Page 1

UG 2020

-

32

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

About this document

Scope and purpose

This user guide provides an overview of the reference board REF-DR3KIMBGSICMA including its main features,

key data, pin assignments and mechanical dimensions.

REF-DR3KIMBGSICMA is a reference design contains two PCBs (named as driver board and power board

respectively), including driver circuit and a three-phase inverter for motor-drive application. The driver circuit

is based on EiceDriverTM IC - 1EDI20I12MH with miller clamp function. CoolSiCTM MOSFET – IMBG120R45M1H is

the main component for the three-phase inverter.

The REF-DR3KIMBGSICMA was developed to support customers during their first steps in designing with

EiceDriverTM IC and CoolSiCTM MOSFET for a servo motor with inverter integration. This reference design is the

power part of demonstration of the integrated servo motor, which is an Infineon joint development project

with partner JingChuan and Maxsine.

Intended audience

This user guide is intended for all technical specialists working with the REF-DR3KIMBGSICMA.

Reference Board/Kit

The Infineon product(s) are embedded on this PCB with functions and form factor close to a commercial

design. PCB and auxiliary circuits are optimized for the final design.

Note: Boards do not necessarily meet safety, EMI, quality standards (for example UL, CE) requirements.

User guide Please read the Important notice and the Safety precautions and the Warnings V 1.0

