Page 1

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

User Manual

About this document

Scope and purpose

This document provides an introduction to the 3D Magnetic Sensor 2 Go kit and should enable the reader to

eiciently carry out own evaluations with the 3D magnetic sensor TLE493D-A2B6.

Intended audience

This document is aimed at everyone who wants to work with the 3D Magnetic Sensor 2 Go evaluation kit.

User Manual Please read the Important Notice and Warnings at the end of this document 1.2

www.infineon.com 2019-09-06

Page 2

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Table of contents

Table of contents

User Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Hardware overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Soware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Hardware extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 EvalBoard description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Optional external power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Pin header connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 EvalBoard schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3 Soware installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Driver installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 3D magnetic sensor evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.1 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.2 Graph View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 Joystick view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4 Rotation view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 Linear movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6 Out of sha . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Example code for developers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6 XMC for Arduino . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

User Manual 2 1.2

2019-09-06

Page 3

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Introduction

1 Introduction

Infineon’s 3D Magnetic Sensor 2 Go is a compact evaluation kit to familiarize the user with the 3D Hall sensor

TLE493D-A2B6. In a short time the board is set up and own 3D magnetic measurements can be executed. All

required hardware is included and the soware can be downloaded for free from the Infineon web page.

This user manual describes the dierent parts of the board, the soware installation process and clarifies how

the Graphical User Interface (GUI) can be used to do first evaluations. Further it is shown where to find example

code and an Arduino library as a easy starting point for own developments.

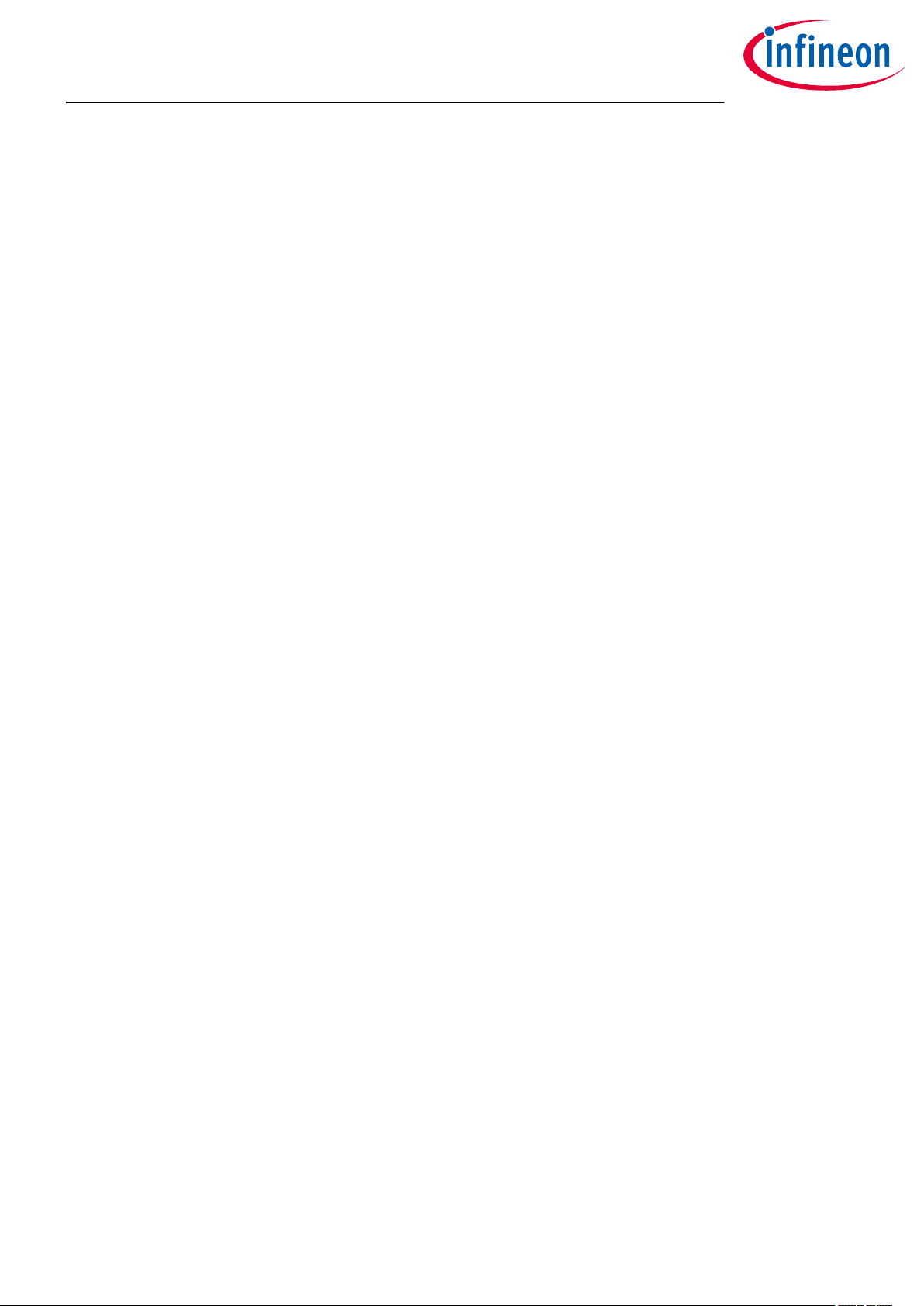

1.1 Hardware overview

The 3D Magnetic Sensor 2 Go kit contains:

• The 3D evaluation board (EvalBoard) as shown in Figure 1, a ready-to-use printed circuit board (PCB) with

the 3D Hall sensor. The EvalBoard is based on the XMC2Go-Kit. More technical documents and detailed

description can be found at http://www.infineon.com/xmc2go

• A standalone 7x7x5 mm ferrite block magnet

To use the 3D Magnetic Sensor 2 Go kit the user has to acquire a USB cable with a micro USB connection-end for

the EvalBoard side and a conventional USB connection for the PC side.

14mm

50mm

Figure 1 3D Magnetic Sensor 2 Go EvalBoard

1.2

The required soware to run the kit can be found at the Infineon web site. For further information refer to the

chapter Soware installation.

The soware package contains:

• A Graphical User Interface (GUI) for sensor evaluation.

