Page 1

Application Note Please read the Important Notice and Warnings at the end of this document V 1.1

www.infineon.com page 1 of 54 2021-02-01

AN_1906_PL18_1908_180413

Scalable power inverter driving an electric

motor

Using the low voltage drives scalable power demonstration board

About this document

Scope and purpose

The low voltage drives scalable power demonstration board is a scalable platform for high power motor drive

applications. It has been developed to provide a flexible test environment for initial designs and technology

comparison. This document provides a detailed description of the platform modules, so the user will be able to

adapt the boards according to specific system requirements, and investigate and compare the capabilities of

power MOSFETs.

Intended audience

This document is intended for engineers using the "Low voltage drives scalable power demonstration board"

evaluation platform, or those evaluating the platforms suitability for use.

Table of contents

About this document ....................................................................................................................... 1

Table of contents ............................................................................................................................ 1

1 Introduction .......................................................................................................................... 3

2 Board overview ...................................................................................................................... 4

2.1 Power boards .......................................................................................................................................... 5

2.2 Master Mother Board and Mother Boards ............................................................................................ 10

2.2.1 Gate drivers option I – 2EDL23N06PJ .............................................................................................. 13

2.2.2 Gate drivers option II – 1EDN8550B ................................................................................................. 14

2.2.2.1 Functional principle of the 1EDN8550B (TDI) gate driver .......................................................... 15

2.2.2.2 Performance results with KIT_LGMB_BOM004 & KIT_LGMB_BOM504 ..................................... 16

2.3 Daughter boards .................................................................................................................................... 21

2.4 Functional principle of the 1EDN8550B (TDI) gate driver Capacitor boards ....................................... 22

2.5 Control board ........................................................................................................................................ 24

3 Three phase motor drive setup (B6) ......................................................................................... 25

3.1 Supply voltage ....................................................................................................................................... 26

3.2 Board interconnections in multiphase setups and power board paralleling ..................................... 26

3.2.1 Control signals – control board interface ........................................................................................ 27

3.2.2 Mother board bus ............................................................................................................................. 28

3.2.3 Daughter board bus ......................................................................................................................... 29

3.3 Using the V/f control for induction motor ............................................................................................ 29

3.3.1 Using the GUI .................................................................................................................................... 32

3.3.2 Driving an induction motor .............................................................................................................. 34

4 Performance of a B6 setup in a motor drive application ............................................................. 36

4.1 No paralleling ........................................................................................................................................ 37

4.1.1 Operating point 1 ............................................................................................................................. 38

4.1.2 Operating point 2 ............................................................................................................................. 40

4.2 Two per phase parallel connection ...................................................................................................... 42

Page 2

Application Note 2 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Introduction

4.2.1 Operating point 3 ............................................................................................................................. 43

4.2.2 Operating point 4 ............................................................................................................................. 46

4.3 Four per phase parallel connection ...................................................................................................... 48

4.3.1 Operating point 5 ............................................................................................................................. 49

5 Summary ............................................................................................................................. 51

6 Reference ............................................................................................................................. 52

Revision history............................................................................................................................. 53

Page 3

Application Note 3 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Introduction

1 Introduction

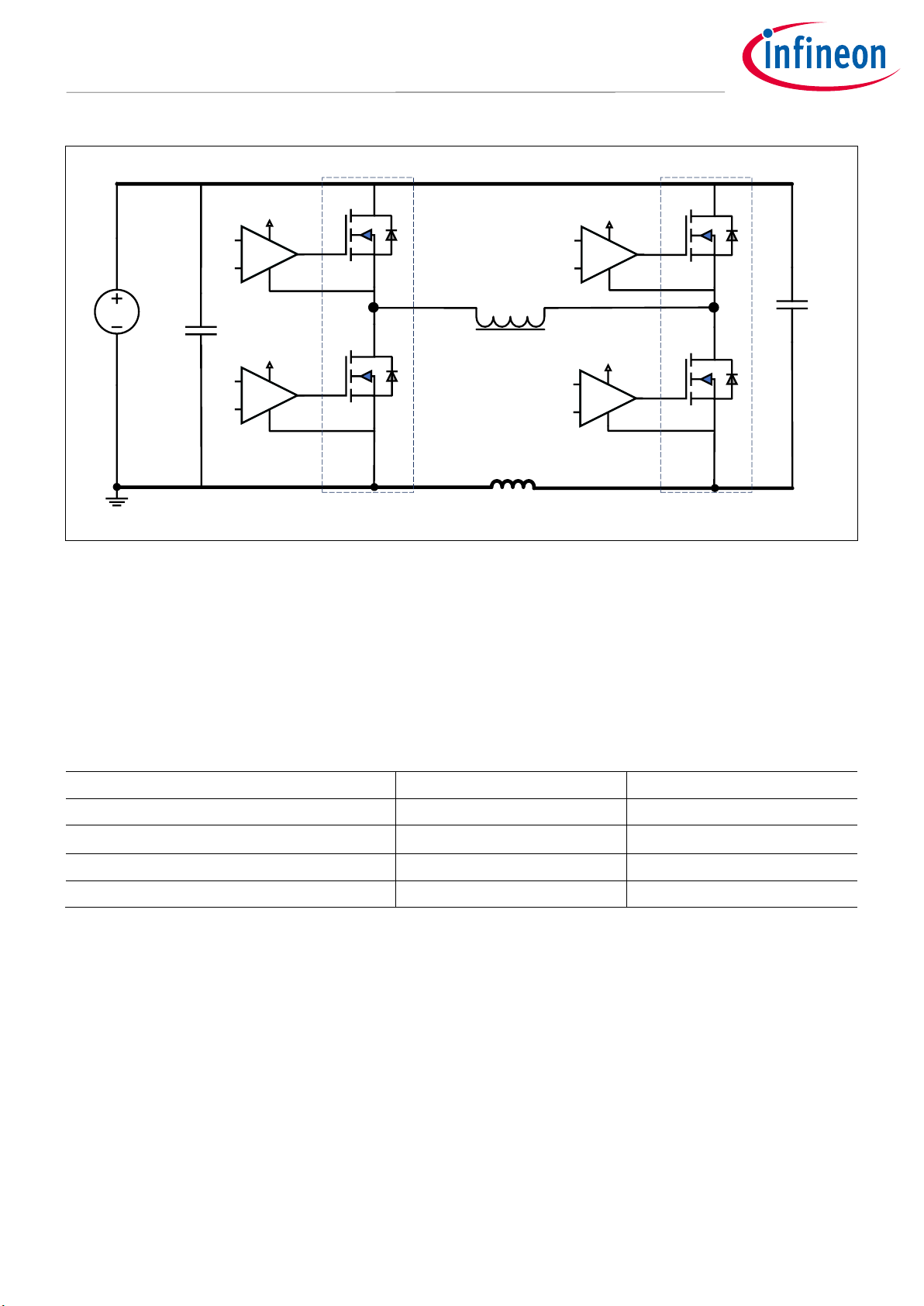

The low voltage drives scalable power demonstration board offers the possibility of building a three-phase

motor drive setup of various power capabilities due to its MOSFET paralleling flexibility. The setup shown in

Figure 1 is an example of a three-phase inverter (also known as a B6 topology) for motor drive. The detailed

procedure of building such a setup is described in the “Low voltage drives scalable power demonstration board

user manual” [1].

The example is implemented with four MOSFETs connected in parallel in place of each B6 switch. The platform

was designed to be able to adapt the amount of MOSFET paralleling to the system requirements, by simply

adding or removing the power half-bridge modules. All components typically used for trimming performance

are located on FR4-based modules, while the power modules are implemented in IMS PCB technology adapted

to improve heat transfer using additional heatsinks – air-cooled or water-cooled.

This application note describes the details of the individual modules, their interconnection, and a graphical

user interface (GUI) complementing the supporting firmware. The aim is to provide the user with sufficient

knowledge to be able to utilize the modules in a working setup, and adapt the circuits to their own

requirements.

The examples provide a performance overview of the three-phase setup.

Figure 1 Typical setup for three-phase motor drive

Page 4

Application Note 4 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

2 Board overview

The modular platform consists of different boards (modules) that can be used to design a fully functional

assembly, where each board has a specific role in a given setup. The modularity offers a wide range of possible

topologies. The concept supports half-bridge, full-bridge or three-phase topologies.

