Page 1

UM TLD5542-1 eval

TLD5542-1 Multichannel evalboard V4.5

User Manual

About this document

Product description

TLD5542-1QV: H-Bridge buck-boost DC/DC controller designed for high power, high efficiency automotive

applications

• Constant current (LED) and constant voltage regulation

• SPI for diagnostics and control

• Limp Home function (fail-safe mode)

• EMC optimized device: Spread Spectrum

Scope and purpose

Scope of this user manual is to provide to the audience instructions on usage of the TLD5542-1 Multichannel

evalboard V4.4 and relative PC GUI.

The TLD5542-1 Multichannel evalboard V4.4 it is an evaluation platform for the TLD5542-1, which can drive 3 LED

functions (HB, LB, DRL), with a single efficient DC/DC converter. The board shows good EMC performance, EMC

report available for download on the evaluation board webpage.

Intended audience

Hardware engineers, software engineers, system architects

User Manual Please read the Important Notice and Warnings at the end of this document Rev.1.12

www.infineon.com page 1 of 17 2020-04-02

Page 2

TLD5542-1 Multichannel evalboard V4.5

User Manual

Table of contents

1 Table of contents

About this document ......................................................................................................................... 1

1 Table of contents ...................................................................................................................... 2

2 Glossary .................................................................................................................................. 3

3 Description .............................................................................................................................. 4

4 Quick start procedure ............................................................................................................... 5

5 Possible light scenarios ............................................................................................................. 8

6 Operating range and power derating ......................................................................................... 9

7 Electrical characteristics ..........................................................................................................10

8 Diagnostic ..............................................................................................................................11

9 PCB layout ..............................................................................................................................12

10 Schematic ...............................................................................................................................13

Revision history ...............................................................................................................................16

User Manual 2 of 17 Rev.1.12

2020-04-02

Page 3

TLD5542-1 Multichannel evalboard V4.5

User Manual

2 Glossary

DRL: Daytime Running Light function

POS: position light obtained by dimming down the DRL function

LB: Low Beam function

HB: High Beam function

H-Bridge: 4 switches topology buck-boost DC/DC converter (see Figure 1)

Figure 1 4 switches H-Bridge architecture overview

User Manual 3 of 17 Rev.1.12

2020-04-02

Page 4

TLD5542-1 Multichannel evalboard V4.5

User Manual

3

The TLD5542-1 multichannel evalboard V4.4 it is an evaluation platform for the TLD5542-1, which can drive 3 LED

functions (HB, LB, DRL), with a single efficient DC/DC converter.

In the single DC/DC multichannel system night-time functions (e.g. HB and LB) are connected in series and the

complementary daytime (DRL) function in parallel by mean of switches (Figure 2). The switches properly

distribute the DC/DC converter output current in order to obtain the requested LED currents. This approach is

called multi floating switch (MFS) architecture.

Description

Figure 2 LED driver with 3 functions on MFS architecture

The TLD5542-1 Multichannel evalboard V4.4 has an ePower microcontroller TLE9842-2 pre-programmed with the

application software V4.0 or higher. A PC GUI can configure load currents and duty cycles via USB (UART over

LIN).

Figure 3

TLD5542-1 Multichannel evalboard V4.4

On the board, in addition the following are present:

•

A 300 mA LS switch to drive an external FAN

•

Limp Home push button show fail safe operation

•

Extra push button whose functionality can be programmed by the user

•

LIN interface and a detachable USB serial to LIN daughter board

User Manual 4 of 17 Rev.1.12

2020-04-02

Page 5

TLD5542-1 Multichannel evalboard V4.5

User Manual

4

The TLD5542-1 multichannel evalboard comes with USB to LIN daughter board, avoid detaching it from the

main board in order to be able to control the board via USB.

Humming noise may be heard from the board due to piezoelectric effect on output capacitors, this does not

affect the performance.

Step by step procedure

1.

Connect the load(s) to the HB, LB, DRL connectors as shown in Figure 4 , the software will automatically

disable unconnected terminals

Quick start procedure

Figure 4 TLD5542-1 Multichannel evalboard V4.4 - connect loads

2.

Connect a 12 V 5 A power supply to the VIN connector

Figure 5 TLD5542-1 Multichannel evalboard V4.4 - connect power supply

3.

Load will be powered with Default configuration:

LB 1000 mA, HB 800 mA , POS 28 mA (400 mA @ 7%)

4.

In order to control the TLD5542-1 Multichannel evalboard, install the GUI V1.0 to the control PC (chapter

Error! Reference source not found.)

