example with collision avoidance CA bit =0B and INT bit = 0

Usermanual 24 Ver. 1.0

B

2020-12-11

Page 25

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

2.2.2 Clock stretching (CA bit = 0B and INT bit = 1B)

With the clock stretching feature, the data read out starts aer the ADC conversion is finished. Thus it can be

avoided that during an ADC conversion old or corrupted measurement results are read out, which may occur

when the ADC is writing to a register while this is being read out by the microcontroller. The clock stretching

feature is shown in Figure 12 in combination with a 1-byte read command. Clock stretching can also be used

with a 2-byte read command.

The sensor pulls the SCL line to low during the following situation:

• An ADC conversion is in progress

• The sensor is addressed for register read (writes are never aected by clock stretching)

• The sensor is about to transmit the valid ACK in response to the I²C addressing of the microcontroller

ADC

conversion

Start condition

SDA

1 1 1 1 0 0 0 1 0

SCL

I

2

C master is driving data (µC)

By Bz T

(read)

H

Sensor address

F1

Read command

C l o c k s t r e t c h i n g

2

I

ACK

Read data reg. 00

0

C slave is driving data (sensor)

Figure 12 Example with clock stretching CA bit =0B and INT bit = 1

01

B

Read data reg.

H

… 06

ACK

H

Stop condition

H

NACK

1

Usermanual 25 Ver. 1.0

2020-12-11

Page 26

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

2.3 Sensor reset by I²C

If the microcontroller is reset, the communication with the sensor may be corrupted, possibly causing the

sensor to enter an incorrect state. The sensor can be reset via the I²C interface by sending the following

command sequence from the microcontroller to the sensor:

• Start condition

• Sending FF

• Stop condition

• Start condition

• Sending FF

• Stop condition

• Start condition

• Sending 00

• Stop condition

• Start condition

• Sending 00

• Stop condition

• 30 µs delay

Aer a reset, the sensor must be reconfigured to the desired settings. The reset sequence uses twice the

identical data to assure a proper reset, even when an unexpected /INT pulse occurs.

Spikes can be interpreted as bus signals causing an action. For example when the collision avoidance feature

is active and if the SDA line spikes together with SCL line this could be interpreted as start condition, blocking

further /INT pulses until a stop condition appears on the bus. In such a case the sensor must be reset in order to

initialize it. If the sensor does not respond aer the reset, it must be considered defective.

Such spikes may occur as the sensor powers up. Because of this we recommend to using the reset sequence

aer each power up before configuring the sensor.

If the microcontroller resets during an ongoing I²C communication, the SDA line could get stuck low. This would

block the I²C bus and is a well-known limitation of the I²C interface. To recover from this situation please use the

reset sequence described in this chapter.

H

H

H

H

Usermanual 26 Ver. 1.0

2020-12-11

Page 27

system init /INT handler

I²C: reset sensor

S FFH P, S FFH P,

S 00H P, S 00H P

I²C: write sensor

configuration

init I²C peripheral

configure interrupt

and enable /INT pin

wait for /INT goes

high again

disable /INT pin

I²C: read sensor data

and diagnosis

enable /INT pin

return

I²C read

successful?

/INT pulse

from sensor

application main

loop, takes sensor

data and errors for

processing

Valid sensor

data?

handle I²C peripheral

(reconfiguration, …)

flag sensor error

no

flag new sensor data

no

Evaluate diagnosis

information

yes

yes

serious error

situation?

