现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

Jens Eju

ry July 13, 2006 San Jose, CA

Data Sheet

High-Performance DrMOS

6mm x 6mm x 0.8mm IQFN

TDA21211- Data Sheet

August - 2009

Published by Infineon Technologies AG

http://www.infineon.com/DCDC

Power Management & Drive

Data Sheet

Never stop thinking

.

Page 1 of 20

TDA21211

6x6 QFN High-Performance DrMOS

Features:

• Intel compliant DrMOS, Power MOSFET and

Driver in one package

• For Synchronous Buck - step down voltage

applications

• Maximum Average Current of 35A

• Wide input voltage range +5V to +30V

• Low power dissipation

• Extremely fast switching technology for

improved performance at high switching

frequencies (>1MHz)

• Remote Driver Disable function

Type Package Marking

6x6x0.8mm3

TDA21211

PG-IQFN-40-1

TDA21211

• Switching Modulation (SMOD#) of low side

MOS

• Includes active PMOS structure as integrated

bootstrap circuit for reduced part count

• Shoot through protection

• +5V High and Low Side Driving voltage

• Compatible to standard PWM controller ICs with

+3.3 and 5V logic

• Three-State PWM input functionality

• Small Package: IQFN40 (6 x 6 x 0.8 mm3)

• RoHS Compliant

Applications:

• Desktop and Server

VR11.X and VR12 Vcore

and non-Vcore buckconverters

• Network and Telecom

processor VR

• Single Phase and MultiPhase POL

• CPU/GPU Regulation in

Notebook, Graphics Cards,

and Gaming

• Voltage Modules requiring

high power density

• Memory (DDR2/3)