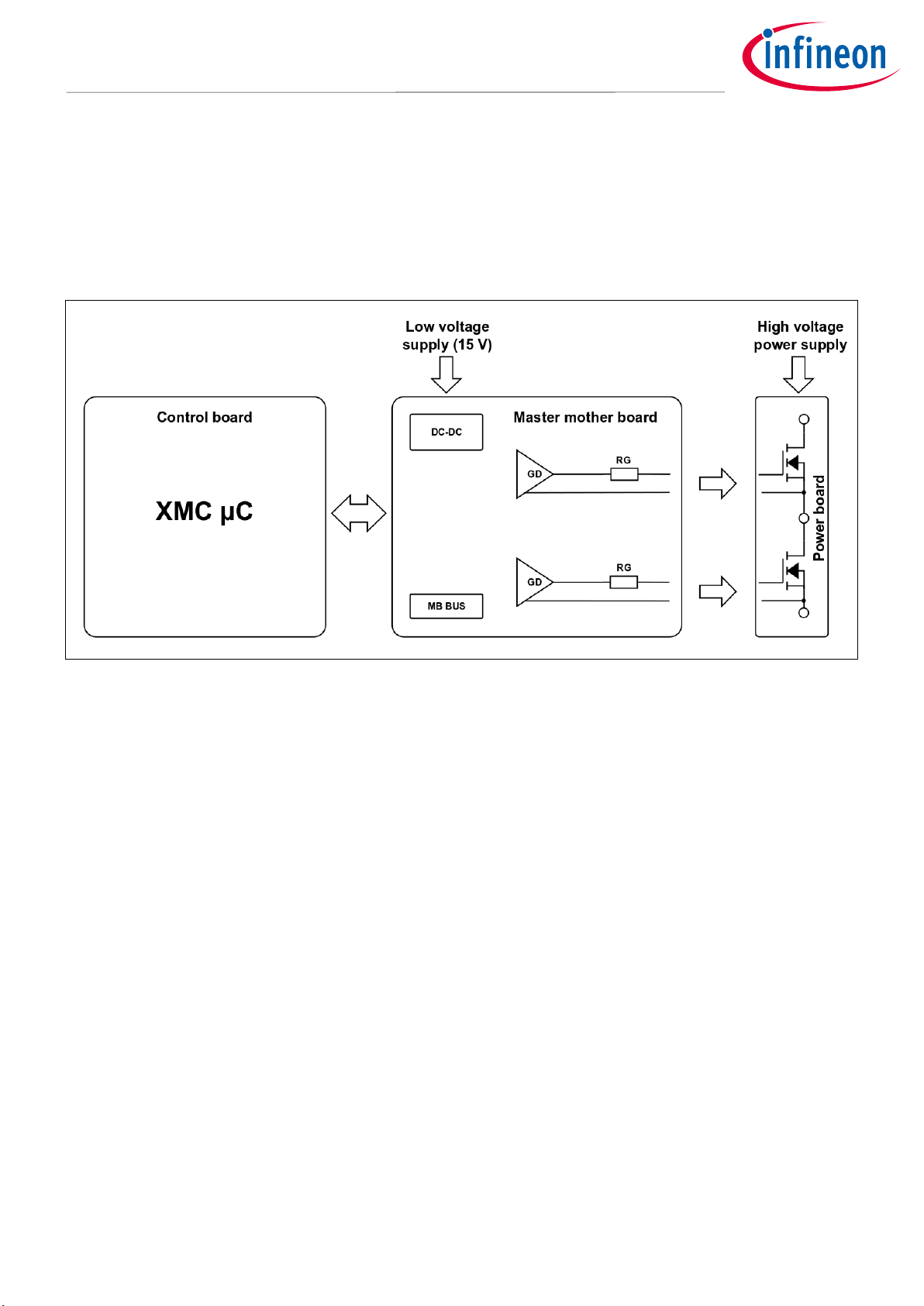

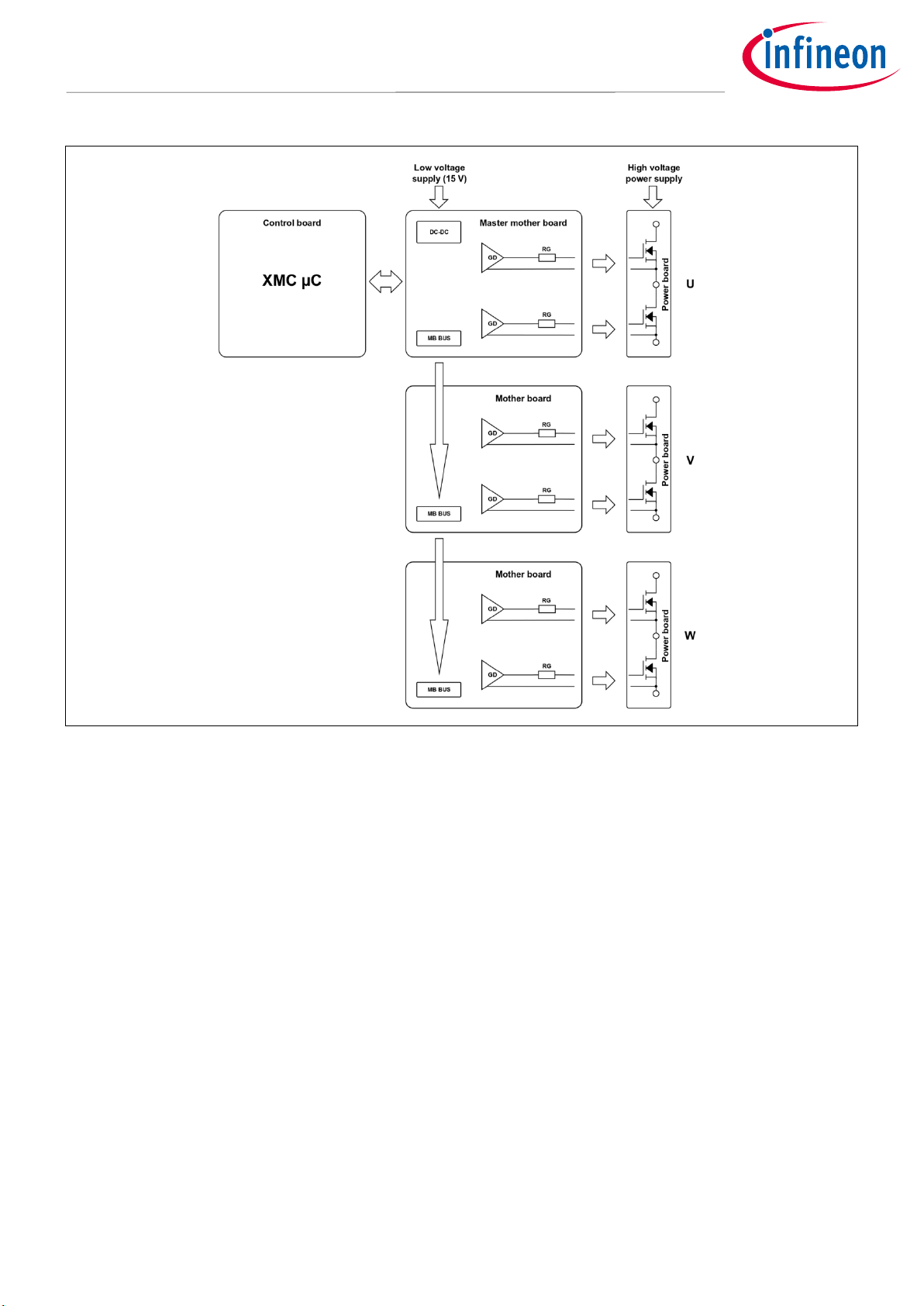

The basic principle of board functionality is illustrated in the block diagram in Figure 2.

Figure 2 Modular design – basic principles

By role (or functionality) in the setup, the modules are divided into five categories:

Power board: MOSFET half-bridge configuration

Mother board and master mother board: gate driver board – connects to the first paralleled power board

Daughter board: interconnection between the gate driver and the paralleled power boards

Capacitor board: PCB accommodating up to 12 capacitors connected to the DC bus

Control board: drive card XMC4400 demonstration board

Figure 2 shows a single-power half-bridge (power board), driven by the gate drivers (master mother board)

controlled by the XMCTM drive card (control board). Any setup is controlled by a control board (e.g. XMCTM drive

card – XMC4400) connected to the master mother board via the X3 connector.

The setup can be expanded to a multiphase setup using additional mother boards connected at the mother

board bus(MB bus) via a ribbon cable.

Each phase can be expanded with several power boards connected in parallel.

Page 5

Application Note 5 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

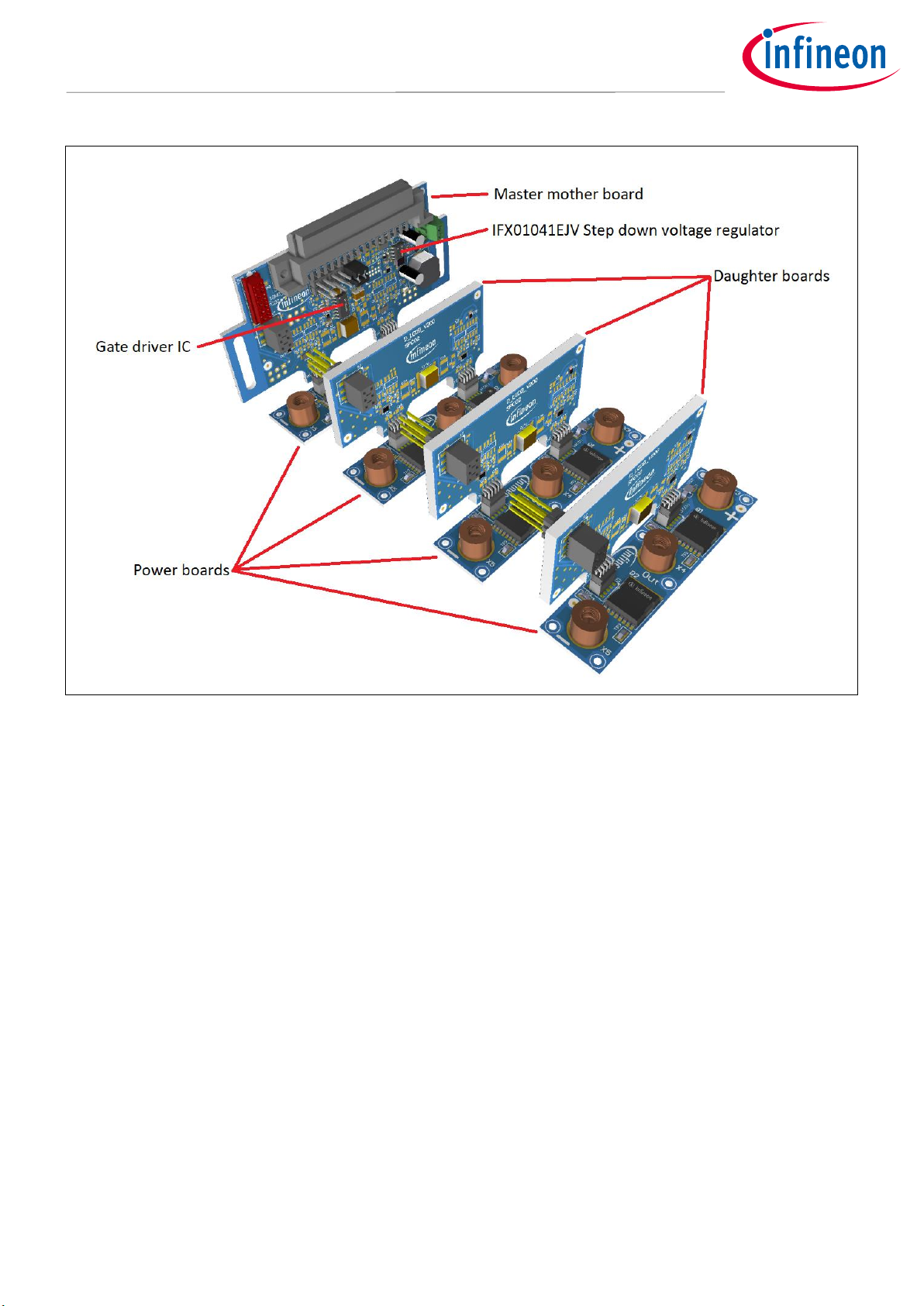

Figure 3 Single-phase assembly with paralleled power boards (exploded view)

Figure 3 shows an example of a single-phase (“U”) assembly with four power boards connected in parallel,

interconnected to the corresponding master mother board and three daughter boards.

2.1 Power boards

The power boards are the main building blocks of the three-phase assembly. They are IMS PCB-based halfbridge sub-assemblies, comprising a single high-side (HS) and a single low-side (LS) MOSFET with all the

necessary connectors for power and signal lines.

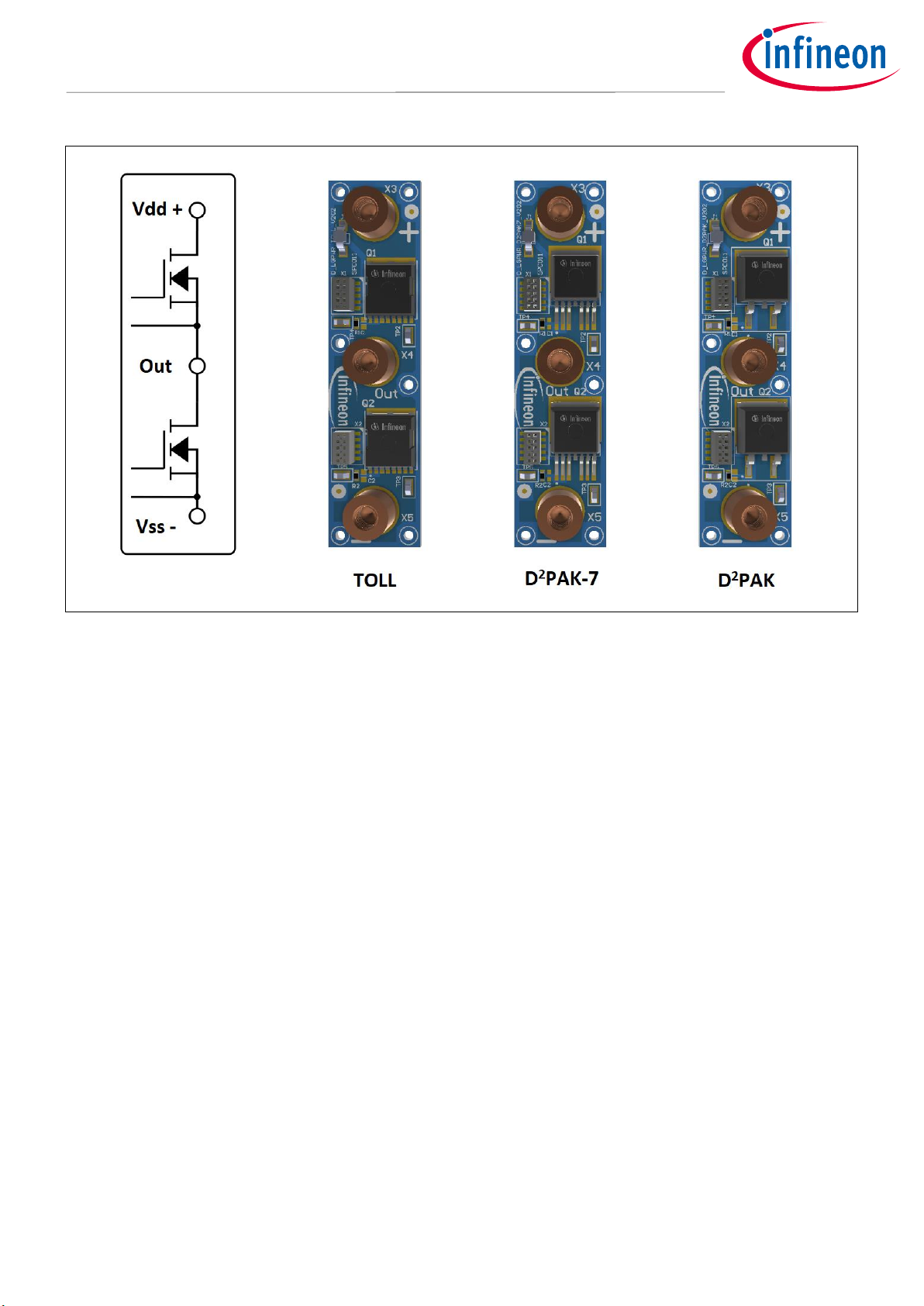

Figure 4 shows the different versions of the power boards available.

Page 6

Application Note 6 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Figure 4 Power board versions: TOLL, D

2

PAK-7, D2PAK

Each board implements a different MOSFET package while maintaining the same interconnection layout, so

that all the different power board versions are interchangeable.

The featured packages are:

TO-leadless (TOLL)

D

2

PAK-7 (PG-TO263-7)

D

2

PAK (PG-TO263-2)

All available versions with regard to specific MOSFET products are provided online.

