Page 1

Boost to battery evaluation kit

User Manual

TLD5098EP

About this document

Product description

The TLD5098EP is an AEC qualified DC-DC boost controller, especially designed to drive LEDs.

• Built-in diagnosis and protection features

• Designed to support multiple topologies such as Boost, Buck, Buck-Boost, SEPIC and Flyback

Scope and purpose

Scope of this user manual is to provide instructions on the usage of TLD5098EP boost to battery evaluation

board.

Intended audience

This document is intended for engineers who need to perform measurements and check performances with

TLD5098EP boost to battery evaluation board.

Table of contents

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2 Quick start procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Current adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4 Power derating (battery dependent current) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

5 Cold crank survival circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7 PCB layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9 Eiciency measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10 Maximizing eiciency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

11 Minimizing EM emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

User Manual

www.infineon.com 2020-09-17

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Please read the Important Notice and Warnings at the end of this document

Page 2

Boost to battery evaluation kit

TLD5098EP

1 Description

1 Description

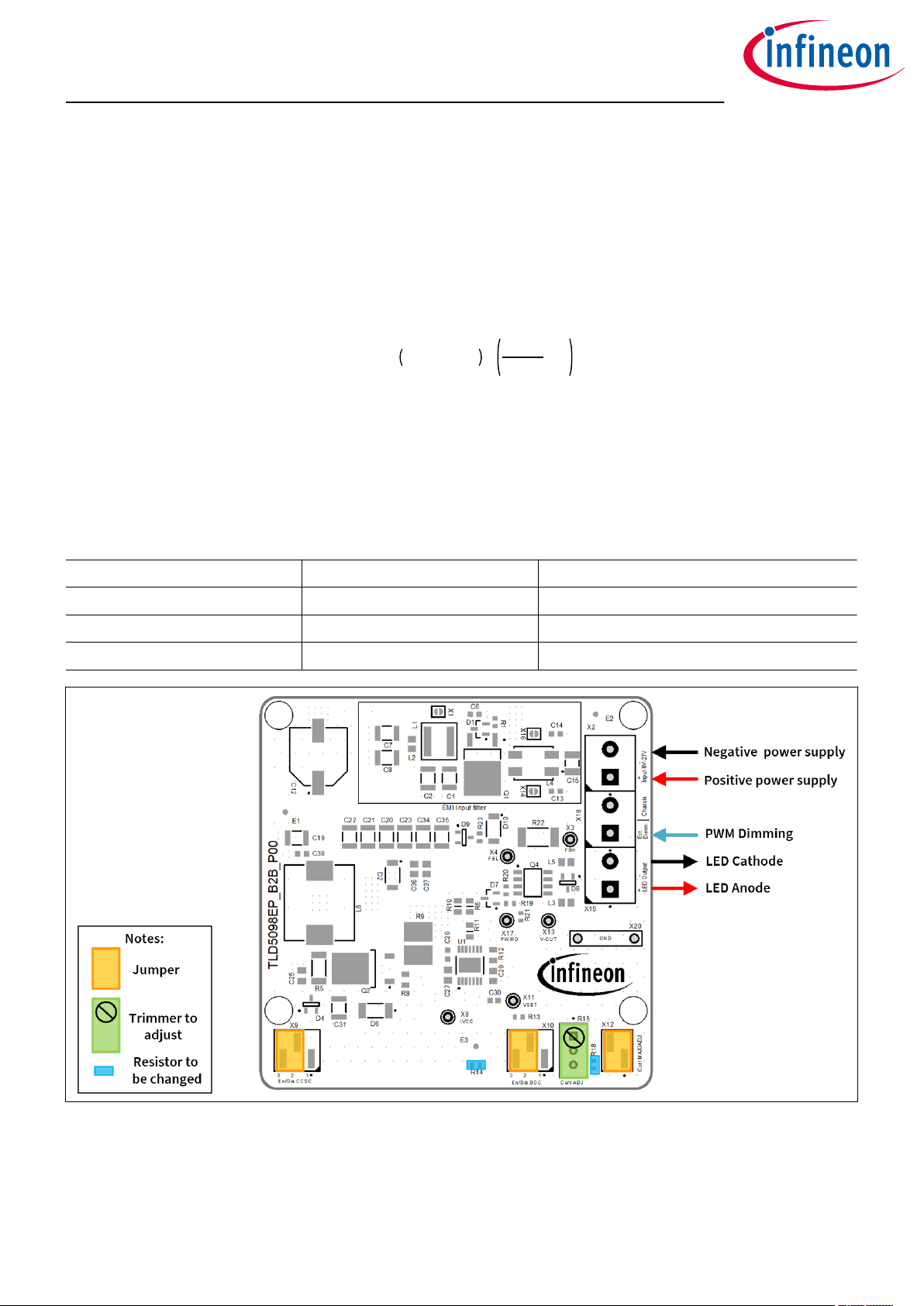

Evaluation board for high power LED application with TLD5098EP product in boost to battery topology.