Data Sheet

Page 2 of 20

TDA21211

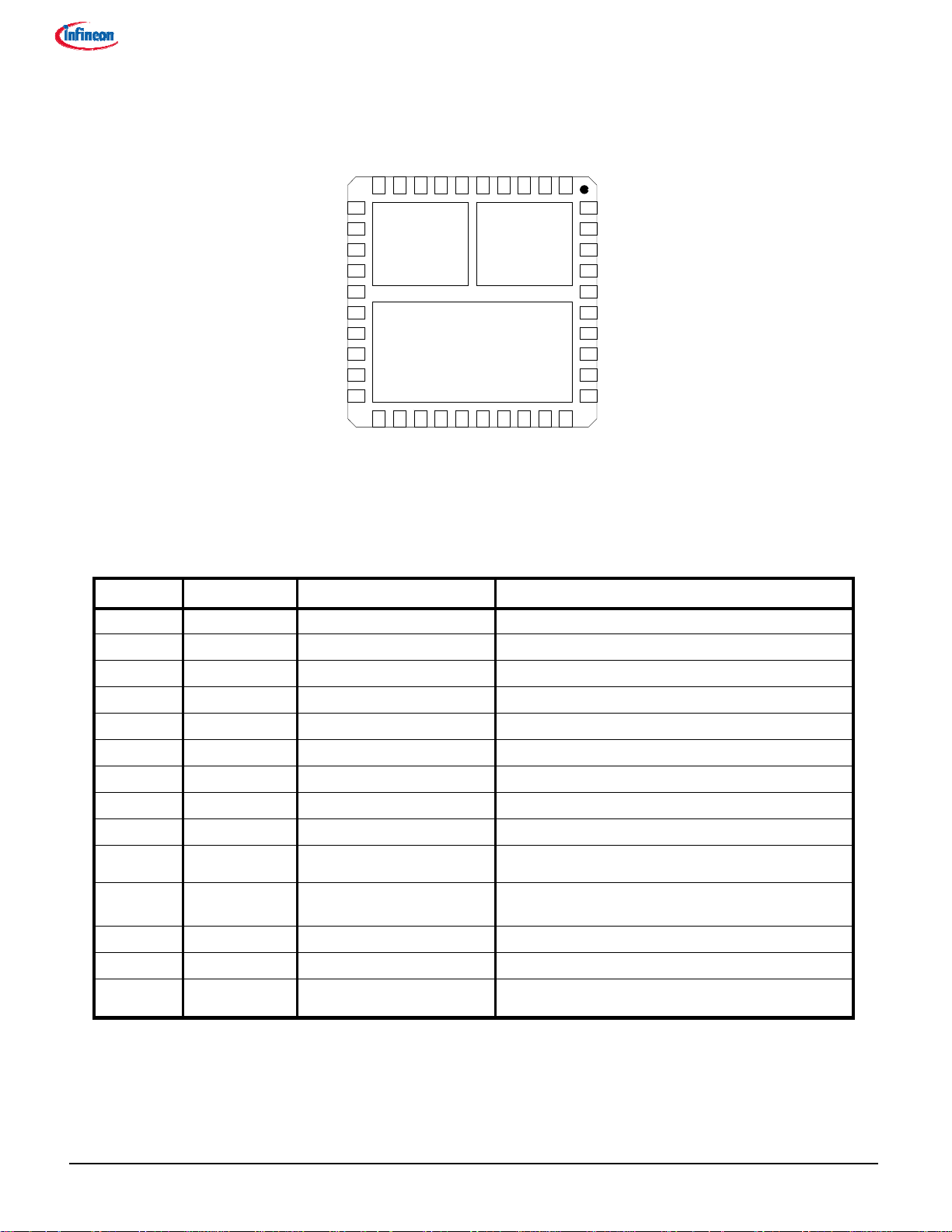

Pinout

VIN

VIN

VIN

VIN

VIN

VIN

VIN

VIN

VSWH

VSWH

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

VIN

VIN

VIN

VIN

11

12

13

14

15

16

17

18

19

20

22 23 24 25 26 27

21

PGND

PGND

PGND

PGND

8910

VIN

NC

NC

PGND

PGND

PHASE

PHASE

7

VSWH

PGND

PGND

6

GH

GH

PGND

PGND

CGND

CGND

PGND

PGND

BOOT

BOOT

VDRV

VDRV

CGND

28

PGND

PGND

PGND

PGND

SMOD#

SMOD#

VCIN

VCIN

12345

PWM

PWM

40

39

DISB#

DISB#

38

NC

NC

37

CGND

CGND

36

GL

GL

35

VSWH

VSWH

VSWH

34

VSWH

33

VSWH

VSWH

32

VSWH

VSWH

31

VSWH

VSWH

29

30

VSWH

VSWH

VSWH

VSWH

Note:

Signals marked

with "#" at the

end are active

low signals.

Figure 1. Pinout, numbering and name of pins (Transparent Top View)

Pin Description

Pin Name Pin No. Description Remarks

CGND 5, 37,CGND Pad Control signal ground Should be connected to PGND externally

SMOD# 1 Low side gate disable pin when SMOD# is “low” the GL is OFF

VCIN 2 Logic supply voltage 5V bias voltage for the internal logic.

VDRV 3 FET gate supply voltage High & Low Side gate drive 5V

BOOT 4 Bootstrap voltage pin Connect to boot capacitor

GH 6 High side gate signal

PHASE 7 Switch node output Internally connected to VSWH pin

NC 8, 38 No connect Can be connected to any potential

VIN

VSWH

9 to 14, Vin Pad

15, 29 to 35,

Input Voltage connection to the drain of the HS FET

Switch node output high current output switch node

VSWH Pad

PGND

16 to 28

Power ground

GL 36 Low side gate signal

DISB# 39 Disable Signal (active low) pull to GND to disable the IC

PWM 40 PWM drive logic input

pin for monitoring gate of HS FET

All of these pins must be connected to the power GND plane

through multiple, low inductance vias.

