Page 1

User Manual Please read the Important Notice and Warnings at the end of this document Rev.1.00

www.infineon.com page 1 of 14 2020-12-03

Z8F80036493

TLD2252-2EP rear combination lamp evaluation

board

User Manual

About this document

Scope and purpose

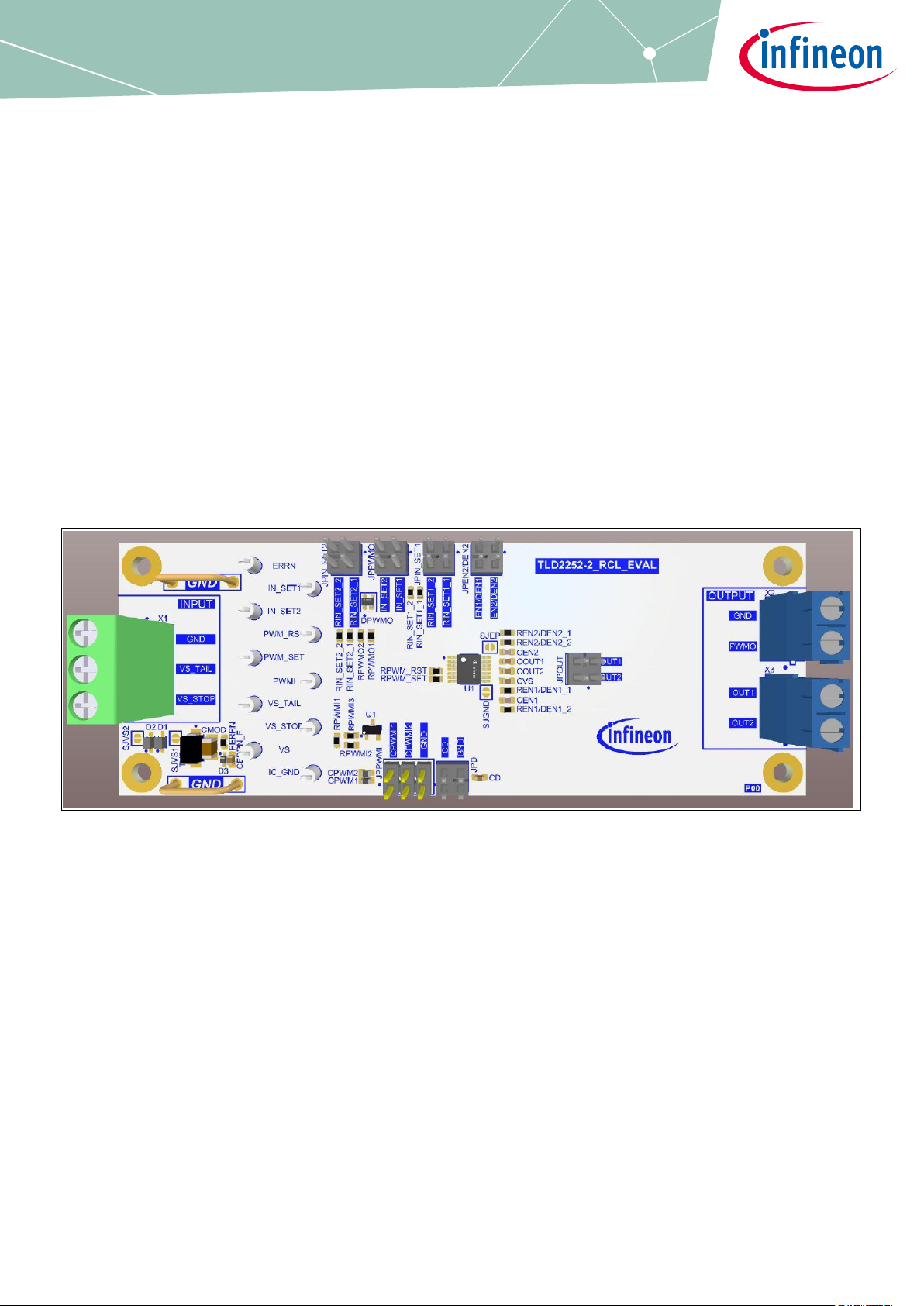

The purpose of the TLD2252-2EP rear combination lamp evaluation board (TLD2252-2_RCL_EVAL) board is to

help designers evaluate the features and the performance of the TLD2252-2EP, a two-channel linear current

source LED driver for automotive LED lighting applications. TLD2252-2EP provides a simple and compact

solution for the implementation of a rear combination lamp (RCL).

This user manual provides the usage instructions of the TLD2252-2 _RCL_ EVAL board (schematic version S00,

PCB version P00).