The default configuration of the board is boost to battery topology without any additional features enabled. In

this configuration it can deliver up to 21 W to the load with an eiciency above 85%. Auxiliary circuits, which

protect the DC-DC and the load during short to ground, are present.

The board is also equipped with the following features that are enabled by jumpers:

• Output current adjustment trimmer

• Power derating circuitry

• Cold crank survival circuit (CCSC)

Figure 1 Board picture

User Manual 2

2020-09-17

Page 3

Boost to battery evaluation kit

TLD5098EP

1 Description

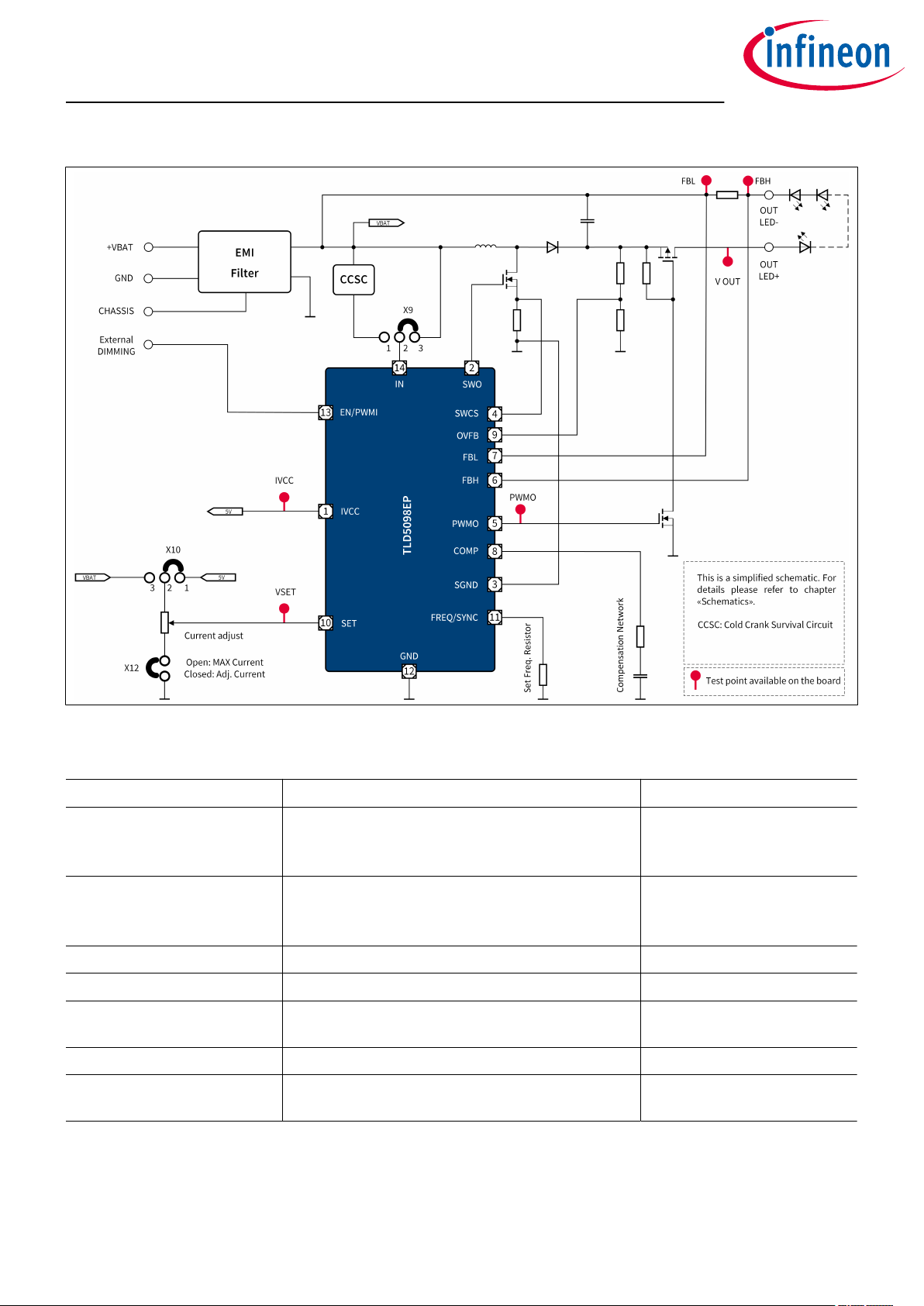

Figure 2 Simplified schematic

Table 1 Performance summary

Parameter Conditions Value

Input supply voltage Jumper X9 in position 2-3 (CCSC deactivated)

Parameter degradation below 6.5 V

Input supply voltage Jumper X9 in position 1-2 (CCSC active) 8 V to 27 V

Output current Jumper X12 open 1 A

Switching frequency VIN = 13.2 V 400 kHz

Eiciency Measured with 7 white standard LED 3 V @ 1 A

output current

Output voltage range Output voltage related to positive input 16 V to 23 V

Output overvoltage

protection

Output voltage related to ground 59 V

8 V to 27 V

(Down to 6.5 V for less than

2 s)

(Down to 3.0 V for less than

2 s)