yes: restart

no

Delay = 30µs

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

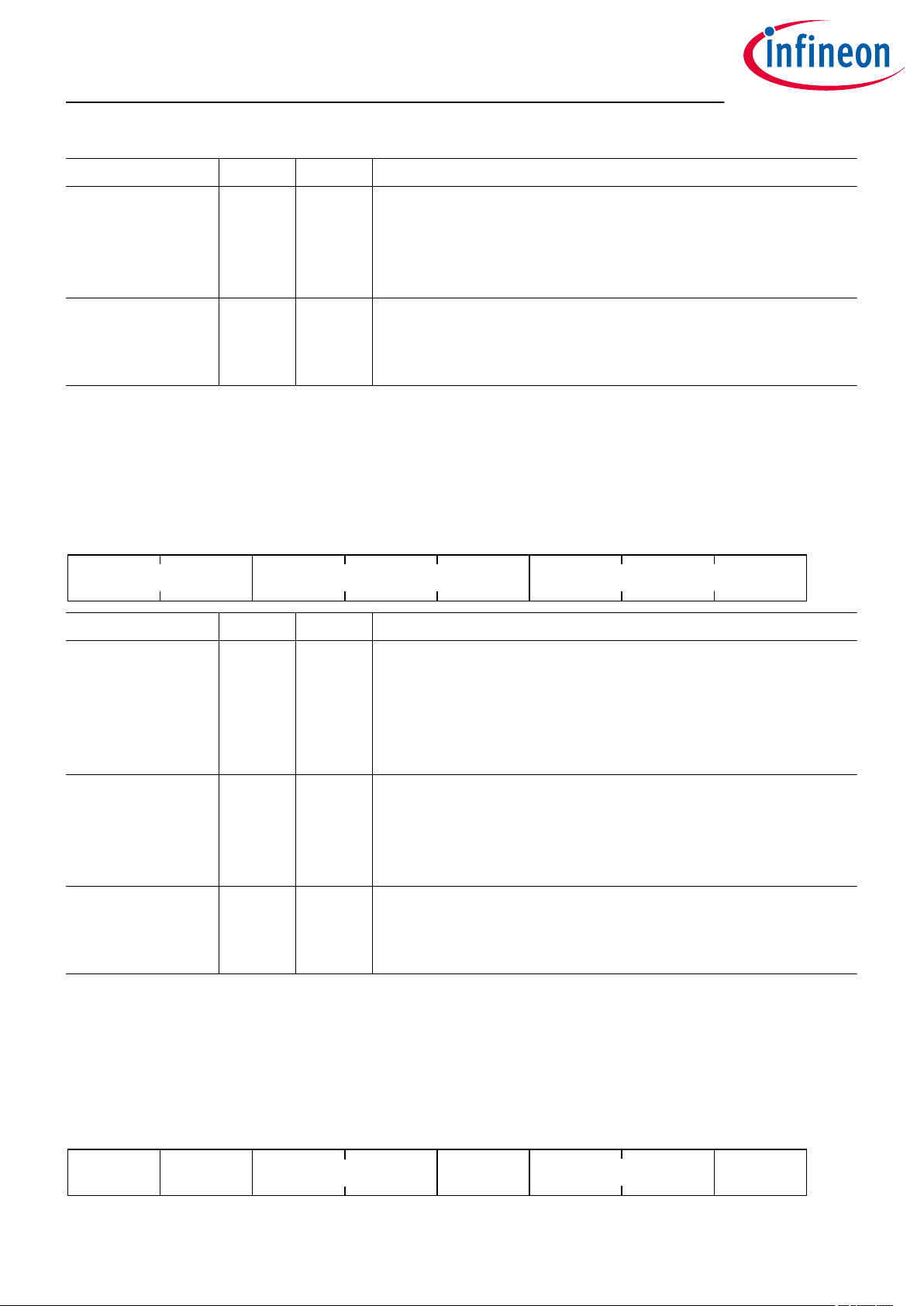

2.4 Sensor Initialization and Readout example

To ensure that both the microcontroller and the sensor are synchronized and properly initialized, it is

recommended to apply the I²C reset and upload the fuse register settings each time the microcontroller is

reset, see Figure 13.

Figure 13 Microcontroller soware flowchart for TLE493D-P2B6

Usermanual 27 Ver. 1.0

2020-12-11

Page 28

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

2 I²C Interface

2.5 Loss of VDD impact on I²C bus

If the SDA or SCL line is pulled “low” and the sensor is disconnected from the VDD supply line, the aected I²C

line will most likely get a stuck in the Low state and will interfere with the communication on the bus.

Power supply loss

V

DD

Sensor

1

TLE493D-

P2B6

I²C bus

Sensor

n

I²C bus can

be disturbed

Microcontroller

Figure 14 Example of I²C bus and a TLE493D-P2B6 with disconnected V

When VDD is pulled to GND the SDA and SCL line will not disturb the bus.

DD

Usermanual 28 Ver. 1.0

2020-12-11

Page 29

t

/INT

Measurement and

ADC sampling

B-field (X,Y or Z)

Wake Up

upper threshold

Wake Up

lower threshold

Wake Up causes

the external µC

to update the

levels

f

Update

1

B

X,Y,Z

t

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

3 Wake Up mode

3 Wake Up mode

The Wake Up mode (or short WU mode) is intended to be used together with the automated sensor modes (e.g.