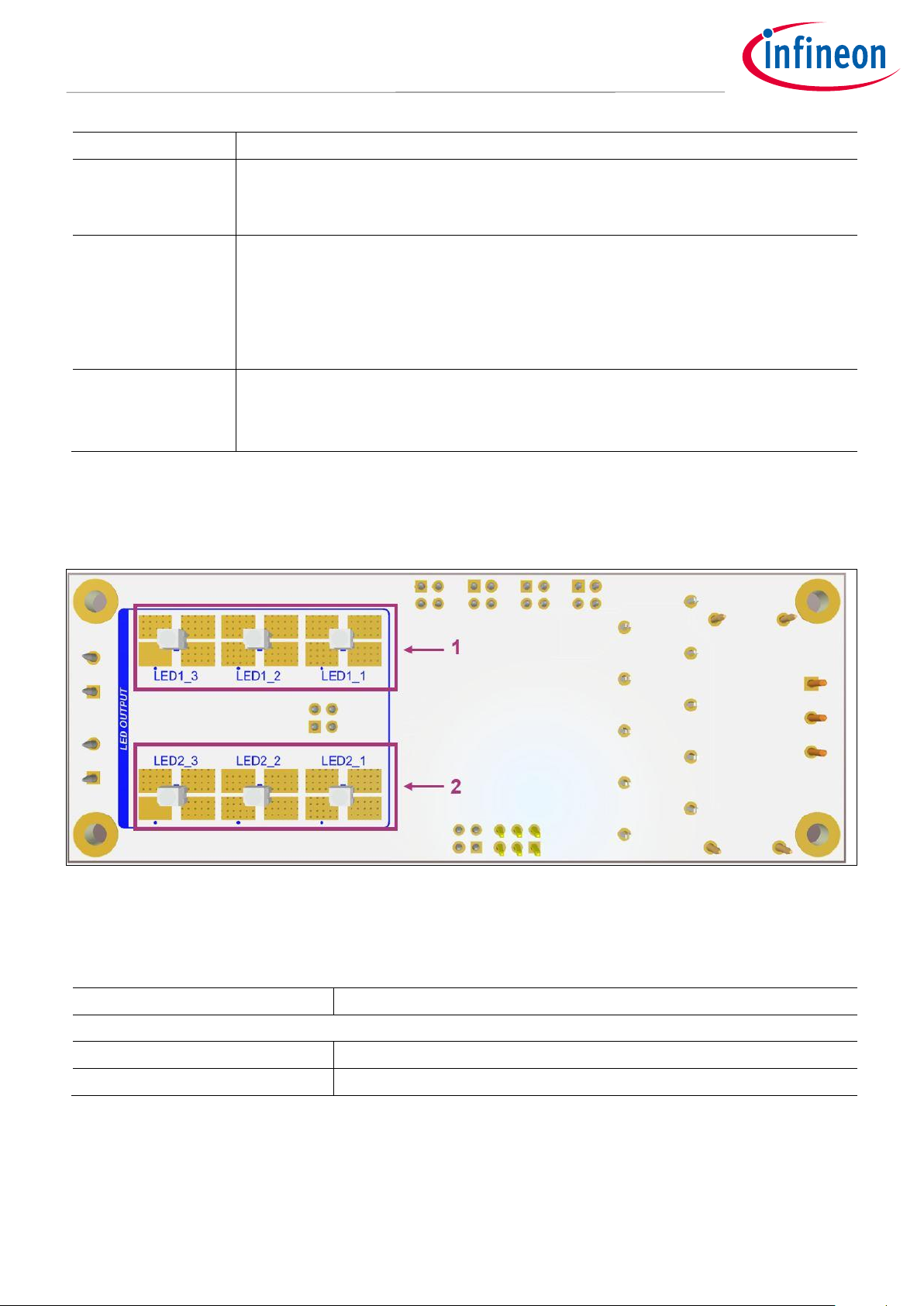

Figure 1 TLD2252-2_RCL_EVAL board

Intended audience

Hardware engineers, system architects.