• Firmware to be flashed into the XMC microcontroller for the low level communication with the sensor.

• USB driver J-Link from Segger which is necessary to establish the USB connection.

This soware was designed to be used with Windows 7 and Windows 10. It is compatible with both 32-bit and

64-bit system types. Backward compatibility with older Windows versions is ensured only by the .NET platform

as specific tests were not conducted on older operating systems.

The USB protocols capabilities are defined by the Segger driver. Versions USB 2.0 and USB 3.0 are compatible.

The GUI is used to enable a communication between the sensor and the PC. The user can configure the sensor

to operate in dierent modes. In those modes the update rate of the magnetic field measured (X, Y and Z

components) and current consumption vary.

Soware

User Manual 3 1.2

2019-09-06

Page 4

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Introduction

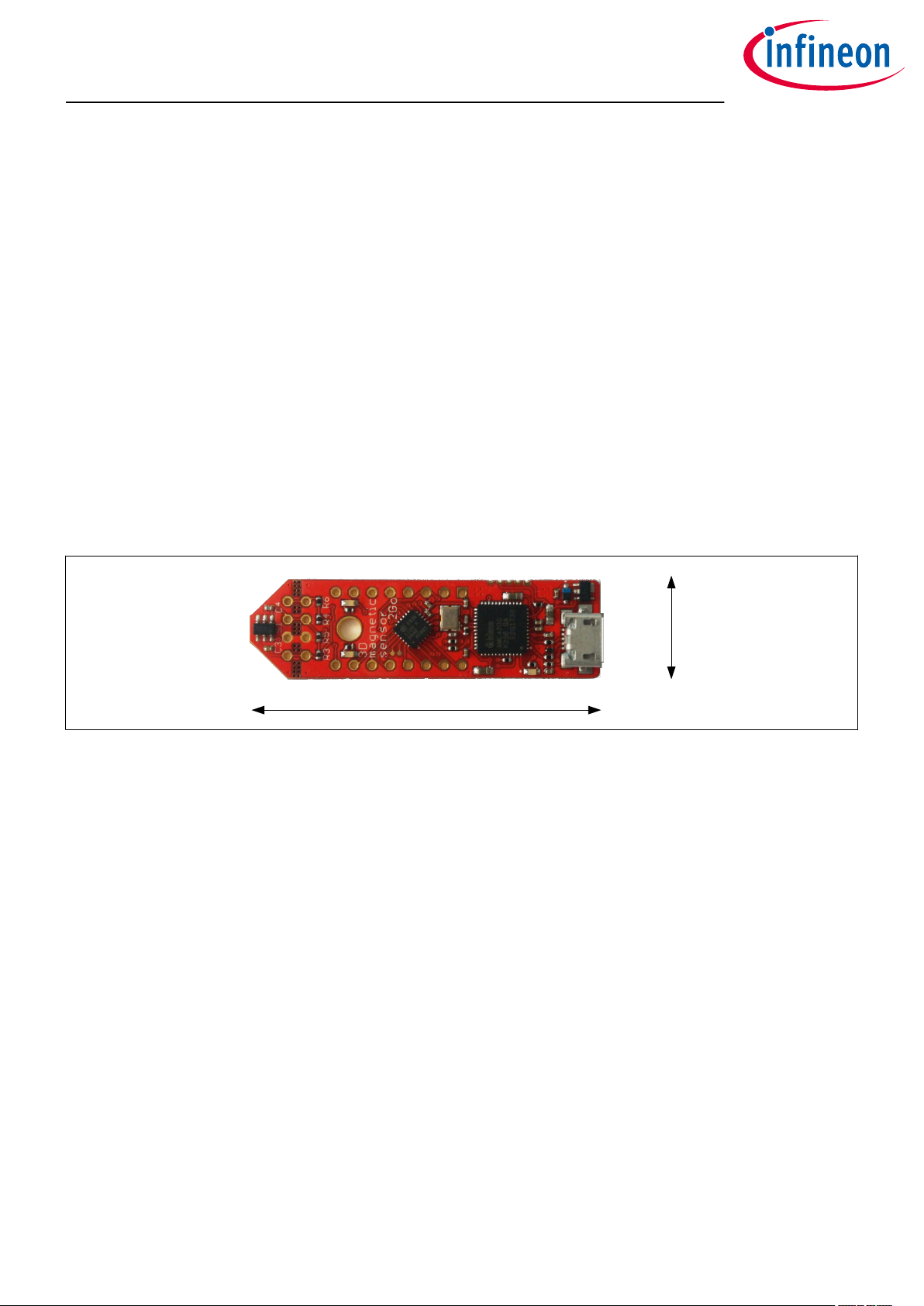

1.3 Hardware extensions

Additionally to the provided standalone magnet there are several dedicated extensions available that can be

mounted to the 3D Magnetic Sensor 2 Go kit.

Table 1 3D Magnetic Sensor 2 Go extensions

Type Orderable part number (OPN)

Joystick JOYSTICKFOR3D2GOKITTOBO1

Rotation knob ROTATEKNOB3D2GOKITTOBO1

Linear slider LINEARSLIDER2GOTOBO1

Out of sha OUTOFSHAFTFOR3D2GOTOBO1

Figure 2 Joystick and rotation knob extensions for the 3D Magnetic Sensor 2 Go kit

