Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

iMOTION™ IMM101T/IMM102T - Smart IPM for motor control

Fully integrated high-performance turnkey motor control system

Quality requirement category: Industry

IMM101T/IMM102T series is a family of fully-integrated, turnkey high-voltage Motor Drive Module designed for

high-performance, high-efficiency PMSM/BLDC motor drive applications such as fans, pumps and compressors. It

integrates Infineon’s Advanced Motion Control Engine (MCE), gate driver and six power MOSFETs in a single

12x12mm package.

Feature list

Motion control engine (MCE) as ready-to-use controller solution for variable speed drives

Field oriented control (FOC) for permanent magnet synchronous motor (PMSM)

Space vector PWM with sinusoidal commutation and integrated protection features

Current sensing via single or leg shunt through direct interface

Sensorless operation

Integrated analog comparators for over-current protection

Built-in temperature sensor

3.3V or 5.0V supply voltage options for controller

15V supply voltage for gate driver

3 different power MOSFET options: 6Ω/500V, 1.4Ω/650V and 0.95Ω/650V

Integrated bootstrap FET

Support for hall sensors

Boost PFC control (IMM102T only)

Flexible host interface options for speed commands: UART, PWM or analog signal

Support for IEC 60335 (‘Class B’)

Isolation 1500V

RMS

1min

Very compact 12x12mm PQFN package

Applications

Fans

Pumps

Compressors

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

IMM100 series description

IMM101T/IMM102T devices belong to IMM100 series of iMOTION™ Smart IPMs. IMM100 series is a family of fullyintegrated, programmable or configurable (“turnkey”) high-voltage Motor Drive Modules designed for highperformance, high-efficiency PMSM (BLDC) motor drive applications such as fans, pumps and compressors. It

integrates a controller, a gate driver and six power MOSFETs. IMM100 series is available in two variants: “A”-variant

and “T”-variant. “A”-variant (IMM100A-xxx) includes a fully programmable ARM® Cortex®-M0 controller, while “T”-

variant (IMM10xT-xxx) features the Infineon’s patented Motion Control Engine (MCE).

Both variants offer different control configuration options for PMSM motor-drive system in a compact 12x12mm

surface-mount package which minimizes external components count and PCB area. This thermally enhanced

package provides excellent thermal performance working with or without heatsink. The package features a

1.3mm creepage distance between the high-voltage pads beneath the package to ease the surface mounting with

standard SMT process and increase the robustness of the system.

IMM100 series integrates either 500V FredFET or 650V CoolMOS and the industry benchmark 3-phase high-voltage,

rugged gate driver with integrated bootstrap functionality. Depending on the power MOSFETs employed in the

package, IMM100 series covers applications with a rated output power from 25W to 80W with 500V/600V maximum

DC voltage. In the 600V versions, the Power MOS technology is rated 650V, while the gate driver is rated 600V,

which determines the maximum allowable DC voltage of the system.

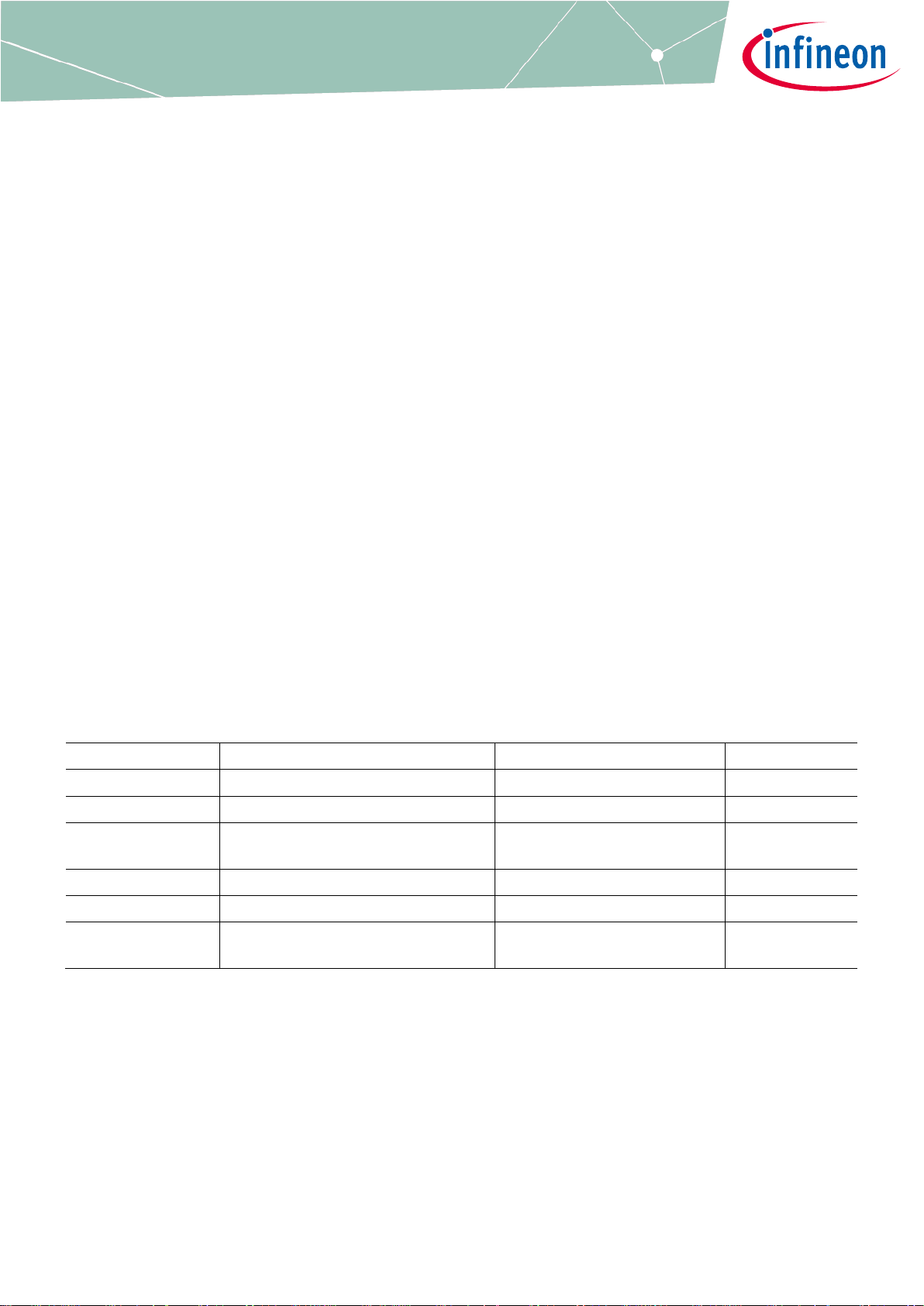

Ordering information

IMM100T devices integrate an MCE for the control of variable speed drives. By integrating both the required

hardware and software to perform control of a permanent magnet synchronous motor (PMSM) they provide

the shortest time to market for any motor system at the lowest system and development cost.

Product type

Application

Output Rating

R

DS(ON)

Typ

IMM101T-015M

Single Motor Control

500V / 1A

4.8 Ω

IMM101T-046M

Single Motor Control

600V / 4A

1.26 Ω

IMM101T-056M

Single Motor Control

600V / 4A (optimized for lowfrequency operation)

0.86 Ω

IMM102T-015M

Single Motor Control + Boost PFC

500V / 1A

4.8 Ω

IMM102T-046M

Single Motor Control + Boost PFC

600V / 4A

1.26 Ω

IMM102T-056M

Single Motor Control + Boost PFC

600V / 4A (optimized for lowfrequency operation)

0.86 Ω

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Table of Contents

Table of Contents

iMOTION™ IMM101T/IMM102T - Smart IPM for motor control .......................................... 1

Feature list ................................................................................................................. 1

Applications ................................................................................................................ 1

IMM100 series description ............................................................................................ 2

Ordering information .................................................................................................. 2

Table of Contents ........................................................................................................ 3

1 Overview ..................................................................................................... 5

1.1 IMM100T – Motion Control Engine .......................................................................................................... 5

1.2 Gate Driver ............................................................................................................................................... 5

1.3 Switches ................................................................................................................................................... 5

1.4 Application Diagrams .............................................................................................................................. 6

1.5 IMM100T Application Use Cases ............................................................................................................. 7

1.5.1 Sensorless Single-Shunt .................................................................................................................... 7

1.5.2 Sensorless Leg Shunts ....................................................................................................................... 8

1.5.3 Configuration with 2 Hall Sensors ..................................................................................................... 9