> 85%

User Manual 3

2020-09-17

Page 4

Boost to battery evaluation kit

TLD5098EP

2 Quick start procedure

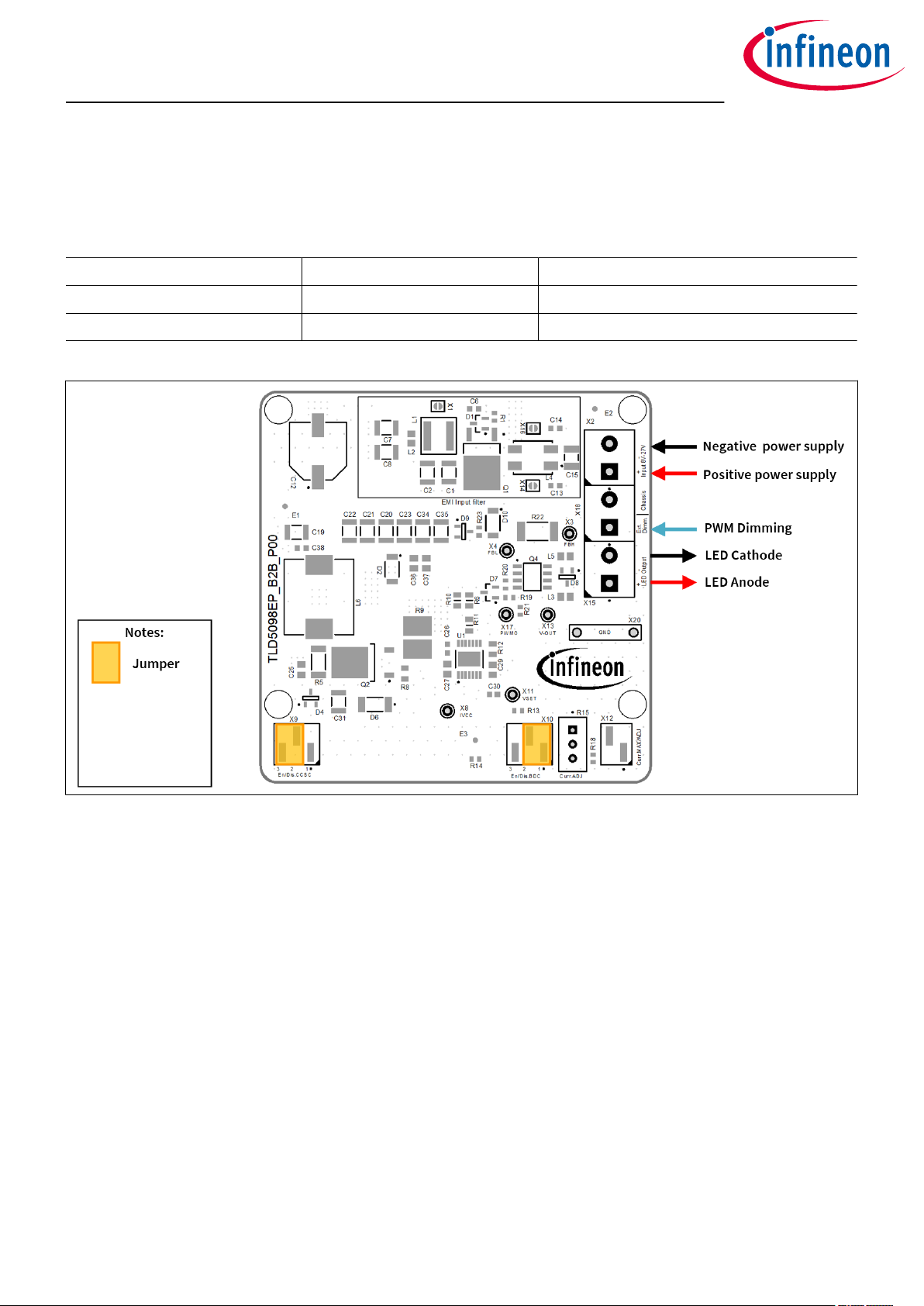

2 Quick start procedure

The default configuration of the board has all additional features disabled. In this configuration the output

current cannot be adjusted. The PWM signal has to be applied as digital signal on X18 (max. 45 V).

Jumpers are populated as follows:

Jumper number Condition Meaning

X9 Close 2-3 Disable CCSC

X10 Close 2-1 Disable battery dependent current

The default configuration is depicted below:

Figure 3 Default configuration of the board

User Manual 4

2020-09-17

Page 5

Boost to battery evaluation kit

TLD5098EP

3 Current adjustment

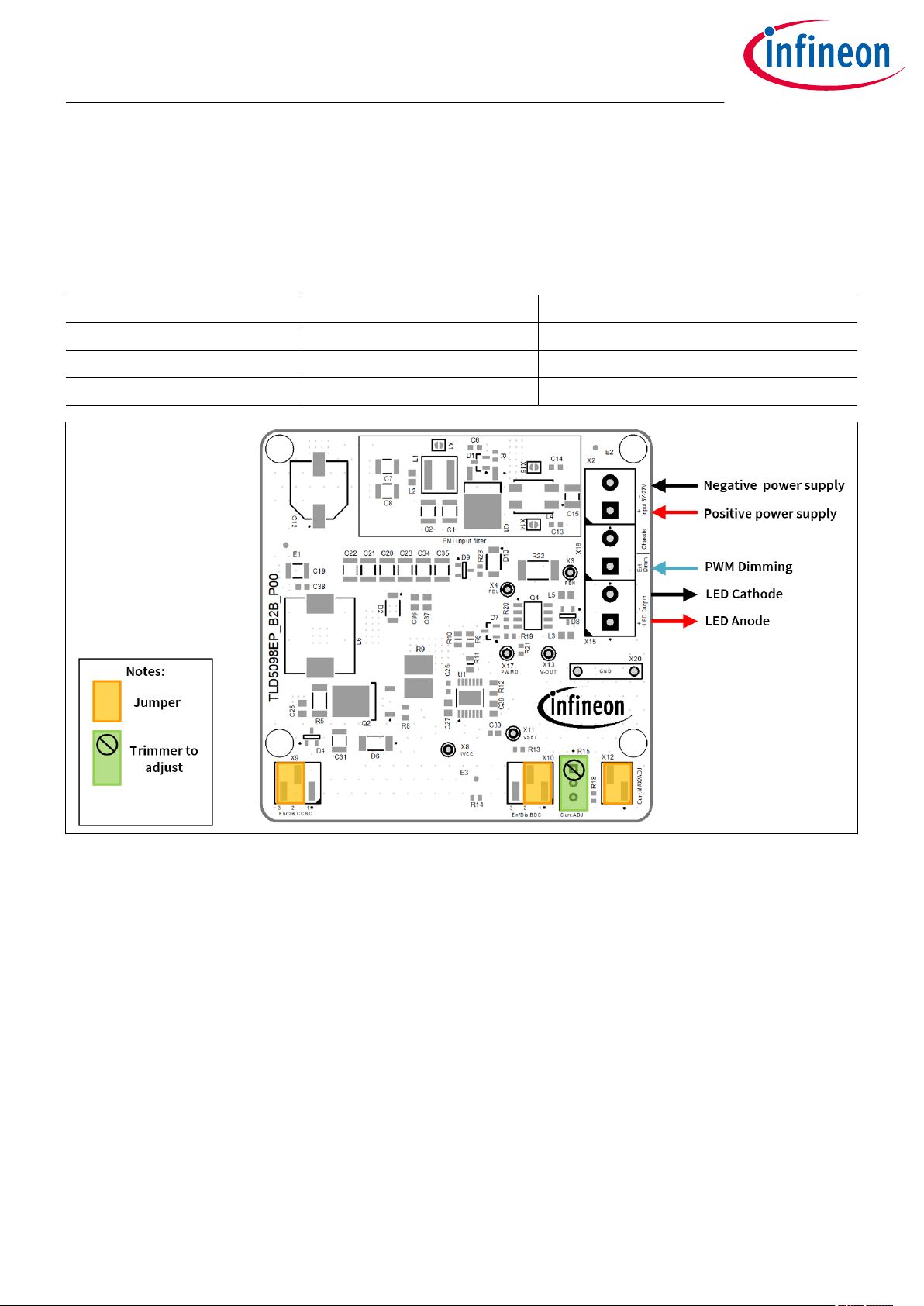

3 Current adjustment

The output current adjustment can be performed by changing the value of trimmer R15 with a screwdriver,

when X10 is closed in position 1-2 and X12 is closed. The output current can vary from 0 to 100% of the

maximum output current (in this evaluation board from 0 to 1 A). By removing the X12 jumper the output

current will reach its maximum value. The PWM signal has to be applied as digital signal on X18 (max. 45 V).

Jumpers are populated as follows:

Jumper number Condition Meaning

X9 Close 2-3 Disable CCSC

X10 Close 2-1 Disable battery dependent current

X12 Closed Adjustable output current enabled

Figure 4 Current adjustment

User Manual 5

2020-09-17

Page 6

Boost to battery evaluation kit

TLD5098EP

4 Power derating (battery dependent current)

4 Power derating (battery dependent current)

The power derating acts by reducing V

(and thus the output current) when the battery voltage drops below

SET

8 V. It works better when R15 is trimmed to its maximum value. Otherwise a dierent derating profile is applied.

If a dierent derating profile is needed, R14 has to be changed. The aim is to have 1.6 V on pin SET when the

battery voltage reaches the desired threshold, below which the output current must decrease proportionally.

R14 can be calculated using:

(1)

V

BATT

R14 = R15 + R18 ⋅

1.6

− 1

where:

• R15 = 10 kΩ

• R18 = 560 Ω

For example, if the power derating should start when the battery voltage drops under 12 V, R14 must be

replaced with a 68 kΩ 0603 resistor (please refer to the TLD5098EP datasheets for more information).

