Page 1

User Guide Please read the Important notice and the Safety precautions and the Warnings

www.infineon.com page 1 of 38 2021-01-29

UG-2020-28

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

About this document

Scope and purpose

This user guide provides an overview of the evaluation kit REF-22K-GPD-INV-EASY3B including its main

features, key data, pin assignments, mechanical dimensions and corresponding control card. The reference kit

REF-22K-GPD-INV-EASY3B is an industrial motor drive for three-phase 400 V AC grids and has a nominal power

of 22 kW.

The REF-22K-GPD-INV-EASY3B includes the Easy3B power module FP100R12W3T7_B11, the current sensor

TLI4971-A120T5, the gate driver IC 1ED3131MC12H, the 1.7 kV SiC-MOSFET IMBF170R1K0M1 and the

microcontrollers XMC4800-F144F2048 and XMC4300-F100K256. The combination of these Infineon products

allows the customer to evaluate these products in one design and experience the interaction between the

products.

Beside the hardware, the REF-22K-GPD-INV-EASY3B offers you software for control and communication. The

inverter can be controlled via a touch screen and PC-GUI.

Note: Please note that this product is not qualified according to the AEC Q100 or AEC Q101 documents of

the Automotive Electronics Council.

Intended audience

This user guide is intended for all technical specialists working on industrial drives and those interested in how

the latest Infineon products like IGBT7, XENSIV™ current sensors, EICE™ drivers and CoolSiC™ MOSFETs perform

under application conditions.

Reference Kit

The Infineon products are embedded on this PCB with functions and form factor close to a commercial design.

PCB and auxiliary circuits are optimized for the final design.

Note: Boards do not necessarily meet safety, EMI, quality standards (for example UL, CE) requirements.

Page 2

User Guide 2 of 38

2021-01-29

User Guide for REF-22K-GPD-INV-EASY3B

Reference design for motor general purpose drives

The reference board at a glance

Important notice

“Evaluation Boards and Reference Boards” shall mean products embedded on a printed circuit board

(PCB) for demonstration and/or evaluation purposes, which include, without limitation, demonstration,

reference and evaluation boards, kits and design (collectively referred to as “Reference Board”).

Environmental conditions have been considered in the design of the Evaluation Boards and Reference

Boards provided by Infineon Technologies. The design of the Evaluation Boards and Reference Boards

has been tested by Infineon Technologies only as described in this document. The design is not qualified

in terms of safety requirements, manufacturing and operation over the entire operating temperature

range or lifetime.

The Evaluation Boards and Reference Boards provided by Infineon Technologies are subject to functional

testing only under typical load conditions. Evaluation Boards and Reference Boards are not subject to the

same procedures as regular products regarding returned material analysis (RMA), process change

notification (PCN) and product discontinuation (PD).

Evaluation Boards and Reference Boards are not commercialized products, and are solely intended for

evaluation and testing purposes. In particular, they shall not be used for reliability testing or production.

The Evaluation Boards and Reference Boards may therefore not comply with CE or similar standards

(including but not limited to the EMC Directive 2004/EC/108 and the EMC Act) and may not fulfill other

requirements of the country in which they are operated by the customer. The customer shall ensure that

all Evaluation Boards and Reference Boards will be handled in a way which is compliant with the relevant

requirements and standards of the country in which they are operated.

The Evaluation Boards and Reference Boards as well as the information provided in this document are

addressed only to qualified and skilled technical staff, for laboratory usage, and shall be used and

managed according to the terms and conditions set forth in this document and in other related

documentation supplied with the respective Evaluation Board or Reference Board.

It is the responsibility of the customer’s technical departments to evaluate the suitability of the

Evaluation Boards and Reference Boards for the intended application, and to evaluate the completeness

and correctness of the information provided in this document with respect to such application.

The customer is obliged to ensure that the use of the Evaluation Boards and Reference Boards does not

cause any harm to persons or third party property.

The Evaluation Boards and Reference Boards and any information in this document is provided "as is"

and Infineon Technologies disclaims any warranties, express or implied, including but not limited to

warranties of non-infringement of third party rights and implied warranties of fitness for any purpose, or

for merchantability.

Infineon Technologies shall not be responsible for any damages resulting from the use of the Evaluation

Boards and Reference Boards and/or from any information provided in this document. The customer is

obliged to defend, indemnify and hold Infineon Technologies harmless from and against any claims or

damages arising out of or resulting from any use thereof.

Infineon Technologies reserves the right to modify this document and/or any information provided

herein at any time without further notice.

Page 3

User Guide 3 of 38

2021-01-29

User Guide for REF-22K-GPD-INV-EASY3B

Reference design for motor general purpose drives

The reference board at a glance

Safety precautions

Note: Please note the following warnings regarding the hazards associated with development systems.

Table 1 Safety precautions

Warning: The DC link potential of this board is up to 1000 VDC. When measuring

voltage waveforms by oscilloscope, high voltage differential probes must be used.

Failure to do so may result in personal injury or death.

Warning: The evaluation or reference board contains DC bus capacitors which take

time to discharge after removal of the main supply. Before working on the drive

system, wait five minutes for capacitors to discharge to safe voltage levels. Failure to

do so may result in personal injury or death. Darkened display LEDs are not an

indication that capacitors have discharged to safe voltage levels.

Warning: The evaluation or reference board is connected to the grid input during

testing. Hence, high-voltage differential probes must be used when measuring voltage

waveforms by oscilloscope. Failure to do so may result in personal injury or death.

Darkened display LEDs are not an indication that capacitors have discharged to safe

voltage levels.

Warning: Remove or disconnect power from the drive before you disconnect or

reconnect wires, or perform maintenance work. Wait five minutes after removing

power to discharge the bus capacitors. Do not attempt to service the drive until the bus

capacitors have discharged to zero. Failure to do so may result in personal injury or

death.

Caution: The heat sink and device surfaces of the evaluation or reference board may

become hot during testing. Hence, necessary precautions are required while handling

the board. Failure to comply may cause injury.

Caution: Only personnel familiar with the drive, power electronics and associated

machinery should plan, install, commission and subsequently service the system.

Failure to comply may result in personal injury and/or equipment damage.

Caution: The evaluation or reference board contains parts and assemblies sensitive to

electrostatic discharge (ESD). Electrostatic control precautions are required when

installing, testing, servicing or repairing the assembly. Component damage may result

if ESD control procedures are not followed. If you are not familiar with electrostatic

control procedures, refer to the applicable ESD protection handbooks and guidelines.

Caution: A drive that is incorrectly applied or installed can lead to component damage

or reduction in product lifetime. Wiring or application errors such as undersizing the

motor, supplying an incorrect or inadequate AC supply, or excessive ambient

temperatures may result in system malfunction.

Caution: The evaluation or reference board is shipped with packing materials that

need to be removed prior to installation. Failure to remove all packing materials that

are unnecessary for system installation may result in overheating or abnormal

operating conditions.

Page 4

User Guide 4 of 38

2021-01-29

User Guide for Ref_22k_GPD-INV_Easy3B

Reference design for motor general purpose drives

Table of contents

Table of contents

About this document ....................................................................................................................... 1

Important notice ............................................................................................................................ 2

Safety precautions .......................................................................................................................... 3

Table of contents ............................................................................................................................ 4

1 The reference board at a glance ............................................................................................... 5

1.1 Delivery content ...................................................................................................................................... 5

1.2 Block diagram .......................................................................................................................................... 5

1.3 Main features ........................................................................................................................................... 7

1.4 Board parameters and technical data .................................................................................................... 7

1.4.1 Overload profile normal duty ............................................................................................................ 8

1.4.2 Heavy duty overload profile .............................................................................................................. 9

2 System and functional description .......................................................................................... 10

2.1 Commissioning ...................................................................................................................................... 10

2.2 Description of the functional blocks ..................................................................................................... 14

2.2.1 Hardware partitioning ..................................................................................................................... 14

2.2.2 Isolation coordination ..................................................................................................................... 16

2.2.3 Board interconnection schemes ..................................................................................................... 17

2.2.4 Supply schemes ............................................................................................................................... 18

2.2.5 Component selection ....................................................................................................................... 18

3 System design....................................................................................................................... 19

3.1 Schematics ............................................................................................................................................ 19

3.2 Layout .................................................................................................................................................... 19

3.2.1 Power board ..................................................................................................................................... 19

3.3 Inverter cooling concept ....................................................................................................................... 21

3.4 Disassembly of the housing .................................................................................................................. 22

3.5 Bill of material ....................................................................................................................................... 25

3.6 Connector details .................................................................................................................................. 25

4 System performance ............................................................................................................. 28

4.1 Test results inverter start-up ................................................................................................................ 28

4.2 Operation under rated conditions ........................................................................................................ 29

4.3 Switching behavior of the IGBT turn-on ............................................................................................... 31

4.4 Switching behavior of the IGBT – turn-off ............................................................................................ 32

4.5 Thermal behavior of the inverter under high overload ....................................................................... 33

4.6 Short-circuit measurement ................................................................................................................... 34

5 References and appendices .................................................................................................... 36

5.1 Abbreviations and definitions ............................................................................................................... 36

5.2 References ............................................................................................................................................. 36

Revision history ............................................................................................................................. 37

Page 5

User Guide 5 of 38

2021-01-29

The reference board at a glance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

1 The reference board at a glance

1.1 Delivery content

The reference kit is a general purpose drive developed for applications like pumps, fans, compressors,

conveyor belts. The design has the look and feel of a typical drive and includes EMI filter, pre-charge and

capacitor bank, isolated power supplies, power module, controls and heat sink with fan. It can be operated

directly on a three-phase grid, enabling a fast evaluation of Infineon's newest technologies like IGBT7, gate

driver, current sensor and control in one system. This enables the unique opportunity to see the improvement

by combining Infineon's newest technologies. You will see how the new IGBT7 modules work with the EICE™

gate driver, or test the accuracy of the current sensor.