Joystick

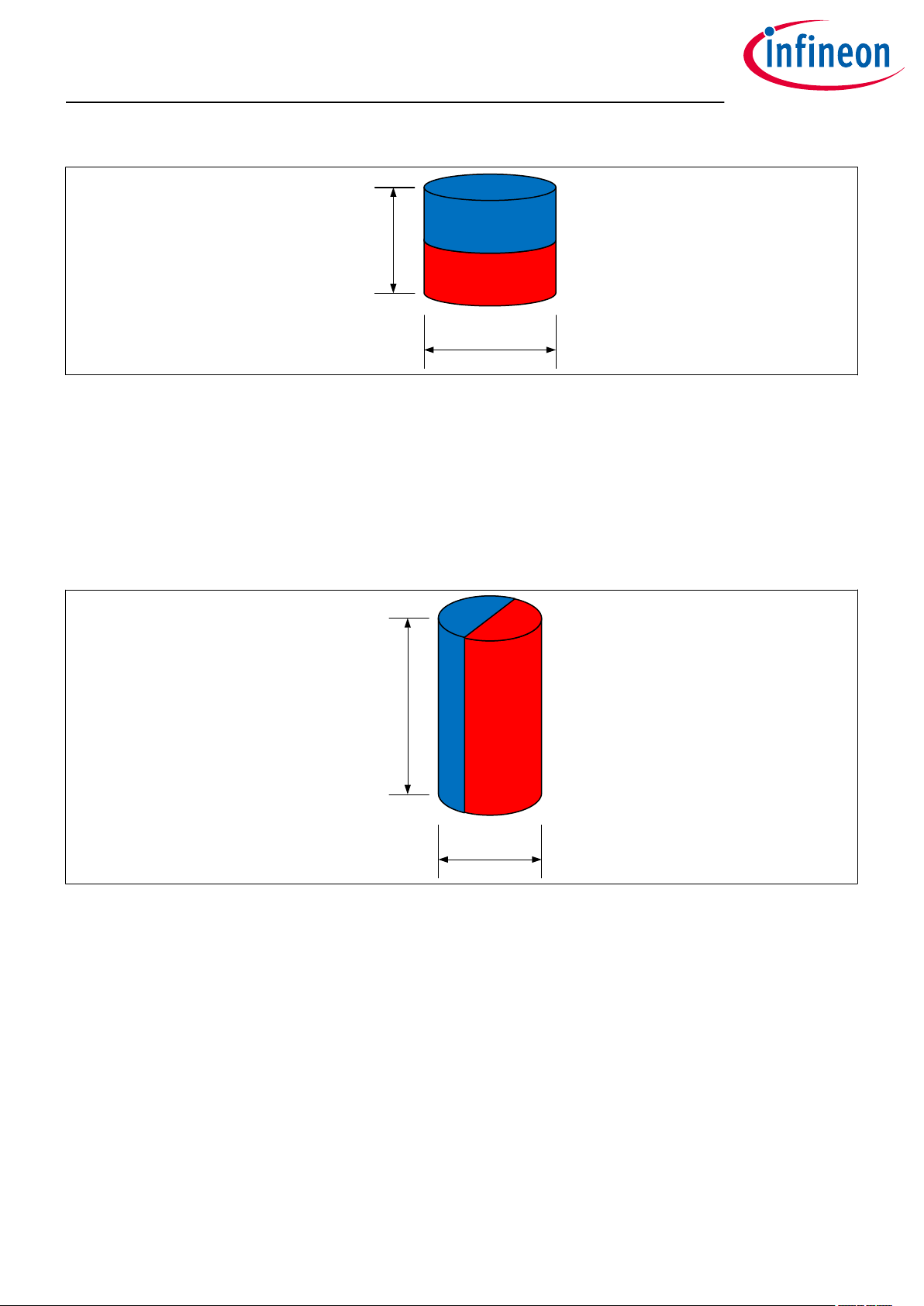

The magnet used in the joystick extension is an axial magnetized magnet as shown in Figure 3. The magnet

material is ferrite, of class Y35, which is equivalent to a remanence of between 400 mT and 410 mT. The magnet

disk has a size of 5 mm diameter and 5 mm thickness. For more information about the magnet, please follow

this link:

https://www.supermagnete.de/eng/disc-magnets-ferrite/disc-magnet-5mm-5mm_FE-S-05-05