Page 7

Application Note 7 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

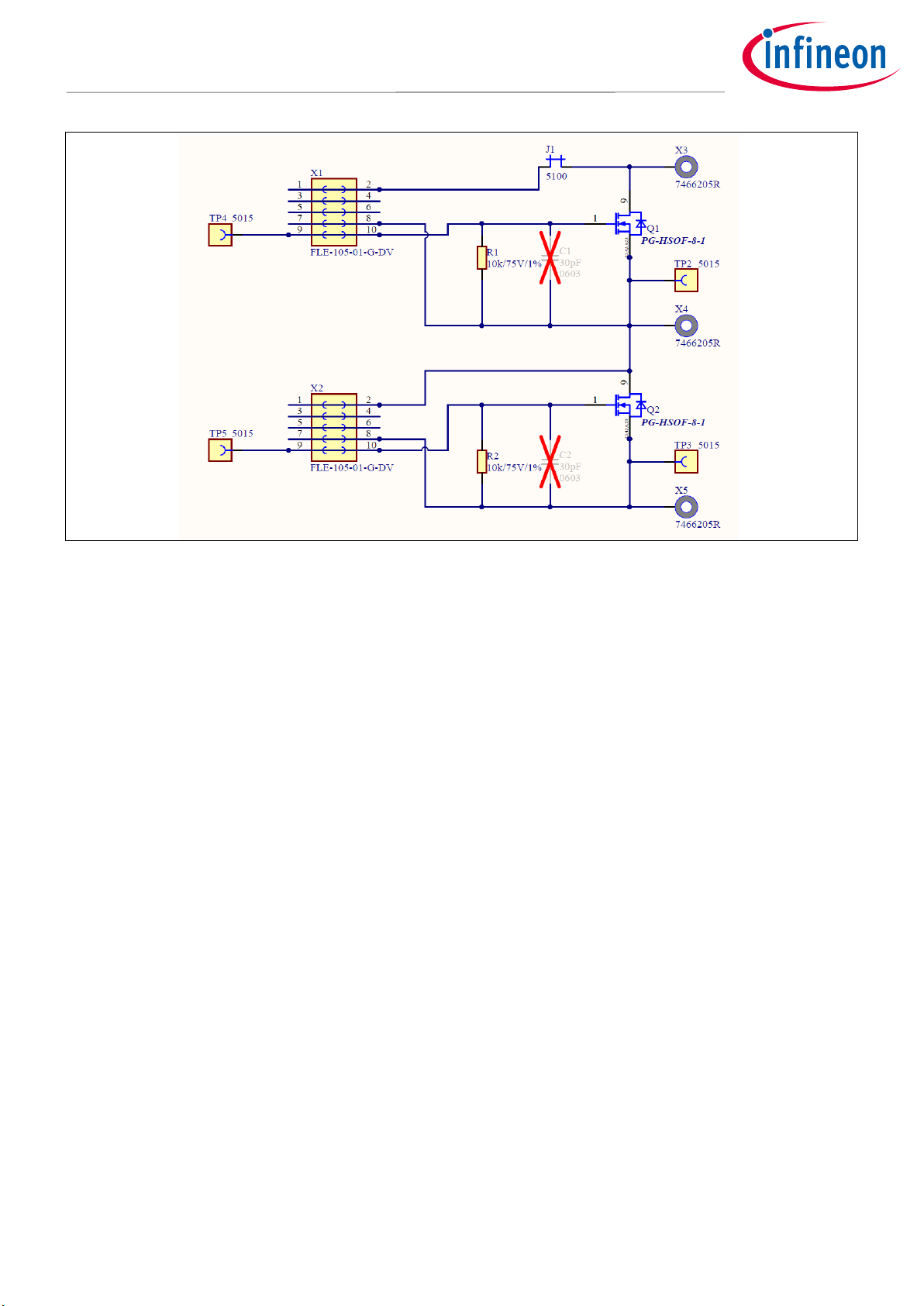

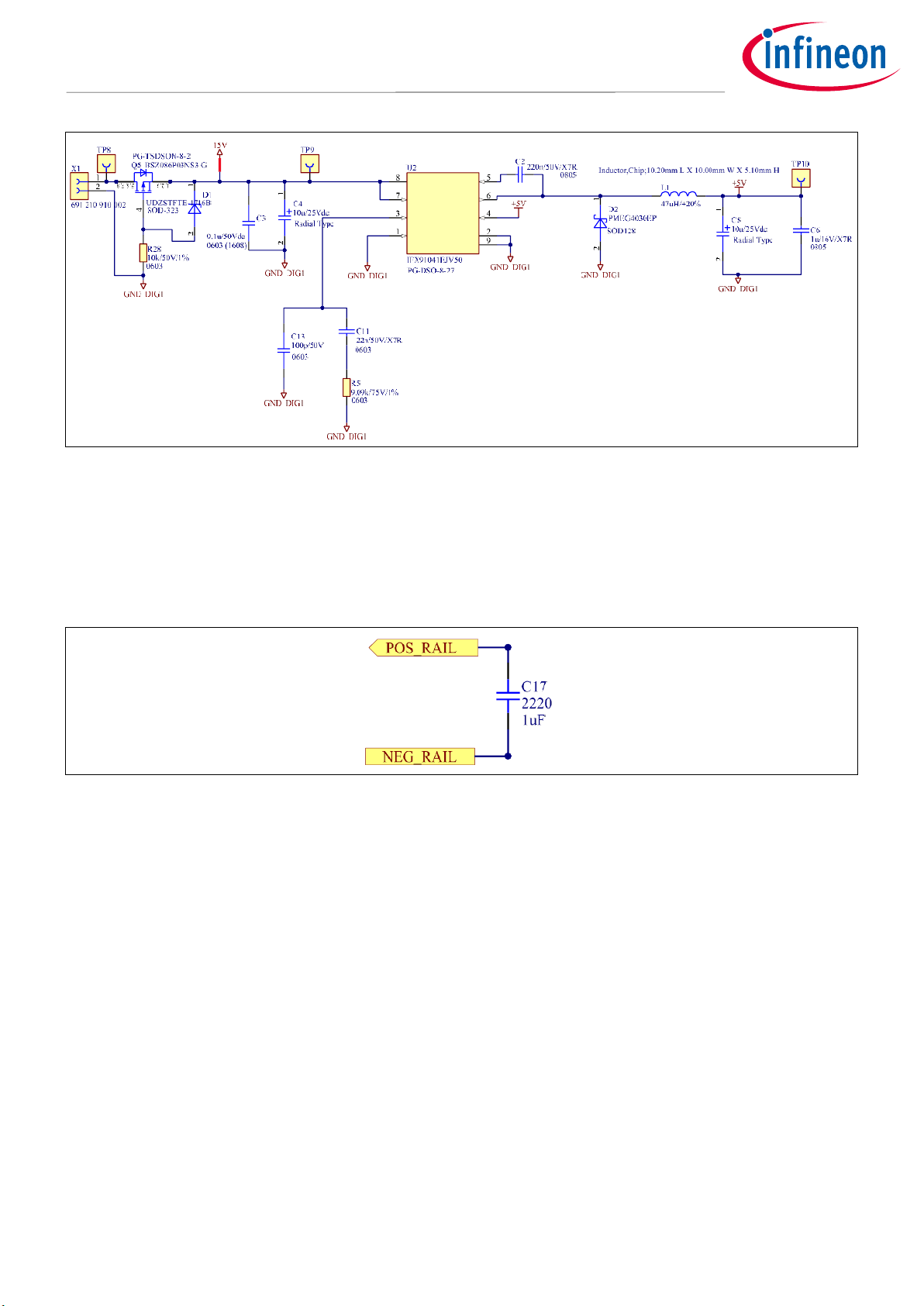

Figure 5 Power board schematic

The schematic shown in Figure 5 applies to all the power board versions. A number of test point connectors are

provided on the boards, since the platform is intended for test purposes.

The SMD connectors X3, X4 and X5 are provided for interconnection with high current capability. Either cable

lugs or copper bars can be used for the power connection to the connector via standard M5 screws.

Connectors X1 and X2 connect to the HS and LS MOSFETs respectively. All three MOSFET node (G, D, S)

connections are provided at the X1 and X2 connectors. The gate (G) and source (S) nodes connect to the gate

driver circuitry. Additionally, the HS drain (D) and the LS source (S) (i.e. the DC bus) are connected to a ceramic

capacitor located on the (master) mother boards or daughter boards via X1 and X2 connectors. The ceramic

capacitor provides the additional DC bus stability due to its proximity to the respective power board.

The test points (TP2, TP3, TP4, TP5) are small test hooks provided for connection of the oscilloscope probe clip.

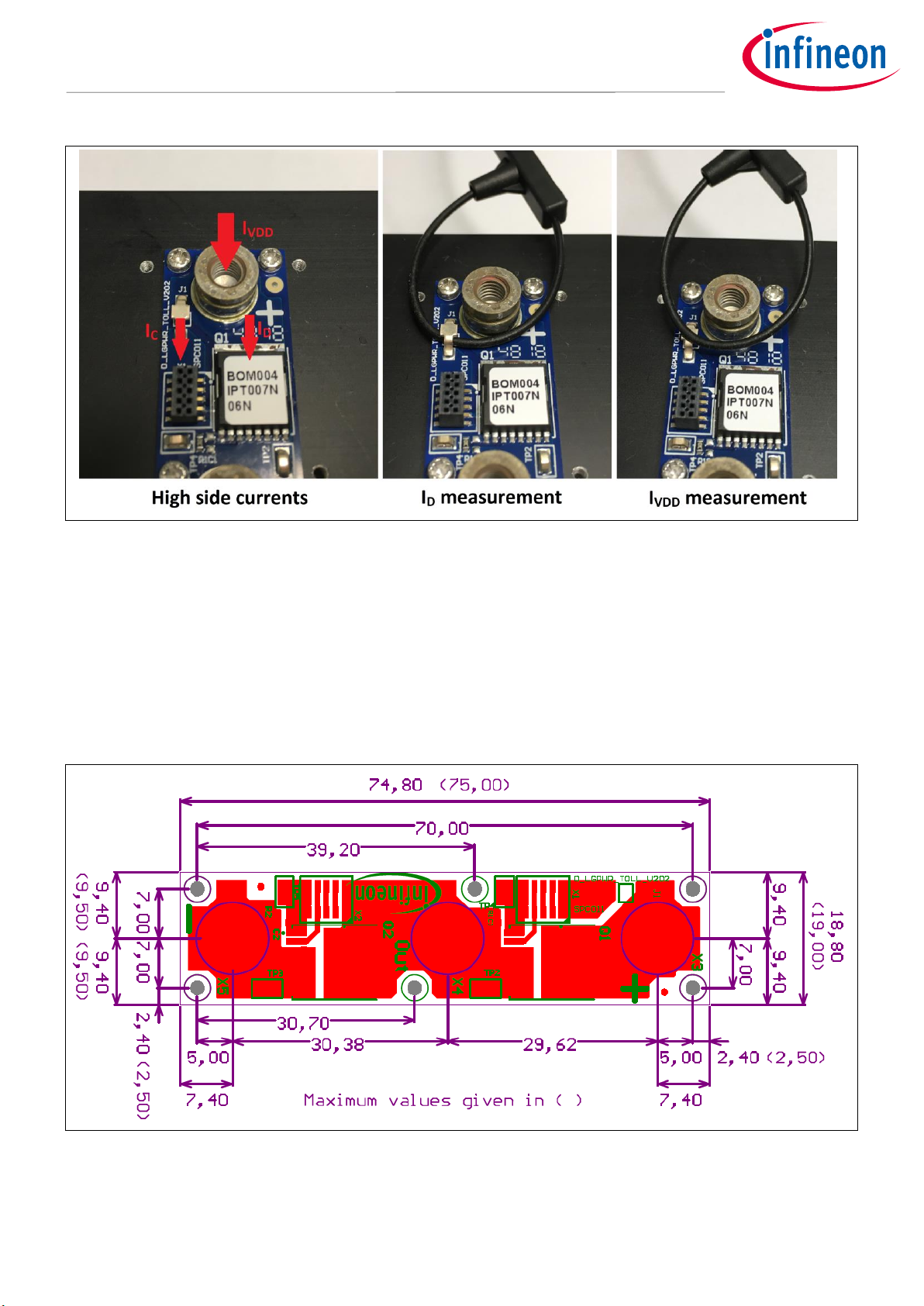

The jumper (J1) provided at the HS drain (the VDD+ node) enables the user to utilize a Rogowski current probe

for HS MOSFET drain current measurements (ID), as demonstrated in Figure 6. The current I

VDD

flowing from the

DC power supply V

DD+

through the X3 power terminal is split between the MOSFET drain current ID, and IC

(current flowing to the capacitor through X1). Considering that the capacitor current IC is flowing through the J1

jumper, the user can choose between measuring ID (Rogowski coil enclosing X3 and J1) and I

VDD

(Rogowski coil

reaching around X3 and above J1).

Page 8

Application Note 8 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Figure 6 Rogowski probe for measuring HS I

D

or I

VDD

2.1.1 Power board PCB layout

The IMS boards are intended to be attached to a heatsink via six M2 screws. To prepare the threaded holes in

the heatsink consider the dimensions in Figure 7. The placement of the screw holes and the power connectors

are the same for all the power board versions of the modular platform.

When machining the copper bars for the power connections, 19 mm spacing between the screw holes is

recommended.

Figure 7 Power board layout and dimensions

Page 9

Application Note 9 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

2.1.2 IMS board and heatsink

The power boards use the Ventec VT-4B3 IMS type. Table 1 lists some of the main properties.