Page 2

User Manual 2 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

TLD2252-2_RCL_EVAL description

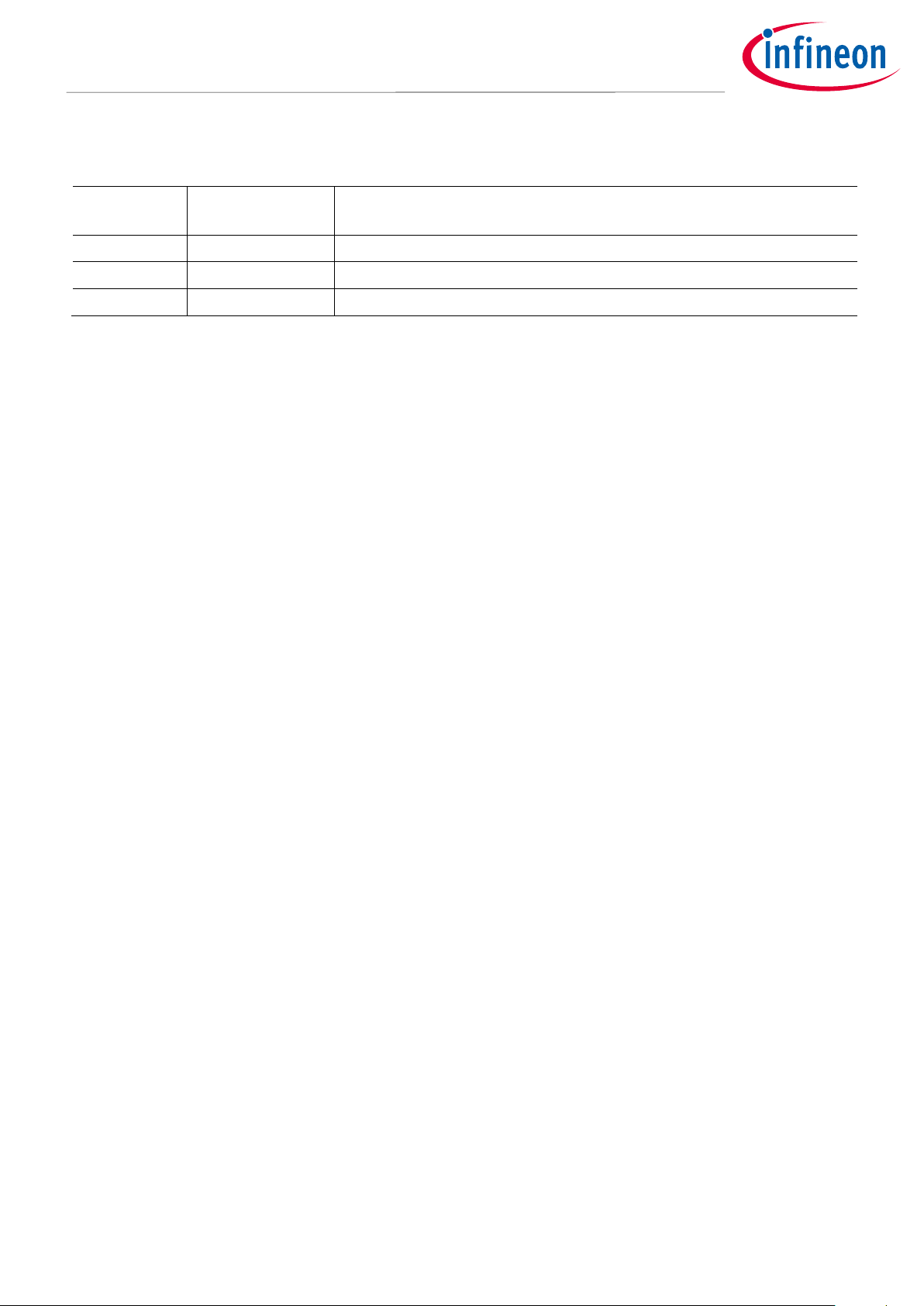

Related information

Table 1 Supplementary links and document references

Reference

Description

LITIX™ Basic+ TLD2252-2EP

product home page

Product website which contains reference information for the LITIX™ Basic+

TLD2252-2EP including datasheet, application notes, simulation models,

boards and relevant training

LITIX™ Basic+ family website

All information about LITIX™ Basic+ family products

LITIX™ Basic+ LED driver

family: How to implement a

rear combination lamp

Application note regarding the main operating principles of the pulse width

modulation (PWM) engine integrated into the LITIX™ Basic+ TLD2252-2EP,

TLD2141-3EP and TLD2142-1EP, and how to build a rear combination lamp

(RCL) using PWM

LITIX™ Basic+ LED driver

family: Diagnosis and fault

management

Application note regarding the main operating principles of the diagnosis

and fault management features integrated in the LITIX™ Basic+ family.

LITIX™ Basic+ Boards

Available evaluation boards for LITIX™ Basic+

LED rear lighting - application

page

Application website for rear LED lighting

Table of contents

About this document ......................................................................................................................... 1

Table of contents .............................................................................................................................. 2

1 TLD2252-2_RCL_EVAL description .............................................................................................. 3

1.1 Key features ............................................................................................................................................. 3

1.2 Connectors and jumpers ......................................................................................................................... 4

1.3 On-board load ......................................................................................................................................... 5

1.4 Test points ............................................................................................................................................... 6

2 Quick start ............................................................................................................................... 7

3 Schematics, layout and bill of material ...................................................................................... 8

3.1 Schematics .............................................................................................................................................. 8

3.2 Layout .................................................................................................................................................... 10

3.3 Bill of materials ...................................................................................................................................... 11

3.4 PCB design data .................................................................................................................................... 12

Revision history ...............................................................................................................................13