User Manual 4 1.2

2019-09-06

Page 5

5 mm

5 mm

10 mm

4 mm

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Introduction

Figure 3 Magnet used in the Joystick extension

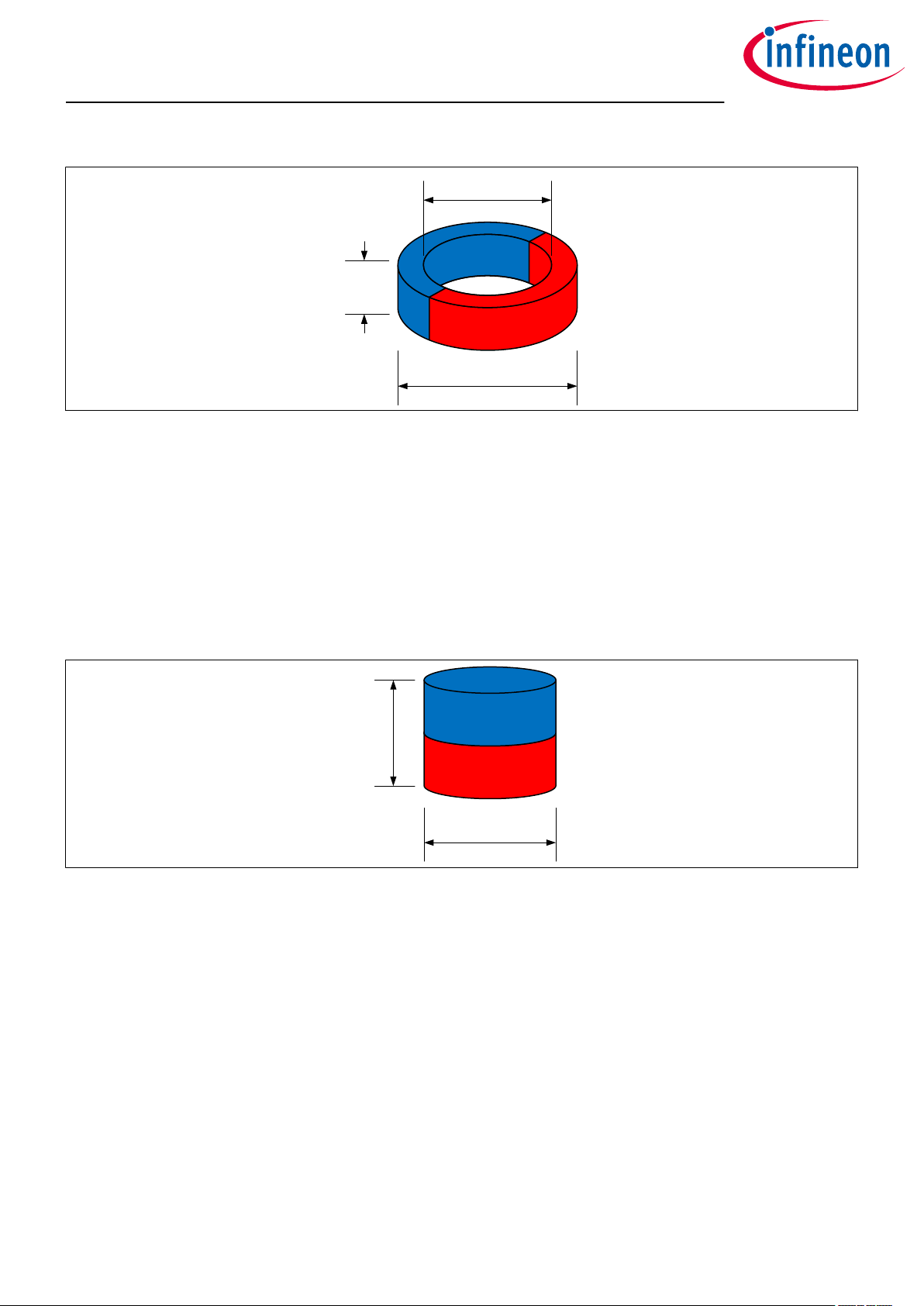

Rotation knob

The magnet used in the rotate knob extension is a diametrically magnetized magnet as shown in Figure 4. The

magnet material is Neodymium Iron Boron (NdFeB) of class N45. The magnet is protected against corrosion

with Nickel coating (Ni-Cu-Ni). The magnet size is 4 mm diameter and 10 mm thickness. For more information

about the magnet, please follow this link:

https://www.supermagnete.de/eng/rod-magnets-neodymium/rod-magnet-diameter-4mm-height-10mmneodymium-n45-nickel-plated_S-04-10-DN

Figure 4 Magnet used in the rotation knob extension

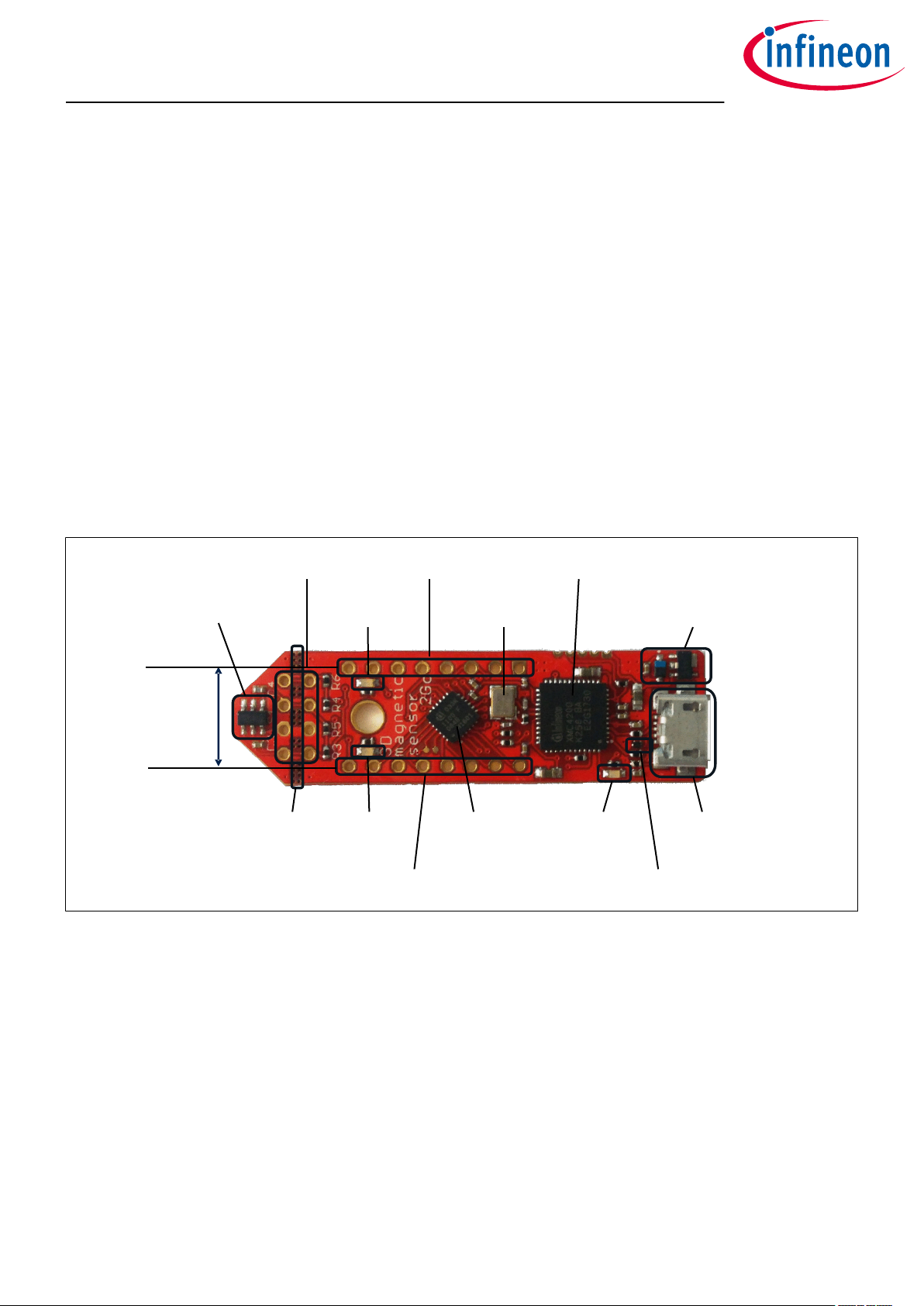

Out of sha

The magnet used in the out of sha extension is a diametrically magnetized ring magnet as shown in Figure 5 .

The magnet material is Neodymium Iron Boron (NdFeB) of class N45. The magnet is protected against corrosion

with Nickel coating (Ni-Cu-Ni). The magnet size is 10 mm outer diameter, 7 mm inner diameter and 3 mm

thickness. For more information about the magnet, please follow this link:

https://www.supermagnete.de/eng/ring-magnets-neodymium/ring-magnet-10mm-7mm-3mm_R-10-07-03DN

User Manual 5 1.2

2019-09-06

Page 6

10 mm

7 mm

3 mm

5 mm

5 mm

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Introduction

Figure 5 Magnet used in the out of sha extension

Linear slider

The linear slider extension comes with two axial magnetized magnets of the same size as shown in Figure 6. The

first magnet material is Neodymium Iron Boron (NdFeB) of class N45. The magnet is protected against corrosion

with Nickel coating (Ni-Cu-Ni). The second magnet material is ferrite, of class Y35, which is equivalent to a

remanence of between 400 mT and 410 mT. Both magnet disk has a size of 5 mm diameter and 5 mm thickness.