1.5.4 Sensorless single-shunt with boost PFC ......................................................................................... 10

2 Pinout – IMM100T series .............................................................................. 11

3 Gate Driver Function ................................................................................... 13

3.1 Features and Protections ...................................................................................................................... 13

3.1.1 Integrated Bootstrap Functionality ................................................................................................. 13

3.1.2 Undervoltage Lockout Protection ................................................................................................... 14

3.2 Block Diagram ....................................................................................................................................... 15

4 DC Characteristics ...................................................................................... 16

4.1 Absolute Maximum Ratings .................................................................................................................. 16

4.2 Recommended Operating Conditions .................................................................................................. 17

4.3 Static Electrical Characteristic .............................................................................................................. 17

4.4 Dynamic Electric Characterisitic ........................................................................................................... 18

4.5 MOSFET Avalanche Characteristics ...................................................................................................... 19

4.6 Thermal Characteristics ........................................................................................................................ 19

4.7 Thermal Characterization ..................................................................................................................... 20

4.8 Power Consumption IMM100T series ................................................................................................... 23

4.9 Flash Memory Parameters .................................................................................................................... 24

4.10 Digital I/O DC Characteristics ................................................................................................................ 24

4.11 Analog I/O DC Characteristics ............................................................................................................... 25

4.12 Under Voltage Lockout DC characteristics ........................................................................................... 25

4.13 Analog to Digital Converter – IMM100T series ...................................................................................... 26

4.14 Temperature Sensor Characteristic ..................................................................................................... 26

5 AC Characteristics ....................................................................................... 27

5.1 Internal Oscillator AC Characteristics ................................................................................................... 27

5.2 Power-Up and Supply Threshold Characteristics ................................................................................ 28

5.3 Motor Control Parameters – IMM100T series ....................................................................................... 28

5.3.1 PWM Characteristics – IMM100T series ............................................................................................ 28

5.3.2 Fault timing – IMM100T series ......................................................................................................... 28

5.4 Power Factor Correction (PFC) parameters – IMM102T ....................................................................... 29

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Table of Contents

5.4.1 Boost PFC characteristics – IMM102T .............................................................................................. 29

5.5 Communication interface parameters – IMM100T series .................................................................... 29

5.5.1 UART interface - IMM100T series ..................................................................................................... 29

6 I/O Structure .............................................................................................. 30

7 Package Outline ......................................................................................... 31

8 Part Marking Information ............................................................................ 33

9 Quality Declaration ..................................................................................... 34

Revision history ........................................................................................................ 34

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Overview

1 Overview

IMM100T modules contain a processor core that can address the real-time control needs of motor control. It can

use low-cost single shunt or leg shunts as motor current feedback by a combination of on-chip hardware and

firmware. Complex FOC control algorithms either sensorless or with sensors, as well as system level control can

be easily implemented inside IC and meet fan, pump and compressor applications requirements.

A standby mode helps to decrease system power consumption when the motor is stopped. The high-voltage

level shifting function with boot strap diode function is integrated into the gate driver IC. The device also contains

the six low-loss 500V power FET or 650V CoolMOS which form the three phase inverter circuit.

1.1 IMM100T – Motion Control Engine

iMOTION™ IMM100T is the latest generation inverter including controller designed as a single package solution

for inverterized motor control applications with or without power factor correction. The IMM100T series provides

a built-in closed loop sensorless (or optionally sensor based) control algorithm using the unique flexible Motion

Control Engine (MCE) for permanent magnet motors. Infineon’s patented and field proven MCE implements field

oriented control (FOC) using single or leg shunt current feedback and uses space vector PWM with sinusoidal

signals to achieve highest energy efficiency. In addition to the motor control algorithm it also integrates multiple

protection features like over- and under-voltage, over current, rotor lock etc. The IMM100T series takes

advantage of a new hardware platform combining an ARM® Cortex® core with an innovative set of analog and

motor control peripherals. The high-level of integration in terms of hardware and software results in a minimum

number of external components required for the implementation of the inverter control.

The next generation of the MCE not only further improves the performance of the control algorithm but also adds

functionality like sensor support for accurate rotor positioning, ready-to-use PFC algorithm as well as more and

flexible and faster host interface options.

The IMM100T series is offered in several device variants ranging from single motor control to motor control plus

PFC. All devices can be used in applications requiring functional safety according to IEC 60335 (‘Class B’).

This data sheet provides all electrical, mechanical, thermal and quality parameters. A more detailed description

of the features and functionality can be found in the respective reference manual of the MCE software.

There are multiple versions of the MCE software offered from Infineon and made available via download from

the Infineon web site. By using a special secure boot algorithm it is assured that the MCE software versions can

only be installed onto the matching hardware derivative, i.e. IMM100T variants for which the software has been

tested and released. Infineon provides the tools to program these software images.

1.2 Gate Driver

The gate driver is designed to work with MCE within an integrated power module. It has integrated boot strap

bootFET structure, only external bootstrap capacitors are needed outside the module. The gate driver includes

an under voltage protection and a fault reporting system. The gate driver is based on 600V High-Voltage Junction

Isolation technology.

1.3 Switches

The IMM100T modules are available in three different power stage options

6 Ohm 500V Trench MOSFETs in versions IMM101T-015 and IMM102T-015

1.4 Ohm 650V CoolMOS™ in versions IMM101T-046 and IMM102T-046 (600V maximum voltage is defined

by gate driver technology)

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Overview

0.95 Ohm 650V CoolMOS™ in versions IMM101T-056 and IMM102T-056 (600V maximum voltage is defined

by gate driver technology)

1.4 Application Diagrams

VCC

VB3

U

Power

Supply

VSS1

pin 6

COM

VBUS

2K

Rs

VB2

VB1

V

W

VSS2

pin 36

VDD

JTAG

UART

Digita l I/O

AIN0/V bus

AIN1/V sp

Analog speed

control

UART

HIN1

HIN2

HIN3

LIN1

LIN2

LIN3

RFE

MCE

GATE

DRIVER

15V

3.3V

AIN2 wit h

Gain x3

220p

3.3V

10K

100

Figure 1 Application Block Diagram using IMM101T – Single Shunt Configuration

VCC

VB3

Power

Supply

VSS1

pin6

COM

VBUS

2K

VB2

VB1

VSS2

VDD

JTAG

UART

Digita l I/O

AIN10/ Vbus

AIN0/V sp

Analog speed

control

UART

HIN1

HIN2

HIN3

LIN1

LIN2

LIN3

RFE

MCE

GATE

DRIVER

15V

3.3V up to 5V

AIN9

2K

2K

220pF

3.3V

10K

3.3V

10K

3.3V

10K

100

100

AIN6

AIN2

220pF

100

220pF

100

RS1

RS2 RS3

Figure 2 Application Block Diagram using IMM101T – Leg Shunts Configuration

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Overview

1.5 IMM100T Application Use Cases

This chapter provides more details about most common application use cases for IMM100 series’ devices,

including necessary passive components and pin connections. For full information about each pin functionality,

refer to Table1.

1.5.1 Sensorless Single-Shunt

The sensorless single-shunt use case shown below is a most common application use case for IMM100 devices,

alowing lowest BOM cost and highest number of available programmable pins for system-level functions.

M

VSS

RXD0

TXD0

IS

Vbus

1M

1M

13.3k

Vbus sense

2K

Rs

10K

3.3V

Vsp

VrW

Vbus

VsU

VrU

VrV

VbW

VbV

Vss1

Vcc

P1.7

Vdd

P2.10

P2.9

P2.6

Vss2

P2.2

P2.0 / P4.6

P0.15

P0.14

VsU

VbU

VsV

VsW

P2.11 / P2.13

3.3V

VsV

VsW

C_REF

AIN2

15V

Vbus sense

AIN6

Options for Input Set Point:

1- Analog Input Vsp to pin34 P2.0

2- UART input through P0.14 and P0.15

3- Duty (PWM) or frequency input on pin34 P4.6

Other Pins available to the user:

P2.6, P2.2, P1.7

100

220pF

Figure 3 IMM101T Sensorless, single shunt configuration

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Overview

1.5.2 Sensorless Leg Shunts

The sensorless leg shunts configuration may be used in applications where only very low acoustic noise is

requrired.