Table 1 IMS board details

Description

Dimension

Substrate thickness

1.4 mm

Dielectric thickness

100 µm

Copper thickness

105 µm

Overall board thickness

1.6 mm

Dielectric specific thermal conductivity λ [W/m*K]

3 W/(m*K)

2.1.3 Board assembly and X-ray investigation of the power boards

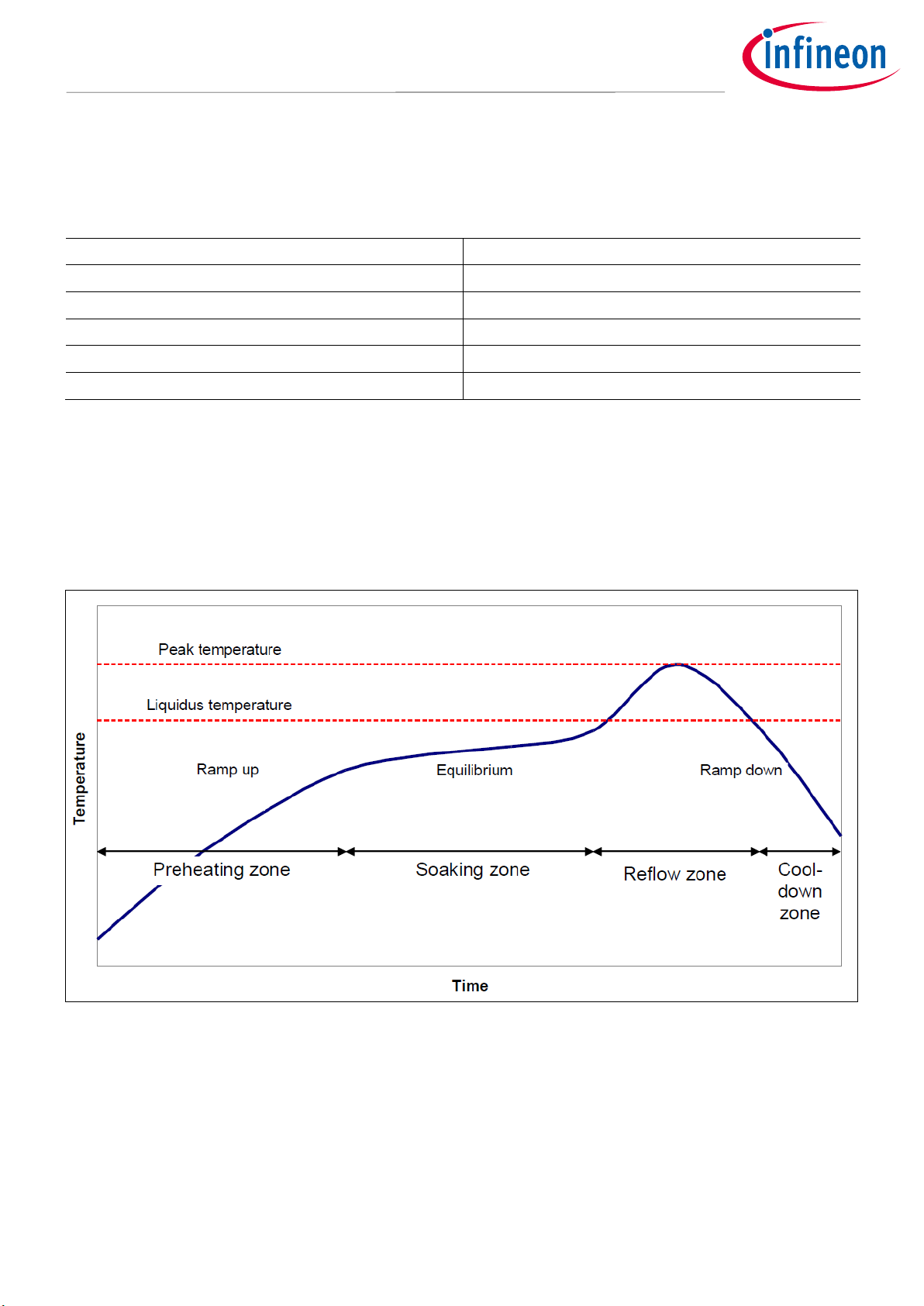

The soldering method used for the IMS board assembly was vapor phase soldering. The temperature profile of

this process is similar to the standard reflow process, with the peak temperature of the process at 250°C

defined by the phase change temperature of the inert liquid being used. The reflow zone time interval was 3

minutes.

Figure 8 Temperature profile [2]

Further details and recommendations for assembly of Infineon packages are available online [2].

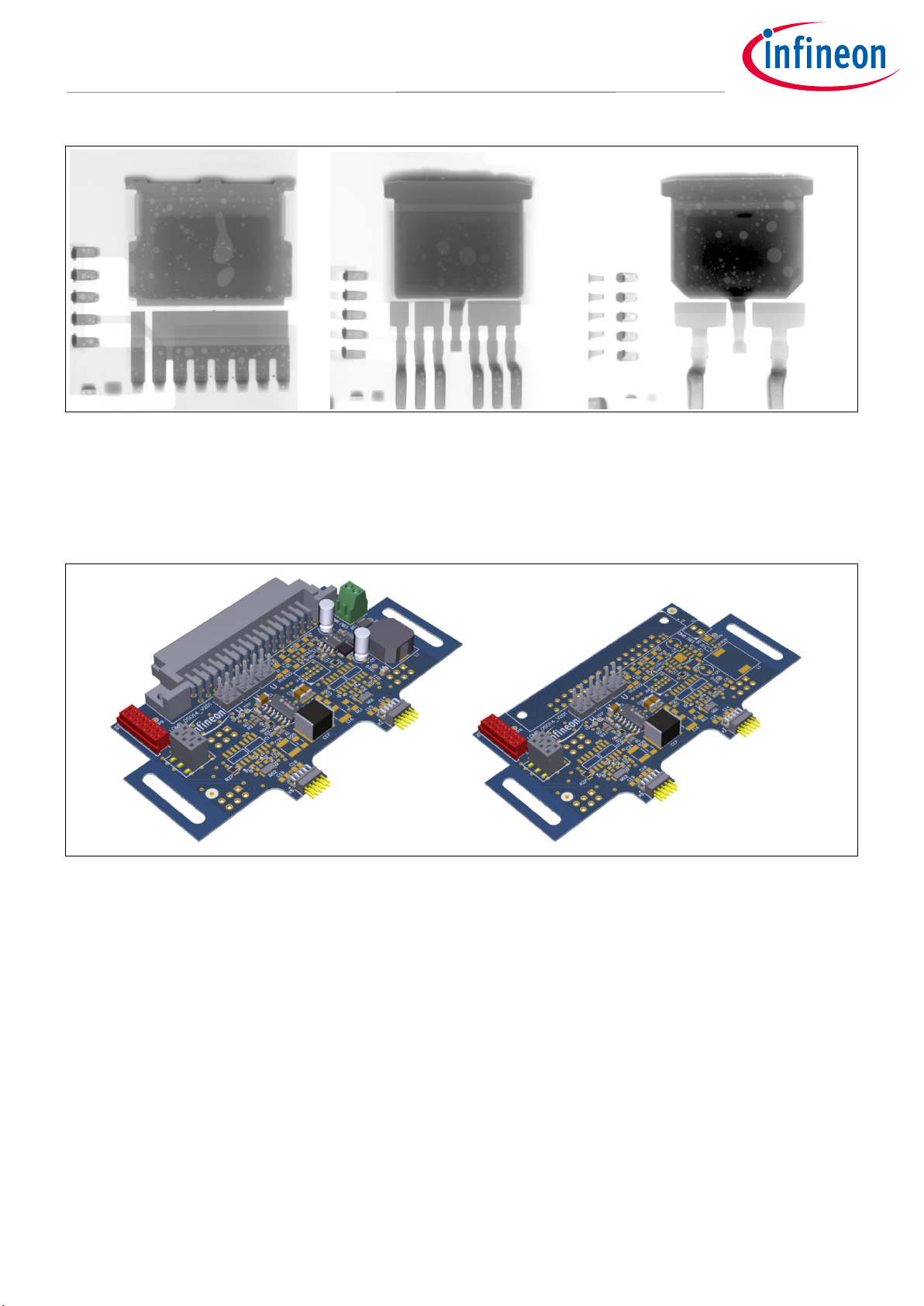

X-ray imaging was used to inspect the quality of the soldering process. The result is shown in Figure 9. A certain

number of voids are to be expected and can only be eliminated using a more advanced process of reflow

soldering in vacuum. However, the images show a fairly successful result with voids representing less than 10

percent of the soldered surface area.

Page 10

Application Note 10 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Figure 9 X-ray inspection – voids between lead-frame and PCB

2.2 Master mother board and mother boards

The master mother board and the mother board shown in Figure 10 provide the gate drivers for the HS and LS

MOSFETs for each of the half-bridges, as shown in Figure 11.

Figure 10 Master mother board and mother board

Page 11

Application Note 11 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Figure 11 Utilization of master mother board and mother boards in multiphase setups (e.g. U, V, W)

The difference between the two is in the connection to the XMCTM control board. The control board connects to

the master mother board, and the signals to the mother boards are propagated via the mother board bus.

Mother boards are only used alongside the master mother board when a two- or three-phase system is

implemented, as shown in Figure 11.

The master mother board also includes the onboard power supply sub-circuit that provides the 5 V supply line

powering the XMCTM control board. The 15 V supply for the gate drivers is propagated via the mother board bus

to the mother boards.

System supply

Note: The master mother board must be supplied from an external 15 V power source (at the X1

connector teminal).

The onboard IFX91041EJV50 generates the 5 V supply.

Page 12

Application Note 12 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Figure 12 15 V to 5 V converter (master mother board)

DC bus ceramic capacitors

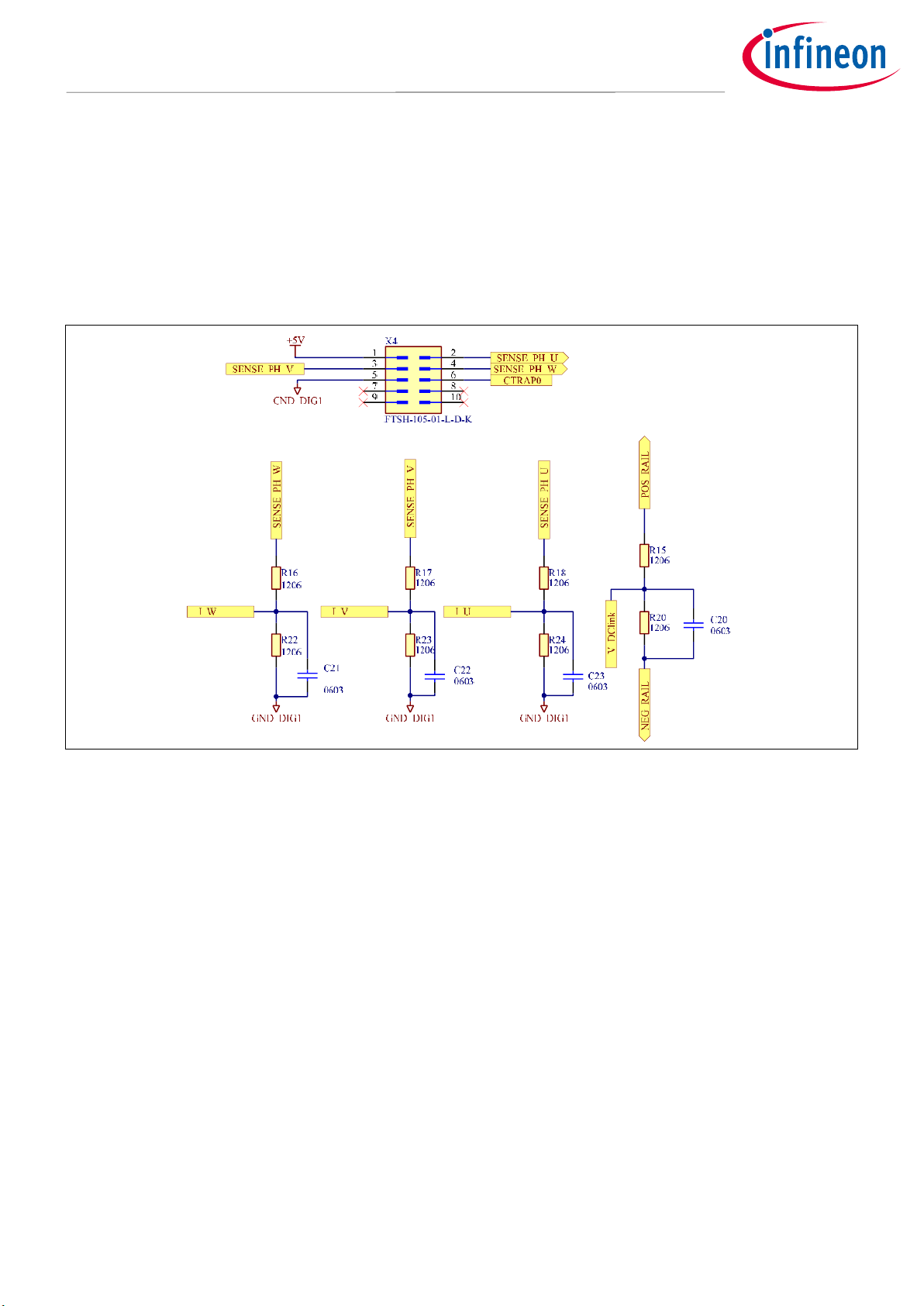

The master mother board and the mother boards provide a ceramic capacitor C17(c) connected to the high

voltage DC bus through the X2 and X5 headers. The intention is to provide the low ESR capacitors as close as

possible to each of the power boards in order to stabilize the DC bus voltage.