User Manual 5 of 17 Rev.1.12

2020-04-02

Page 6

TLD5542-1 Multichannel evalboard V4.5

User Manual

5.

Connect a micro USB cable from the TLD5542-1 evalboard to the PC (Figure 6)

Figure 6 Connect a microUSB cable from the PC to the evalBoard

6.

Launch the “TLD5542-1_MULTICH_GUI_V1.0.xlsm” to execute the excel GUI ( Figure 7 )

Figure 7 TLD5542-1 Excel GUI V1.0 screenshot on communication established

7.

Connection cell will turns green (Figure 7) on the GUI if the right COM port is selected

8.

Select desired load current and duty cycle and press “Send Configuration” button

9.

LED load will be powered with selected configuration

Note:

Due to the schematic implementation, if POS is ON, then the maximum possible duty cycle on LB/HB is reduced by

the POS duty cycle + load change time (duty cycle losses: Figure 8). The software automatically increases the

LB/HB current to keep average current equal to the requested current, so peak current could be different than the

requested one. During LB/HB+POS scenario, POS duty cycle has to be < 10% in order to minimize LB/HB current

increase.

User Manual 6 of 17 Rev.1.12

2020-04-02

Page 7

TLD5542-1 Multichannel evalboard V4.5

User Manual

Example: User requested scenario is:

LB current = 1 A @100% duty POS = 300 mA @7% duty

Produced scenario (depending by LB and DRL voltage):

LB current = 1.14 A @88% duty=> 1A avg POS = 300 mA @ 7% duty

Figure 8 Time sharing and duty cycle losses

For further information please read the TLD5542-1 cost optimized application note and SW description documents:

Infineon-Z8F67062262_Cost_Optimized_TLD5542-AN.pdf

Infineon-Z8F64914635_TLD5542-1_Software_Description-AN.pdf

User Manual 7 of 17 Rev.1.12

2020-04-02

Page 8

TLD5542-1 Multichannel evalboard V4.5

User Manual

5 Possible light scenarios

On the TLD5542-1 multichannel evalboard, LB (master) and HB (slave) channels are connected in series, so that

the instantaneous current on the 2 strings is the same. Different average current can be achieved by applying

PWM dimming to the HB.

HB duty cycle can be smaller or equal to the LB duty cycle.

Table 1 TLD5542-1 Multichannel evalboard V4.4 - possible light scenarios

LB HB DRL POS (<10% duty)

LB ON ANY OFF ANY

HB ON ON OFF ANY

DRL OFF OFF ON OFF

POS ANY ANY OFF ON

DEFAULT

ON

(1000 mA)

ON

(800 mA)

OFF

ON

(28 mA = 400 mA@7%)

By pressing Limp Home button on the evalboard, LHI pin of the TLD5542-1 is activated, and the bypass switches

are configured by a dedicated circuitry in order to power LB only @ 850 mA. The μC SPI commands and GPIOs

are ignored, simulating a fail-safe operation. The resistor divider on the SET pin configures the output current

in limp home operation (850 mA).

User Manual 8 of 17 Rev.1.12

2020-04-02

Page 9

TLD5542-1 Multichannel evalboard V4.5

User Manual

6 Operating range and power derating

Software power derating is implemented on SW 3.8, and it reduces output current (and thus the output power)

when the battery voltage drops below 9V at the board connector. Power derating profile is set as shown in

Figure 9 (6W/V).

P

[W]

out

50

40

32

25

P

out-peak

P

out-average

6

9

18

V

[V]

bat

Figure 9 Average (blue) and peak (red) output power derating profile

The SW V3.8 is limits only the peak output power (red curve on Figure 9), but if POS function is ON, then the

effective LB/HB average power available on LB is reduced to Pout-average (blue curve on Figure 9).

Please note that the module does not implement thermal protection, so ensure proper cooling when output

power is above 30 W. Place a heat sink below switching MOSFETs as shown on Figure 10.

Figure 10 TLD5542-1 Heat sink placement

The Heat sink should be thermally coupled but electrically insulated from the PCB by mean of a thermal pad.