M

VSS

RXD0

TXD0

Vbus

1M

1M

13.3k

Vbus sense

Vsp

3.3V

VsV

VsW

C_REF

15V

Rs1

I_Rs1

Rs2

I_Rs2

I_Rs3

Rs3

IW

IU

I_RS3

IV

Vbus sense

Options for Input Set Point:

1- Analog Input Vsp to pin34 P2.0

2- UART input through P0.14 and P0.15

3- Duty (PWM) or frequency input on pin34 P4.6

Other Pins available to the user:

P1.7

If only two shunts are used, P2.2 is available

VrW

Vbus

VsU

VrU

VrV

VbW

VbV

Vss1

Vcc

P1.7

Vdd

P2.10

P2.9

P2.6

Vss2

P2.2

P2.0 / P4.6

P0.15

P0.14

VsU

VbU

VsV

VsW

P2.11 / P2.13

2K

10K

3.3V

100

220pF

I_RS2

2K

10K

3.3V

100

I_RS1

2K

10K

3.3V

100

220pF

220pF

Figure 4 IMM101T Sensorless, three leg shunts configuration

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Overview

1.5.3 Configuration with 2 Hall Sensors

Options for Input Set Point:

1- Analog Input Vsp to pin34 P2.0

2- UART input through P0.14 and P0.15

3- Duty (PWM) or frequency input on pin 34 P4.6

Other Pins available to the user:

P1.7

If DcBus is not measured, P2.10 is

available

M

VSS

RXD0

TXD0

IS

Vbus

1M

1M

13.3k

Vbus sense

2K

Rs

10K

3.3V

Vsp

VrW

Vbus

VsU

VrU

VrV

VbW

VbV

Vss1

Vcc

P1.7

Vdd

P2.10

P2.9

P2.6

Vss2

P2.2

P2.0 / P4.6

P0.15

P0.14

VsU

VbU

VsV

VsW

P2.11 / P2.13

3.3V

VsV

VsW

C_REF

15V

Vbus

sense

100

220pF

H0

3.3V

1.2k

3.3V

1nF

H1

3.3V

1.2k

3.3V

1nF

Figure 5 IMM101T Two Hall sensors, single shunt configuration

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Overview

1.5.4 Sensorless single-shunt with boost PFC

M

RXD0

TXD0

IS

Vbus

1M

1M

13.3k

Vbus sense

Rs

VrW

Vbus

VsU

VrU

VrV

VbW

VbV

Vss1

Vcc

P1.7

Vdd

P2.10

P2.9

P2.6

Vss2

P2.2

P2.0 / P4.6

P0.15

P0.14

VsU

VbU

VsV

VsW

P2.11 / P2.13

3.3V

VsV

VsW

C_REF

IPFC

15V

Vbus sense

Options for Input Set Point:

UART input through P0.14 and P0.15

PFCG

PFC

gate

driver

VSS

Rpfc

PFC Shunt

PFCG

AC line ~

1M

1M

15k

1M

1M

15k

VAC+ VAC-

VAC+

VAC-

15V

0.47k

12k

3.3V

100

100

1.0

220p

5K

12k

3.3V

1k

PFC Shunt

1n

Figure 6 IMM102T Sensorless Single shunt with Boost PFC function

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Pinout – IMM100T series

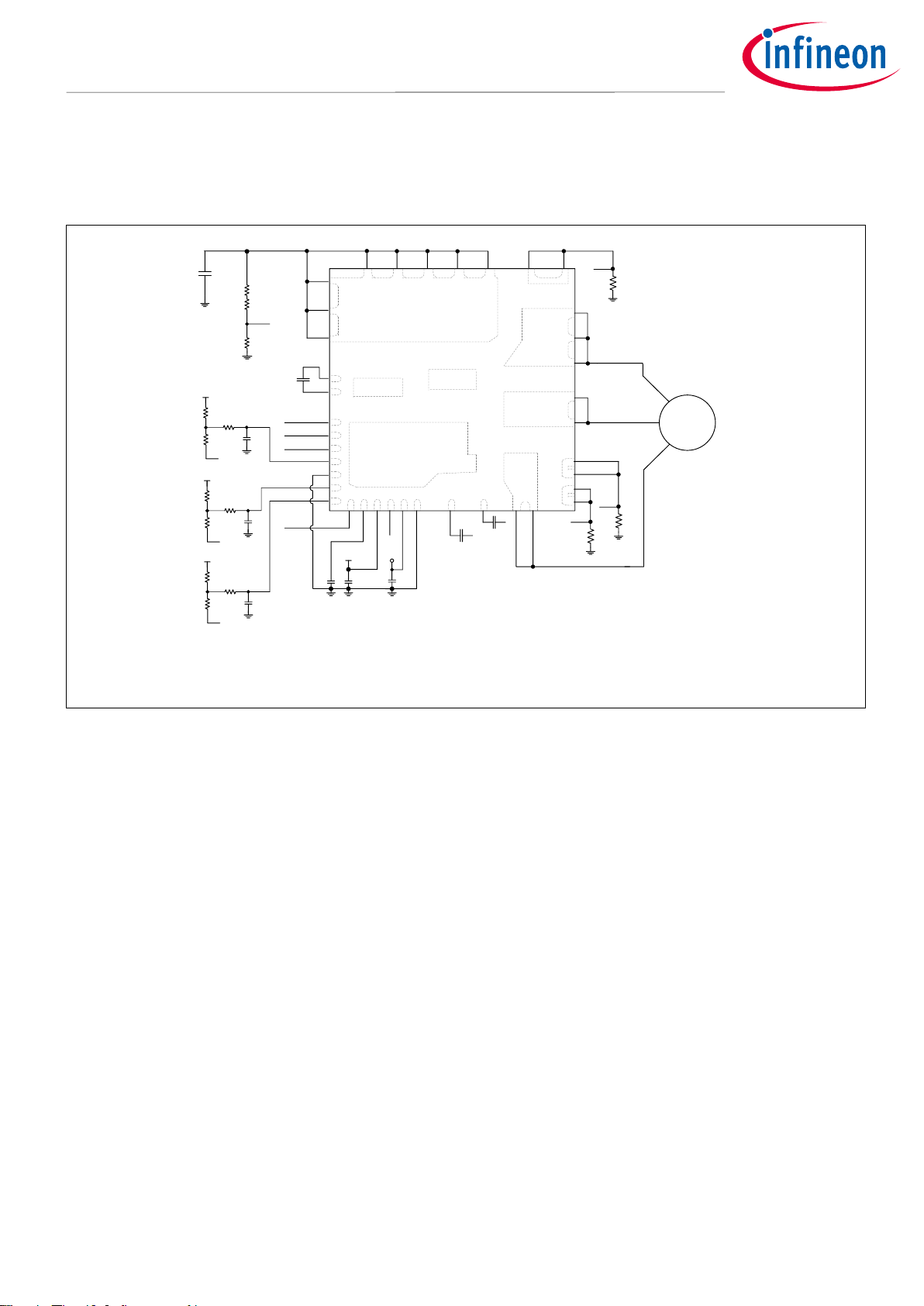

2 Pinout – IMM100T series

Table 1 Pinout description IMM101T series – single motor control – typical configuration

Pin

Name

Type

Description

1

Vbus scaled

I

Vbus scaled ADC input

2

CREF

I/O

Analog Overcurrent Comparator threshold DAC

3

VDD

P

Digital VDD input [3.3V – 5.0V]

4

P1.7

I/O

Digital Input --- Analog and Digital Output

5

Vcc

P

15V gate driver power supply input

6

VSS1

P

Gate Driver Power ground, connect externally via PCB to pin 36

7

VbV

P

V phase bootstrap capacitor positive

8

VbW

P

W phase bootstrap capacitor positive

9,10

VsU

P

U phase output

11,12

VrU

P

Leg U return – Low-Side MOS source

13,14

VrV

P

Leg V return – Low-Side MOS source

15,16, 40

VsV

P

V phase output and V phase bootstrap capacitor negative

17,18,19

VsW

P

W phase output and W phase bootstrap capacitor negative

20,21

VrW

P

Leg W return – Low-Side MOS source

22~29

Vbus

P

DC bus voltage

30, 39

VsU

P

U phase bootstrap capacitor negative

31

VbU

P

U phase bootstrap capacitor positive

32

RX0

I

Serial Port Receive input

33

TX0

O

Serial Port transmit output

34

Vsp/AIN 0

I

Analog Voltage Set Point Input

35

IW (or H0)/AIN 2

I

Analog Current sense input phase W or Hall0 input

36,41

VSS2

P

Signal ground --- Connect externally via PCB to pin 6

37

IV (or H1)/AIN 6

I

Analog Current sense input phase V or Hall1 input

38

ISS or IU

I

Analog Current sense input phase U or single Shunt

29

28

21 20

1

Top View

27

39

40

41

23 2225 2426

2 3 4 5 6 7 8

9 10

12

13

16

15

17

18

19

30

31

32

33

34

35

36

37

38

Note

Pins 39 and 40 are no t required

to be connected elect rically on

the PCB b ut are recomme nded

to be so ldered for mech anical

stability.