www.infineon.com page 1 of 22 2020-11-15

Page 2

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

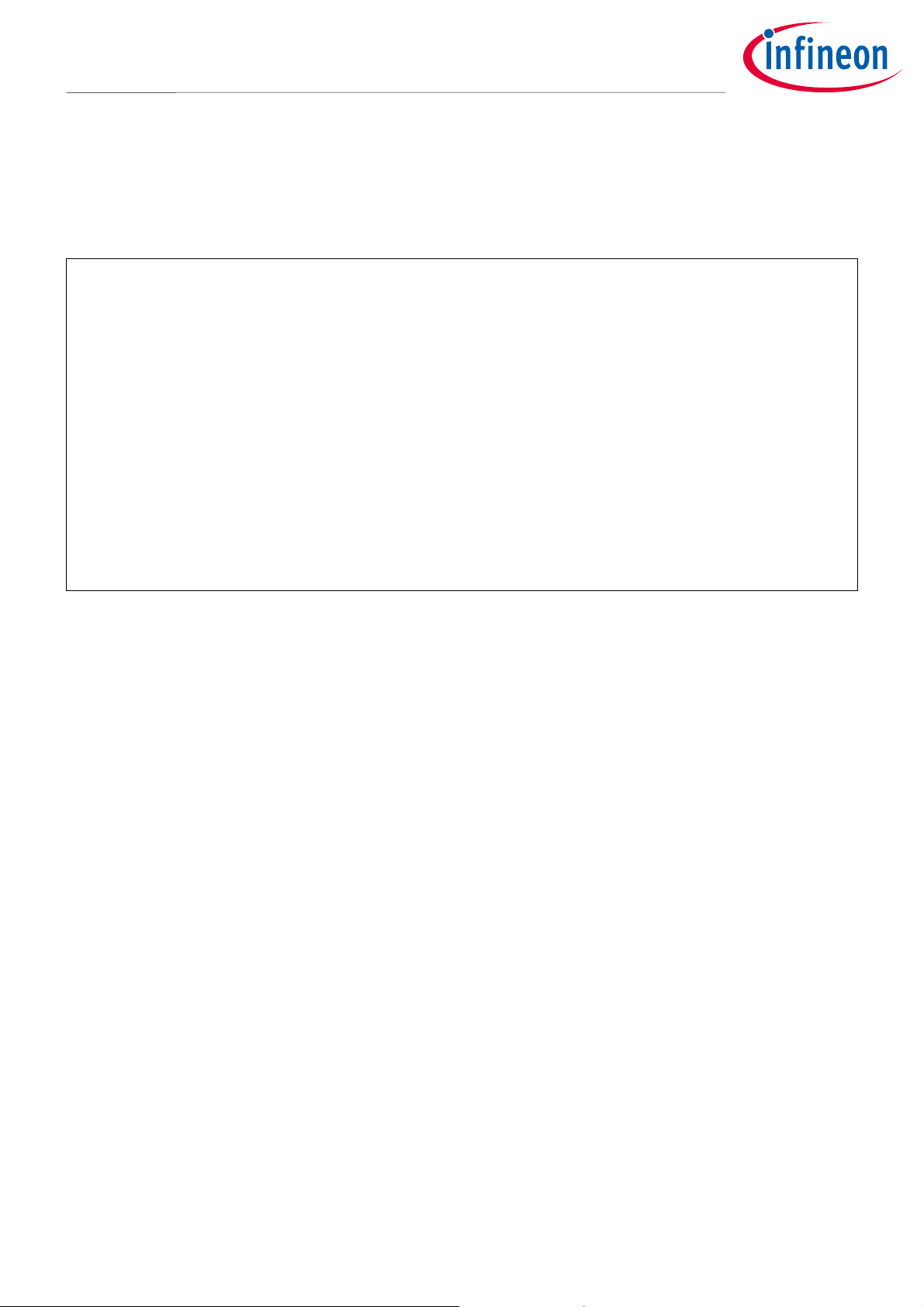

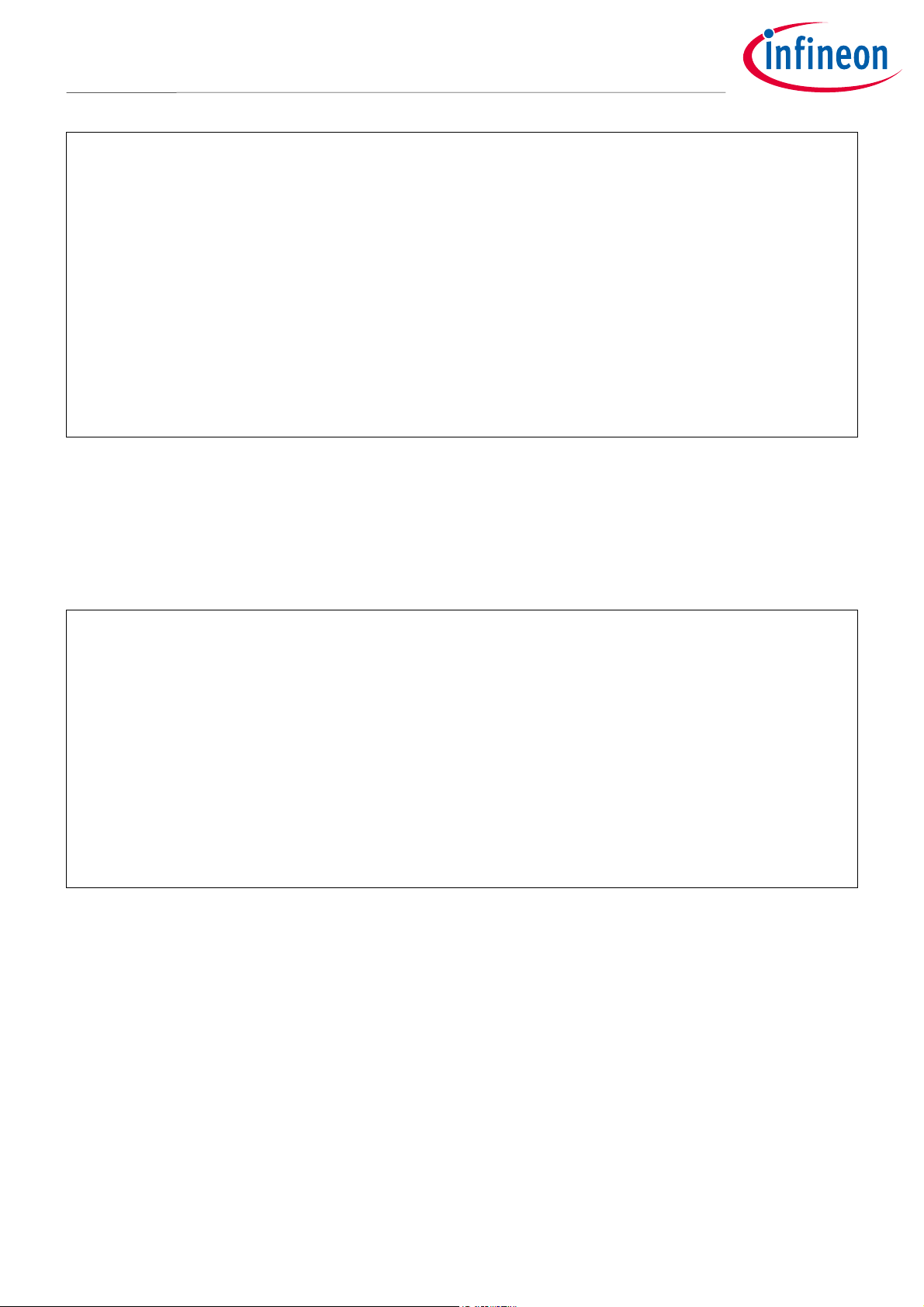

Important notice

Important notice

“Evaluation Boards and Reference Boards” shall mean products embedded on a printed circuit board

(PCB) for demonstration and/or evaluation purposes, which include, without limitation, demonstration,

reference and evaluation boards, kits and design (collectively referred to as “Reference Board”).

Environmental conditions have been considered in the design of the Evaluation Boards and Reference

Boards provided by Infineon Technologies. The design of the Evaluation Boards and Reference Boards

has been tested by Infineon Technologies only as described in this document. The design is not qualified

in terms of safety requirements, manufacturing and operation over the entire operating temperature

range or lifetime.