Low Power mode or Fast mode). In principle, it works with the Master Controlled mode as well, but it might not

really be useful there because a controlled trigger usually implies the need to acquire a new measurement.

This WU mode can be used to allow the sensor to continue making magnetic field measurements while the µC

is in the power-down state, which means the microcontroller will only consume power and access the sensor

if relevant measurement data is available. This can be done either by using static thresholds (for example for

applications where only movements of magnets away from a default position are relevant) or by using dynamic

thresholds (where any movement over a specific uncertainty limit should be detected once). The figure below

illustrates these two cases.

Figure 15 Static or Dynamic Wake Up Threshold Operation of the TLE493D-P2B6

This dynamic WU mode operation oers another option which is particularly useful in Fast mode with limited

I²C bus capabilities and/or low bit rates. In this case, the WU mode can act as a “data filter” to reduce the

bus load by preventing sensor data from being read that does not change significantly. So due to an interrupt,

the new WU levels are adapted to the actual value read (for each X, Y, Z channel individually). This provides

low latencies for detecting changes but reduces interrupts caused by similar values. If the collision avoidance

feature is also used, the readout may take even longer than one conversion time (but this readout speed adds

to the overall signal latency as well). As the thresholds also need to be set, a complete data read and set of

new WU thresholds is not even feasible with the fastest specified bit rate within one sensor sample time in Fast

mode.

The next figure illustrates this more clearly:

Usermanual 29 Ver. 1.0

2020-12-11

Page 30

t

t

the /INT pulses are suppressed

as communication is ongoing

Fast Mode

t

read

ADC

set

WU

read

ADC

set

WU

SCL

/INT

B

X,Y,Z

B-field (X,Y or Z)

Wake Up causes

the external µC to

update the levels

SDA

read

ADC

set

WU

read

ADC

set

WU

„Wake Up upper threshold“D > „Wake Up lower threshold“

D

„Wake Up upper threshold“D - „Wake Up lower threshold“D < 2048DLSB

12

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

3 Wake Up mode

Figure 16 Dynamic Wake Up Threshold Operation of the TLE493D-P2B6 for Bandwidth Reduction

To sum this up, we can state that this dynamic WU mode operation together with the Fast mode set allows

detecting and reading significant value changes with low latency, even if the bit rate of the I²C cannot be set fast

enough to read the data for each set of sensor data generated.

3.1 Wake Up activation

The Wake Up function can be activated with the WU bit and by modifying at least one of the Wake Up threshold

registers of address 07H to 0FH, see Configuration registers combined in the I²C parity flag “CF”.

Please note that the Wake Up registers cover bit 11 to bit 1. Bit 0 is not accessible, but internally set with 0B to

get a 12-bit value, for comparison with the 12-bit magnetic field value registers Bx, By and Bz.

3.2 Wake Up constraints

The Wake Up threshold range disabling /INT pulses between upper threshold and lower threshold is limited to a

window of the half output range.

This window itself can be moved inside the full output range, as illustrated in Figure 17.

Equation 1

Equation 2

Usermanual 30 Ver. 1.0

2020-12-11

Page 31

+2047 LSB12 ADC upper limit Bx, By, Bz

-2048 LSB12 ADC lower limit Bx, By, Bz

0

/INT disabled

/INT disabled

/INT disabled

/INT enabled

/INT enabled

/INT

enabled

/INT enabled

/INT disable range

can be decreased, but must

not be increased.

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

3 Wake Up mode

Figure 17 Wake Up enable and disable range examples

3.3 Wake Up in combination with the angular mode

In angular mode, see DT and AM bit, the

• “Wake Up Y upper threshold” must be written to the registers 0CH and 0FH (5 ... 3)(ZH in Figure 1)

• “Wake Up Y lower threshold” must be written to the registers 0BH and 0FH (3 ... 1)(ZL in Figure 1)

Usermanual 31 Ver. 1.0

2020-12-11

Page 32

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

4 Diagnostic and tests

4 Diagnostic and tests

The sensor TLE493D-P2B6 provides diagnostic functions and test functions:

• Diagnostic functions:

These functions are running in the background, providing results, which can be checked by the

microcontroller for the verification of the measurement results.