Page 3

User Manual 3 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

TLD2252-2_RCL_EVAL description

1 TLD2252-2_RCL_EVAL description

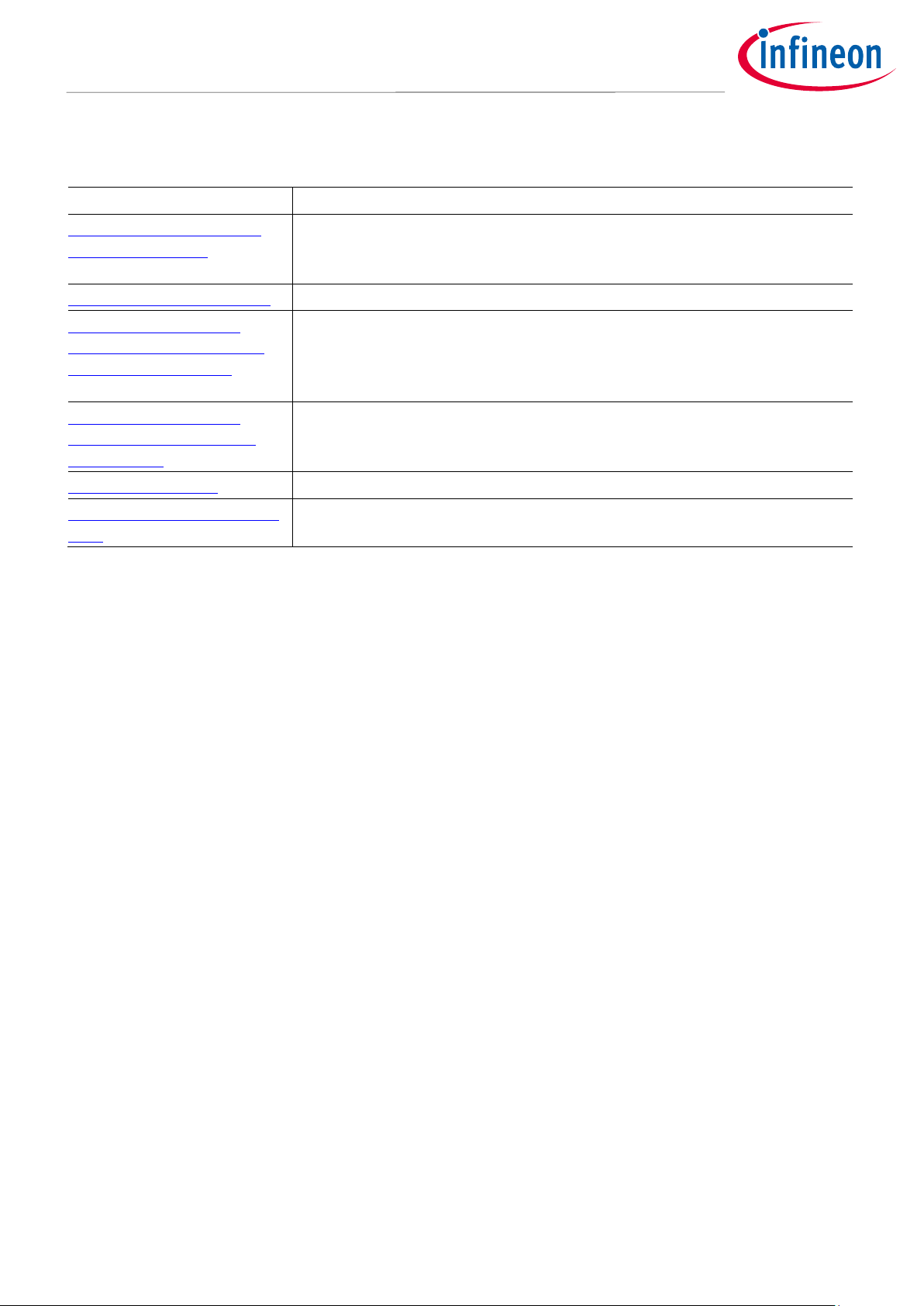

The TLD2252-2_RCL_EVAL is an evaluation board equipped with one LITIX™ Basic+ TLD2252-2EP and on-board

LEDs for easy evaluation of an RCL application when realized with use of the TLD2252-2EP pulse width

modulation (PWM) engine.

The board can be used within the typical automotive voltage range, 8 V to 16 V. It gives the user the freedom to

evaluate all of the TLD2252-2EP features and possible configurations by setting the necessary jumpers

accordingly.

As the PWM-engine of LITIX™ Basic+ TLD2252-2EP can be used to drive other LITIX™ Basic+ devices, the

TLD2252-2_RCL_EVAL board can be used in combination with the BASICPLUS_DEMOBOARD for combined

family evaluation.

Figure 2 Rear combination lamp implemented with LITIX™ Basic+ TLD2252-2EP

1.1 Key features

The TLD2252-2_RCL_EVAL has the following features:

1. Equipped with one LITIX™ Basic+ TLD2252-2EP

2. Typical supply voltage range 8 V to 16 V

3. Equipped with jumpers for evaluation of the features in different configurations (e.g. PWM-engine)

4. On-board LED load, 3 LEDs per output channel

5. Possibility to connect external load

6. Possibility to drive other LITIX™ Basic+ devices with PWM-signal, in combination with

BASICPLUS_DEMOBOARD

7. 11.4 cm x 4.2 cm 2-layer PCB

OUT1

OUT2

TLD2252-2EP

VS

D

EN/DEN1

ERRN

IN_SET1

C

VS

*

C

D

R

SET1

R

EN/DEN2

V

STOP

R

EN/DEN1

R

ERRN

* For EMI improvement,

if required (e.g. 4,7 or 10nF)