User Manual 9 of 17 Rev.1.12

2020-04-02

Page 10

V

V

TLD5542-1 Multichannel evalboard V4.5

User Manual

7 Electrical characteristics

Table 2 TLD5542-1 multichannel evalboard V4.4 – electrical characteristics

Parameter Symbol

Unit Note/Test Condition

Min Typ Max

Value

Input Voltage

Out voltage

Output current

HB,LB average

Output current

DRL

Output Power

Switching

frequency

PWM frequency PWM

VIN (Normal)

VIN (Extended)

VIN (Survival)

3 – 50

OUT

(HB,LB)

I

OUT

(DRL/POS) 250 – 1500 mA

I

OUT

(LB,HB)

P

OUT

(DRL)

P

OUT

Switching

frequency

200 – – Hz –

freq

System efficiency Eff – 93 – %

9

6

-18

250

250

18

–

18

V ˜

+40

–

1350

mA

–

1200

mA

3 – 40 W

– 384 – kHz Spread Spectrum deviation is present

–

scenario = LB/HB only POS = OFF

scenario = LB/HB + POS, POS duty cycle < 10%

CHA and CHB string voltage difference < 30 V

Limited by software power derating

Average Pout for

VIN down to 9V

Board efficiency, including μC:

LB 5 LED 1200 mA,

HB 4 LED 960 mA ,

POS 10 LED 400 mA @7%

= 13.5 V

V

IN

= 34.7 W

P

IN

(LB+HB+DRL)= 32.4 W

P

OUT

User Manual 10 of 17 Rev.1.12

2020-04-02

Page 11

TLD5542-1 Multichannel evalboard V4.5

User Manual

8 Diagnostic

TLD5542-1 multichannel software version 4.0 (or higher) is able to detect several failures on the LED load:

Table 3 Failure detection

Failure type Description

LB (FA2)

Open

Short

FA2 open is always reported as FA2 & FA3 open due to schematic

implementation

When FA2(LB) fails, also FA3(HB) is disabled, DRL/POS is available

HB (FA3) Open/Short When FA3(HB) fails , FA2 (LB) and DRL/POS are still available

DRL/POS Open/ShortT When DRL/POS fails , FA2 (LB) and FA3(HB) are still available

Undervoltage (V

< 6 V)

IN

Restart after V

undervoltage when VIN > 8 V

IN

VIN

Overvoltage (V

> 20 V)

IN

Restart after V

overvoltage when VIN < 18 V

IN

A function is considered shorted if its voltage is below 2 V.

Diagnostic is visible also on the PC GUI as shown on Figure 11.