• Test functions:

These functions are only executed by the sensor following a request by the microcontroller. The test

functions provides test values instead of measurement values, which can be used to check if the sensor is

working properly.

4.1 Diagnostic functions

To ensure the integrity of received data the following diagnostic functions are available.

4.1.1 Parity bits and parity flags

Parity bits:

• FP (mode parity bit)

• CP (Wake Up and configuration parity bit)

• P (bus parity bit)

Parity flags:

• FF (mode parity flag)

• CF (Wake up and configuration parity flag)

4.1.2 Test mode

The device is in test mode, this is indicated by the T register (Diag register 06H bit 4).

4.1.3 Power-down flags

During measurements and during ADC conversion, the sensor monitors if the supply voltage is correct and if the

conversion is finished. This is indicated by the PD3 and PD0 registers.

4.1.4 Frame counter

The frame counter FRM register is incremented by one when a conversion is completed.

4.1.5 Device address

The TLE493D-P2B6 can be ordered with dierent default addresses. This device address can be read out with

the IICadr registers.

4.2 Test functions

The TLE493D-P2B6 includes three test functions which can be activated by the microcontroller, using the TST

registers in combination with the PH registers:

• Vhall/Vext test: checks the whole signal path from sensor to microcontroller

• Spintest: checks all Spin-switches, the Hall-oset and the ADC-oset

• SAT-test: checks the whole digital path from sensor to microcontroller

Usermanual 32 Ver. 1.0

2020-12-11

Page 33

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

4 Diagnostic and tests

4.2.1 Vhall/Vext test mode

This test checks the whole signal path, including the Hall plates, Hall biasing, multiplexer, ADC, data registers,

oscillator, power management unit, interface, and the bandgap reference voltage. It also detects whether any

Hall switch for the spinning (also known as chopping) is open or short.

4.2.1.1 Test description

Instead of measuring the actual Hall voltages on the probe (which depend on the external magnetic field), a

measurement cycle is performed where a voltage drop across the Hall probes is measured. For the temperature

sensor, an external voltage (via the VDD pin) is connected.

As the voltage drop across the Hall probes and the external voltage is known, any unexpected output would

detect a malfunctioning of the internal Hall biasing or the signal path.

This test should be executed in module production test first. The values generated in this first test should be

compared, if inside the limits listed in Table 7 and stored on module level. During module life time this stored

values should be compared with additional life time tests and compared, if the values are inside the limits listed

in Table 7.

4.2.1.2 Test implementation

The test is performed as described below:

• Set the TST registers according to Vhall/Vext test

• Trigger a new measurement

• Read the value of Bx, By, Bz and Temp

Vhall test:

• Check that Bx, By, Bz and T have values inside the limits of Table 7

• Testing one voltage reference is suicient to cover the Vhall test

Vext test:

• Make the microcontroller aware of the VDD-pin voltage

• Convert the Temp registers (11 ... 2) to Vext (11 ... 0) by multiplying the 10-bit Temp registers by 4

• Check that the Vext value corresponds to the values listed in Table 7

Aer the test:

• Continue with another test or leave the test mode by setting the TST registers accordingly

Timing:

• Typ. 0.5 ms are required for this implementation at an I²C interface baud rate of 400 kbit/s

• Typ. 0.3 ms are required for this implementation at an I²C interface baud rate of 1 Mbit/s

4.2.1.3 Test reference values

D

The test limits are dierent for production and life time. Both is shown in Table 7 and illustrated in Figure 18.