14

11

Figure 7 IMM100T series pinout

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Pinout – IMM100T series

Table 2 Pinout description IMM102T series – single motor + PFC – typical configuration

Pin

Name

Type

Description

1

Vbus scaled

I

Vbus scaled ADC input

2

CREF

I/O

Analog Overcurrent Comparator t hreshold DAC

3

VDD

P

Digital VDD input [3.3V – 5.0V]

4

PFCG

O

PWM Output to PFC gate driver

5

Vcc

P

15V gate driver power supply input

6

VSS1

P

Gate Driver Power ground, connect externally via PCB to pin 36

7

VbV

P

V phase bootstrap capacitor positive

8

VbW

P

W phase bootstrap capacitor positive

9,10

VsU

P

U phase output

11,12

VrU

P

Leg U return – Low-Side MOS source

13,14

VrV

P

Leg V return – Low-Side MOS source

15,16, 40

VsV

P

V phase output and V phase bootstrap capacitor negative

17,18,19

VsW

P

W phase output and W phase bootstrap capacitor negative

20,21

VrW

P

Leg W return – Low-Side MOS source

22~29

Vbus

P

DC bus voltage

30, 39

VsU

P

U phase bootstrap capacitor negative

31

VbU

P

U phase bootstrap capacitor positive

32

RX0

I

Serial Port Receive input

33

TX0

O

Serial Port transmit output

34

Vac+

I

Vac input ac+ voltage sensing through resistor external divider

35

Vac-

I

Vac input ac- voltage sensing through resistor external divider

36,41

VSS2

P

Signal ground --- Connect externally via PCB to pin 6

37

IPFC

I

Analog Current sense input PFC

38

ISS

I

Analog Current sense input single Shunt

Note: IMM101T and IMM102T share same package footprint.

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Gate Driver Function

3 Gate Driver Function

3.1 Features and Protections

The 3-phase high-voltage gate driver function is integrated in IMM100 series product. The driver output impedance

is designed to meet an optimal dv/dt for EMI and switching loss trade offs. It is designed for 5-6 V/nsec at a rated

current condition. The driver employs the anti-shoot-through protection, the integrated bootstrap function for

high-side floating supplies, the low standby power and the undervoltage lockout protection function for VCC and

high-side VBS supplies. The under voltage lockout for Vcc is reported as latched fault at pin RFE. The ITRIP

comparator between COM and VSS pin is disabled in IMM100. The gate driver block diagram is shown in Figure 10.

3.1.1 Integrated Bootstrap Functionality

The IMM100 series embeds an integrated bootstrap FET (BootFet) that allows an alternative drive of the bootstrap

supply for a wide range of applications. Each bootstrap FET is connected between the respective floating supply

VB (e.g. VBU, VBV and VBW, see page 15) and VCC:

Figure 8 Simplified BootFET connection

The bootstrap FET is suitable for most PWM modulation schemes, including trapezoidal control, and can be used

either in parallel with the external bootstrap network (diode+ resistor) or as a replacement of it. The use of the

integrated bootstrap FET as a replacement of the external bootstrap network may have some limitations at a very

high PWM duty cycle due to the bootstrap FET equivalent resistance (RBS, see page 17).

The integrated bootstrap FET is turned on during the time when LO is ‘high’ (e.g. LOU, LOV, LOW, see page 15), and

it has a limited source current due to RBS. The VBS voltage will be charged each cycle depending on the on-time of

LO and the value of the CBS capacitor, the drain-source drop of the MOSFET, and the low-side free-wheeling diode

drop.

The bootstrap FET follows the state of low-side output stage, the bootstrap FET is ON when LO is high, unless the

VB voltage is higher than approximately VCC. In that case, the bootstrap FET is designed to remain off until VB returns

below that threshold; this concept is illustrated in Figure 9.

Figure 9 Bootstrap FET timing diagram

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Gate Driver Function

3.1.2 Undervoltage Lockout Protection

This IC provides under-voltage lockout protection on both the VCC (logic and low-side circuitry) power supply and

the VBS (highside circuitry) power supply. Figure 10 is used to illustrate this concept; VCC (or VBS) is plotted over time

and as the waveform crosses the UVLO threshold (V

CCUV+/-

or V

BSUV+/-

) the under-voltage protection is enabled or

disabled.

Upon power-up, should the VCC voltage fail to reach the V

CCUV+

threshold, the IC will not turn-on. Additionally, if the

VCC voltage decreases below the V

CCUV-

threshold during operation, the under-voltage lockout circuitry will

recognize a fault condition and shutdown the high and low-side gate drive outputs.

Upon power-up, should the VBS voltage fail to reach the V

BSUV+

threshold, the IC will not turn-on. Additionally, if the

VBS voltage decreases below the V

BSUV-

threshold during operation, the under-voltage lockout circuitry will

recognize a fault condition, and shutdown the high-side gate drive outputs of the IC.

The UVLO protection ensures that the IC drives the external power devices only when the gate supply voltage is

sufficient to fully enhance the power devices. Without this feature, the gates of the external power switch could

be driven with a low voltage, resulting in the power switch conducting current while the channel impedance is

high; this could result in very high conduction losses within the power device and could lead to power device

failure. (V

CCUV+/-

and V

BSUV+/-

, see page 25)