pin for monitoring gate of LS FET

the three-state PWM input is compatible with 3.3V and 5V

logic

Data Sheet

Page 3 of 20

TDA21211

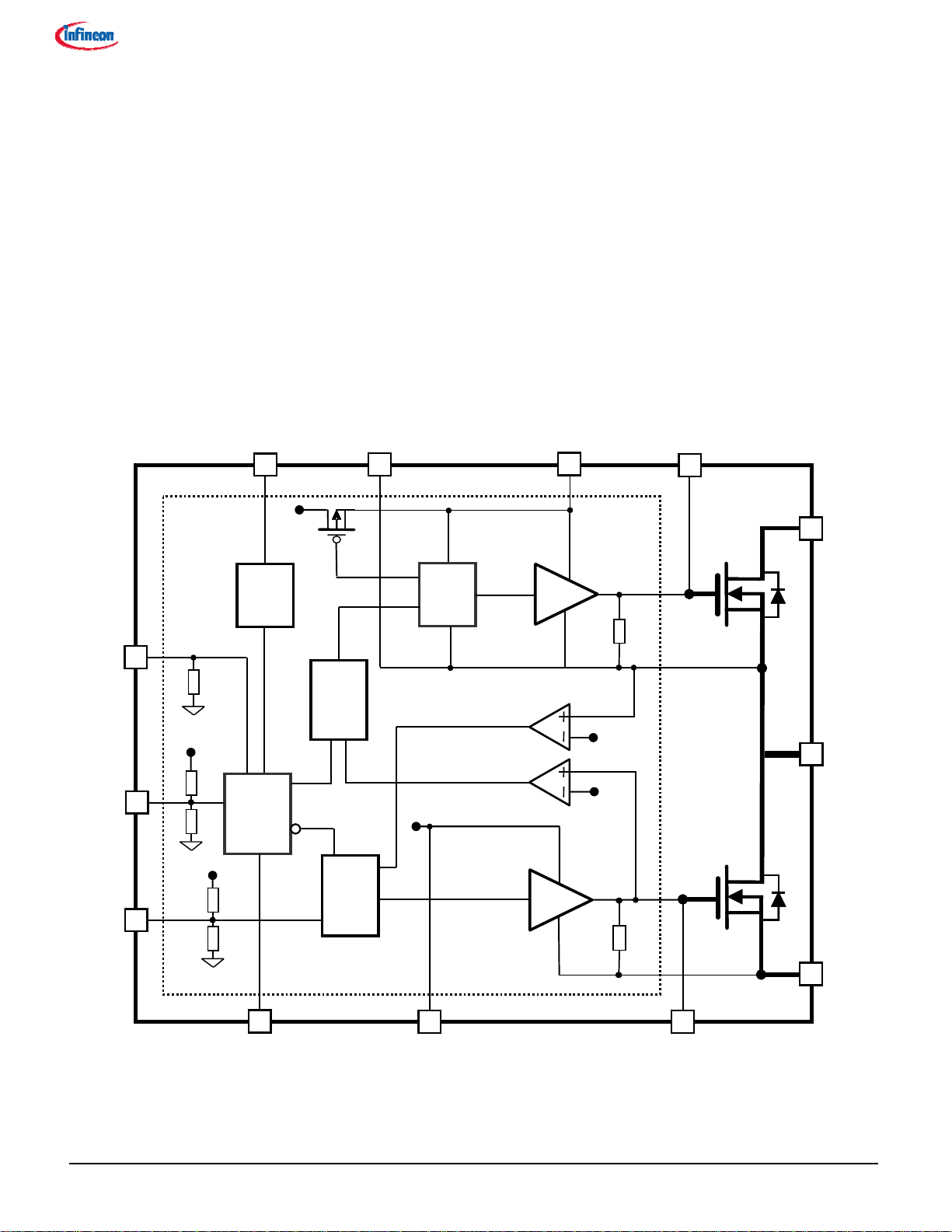

General Description

The Infineon TDA21211 is a multichip module that incorporates Infineon’s premier MOSFET technology for a single high

side and a single low side MOSFET coupled with a robust, high performance, high switching frequency gate driver in a

single 40 pin QFN package. The optimized gate timing allows for significant light load efficiency improvements over

discrete solutions. State of the art MOSFET technology provides exceptional full load performance. Thus this device has

a clear advantage over exisiting approaches in the marketplace when both full load and light load efficiencies are

important.

The Driver+MOSFET IC TDA21211 (DrMOS) is pin to pin compatible and compliant with the Intel 6x6 DrMOS

specification. The device package height is only 0.8mm, and is an excellent choice for applications with critical height

limitations.