For more information about the magnets, please follow this links:

https://www.supermagnete.de/eng/disc-magnets-neodymium/disc-magnet-5mm-5mm_S-05-05-N

https://www.supermagnete.de/eng/disc-magnets-ferrite/disc-magnet-5mm-5mm_FE-S-05-05

Figure 6 Magnet used in the linear slider extension

User Manual 6 1.2

2019-09-06

Page 7

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

EvalBoard description

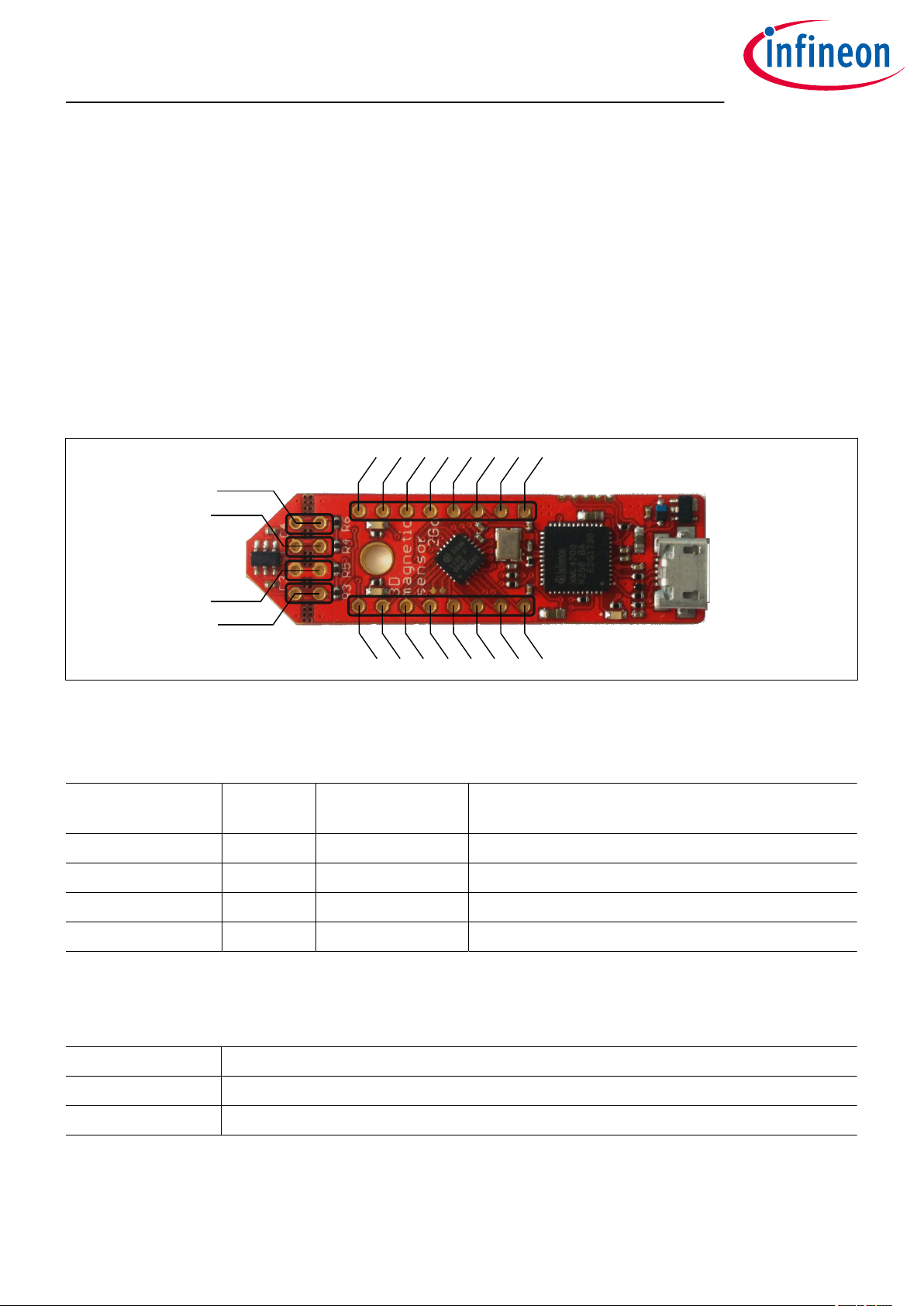

2 EvalBoard description

The evaluation board (EvalBoard) is a ready-to-use printed circuit board (PCB) which contains:

• The 3D magnetic sensor TLE493D-A2B6. For the availability of 3D Magnetic Sensor 2 Go kits with dierent

sensor variants check the Infineon web page: https://www.infineon.com/cms/en/product/sensor/

magnetic-sensors/magnetic-position-sensors/3d-magnetics/

• XMC1100 microcontroller based on ARM Cortex™-M0 at 48 MHz frequency connected to the 3D sensor.

• XMC4200 microcontroller based on ARM Cortex™-M4 at 144 MHz frequency used for debugging and USB

communication.

• Micro USB connector for power supply and communication with the Graphical User Interface (GUI).

• LED for indication of power supply and debugging.

• Two LEDs for user configuration.

• Voltage regulator, reverse current protection diode and ESD protection diode.

• Pin headers to access data lines (e.g. via oscilloscope, external microcontroller).

The dierent components and its location are shown in Figure 7. The 3D magnetic sensor can be separated

from the rest of the EvalBoard by cutting the break line.

TLE493D-A2B6

pin header

distance fits

to breadbord

pin header X3

user LED2

break

line

user LED1

pin header X1

@P1.1

@P0.12

pin header X2

crystal for

debug IC

XMC 1100

mircocontroller

Figure 7 Main components of the EvalBoard

2.1 Optional external power supply

XMC4200 debug IC and

UART to USB bridge

voltage regulator and reverse

current protection diode

power and

debug LED

ESD protection

diode

mirco USB

connector

The 3D Magnetic Sensor 2 Go EvalBoard is supplied via the USB cable. It is also possible to provide an external

power supply. If this is the case, a few considerations must be taken into account as described below.