1.2 Block diagram

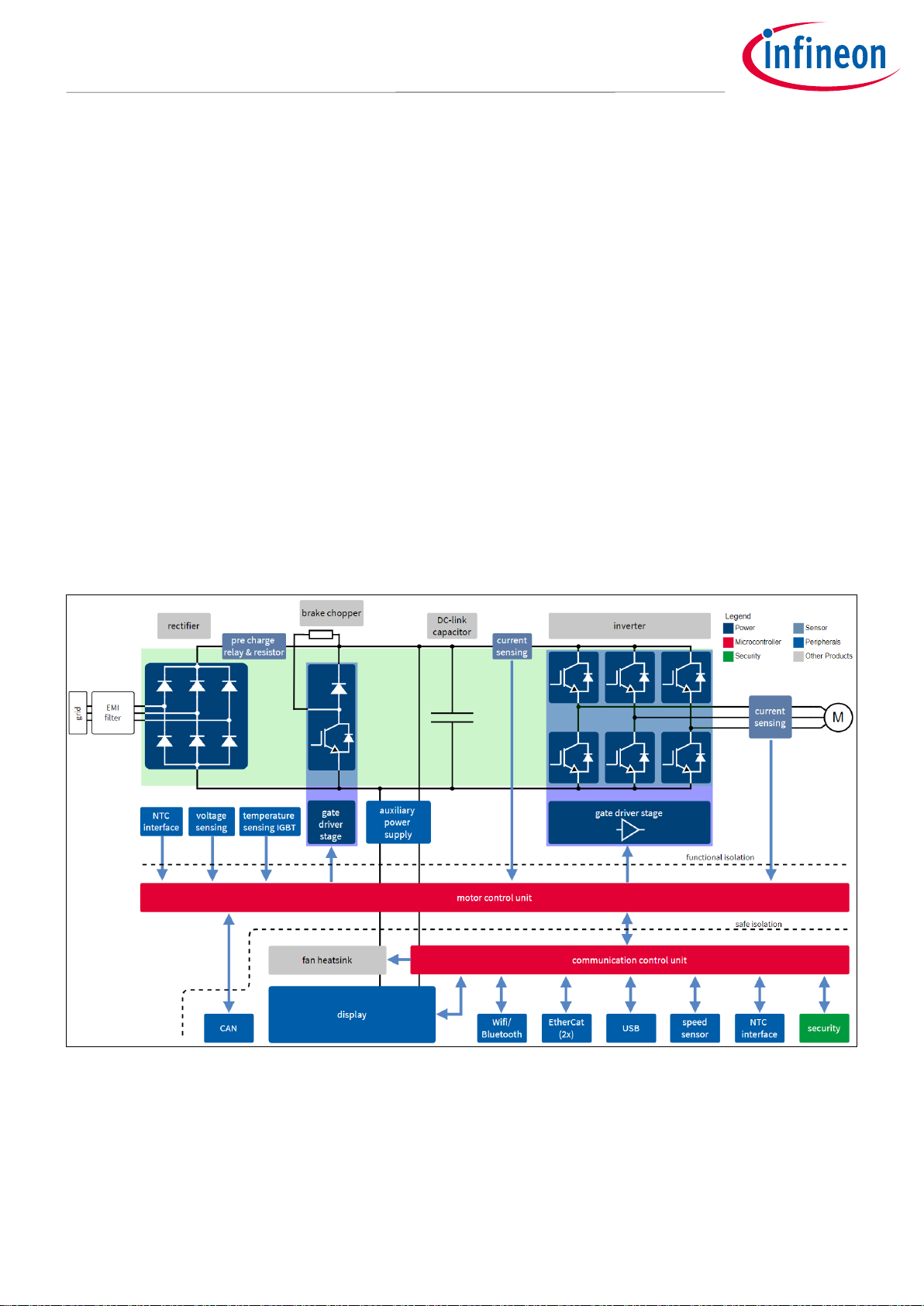

The block diagram of the inverter REF-22K-GPD-INV-EASY3B is shown in Figure 1. The board consists of five

boards: power board, EMI filter, high-voltage logic board, low-voltage interface board, and the DC-link board

which are mounted in one housing. For more details see Section 2.2.1.

Figure 1 Block diagram of the inverter

The reference kit REF-22K-GPD-INV-EASY3B is a fully operation industrial drive inverter which can be connected

to a three-phase AC input supply. The reference kit includes an input EMI-filter. The AC voltage is rectified via

the uncontrolled diode full bridge. The inrush current is limited by pre-charge circuitry. The rectified AC voltage

is stabilized by a DC-link capacitor bank. The IGBT six pack allows for the modulation of a three-phase output

voltage/current which can be varied in terms of its amplitude and frequency. This three-phase current is used

Page 6

User Guide 6 of 38

2021-01-29

The reference board at a glance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

for controlling the speed and torque of the motor. During braking or deceleration of the motor, energy is

transferred back into the DC-link capacitor increasing the DC bus voltage. Therefore, a brake chopper is

included that absorbs this energy by switching an external brake resistor across the DC bus capacitors. The

three-phase input rectifier, the six pack as well as the brake chopper are all included in one power module, the

Easy3B IGBT FP100R12W3T7_B11. All IGBTs are switched using EICE™ drivers, the 1ED3131MC12H. The isolation

coordination details of the unit can be found in Section 2.2.2.

The current measurement of the three-phase output current is done with TLI4971-A120T5 current sensors. The

current signals are used for the motor control; additionally, these sensors are used to detect an external short

circuit for the IGBT’s. To protect the module against an internal short circuit, a fourth current sensor is

integrated between the DC-link capacitor and the IGBT module.

The auxiliary voltage for the inverter is generated with a DC/DC switch mode power supply (SMPS) converter.

The CoolSiC™-MOSFET IMBF170R1K0M1 is used in a flyback topology. More details about the flyback SMPS are

listed in Section 2.2.4.

The reference inverter uses two microcontrollers; one for control and one for communication. For control the

XMC4800-F144F2048 is used, for communication the XMC4300-F100K256 AA is designed in. Both

microcontrollers communicate via an UART interface. The communication microcontroller allows the inverter

to be controlled via a touch-screen or a PC-GUI. More details on the communication interface can be found in

Section 2.2.1.

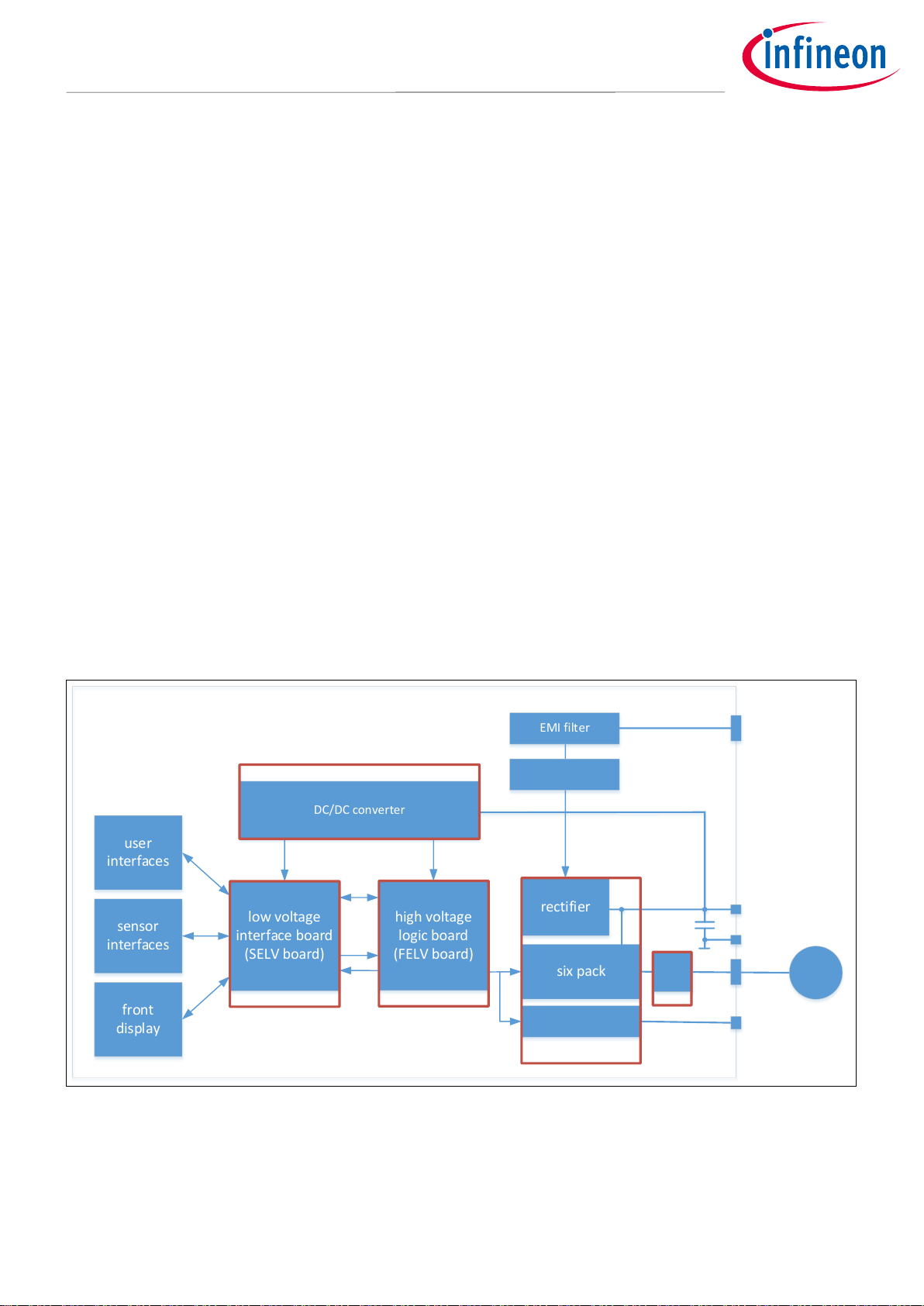

A simplified block diagram is shown in Figure 2. The block diagram shows the main components of the boards,

the DC/DC SMPS converter, the low-voltage interface board (SELV board), high-voltage logic board (FELV

board), the IGBT module incl. the gate driver IC, and the output phase current measurement. Also the main

Infineon components used in the specific blocks are listed in the diagram.