The Evaluation Boards and Reference Boards provided by Infineon Technologies are subject to functional

testing only under typical load conditions. Evaluation Boards and Reference Boards are not subject to the

same procedures as regular products regarding returned material analysis (RMA), process change

notification (PCN) and product discontinuation (PD).

Evaluation Boards and Reference Boards are not commercialized products, and are solely intended for

evaluation and testing purposes. In particular, they shall not be used for reliability testing or production.

The Evaluation Boards and Reference Boards may therefore not comply with CE or similar standards

(including but not limited to the EMC Directive 2004/EC/108 and the EMC Act) and may not fulfill other

requirements of the country in which they are operated by the customer. The customer shall ensure that

all Evaluation Boards and Reference Boards will be handled in a way which is compliant with the relevant

requirements and standards of the country in which they are operated.

The Evaluation Boards and Reference Boards as well as the information provided in this document are

addressed only to qualified and skilled technical staff, for laboratory usage, and shall be used and

managed according to the terms and conditions set forth in this document and in other related

documentation supplied with the respective Evaluation Board or Reference Board.

It is the responsibility of the customer’s technical departments to evaluate the suitability of the

Evaluation Boards and Reference Boards for the intended application, and to evaluate the completeness

and correctness of the information provided in this document with respect to such application.

The customer is obliged to ensure that the use of the Evaluation Boards and Reference Boards does not

cause any harm to persons or third party property.

The Evaluation Boards and Reference Boards and any information in this document is provided "as is"

and Infineon Technologies disclaims any warranties, express or implied, including but not limited to

warranties of non-infringement of third party rights and implied warranties of fitness for any purpose, or

for merchantability.

Infineon Technologies shall not be responsible for any damages resulting from the use of the Evaluation

Boards and Reference Boards and/or from any information provided in this document. The customer is

obliged to defend, indemnify and hold Infineon Technologies harmless from and against any claims or

damages arising out of or resulting from any use thereof.

Infineon Technologies reserves the right to modify this document and/or any information provided

herein at any time without further notice.

User guide 2 of 22 V 1.0

2020-11-15

Page 3

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

Safety precautions

Safety precautions

Please note the following warnings regarding the hazards associated with development systems.