The 3D Magnetic Sensor 2 Go EvalBoard must be supplied by external 5 Volt DC power supply connected to the

micro USB plug. The voltage regulator shis the voltage level to 3.3 V for the microcontrollers and the 3D

magnetic sensor. The Power & Debug LED indicates that the presence of the generated 3.3 V supply voltage.

Out of the box with the pre-programmed application and the on-board debugger in operation the EvalBoard

typically draws about 75 mA. This current can be delivered via the USB plug of a PC, which is specified to deliver

up to 500 mA. An on-board reverse current protection diode will ensure safe operation and protects the USB

port of the Laptop/PC in case power is provided through the pin header X1.

User Manual 7 1.2

2019-09-06

Page 8

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

EvalBoard description

It is not recommended to apply an additional power supply to the VDD pin of X1 (3.3 V) when the board is

powered via USB, because the 3.3 V supply could drive against the on-board power supply. The VDD pin can be

used to power an external circuit. But care must be taken not to draw more current than 150 mA, which is the

maximum current the on-board voltage regulator can deliver. Aer power-up the Debug LED starts blinking. In

case there is connection to a PC with correctly installed drivers, the Debug LED will turn from blinking to

constant illumination.

2.2 Pin header connector

The pin headers X1 and X2 can be used to extend the evaluation board or to perform measurements on the

XMC1100. The order of pins available at X1 and X2 corresponds to the pinning schema of the XMC1100

microcontroller in the TSSOP-16 pin package. The pinning table is also printed onto the bottom side of the PCB

(depending on the version). The pin header X3 can be used to access directly the 3D magnetic sensor pins.

P2.9

SDA (P2.10)

SCL (P2.11)

X3

X1

P0.5

P0.0

3.3 V

GND

P2.11

P2.10

P2.7

GND

V

DD

(P1.0)

X2

P0.6

P0.7

P0.8

P0.9

P0.14

P0.15

P2.0

P2.6

Figure 8 EvalBoard pin header connectors

The 3D Hall sensor pins can be accessed via the pin headers as shown in Table 2.

Table 2 Pin header description for the 3D magnetic sensor (X3)

TLE493D-A2B6 pin

number

Pin name

on board

XMC1100 port pin Sensor pin description

1 SCL P2.11 Interface clock and \INT pin, open drain

3 GND GND Ground pin

4 +3V3 P1.0 Supply pin

6 SDA P2.10 Interface data pin, open drain

The XMC1100 port pins P0.12 and P1.1 are connected the two user LEDs and are not available on the pin

headers.

Table 3 Pins used for the user LEDs

LED XMC1100 port pin

LED1 P0.12

LED2 P1.1

User Manual 8 1.2

2019-09-06

Page 9

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

EvalBoard description

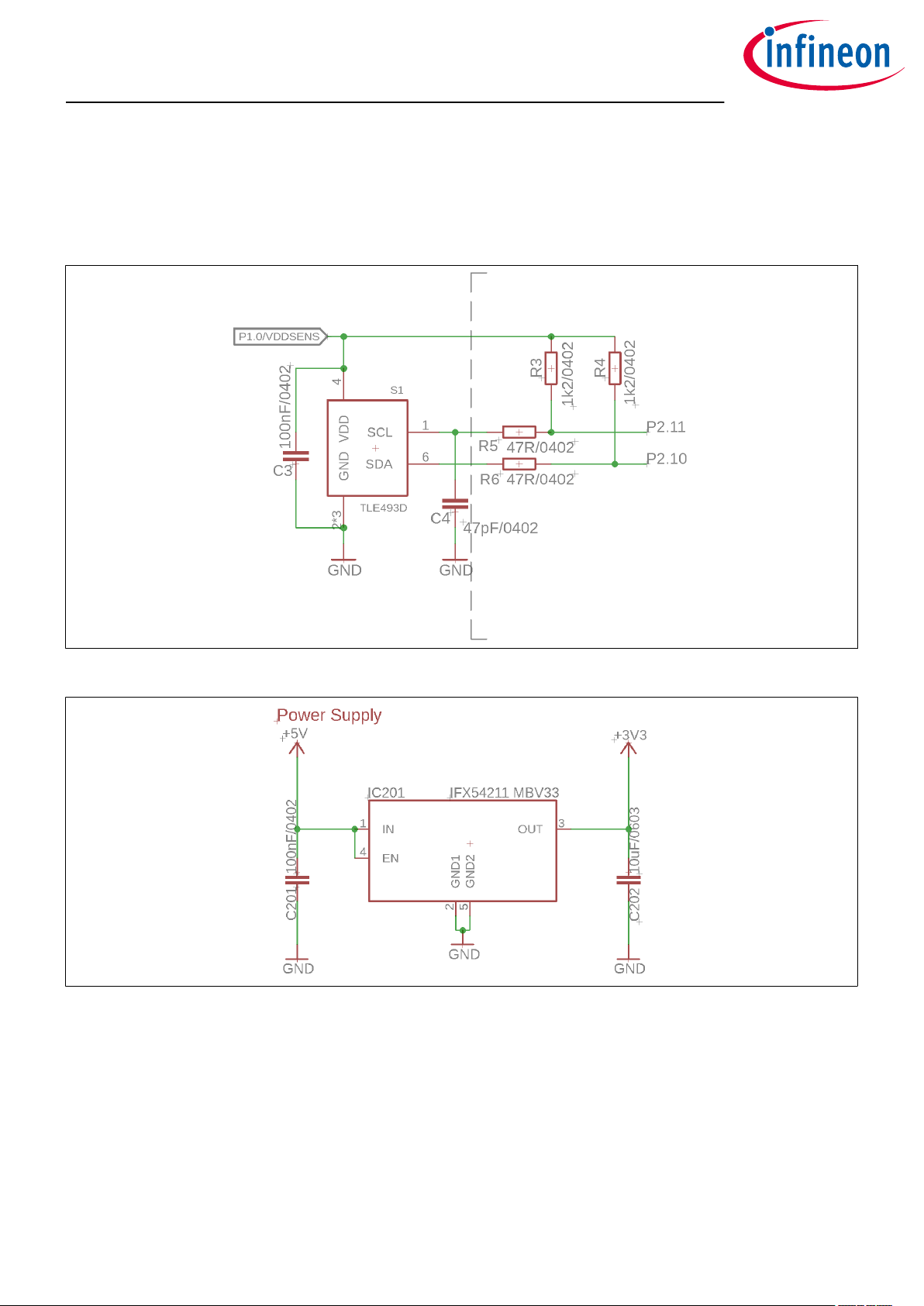

2.3 EvalBoard schematics

The schematics of the dierent blocks from the EvalBoard of the3D Magnetic Sensor 2 Go kit are provided in

this chapter. They can be used to design customized PCBs. The user (integrator) is responsible for the correct

functioning on system level as well as for the validation and testing.