-_

high voltage

logic board

(FELV board)

low voltage

interface board

(SELV board)

rectifier

DC/DC converter

EMI filter

six pack

3Ph

Motor

user

interfaces

front

display

sensor

interfaces

3 phase

AC Input

3 phase

AC output

brake chopper

DC-Link

brake resistor

pre charge

resistor/relay

FP100R12W3T7_B11

1ED3131MC12H

curr

3 ph

TLI4971

IMBF170R1K0M1

XMC4800

XMC4300

Figure 2 Simplified block diagram of the inverter

Page 7

User Guide 7 of 38

2021-01-29

The reference board at a glance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

1.3 Main features

FP100R12W3T7_B11: EASY3B IGBT7 module for high-current and high-power density [3]

TLI4971-A120T5: XENSIV

TM

current sensor for measuring high currents with minimal power loss [4]

1ED3131MC12H: Gate driver for optimal EMI performance and reduced power losses [5]

IMBF170R1K0M1: Infineon CoolSiC

TM

MOSFET 1700 V enables direct drive by most flyback controllers [6]

XMC4800-F144F2048 and XMC4300-F100K256 AA: XMC microcontrollers for inverter control and

communication [7]

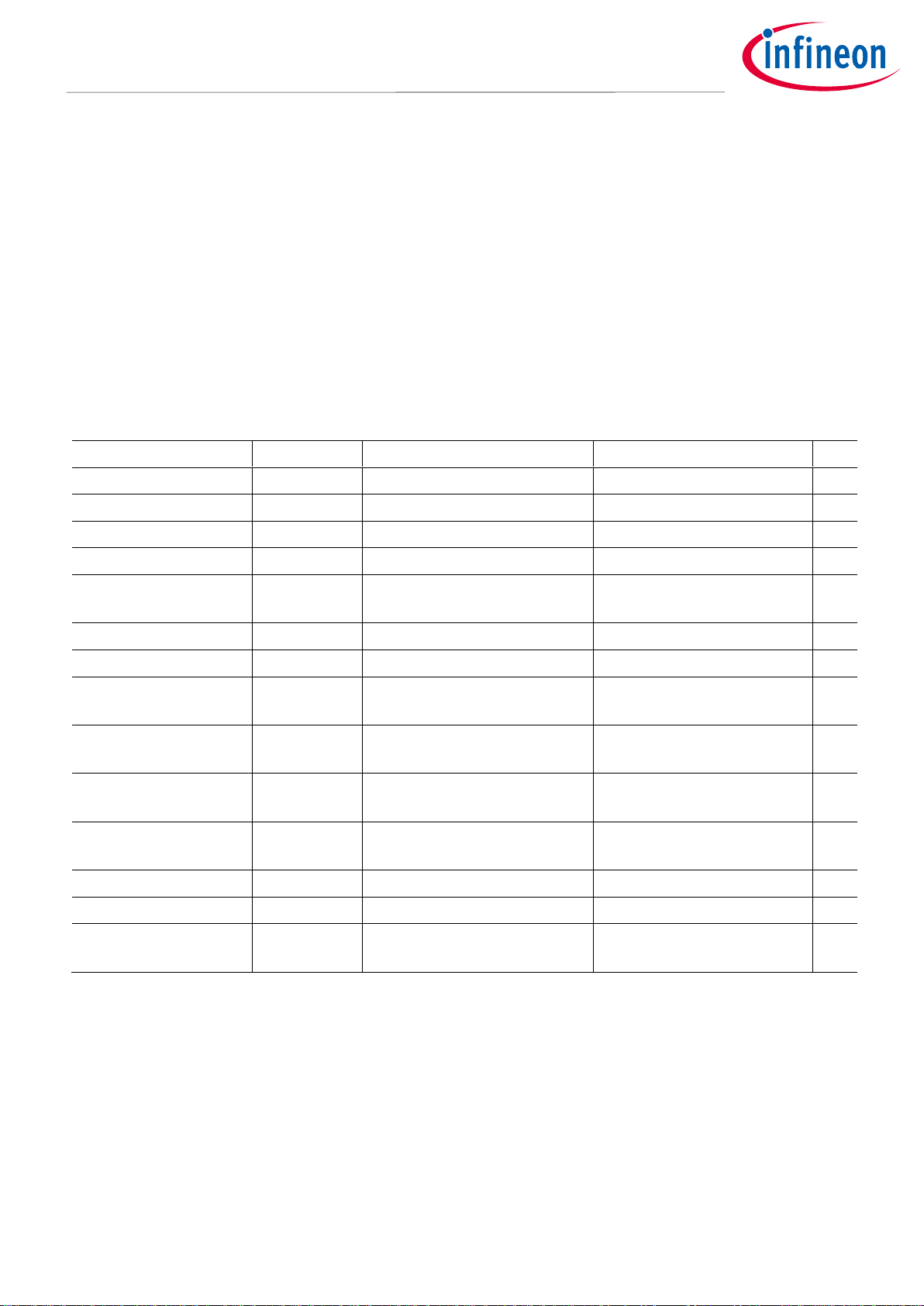

1.4 Board parameters and technical data

The key parameters of the REF-22K-GPD-INV-EASY3B are shown in Table 2.

Table 2 Parameters of REF-22K-GPD-INV-EASY3B

Parameter

Symbol

Conditions

Value

Unit

Input line voltage

Vin

Three-phase AC ± 10%

380 … 480

V

Input frequency

fin

± 3 Hz

50 … 60

Hz

Output voltage

V

out

three-phase AC

0 V … 0.95 x input voltage

V

Output frequency

f

out

0 … 550

Hz

Switching frequency of

motor output

fsw

Factory setting 4 kHz

4

kHz

Rated power

P

rated

22

kW

Rated current

I

rated

45

A

Low overload - base

load power

PLO

T

amb

<= 35°C

22

kW

Low overload - base

load current

ILO 45

A

High overload - base

load power

PHO 18.5

kW

High overload - base

load current

IHO 38

A

Power losses

P

loss

< 700

W

Weight

m

inv

< 10

kg

Ambient temperature

T

amb

Relative humidity RH; 30% <

RH< 80%

10 to 35

°C

Page 8

User Guide 8 of 38

2021-01-29

The reference board at a glance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

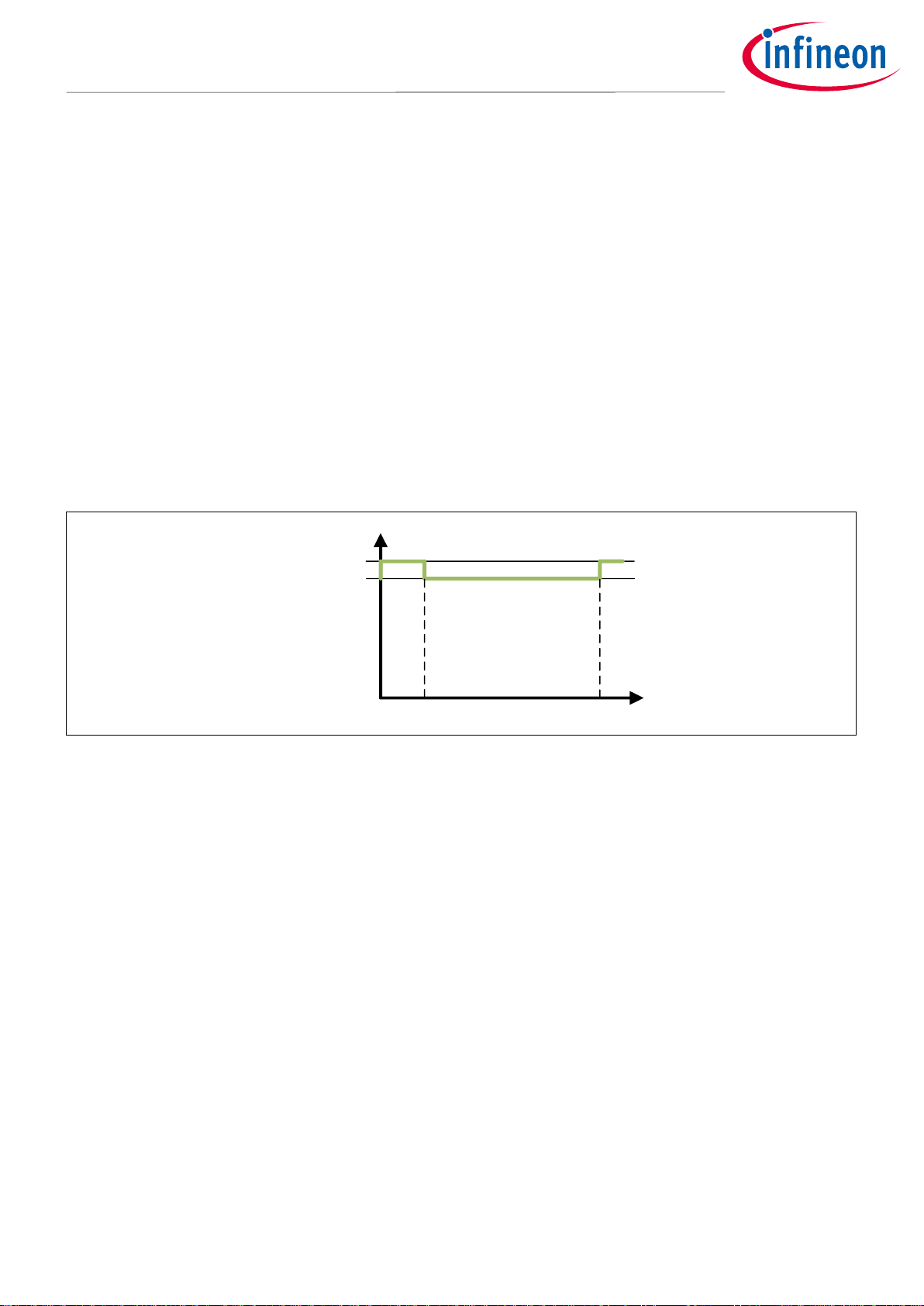

1.4.1 Overload profile normal duty

The normal duty (ND) load cycle assumes a uniform base load with low requirements during short acceleration

times at high torque; see Figure 3. Typical applications when designing according to normal duty include:

- Pumps, fans and compressors

- Wet or dry blasting technology

- Mills, mixers, kneaders, crushers, agitators

- Basic spindles

- Rotary kilns

- Extruders

Typical converter load cycle:

110% I

LO

= 50 A

60

300

time in s

100% of I

LO

= 45 A

current

in A

Figure 3 Overload profile normal duty

Page 9

User Guide 9 of 38

2021-01-29

The reference board at a glance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

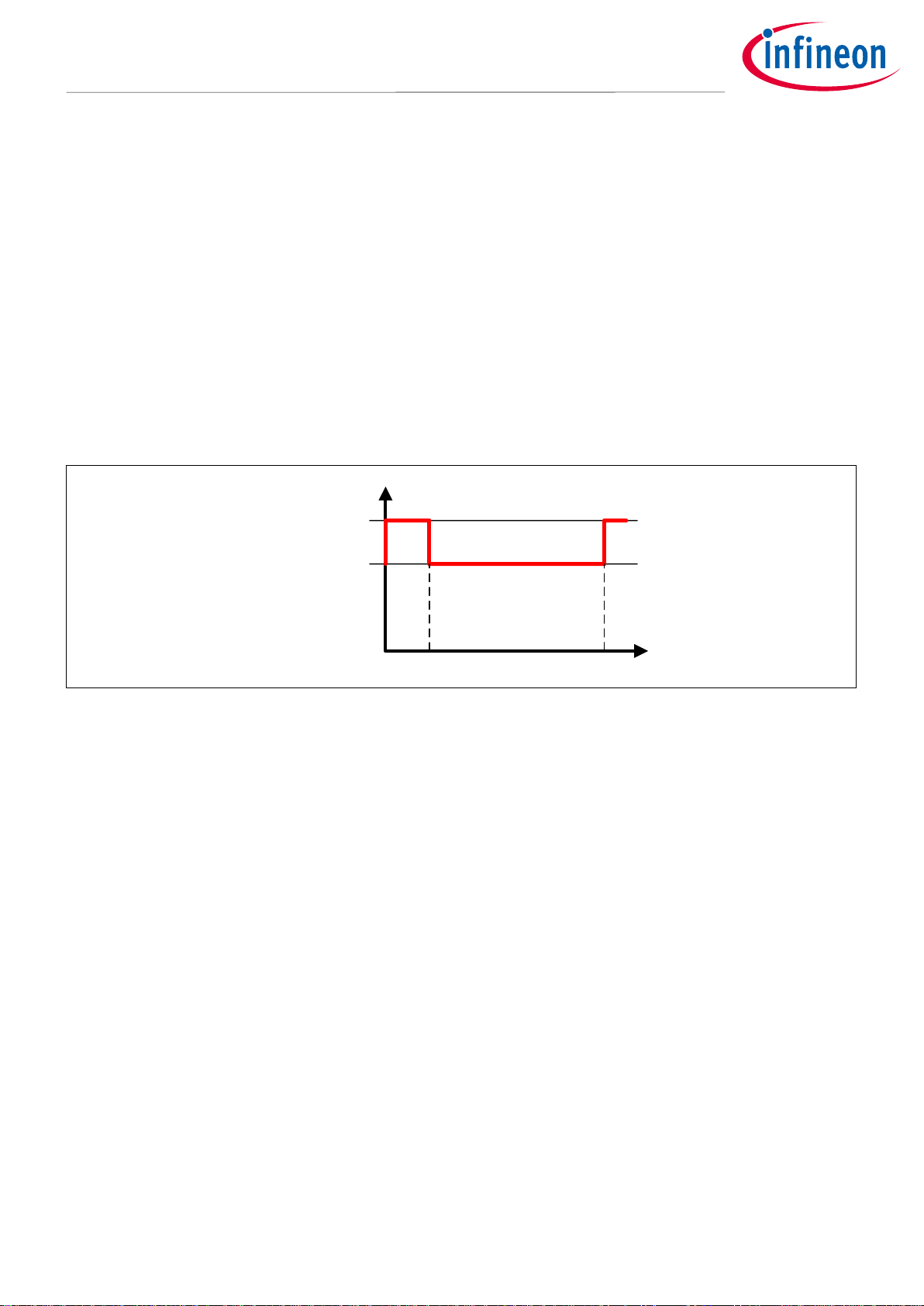

1.4.2 Heavy duty overload profile

The heavy duty (HD) load cycle permits dynamic accelerating phases at a reduced base load; see Figure 4.

Typical applications when designing according to heavy duty include:

- Horizontal and vertical conveyor technology (conveyor belts, roller conveyors, chain conveyors)

- Centrifuges

- Escalators/moving stairways

- Lifters

- Elevators

- Gantry cranes

- Storage and retrieval machines

Typical converter load cycle:

150% of I

HO

= 57 A

60

300

100% of I

HO

= 38 A

time in s

Figure 4 Overload profile heavy duty

Page 10

User Guide 10 of 38

2021-01-29

System and functional description

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

2 System and functional description

2.1 Commissioning

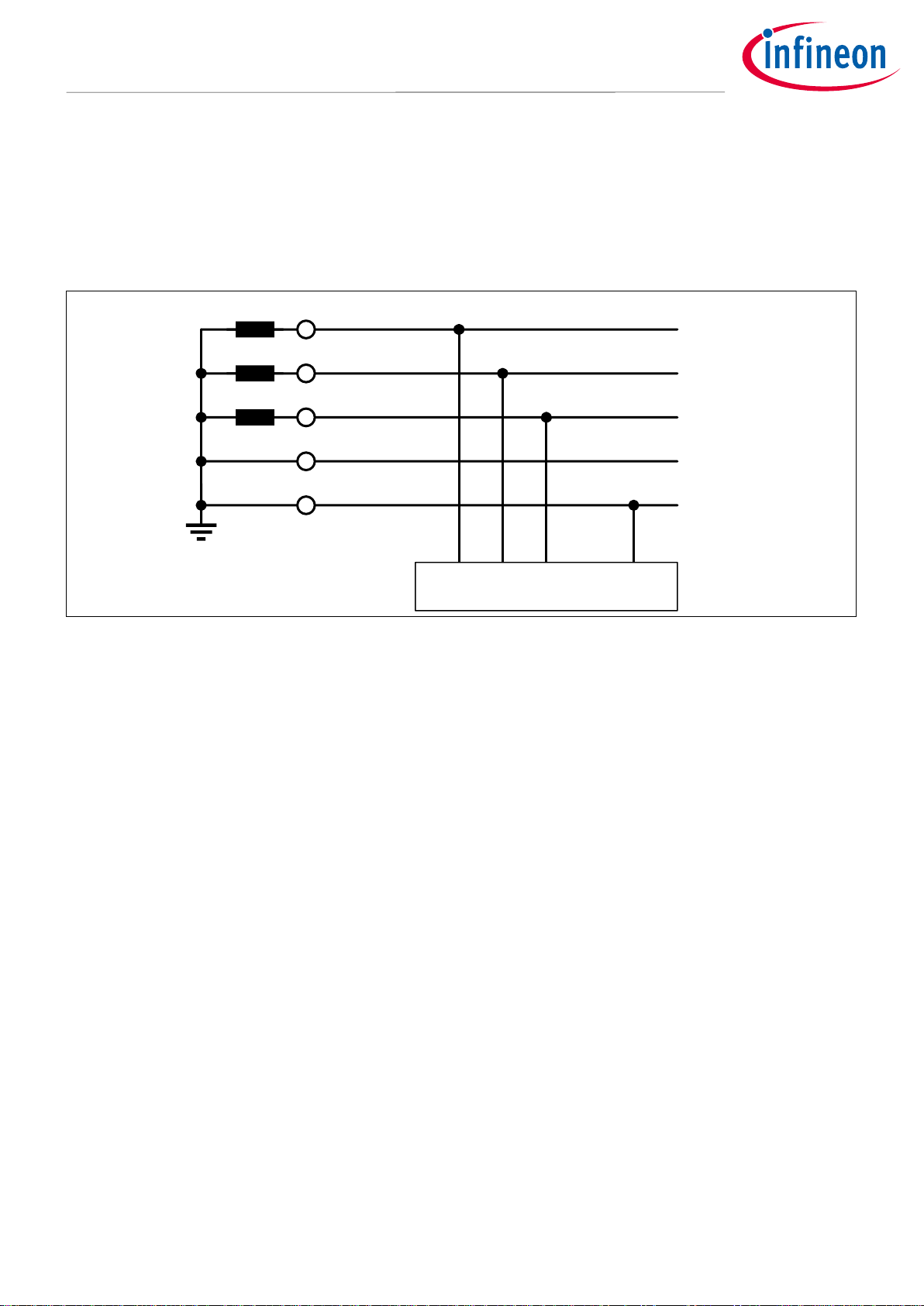

The REF-22K-GPD-INV-EASY3B must be connected to a TN-S line system as shown in Figure 5. The connections

to the inverter can be made only after the converter is unpacked and all packaging material has been removed.