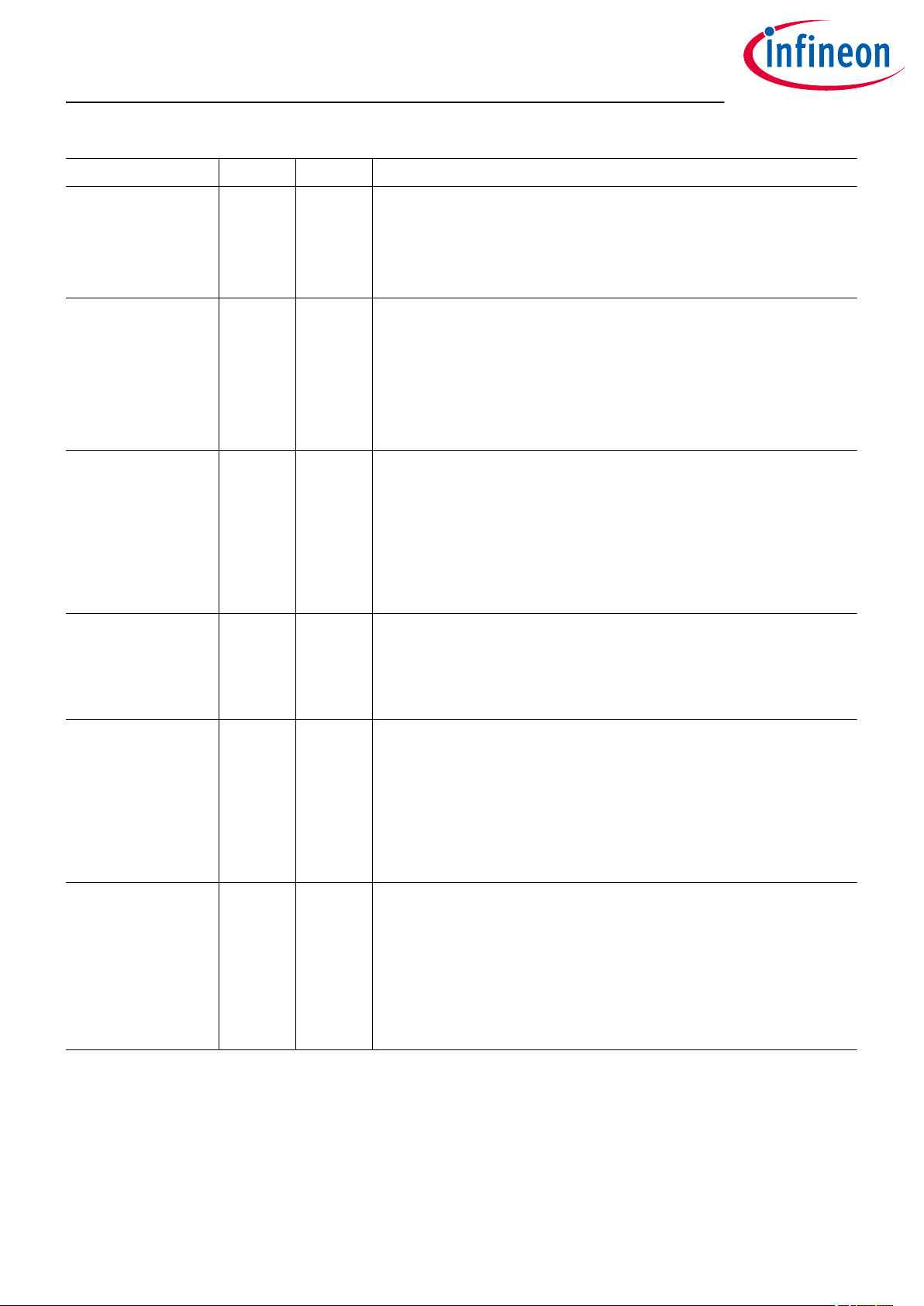

Table 7 Vhall/Vext diagnostic limits TLE493D-P2B6

Diagnostic test Module production test

Checked and stored for product life time

Temperature and lieime dri

of stored product values

Unit min. typ. max. Unit min. max.

Vhall X @ VDD = 2.8 V to 3.5 V LSB

Vhall Y @ VDD = 2.8 V to 3.5 V LSB

Vhall Z @ VDD = 2.8 V to 3.5 V LSB

Vext @ 3.3 V LSB

Usermanual 33 Ver. 1.0

12

12

12

12

400 630 900 % -20 20

400 630 900 % -20 20

500 830 1200 % -30 30

1100 1370 1650 % -5 5

2020-12-11

Page 34

Product life time

Sensor production

Module production

Vhall/Vext test limits

„Module production test“

Store initial test data on module

Item

operational

Vhall/Vext test limits

„Temperature and lifetime drift“

Compared to

stored initial test data on module

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

4 Diagnostic and tests

Table 7 Vhall/Vext diagnostic limits TLE493D-P2B6 (continued)

Diagnostic test Module production test

Checked and stored for product life time

Unit min. typ. max. Unit min. max.