Figure 10 UVLO protection

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Gate Driver Function

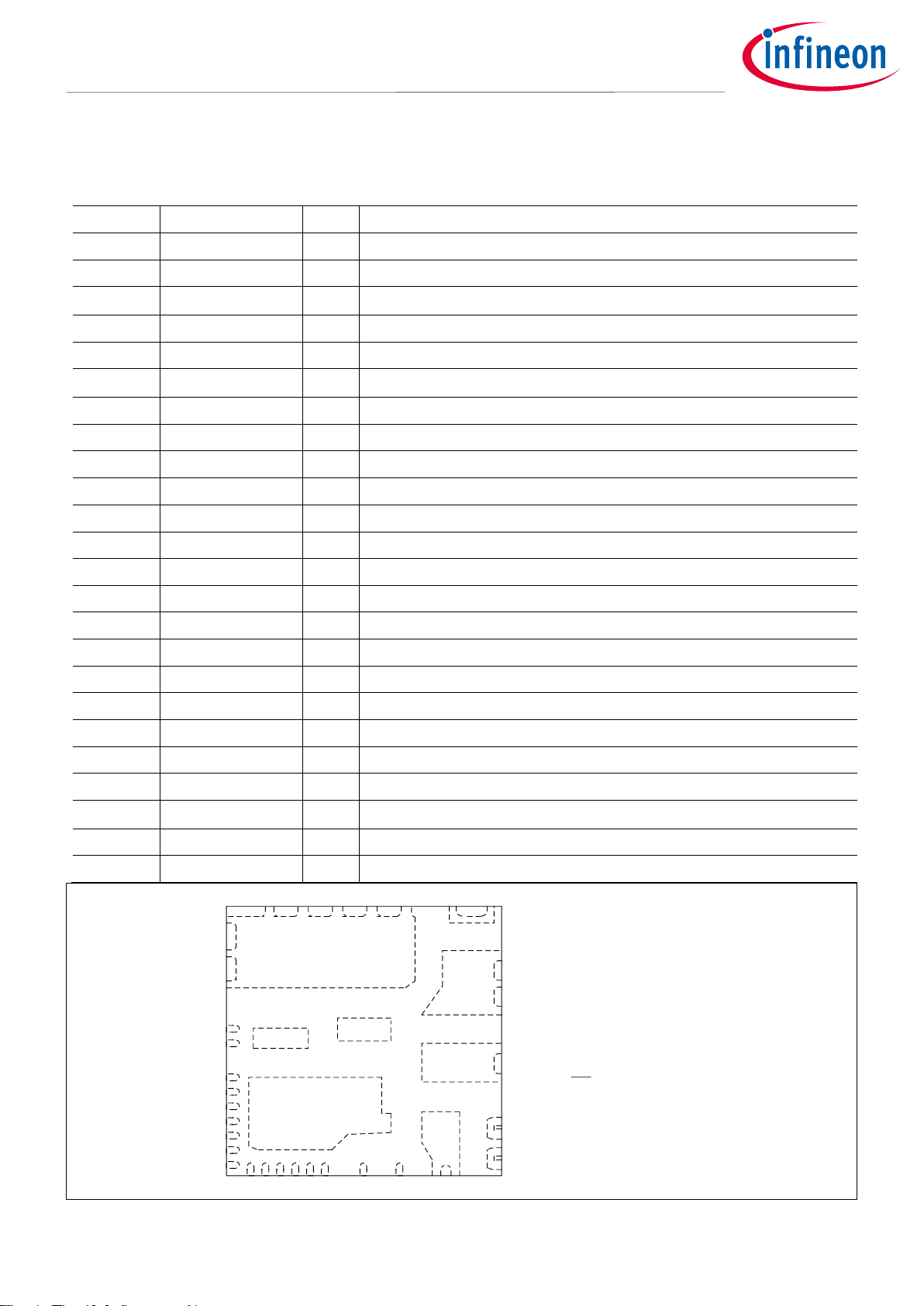

3.2 Block Diagram

Input

Noise

filter

Input

Noise

filter

Input

Noise

filter

Input

Noise

filter

Input

Noise

filter

Input

Noise

filter

Deadtime &

Shoot-Through

Prevention

Deadtime &

Shoot-Through

Prevention

Deadtime &

Shoot-Through

Prevention

HV Level

Shifter

VSS/COM

Level

Shifter

Latch

&

UV Detect

S

R

Driver

Integrated

BootFet

HV Level

Shifter

VSS/COM

Level

Shifter

Latch

&

UV Detect

S

R

Integrated

BootFet

HV Level

Shifter

VSS/COM

Level

Shifter

Latch

&

UV Detect

S

R

Driver

Integrated

BootFet

Driver

VSS/COM

Level

Shifter

VSS/COM

Level

Shifter

VSS/COM

Level

Shifter

Delay

Delay

Delay

Driver

Driver

Driver

PWM

L W

PWM

H W

PWM

L V

PWM

H V

PWM

H U

PWM

L U

VSS

VBW

HOW

VSW

VBV

HOV

VSV

VBU

HOU

VSU

VCC

LOW

LOV

LOU

COM

PWM

enable

H W

L W

H V

L V

H U

L U

VCC

UVLO

POR

RFE

Noise

filter

(500 ns)

VCC

EN

STBY

filter

(10us )

ITRIP LATCH

(set dominant)

S

R

Q

H

W

LU HU

LV HV

LW

EN

STAND-BY

Figure 11 Block diagram of gate driver function

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

4 DC Characteristics

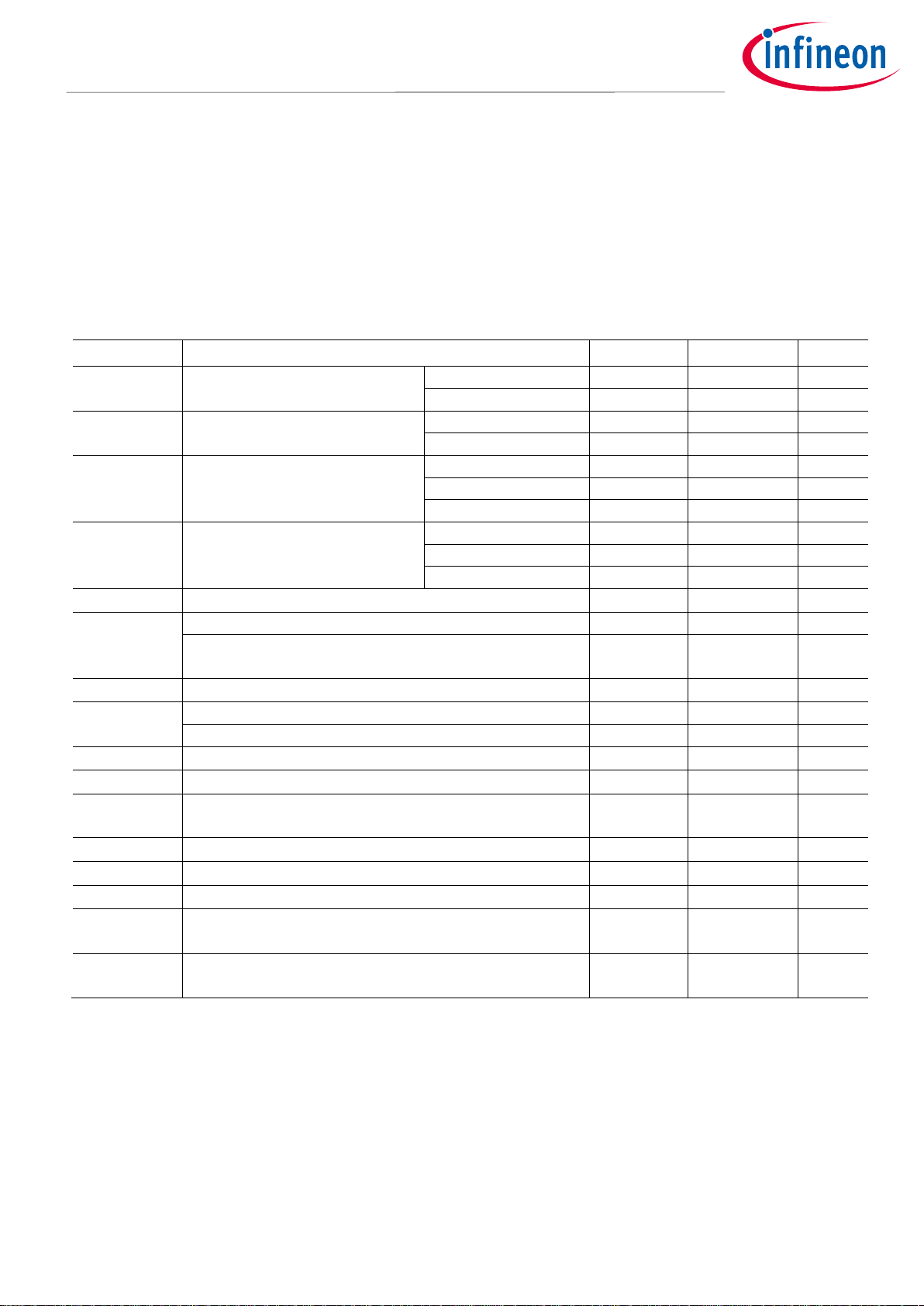

4.1 Absolute Maximum Ratings

Absolute maximum ratings indicate sustained limits beyond which damage to the module may occur. These are

not tested at manufacturing. All voltage parameters are absolute voltages referenced to VSS unless otherwise

stated in Table 2.

Table 2 Absolute Maximum Rating

Symbol

Description

Min

Max

Unit

BV

DSS

MOSFET Blocking Voltage

-015M

---

500

V

-046M and -056M

---

650

V

IO @TC=25°C

DC Output Current per MOSFET

-015M

--- 1 A

-046M and -056M

--- 4 A

IOP

Pulsed Output Current 1)

-015M

--- 6 A

-046M

---

8.2

A

-056M

---

11

A

PD @TC=25°C

Maximum Power Dissipation per

MOSFET 2)

-015M

---

11 W -046M

---

28.4

W

-056M

---

36.7

W

V

S U,V,W

Gate Driver High-Side Floating Supply Offset Voltage

V

B U,V,W

-20

V

B U,V,W

+0.3

V

V

B U,V,W

Gate Driver High-Side Floating Rated Voltage - 015

-0.3

600

V

Gate Driver High-Side Floating Rated Voltage - 046 --056

-0.3 600 V

VCC

Gate Driver Low-Side Supply Voltage

-0.3

20

V

BV

MODULE

Power Module Max Voltage -015M

---

500

V

Power Module Max Voltage -046M -056M

---

600

V

VDD

Digital IC Supply Voltage

-0.3 6 V

VID

Digital and Analog Pin Voltage

-0.3

VDD+0.3

V

TJ

Operating Junction Temperature - defined by

Controller technology

-40

115

°C

TL

Lead Temperature (Soldering, 30 seconds)

---

260

°C

TS

Storage Temperature

-40

125

°C

V

ISO

Isolation Voltage (1min)

---

1500

V

RMS

I

IN

Input current on any controller pin during overload

condition

-10 10 mA

ƩIIN

Absolute sum of all controller input currents during

overload condition

-50

50

mA

1)

Pulse Width=100µs, TC=25°C, Duty=1%.

2)

Single MOSFET in TO220 package at Tcase = 25°C

Note: Characterized, not tested at manufacturing.

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

4.2 Recommended Operating Conditions

All voltage parameters are referenced to VSS.