Figure 13 DC bus capacitor

Current sensor connection

The X4 connector on the master mother board, enables the user of optionally connecting voltage nodes or

current sensors, to the microcontroller analog inputs. The subcircuit is shown in Figure 14

A Samtec FTSH-105-01-L-D-K header connector can be used in place of the X4 connector to interface the

external sensors. The voltage dividers need to be adjusted according to the sensor output voltage range, and

the filtering capacitors to the required frequency range. The pins on X4 are intended to connect to the external

nodes while the nodes leading to the XMCTM inputs through the X3 connector are:

I_U

I_V

I_W

V_DClink

Page 13

Application Note 13 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

The connection of two-phase current sensors enables the current limit feature in the GUI (described in chapter

3.3). The feature uses the two-phase currents to calculate the current vector amplitude and compares it to the

current limit set in the GUI.

In order to enable the feature, the current sensors need to be connected to:

SENSE_PH_U (X4 - pin 2)

SENSE_PH_W (X4 - pin 4)

Figure 14 Current sensor connection

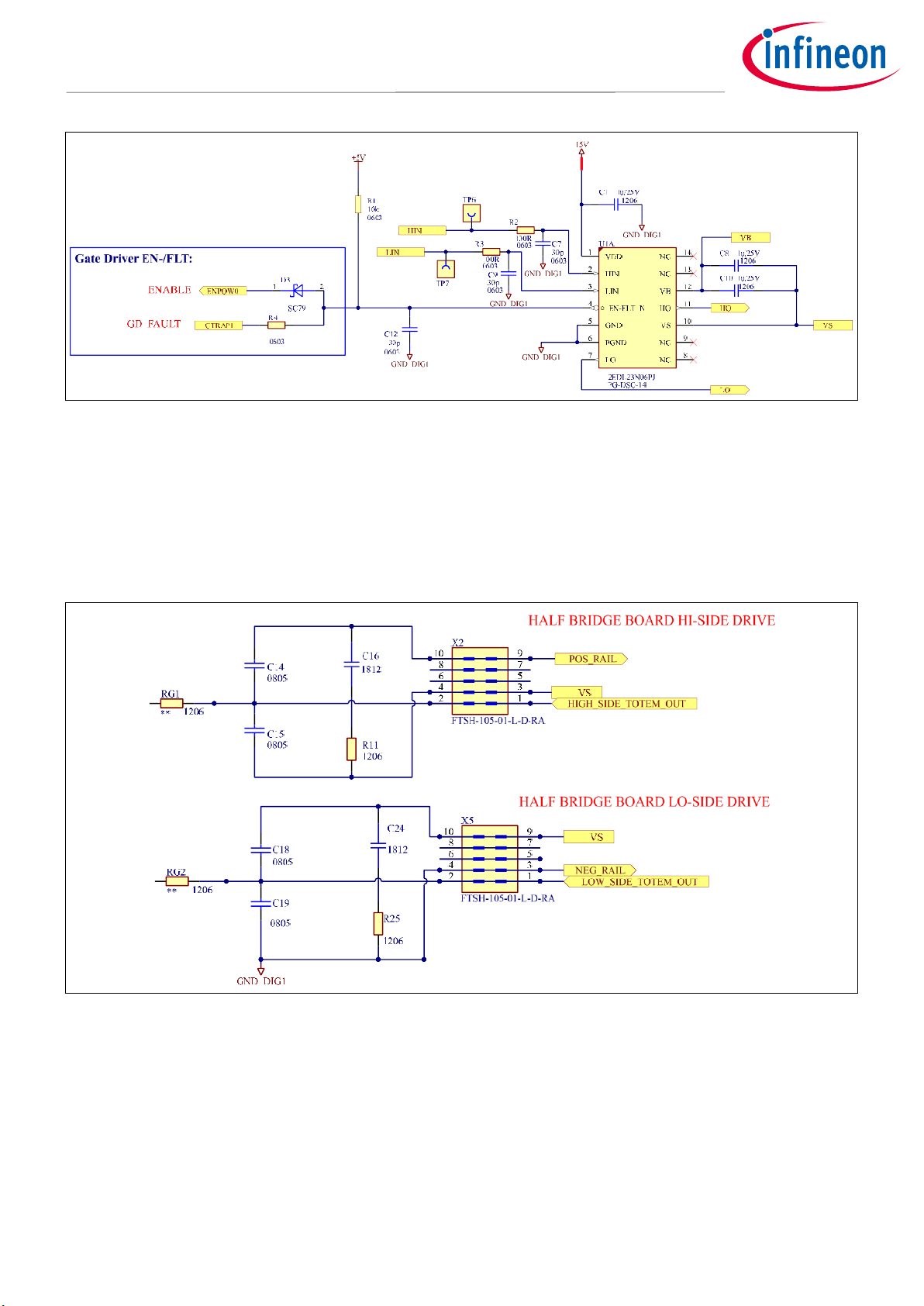

2.2.1 Gate drivers option I – 2EDL23N06PJ

KIT_LGMB_BOM003 & KIT_LGMB_BOM503

The 2EDL family gate drivers feature integrated HS and LS gate drivers, with an integrated bootstrap diode. The

gate driver output signals are propagated to the power board through header connectors X2 and X5. Mother

boards also include the gate resistors (RG1, RG2) for the two MOSFET gates connected at X2 and X5.

The default populated gate resistor (RG1 and RG2) values are 47 Ω. This value is suitable to be used with most

of the MOSFETs; however, it is not to be considered an optimum value. The intention of the platform is to

provide the option to easily change the RG values and adapt them to specific application requirements.

Page 14

Application Note 14 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Figure 15 Mother board implementation of 2EDL23N06PJ

In addition to the gate resistors, the board offers the possibility to connect additional capacitors between the

MOSFET terminals (G-S, G-D, D-S), as shown in Figure 16 for the HS and LS MOSFETs (refer to Figure 5 for power

board connections). This enables even greater influence on switching behavior optimization.

The components (C14, C15, C16, R11, C18, C19, C24, R25) are not populated by default. Only the PCB footprints

are available for the user to utilize according to project requirements.

Figure 16 Power board interface – MOSFET interconnection

2.2.2 Gate drivers option II – 1EDN8550B

KIT_LGMB_BOM004 & KIT_LGMB_BOM504

The pin-outs of the external connections are functionally the same in both options to accommodate

interchangeablity of the mother boards in the overall system. Other than some layout improvements, the

differences between the options are associated with the gate driver specifics.

Page 15

Application Note 15 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Figure 17 Mother board implementation of 1EDN8550B

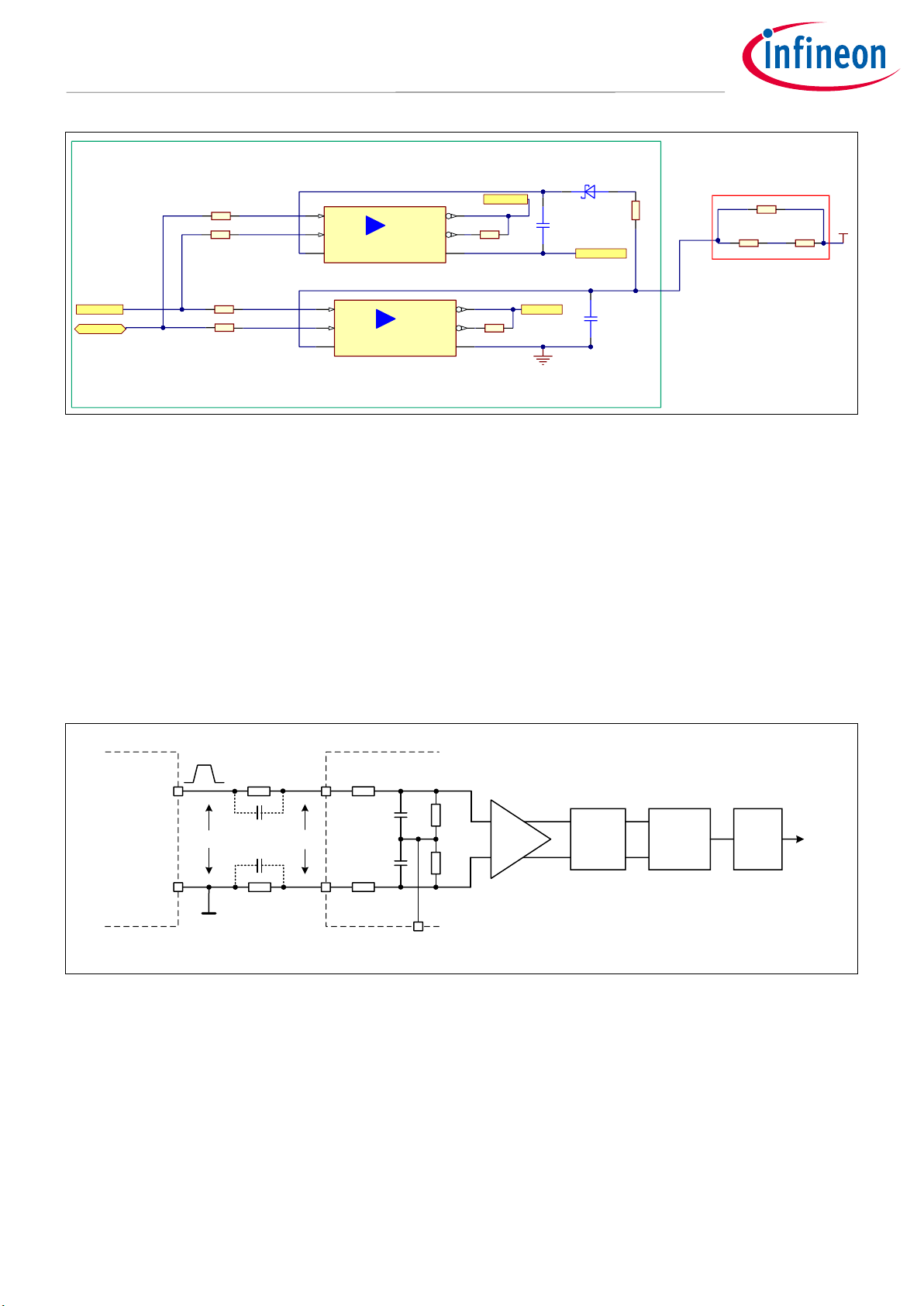

2.2.2.1 Functional principle of the 1EDN8550B (TDI) gate driver

The EiceDRIVER™ 1EDN8550B is a single-channel non-isolated gate driver with truly differential inputs (TDI) [3].

This concept for the input side of the gate driver makes it able to overcome the driving issues when a DC

ground-shift or an AC oscillation exists between the microcontroller and the driver IC ground potentials.

Common situations characterized by DC and AC ground-shifts are, for example, driving a HS switch in a halfbridge configuration, or driving in noisy environments with significant stray inductance on the ground path.

Some interesting use cases can be found in industrial, server and telecom SMPS as well as motor drive, wireless

charging applications, home appliances, power tools and solar micro-inverters. Figure 18 represents the

functional principle of the TDI gate driver and how it should be connected to the controller in order to

effectively prevent false triggering of the power switches.

IN+

IN-

Differential

Schmitt

Trigger

Av = 4.5

12 MHz

2nd order

Lowpass

Controller

PWM

SGND

0

R

in1

R

in2

2kW

2kW

1kW

1kW

15pF

15pF

1EDN8550

GND

Pulse

Extender

C

p2

C

p1

VS 5V

DV

Rin

DV

Rin

/ k

k = (R

in

[kW] + 3) / 3 = (51 + 3) / 3 = 18

51kW

51kW

Figure 18 Functional principle of the single-channel non-isolated gate driver with TDI

The controller PWM output signal, switching between controller supply voltage (VS) and zero, is applied on one

leg of a differential voltage divider, while the other is connected to the controller ground SGND. The divider

ratio has to be adapted to VS to allow a fixed Schmitt trigger threshold voltage. For VS = 5 V, R

in1

and R

in2

are

chosen to be 51 kΩ (see Table 1 [4]), resulting in a static divider ratio of k = 18 at the driver inputs. Taking into

account the resistor-capacitor (RC) filter in front of the internal voltage amplifier, the overall input path exhibits

the frequency behavior of a third-order low-pass filter with a corner frequency around 12 MHz. The suppression

of high frequencies is important for two reasons. Inductive common-mode (CM) ringing in fast-switching power

systems is typically in the 100 MHz and above range, and thus is effectively damped. The high-frequency

symmetry of the voltage divider is influenced by parasitic capacitances, particularly Cp1 and Cp2, the parallel

HO

LO

PHASE

HO

LO

1 2

D3

S100

HIN

LIN

HINGD

LINGD

0603

R2

1R/1%

0603

R4 33k/0.1%

0603

R8 33k/0.1%

HIN

LIN

When HIN and LIN max 3.3V then R1,R3,R4,R8=33k, 0603, 0.1% (PHASE voltage limited to 84V)

PGND

1206

Rp3

0R

+15V

RG3

4.7R

VDD

4

IN_P

3

IN_N

1

OUT_SNK_N

6

GND

2

OUT_SRC_N

5

U1

1EDN8550B

VDD

4

IN_P

3

IN_N

1

OUT_SNK_N

6

GND

2

OUT_SRC_N

5

U3

1EDN8550B

0R 1206

Rp2

22u/25V/X5R

1206

C12

4.7u/25V/X7R

1206

C9

Use 20x MOSFET input capacitance for Bootstrap capacitor

RG4

4.7R

0603

R1

33k/0.1%

0603

R3

33k/0.1%

Rp1

0R 1206

Page 16

Application Note 16 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

capacitances of R

in1

and R

in2

. They are typically in the 50 to 100 fF range, independent of resistor size. Without

filtering, any asymmetry would translate high-frequency CM signals into differential signals. The filtered signal

is then applied to a differential Schmitt trigger with accurate trimmed threshold levels and converted to the

logic switch control signal. The subsequent pulse extender function guarantees that no pulses shorter than 25

ns are transmitted to the output, thereby further improving noise immunity. Due to the filtering requirements,

the input-to-output propagation delay is slightly increased to around 45 ns. By means of on-chip trimming,

however, the usually more relevant propagation delay variation can still be kept low at +10/-7 ns.