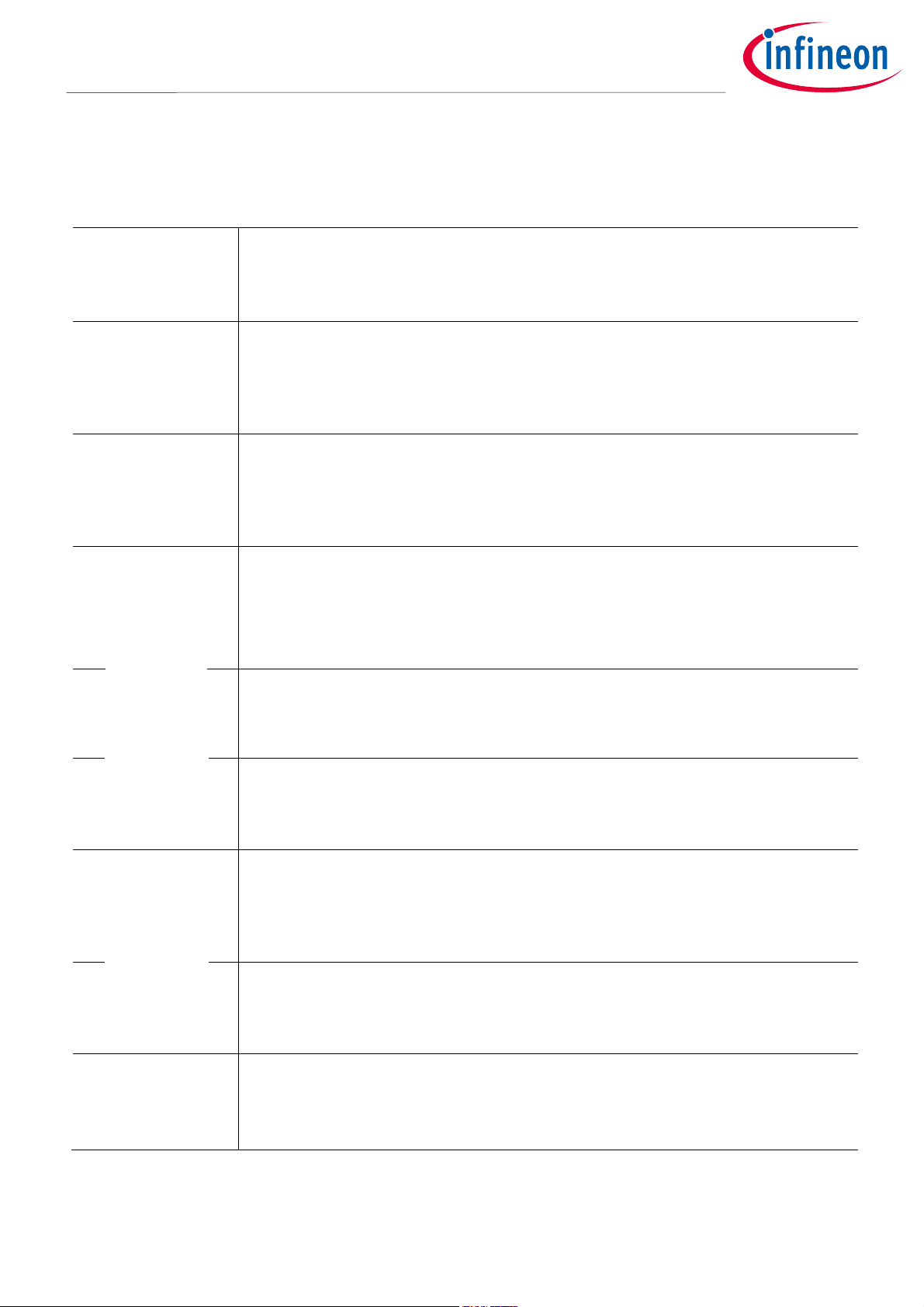

Table 1 Safety precautions

Warning: The DC link potential of this board is up to 1000 VDC. When measuring

voltage waveforms by oscilloscope, high voltage differential probes must be used.

Failure to do so may result in personal injury or death.

Warning: The evaluation or reference board contains DC bus capacitors which take

time to discharge after removal of the main supply. Before working on the drive

system, wait five minutes for capacitors to discharge to safe voltage levels. Failure to

do so may result in personal injury or death. Darkened display LEDs are not an

indication that capacitors have discharged to safe voltage levels.

Warning: The evaluation or reference board is connected to the grid input during

testing. Hence, high-voltage differential probes must be used when measuring voltage

waveforms by oscilloscope. Failure to do so may result in personal injury or death.

Darkened display LEDs are not an indication that capacitors have discharged to safe

voltage levels.

Warning: Remove or disconnect power from the drive before you disconnect or

reconnect wires, or perform maintenance work. Wait five minutes after removing

power to discharge the bus capacitors. Do not attempt to service the drive until the bus

capacitors have discharged to zero. Failure to do so may result in personal injury or

death.

Caution: The heat sink and device surfaces of the evaluation or reference board may

become hot during testing. Hence, necessary precautions are required while handling

the board. Failure to comply may cause injury.

Caution: Only personnel familiar with the drive, power electronics and associated

machinery should plan, install, commission and subsequently service the system.

Failure to comply may result in personal injury and/or equipment damage.

Caution: The evaluation or reference board contains parts and assemblies sensitive to

electrostatic discharge (ESD). Electrostatic control precautions are required when

installing, testing, servicing or repairing the assembly. Component damage may result

if ESD control procedures are not followed. If you are not familiar with electrostatic

control procedures, refer to the applicable ESD protection handbooks and guidelines.

Caution: A drive that is incorrectly applied or installed can lead to component damage

or reduction in product lifetime. Wiring or application errors such as undersizing the

motor, supplying an incorrect or inadequate AC supply, or excessive ambient

temperatures may result in system malfunction.

Caution: The evaluation or reference board is shipped with packing materials that

need to be removed prior to installation. Failure to remove all packing materials that

are unnecessary for system installation may result in overheating or abnormal

operating conditions.

User guide 3 of 22 V 1.0

2020-11-15

Page 4

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

Table of contents

Table of contents

About this document ....................................................................................................................... 1

Important notice ...................................................................................... Error! Bookmark not defined.

Safety precautions .......................................................................................................................... 3

Table of contents ............................................................................................................................ 4

1 The board at glance ................................................................................................................ 5

1.1 Delivery content ...................................................................................................................................... 5

1.2 Block diagram .......................................................................................................................................... 6

1.3 Main features ........................................................................................................................................... 6

1.4 Board parameters and technical data .................................................................................................... 7

2 System and functional description ........................................................................................... 8

2.1 Commissioning ........................................................................................................................................ 8

2.2 Example: Basic operation using MAKD controller .................................................................................. 9

3 System design ...................................................................................................................... 11

3.1 Schematics ............................................................................................................................................ 11

3.2 Layout .................................................................................................................................................... 13

3.3 Bill of material ....................................................................................................................................... 14

3.4 Connector details .................................................................................................................................. 16

4 System performance ............................................................................................................. 18

5 References and appendices .................................................................................................... 20

Revision history............................................................................................................................. 21

User guide 4 of 22 V 1.0

2020-11-15

Page 5

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

The board at glance

1 The board at glance

The REF-DR3KIMBGSICMA are the inverter board and the gate driver board for the demonstration of an

integrated servo motor and drive. The driver circuit is based on EiceDriver™ IC - 1EDI20I12MH with miller clamp

function. CoolSiC™ MOSFET – IMBG120R45M1H is the main component for the three-phase inverter.