Table 3 Recommended Operating Conditions

Symbol

Description

Min

Typ

Max

Unit

V

DCP

Positive DC Bus Input Voltage - 015

---

380

400

V

Positive DC Bus Input Voltage – 046 -- 056

---

400

480

V

V

B U,V,W

Gate Driver High-Side Floating Supply Voltage

VS+12

---

VS+18

V

VCC

Gate Driver Low-Side Supply Voltage

13.5

15.0

16.5

V

VDD

Digital IC Supply Voltage (3.3 V +/- 10%)

2.97

3.3

3.63

V

VDD

Digital IC Supply Voltage (5.0V +/- 10%)

4.5

5.0

5.5

V

MCLK

Master clock frequency

---

48.0

---

MHz

PCLK

Peripheral clock frequency

---

96.0

---

MHz

IOV

Input current on any port pin during overload

condition

-5

--5

mA

I

OVS

Absolute sum of all input circuit currents during

overload condition

---

--25

mA

Figure 12 Input Overload Current via ESD structures

4.3 Static Electrical Characteristic

Vcc=15 V, TA=25°C unless otherwhise specified.

Table 4 Static Electrical Characteristic

Symbol

Description

Min

Typ

Max

Units

I

LKH

@TJ=25°C,

VDS=500/650V

Leakage Current of

High-Side FETs in

Parallel

-015M

--- 1 ---

µA

-046M

--- 1 ---

-056M

--- 1 ---

I

LKL

@TJ=25°C,

VDS=500/650V

Leakage Current of

Low-Side FETs with

-015M

--- 4 ---

µA

-046M

--- 4 ---

-056M

--- 4 ---

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

Symbol

Description

Min

Typ

Max

Units

Gate Drive IC in

Parallel

R

DS(ON)

@TJ=25°C,

VGS=10V,

ID=1.5A

Drain to Source ON

Resistance

-015M

---

4.8

6 Ω -046M

---

1.26

1.4

-056M

---

0.855

0.95

I

DSS

@TJ=25°C,

VDS=500/650

V, VGS=0 V

Zero Gate Voltage

Drain Current

-015M

---

---

1

µA

-046M

---

---

1

-056M

---

---

1

VSD @TJ=25 °C,

VGS=0 V, IF=0.5

A (-015M),

IF=1.5 A (046M), IF=2.2 A

(-056M)

MOSFET Diode

Forward Voltage Drop

-015M

---

0.8

--- V -046M

---

0.9

---

-056M

---

0.9

---

RBS

Bootstrap FET

Resistance

-015M

---

200

--- Ω -046M

---

200

---

-056M

---

200

---

Note: All values obtained during characterization, not tested at munfacturing.

4.4 Dynamic Electric Characterisitic

VCC=15 V, TA=25°C, all voltage parameters are referenced to VSS unless otherwise specified.

Table 5 Dynamic Electric Characteristic

Symbol

Description

Min

Typ

Max

Units

EON @TJ=25 °C,

V+=300 V, ID=0.5

A

Switching Energy,

Turn On Condition

-015M

---

27.2

---

µJ

-046M

---

36.6

---

-056M

---

44.4

---

E

OFF

@TJ=25 °C,

V+=300 V, ID=0.5

A

Switching Energy,

Turn Off Condition

-015M

---

2.00

---

µJ

-046M

---

1.97

---

-056M

---

2.53

---

E

REC

@TJ=25 °C,

V+=300 V, ID=0.5

A

Switching Energy,

Diode Reverse

Recovery

-015M

---

10.8

---

µJ

-046M

---

8.43

---

-056M

---

9.88

---

EON @TJ=115 °C,

V+=300 V, ID=0.5

A

Switching Energy,

Turn On Condition

-015M

---

31.8

---

µJ

-046M

---

49.7

---

-056M

---

59.7

---

E

OFF

@TJ=115

°C, V+=300 V,

ID=0.5 A

Switching Energy,

Turn Off Condition

-015M

---

1.96

---

µJ

-046M

---

1.81

---

-056M

---

2.27

---

-015M

---

12.6

---

µJ

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

Symbol

Description

Min

Typ

Max

Units

E

REC

@TJ=115

°C, V+=300 V,

ID=0.5 A

Switching Energy,

Diode Reverse

Recovery

-046M

---

7.94

---

-056M

---

9.91

---

Note: All values obtained during characterization, not tested at munfacturing.

4.5 MOSFET Avalanche Characteristics

Table 6 MOSFET Avalanche Characteristic

Symbol

Description

Min

Typ

Max

Units

EAS, V+=100 V,

ID=1.7 A

Single Pulse

Avalanche Energy

-015M

---

---

49

mJ

EAS, V+=50 V,

ID=0.6 A

-046M

---

---

26

EAS, V+=50 V,

ID=1 A

-056M

---

---

50

Note: All values obtained during characterization, not tested at munfacturing.

4.6 Thermal Characteristics

Table 7 Thermal Characteristics

Symbol

Description

Min

Typ

Max

Units

R

th(J-amb)

Total Thermal

Resistance Junction

to Ambient

---

27.7

---

°C/W

Note: All values obtained during characterization, not tested at munfacturing.

The previous value of R

th(J-amb)

has been obtained under the following testing condition: T

amb

=25°C, T

hotspot

=51.6°C

and a dissipated power of 1W. A FR4 PCB with 2oz copper has been used and the PCB layout is shown in Figure 13.

Figure 13 PCB layout used for thermal characterization: 2oz copper, 2 layers. DcBus Pad: 3,0 cm x 1,8 cm

on both layers with 144 vias.

Module

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

4.7 Thermal Characterization

Figure 14, 15, 16, 17, 18, 19 show the thermal characterizations of the three part numbers. The tests reported in

Figure 14, 15, 16 have been performed under the following conditions: T

amb

=25°C, different phase current values

until the case reaches 105°C, two PWM frequencies (6 and 16kHz) and two different modulation types (3-phase

modulation and 2-phase flat bottom modulation). The tests reported in Figure 17, 18, 19 have been performed

under the following conditions: T

amb

=60°C, different phase current values until the case reaches 105°C, two PWM

frequencies (6 and 16kHz) and two different modulation type (3-phase modulation and 2-phase flat bottom

modulation). 2-ph flat bottom modulation allows the reduction of the switching losses compared with 3-phase

SVPWM (symmetrical placement of zero vectors). For the test with T

amb

=60°C, the 3-phase modulation has not

been used. For all the tests, the phase current has been limited to 600 mArms in order to avoid damage to the

motor used for the tests. A FR4 PCB with 2oz copper has been used and the PCB layout is shown in Figure 13.

Figure 14 IMM101T-015M Thermal Characterization, T

amb

=25°C, different phase current values until the

case reaches 105°C, FR4 PCB with 2oz copper

0

20

40

60

80

100

120

180.0 230.0 280.0 330.0 380.0

T

case

[°C]

Phase Current [mA

rms

]

IMM101T-015M, Thermal Characterization T

amb

=25°C

3-phase modulation 16kHz

2-phase modulation 16kHz

3-phase modulation 6kHz

2-phase modulation 6kHz

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

Figure 15 IMM101T-046M Thermal Characterization, T

amb

=25°C, different phase current values until the

case reaches 105°C, FR4 PCB with 2oz copper

Figure 16 IMM101T-056M Thermal Characterization, T

amb

=25°C, different phase current values until the

case reaches 105°C, FR4 PCB with 2oz copper

0

20

40

60

80

100

120

180.0 230.0 280.0 330.0 380.0 430.0 480.0 530.0 580.0 630.0

T

case

[°C]

Phase Current [mA

rms

]

IMM101T-046M, Thermal Characterization T

amb

=25°C

3-phase modulation 16kHz

2-phase modulation 16kHz

3-phase modulation 6kHz

2-phase modulation 6kHz

0

20

40

60

80

100

120

180.0 230.0 280.0 330.0 380.0 430.0 480.0 530.0 580.0 630.0

T

case

[°C]

Phase Current [mA

rms

]

IMM101T-056M, Thermal Characterization T

amb

=25°C

3-phase modulation 16kHz

2-phase modulation 16kHz

3-phase modulation 6kHz

2-phase modulation 6kHz

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

Figure 17 IMM101T-015M Thermal Characterization, T

amb

=60°C, different phase current values until the

case reaches 105°C, FR4 PCB with 2oz copper

Figure 18 IMM101T-046M Thermal Characterization, T

amb

=60°C, different phase current values until the

case reaches 105°C, FR4 PCB with 2oz copper

60

65

70

75

80

85

90

95

100

105

110

190.0 210.0 230.0 250.0 270.0 290.0 310.0 330.0

T

case

[°C]

Phase Current [mA

rms

]

IMM101T-015M, Thermal Characterization T

amb

=60°C

2-phase modulation 16 kHz

3-phase modulation 6 kHz

2-phase modulation 6 kHz

60

65

70

75

80

85

90

95

100

105

110

190.0 240.0 290.0 340.0 390.0 440.0 490.0 540.0 590.0

T

case

[°C]

Phase Current [mA

rms

]

IMM101T-046M, Thermal Characterization T

amb

=60°C

2-phase modulation 16 kHz

3-phase modulation 6 kHz

2-phase modulation 6 kHz

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

Figure 19 IMM101T-056M Thermal Characterization, T

amb

=60°C, different phase current values until the

case reaches 105°C, FR4 PCB with 2oz copper

Note: Characterized, not tested at manufacturing.