The static voltage range at the input pins is limited to -7 V/+6 V to guarantee accurate linear operation of the

input circuitry. Any imbalance in the signal path converts a CM signal to a differential signal. To utilize the full

CM range as calculated above, the high accuracy of the trimmed on-chip network must not be affected by the

external voltage divider resistors. This condition is easily fulfilled when choosing R

in1

and R

in2

with 0.1 percent

tolerance. However, the power rating and the size of the external resistor pair play an important role as

“bottleneck” to achieve high DC and AC ground-shift robustness. In this case, a 1206-size resistor has been

selected to ensure a proper creepage and clearance at the PCB level. Since the 51 kΩ/0.1 percent/1206 resistors

available in the market are typically rated 200 V, the static CMR of the driving configuration in Figure 18 is

limited to the range of -126 V/+108 V.

Benefits:

Immunity to interference

Decoupling of signal and power GND

2.2.2.2 Performance results with KIT_LGMB_BOM004 and KIT_LGMB_BOM504

The key components used in this setup to conduct the following gate driver tests are:

1. Driver IC (mother board) – 1EDN8550B (EiceDRIVER

TM

)

2. MOSFET (power board) – IPB017N10N5 (OptiMOS

TM

)

3. Controller (controller card) – XMC4400 (XMC

TM

)

High dv/dt immunity:

This section highlights the ripple noise between the signal ground and power ground and on high dv/dt of the

output node. The setup was designed to create the worst-case conditions for switching. As the objective is to

measure the ripple noise, the double pulse testing method is used instead of continuous switching. The

switching speed for turn-on and turn-off are swept by changing the value of external gate resistance (Rg) in

steps to reach the harsh conditions described above with high output dv/dt, high di/dt of ID and high groundshift ripples.

Page 17

Application Note 17 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Inductive

Load

C_Bank

48V

DC

U W

C_Bank

TDI

HS

TDI

LS

TDI

HS

TDI

LS

V

DD

V

DD

V

DD

V

DD

Ground Shift (LParasitic)

Positive Rail

Negative Rail V

U_GND

V

W_GND

x 4 x 4

Figure 19 Ground-shift realization in HB/FB applications

The microcontroller ground is only connected to a single point in the circuit (in this case V

U_GND

). The voltage

difference between the signal ground (V

U_GND

→ SGND) and power ground (V

W_GND

→ PGND) is a result of induced

voltage in the L

parasitic

, as shown in Figure 19. The switching properties (output dv/dt, ID di/dt) are shown in Table

2. The noise produced in the system, measured as the oscillation of the ground-shift, varies with a high peak-topeak amplitude of 14.24 V and lasts for less than five cycles (less than 12 µs) of decreasing magnitude, and is

within the CMR of TDI driver IC.

Table 2 Switching speed measurements of test setup

Measurement parameter

Turn-off

Turn-on

Switch-node dv/dt

350 V/µs

4200 V/µs

Drain current diD/dt (A/µs)

800 A/µs

900 A/µs

Voltage PGND vs. SGND dv/dt (V/µs)

65 V/µs

33 V/µs

Voltage PGND vs. SGND amplitude (pk-pk)

14.24 V

14.24 V

Page 18

Application Note 18 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Figure 20 Ground-shift between signal ground and power ground

The difference in potentials between the signal (µC) ground and power ground (i.e. ground-shift) shown in

Figure 20 represent the CM voltage of the LS differential input, and the switch-node voltage represents the HS

differential input. In both cases the CM is not influencing the gate driver input, and high-frequency CM voltages

(ringing) greater than 333 kHz are further dampened by the input low-pass filter. In such fast-switching

situations, the high robustness of 1EDN8550B with respect to switching interference is extremely valuable and

allows good performance even in systems with significant parasitic PCB inductances.

The ground-shift problem in specific applications can be addressed by Infineon’s TDI gate driver IC, and in the

same way, the TDI can handle the voltage offset and high dv/dt of a bootstrapped gate driver.

Gate driver supply filter:

This section descibes the optimization of the input filter for the gate driver supply side. Usually SGND-coupled

VDD cannot be used directly as the driver supply due to the high ripples of ground-shift. The filter can be a

simple resistor or a resistor in series with a diode, or series and parallel combinations of these components

together with the decoupling capacitor (C12) as indicated in Figure 17 (Rp1, Rp2, Rp3). The filter can also be a

proper ferrite bead depending on application and cost requirements. To choose the filter components

optimally, the LVDSPD setup has been continuously switched in worst-case conditions described above with a

DC current flowing in an R-L load.

The test specifications are:

GD supply: V

DD

= 15 V

Switching frequency: f_PWM = 20 kHz

Duty cycle: D = 11 percent

Load current: I_L = 210 A

Drain current I

D

: di/dt = 900 A/µs (Rg1 = 15 Ω, Rg3 = 10 Ω)

Switch-node voltage V

(SW)

: dv/dt more than 4000 V/µs

The variations to the test setup are:

Page 19

Application Note 19 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Only R filter

Only diode

Diode with resistors

Figure 21 shows:

The switch-node voltage

TDI driver IC supply voltage seen across bypass capacitor C12 (last combination of values – diode with

resistors)

The ripple voltage at the filter input

Figure 21 Ripple across gate driver input supply

The filter components comprise Rp1, Rp2 and Rp3 – 1206 footprint (Figure 17). Changing these components

results in different thermal situations and different resulting voltages on C12. The results for a few value

combinations are shown in Table 3. The temperatures recorded from images captured by thermal camera are

shown in Figure 22 for the optimized filter (Rp1 = diode, Rp2 = 10 Ω, Rp3 = 47 Ω). Please note that both the

driver ICs are cooler than 50°C. The rest of the board does not get significantly hot.

Figure 22 Thermal captures of filter section

Page 20

Application Note 20 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Table 3 Measurement parameters of optimized filter section

Measurement

Rp1 = n.p.

Rp2 = n.p.

Rp3 = 15 Ω

Rp1 = n.p.

Rp2 = n.p.

Rp3 = diode

Rp1 = diode

Rp2 = 10 Ω

Rp3 = 22 Ω

Rp1 = diode

Rp2 = 10 Ω

Rp3 = 47 Ω

Voltage PGND to SGND (pkpk)

19.0 V

18.7 V

19.1

20.98 V

Voltage VC12 (mean)

14.63 V

19.65 V

15.16 V

15.32 V

Temperature of filter

components

(Rp1, Rp2, Rp3)

84.2°C

43°C

38.9°C

54.3°C

67.4°C

36.81°C

50.9°C

48.7°C

Temperature of C12

43.1°C

44.6°C

54.3°C

33.1°C

Temperature of PCB

38°C

38.6°C

30.2°C

30.9°C

Temperature of LS GD (U3)

46.1°C

51.6°C

38.4°C

37°C

Temperature of HS GD (U1)

49°C

62.1°C

40.1°C

38.5°C

The results in Table 3 indicate the preferred combination of components as:

Rp1 = diode (SBD – SS14L SMA 1 A 40 V, V

f

= 0.196 V),

Rp2 = 10 Ω and

Rp3 = 22 Ω or 47 Ω

However, in a system with less ripple other combinations are also acceptable, and may simplify the design.

Gate driver output loading:

This section estimates the loading on the gate driver by emulating the MOSFETs by R and C components (Figure

23). The switching frequency of the PWM is set at 20 kHz.

The test setup values are:

Capacitive load: C

L

= 210 nF (0805)

GD supply: V

DD

= 15 V

External gate resistance: R

g

a. R

g2

= 0 Ω; Rg4 = 4.7 Ω, 2.2 Ω and 1 Ω

b. R

g2

= 15 Ω, Rg4 = 10 Ω

12V

55k

55k

SGND

VRin

IN-

GND

IN+

OUT_SNK

OUT_SRC

VDD

CVDD

1EDN8550B

CL

Controller

SGND

PWM_Out

Rg4

Rg2

Figure 23 Schematic for gate driver output loading

Page 21

Application Note 21 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

The source and sink resistances in this case will be Rg2 + Rg4 and Rg2 respectively. The power dissipation in the

gate driver heats up the IC and the temperatures are recorded with a thermal camera. The recorded data is

shown in Table 4.

Table 4 Gate driver output loading measurements

f_PWM (kHz)

Rg (Ω)

Temperature (T) (°C)

IC-U3 (°C)

Rg4 (°C)

Rg2 (°C)

20 kHz

Rg2 = 0 Ω, Rg4 = 4.7 Ω

64.5

79.8

–

Rg2 = 0 Ω, Rg4 = 2.2 Ω

66.4

68.6

–

Rg2 = 0 Ω, Rg4 = 1 Ω

76.3

61.7

–

Rg2 = 15 Ω, Rg4 = 10 Ω

40.2

55.3

89

The data from the Table 4 shows the application of the TDI gate driver for different switching speed

applications and temperature limitation problems. Depending on the values of Rg2 and Rg4, the parts of the IC

that represent the sourcing output and sinking output may be at different temperatures.

2.3 Daughter boards

Daughter boards are used for the interconnection between the gate driver outputs and power boards (MOSFET

gates) via X7 and X11 header connectors, when adding power boards in parallel.

Figure 24 Daughter board

Typically, MOSFETs connected in parallel are driven by a single gate driver, while the gate resistors (RG) are

provided for each MOSFET gate. The gate driver signal branches out at the gate driver output – before the RG

resistors and not at the gate nodes. The daughter boards are therefore connected to the gate driver outputs at

one side (forming the daughter board bus – Chapter 3.2.3), and to the MOSFET gate and source connection at

the other side (Figure 5). Each daughter board provides each additional power board with the respective HS

and LS gate resistors. The principle is illustrated in Figure 25.

Page 22

Application Note 22 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

Figure 25 Paralleling approach

2.3.1 Power board interface

At the point of connection to the power board, the same optional components are available as in the mother

boards. The schematic is shown in Figure 16 and Figure 13. The ceramic capacitor C17(c) is populated by

default.

2.4 Functional principle of the 1EDN8550B (TDI) gate driver capacitor

boards

The capacitor boards provide the option to connect leaded capacitors to the high-power DC bus. The highcurrent connectors have the same spacing as the power board DC bus connectors. This way the copper bars

can be extended in order to make the low parasitic inductance connection between the power board and the

capacitor board.

Figure 26 Capacitor board

Page 23

Application Note 23 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

The capacitor boards are populated with power connectors only. This way the user can select the capacitors

according to project requirements.

It is recommended to use capacitors with low ESR values.

Table 5 Capacitor selection size requirements

Parameter

Values

Unit

Min.

Typ.

Max.

Capacitor diameter

18

mm

Lead spacing

7.5 mm

Figure 27 Capacitor board dimensions

Attention: Normally the bus capacitors are discharged when the lab power supply is switched off. But if

the power connector is removed while the capacitor is charged (not recommended!), the

voltage preserved at the bus capacitors can reach a dangerous level. Be sure that capacitors

are discharged before handling the board.

Page 24

Application Note 24 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Board overview

2.5 Control board

Various control boards can be adapted to interface the master mother board. The X3 connector (Hirose PCN1332S-2.54DS(71)) on the master mother board is provided for interfacing with Infineon’s XMC™ demonstration

board: XMC4400 drive card (KIT_XMC4400_DC_V1), which is used in the examples covered in this document.

The control signals are propagated to the master mother board gate driver, and the mother board bus as

described in chapter 3.2.

Figure 28 XMC4400 drive card demonstration board

A detailed description of the XMC4400 drive card can be found online.

Page 25

Application Note 25 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

3 Three-phase motor drive setup (B6)

Alongside versatility, the platform was designed with motor drive applications in mind. The main focus of this

application note is therefore a three-phase motor drive setup (i.e. B6 inverter), represented in Figure 29. Some

performance examples of a B6 motor drive inverter, at different power board paralleling options, are given in

chapter 4.