Figure 1 The demonstration of an integrated servo motor with drive

The full demonstration consists of: an inverter board, a gate driver board, a controller board and a servo motor,

as show in Figure 1. The control board and the motor are not part of the reference design.

To evaluate the electrical performance of the system, the iMOTION™ MADK EVAL-M1-101T can be used to

provide a simple control. An adapter cable is included for simple connection, between the EVAL-M1-101T and

REF-DR3KIMBGSICMA. Also, a heatsink is also provided to represent the motor housing for cooling. Even

through the system could work without a cooling fan, a fan and a holder is also included for easy evaluation.

1.1 Delivery content

The reference board REF-DR3KIMBGSICMA is delivered together with complete documentation in an

environmentally friendly carton box.

As depicted, the box contains:

• Reference board assembled as a stack with a size of 12 cm x 11.3 cm x 10 cm (LxWxH), including an

inverter board, a gate driver board, a heatsink and a cooling fan.

• An adapter cable, for connection between EVAL-M1-101T and REF-DR3KIMBGSICMA

• User guide

• Introduction sheet

User guide 5 of 22 V 1.0

2020-11-15

Page 6

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

The board at glance

Figure 2 Content of delivery

1.2 Block diagram

The inverter is a standard 3 phase 2 level topology, with DC link capacitor and 6 CoolSiC™ MOSFET D2PAK

IMBG120R45M1H. The components are soldered on a single layer IMS board. All CoolSiC™ MOSFET are driven by

isolated gate driver, EiceDriverTM IC - 1EDI20I12MH with miller clamp function.

Figure 3 Block diagram

1.3 Main features

• 3 phase servo motor with integrated drive

• 1200 V/45mΩ CoolSiC™ MOSFET in SMD package (TO263-7L), with .XT interconnection technology

• Compact design: PCB diameter 110mm

• IMS (Insulated Metallic Substrate) PCBs with high thermal conductivity

• With over current protection

• Input voltage 350 – 800 VDC

• Output voltage 220VAC, 380VAC, 480VAC

User guide 6 of 22 V 1.0

2020-11-15

Page 7

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

The board at glance

1.4 Board parameters and technical data

Table 2 Keys Parameters

Parameter Values Conditions

Input voltage (DC) 350 ~ 800 V

Output voltage (AC, 3-ph) 220 ~ 480 V

Output current (AC, 3-ph) 5 A Without forced air

Output peak current (AC, 3-ph) 15 A Without forced air, < 0.25 s

Output power 4 kW Without forced air

Ambient temperature From 0 to 40 °C

User guide 7 of 22 V 1.0

2020-11-15

Page 8

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

Auxillary

power supply

3ph gate signsals

Phase current feedback

Feedback signals

System and functional description

2 System and functional description

2.1 Commissioning

The REF-DR3KIMBGSICMA board is intended for evaluation of CoolSiC™ MOSFET solution in the integrated

servo drive application. Therefore, the control of the servo motor is not the focus. This section introduces the

minum conections to start the evaluation.

The gate driver board minimum connection:

• Auxillary power supply connection CN1 (input): 0 ~ 24V DC from an external power supply

• Gate driver signal connection P12, pin1~6 (input): controller 3 phase gating signals

connection CN1

For feedback control, the following measurements are also provided: phase current, DC link voltage, DC

current, temperature feedback.

The power board minimum connection:

• DC link connection (input): 350 ~ 800 V DC from an external power supply

• 3 phase AC (output): to 3ph motor or RL load

User guide 8 of 22 V 1.0

2020-11-15

Page 9

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

DC link connection

3 phase AC output

System and functional description

connection

2.2 Example: Basic operation using MAKD controller

The REF-DR3KIMBGSICMA board is intended for evaluation of CoolSiC™ MOSFET solution in the integrated

servo drive application. Therefore, the control of the servo motor is not the focus. For an easy evaluation, the

iMOTION™ MADK EVAL-M1-101T can be used to start with. A detailed description of the drive card can be found

online:

https://www.infineon.com/cms/en/product/evaluation-boards/eval-m1-101t/

Figure 4 iMOTION™ MADK EAVL-M1-101T

The detailed connection between REF-DR3KIMBGSICMA and EVAL-M1-101T is shown in Figure 5.

User guide 9 of 22 V 1.0

2020-11-15

Page 10

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

System and functional description

Figure 5 Connection diagram

For an easy connection, an adaption cable is included in the delivery box.

Figure 6 Connection between REF-DR3KIMBGSICMA and EVAL-M1-101T using the adaption cable

The detailed description of V/F modulation using EVAL-M1-101T is shown in the reference.