Ref_22k_GPD-INV_Easy3B

Transformer

or generator

L1

L2

L3

N

PE

Figure 5 Connection of the inverter to TN-S line system

A TN-S system transfers the PE protective conductor to the installed plant or system using a cable. Generally, in

a TN-S system, the neutral point is grounded. A TN system can transfer the neutral conductor N and the PE

protective conductor either separately or combined. Also the connection to a TT system is permissible, but the

connection to an IT is not permissible. The reason here is the missing or high-impedance earth connection.

The connection of the inverter is shown in Figure 6. The cross-section of the wires for the line connection, the

brake chopper and the motor cable are in the range of 1.5 to 10 mm². Ensure that the inverter is in a no-voltage

condition and the DC-link is discharged.

Page 11

User Guide 11 of 38

2021-01-29

System and functional description

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

To connect the line feeder cables (L1, L2, L3 and PE), see Figure 6. To ensure correct fusing, it is recommended

to make a selection according to IEC is 3NA3824 (80A). Also, connect the motor feeder cables (PE, U, V and W) to

the inverter. The connection of a brake resistor is optional.

L1

L2

L3

PE

PE

U

V

W

R

brake

Figure 6 Connecting of the inverter

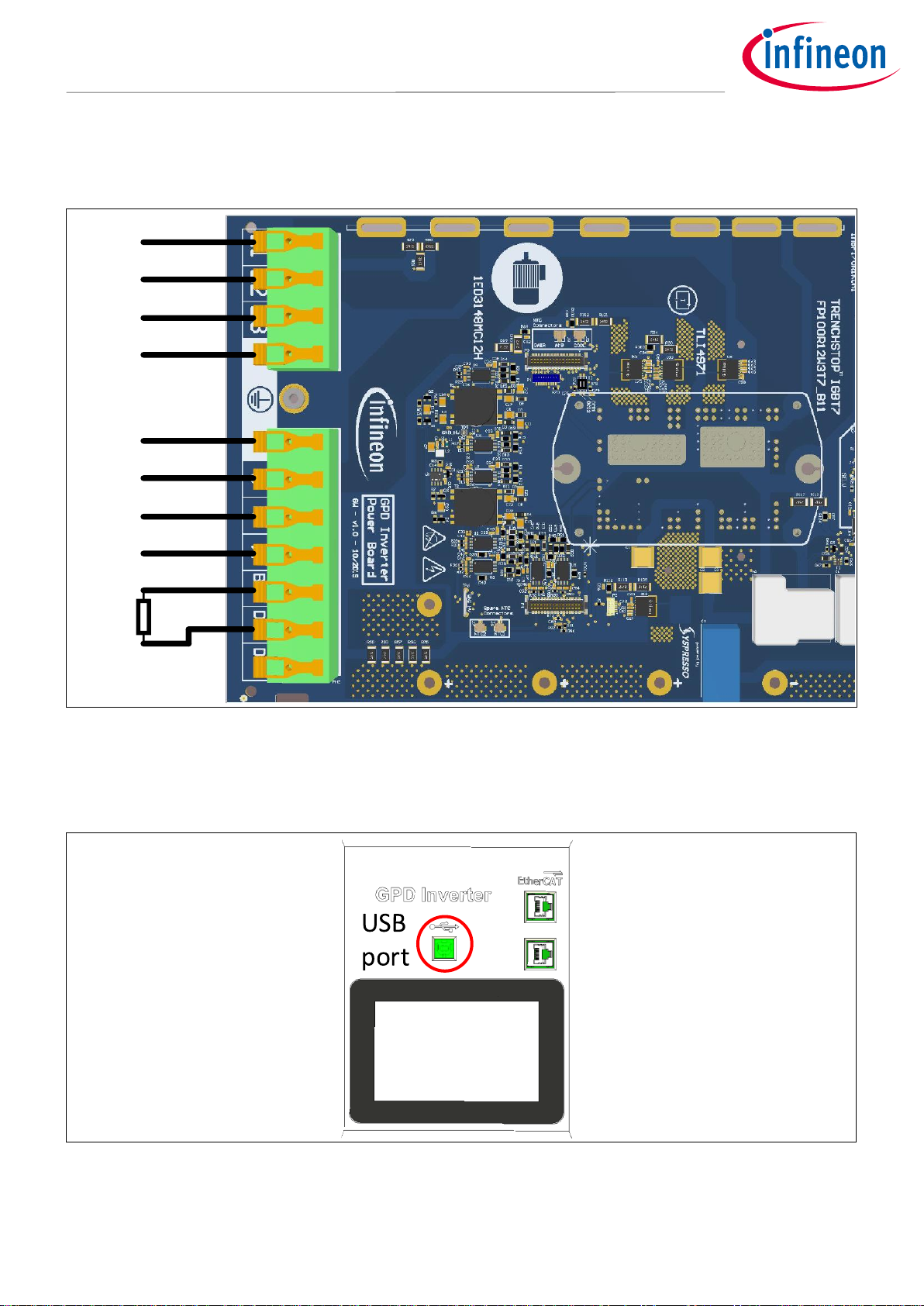

Also connect a USB cable to the inverter allowing for communication with the drive. The USB port is located at

the front of the inverter; see Figure 7.

Figure 7 USB port of the inverter

Page 12

User Guide 12 of 38

2021-01-29

System and functional description

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Before you start the inverter, you need to install the XMC driver and launch the GUI. The software can be

downloaded via Infineon.com. Please register your inverter to get access to the software.

For installation, it is required to have admin rights on your computer. The software was tested with a laptop

(HP EliteBook 840 G5) and Windows 10 Enterprise (Build: 10.0.17134). You have to first install the USB driver, so

extract the file XMC_WinUSBDriver.zip.

To start with the installation, connect your computer with a USB cable to the inverter, and apply an appropriate

voltage to the line feeder cable. The inverter will start operation in idle mode. Now you can install the USB

driver: Go to “Control Panel\All Control Panel Items” then to “Device Manager.” Select the new USB device

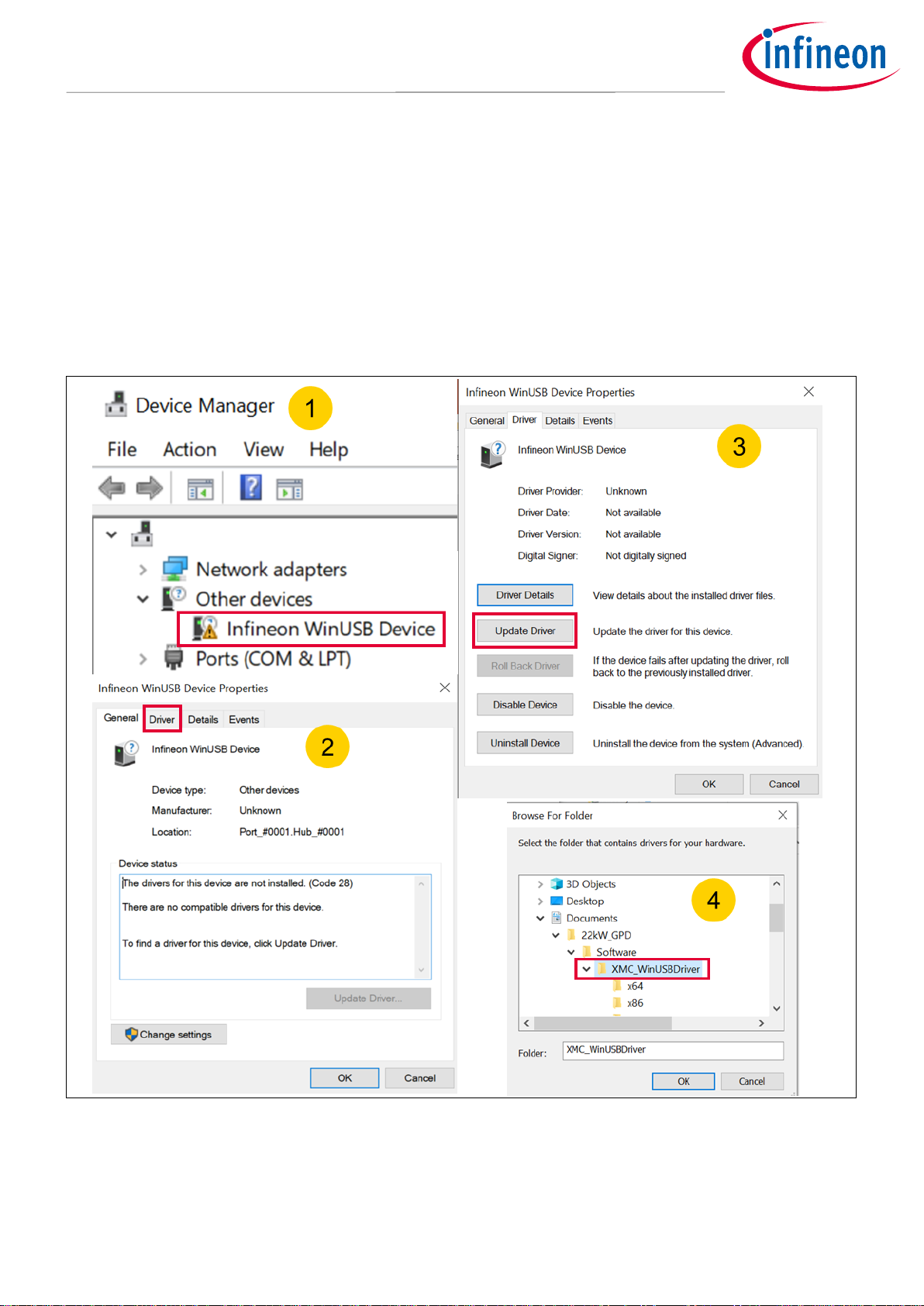

“Infineon WinUSB Device;” see Figure 8 part 1, and double click it.