BLOCK DIAGRAM

GU

VCIN

VCIN

PHASE

PHASE

BOOT

BOOT

GU

DISB#

DISB#

PWM

PWM

SMOD#

SMOD#

VCIN

VCIN

CGND

CGND

CGND

CGND

500k

500k

33k

33k

14k

14k

CGND

CGND

VCIN

VCIN

UVLO

UVLO

Input

Input

Logic

Logic

3-State

3-State

400k

400k

600K

600K

VDRV

VDRV

HS

HS

Logic

Logic

LS

LS

Logic

Logic

Level

Level

Shifter

Shifter

Shoot Through

Shoot Through

VDRV

VDRV

IC DRIVER

IC DRIVER

HS Driver

HS Driver

Protection

Protection

LS Driver

LS Driver

500k

500k

500k

500k

HS

HS

MOS

MOS

LS

LS

MOS

MOS

VIN

VIN

VSWH

VSWH

PGND

PGND

Data Sheet

CGND

CGND

VDRV

VDRV

Figure 2. Simplified block diagram

Page 4 of 20

GL

GL

TDA21211

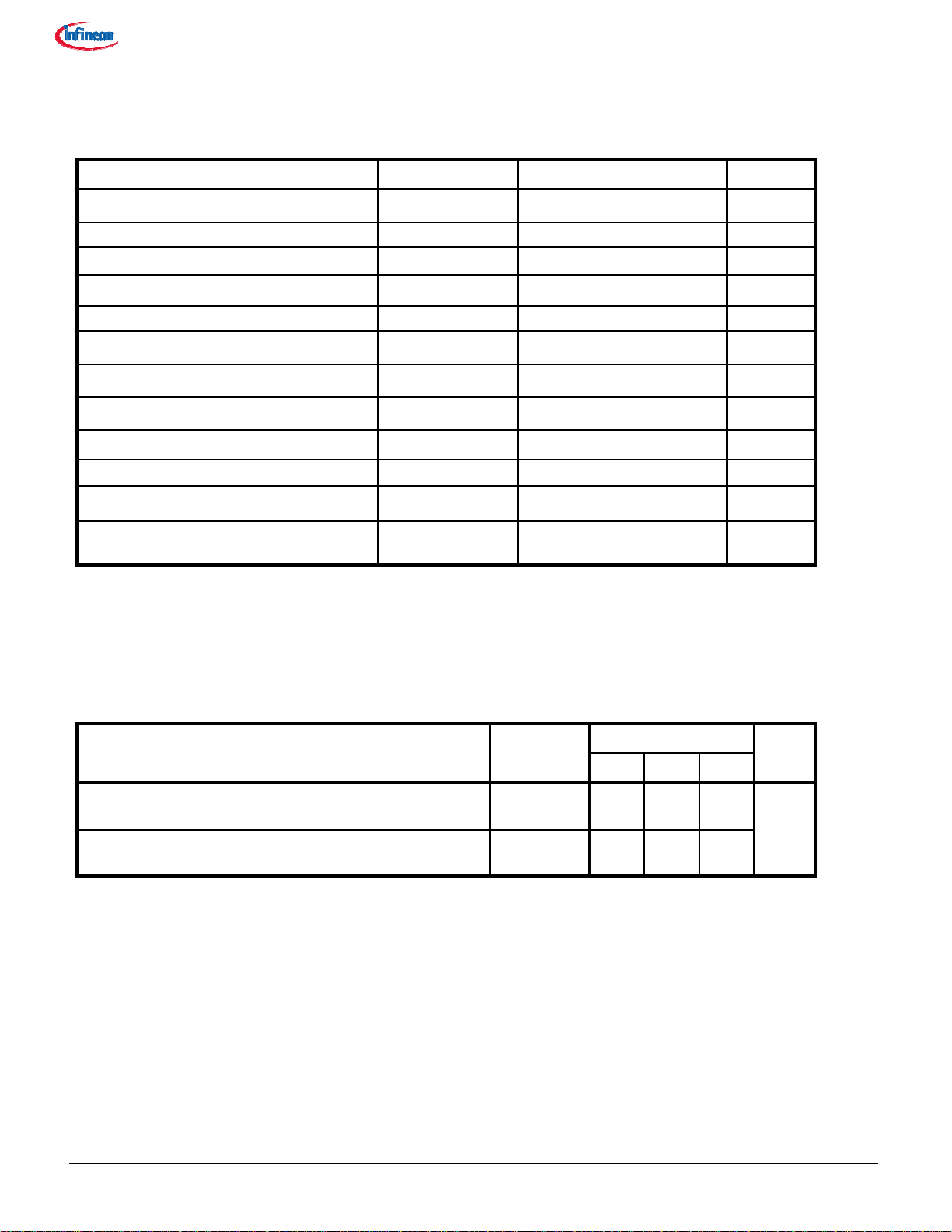

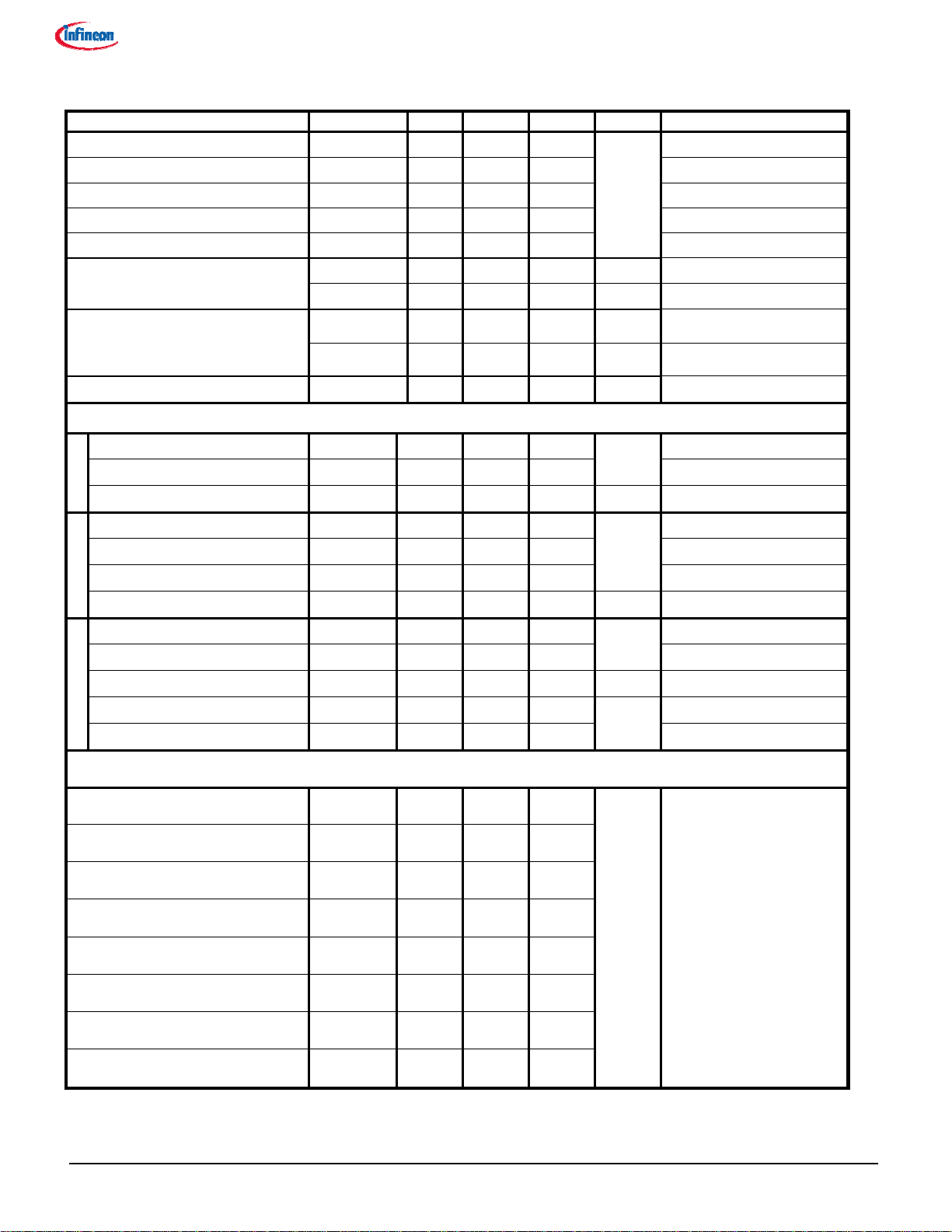

Electrical Specification Table

Absolute Maximum Ratings (Ta = 25°C)

Item Symbol Rating Units

Frequency f

SW

1.2 MHz

Average output current Iout 35 A

Input voltage VIN (DC) -0.3 to +30 V

Supply voltage VCIN (DC) -0.3 to +5.5 V

High and Low side driver voltage VDRV (DC) -0.3 to +5.5 V

Switch node voltage VSWH (DC) -1 to +30 V

BOOT voltage V

SMOD# voltage V

DISB# voltage

PWM voltage

1

1

BOOT-PHASE

SMOD#

VDISB -0.3 to +5.5 V

Vpwm -0.3 to +5.5 V

(DC) -1 to +5.5 V

(DC) -0.3 to +5.5 V

Operating junction temperature Tj-opr -40 to +150 °C

Storage temperature Tstg -55 to +150 °C

Note: All rated voltages are relative to voltages on the CGND and PGND pins unless otherwise specified.

1

Latch Up class II- Level B (Jedec 78). Please refer to Quality Report for details.

Thermal Characteristics

Parameter Symbol

Thermal resistance, junction-soldering point

Thermal resistance, junction-top of package

1

junction-soldering point is referred to the VSWH bottom exposed pad.

1

Values

Unit

Min. Typ. Max.

θ

JS