User guide 10 of 22 V 1.0

2020-11-15

Page 11

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

System design

3 System design

3.1 Schematics

The schematics of the power board is shown in Figure 7.

Figure 7 The schematics of the power board (REF-DR3KIMBGSICMA-P)

User guide 11 of 22 V 1.0

2020-11-15

Page 12

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

System design

The schematics of the gate driver board is shown in Figure 8.

Figure 8 The schematics of the gate driver board (REF-DR3KIMBGSICMA-D)

User guide 12 of 22 V 1.0

2020-11-15

Page 13

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

System design

3.2 Layout

The power board is a single layer IMS board. And the gate driver board is a 4 layers PCB board. The layouts of

each board are shown in Figure 9 and Figure 10.

Figure 9 The layout of the power board (REF-DR3KIMBGSICMA-P)

Figure 10 The layout of the driver board (REF-DR3KIMBGSICMA-D)

User guide 13 of 22 V 1.0

2020-11-15

Page 14

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

System design

3.3 Bill of material

The complete bill of material is available on the download section of the Infineon homepage.

Table 3 BOM of power board

No. Ref Designator Description Manufacturer Manufacturer P/N

1 Q1, Q2, Q3, Q4, Q5, Q6

2 C1, C2 DC bulk capacitor EPCOS(TDK) B32774D8126K000

3 C9, C10, C11

4 R1, R2, R3, R4, R5, R6 2512-10mΩ-1% 2W / PE2512FKE7W0R01L

5 R7, R8, R10, R11, R12, R13 120K(1%)-1206 /

6 R9 200Ω(1%)-0805 /

7 R14, R15, R16, R17, R18, R19

8 RT1 Thermal resistor 10K-0805 / 10K-0805

9

10 U,V,W,P+,P- M3*φ5.56*L4+1.53 / SMTS06040CTJ

11 JU1, JU2 Brass jumper 35*10*7mm /

P1, P2, P3, P4, P5, P6, P7, P8,

P9, P10, P11

CoolSiC™ 1200V SiC

Trench MOSFET

Snubber capacitor

0.1UF/1KV X7R 2512

Resistor

20K/0805

Surface mounting

connector

2.54mm 2*2P

Infineon IMBG120R045M1H

/

/

/ 2.54mm -2*2P

Table 4 BOM of gate driver board

No. Ref Designator Description Manufacturer Manufacturer P/N

1 U1, U2, U3, U4, U5, U6

C1, C3, C6, C7, C8, C9, C10, C11,

C14, C15, C16, C17, C19, C20,

2

C21, C25, C26, C28, C31, C34,

C43, C44, C47, C50, C56, C58,

C62, C63, C64

C5, C13, C18, C27, C36, C48,

3

C57, C61

4 C2 20P-C0603 / /

5 C33 122-C0603 / /

6 C32 222-C0603 / /

7 C12, C49, C53, C54, C55 106-C1206 / /

8 C37, C41 106-C0805 / /

9 C39 106-C1210 / /

10 C45 102-C1206 / /

Driver IC with miller clamp

function

104-C0805 / /

472-C0603 / /

Infineon 1EDI20I12MH

11 C24, C42, C46 103-C0603 / /

User guide 14 of 22 V 1.0

2020-11-15

Page 15

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

R45

3K(1%)

-

R0805

R27

11K(1%)

-

R0805

R18, R33

15K(1%)

-

R0805

R41

20K(1%)

-

R0805

R3

100K

-

R0805

R17, R28

1K(1%)

-

R0603

R6

14.3K(1%)

-

R0402

R4

75K(1%)