The PWM signal has to be applied as digital signal on X18 (max. 45 V).

Jumpers are populated as follows:

Jumper number Condition Meaning

X9 Close 2-3 Disable CCSC

X10 Close 2-3 Enable battery dependent current

X12 Closed Adjustable output current enabled

Figure 5 Power derating

User Manual 6

2020-09-17

Page 7

Boost to battery evaluation kit

TLD5098EP

5 Cold crank survival circuit

5 Cold crank survival circuit

This feature helps the system to survive LV124 test E11 "severe test pulse", when the input voltage drops below

4.5 V, which is the minimum input voltage for the TLD5098EP. This circuit feeds back the device with the output

voltage when the input voltage drops. To activate this feature, close X9 in position 1-2. Other settings can be le

as preferred.

Note: The CCSC uses a Zener diode to adapt the output voltage to the required voltage for the TLD5098EP, so

that it can derate the eiciency performance.

Figure 6 Cold crank survival circuit

User Manual 7

2020-09-17

Page 8

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

D D

C C

B B

A A

12/03/2020 10:27:37Date:

Sheet of

Time:

© Infineon Technologies AG 2019. All Rights Reserved.

Author: Riccardo Zuin

03-TLD5098EP_B2B_S00_Input Filter.SchDoc

Infineon Technologies AG

IFI DC ATV BP

Via Niccolo Tommaseo 65b 35131 Padova Italy

S00

Title

Size: Rev.

A3

Document Name

03-TLD5098EP_B2B_S00_Input Filter.SchDoc

Rel.

REL

Variant

TLD5098EP_B2B

[No Variations]

Approved

<Appr.>

SVN Revision: Not in version control

GND

External Dimming

12

50V

C12

220uF

GND

2 3

1

Q1

IPD90P04P4L-04

R1

10k

GND GND

Vbat_FIL

4A PI type filter. Suitable for switching frequency down to 200kHz

N.M.