5

K/W

θ

Jtop

20

Data Sheet

Page 5 of 20

TDA21211

Recommended Operating Conditions and Electrical Characteristics (VCIN = 5V, Ta = 25°C)

Parameter Symbol Min Typ Max Units Test Conditions

Input Voltage VIN 5 25

Driving Voltage VDRV 5

Bias Supply Voltage VCIN 4.5 5 5.5

UVLO Rising V

UVLO Falling V

Driver Current

UVLO_R

UVLO_F

I

VDRV_300kHz

I

VDRV_PWML

I

VCIN_PWML

2.9 3.5 3.9

2.5 3.1 3.3

10 mA

25 µA

250 µA

IC Current (Control)

370 µA

270 µA

IC quiescent

I

VCIN_O

I

CIN+IDRV

Logic Inputs and Thresholds

V

VCIN rising

VCIN falling

DISB# = 5V, f

DISB# = 5V, PWM = 0V

DISB# = 5V, PWM = 0V

SMOD# = Open

DISB# = 5V, PWM = Open

SMOD# = Open

DISB# = 0V

= 300kHz

SW

Input low

Input high

DISB#

Sink Current

Input low

Input high

Open Voltage

SMOD#

Sink Current

Input low

Input high

Input resistance

PWM

Open Voltage

Tri-state Shutdown Window

Dynamic Characteristic

Three State to GL/GH rising

propagation delay

GL/GH Three State Shutdown

Hold-Off time,

GH Turn-on propagation delay

V

DISB_L

V

DISB_H

I

DISB

V

SMOD#_L

V

SMOD#_H

V

SMOD#_O

I

SMOD#

V

PWM_L

V

PWM_H

R

IN-PWM

V

PWM_O

V

PWM_S

T_pts

T_tsshd

T_pdhu

0.7 1.1 1.3 V

V

1.9 2.1 2.4

2 µA V

0.7 1.1 1.3 V

1.9 2.1 2.4 V

V

3.0

-8 µA V

0.7 V

V

2.4

6.5 9.5 12.5 kΩ V

1.5 V

V

1.2 1.9

15

240

15

DISB

V

DISB

DISB

SMOD#

SMOD#

SMOD#

PWM

V

PWM

PWM

PWM_O

falling

rising

= 1V

falling

rising

= 1V

falling

rising

= 1V

T_pdlu

T_pdhl

T_pdll

T_pdl_DISB

T_pdh_DISB

GH Turn-off propagation delay

GL Turn-on propagation delay

GL Turn-off propagation delay

DISB#Turn-off propogation

delay falling

DISB#Turn-on propogation

delay rising

1

Unless otherwise specified, VCIN=VDRV

Data Sheet

20

20

10

20

20

Page 6 of 20

ns

GH, GL unloaded.