PWMO

PWM_SET

GND

R

PWM_SET

R

PWM_RST

PWM_RST

PWMI

C

PWMI

V

TAIL

EN/DEN2

IN_SET2

Supply

Protection

R

SET2

R

EN/DEN2_2

R

EN/DEN1_2

C

OUT

*

C

OUT

*

R

PWMO

Page 4

User Manual 4 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

TLD2252-2_RCL_EVAL description

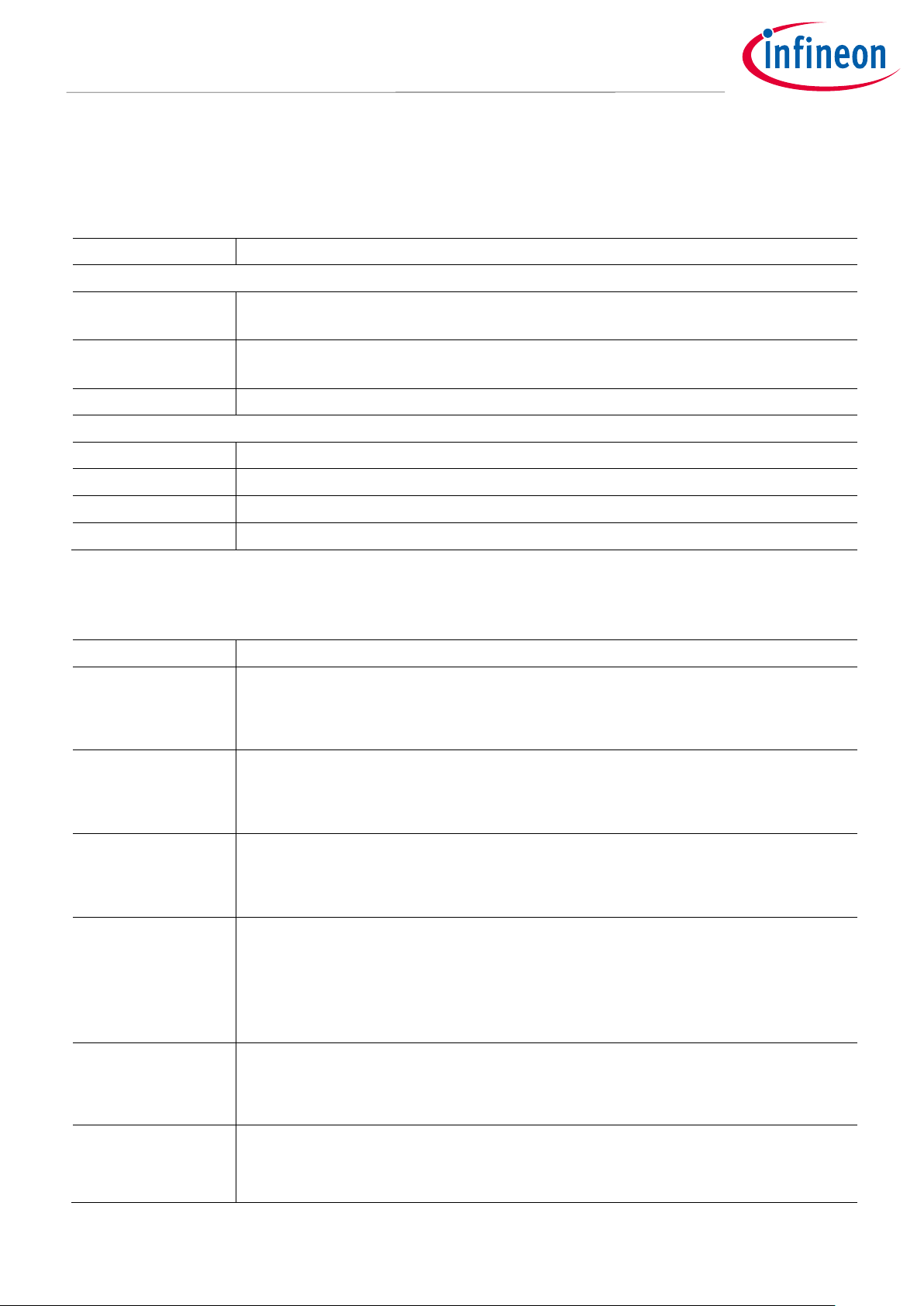

1.2 Connectors and jumpers

The TLD2252-2_RCL_EVAL board connectors are described in Table 2.

Table 2 TLD2252-2_RCL_EVAL connectors

Connector

Description

INPUT

VS_STOP

Power supply, typical 8 V to 16 V, and deactivation of the internal PWM engine of the

LITIX™ Basic+ TLD2252-2EP

VS_TAIL

Power supply, typical 8 V to 16 V, and activation of the internal PWM engine of the

LITIX™ Basic+ TLD2252-2EP

GND

Ground

OUTPUT

GND

Ground

PWMO

LITIX™ Basic+ TLD2252-2EP PWM signal to drive other LITIX™ Basic devices

OUT1

External load for output channel 1, OUT1

OUT2

External load for output channel 2, OUT2

The TLD2252-2_RCL_EVAL board jumpers are described in Table 3.

Table 3 TLD2252-2_RCL_EVAL board jumpers

Jumper

Description and configuration

JPN_SET1

Sets the output current of OUT1:

• RIN_SET1_1 (36.5 kΩ): sets the output current to 10 mA

• RIN_SET1_2 (7.32 kΩ): sets the output current to 50 mA

JPPWMO

PWM output enable:

• IN_SET1: enables PWM at OUT1

• IN_SET2: enables PWM at OUT2

JPN_SET2

Sets the output current of OUT2:

• RIN_SET2_1 (14.7 kΩ): sets the output current to 50 mA

• RIN_SET2_2 (7.32 kΩ): sets the output current to 100 mA

JPEN2/DEN2

Activate the device and diagnosis for OUT2:

• EN1/DEN1: use the resistor divider on EN1/DEN1 (REN1/DEN1_1) to activate OUT2

• EN2/DEN2: use separate resistor divider EN1/DEN1 (REN1/DEN1_1) to activate

OUT2. During tail function (board supplied via VS_TAIL), place jumper on

EN1/DEN1 position

JPOUT

On board load connection

• OUT1: connects OUT1 to on-board load

• OUT2: connects OUT2 to on-board load

JPD

Diagnosis management

• GND: when a fault is detected only the channel under fault condition will be

deactivated. The error will be communicated via ERRN

Page 5

User Manual 5 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

TLD2252-2_RCL_EVAL description

Jumper

Description and configuration

• Open: when a fault is detected both channels will switch off

• CD: when a fault is detected both channels will switch off after a delay time t

D(set)

.

Delay time is set by CD capacitor

JPPWMI

PWMI connection

• CPWMI1 (120 nF): sets the PWM frequency to 220 Hz and duty cycle 10%

• CPWMI2 (68 nF): sets the PWM frequency to 400 Hz and duty cycle 10%

• GND: duty cycle is 100%

The duty cycle is set by the RPWM_SET (4.53 kΩ) and RPWM_RST (41.2 kΩ) resistors

JPOUT

On board load connection

• OUT1: connects OUT1 to on-board load. Leave open to connect to external load

• OUT2: connects OUT2 to on-board load. Leave open to connect to external load

1.3 On-board load

The TLD2252-2_RCL_EVAL board is equipped with on-board LED load (on the bottom side) for easy evaluation.

Figure 3 On-board LED load

The on-board LED load shown in Figure 3 is described in Table 4.

Table 4 On-board LED load

Load

Description

LED OUTPUT

Load 1

3 x 1 LEDs in series; used when OUT1 of JPOUT is bypassed

Load 2

3 x 1 LEDs in series; used when OUT2 of JPOUT is bypassed

Page 6

User Manual 6 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

TLD2252-2_RCL_EVAL description

1.4 Test points

The TLD2252-2_RCL_EVAL board is equipped with several test points and two ground terminals for easy

monitoring of significant voltages, Figure 4.