50V

C6

100nF

GND GND GND

MPZ2012S101ATD25

L2

100R

1 2

X1

Solder Jumper 2 Pins

GND

V bat

Ext_Dim

GND

1 2

X14

Solder Jumper 2 Pins

1 2

X16

Solder Jumper 2 Pins

50V

C14

470pF

50V

C13

470pF

1 4

2 3

ACM70V-701-2PL-TL00

L4

700R

Chassis

50V

C1

10uF

50VC210uF

50VC710uF

50VC810uF

50V

C15

4.7uF

XAL6060-103MEB

L1

10uH

MIN Input Voltage (V bat): 8V

TYP Input Voltage (V bat): 13,2V

MAX Input Voltage (V bat): 27V

MIN Input Voltage (V bat): 6.5V (for less than 2s)

1

2

Phoenix Contact

X18

1935776

1

2

Phoenix Contact

X2

1935776

31

NC

2

BZX84C10LT1G

D1

10V

Boost to battery evaluation kit

TLD5098EP

6 Schematics

6 Schematics

Figure 7 Input filter

User Manual 8

2020-09-17

Page 9

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

D D

C C

B B

A A

12/03/2020 10:28:51Date:

Sheet of

Time:

© Infineon Technologies AG 2019. All Rights Reserved.

Author: Riccardo Zuin

04-TLD5098EP_B2B_S00_Main Power.SchDoc

Infineon Technologies AG

IFI DC ATV BP

Via Niccolo Tommaseo 65b 35131 Padova Italy

S00

Title

Size: Rev.

A3

Document Name

04-TLD5098EP_B2B_S00_Main Power.SchDoc

Rel.

REL

Variant

TLD5098EP_B2B

[No Variations]

Approved

<Appr.>

SVN Revision: Not in version control

Vbat_FIL

50V

C26

100nF

GND

16V

C27

10uF

GND

IVCC(5V)

Vbat_FIL

GND

Rfreq

VSET

1

2

X12

TSM-102-01-S-SV

123

R15

10k

GND

IVCC(5V)

CurrentAdjust

Open: MAX Current

Closed: Adj. Current

R13

22k

R18

560R

VSET

Set output continuous current

GND

C29

100nF

GND

50V

C19

10uF

GND

GND GND

12

D2

PMEG6030EP,115

50V

C20

10uF

50V

C21

10uF

50V

C22

10uF

0,1V

1,6V

PWR_Out

GND

PWMO

16-23V referred to V bat / 1A

2818R933mR

R10

1k

50V

C23

10uF

X3

5001

X4

5001

X8

5001 IVCC

FBH FBL

X11

5001

VSET

GND

CCSC

123

X9

TSM-103-01-S-SV

Vbat_FIL

(3-2) Disable CCSC

(1-2) Enable CCSC

1

2

3

X10

TSM-103-01-S-SV

Vbat_FIL

(3-2) Enable V bat depending current

(1-2) Disable V bat depending current

FBH

FBL

35V

C30

1uF

23

1

Q2

IPD22N08S2L-50

50V

C34

10uF

50V

C35

10uF

OVFB > 1,25V when V OUT > 59V

PWR_Out

R12

0R

2010R52.2R

100V

C36

100nF

GND GND

50V

C38

100nF

GND

100V

C25

1nF

31

NC

2

D4

BAS16

Vbat_FIL

50V

C31

10uF

GND

CCSC

Cold Crank Survival Circuit (CCSC)

PWR_Out

GND

100V

C37

1uF

R14

39k

R8

0R

12

ZMY10-GS08D610V

SRP1265A-470M

L6

47uH

X20

D3082-05

SWO

2

SWCS

4

IVCC

1

SGND

3

COMP

8

PWMO

5

FBH

6

FBL

7

OVFB

9

SET

10

FREQ/SYNC

11

GND

12

EN/PWMI13IN

14

EP

15

U1

TLD5098EP

Ext_Dim

R11

14k

R6

46.4k

(400kHz)

Boost to battery evaluation kit

TLD5098EP

6 Schematics

Figure 8 Main power

User Manual 9

2020-09-17

Page 10

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

D D

C C

B B

A A

15/07/2020 15:56:58Date:

Sheet of

Time:

© Infineon Technologies AG 2019. All Rights Reserved.

Author: Riccardo Zuin

05-TLD5098EP_B2B_S00_Output Stage.SchDoc

Infineon Technologies AG

IFI DC ATV BP

Via Niccolo Tommaseo 65b 35131 Padova Italy

S00

Title

Size: Rev.