TDA21211

Typical Application

+ 3.3 V

VDD

VID7

VID6

VID5

VID4

VID3

VID2

VID1

VID0

PSI#

OUTEN

VR_READY

FAULT1

FAULT2

FAULT3

VIN_SEN

PX3560

SEN1N

SEN1P

SEN2N

SEN2P

SEN3N

PWM1

PWM1

ISEN1N

ISEN1P

PWM2

ISEN2N

ISEN2P

PWM2

PWM3

ISEN3N

ISEN3P

PWM4

ISEN4N

ISEN4P

PWM5

PWM3

ISEN5N

V

IN

+12 V

C

boot

BOOT

VIN

V

CIN

TDA21211

V

DRV

PWM

C

boot

BOOT

VIN

V

CIN

TDA21211

V

DRV

PWM

C

boot

BOOT

VIN

V

CIN

TDA21211

V

DRV

PWM

CGND

CGND

CGND

R

boot

PHASE

R

boot

PHASE

R

boot

PHASE

VSWH

PGND

VSWH

PGND

VSWH

PGND

Rb

Rb

Rb

L

Cb

L

Cb

L

Cb

V

CIN

+

Data Sheet

SEN3P

SDA

SCL

SADDR_M

ISEN5P

PWM6

ISEN6N

ISEN6P

C

boot

BOOT

VIN

V

CIN

TDA21211

V

DRV

R

boot

PHASE

VSWH

Rb

L

Cb

SADDR_L

VD25

PWM4

SEN4N

PWM

CGND

PGND

GND

SEN4P

VSENP

VSENP

VSENN

V

OUT

C

OUT

VSENN

Figure 3. Four Phases Voltage Regulator Typical Application (Simplified Schematic)

Page 7 of 20

TDA21211

Theory of Operation

The TDA21211 incorporates a high performance gate driver, one high side power MOSFET and one low-side power

MOSFET in a single 40 lead QFN package. The advantages of this arrangement are found in the areas of increased

performance, increased efficiency and lower overall package and layout inductance.This module is ideal for use in

Synchronous Buck Regulators either as a stand-alone power stage that can deliver up to 35A or with an interleaved

approach for higher current loads.

The power MOSFETs are tailored for this device. The gate driver is an extremely robust high-performance driver rated

at the switching node for DC voltages ranging from -1V to +30V. The closely coupled driver and MOSFETs enable

efficiency improvements that are hard to match using discrete components. The power density for transmitted power

2

V

UVLO_F

area.

Enable

V

UVLO_R

V

CIN

of this approach is approximately 30W within a 36mm

Driver Characteristics

The gate driver of the TDA21211 has 2 voltage inputs, VCIN and VDRV. VCIN is the 5V bias supply for the driver.

VDRV is also 5V and is used to drive the High and Low Side MOSFETs. Ceramic capacitors should be placed very

close to these input voltage pins to decouple the sensitive control circuitry from a noisy environment.

The MOSFETs selected for this application are optimized for 5V gate drive, thus giving the end user optimized high

load as well as light load efficiency. The reference for the power circuitry including the driver output stage is PGND

and the reference for the gate driver control circuit (VCIN) is CGND.

Referring to the Block Diagram, Figure 2 VCIN is internally connected to the UVLO circuit and for VCIN voltages less

than required for proper circuit operation will provide shut-down. VDRV supplies both, the floating high side drive and

the low-side drive circuits. An active boot circuit for the high side gate drive is also included. A second UVLO circuitry,

sensing the BOOT voltage level, is implemented to prevent false GH turn on during insufficient power supply level

condition (BOOT Cap charging/discharging sequence). During undervoltage both GH and GL are driven low actively;

further passive pull down (500k Ohm) is placed on each gate.

Note: output signal from UVLO unit.

UVLO Output

Logic Level

“H”

“L”

Shutdown

Data Sheet

Page 8 of 20

TDA21211

Inputs to the internal control circuit are PWM, DISB# and SMOD#:

The PWM is the control input to the IC from an external PWM controller and is compatible with 3.3V and 5V logic.

The PWM input has three-state functionality. When the voltage remains in the specified PWM-shutdown-window for at

least the PWM-shutdown-holdoff time T_tsshd, the operation will be suspended by keeping both MOSFET gate outputs

low. Once left open, the pin is internally fixed to V

= 1.5 V level

PWM_O

PWM Driver Output

L GL=H, GH = L

H GL=L, GH = H

Open GL=L, GH = L

The DISB# is an active low signal. When DISB# is pulled low, the power stage is disabled.