4.8 Power Consumption IMM100T series

VCC=15V, VDD=5V, V

BUS

= 300V, Ta = 25˚C, unless specified otherwise.

Note: These parameters are not subject to production test, but verified by design and/or characterization.

Table 8 Power Consumption – IMM100T series

Symbol

Parameter

Min

Typ

Max

Unit

Condition

P

MOTOR

Power Consumption – motor

active and PFC not active

---

50

100

mW

P

MOTOR+PFC

Power Consumption – motor

and PFC active

---

70

100

mW

IMM102T only

I

DDPDS

Deep Sleep mode controller

current

---

0.27

---

mA

t

SSA

Controller Wake-up time from

Sleep to Active mode

---- 6 ---

Clock

cycles

t

DSA

Controller Wake-up time from

Deep Sleep to Active mode

---

290

---

µs

60

65

70

75

80

85

90

95

100

105

110

190.0 240.0 290.0 340.0 390.0 440.0 490.0 540.0 590.0

T

case

[°C]

Phase Current [mA

rms

]

IMM101T-56M, Thermal Characterization T

amb

=60°C

2-phase modulation 16 kHz

3-phase modulation 6 kHz

2-phase modulation 6 kHz

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

4.9 Flash Memory Parameters

Note: These parameters are not subject to production test, but verified by design and/or characterization.

Table 9

Symbol

Parameter

Min

Typ

Max

Unit

Condition

t

RET

Data

Retention

Time

10

---

---

years

Max. 100

erase /

program

cycle

N

ECYC

Erase Cycles

---

---

5 x 104

cycles

Sum of

pages and

sector erase

cycles

N

TECYC

Total Erase

Cycles

---

---

2 x 106

cycles

4.10 Digital I/O DC Characteristics

VDD=3.3V, Ta = 25˚C, all voltage parameters are referenced to VSS unless specified otherwise.

Note: These parameters are not subject to production test, but verified by design and/or characterization.

Table 10 Digital I/O Charasteristics

Symbol

Parameter

Min

Typ

Max

Unit

Condition

V

ILPS

Input Low-Voltage on port pins

with std Hysteresis

---

---

0.19 x

VDD

V V

IHPS

Input High-Voltage on port pins

with std Hysteresis

0.7 x

VDD

---

--- V

V

ILPL

Input Low-Voltage on port pins

with large Hysteresis

---

---

0.08 x

VDD

V V

IHPL

Input High-Voltage on port pins

with Large Hysteresis

0.85 x

VDD

---

--- V

V

OLP

Output Low-Voltage on port pins

(with standard pads)

---

---

0.4 V IOL = 3.5 mA

V

OLP1

Output Low-Voltage on highcurrent pads

---

---

0.32

V

IOL = 10 mA

V

OHP

Output High-Voltage on port pins

(with standard pads)

VDD-0.4

---

--- V IOH = -2.5 mA

V

OHP1

Output High-Voltage on

high-current pads

VDD –

0.32

---

--- V IOH = -6 mA

IL

Input leakage current

-1

--- +1

μA

VO = 3.3V or 0V

IOL

Low-Level output current

---

--5

mA

VO = 0.4V

IOH

High-Level output current

---

---

-7

mA

VO = 2.4V

t

HCPR tHCPF

Rise/fall time on High-Current

Pad

---

--12

ns

50 pF

tR tF

Rise/fall time on std Pad

---

---

15

ns

50 pF

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

Symbol

Parameter

Min

Typ

Max

Unit

Condition

CIO

Pin capacitance (digital

inputs/outputs)

---

--10

pF

I

PUP

Pull-up current on port pins

---

---

-50

µA

VIH,min

Pull-up current on port pins

-65

---

---

µA

VIL,max

I

PDP

Pull-down current on port pins

---

---

30

µA

VIL,max

Pull-down current on port pins

60

---

---

µA

VIH,min

VPO

Voltage on any pin during VDD

power off

---

---

0.3 V

4.11 Analog I/O DC Characteristics

VDD=3.3V, Ta = 25˚C, all voltage parameters are referenced to VSS unless specified otherwise.

Note: These parameters are not subject to production test, but verified by design and/or characterization.

Table 11 Analog I/O Charasteristics

Symbol

Parameter

Min

Typ

Max

Unit

Condition

CIN

Switched capacitance of analog

inputs

---

1.2 2 pF

Gain 1, 3

---

4.5 6 pF

Gain 6, 12

ADC

GAIN

ADC Configurable Gain

---

1 – 3 – 6 –

12

---

C

AINT

Total capacitance of

an analog input

---

---

10

pF

C

AREFT

Total capacitance of

reference input

---

---

10

pF

4.12 Under Voltage Lockout DC characteristics

Ta = 25˚C, all voltage parameters are referenced to VSS unless specified otherwise.

Note: These parameters are not subject to production test, but verified by design and/or characterization.

Table 12 Undervoltage Lockout DC Charasteristics

Symbol

Parameter

Min

Typ

Max

Unit

Condition

V

DDPBO

VDD Brownout reset voltage

1.55

1.62

1.75

V

V

DDPA

VDD voltage to ensure defined

pad states

---

1.0

---

V

t

SSW

Start-up time from power-on

reset

---

260

---

µs

t

BMI

BMI program time

---

8.25

---

ms

V

CCUV+

V

BSUV+

VCC and VBS supply undervoltage

positive going threshold - gate

driver

8.0

8.9

9.8

V

V

CCUV-

V

BSUV-

VCC and V

BS

supply undervoltage

negative going threshold - gate

driver

7.4

8.2

9.0

V

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

DC Characteristics

V

CCUVH

V

BSUVH

V

CC

and V

BS

supply under voltage

hysteresis – gate driver

---

0.7

---

V

4.13 Analog to Digital Converter – IMM100T series

The following table shows the Analog to Digital Converter (ADC) characteristics. This specification applies to all

analog input as given in the pin configuration list.

Note: These parameters are not subject to production test, but verified by design and/or characterization.

Table 13 ADC Characteristics – IMM100T series

Symbol

Parameter

Min

Typ

Max

Unit

Condition

V

AIN

Analog input voltage range

Vss –

0.05

---

VDD +

0.05

V

t

sample

Sample Time

---

200

---

ns EN

RMS

RMS noise

---

1.5

---

LSB 12

EA

DNL

DNL error

---

+/- 2.0

---

LSB 12

EA

INL

INL error

---

+/- 4.0

---

LSB 12

EA

GAIN

Gain error with external

reference

---

+/- 0.5

---

%

EA

OFF

Offset error

---

+/- 8.0

---

mV

4.14 Temperature Sensor Characteristic

IMM101T and IMM102T have an internal temperature sensor that is used by MCE to linearly derate the power

consumption and protect the power section. The linear power derating function with temperature shutdown is

defined by parameters programmed by the user.

The power dissipation must be limited so that the average controller junction temperature does not exceed 115

°C.

Note: Temperature sensor characteristic is not subject to production test, but verified by design and/or

characterization.

Table 14 Temperature Sensor Characteristics

Symbol

Parameter

Min

Typ

Max

Unit

Condition

tM

Measurement time2)

---

---

10

ms TSR

Temperature sensor range

-40

---

115

°C

T

TSAL

Sensor Accuracy1)

-6

--- 6 °C

TJ > 20°C

-10

---

10

°C

0°C ≤ TJ ≤ 20°C

---

+/-8

---

°C

TJ < 0°C

1) The temperature sensor accuracy is independent of the supply voltage.

2) The temperature of the different parts of the IMM100 is strongly impacted by the thermal design of the

application and may be different from the temperature sensor reading. It is the designers’ responsibility

to always ensure that the maximum ratings given in this datasheet are never exceeded.