Figure 8 USB device installation

The window, as shown in Figure 8 part 2, will then appear. Click on the “Driver” tab, then “Update Driver” as

shown in Figure 8 part 3. Now select the extracted folder “XMC_WinUSBDriver” as shown in Figure 8 part 4. Click

on “OK” and close all windows you opened previously. The USB driver is now installed.

Page 13

User Guide 13 of 38

2021-01-29

System and functional description

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

The next step is to extract the file GUI_20200819.zip; the software is available at Infineon.com. Open the folder

“Debug” and double click on “GPD Inverter.exe”. A window as shown in Figure 9 (left side) appears. You can

connect your drive system by selecting the USB device via the drop-down menu and click on “Connect.” Now

your computer is communicating with the drive system.

Figure 9 Main GUI and Config tab

Be clicking on the “Config” tab, a window will be shown as in Figure 9 (right side). You can read the Config file

from your inverter by clicking on “Read config.” Now you can change the settings. The “Control Method” can be

selected either as “V/f” or “Manual.” The parameters for the “V/f” mode can be adjusted in the “Inverter

Configuration” window. In the manual mode, you can select the “Speed” value and the “Amplitude” value

manually; see the “General” Tab of the GUI. In the “Config” tab you can also change the “IGBT Overtemp

shutdown” value. The “Load Pulse Pattern Config” window allows you to operate the inverter in a periodic or

cyclical mode. This function works only in “Manual” mode, and changes the duty-cycle value for a specific time.

This approach allows for an easy implementation of an overload pattern, as shown in Figure 3 using an

inductive-resistive load. In addition, a short-circuit test is also possible via the GUI; further details will be

explained in Section 4.6.

Via the “General” tab, you can start the motor. You can run the motor in “V/f” mode; see section “Control

Method.” The speed of the motor, hence the output frequency of the inverter, can be adapted by the slider

“Speed.” After selecting your speed, click on “Update.” You can change the “V/f” ration in the “Config” tab, as

already mentioned. Via the “Manual” control mode, you can select the “Speed” and the “Amplitude” which

represents the modulation index.

Page 14

User Guide 14 of 38

2021-01-29

System and functional description

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

The current status of the inverter can be seen by clicking on “Diagnostics.” A window will appear as shown in

Figure 10 (left side). The voltage levels of the different power supplies will be shown, as well as any flagged

faults in the inverter.

Figure 10 Diagnostics and oscilloscope of the GUI

An additional feature of the inverter GUI is the oscilloscope function, which is shown in Figure 10 (right side).

The oscilloscope allows the measurement signals of the inverter to be shown, e.g. the phase output current, the

DC-link voltage or the NTC-temperature of the IGBT module.

2.2 Description of the functional blocks

2.2.1 Hardware partitioning

The inverter hardware is partitioned into five boards:

- Power board

- EMI filter

- High-voltage logic board

- Low-voltage interface board

- DC-link board

Thanks to the separation of these individual functions, a high level of functionality can be implemented with

minimum board space. Each board will be described in the following:

Power board:

The power board is used as a central connection and wiring unit between all other sub-boards. It contains the

main connectors (power inlet and outlet), the power module, the main DCDC-converter and the gate driver

including their power supplies. While the power board itself only contains a small DC-link capacitor, it connects

to the capacitor bank which has ix (3 sets of 2 in series) electrolytic capacitors.

DC-link board:

The board has the electrolytic capacitors of the inverter. The separation of the capacitors on an additional

board allows more design freedom and a more compact design of the inverter.

Page 15

User Guide 15 of 38

2021-01-29

System and functional description

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

EMI-Filter:

The EMI input filter is used to suppress RF noise generated by the inverter operation. It is designed as threephase CLC-topology. Due to the size and weight of the individual components, it is implemented on a separate

sub-board that connects to the power board via solder connectors.

High-voltage logic board (FELV board):

All logic functions required to control the drive motor are implemented on the high-voltage (HV) logic board. It

is based on a XMC4800 microcontroller as its central processing unit. The board contains the infrastructure to

supply and supervise the microcontroller, diagnostic functions for the high-voltage part of the drive as well as

all safety and protection functions needed to protect the inverter in case of overload or short-circuit conditions.

The HV board features a direct connection the components on the power board. All control inputs for the motor

control as well as the diagnostic status information are provided via a UART link to the low-voltage (SELV)

interface board. Besides the UART link, the board features both a digital status input and output signal to

indicate and receive information on critical error or fault conditions.

In order to minimize the number of required isolation barriers, the FELV board is referenced to the negative

potential of the DC-link.

Low-voltage logic board (SELV board):

The low-voltage logic board is used to provide the user and external sensor interface functions. It features

connectivity options for:

- EtherCat

- USB 2.0

- WLAN

- Bluetooth

- RS485

- High-Speed CAN

Besides the user interface function, the board also provides the capability to interface with external sensors,

such as:

- High-resolution rotor speed sensor (two wire current interface)

- High-resolution rotor angle sensor (GP-HSSI Interface)

- Temperature sensor

Besides the connectivity options to remote control units, the SELV board can also be connected to a local touch

pad display. This local control input allows the display of current operating conditions as well as basic user

control.

The data exchange between SELV and FELV board is established via a bidirectional UART link. All relevant

control commands received via the above-listed interface options or the touch display are forwarded to the

FELV board via this link. For safety and redundancy reasons, the board provides two additional direct

connections to the FELV board (1x input, 1x output) for error indication on the respective board. In case of a

broken UART connection, critical error conditions on either board can be indicated via these redundant signals

to cause the inverter to transition into a safe state.

Page 16

User Guide 16 of 38

2021-01-29

System and functional description

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

In order to simplify the supply scheme for the multiple external user interfaces, the SELV board is supplied via a

safety-isolated, low-voltage power supply. The connection to the high voltage logic board (UART, direct

connection lines) is therefore established via digital isolator devices featuring reinforced isolation capability.

2.2.2 Isolation coordination

The inverter design provides three major main voltage domains:

- A mains-connected domain

- A low-voltage domain with functional isolation

- A safety-isolation domain

In Figure 11 you will find a drawing of the basic isolation coordination scheme.

Figure 11 Basic isolation coordination scheme, the low- voltage interface board is referenced to PE

and the high- voltage logic board is referenced to DC-

All power components (EMI filter, rectifier, IGBT inverter, brake switch) are directly connected to the mains

supply domain. The main controller is based on a functional isolated scheme, which is connected to the DCpotential of the power domain. Thanks to this isolation scheme, all interfaces between the power domain and

the main control domain only provide functional isolation. This applies in particular for the gate drivers, their

power supply, the output current sensors and the voltage measurement circuits. All user interface connections

are implemented on a safety-insulated domain. In order to establish a communication link between the safetyisolation domain and the functional isolation domain, a digital interface using a safety isolated data coupler is

Page 17

User Guide 17 of 38

2021-01-29

System and functional description

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

implemented. The supply for the entire board is provided by a centralized DC/DC converter which takes power

from the mains supplied DC-link. The converter provides two output voltages, a functional isolated output for

the functional isolation domain (FELV) and a reinforced output voltage for the user interface (SELV) domain.

2.2.3 Board interconnection schemes

The power board is used as a main platform for all sub-boards. The mains power connection is performed by

power connectors on the bottom-left side of the inverter board. After passing the EMI filter board, which is

connected to the left side of the power PCB, the power is routed to the power module. The rectification of the

AC input power is performed in the power module; the DC-link capacitors are located on the right side of the

inverter and are connected via the power PCB. Since the capacitor bank is implemented as a separate unit, the

mechanical and electrical connections are made by special mounting screws. A CAD-model of the inverter is

shown in Figure 12.

Figure 12 Inverter Construction Scheme (front-left view), Housing removed

The inverter power supply is performed by a DC/DC converter which generates galvanically isolated supply

voltages for the power board, the high-voltage control board and the user interface board; see Figure 13. Both

user interface boards as well as the high-voltage control board are connected the power board via pin headers.

The user interface board connects to the power board on a safety-isolation island which provides the DC power

for the board and the isolation stage for the digital communication link to the high-voltage control board.

Connections to external sensors (e.g. rotor position sensor) or external communication buses (EtherCAT, USB,

RS485, CAN) are directly provided by the user interface board. All gate-driver control signals as well as all

voltage and current measurement signals are routed to the high-voltage control board via high pin-count

connectors.

High Voltage Control Board (FELV)

User Interface Board (SELV)

Power Board

EMI Filter

Board

Mains Supply Input

Power Output

Page 18

User Guide 18 of 38

2021-01-29

System and functional description

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Figure 13 Inverter Construction Scheme (top-right view), Housing removed

2.2.4 Supply schemes

The three-phase AC input voltage is rectified to the DC-link supply voltage by the B6 rectifier bridge in the

power module. In order to prevent high inrush currents during power-up when the three-phase supply is first

connected, the DC-link capacitors are pre-charged via power resistors. After the capacitors are charged to

match the line voltage, the power resistors are shorted out using power relays.

The DC-link voltage is converted to two low-voltage domains by a SiC-based flyback converter. A first output

voltage (V15_HV) is used as the low-voltage supply for the functional isolated part of the inverter, supplying the

gate drivers and the high-voltage logic board. The second voltage domain (V24_SELV ) is used to power the lowvoltage user interface board, local sensors (e.g. heat sink temperature sensor) and the cooling fans.