DISB# Driver Output

L Shutdown Æ GL, GH = L

H EnableÆ GL, GH = “Active”

Open Shutdown Æ GL, GH = L

The SMOD# feature is provided to disable the low-side MOSFET during active operation. When synchronized with the

PWM signal (as shown in Figure 7), SMOD# is intended to improve light load efficiency by saving the gate charge loss

of the low-side MOSFET. Once left open, the pin is internally fixed to V

SMOD#_O

= 3 V level.

SMOD# GL Status

L L

H Enable Æ GL= “Active”

Open Enable Æ GL= “Active”

The TDA21211 driver includes gate drive functionality to protect against shoot through. In order to protect the power

stage from overlap, both HS and LS MOSFETs being on at the same time, the adaptive control circuitry monitors the

voltage at the “VSWH” pin. When the PWM signal goes low, HS, the High-side MOSFET will begin to turn off, after the

propagation delay (T_pdlu). Once the “VSWH” pin falls below 1V, LS, the Low-side MOSFET is gated on after the

predefined delay time, (T_pdhl). Additionally, the gate to source voltage of the HS-MOSFET is also monitored. When

VGS(HS) is discharged below 1V, a threshold known to turn HS off, a secondary delay is initiated, (T_pdhl), which

results in LS being gated “ON” irregardless of the state of the “VSWH” pin.This way it will be ensured that the converter

can sink current efficiently and the bootstrap capacitor will be refreshed appropriately during each switching cycle. See

Figure 5 for more detail.

GH and GL are monitoring pins to check the internal gate drive signals.

Data Sheet

Page 9 of 20

TDA21211

V

IN

C

IN

4x10u F

(+ 5 ÷ 24 v)

VIN

VSWH

PGND

C

BOOT

0.1 ÷ 1u F

R

BOOT

0 ÷ 5 Ω

VIN

NC

8910

11

12

13

14

15

16

17

18

VIN

PHASE

7

GH

CGND

6

VSWH

+ 5 v

VDRV

BOOT

CGND

VCIN

1u F

1u F

12345

CGND

CGND

SMOD

40

39

38

37

36

35

34

33

CGND

PWM

DISB#

NC

CGND

GL

VSWH

19

20

Signal GND Power GND

22 23 24 25 26 27

21

Figure 4. Pin interconnection outline (Transparent Top View)

NOTE: R

value is related to the input voltage level.

BOOT

Pin PHASE is internally connected to VSWH node.

32

31

28

PGND

30

29

L

V

OUT

VSWH

Data Sheet

Page 10 of 20

TDA21211

V

V

V

V

V

Gate Driver Timing Diagrams

PWM_H

PWM_L

PWM

T_pdll

GL

T_pdhl

PWM_H

PWM_L

T_tsshd

T_pts

GH

SWH

1 V

T_pdhu

T_tsshd

T_pdlu

1 V

T_pts

Note: VSWH during entering/exit to tri-

state behaves accordingly to inductor

current.

Figure 5: Adaptive Gate Driver Timing Diagram

Data Sheet

Page 11 of 20

TDA21211

)

V

V

DISBL#

DISB_H

DISB_L

GH/GL

SMOD

T_pdl(DISB

Figure 6: Disable Timing Diagram

T_pdh(DISB)

SMOD disabled

SMOD active

PWM

GL

T_pdlu

T_pdlu

CCM

DCM

T_pdlu

CCM

Figure 7 SMOD# Timing Diagram

Data Sheet

Page 12 of 20

TDA21211

×

Test Circuit

V

V

IN

IN

V

V

CIN

CIN

V

V

DRV

DRV

PWM

PWM

I

I

IN

IN

I

I

CIN

CIN

I

I

DRV

DRV

A

A

C

V

V

A

A

C

C

CIN

V

V

A

A

V

V

VDRV

VDRV

PWM

PWM

CIN

C

C

DRV

DRV

VIN

VIN

BOOT

BOOT

C

IN

IN

C

C

BOOT

BOOT

PHASE

PHASE

VSWH

VSWH

PGND

PGND

300n H

300n H

R

R

b

b

L

L

C

C

V

V

OUT

OUT

I

I

OUT

OUT

b

b

C

C

OUT

OUT

PX3560

PX3560

V

V

V

V

I

I

SENN

SENN

I

I

SENP

SENP

SENP

SENP

SENN

SENN

VCIN

VCIN

DISBL#

DISBL#

SMOD#

SMOD#

CGND

CGND

TDA21211

TDA21211

Figure 8. Test Circuit

P

OUT

Efficiency =

P

IN

IVIVIVP

ININCINCINDRVDRVIN

Page 13 of 20

TDA21211

Data Sheet

IVP ×=

OUTOUTOUT

PPP −=

OUTINLOSS

+×+×=

Performance Curves – Typical Data

Operating conditions (unless otherwise specified): VIN= +12V, V

59P9081N01, DCR (typ) =0.43m Ω) T

=25° C, load line=0mΩ, airflow=100 LFM, no heatsink. Power Efficiency and Power Loss data

A

CIN=VDRV

= +5V, V

=1.1 V, F=362k Hz, 300nH inductor (VITEC-

OUT

reported herein includes TDA21211 and inductor losses but no other system losses (unless otherwise specified).