Figure 11 TLD5542-1 PC GUI: diagnostic indicators

User Manual 11 of 17 Rev.1.12

2020-04-02

Page 12

TLD5542-1 Multichannel evalboard V4.5

User Manual

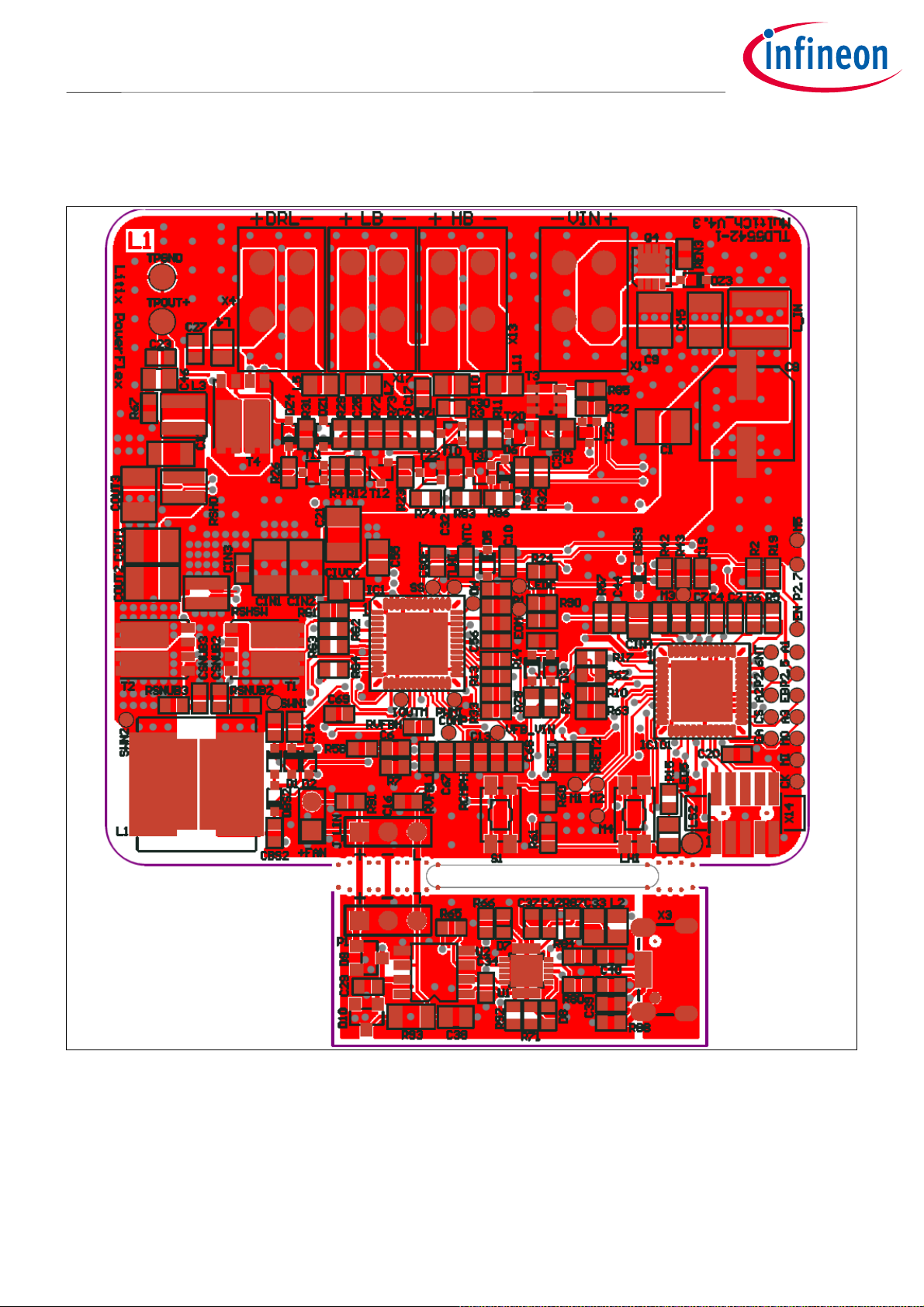

9 PCB layout

Figure 12 PCB layout top view

User Manual 12 of 17 Rev.1.12

2020-04-02

Page 13

TLD5542-1 Multichannel evalboard V4.5

User Manual

10 Schematic

User Manual 13 of 17 Rev.1.12

2020-04-02

Page 14

TLD5542-1 Multichannel evalboard V4.5

User Manual

User Manual 14 of 17 Rev.1.12

2020-04-02

Page 15

TLD5542-1 Multichannel evalboard V4.5

User Manual

User Manual 15 of 17 Rev.1.12

2020-04-02

Page 16

e

e

n

s

n

n

y

n

y

e

n

Revision history

Document

Date of release Description of changes

version

Rev. 1.00 2020-01-14 Initial User Manual

Rev. 1.10 2020-01-16 Updated LED load symbol polarity on Figure 4

Rev. 1.10 2020-01-16 Added USB connection image: Figure 6

Rev. 1.10 2020-01-16 Updated GUI screenshots with SW version

Rev. 1.10 2020-01-16 Updated Labview installation version 2018

Rev. 1.10 2020-01-16 correct Switching frequency to 384 kHz on Electrical characteristics

Rev. 1.11 2020-02-05 Updated SCH to version 4.5

Rev. 1.12 2020-04-02 Updated with excel GUI V1.0

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2020-04-02

Published by

Infineon Technologies AG

81726 München, Germany

© 2020 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

UM TLD5542-1 eval

IMPORTANT NOTICE

The information given in this document shall in no

event be regarded as a guarantee of conditions or

characteristics (“Beschaffenheitsgarantie”) .

With respect to any examples, hints or any typical

values stated herein and/or any information

regarding the application of the product, Infineon

Technologies hereby disclaims any and all

warranties and liabilities of any kind, including

without limitation warranties of non-infringement of

intellectual property rights of any third party.

In addition, any information given in this document

is subject to customer’s compliance with its

obligations stated in this document and any

applicable legal requirements, norms and standards

concerning customer’s products and any use of the

product of Infineon Technologies in customer’s

applications.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments

to evaluate the suitability of the product for the

intended application and the completeness of the

product information given in this document with

respect to such application.

For further information on the product, technology

delivery terms and conditions and prices pleas

contact your nearest Infineon Technologies offic

(www.infineon.com).

WARNINGS

Due to technical requirements products may contai

dangerous substances. For information on the type

in question please contact your nearest Infineo

Technologies office.

Except as otherwise explicitly approved by Infineo

Technologies in a written document signed b

authorized representatives of Infineo

Technologies, Infineon Technologies’ products ma

not be used in any applications where a failure of th

product or any consequences of the use thereof ca

reasonably be expected to result in personal injury.

Loading...

Loading...