A3

Document Name

05-TLD5098EP_B2B_S00_Output Stage.SchDoc

Rel.

REL

Variant

TLD5098EP_B2B

[No Variations]

Approved

<Appr.>

SVN Revision: Not in version control

PWR_Out

PWMO

2

4

1

3

7,8

5,6

Q4A

BSO615CGHUMA1

R21

10R

GND

31

NC

2

BZX84C10LT1G

D7

10V

OUT LED+ (16-23V referred to V bat / 1A)

OUT LED-

X13

5001

V OUT

X17

5001

PWMO

MPZ2012S102ATD25

L5

1kR

MPZ2012S102ATD25

L3

1kR

R23

10k

31

NC

2

D9

BAS16

31

NC

2

D8

BAS16

1 2

D10

PMEG6030EP,115

Vbat_FIL

FBH

FBL

Suggested Output: Light White LEDs

LED Type: Seoul Semi WICOP-C

Number of LEDs in series: 2-7

LED part number: SWW0CS11S

2512

R22

300mR

1

2

Phoenix Contact

X15

1935776

R20

22k

R19

27k

Boost to battery evaluation kit

TLD5098EP

6 Schematics

Figure 9 Output stage

User Manual 10

2020-09-17

Page 11

Boost to battery evaluation kit

TLD5098EP

7 PCB layout

7 PCB layout

Figure 10 PCB layout top view

Figure 11 PCB layout bottom view

User Manual 11

2020-09-17

Page 12

Boost to battery evaluation kit

TLD5098EP

8 Bill of material

8 Bill of material

Table 2 Bill of material

Designator Value Manufacturer Manufacturer order number

C1, C2, C7, C8, C19, C20,

C21, C22, C23, C31, C34,

C35

C6, C26, C38 100 nF AVX 06035C104K4Z2A

C12 220 uF Panasonic EEEFK1H221P

C13, C14 470 pF muRata GCM1885C1H471JA16

C15 4.7 uF Kemet C1210C475K5RACAUTO

C25 1 nF TDK Corporation CGA4F2X7R2A102M085AE

C27 10 uF TDK CGA4J1X7S1C106K125AC

C29, C36 100 nF TDK CGA4J2X7R2A104M125AE

C30 1 uF TDK CGA3E1X7R1V105K080AC

C37 1 uF TDK Corporation CGA4J3X7S2A105K125AB

D1, D7 10 V ON Semiconductor BZX84C10LT1G

D2, D10 PMEG6030EP,115 Nexperia PMEG6030EP,115

D4, D8, D9 BAS16 Infineon Technologies BAS16

D6 10 V Vishay ZMY10-GS08

L1 10 uH Coilcra XAL6060-103MEB

10 uF Murata GCM32EC71H106KA03

L2 100 Ω @ 100 MHz TDK Corporation MPZ2012S101ATD25

L3, L5 1 kΩ @ 100 MHz TDK MPZ2012S102ATD25

L4 TDK ACM70V-701-2PL-TL00

L6 47 uH Bourns SRP1265A-470M

Q1 IPD90P04P4L-04 Infineon Technologies IPD90P04P4L-04

Q2 IPD22N08S2L-50 Infineon Technologies IPD22N08S2L-50

Q4 BSO615CGHUMA1 Infineon Technologies BSO615CGHUMA1

R1, R23 10 kΩ Vishay CRCW060310K0FK

R5 2.2 Ω Vishay CRCW20102R20FK

R6 46.4 kΩ Vishay CRCW080546K4FK

R8, R12 0 Ω Yageo AC0805JR-070RL

R9 33 mΩ Vishay WSHM2818R0330FEA

R10 1 kΩ Vishay CRCW08051K00FK

R11 14 kΩ Vishay CRCW080514K0FK

R13, R20 22 kΩ Vishay CRCW060322K0FK

R14 39 kΩ Vishay CRCW060339K0FK

R15 10 kΩ Vishay T93YA103KT20

R18 560 Ω Vishay CRCW0603560RFK

User Manual 12

2020-09-17

Page 13

Boost to battery evaluation kit

TLD5098EP

8 Bill of material

Table 2 Bill of material (continued)