94

92

90

88

86

1. 6 V

1. 5 V

1. 2 V

1. 0 V

0.8V

7

0.8V

6

5

1. 0 V

1. 2 V

1. 5 V

1. 6 V

4

3

Efficiency (%)

Power Loss (W)

84

82

80

0 5 10 15 20 25 30

Output Current (A)

Figure 9. Efficiency vs. VOUT

2

1

0

0 5 10 15 20 25 30

Output Current (A)

Figure 10. Power Loss vs. VOUT

94

92

90

88

86

Efficien cy (%)

84

82

80

0 5 10 15 20 25 30

O utput Current (A)

Figure 11. Efficiency vs. Switching Frequency

296Khz

362Khz

407Khz

465Khz

592Khz

7

6

59 2Khz

4 65Khz

4 07Khz

362Khz

296Khz

5

4

3

Power Loss (W)

2

1

0

0 5 10 15 20 25 30

Output Current (A)

Figure 12. Power Loss vs. Switching Frequency

Data Sheet

Page 14 of 20

TDA21211

94

92

90

88

86

Efficiency (%)

84

82

80

0 5 10 15 20 25 30

Output Current (A)

Figure 13. Efficiency vs. VIN

10 V

12 V

14 V

16 V

18 V

20V

7

20V

6

5

18 V

16 V

14 V

12 V

10 V

4

3

Power Loss (W)

2

1

0

0 5 10 15 20 25 30

O u tp u t Current (A)

Figure 14. Power Loss vs. VIN

94

92

90

88

86

Effici ency (%)

84

82

80

0 5 10 15 20 25 30

Output Current (A)

25C

65C

85C

10 5C

7

10 5C

6

85C

65C

25C

5

4

3

Power Loss (W)

2

1

0

0 5 10 15 20 25 30

O u tpu t Current (A)

Data Sheet

Figure 15. Efficiency vs. T

CASE

Page 15 of 20

Figure 16. Power Loss vs. T

TDA21211

CASE

V

V

V

7

in=12V

VCIN=VDRV=5V

6

Vout=1.3V

F=600kHz

5

L=510nH

T= 25° C

4

3

Power Loss (W)

2

1

0

0 5 10 15 20 25 30

Output Current (A)

Figure 17.

(inductor losses not included)

Power Loss vs. Iout

1,20

in=12V

1,15

1,10

1,05

VCIN=VDRV=5V

Vout=1.3V

Iout=25A

L=510nH

T= 25° C

1,00

0,95

0,90

0,85

300 400 500 600 700 800 900 1000

Figure 18.

Switching Frequency (kHz)

Normalized Power Loss @ Iout=25 A

(inductor losses not included)

(mA)

CIN

+ I

DRV

I

35

30

25

20

15

10

in=12V

VCIN=VDRV=5V

Vout=1.3V

Iout=25A

L=510nH

T= 25° C

5

0

100 200 300 400 500 600 700 800 900 1000

Switching Frequency (kHz)

Figure 19.

Data Sheet

Power Supply Current (IDRV + ICIN) vs. Fsw

Page 16 of 20

TDA21211

Package Outline

PIN#1 IDENT

Data Sheet

Page 17 of 20

TDA21211

Figure 20: Footprint and Solder Stencil Recommendation

Data Sheet

Page 18 of 20

TDA21211

PCB Layout Example.

Figure 21 Single Phase DrMOS typical Application Circuit

Data Sheet

Figure 22 Single Phase DrMOS PCB Layout Example (Top Side View)

(for DrMOS Design support a customer PCB layout guide is available upon request)

Page 19 of 20

TDA21211

For questions on technology, delivery and prices please contact the Infineon Technologies Offices in Germany or the

Infineon Technologies Companies and Representatives worldwide: see the address list on the last page or our webpage

at

http://www.infineon.com/DCDC

CoreControlTM, OptiMOS™ and OptiMOS II™ are trademarks of Infineon Technologies AG.

We listen to Your Comments

Any information within this document that you feel is wrong, unclear or missing at all?

Your feedback will help us to continously improve the quality of this document.

Edition 2004-11-10

Published by Infineon Technologies AG,

St.-Martin-Strasse 53,

D-81541 München

© Infineon Technologies AG 2004.

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as warranted characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement, regarding circuits, descriptions and charts stated herein.

Infineon Technologies is an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest Infineon Technologies Office in Germany or our Infineon

Technologies Representatives worldwide (see address list).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in question please contact your nearest Infineon Technologies

Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written approval of Infineon Technologies, if a failure of such

components can reasonably be expected to cause the failure of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain and/or protect human life. If they fail, it is reasonable to

assume that the health of the user or other persons may be endangered.

Data Sheet

Page 20 of 20

TDA21211

Loading...

Loading...