Figure 4 Test points and ground terminals

Page 7

User Manual 7 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

Quick start

2 Quick start

• Connect a voltage source to VS_TAIL or VS_STOP and GND, typical 8 V to 16 V

• Select the output current by placing jumpers at JPN_SET1 and JPN_SET2

• Configure the diagnosis management at JPD

• Select if PWM will be used by placing a jumper at JPPWMI (only available when suppy at VS_TAIL)

• Select the output channels that will driven by the PWM engine by placing a jumper at JPPWMO (only

available when suppy at VS_TAIL)

• Enable output channel 2 by placing a jumper at JPEN/DEN2 (when suppy at VS_TAIL, bypass EN1/DEN1)

• Select load by bypassing OUT1 and OUT2 of JPOUT in order to use the on-board LED load

Page 8

User Manual 8 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

Schematics, layout and bill of material

3 Schematics, layout and bill of material

For the calculation of the external components required for the LITIX™ Basic+ TLD2252-2EP and used on the

TLD2252-2_RCL_EVAL board refer to the following documentation:

• LITIX™ Basic+ TLD2252-2EP data sheet

• LITIX™ Basic+ LED driver family: How to implement a rear combination lamp

• LITIX™ Basic+ LED driver family: Diagnosis and fault management

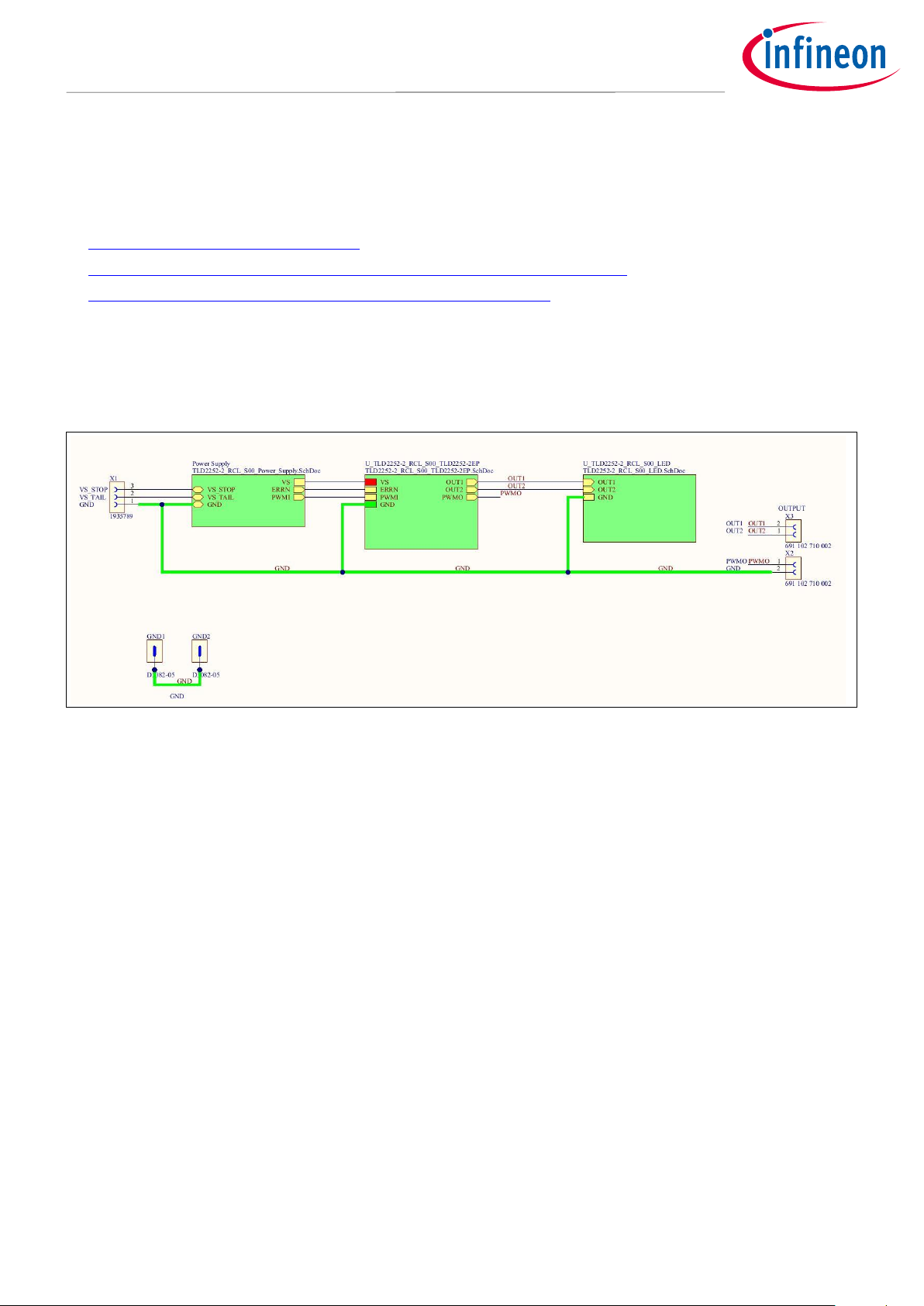

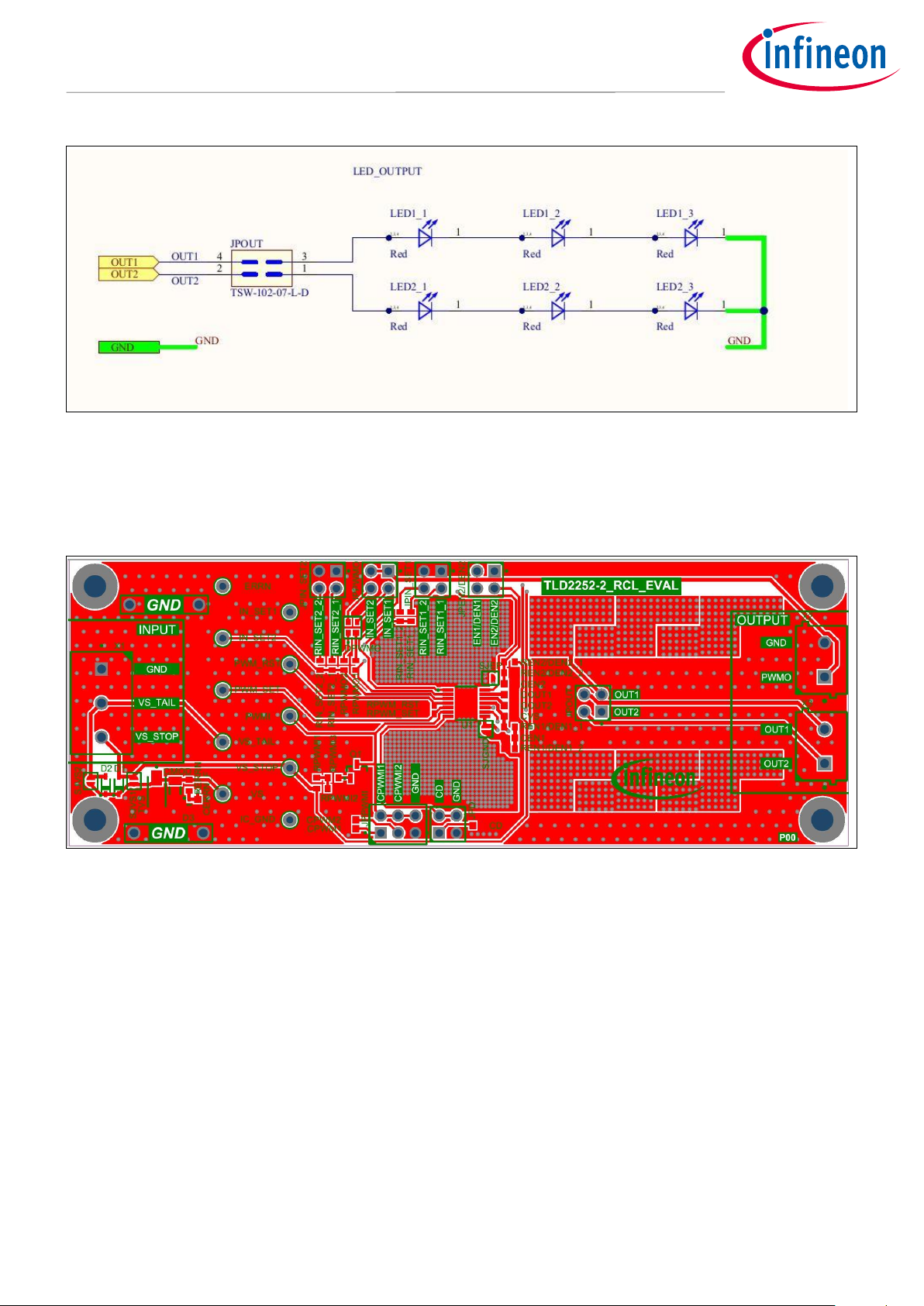

3.1 Schematics

In Figure 5, the top-level schematic of the TLD2252-2_RCL_EVAL board is shown. Figure 6, Figure 7 and Figure 8

show the schematic of the power supply circuit, the TLD2252-2EP and the on-board LED load respectively.

Figure 5 Schematic of TLD2252-2_RCL_EVAL board – top level

Page 9

User Manual 9 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

Schematics, layout and bill of material

Figure 6 Schematic of TLD2252-2_RCL_EVAL board – power supply

Figure 7 Schematic of TLD2252-2_RCL_EVAL board – TLD2252-2EP

Page 10

User Manual 10 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

Schematics, layout and bill of material

Figure 8 Schematic of TLD2252-2_RCL_EVAL board – on-board LED load

3.2 Layout

Figure 9 and Figure 10 show the layout of the TLD2252-2_RCL_EVAL board.