Vext gain @ VDD = 2.8 V to 3.5 V LSB12/V 300 430 500 % -10 10

Figure 18 Vhall/Vext diagnostic limits vs. lifetime

Temperature and lieime dri

of stored product values

4.2.2 Spintest mode

This test checks the correct spinning (also known as chopping) of all four phases of a Hall probe for the three

channels Bx, By and Bz of the sensor and that the Hall probes oset and the ADC oset is within specified

limits. Also oers diagnostic coverage for the multiplexer, ADC, oscillator and power management unit. Limited

coverage for the biasing, registers and interface as well.

4.2.2.1 Test description

Equation 3

In a magnetic measurement run, the result of the four spins is:

• VH is the voltage at the Hall probes

• VOh is the voltage oset at the Hall probes

• VOa is the voltage oset at the ADC

By spinning the measurement four times at the Hall probes, the Hall oset and the ADC oset are eliminated in

magnetic measurements. The Spintest can be used to measure these osets.

The PH register selects, which Hall probe is measured by the Spintest, see Table 3. This Hall probe is then

measured four times, and every time another spinning phase is disregarded, see Figure 19. Thus, four results

are stored in the registers Bx (11 ... 0), By (11 ... 0), Bz (11 ... 0) and T (11 ... 2).

The ADC oset can be measured with PH = 11B. In this Spintest, the ADC compares the temperature sensor

with an internal reference voltage. During the test, the temperature and the reference are swapped (setting1

and setting2). The oset of the ADC can be calculated according to Equation 7. The temperature, including the

oset, can be calculated according to Equation 6.

Each Spintest Bx, By, Bz and T has the same duration as a measurement cycle consisting of a Bx, By, Bz and T

measurement.

Usermanual 34 Ver. 1.0

2020-12-11

Page 35

Hall

probe

Spin-0

Spin-3

Spin

-

1

Spin

-

2

Spin-0

Spin-1

Spin-2

Spin-3

Bx (11 … 0),

spin-0 disabled

By (11 … 0),

spin-1 disabled

Bz (11 … 0),

spin-2 disabled

T (11 … 2),

spin-3 disabled

Spin-0

Spin-1

Spin-2

Spin-3

Spin-0

Spin-1

Spin-2

Spin-3

Spin-0

Spin-1

Spin-2

Spin-3

Bitmap Register

Bitmap Register

Bitmap Register

Bitmap Register

t

1

t

2

t

3

t

4

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

4 Diagnostic and tests

Figure 19 Spintest concept of one Hall probe, please see also Table 3

Disabling the first or the forth phase leads to the following result:

Equation 4

Disabling the second or the third phase leads to the following result:

Equation 5

Spintest magnetic field calculation:

Equation 6

Spintest oset calculation:

Equation 7

Usermanual 35 Ver. 1.0

2020-12-11

Page 36

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

4 Diagnostic and tests

4.2.2.2 Test implementation

The test is performed as described below:

• Set the TST registers according “no test”

• Read and store the values of Bx, By and Bz of any magnetic measurement

• Set the TST registers according Spintest

• Set the PH registers to 00B to test the Bx Hall probe

• Trigger a new measurement

• Read the value of Bx, By, Bz and Temp.

Please note: The Temp (11 ... 2) needs to be multiplied by 4D to get the 12-bit Temp-value

• Calculate the oset with Equation 7 and check against the values listed in Table 8

• For a proper test result the magnetic field must be stable during the test. This can be checked by

calculating the magnetic field from the Spintest with Equation 6 and comparing the result with the latest

“no test” measurement. If a dierence in value is identified, the test can be run again to discard that the

fault is due to a change of the magnetic field (instead of a chip fault)

• Repeat the last five steps (PH setting, measurement trigger, value read out, ...) with PH registers

incrementing to 01B, 10B and 11B, according Table 3

Aer the test:

• Continue with another test or leave the test mode by setting the TST registers accordingly

Timing:

• Typ. 2.3 ms are required for this implementation at an I2C interface baud rate of 400 kbits/s

• Typ. 1.4 ms are required for this implementation at an I2C interface baud rate of 1 Mbit/s

4.2.2.3 Test reference values

The test limits are dierent for production and life time. Both is shown in Table 8 and illustrated in Figure

20. The spintest should be executed during the module production test first. The oset values (Equation 7)

generated in the first test should be compared to make sure that they are inside the limits specified in Table

8, section “Module production test” and stored on module level. During module lifetime these stored values

must be compared in an additional Spintest to check if the values are inside the limits listed in Table 8, section

“Temperature and lifetime dri”.