2.2.5 Component selection

The power module is in an EASY 3B package, part number FP100R12W3T7_B11, based on the latest IGBT7

technology allowing a compact and economic solution for an industrial drive. The FP100R12W3T7_B11 module

carries all power semiconductors which are needed to control the motor current [1]. Due to the reduced VCEsat

voltage compared to IGBT4 and enhanced switching controllability, the IGBT7 technology is tailored for

industrial drives. For short-circuit protection of the IGBTs and for motor current control, the current sensor

TLI4971-A120T5 is used. The TLI4971-A120T5 provides a fast short-circuit detection time and accurate

measurement results over a wide temperature range [2]. For the gate driver IC, the EICE™ driver 1ED3131MC12H

was selected. It is a single-channel isolated IGBT gate driver IC with a source and sink capability of 3 A.

The Infineon CoolSiCTM MOSFET IMBF170R1K0M1 with a blocking capability of 1700 V is used for the auxiliary

power supply. By using the SiC-MOSFET, the design of the flyback inverter can be simplified.

The reference inverter uses two microcontrollers; one for control and one for communication. For control, the

XMC4800-F144F2048 is used, for communication, the XMC4300-F100K256 AA is designed in. Both

microcontrollers communicate via a UART interface.

DC-Link Capacitors

DC/DC Converter

Page 19

User Guide 19 of 38

2021-01-29

System design

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

3 System design

3.1 Schematics

The schematics of the design are available via Infineon.com. Keep in mind that the inverter consists of five

boards, hence you will find one schematic for each board.

Table 3 Schematic overview

Board name

File name in zip folder

Power board

22kW_Inverter_Power_Board_v1.3_2021-01-11.pdf

DC-link board

U109_GPD_DCLinkCaps_v1.0_2019-10-23.pdf

EMI filter

U109_22kWGPD_EMI-filter_v2.1_2020-12-02.pdf

High voltage logic board

22kW_Inverter_Logic_v1.2_2020-09-01.pdf

Low voltage interface

22kW_Inverter_Interfaces_v1.2_2020-12-02.pdf

Connection between high

voltage logic board and low

voltage Interface

U109_GPD_FlexPCBConnector_v1.0_2020-12-02.pdf

Isolation sheet between

power board and heat sink

U109_GPD_HeatsinkIsolation_v1.0_2020-12-02.pdf

Gasket to separate clean

and dirty air

U109_GPD_Sealing_v1.0_2020-12-02.pdf

The Altium™ project files are available on request.

3.2 Layout

3.2.1 Power board

The layout of the power board is shown in Figure 14; in Table 4 you will find the names of each block.

The AC input connector (1), AC output connector (2), the brake resistor connector (3) as well as the DC-link

connections (4) are located on the left hand side of the power board. The EMC filter is connected to the board in

the area marked (5). The high-side gate drivers are located in the area marked (6) and the low-side gate driver

are marked in section (12).

The interface to the high-voltage logic board (FELV board) is marked (7); this board has the interface

connectors. The output phase current measurement is marked (8); all three-phase currents are measured, also

the current between the DC-link capacitor and IGBT module is measured.

The IGBT module will be pressed in the area marked (9). The auxiliary power supply is located in the area

marked (10), the SiC MOSFET is soldered to the PCB in the area (11). The DC-link board is screwed to the power

board in the area marked (12).

The interface to the low-voltage interface board (SELV board) is marked (13). The safe isolation communication

between the high-voltage logic board (FELV board) and low-voltage interface board (SELV board) is realized

with the IC located on the PCB in area (14). The position of the pre-charge relay is shown at (16) and the precharge resistors are shown at (17).

Page 20

User Guide 20 of 38

2021-01-29

System design

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Figure 14 Layout of the power board

Table 4 Functional block - power board layout

Block number

Function

1

AC input connector

2

AC output connector

3

Brake resistor connector

4

DC-link connector

5

EMI-filter connections

6

High-side gate driver with gate driver IC 1ED3131MC12H

7

Connector for motor control board

8

Output phase current sensor measurement with TLI4971-A120T5

9

IGBT module with IGBT7 - FP100R12W3T7_B11

10

Auxiliary power supply

11

CoolSiCTM MOSFET IMBF170R1K0M1 of the auxiliary power supply

12

Low-side gate driver with gate driver IC 1ED3131MC12H

13

Connector for communication interface board

14

Isolation barrier for communication between high-voltage logic board (FELV board) and low

voltage interface board (SELV board)

15

DC-link current sensor TLI4971-A120T5

16

Pre-charge relay

17

Pre-charge resistors

18

DC-Link

Page 21

User Guide 21 of 38

2021-01-29

System design

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

The gate layout of the high-side IGBT of the phase U is shown as an example in Figure 15. The traces of the

emitter and gate trace are on top of each other, which minimizes any parasitic inductances.

gate

emitter

minimize the stray

inductance by overlaying

gate and emitter trace

Figure 15 Gate layout of the high-side IGBT of phase U

3.3 Inverter cooling concept

A three-channel cooling system provides the cooling of the inverter, as seen in Figure 1 and Figure 16.

The main cooling of the IGBT is done by a heat sink and an integrated 92 mm fan with a temperature controlled

flowrate of 0-270 m³/h. The air is drawn in the bottom of the unit and blown up through the heat sink to the

outlet at the top of the enclosure, assuming a normal wall mounting position.

A 52 mm auxiliary fan cools the DC-link capacitors and operates at a constant speed with a flow rate of 20m³/h.

As shown in Figure 16 the air is blown into an air channel at the bottom of the capacitor array. To provide an

improved cooling over the entire surface of each capacitor the air is directed up one side and then channeled

via small slits between each capacitor and then finally along the side of the heat sink to the air outlet at the top

of the enclosure.

A second 52 mm fan, also operating at a constant speed, cools a third channel containing the EMI filter. The air

flows beside the heat sink and over the indictors and capacitors of the EMI filter. This cooling channel has a

separate air outlet at the top of the enclosure.

Page 22

User Guide 22 of 38

2021-01-29

System design

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Figure 16 Airflow through the heat sink

3.4 Disassembly of the housing

The inverter enclosure consists of three separate parts that are screwed together as seen in Figure 17.

1. A low-voltage cover which acts as a frame and holder for the front panel display and protects the high

power connectors and the SELV interface PCB.

2. A high-voltage cover mounted underneath the low-voltage cover protects the isolated PCB connector

mounted to the power PCB below. All sensors and the display are connected there.

In addition, the main connectors for the electric motor and the supply are available there.

3. The high-voltage cover protects all the non-isolated high voltage parts. The top side of the cover is

marked with a danger sign and should only be removed by safety experts!

4. The main housing encloses all the electronic components and the cooling system, which are located

there. The power electronics at the upper or front level of the main housing are separated from the

main airflow over the heat sink, and potential dirt and dust, by a gasket. See Figure 17.

Page 23

User Guide 23 of 38

2021-01-29

System design

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Figure 17 Covers of the drive system

Disassembly of the covers:

1. Low-voltage cover: remove four screws at the side of the cover; see Figure 18.

Figure 18 Disassembly of the front cover

2. High-voltage cover: remove four screws at the side of the cover; see Figure 19.

Remove the safety screw at the center of the cover.

Attention! This cover should only be removed by trained safety experts only!

Page 24

User Guide 24 of 38

2021-01-29

System design

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Figure 19 Disassembly of the high-voltage cover

3. If all front covers are removed, the power board PCB is visible, as shown in Figure 20.

Figure 20 Inverter without front covers

Page 25

User Guide 25 of 38

2021-01-29

System design

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

3.5 Bill of material

The complete bill of material is available on the download section of the Infineon homepage. A log-in is

required to download this material.

Table 5 BOM of the most important/critical parts of the evaluation or reference board (example)

Board name

File name in zip folder

Power board

BOM_22kW_Inverter_Power_Board_v1.3_2021-01-11.xlsx

DC-link board

BOM_U109_GPD_DCLinkCaps_v1.0_2019-10-21.xlsx

EMI filter

BOM_U109_22kWGPD_EMI-filter_V2_v1.0_2020-12-02.xlsx

High voltage logic board

BOM_22kW_Inverter_Logic_v1.2_2020-09-01.xlsx

Low voltage interface

BOM_U109_22kW_Inverter_Interfaces_v1.2_2020-12-02.xlsx

Connection between high

voltage logic board and low

voltage Interface

BOM_U109_GPD_FlexPCBConnector_v1.0_2020-12-02.xlsx

3.6 Connector details

Connectors of the power board:

Table 6 Connector PH1

PIN

Label

Function

1

Earth

Earth potential for safe operation always connect to earth

2

L3

Line feeder cable phase L3

3

L2

Line feeder cable phase L2

4

L1

Line feeder cable phase L1

Table 7 Connector PH2

PIN

Label

Function

1

Earth

Earth potential for safe operation always connect to earth

2

DC-

DC-minus voltage

3

DC+

DC-plus voltage, the brake resistor must be connected here

4

brake

The brake resistor must be connected here, it is connect between

DC+ and brake

5 W Motor feeder cable phase W

6 V Motor feeder cable phase V

7 U Motor feeder cable phase U

Page 26

User Guide 26 of 38

2021-01-29

System design

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Connectors of the user interface board:

Table 8 Connector P1

PIN

Label

Function

1

SPEED_1

Input signal speed sensor

2

V9_SELV

9 V power supply

Table 9 Connector P2

PIN

Label

Function

1

Input

Input signal NTC

2

GND

Ground

Table 10 Connector P4

PIN

Label

Function

1

VCC

Supply voltage

2

D-

Data signal -

3

D+

Data signal +

4

GND

Ground

The USB port for remote control via the PC-GUI can be found at the front side of the inverter.