Figure 9 Layout of TLD2252-2_RCL_EVAL board – top layer

Page 11

User Manual 11 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

Schematics, layout and bill of material

Figure 10 Layout of TLD2252-2_RCL_EVAL board – bottom layer

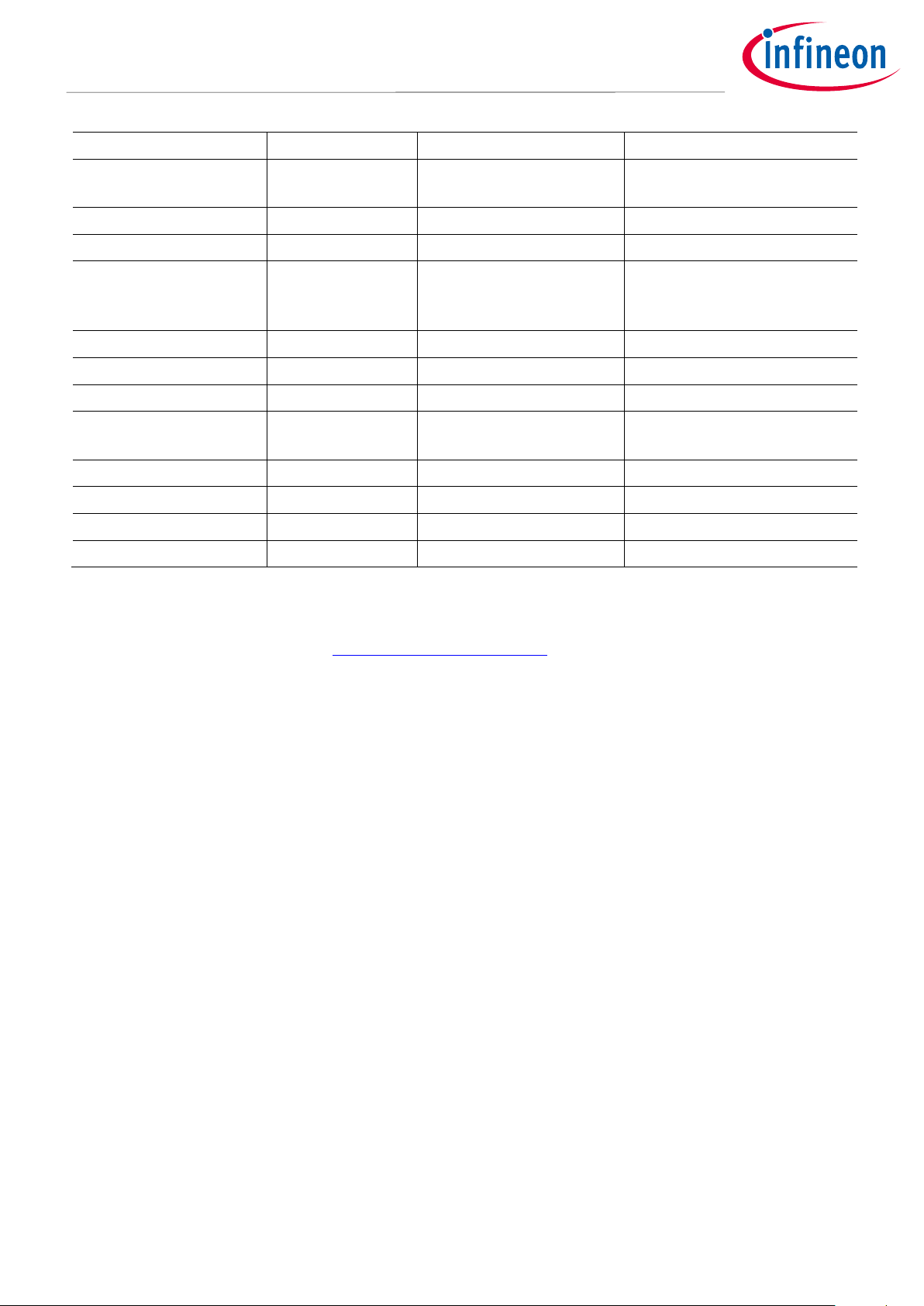

3.3 Bill of materials

Table 5 shows theTLD2252-2_RCL_EVAL board bill of material.

Table 5 Bill of material

Designator

Value

Manufacturer

Manufacturer order number

CD, CERRN_F, COUT1,

COUT2, CVS

10 nF

AVX

06035F103K4Z2A

CEN1, CEN2

10 nF

MuRata

GCM188R71H103JA37

CMOD

2.2 μF

MuRata

GRM31CR71H225KA88

CPWM1

120 nF

Kemet

C0603C124K4RACTU

CPWM2

68nF

Kemet

C0603C683M4RACTU

D1, D2

BAT165

Infineon Technologies AG

BAT165

D3

5.60V

Vishay

BZX584C5V6-V-G

DPWMO

BAS40-07W

Infineon Technologies AG

BAS40-07W

ERRN, IC_GND, IN_SET1,

IN_SET2, PWM_RST,

PWM_SET, PWMI, VS,

VS_STOP, VS_TAIL

5002

Keystone Electronics

Corp.

5002

GND1, GND2

D3082-05

Harwin

D3082-05

JPD, JPEN2/DEN2,

JPIN_SET1, JPIN_SET2,

JPOUT, JPPWMO

TSW-102-07-L-D

Samtec

TSW-102-07-L-D

JPPWMI

TSW-103-08-G-D

Samtec

TSW-103-08-G-D

LED1_1, LED1_2, LED1_3,

LED2_1, LED2_2, LED2_3

Red

OSRAM Opto

Semiconductors

Q65110A4135

Q1

BC846ALT1G

ON Semiconductor

BC846ALT1G

REN1/DEN1_1,

REN2/DEN2_1, RPWMI1,

RPWMI3

10k

Yageo

RC0603FR-0710KL

Page 12

User Manual 12 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

Schematics, layout and bill of material

Designator

Value

Manufacturer

Manufacturer order number

REN1/DEN1_2,

REN2/DEN2_2, RPWMI2

3.6k

Yageo

AC0603FR-073K6L

RERRN

20k

Yageo

AC0603JR-0720KL

RIN_SET1_1

36.5k

Vishay

CRCW060336K5FK

RIN_SET1_2,

RIN_SET2_2, RPWMO1,

RPWMO2

7.32k

Vishay

CRCW06037K32FK

RIN_SET2_1

14.7k

Vishay

CRCW060314K7FK

RPWM_RST

41.2k

Vishay

CRCW060341K2FK

RPWM_SET

4.53k

Vishay

CRCW06034K53FK

SJEP, SJGND, SJVS1,

SJVS2

Solder Jumper 2

Pins

Infineon Technologies AG

Solder Jumper 2 Pins

TVS

SMAJ30CA

Littelfuse

SMAJ30CA

U1

TLD2252-2EP

Infineon Technologies AG

TLD2252-2EP

X1

1935789

Phoenix Contact

1935789

X2, X3

691 102 710 002

Wurth Elektronik

691 102 710 002

3.4 PCB design data

The Altium project is available on the TLD2252-2_RCL_EVAL website.

Page 13

User Manual 13 of 14 Rev.1.00

2020-12-03

TLD2252-2EP rear combination lamp evaluation board

User Manual

Revision history

Revision history

Document

version

Date of release

Description of changes

Rev.1.00

2020-12-03

Initial release

Page 14

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2020-12-03

Z8F80036493

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2020 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

IMPORTANT NOTICE

The information contained in this application note is

given as a hint for the implementation of the product

only and shall in no event be regarded as a

description or warranty of a certain functionality,

condition or quality of the product. Before

implementation of the product, the recipient of this

application note must verify any function and other

technical information given herein in the real

application. Infineon Technologies hereby disclaims

any and all warranties and liabilities of any kind

(including without limitation warranties of noninfringement of intellectual property rights of any

third party) with respect to any and all information

given in this application note.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments

to evaluate the suitability of the product for the

intended application and the completeness of the

product information given in this document with

respect to such application.

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of the

product or any consequences of the use thereof can

reasonably be expected to result in personal injury.

Loading...

Loading...