Table 8 Spintest diagnostic limits TLE493D-P2B6

Diagnostic test VOh module production test.

Checked and stored for product life time

Unit min. max. Unit min. max.

Spintest X @ VDD = 2.8 V to 3.5 V LSB

Spintest Y @ VDD = 2.8 V to 3.5 V LSB

Spintest Z @ VDD = 2.8 V to 3.5 V LSB

Spintest T @ VDD = 2.8 V to 3.5 V LSB

12

12

12

12

-200 200 LSB

-200 200 LSB

-160 160 LSB

-160 160 LSB

Temperature and lifetime dri

of stored product VOh values

12

12

12

12

-130 130

-130 130

-60 60

-60 60

Usermanual 36 Ver. 1.0

2020-12-11

Page 37

Product life time

Sensor production

Module production

Spintest limits

„VOh module production test“

Store initial test data on module

Spintest limits

„Temperature and lifetime drift“

Compared to

stored initial test data on module

Item

operational

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

4 Diagnostic and tests

Figure 20 Spintest diagnostic limits vs. lifetime

4.2.3 SAT-test mode

This test checks the whole digital signal path from sensor to microcontroller. This includes the ADC’s digital

core, the data register, the I2C interface and the I2C bus as well.

4.2.3.1 Test description

This test checks the Successive Approximation and Tracking (SAT) mechanism used for the four spin phases of

each data channel (Hall probes and temperature sensor).

The results, listed in Table 3 are outside of the specified linear range for Hall values and temperature. Thus,

it is possible to easily distinguish between values from the test mode and values from normal operation. An

unintended enabling of the test can therefore be identified.

4.2.3.2 Test implementation

The test is performed as described below:

• Set the test register TST accordingly

• Select one combination of PH and X2 register out of Table 3

Please note: One combination is suicient for a valid SAT-test

• Trigger a new measurement

• Read the values of Bx, By, Bz and Temp and compare if they are inside the limits specified in Table 3

Aer the test:

• Continue with another test or leave the test mode by setting the TST registers accordingly

Timing:

This test requires one write command with three data bytes and one readout with seven data bytes and

the measurement run time. The readouts may take place immediately aer a new diagnostic is set and the

measurement is triggered.

• Typ. 0.5ms are required for this implementation at an I2C interface baud rate of 400kbit/s

• Typ. 0.3ms are required for this implementation at an I2C interface baud rate of 1Mbit/s

Usermanual 37 Ver. 1.0

2020-12-11

Page 38

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

4 Diagnostic and tests

4.3 Magnetic measurement implementation

A magnetic measurement can be performed as described below:

• Set the TST registers according “no test”

• Trigger a measurement

• Read the value of Bx, By, Bz and Temp

Please note: The Temp (11 ... 2) needs to be multiplied by 4D to get the 12-bit Temp-value

Timing:

• Typ. 0.5 ms are required for this implementation at an I2C interface baud rate of 400 kbit/s

• Typ. 0.3 ms are required for this implementation at an I2C interface baud rate of 1 Mbit/s

Usermanual 38 Ver. 1.0

2020-12-11

Page 39

Usermanual TLE493D-P2B6

High Accuracy Low Power 3D Hall Sensor with I²C Interface

5 Terminology

5 Terminology

A

ACK Acknowledge

ADC Analog/Digital Converter

adr address

E

EMC Electromagnetic Compatibility

G

GND Ground

I

ID IDentification

I²C (I2C) Inter - Integrated Circuit

/INT Interrupt pin, Interrupt signal

L

LSB Least Significant Bit

M

Magnetic field Magnetic flux density that the sensor measures

min minimum

MSB Most Significant Bit

max maximum

P

PCB Printed Circuit Board

R

reg register

S

SCL Clock pin

SDA Data pin

Sensor Refers to the TLE493D-P2B6 product

Sensor module Refers to the TLE493D-P2B6 product and all the passive elements in the

customer‘s module

Supply Refers to the sensor supply pins VDD and GND (the unused pins are assumed to be