Designator Value Manufacturer Manufacturer order number

R19 27 kΩ Vishay CRCW060327K0FK

R21 10 Ω Vishay CRCW060310R0FK

R22 300 mΩ Vishay WSL2512R3000FEA

U1 TLD5098EP Infineon Technologies TLD5098EP

X1, X14, X16 Solder Jumper 2

Pins

X2, X15, X18 1935776 Phoenix Contact 1935776

X3, X4, X8, X11, X13, X17 5001 Keystone 5001

X9, X10 TSM-103-01-S-SV Samtec TSM-103-01-S-SV

X12 TSM-102-01-S-SV Samtec TSM-102-01-S-SV

X20 D3082-05 Harwin D3082-05

Solder Jumper 2 Pins

User Manual 13

2020-09-17

Page 14

Boost to battery evaluation kit

TLD5098EP

9 Eiciency measurements

9 Eiciency measurements

Figure 12 Eiciency vs. input voltage

This eiciency performance has been obtained with:

Table 3 Parameters influencing eiciency

Output load: Series of 7 white standard LEDs with VJ ~ 3 V kept cooled with forced air

EMI filter: Totally bypassed by closing the jumpers X1, X14 and X16

CCSC: O (jumper X9 closed on 2-3)

Current adjustment: O (jumper X12 le open)

Dimming: 100% D.C.

Power derating: O (jumper X10 closed on 1-2)

Eiciency performances can be increased, see Chapter 11.

User Manual 14

2020-09-17

Page 15

Boost to battery evaluation kit

TLD5098EP

10 Maximizing eiciency

10 Maximizing eiciency

This evaluation board has been designed to reach a fair compromise between eiciency performance and EM

emissions compliance.

Nevertheless, if the maximum eiciency is needed, the following actions should be considered:

1. Remove the snubber circuit consisting of R5 and C25, or choose a lower value for the capacitor C25 (for

example 470 pF)

2. Bypass the whole EMI filter by bridging the jumpers X1, X14 and X16

3. Bypass the output ferrite beads L3 and L5

4. Replace the main inductor L6 with one that boasts a lower parasitic DC resistance, for example

• Vishay IHLP6767GZER470M8A

• Bourns SRP1770TA-470M

5. Turn o the CCSC by placing the jumper X9 on position 2-3

User Manual 15

2020-09-17

Page 16

Boost to battery evaluation kit

TLD5098EP

11 Minimizing EM emissions

11 Minimizing EM emissions

This evaluation board has been designed to reach a fair compromise between eiciency performance and

conducted EM emissions compliance from 150 kHz to 108 MHz.

Nevertheless, if the minimum EM emission is required, the following actions should be considered:

1. Choose a higher value for the capacitor C25 (for example 2.2 nF)

2. Include the whole EMI filter by removing bridges from the jumpers X1, X14 and X16

3. Replace the 0 Ω resistor R8 with a small value such as 10 Ω or 22 Ω

4. Replace the main inductor L6 with a shielded one (for example Cyntec VCHE106G-470MS6) and connect

the shield to ground

5. Connect the CHASSIS terminal with a short piece of wire as close as possible to the test ground plane

where the board is placed

User Manual 16

2020-09-17

Page 17

Boost to battery evaluation kit

TLD5098EP

12 Revision history

12 Revision history

Document

version

Rev. 1.00 2020-09-17 First release related to evalboard S00_P00

Date of release Description of changes

User Manual 17

2020-09-17

Page 18

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2020-09-17

Published by

Infineon Technologies AG

81726 Munich, Germany

©

2020 Infineon Technologies AG

All Rights Reserved.

Do you have a question about any

aspect of this document?

Email: erratum@infineon.com

Document reference

IFX-dih1595234916088

IMPORTANT NOTICE

The information contained in this application note is

given as a hint for the implementation of the product

only and shall in no event be regarded as a description

or warranty of a certain functionality, condition

or quality of the product. Before implementation

of the product, the recipient of this application

note must verify any function and other technical

information given herein in the real application.

Infineon Technologies hereby disclaims any and all

warranties and liabilities of any kind (including without

limitation warranties of non-infringement of intellectual

property rights of any third party) with respect to any

and all information given in this application note.

The data contained in this document is exclusively

intended for technically trained sta. It is the

responsibility of customer’s technical departments to

evaluate the suitability of the product for the intended

application and the completeness of the product

information given in this document with respect to such

application.

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies oice.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon Technologies,

Infineon Technologies’ products may not be used in

any applications where a failure of the product or

any consequences of the use thereof can reasonably

be expected to result in personal injury.

Loading...

Loading...