Figure 29 B6 inverter – block diagram

Assembly procedures for constructing a B6 inverter can be found in the Low voltage drives scalable power

demo board – user manual.

Page 26

Application Note 26 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

3.1 Supply voltage

3.1.1 LV supply

The 15 V supply for the system connected at the X1 terminal is limited by the gate driver specification.

Table 6 LV system supply

Parameter

Values

Unit

Note

Min.

Typ.

Max.

LV system supply

12

15

20 V Max. according to 2EDL23N06PJ

3.1.2 Highvoltage/high power supply

Attention: In addition to high power supply voltage, the voltage spikes caused by MOSFET switching

need to be considered. The V

DSS

should not exceed the V

(BR)DSS

rating of the MOSFET at any

point. The supply voltage needs to be adapted accordingly.

The supply voltage used on the power side of the set-up will be limited by the MOSFET drain-source breakdown

voltage (V

(BR)DSS

). Recommended nominal supply voltages are given in Table 7, with regard to the breakdown

voltage rating of the MOSFET being used.

Table 7 Nominal power supply voltage recommendations

MOSFET V

(BR)DSS

rating (V)

Supply voltage

Unit

Typ.

Max.

60

24

32

V

80

48

V

100

48

V

150

72

96

V

200

144

V

250

157

V

3.2 Board interconnections in multiphase setups and power board

paralleling

Mother boards are used alongside a master mother board when two- or three-phase systems are implemented.

The mother boards are connected to the master mother board through the mother board bus via a ribbon cable

to connector X6, and provide the additional gate drivers for the additional two phases.

Daughter boards are used to propagate the gate driver signals to the power MOSFETs when paralleling of

power boards is implemented.

The following chapters describe the signals used to interconnect the boards in a particular setup.

Page 27

Application Note 27 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

3.2.1 Control signals – control board interface

The master mother board interface to the control board uses the pin-out as defined in the “Power board

connector” chapter of the XMC4400 drive card user manual: “Board_Users_Manual_DriveCard_XMC4400” found

on the demonstration board website:

https://www.infineon.com/cms/en/product/evaluation-boards/kit_xmc4400_dc_v1/

The document provides further details about the XMC4400 drive card.

The control board signals used are listed in Table 8 and Figure 30.

Table 8 Signal description

Signal name

Description

Comment

+5 V

XMCTM/control board supply

I_U, I_V, I_W

Current sensor feedback. From master

mother board onboard voltage

dividers/filters.

Optional – the voltage divider/filter

components are not populated by default

V_DClink

Supply voltage feedback. From master

mother board onboard voltage

divider/filter.

Optional – the voltage divider/filter

components are not populated by default

U_L, U_H, V_L,

V_H, W_L, W_H,

Gate driver control signals

CTRAP0, CTRAP1

Digital feedback signals connected to the

µC pins with “TRAP Function” capability

See XMC4400 microcontroller reference

manual for details

ENPOW0

Gate driver enable signal

Figure 30 XMC

TM

drive card connector pin-out – mother board PCB top view

Page 28

Application Note 28 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

3.2.2 Mother board bus

The mother board bus (ribbon cable connected at connector X6) propagates the gate drive control signals to

the “W” and “V” mother boards. It also connects the gate driver supply (15 V), and the gate driver enable signal.

ENPOW0 can be used to disable the gate drivers via the microcontroller. CTRAP1 connects all the gate driver

enable pins to a common pull-up to enable them. A fault condition (disable) on the gate driver will pull its

enable pin down (open drain configuration). This pull-down will also be propagated across CTRAP1 to the other

gate drivers, to disable them.

Figure 31 Mother board bus pin-out – top view

Selection jumpers “U”, “V” and “W” are provided to assign the control signals to each of the gate drivers. Since

all three control signals are present on the master mother board, and “V” and “W” control signals are present at

the mother board bus (propagated through the ribbon cable), the jumpers are used to physically connect either

of them to the gate driver inputs. In a three-phase setup the master mother board shall always be selected as

the “U” phase, since the “U” control signals are not present at the mother board bus.

Phase “U” Phase “V” Phase “W”

Figure 32 Jumper placement for phase selection

Page 29

Application Note 29 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

3.2.3 Daughter board bus

In the case of power board paralleling, the gate driver output signals are propagated to the parallel power

MOSFETs via X7 or X11 headers that branch out the gate driver output and source connections through the

corresponding daughter boards. The pin-out is shown in Figure 33.

All the nodes (gate driver outputs) are therefore present on all the daughter boards. The gate driver outputs

pass through a gate resistor at each of the daughter boards and connect to the power board (gate terminal).

Figure 33 Daughter board bus pin-out – top view

3.3 Using the V/f control for induction motor

Infineon provides a software package supporting the demonstration board. The software package is intended

for use with the B6 set-up to drive a three-phase induction motor. Provided in the software package are the

firmware for Infineon’s XMC™ demonstration board XMC4400 drive card, and a GUI for controlling the set-up.

The implemented induction motor drive firmware is based on the open-loop V/f control scheme. In principle V/f

control uses voltage sine wave signals to drive the motor. It varies the voltage signal amplitude in linear

relation to field rotation speed (electrical frequency of the motor). In switch-mode applications (utilizing the B6

topology) the voltage sine waves are generated via PWM signals at each of the phases, resulting in effective

voltages equivalent to the sine wave signals that the V/f ratio refers to.

The implemented characteristics of voltage amplitude in relation to the motor electrical frequency are shown

in Figure 34.

Ideally the ratio is maintained all the way to zero; however, at low speeds the voltage is typically increased to

compensate for the voltage drop across the stator resistance, which is not negligible at small voltages. This

voltage increase for low speeds is determined by the “V offset”, also seen in Figure 34.

Page 30

Application Note 30 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

Figure 34 V/f control characteristics with V offset implementation

The V/f ratio, V offset and field rotation speed (i.e. synchronous speed) are adjustable by the user via GUI

parameters. The first and second tab of the GUI are shown in Figure 35 and Figure 36.

Figure 35 GUI – motor control tab

Page 31

Application Note 31 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

The V/f ratio is set by the user according to motor characteristics and the applied load. For a given motor at

stable supply voltage, the load will determine the maximum achievable turning speed according to torque vs.

phase voltage characteristics of the motor.

The DC bus utilization bar represents roughly the ratio between the effective phase voltage amplitude and

supply voltage. It indicates the maximum duty cycle of the PWM within the motor electrical period.

In effect, the bar indicates the limit of the motor control settings – it considers the following parameters:

Input voltage (V)

Field rotation speed (RPM)

Voltage/frequency ratio (mV/Hz)

V/f offset

The limit is set to 90 percent, which also takes into consideration minimum charge times for charging a HS

bootstrap capacitor (some margin also included). The bootstrap is charged when the LS MOSFET conducts. The

critical timings in this regard are therefore achieved during high PWM duty cycles.

Figure 36 GUI – settings tab

Page 32

Application Note 32 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

Table 9 lists the parameters used by the GUI for interfacing the microcontroller.

Table 9 GUI settings description

Setting

Description

Field rotation speed

(RPM)

Setting of the stator field rotation speed. Type the value and confirm with “ENTER”, or

use the mouse scroll button while hovering above the value.

Voltage/frequency

ratio (mV/Hz)

The ratio of effective output voltage amplitude vs. field rotation speed

Number of motor

poles

Counted in stator pole pairs

V/f offset (mV)

Effective output voltage at standstill – see Figure 34 for characteristic curve. Set to zero

for linear V/f charateristics.

Ramp up (Hz/s)

Rate of change of the field rotation speed (when changing field rotation speed setting)

Input voltage (V)

DC power supply voltage used

I sensor gain (mV/A)

Gain of the current sensor used in mV/A

(It is recommended to use sensors with galvanic isolation, e.g. the ASC758 (±200 A

range, 10 mV/A output gain)

Current limit (A)

Current limit – disable if not using a sensor

PWM frequency (Hz)

PWM frequency setting

Dead-time (ns)

Dead-time setting (off-time of the complementary control signals)

3.3.1 Using the GUI

While the microcontroller is running the V/f control algorithm, the user can control the motor via parameters

provided by the GUI.

Before any parameter can be set, the GUI needs to establish connections with the microcontroller. The

interface settings can be found on the XMC_Connection tab, in the upper left corner (Figure 36). Set the baud

rate to 115200, and after connecting the drive card to a USB port, refresh the ports and select the

corresponding port with the drop-down menu.

When the connection is established the GUI will run a short diagnostics procedure on communication with the

microcontroller, and update the parameters on the microcontroller according to the parameters set on the GUI.

If the diagnostics show an error in GUI performance, or a restart of the GUI, the parameters will be sent from the

microcontroller to the GUI.

3.3.2 Configuration parameters

Before turning on the motor, the configuration parameters on the XMC_Communication tab need to be set.

Different methods of changing the parameters are available. The six parameters marked by the orange boxin

Figure 37 have three options for setting the value:

Scrolling with the mouse wheel while hovering above the box (value change is three units per scroll step)

→ µC is updated continuously

Clicking the up/down arrows (value change is one unit per click)

→ µC is updated continuously

Typing the new value in the box and pressing “ENTER”

In this case a warning window will ask to “Confirm updating”

→ µC is updated after confirming by pressing “Yes” (pressing “No” recovers previous value)

Page 33

Application Note 33 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

Figure 37 GUI – configuration parameters

The other two parameters in Figure 37 – “Number of motor poles” and “Ramp up” are only set by entering the

required value and configuring by pressing “ENTER”. The microcontroller is updated immediately.

It is not possible to change the configuration parameters during motor operation. If attempted the GUI will

return a warning, turning the data cell red, and the parameter will not be updated in the microcontroller.

3.3.3 Motor control parameters

The motor control parameters located on the “Motor Control” tab of the GUI are intended to be set during

motor operation. Thay can be set in the same manner as the parameters in Figure 37. The small difference in

setting the “Field Rotation Speed” is that the arrow buttons change the value by 30 units in this case. Entering a

value by typing again requires confirmation in order to avoid accidental large steps.

After setting the synchronous speed and the V/f ratio, pressing the “Start” button will begin to ramp up the

speed with the rate defined by the “Ramp up” configuration parameter. The button changes to “Stop”. Pressing

“Stop” will ramp the speed down at the same rate as the ramp up.

Attention: Stopping the motor with the “Stop” button does not disable the PWM. There is a small PWM

output present even at standstill. This is the “V offset” that is set in the configuration

parameters tab.

Located on both tabs of the GUI is the “Emergency stop” button. Pressing this, unlike pressing stop, will

immediately disable the gate drivers, thus turning off all of the power MOSFETs. The GUI will change the field

rotation speed to zero, and notify the user that the controller has entered “Emergency stop state”. To return

the controller to normal operation, the user needs to re-enable the system by pressing the “Enable_Inverter”

button on the “XMC_Connection” tab.

Page 34

Application Note 34 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

Figure 38 Re-enable inverter after emergency stop

Attention: Make sure to check any potential failures that might have been the cause for the emergency

stop, before re-enabling the inverter!

3.3.4 Driving an induction motor

Depending on the type of load used, the approach of utilizing the V/f method can vary.

On a typical laboratory test bench, using an adjustable load, it is common to change the load at a constant

synchronous speed. Changing the load requires changing the voltage amplitude, so that the slip is maintained

at the rated value. If the slip is increased beyond the point of maximum motor torque, the motor will stall,

causing a considerable increase in phase currents. Using current limitation on the power supply is

recommended.

At a constant setting of the field rotation speed parameter in the GUI, the V/f ratio setting in effect only changes

the voltage amplitude. An easy way to establish an operating point for measurements is to start the motor with

a relatively small V/f ratio setting while keeping the load disabled. After settling at the target speed (rotor slip

considered), the load can be increased simultaneously or alternating with the voltage amplitude.

The actual V/f value required to start turning the motor will depend on the motor characteristics, the load

(including friction losses) and the rotor inertia (including inertia of the brake and any additional mass

attached). Since the inertia will affect torque applied to the motor during acceleration, the ramp-up rate will

also have an effect.

Insufficient values of V/f will result in considerable rotor delays at start-up, or not starting at all. If the response

is considerable at the beginning of ramp-up, but catches up with the field rotation speed before the end of the

ramp up process, it can be speeded up by increasing the V offset in order to increase the tourqe at low

frequencies.

Page 35

Application Note 35 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Three-phase motor drive setup (B6)

When setting the paramenters, the user should consider that the synchronous speed is increased linearly after

pressing the “Start” button, and with proper settings the rotor should ramp-up linearly as well, with the

additional delay of the absolute slip speed (n

slip

= n

sync

– n

rotor

), which should ideally be kept constant.

A good way of evaluating the ramp-up procedure is also to observe the amplitudes of the phase currents during

ramp-up. The current amplitude is expected to be higher but constant during ramp-up, and to drop to a smaller

steady-state value when the rotor speed is settled.

V offset will keep a constant current flowing through the stator windings even at standstill, which can heat the

motor windings.

Excessive values of the V/f coefficient will increase the reactive current to the motor, resulting in higher losses,

and in extreme cases saturation of the stator.