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

AC Characteristics

5 AC Characteristics

5.1 Internal Oscillator AC Characteristics

VDD=3.3V, Ta = 25˚C unless specified otherwise.

Note: These parameters are not subject to production test, but verified by design and/or characterization.

Table 15 96MHz DCO1 Oscillator characteristics

Symbol

Parameter

Min

Typ

Max

Unit

Condition

f

NOM

CC

Nominal Frequency

-

96 - MHz

Δf

LTX

CC

-0.3 - +0.3

%

With respect to f

NOM

(typ),

Ta = -40 °C ~ 105 °C

Δf

LTTS

CC

Accuracy with adjustment

algorithm1) based on temperature

sensor

-0.6 - +0.6

%

With respect to f

NOM

(typ),

Ta = 0 °C ~ 105 °C

-1.9 - +1.0

%

With respect to f

NOM

(typ),

Ta = -25 °C ~ 105 °C

-2.6 - +1.3

%

With respect to f

NOM

(typ),

Ta = -40 °C ~ 105 °C

ΔfLT CC

Accuracy

-1.7 - +3.4

%

With respect to f

NOM

(typ),

Ta = 0 °C ~ 85 °C

-3.9 - +4.0

%

With respect to f

NOM

(typ),

Ta = -40 °C ~ 105 °C

1) MCE version newer or equal to V1.03.00, clock adjustment algorithm for improved accuracy enable.

Table 16 32kHz DCO2 Oscillator characteristics

Symbol

Parameter

Min

Typ

Max

Unit

Condition

f

NOM

CC

Nominal Frequency

32.5

32.75

33

MHz

ΔfST CC

Short term frequency deviation

(over VDD)

-1 - +1

%

With respect to f

NOM

(typ),

Ta = 25°C

ΔfLT CC

Accuracy

-1.7 - +3.4

%

With respect to f

NOM

(typ),

Ta = 0 °C ~ 85 °C

-3.9 - +4.0

%

With respect to f

NOM

(typ),

Ta = -40 °C ~ 105 °C

1) The deviation is related to the factory trimmed frequency at nominal VDD and Ta=+25C°

Under nominal conditions

after trimming

Accuracy with adjustment based

on XTAL as reference

Under nominal conditions1)

after trimming

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

AC Characteristics

5.2 Power-Up and Supply Threshold Characteristics

The guard band between the lowest valid operating voltage and the brownout reset threshold provides a margin

for noise immunity and hysteresis. The electrical parameters may be violated while VDD is outside its operating

range. The brownout detection triggers a reset within the defined range. The prewarning detection can be used to

trigger an early warning and issue corrective and/or fail-safe actions in case of a critical supply voltage drop.

Note: These parameters are not subject to production test, but verified by design and/or characterization.

Note: Operating Conditions apply.

VDD=3.3V, Ta = 25˚C unless specified otherwise. C=100nF between VDD and VSS.

Table 17 Power-Up and Supply

Symbol

Parameter

Min

Typ

Max

Unit

Condition

t

RAMPUP

VDD ramp-up time

---

---

107

µs

S

VDDPOP

VDD slew rate

---

---

0.1

V/µs

Slope during normal

operation

S

VDDP10

---

---

10

V/µs

Slope during fast

transient within +/-10%

of VDD

S

VDDPrise

---

---

10

V/µs

Slope during power-on

or restart after

brownout event

S

VDDPfail

---

---

0.25

V/µs

Slope during supply

falling out of the +/-10%

limits

5.3 Motor Control Parameters – IMM100T series

Motion Control parameters that are defined in the iMOTION™ motion control engine (MCE) software are defined

and explained in iMOTION™ reference Manual.

5.3.1 PWM Characteristics – IMM100T series

Table 18 PWM timing in IMM100T

Symbol

Parameter

Min

Typ

Max

Unit

Condition

f

PWM

PWM frequency

5

16

40

kHz

5.3.2 Fault timing – IMM100T series

Table 19 Fault timing in IMM100T

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

AC Characteristics

Symbol

Parameter

Min

Typ

Max

Unit

Condition

t

FLTwidth

Minimum pulse width of

fault event to be

acknowledged at input over

current comparators

1.0

---

---

µs

t

TRAP

reaction time to

acknowledged overcurrent

at input comparators –

Fault to PWM disable

propoagation time

---

1.3

---

µs

5.4 Power Factor Correction (PFC) parameters – IMM102T

The PFC parameters only refer to the IMM102T with integrated PFC control algorithm and are defined and

explained in iMOTION™ reference Manual.

5.4.1 Boost PFC characteristics – IMM102T

Table 20 PFC PWM timing in IMM102T

Symbol

Parameter

Min

Typ

Max

Unit

Condition

f

PFCPWM

PFC PWM frequency

---

20

70

kHz

5.5 Communication interface parameters – IMM100T series

The IMM100T series provides the following communication interfaces.

Note: These parameters are not subject to production test, but verified by design and/or characterization.

5.5.1 UART interface - IMM100T series

The UART interface is configured as given below.

Note: Operating Conditions apply.

Note: Each bit including start and stop bit is sampled three times at center of a bit at an interval of 1/16

T

BAUD

.

Table 21 UART timing in IMM100T - series

Symbol

Parameter

Min

Typ

Max

Unit

Condition

f

UART

UART baud rate

1200

57600

---

bps

UART mode

---

8-N-1

---

data-parity-stop

bit

t

UARTFIL

UART sampling filter period

---

1/16

---

T

BAUD

=1/f

UART

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

I/O Structure

6 I/O Structure

The following figure shows the I/O structure for all digital I/O pins.

Figure 20 Digital I/O Structure

Figure 21 VCC pin I/O gate driver structure

ESD

Diode

ESD

Diode

V

CC

HIN,

LIN,

or EN

V

SS

R

PD

20 V

Clamp

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Package Outline

7 Package Outline

Figure 22 Bottom View, Dimensions in mm

Figure 23 Bottom View, Dimensions in mm

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Package Outline

Figure 24 Top View and Dimensions

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Part Marking Information

8 Part Marking Information

CYWW?

XXXXX

MCK099A

GYWW

XXXXXX

DATE CODE

ASSEMBLY SITE CODE

LOT CODE

MARKING CODE

IMM101T-046M

MARKING

PART NUMBER

Infineon

Figure 25 Part Marking

Datasheet 4-24-2020 V1.2

IMM100 series - iMOTION™ Smart IPM for motor control

Fully integrated high performance motor control system

Quality Declaration

9 Quality Declaration

Table 22 Quality Parameters

Qualification Level

Qualified for industrial applications according to

the relevant tests of JEDEC47/20/22

Moisture Sensitivity Level

MSL3

(per IPC/JEDEC J-STD-020C)

ESD

Charged Device Model

Class C2B

(per ANSI/ESDA/JEDEC standard JS -002)

Human Body Model

Class C2

(per EIA/JEDEC standard EIA/JESD22-A114-F)

RoHS Compliant

Yes

Note: Test condition for Temperature Cycling test is -40C to 125C.

Revision history

Document Version

Date of Release

Description of changes

v01_00

2019-04-10

Initial version

v01_01

2019-06-05

Typo Corrections

V01_02

2020-04-24

Revised oscillator accuracy specs. Changed max PWM frequency.

Edition 2019-06-05

Published by Infineon Technologies AG

81726 Munich, Germany

© 2019 Infineon Technologies AG All

Rights Reserved.

Do you have a question about any aspect

of this document?

Email: erratum@infineon.com

Document reference

IFX-vqf1553180223116

IMPORTANT NOTICE

The information given in this document shall in no event

be regarded as a guarantee of conditions or

characteristics (“Beschaffenheitsgarantie”).

With respect to any examples, hints or any typical values

stated herein and/or any information regarding the

application of the product, Infineon Technologies

hereby disclaims any and all warranties and liabilities of

any kind, including without limitation warranties of

non-infringement of intellectual property rights of any

third party.

In addition, any information given in this document is

subject to customer’s compliance with its obligations

stated in this document and any applicable legal

requirements, norms and standards concerning

customer’s products and any use of the product of

Infineon Technologies in customer’s applications.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments to

evaluate the suitability of the product for the intended

application and the completeness of the product

information given in this document with respect to such

application.

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types in

question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon Technologies,

Infineon Technologies’ products may not be used in any

applications where a failure of the product or any

consequences of the use thereof can reasonably be

expected to result in personal injury

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Loading...

Loading...