Figure 9 EvalBoard schematic: 3D magnetic sensor

Figure 10 EvalBoard schematic: the voltage regulator (for the power supply)

User Manual 9 1.2

2019-09-06

Page 10

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

EvalBoard description

Figure 11 EvalBoard schematic: the LEDs for user configuration (connected to XMC1100 pins)

Figure 12 EvalBoard schematic: the XMC1100 microcontroller and pin headers

User Manual 10 1.2

2019-09-06

Page 11

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

EvalBoard description

Figure 13 Sketch of the debug connection

User Manual 11 1.2

2019-09-06

Page 12

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

EvalBoard description

Figure 14 EvalBoard schematic: the XMC4200 microcontroller and micro USB connector

User Manual 12 1.2

2019-09-06

Page 13

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Soware installation

3 Soware installation

The following description guides through the installation procedure of the free evaluation soware for the 3D

Magnetic Sensor 2 Go kit.

Steps

1. Download the soware.

Follow the link below to reach the Sensor 2 Go information page on the Infineon website. As shown in

Figure 15, you can find the download link for the latest version of the 3D Magnetic Sensor 2 Go GUI on

the right hand side.

https://www.infineon.com/cms/en/product/promopages/sensors-2go/

Figure 15 Download the "3D Magnetic Sensor 2 Go" soware from the Infineon web

page

2. Start the installation process.

Browse to your download folder and extract the downloaded .zip file. Aerwards, double click on

the .msi file to start the installer. The window in Figure 16 pops up. Click "Next".

User Manual 13 1.2

2019-09-06

Page 14

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Soware installation

Figure 16 Start the soware installation

3. Read the license agreement carefully and tick the box to accept the terms. Click Next.

Figure 17 Accept the license agreement

4. Choose your installation path. The soware requires the SEGGER J-Link driver and .NET framework

version 4.5 or later to be installed on your PC. If not yet available, check the respective items. Click Next

User Manual 14 1.2

2019-09-06

Page 15

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Soware installation

Figure 18 Select you installation folder

5. Confirm the installation settings by clicking on Install.

Figure 19 Confirm the installation

6. Once the installation is complete, click on Finish to close the installer.

User Manual 15 1.2

2019-09-06

Page 16

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Soware installation

Figure 20 Installation finished

7. You can now start the evaluation soware. Open the start menu, browse to Infineon Technologies > 3D

Sensor 2go Kit and open the application by clicking on 3D 2Go.

Figure 21 Shortcut to the 3D Magnetic 2Go evaluation soware (GUI)

3.1 Driver installation

To enable the communication between the 3D Magnetic Sensor 2 Go kit it is necessary to install the J-Link driver

on your PC.

The driver is included in the GUI installer and will start automatically within the installation progress. In case of

issues, you can directly download the latest version from the SEGGER homepage:

https://www.segger.com/downloads/jlink

Steps

1. Start the installation. Invoke your downloaded driver executable or wait for the 3D Magnetic Sensor 2 Go

installer to open the window shown in Figure 22. Click on Next.

User Manual 16 1.2

2019-09-06

Page 17

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Soware installation

Figure 22 J-Link driver setup

2. Read and accept the license agreement. Click on I Agree.

Figure 23 J-Link license agreement

3. Check that the "Install USB Driver for J-Link" option is active. Click on Next.

User Manual 17 1.2

2019-09-06

Page 18

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Soware installation

Figure 24 J-Link installation options

4. Choose the installation folder. It is recommend to keep the default settings. Click on Install. Now the

installation should be executed.

Figure 25 J-Link choose install location

5. Once the installation is completed, close the installer by clicking on Finish.

User Manual 18 1.2

2019-09-06

Page 19

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Soware installation

Figure 26 J-Link installation complete

User Manual 19 1.2

2019-09-06

Page 20

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

3D magnetic sensor evaluation

4 3D magnetic sensor evaluation

This chapter describes how the GUI can be used to make first evaluations with Infineon's 3D magnetic sensor.

4.1 Getting started

Once the soware is installed, the following steps are necessary to do the first magnetic measurements.

Steps

1. Connect the EvalBoard to the PC via the USB cable. Use the micro USB port for the EvalBoard and USB

port for the PC. The power LED on the EvalBoard will switch on, indicating the EvalBoard is supplied with

enough power.

2. Open the 3D 2Go GUI by clicking the shortcut in the start menu. On the top le side you should find the

XMC2Go board in the list. If not, check that the EvalBoard is correctly connected to the PC and the J-Link

driver is installed. Click on the Connect to selected programmer button which is marked in Figure 27 to

establish the connection with the 3D Magnetic Sensor 2 Go kit. The first time you connect the board, a

firmware will be downloaded to the XMC1100 which takes short time. This is indicated by the blinking

power LED on the EvalBoard.

Figure 27 Establish the connection to the EvalBoard

3. The GUI automatically detects the sensor type on the 3D Magnetic Sensor 2 Go kit. Dierent

configuration modes can be selected which are briefly described in Table 4 . For details refer to the

TLE493D-A2B6 data sheet and user manual. Aer you have selected the mode, click on Start to begin

with the measurements.

Table 4 Sensor modes

Sensor mode Description

Low power mode Cyclic sensor measurements with a configurable update rate. The GUI

sets the sensor to the default update rate of 770 Hz (typ.). Between the

measurements, the sensor stays in power down mode, which reduces the

power consumption.