Attention: Make sure that motor limits are not exceeded, or permanent damage to the motor and/or

inverter could occur.

Attention: There are exposed surface areas under high voltage in this setup. Make sure to secure the

setup against accidental contact by people or equipment.

Page 36

Application Note 36 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

4 Performance of a B6 setup in a motor drive application

Performance of a B6 inverter setup with a different number of paralleled power boards has been tested at

different operating points, to evaluate the capabilities of the setup. The power boards were cooled with

aluminum air-cooled heatsinks (each phase separately). The test setup was constructed using the

KIT_LGPWR_BOM003 power board version, which utilizes the IPT012N08N5 MOSFET with a V

(BR)DSS

rating of 80 V.

The B6 setup was used to drive an induction motor, with an electric brake providing the load.

The V/f control was used as described above.

Table 10 lists the components used in the performance tests.

Table 10 Setup overview for four paralleled power boards

Part

Description

Quantity

Power board

KIT_LGPWR_BOM003

12 pieces

Capacitor board

KIT_LGCAP_BOM005

3

Control board

KIT_XMC4400_DC_V1

1

Master mother board

KIT_LGMB_BOM003

1

Mother board

KIT_LGMB_BOM503

2

Daughter board

KIT_LGDB_BOM003

9

Heatsink (aluminum, air-cooled)

100 mm x 100 mm x 40 mm (fins: 30

mm)

3

Copper bars set

See user manual [1]

1 set

Copper spacer

See user manual [1]

6

Screw for power terminals

M5, 6 mm

48

Interconnection bolts and nuts

M5

11 sets

Screw for attaching IMS boards to heatsink

M2, 5 mm

72

Current sensor

VAC – P4640-X150

4

The operating points of the tests are differentiated by load/power output, while the conditions listed in Table

11 are the same for all cases.

Table 11 Specifications and conditions

Parameter

Value

Unit

Ambient temparature

23

°C

Power board break-down voltage

80

V

Supply voltage

48 V f_PWM

8

kHz

Dead-time

2

µs

R

G

47

Ω

Field rotation speed

1800

RPM

Mechanical speed

1760

RPM

Electrical frequency (field

frequency)

60

Hz

Page 37

Application Note 37 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

Using the GUI provided, the operating point was set by gradually increasing the mechanical load and the V/f

coefficient, at a constant synchronous speed.

The thermal images below show a single phase of the setup. The images are taken 3 minutes after reaching the

operating point, which is not fully settled at the heatsink temperature; however, the temperature of

components on the FR4 boards can be considered settled. As the following results show, the ceramic capacitors

on mother boards and daughter boards are often the limiting factor.

Table 12 lists an overview of the results.

Table 12 Overview of test operating point results

Parameter

OP1

OP2

OP3

OP4

OP5

Setup (parallel

MOSFETs per switch)

1 (no

paralleling)

1 (no

paralleling)

2 2 4

P supply [W]

2014.1

5233.1

5474.1

8860.2

10407.2

P electric out [W]

1814.5

4786.2

5112.7

8263.3

9595.7

Inverter efficiency [%]

90.1

91.5

93.4

93.3

92.2

Braking torque [Nm]

8.157

22.12

23.86

38.17

44.06

P mechanical [W]

1503

4078

4397

7034

8121

OP2 and OP4 can serve as good representatives of the setup capabilities. The power output of OP5 was not

limited by heat dissipation on the inverter. The operating point was set at maximum duty cycle of the PWM

signals. This means that the motor and load were defining the maximum load on the inverter in this operating

point. Depending on the load, the inverter with four parallel MOSFETs per switch will therefore be able to

handle even higher power.

4.1 No paralleling

The first two operating points were measured without using any paralleling of the power MOSFETs in the B6

inverter. The B6 setup therefore uses a single power board per phase. This is illustrated in Figure 39.

Page 38

Application Note 38 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

Figure 39 System block diagram – no MOSFET paralleling

4.1.1 Operating point 1

The measurement results of the first operating point are shown in Table 13.

Table 13 OP1 measurements

Parameter

Value

Unit

Torque

8.157

Nm

V/f setting

285

mV/Hz

P supply

2014.1

W

P electric

1814.5

W

Inverter efficiency

90.1

%

P mech

1503

W

Figure 40 shows the current waveforms – three-phase currents and supply current.

Page 39

Application Note 39 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

The relatively high current ripple at 8 kHz, due to the low inductance of the motor windings being used, is not

unusual; however, will cause additional losses on the motor.

When driving an induction motor, the control over the reactive component of phase currents is limited. The

reactive current is the reason for the relatively high amplitudes of the phase currents. This behavior can also be

observed in the other operating points.

Figure 40 Current waveforms

Ch1 (light blue): “U” phase current

Ch2 (yellow): “V” phase current

Ch3 (red): “W” phase current

Ch4 (dark blue): DC supply current

Figure 41 shows the thermal distribution after 3 minutes. According to component temperatures, the system is

capable of handling higher loads.

Page 40

Application Note 40 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

Figure 41 Top-side view and thermal distribution

Table 14 Temperature measurements from Figure 41

Measuring subject

Measuring point

Temperature [°C]

MOSFET_HS1

Area01 (max.)

67.7

MOSFET_LS1

Area02 (max.)

74.0

Heatsink

Spot01

57.0

Spot02

57.7

Average

55.8

4.1.2 Operating point 2

This operating point was tuned to represent the maximum achievable power output of the non-paralleled

system, without exceeding a temperature of 120°C. The results are shown in Table 15.

The current waveforms are shown in Figure 42.

Table 15 OP2 measurements

Parameter

Value

Unit

Torque

22.12

Nm

V/f setting

467

mV/Hz

P supply

5233.1

W

P electric

4786.2

W

Inverter efficiency

91.5

%

P mech

4078

W

Page 41

Application Note 41 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

Figure 42 Current waveforms

Ch1 (light blue): “U” phase current

Ch2 (yellow): “V” phase current

Ch3 (red): “W” phase current

Ch4 (dark blue): DC supply current

Figure 43 shows the thermal distribution after 3 minutes of operation in this operating point. The temperature

difference between the hottest MOSFET and the heatsink in its proximity is ∆T

LS1

= 48.1 K.

Page 42

Application Note 42 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

Figure 43 Top-side view and thermal distribution

Table 16 Temperature measurements from Figure 43

Measuring subject

Measuring point

Temperature [°C]

MOSFET_HS1

Area01 (max.)

97.7

MOSFET_LS1

Area02 (max.)

114.7

Heatsink

Spot01

65.4

Spot02

66.6

Average

61.8

4.2 Two-per-phase parallel connection

The setup used for the following two operating points is illustrated in Figure 44. It uses two power boards

connected in parallel for each phase. It uses an additional daughter board in each phase to connect the

paralleled power boards to the gate drivers.

Page 43

Application Note 43 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

Figure 44 System block diagram – two parallel power boards per phase

4.2.1 Operating point 3

This operating point was selected to use the same V/f setting as OP2, meaning that the PWM signals are the

same. In an ideal setup this would exactly recreate the operating point; however, due to paralleling, the system

performs differently. The results are shown in Table 17.

Table 17 OP3 measurements

Parameter

Values

Unit

Torque

23.86

Nm

V/f setting

467

mV/Hz

P supply

5474.1

W

P electric

5112.7

W

Inverter efficiency

93.4

%

P mech

4397

W

Page 44

Application Note 44 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

Figure 45 shows the current waveforms.

Figure 45 Current waveforms

Ch1 (light blue): “U” phase current

Ch2 (yellow): “V” phase current

Ch3 (red): “W” phase current

Ch4 (dark blue): DC supply current

Figure 46 shows the thermal distribution after 3 minutes of operation. Compared to OP2, there is a

considerable reduction of MOSFET temperatures as expected; however, there is an increase in heat dissipation

on the ceramic DC capacitors on FR4 boards. Since these components are not cooled via IMS boards as the

MOSFETs, the capacitors can reach similar temperatures as the MOSFETs at considerably lower power

dissipation. However, there is an increase in capacitor temperatures in comparison with the non-paralelled

setup. In addition to providing most of the charge during the half-bridge switching transitions, there are

additional losses caused by oscillations between the paralleled capacitors, after each switching transition. The

oscillations are attributed to the unavoidable parasitic inductances surrounding the ceramic capacitors that

are integrated into the system due to the manner of interconnecting the modular half-bridges. The capacitors

and the parasitic inductances therefore form localized C-L resonant subcircuits that add to the current

oscillation of each capacitor, immediately after MOSFET turn-on.

Page 45

Application Note 45 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

Figure 46 Top-side view and thermal distribution

Table 18 Temperature measurements from Figure 46

Measuring subject

Measuring point

Temperature [°C]

C

DC_2

Area01 (max.)

74.3

MOSFET_HS2

Area02 (max.)

60.9

MOSFET_LS2

Area03 (max.)

60.2

MOSFET_HS1

Area04 (max.)

64.2

MOSFET_LS1

Area05 (max.)

66.1

Heatsink

Spot01

50.8

Spot02

51.1

Average

49.4

Page 46

Application Note 46 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

4.2.2 Operating point 4

This operating point represents the maximum achievable power output of the setup with two paralleled power

boards per phase. On top of keeping the temperatures of MOSFETs within safe limits, the ceramic capacitor

temperatures are not to exceed 110°C (some safety margin considered). The results are shown in Table 19.

Table 19 OP4 measurements

Parameter

Value

Unit

Torque

38.17

Nm

V/f setting

617

mV/Hz

P supply

8860.2

W

P electric

8263.3

W

Inverter efficiency

93.3

%

P mech

7034

W

Figure 47 shows the current waveforms.

Figure 47 Current waveforms

Page 47

Application Note 47 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

Ch1 (light blue): “U” phase current

Ch2 (yellow): “V” phase current

Ch3 (red): “W” phase current

Ch4 (dark blue): DC supply current

Figure 48 shows the thermal distribution after 3 minutes of operation. As explained in the previous subchapter,

the ceramic capacitors connected to the DC bus, are the hottest components and will therefore represent the

limiting factor of the setup.

A way to reduce the losses on the ceramics capacitors by reducing the oscillating current ripples would be to

reduce the value of the capacitance of the ceramic capacitors. However, when doing so, an increase of the

voltage overshoot during switching is to be expected. Further tuning the setup according to requirements will

therefore incude a trade-off between the two.

Figure 48 Top-side view and thermal distribution

Table 20 Temperature measurements from Figure 48

Measuring subject

Measuring point

Temperature [°C]

C

DC_2

Area01 (max.)

106.9

MOSFET_HS2

Area02 (max.)

87.5

MOSFET_LS2

Area03 (max.)

84.8

MOSFET_HS1

Area04 (max.)

92.8

MOSFET_LS1

Area05 (max.)

94.3

Heatsink

Spot01

68.6

Spot02

69.9

Average

66.2

Page 48

Application Note 48 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

4.3 Four-per-phase parallel connection

The setup uses four power boards connected in parallel for each phase, as is illustrated in Figure 51. Three

daughter boards are added to each phase to connect the paralleled power boards to the corresponding gate

drivers.

Figure 49 System block diagram – four parallel power boards per phase

Page 49

Application Note 49 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

4.3.1 Operating point 5

In this operating point, besides the ceramic capacitor thermal limit, the load also represents a limiting factor.

The V/f setting has been set to the point of maximum allowed PWM duty cycle. The results are shown in Table

21.

Table 21 OP5 measurements

Parameter

Value

Unit

Torque

44.06

Nm

V/f setting

671

mV/Hz

P supply

10407.2

W

P electric

9595.7

W

Inverter efficiency

92.2

%

P mech

8121

W

The waveforms are shown in Figure 50.

Figure 50 Current waveforms

Page 50

Application Note 50 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor

Using the low voltage drives scalable power demonstration board

Performance of a B6 setup in a motor drive application

Ch1 (light blue): “U” phase current

Ch2 (yellow): “V” phase current

Ch3 (red): “W” phase current

Ch4 (dark blue): DC supply current

Figure 51 shows the thermal distribution after 3 minutes of operation. The effect of the current oscillations on

the ceramic capacitors is even more pronounced with expanded paralleling. As mentioned in chapter 4.2.1,

reducing the ceramic capacitance values needs to be handled in accordance with switching performance.

Figure 51 Top-side view and thermal distribution

Table 22 Temperature measurements from Figure 51

Measuring subject

Measuring point

Temperature [°C]

C

DC_2

Area01 (max.)

109.0

MOSFET_HS4

Area02 (max.)

86.3

MOSFET_LS4

Area07 (max.)

83.8

MOSFET_HS3

Area03 (max.)

89.6

MOSFET_LS3

Area06 (max.)

87.0

MOSFET_HS2

Area04 (max.)

88.9

MOSFET_LS2

Area08 (max.)

87.2

MOSFET_HS1

Area05 (max.)

92.5

MOSFET_LS1

Area09 (max.)

90.9

Heatsink

Spot01

79.8

Spot02

79.7

Average

79.4

Page 51

Application Note 51 of 54 V 1.1

2021-02-01

Scalable power inverter driving an electric motor