-

R0402

U13

TLV70033DDCR

SOT-23-5

U9

LM2903DR

SO-8

U7, U8

AMC1306M25

ACPL_C790

U11

MPM3510AGQV

-

Z/ MPM3506A

U10

LM5017MR

ad8397

U14

Single OP Amp TP2301

-

TR/ SOT-23-5

U12

Optocoupler,LTV

-

817S

-

SMD_LEAD_2.54_4

U15

Optocoupler,AMC1200BDWV

ACPL_C790

D12

Diode,B360

-

F/ DIODE

-

SMC

D7

Diode,LBAV99LT1G

SOT-23

System design

No. Ref Designator Description Manufacturer Manufacturer P/N

12 R1, R16, R26, R34, R42, R48 100Ω-R0805 / /

R5, R22, R29, R35, R36, R37,

13

R43, R49

14 R7, R8 75Ω-R0603 / /

15 R60 6.8Ω-R0805 / /

16 R52, R53 22Ω-R0805 / /

17 R54 470Ω-R0805 / /

18 R24 750Ω-R0805 / /

19 R62, R63 1K-R0805 / /

20 R11, R23, R31, R38, R44, R51 2K-R0805 / /

21 R55 3K-R0805 / /

22 R65 4.7K-R0805 / /

R30, R39, R40, R46, R47, R56,

23

R57, R59, R61, R64

20Ω-R1206 / /

10K-R0805 / /

24 R19 30K-R0805 / /

25 R2 1M-R0805 / /

26 R9, R13, R25, R58 10Ω-R1206 / /

27 R10, R12, R14, R15 300Ω-R1206 / /

28 R20, R21 1M-R1206 / /

29 R50 200Ω(1%)-R0805 / /

30 R32 2.2K(1%)-R0805 / /

31

32

33

34

35

36

37

38

39

40

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/

/

41

42

43

44

45

TA1B

46

47

48

User guide 15 of 22 V 1.0

/

/

/

/

/

2020-11-15

Page 16

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

D5, D8

Diode,ES1D

-

F/ DIODE_SMA

D1, D2, D3, D4, D6

Diode,US1M

-

F/ DIODE_SMA

TRANS1

Transformer,MXEE1011

MXEE1011

ZD1, ZD2, ZD3, ZD4,

ZD8, ZD9

Zener diode,

SOT-23

ZD5, ZD6, ZD7

Zener diode,LUDZS5.1BT1G

SOD-323

E1, E2, E3, E4, E5, E14

Chip electrolytic capacitor,

ECAP_FAI_6.3_SMT

E6, E7, E12, E13

Chip electrolytic capacitor,

ECAP_FAI_6.3_SMT

E10

Electrolytic capacitor,

ECAP_FAI_10

E11

Electrolytic capacitor,

ECAP_FAI_10

C40

Ceramic capacitor,

CD222

C51

223-C0805

C29, C38, C52

103-C0805

C4, C22, C23, C30, C35,

C65

106-C0805

CN1

CON2, 2x2.54

2x2.54

P1, P2, P3, P4, P5, P6, P7, P8, P9,

Dual inline, 2.54x2

P4

P12

Dual inline, 2.54x7

HDR2X7

D9, D10, D11

G

reen LED

-

0603

System design

No. Ref Designator Description Manufacturer Manufacturer P/N

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

P10, P11, P14

64

MMBZ18VALT1G

47uf/35V

100uf/35V

220uF/35V

1000uF/10V

222/2KV

/

/

/

/

/

/

/

/

/ /

/ /

/ /

/

/

/

65

/ /

3.4 Connector details

General information about the connectors of the REF-DR3KIMBGSICMA evaluation board is provided.