Fast mode Sensor measurements are running continuously. Fastest update rate.

User Manual 20 1.2

2019-09-06

Page 21

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

3D magnetic sensor evaluation

Table 4 Sensor modes (continued)

Sensor mode Description

Master controlled

mode

Sensor measurements are triggered by the microcontroller, which

enables high flexibility.

4.2 Graph View

The graph view displays the magnetic field measurements in X, Y and Z direction.

Figure 28 shows the graph view window. On the le hand side there are three histograms which plot the

magnetic field for each measured sample. On the right a table displays all measured data, including the

temperature. With the save button it is possible to export the measurement data into a .csv file. This is

especially helpful for processing the data aerwards. .

If a new mode should to be evaluated click the Stop button on the le control panel. Save the data and Clear it.

Select a new configuration and click again on Start to begin the new evaluation.

Figure 28 Graph view

User Manual 21 1.2

2019-09-06

Page 22

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

3D magnetic sensor evaluation

4.3 Joystick view

The joystick view is a virtual representation of a real joystick with an attached magnet, mounted above the 3D

magnetic sensor.

It is intended to be used with the Joystick adapter available for the 3D Magnetic Sensor 2 Go kit. For order

details and information about the used magnet refer to section Hardware extensions .

The soware measures the magnetic field in all three dimensions and calculates the angles necessary to

determine the joystick position. Further information is given in the application note "Infineon 3D Magnetic

Sensor - How to Make a Magnetic Design for Joystick" which can be found on the Infineon home page.

Figure 29 Joystick view

4.4 Rotation view

In this view the calculated spherical coordinates of the magnetic field are displayed. Additionally it includes a

graphical presentation of the 3D Magnetic Sensor 2 Go rotary knob attachment .

The polar coordinates consist of the radius r as well as the angles Phi and Theta. They are calculated out of the

measured three dimensional magnetic field with following equations:

r = Bx2+ By2+ Bz

Phi = arccos

Theta = arctan

Below the polar coordinates a virtual rotation knob can be found. It can be used with the rotary knob

attachment described in Hardware extensions. When the user turns the hardware knob, also the indicator in

the GUI turns. This is achieved by measuring the magnetic field and calculating the angle between Bx and By as

described above. Also a push functionality is implemented depending on the radius r of the magnetic field.

User Manual 22 1.2

2

Bz

r

By

Bx

2019-09-06

Page 23

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

3D magnetic sensor evaluation

Figure 30 Polar coordinates

4.5 Linear movement

This view is meant to be used with the linear slider extension. It allows to measure the position of the magnet in

a slide by configuration.

For details have a look on the video "3D magnetic sensor linear slider adapter for sensor 2GO Kits" on the

following page:

https://www.infineon.com/cms/en/product/promopages/sensors-2go/#Add-ons-3D-Magnetic-2GO

User Manual 23 1.2

2019-09-06

Page 24

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

3D magnetic sensor evaluation

Figure 31 Linear movement view

4.6 Out of sha

This view is meant to be used with the out of sha extension. It allows to measure the angle of the magnet while

the sensor is placed at the side of it.

For details have a look on the video "3D magnetic sensor out of sha adapter angle measurement" on the

following page:

https://www.infineon.com/cms/en/product/promopages/sensors-2go/#Add-ons-3D-Magnetic-2GO

User Manual 24 1.2

2019-09-06

Page 25

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

3D magnetic sensor evaluation

Figure 32 Out of sha view

User Manual 25 1.2

2019-09-06

Page 26

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Example code for developers

5 Example code for developers

Additionally to the graphical user interface a low level library is provided as a quick entry point for own

developments with the 3D magnetic sensor. It can be downloaded from the link below.

https://www.infineon.com/cms/de/product/sensor/magnetic-sensors/magnetic-position-sensors/3dmagnetics/#!tools

The library comes with a generic C code example as well as a specific implementation for the XMC based 3D

Magnetic Sensor 2 Go kit. An comprehensive documentation can be found under the respective "doc" folder.

For the html version open the "index.html" file with your browser.

User Manual 26 1.2

2019-09-06

Page 27

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

XMC for Arduino

6 XMC for Arduino

Finally, the 3D Magnetic Sensor 2 Go kit can be used in combination with the Arduino IDE. A library is provided

to enable a fast evaluation in the individual application. More details and the download can be found at the link

below:

https://github.com/Infineon/TLE493D-3DMagnetic-Sensor

User Manual 27 1.2

2019-09-06

Page 28

TLE493D-A2B6 MS2GO

3D Magnetic Sensor 2 Go evaluation kit

Revision history

Revision history

Document

version

1.0 2018-05-16 Initial version

1.1 2018-10-12 Title page updated

1.2 2019-09-06 Updated section Hardware extensions

Date of

release

Description of changes

Added new view descriptions to the section 3D magnetic sensor evaluation

Added XMC for Arduino

Added Example code for developers

Various editorial changes

User Manual 28 1.2

2019-09-06

Page 29

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2019-09-06

Published by

Infineon Technologies AG

81726 Munich, Germany

©

2019 Infineon Technologies AG

All Rights Reserved.

Do you have a question about any

aspect of this document?

Email: erratum@infineon.com

Document reference

IFX-hda1518789688364

IMPORTANT NOTICE

The information given in this document shall in no

event be regarded as a guarantee of conditions or

characteristics (“Beschaenheitsgarantie”) .

With respect to any examples, hints or any typical values

stated herein and/or any information regarding the

application of the product, Infineon Technologies

hereby disclaims any and all warranties and liabilities of

any kind, including without limitation warranties of

non-infringement of intellectual property rights of any

third party.

In addition, any information given in this document is

subject to customer’s compliance with its obligations

stated in this document and any applicable legal

requirements, norms and standards concerning

customer’s products and any use of the product of

Infineon Technologies in customer’s applications.

The data contained in this document is exclusively

intended for technically trained sta. It is the

responsibility of customer’s technical departments to

evaluate the suitability of the product for the intended

application and the completeness of the product

information given in this document with respect to such

application.

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies oice.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon Technologies,

Infineon Technologies’ products may not be used in

any applications where a failure of the product or

any consequences of the use thereof can reasonably

be expected to result in personal injury

Loading...

Loading...