Table 11 Connector P14

PIN

Label

Function

1

VCC

Supply voltage

2

VCC

Supply voltage

3

GND

Ground

4

STOA

Safe torque off Channel A

5

STOB

Safe torque off Channel B

6

Chassis_GND

Chassis GND

Page 27

User Guide 27 of 38

2021-01-29

System design

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Table 12 Connector P12

PIN

Label

Function

1

TD+

Transmission data +

2

TD-

Transmission data -

3

RD+

Receiver data +

4

N.C.

5

N.C.

6 RD-

Receiver data -

7

N.C.

8 N.C.

S1

Chassis_GND

S2

Chassis_GND

Page 28

User Guide 28 of 38

2021-01-29

System performance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

4 System performance

4.1 Test results inverter start-up

The inverter is supplied via an auxiliary supply which derives its energy from the DC-link capacitors, so the

power supply starts when the DC-link voltage increases above a threshold voltage, approximately 100 V. In

Figure 21 the inverter start-up is shown. The three-phase rectified AC voltage “Rectifier_AC_In” is shown in red,

the output of phase V is shown (V_Output) in blue. In yellow the DC-link voltage, in the schematic called

“Rectifier_AC” is shown and one output voltage of the auxiliary power supply “V15_HV” is shown in green.

The auxiliary power supply starts working if the voltage “Rectifier_AC” is above 100 V. The voltage “V15_HV” is

moving around the set point due to the light load conditions during start-up. The reason for this is pulse

skipping of the auxiliary supply under light load.

Rectifier_AC_In

V_Output

Rectifier_AC

V15_HV

Figure 21 Inverter Start-up

If the inverter is connected to the grid, the in-rush current must be limited. Therefore, the DC-ink capacitors will

be charged via the pre-charge relay and resistors. This relay will be closed after approximately 2 seconds, as

shown in Figure 22. The pulse width modulation of the output phase starts approximately 200 ms after the relay

closes.

Page 29

User Guide 29 of 38

2021-01-29

System performance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Rectifier_AC_In

V_Output

V15_HV

Relay closure

Figure 22 Relay closure

4.2 Operation under rated conditions

The following chapter shows the nominal operation conditions. The inverter is supplied by a 400 VAC grid and

can be connected at the output to a symmetrical RL-passive load for test purposes rather than a motor load, as

illustrated in Figure 23.

Figure 23 Passive load

The value of the inductor L1, L2 and L3 is 8 mH; the value of the resistor is 3.4 Ω. The sinusoidal output

frequency is set to 50 Hz and output current to 45 A

RMS.

The switching frequency was set to 4 kHz. The

measurement results are shown in Figure 24.

Page 30

User Guide 30 of 38

2021-01-29

System performance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Rectifier_AC

Output current

phase V

Input current L2

V_Output

Figure 24 Inverter under nominal operation conditions

The output phase current (green) and the resistor voltage (red) are almost sinusoidal, whereas the input line

current (blue) shows the typical waveform of a capacitor charging current. The yellow signal shows the rectified

DC-bus voltage of about 562 V.

Page 31

User Guide 31 of 38

2021-01-29

System performance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

4.3 Switching behavior of the IGBT turn-on

The following diagram shows the turn-on behavior of the lower V phase IGBT, marked as IGBT #4, “V_BOT”. The

value for R35 was set to 6.8 Ω and R39 to 4.7 Ω. The RMS current of the inverter was 57.5 A. In the top part of

Figure 25, the “persistence” function of the oscilloscope was used to show the changing dv/dt levels at turn-on.

In the diagram at the bottom, a histogram is shown tabulating the dv/dt slope of 1,000 measured periods. The

histogram shows a spectrum of the dv/dt in the range between 0.5 V/ns and 4.5 V/ns with the average being

around 2 V/ns.

Figure 25 V

CE

voltage slope and dv/dt histogram during turn-on

Page 32

User Guide 32 of 38

2021-01-29

System performance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

4.4 Switching behavior of the IGBT – turn-off

The following diagram shows the turn-off behavior of lower phase V IGBT marked as IGBT #4, “V_BOT”. The

value for R35 was set to 6.8 Ω and R39 to 4.7 Ω. The RMS current of the inverter was set to 57.5 A. In the top part

of Figure 26 the “persistence” function of the oscilloscope was used to show the changing dv/dt levels at turnon. In the diagram at the bottom, a histogram is shown tabulating the dv/dt slope of 1,000 measured periods.

The histogram shows a spectrum of the dv/dt in the range between 0.5 V/ns and 4 V/ns with an average around

2.4 V/ns.

Figure 26 V

CE

voltage slope and dv/dt histogram during turn-off

Page 33

User Guide 33 of 38

2021-01-29

System performance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

4.5 Thermal behavior of the inverter under high overload

A typical drive overload pulse pattern is shown in Figure 4. In a period of 5 minutes, a 1-minute overload

condition of 150% of the nominal current is required.

This overload pattern is applied to the inverter by adapting the modulations index via the GUI with the “Load

Pulse Pattern Config” sub menu. The temperature of the IGBT module NTC (T_NTC) and the heatsink

temperature sensor (T_Heatsink) are recorded with the built-in oscilloscope function of the inverter and the

result is shown in Figure 27. The data can be exported as a csv-file.

Figure 27 Temperature of the IGBT NTC and heatsink during heavy overload

The temperature of the NTC of the IGBT module increases by 12°C during the overload pattern, the temperature

of the heat sink only by 7°C. Both temperatures represent the temperature at the location of the individual

temperature sensor. This means the junction temperature of the IGBT is much higher and will have higher

temperature variation during the overload pattern.

50

55

60

65

70

75

80

0 100 200 300 400 500 600

temperature in

°C

time in s

T_NTC T_Heatsink

Page 34

User Guide 34 of 38

2021-01-29

System performance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

4.6 Short-circuit measurement

The short-circuit behavior of the drive was tested by using the setup, as shown in Figure 28. A short circuit was

applied across the output terminals. The cable length between the terminal U and DC- is 1.2 m and has a cross

section of 6 mm². The drive was powered up and ready for the short-circuit test.

L1

L2

L3

PE

PE

U

V

W

DC-

cable

1.2 m

Measurement of V

GE

Measurement of V

CE

Measurement of I

SC

U

DC+

U LS

U HS

cable

V

GE

V

CE

OCD

Figure 28 Short circuit setup

The short-circuit test can now be performed via the GUI. You will find the “Short Circuit Test Pulse” section at

the “Config” tab. Here you can select the “Pulse length.” It is recommend to set the pulse length to 8 µs. Then

you have to select the switch you want to test; in this case “U LS” (phase U, low side switch). To start the test

click on “Fire.”

Figure 29 GUI of the "Short Circuit Test Pulse"

For verification if the short-circuit turn-off of the IGBT behaves correctly, the following voltages and currents

were measured, see Figure 30. The gate emitter voltage (VGE), the collector-emitter voltage (VCE) and the current

flowing through the short-circuit cable (ISC) are shown in the figure.

Page 35

User Guide 35 of 38

2021-01-29

System performance

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

V

CE,max

= 675 V

OCD value

OCD1 = 202 A

OCD blanking time t = 600 ns

Figure 30 Short circuit measurement

The overcurrent detection (OCD) level of the current sensor is set to 168% of the nominal current measurement

range of 120 A. Hence, the OCD current level is 202 A. The oscilloscope measurement in Figure 30 shows that

the OCD signal of the current sensors triggers after 600 ns, then the IGBT is commanded to turn-off, and the

current ISC declines. The overvoltage overshoot due to the di/dt is moderate with a maximum value of 675 V,

hence an overvoltage of approximately 90 V. This is well within the IGBT 1200 V maximum rating.

Page 36

User Guide 36 of 38

2021-01-29

References and appendices

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

5 References and appendices

5.1 Abbreviations and definitions

Table 13 Abbreviations

Abbreviation

Meaning

CE

Conformité Européenne

EMI

Electromagnetic interference

UL

Underwriters Laboratories

IGBT

insulated-gate bipolar transistor

SiC

silicon carbide

MOSFET

metal–oxide–semiconductor field-effect transistor

GUI

graphical user interface

PCB

Printed circuit board

SELV

safety extra-low voltage

FELV

functional extra-low voltage

5.2 References

[1] Infineon Technologies AG. AN2018-14 (2020): TRENCHSTOP™ 1200 V IGBT7 T7 Application Note. V1.2

www.infineon.com

[2] Infineon Technologies AG. AppNote TLI4971 Electrical Drive (2019): High Voltage General Purpose Drive

(GPD) with Hall-Effect Current Sensor. V1.0 www.infineon.com

[3] Infineon Technologies AG. Datasheet (2020): FP100R12W3T7_B11 EasyPIM™ module. V0.2

www.infineon.com

[4] Infineon Technologies AG. Datasheet (2020): TLI4971 high precision coreless current sensor for industrial

applications in 8x8mm SMD package. V1.1 www.infineon.com

[5] Infineon Technologies AG. Datasheet (2020): EiceDRIVER™ 1ED31xxMU12H Compact. V2.0

www.infineon.com

[6] Infineon Technologies AG. Datasheet (2020): IMBF170R1K0M1 CoolSiC™ 1700V SiC Trench MOSFET Silicon

Carbide MOSFET. V2.1 www.infineon.com

[7] Infineon Technologies AG. Datasheet (2018): XMC4300 Microcontroller Series for Industrial Applications.

V1.1 www.infineon.com

Page 37

User Guide 37 of 38

2021-01-29

User guide for REF-22K-GPD-INV-EASY3B

A reference design for a general purpose drive

Revision history

Revision history

Document

version

Date of release

Description of changes

1.00

2021-01-29

First release

Page 38

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2021 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of the

product or any consequences of the use thereof can

reasonably be expected to result in personal injury.

Edition 2021-01-29

UG-2020-28

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Loading...

Loading...