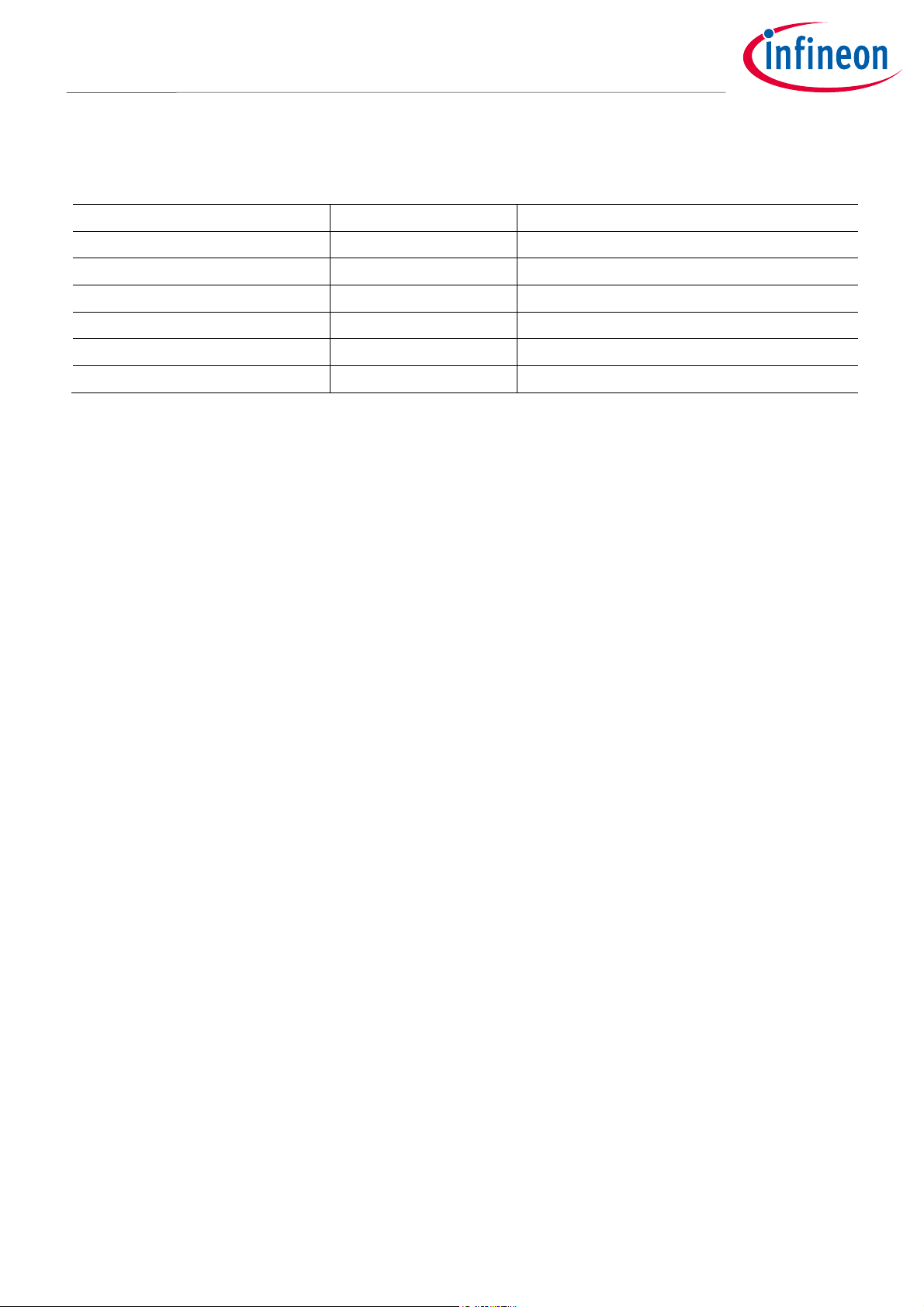

Table 5 Inverter board connectors

PIN Label Function

P+, P- P+, P- Power supply input for DC link

U, V, W U, V, W AC power output for motor

P24V P24V Auxilary power supplly input

Table 6 Gate driver board connector P12

PIN Label Function

1 PWMUH Gating signal, high side, phase U

2 PWMUL Gating signal, low side, phase U

3 PWMVH Gating signal, high side, phase V

4 PWMVL Gating signal, low side, phase V

5 PWMWH Gating signal, high side, phase W

User guide 16 of 22 V 1.0

2020-11-15

Page 17

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

System design

6 PWMWL Gating signal, low side, phase W

7 GND

8 GND

9 +5V 5V output for control board

10 +5V 5V output for control board

11

IC_CLK

Modulator clock input for IC(phase W)

12 IA_CLK Modulator clock input for IA(phase U)

13 IC_DAT Modulator data output for IC(phase W)

14 IA_DAT Modulator data output for IA(phase U)

Table 7 Gate driver board connector P14

1 VB Bus voltage signal

2 ID Power rating identification

3 EIPM Bus current protection

4 Vntc Temperature signal from power board

Table 8 Gate driver board connector CN1

1 24V 24V power supply input

2 GND power supply ground

User guide 17 of 22 V 1.0

2020-11-15

Page 18

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

System performance

4 System performance

The acceleration and deceleration test is a common method to verify the performance of a servo system.

Usually, a simulated inertia load is applied to the motor to complete the acceleration-deceleration action at the

fastest speed. In this test, no additional brake system is required.

The test platform is composed of integrated servo motor and inertia simulator, DC power supply, Beckhoff

controller and computer software platform, as shown in Figure 11.

Figure 11 Experimental setup to measure the integrated servo motor

The motor shaft adapts to an inertia load of about 5 times of its normal inertia, then the integrated servo motor

is reciprocating at +/- 1500rpm in speed mode through the Beckhoff's cx9020 controller. During the experiment,

the SERVO soft Studio software on the PC is used to monitor the real-time signal from speed, current and

torque of the motor. An oscillator is used to gather the signals of line current and arm voltage of SiC-MOSFET.

The test is performed with the DC bus voltage in 600V, acceleration and deceleration from +1500rpm to 1500rpm has accomplished in 150ms and 50ms respectively. In the normal response test, the peak value of line

current reaches to approx.11A. In the fast response test, the peak value is up to approx.28A, thus the most

critical condition is verified successfully.

User guide 18 of 22 V 1.0

2020-11-15

Page 19

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

System performance

Figure 12 Experimental waveform of acceleration and deceleration (from +1500rpm to -1500rpm)

(CH3: AC line current, CH4: Vds of SiC-MOSFET)

User guide 19 of 22 V 1.0

2020-11-15

Page 20

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

References and appendices

5 References and appendices

[1] AN2018-01 EVAL-M1-101T User Manual

[2] IMBG120R045M1H datasheet

User guide 20 of 22 V 1.0

2020-11-15

Page 21

User Guide for REF-DR3KIMBGSICMA

Reference design for motor drive integration

Revision history

Revision history

Document

version

1.0 2020-11-15 Initial version

Date of release Description of changes

User guide 21 of 22 V 1.0

2020-11-15

Page 22

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2020-11-15

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2020 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

UG 2020-32

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of the

product or any consequences of the use thereof can

reasonably be expected to result in personal injury.

Loading...

Loading...