INFINEON IM231-M6S1B Datasheet

Final Datashet Please read the Important Notice and Warnings at the end of this document Revision 2.1

www.infineon.com 2019-07-15

IM231-M6S1B / IM231-M6T2B

CIPOS™ Micro IPM 600V/4A

IM231-M6S1B / IM231-M6T2B

Description

IM231-M6-series 3-phase Intelligent Power Modules (IPM) are designed for high-efficiency appliance motor drives

such as air-conditioner fans and refrigerator compressors. These advanced IPMs, available in both surface

mount and through-hole configurations, offer a combination of low V

CE(sat)

TRENCHSTOPTM IGBT6 technology and

the industry benchmark rugged half-bridge drivers. The IPMs have several protection features including precise

overcurrent protection and temperature feedback.

Features

600V 3-phase inverter including gate drivers &

bootstrap function

Low V

CE(sat)

TRENCHSTOP™ IGBT6

Temperature monitor

Accurate overcurrent shutdown (±5%)

Fault reporting and programmable fault clear

Advanced input filter with shoot-through

protection

Optimized dV/dt for loss and EMI trade offs

Open-emitter for single and leg-shunt current

sensing

3.3V logic compatible

Isolation 2000VRMS, 1min

SOP 29x12 DIP 29x12

Potential Applications

Air-conditioner fans

Refrigerator compressors

Ventilation fans & blower fans

Low power motor drives

Product validation

Qualified for industrial applications according to the relevant tests of JEDEC47/20/22.

Table 1 Part Ordering Table

Base Part Number

Package Type

Standard Pack

Orderable Part Number

Form

Quantity

IM231-M6T2B

DIP 29x12

Tube

240

IM231M6T2BAKMA1

IM231-M6S1B

SOP 29x12

Tube

240

IM231M6S1BALMA1

IM231-M6S1B

SOP 29x12

Tape & Reel

500

IM231M6S1BAUMA1

Final Datashet 2 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-M6S1B / IM231-M6T2B

Table of contents

Table of contents

Description 1

Features 1

Potential Applications ..................................................................................................................... 1

Product validation .......................................................................................................................... 1

Table of contents ............................................................................................................................ 2

1 Internal Electrical Schematic .......................................................................................... 3

2 Pin Configuration........................................................................................................... 4

2.1 Pin Assignment ........................................................................................................................................ 4

2.2 Pin Descriptions....................................................................................................................................... 5

3 Absolute Maximum Rating .............................................................................................. 7

3.1 Module ..................................................................................................................................................... 7

3.2 Inverter .................................................................................................................................................... 7

3.3 Control ..................................................................................................................................................... 7

4 Thermal Characteristics ................................................................................................. 8

5 Recommended Operating Conditions ............................................................................... 9

6 Static Parameters ......................................................................................................... 10

6.1 Inverter .................................................................................................................................................. 10

6.2 Control ................................................................................................................................................... 10

7 Dynamic Parameters ..................................................................................................... 12

7.1 Inverter .................................................................................................................................................. 12

7.2 Control ................................................................................................................................................... 12

8 Thermistor Characteristics ............................................................................................ 13

9 Mechanical Characteristics and Ratings........................................................................... 14

10 Qualification Information .............................................................................................. 15

11 Diagrams & Tables ........................................................................................................ 16

11.1 TC Measurement Point ........................................................................................................................... 16

11.2 Backside Curvature Measurement Points ............................................................................................ 16

11.3 Input-Output Logic Table ...................................................................................................................... 17

11.4 Switching Time Definitions ................................................................................................................... 18

12 Application Guide ......................................................................................................... 19

12.2 TJ vs TTH .................................................................................................................................................. 19

12.3 –VS Immunity ......................................................................................................................................... 20

13 Package Outline ........................................................................................................... 21

13.1 DIP 29x12 ............................................................................................................................................... 21

13.2 SOP 29x12 ............................................................................................................................................. 22

14 Revision History ........................................................................................................... 23

Final Datashet 3 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-M6S1B / IM231-M6T2B

Internal Electrical Schematic

1 Internal Electrical Schematic

Figure 1 Internal electrical schematic.

Half-Bridge

HVIC

Half-Bridge

HVIC

Half-Bridge

HVIC

1 COM

2 V

B1

3 V

CC1

4 HIN1

5 LIN1

6 RFE

7 V

B2

8 V

CC2

9 HIN2

10 LIN2

11 VTH

12 V

B3

13 V

CC3

14 HIN3

15 LIN3

16 ITRIP

17 V+

18 U/V

S1

19 V

R1

20 V

R2

21 V/V

S2

22 V

R3

23 W/V

S3

Final Datashet 4 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-M6S1B / IM231-M6T2B

Pin Configuration

2 Pin Configuration

2.1 Pin Assignment

e

1

2

3

4

5

7

8

9

10

12

13

14

15

16

23

22

21

20

19

18

17

11

6

Figure 2 Module pinout

Table 2 Pin Assignment

Pin

Name

Description

1

COM

Logic ground

2

VB1

High side floating supply voltage 1

3

V

DD1

Low side control supply 1

4

HIN1

Logic Input for high side gate driver - Phase 1

5

LIN1

Logic Input for low side gate driver - Phase 1

6

RFE

RCIN / Fault / Enable

7

VB2

High side floating supply voltage 2

8

V

DD2

Low side control supply 2

9

HIN2

Logic input for high side gate driver - Phase 2

10

LIN2

Logic input for low side gate driver - Phase 2

11

VTH

Thermistor output

12

VB3

High side floating supply voltage 3

13

V

DD3

Low side control supply 3

14

HIN3

Logic Input for high side gate driver - Phase 3

15

LIN3

Logic Input for low side gate driver - Phase 3

16

ITRIP

Current protection pin

17

V+

Dc bus voltage positive

18

U/VS1

Output - phase 1, high side floating supply offset 1

19

VR1

Phase 1 low side emitter

20

VR2

Phase 2 low side emitter

21

V/VS2

Output - phase 2, high side floating supply offset 2

22

VR3

Phase 3 low side emitter

23

W/VS3

Output – phase 3, high side floating suppyl offset 3

Final Datashet 5 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-M6S1B / IM231-M6T2B

Pin Configuration

2.2 Pin Descriptions

HIN(1,2,3) and LIN(1,2,3) (Low side and high side

control pins)

These pins are positive logic and they are

responsible for the control of the integrated IGBT.

The Schmitt-trigger input thresholds of them are

such to guarantee LSTTL and CMOS compatibility

down to 3.3V controller outputs. Pull-down resistor

of about 800k is internally provided to pre-bias

inputs during supply start-up and an ESD diode is

provided for pin protection purposes. Input

Schmitt-trigger and noise filter provide beneficial

noise rejection to short input pulses.

The noise filter suppresses control pulses which are

below the filter time T

FILIN

. The filter acts according

to Figure 4.

CIPOS

TM

INPUT NOISE

FILTER

M8.0

Schmitt-Trigger

SWITCH LEVEL

V

IH

; V

IL

COM

HINx

LINx

Figure 3 Input pin structure

HIN

LIN

HO

LO

low

high

t

FILIN

t

FILIN

a) b)

HIN

LIN

HO

LO

Figure 4 Input filter timing diagram

The integrated gate drive provides additionally a

shoot through prevention capability which avoids

the simultaneous on-state of the high-side and lowside switch of the same inverter phase. A minimum

deadtime insertion of typically 300ns is also

provided by driver IC, in order to reduce crossconduction of the external power switches.

VDD, COM (Low side control supply and reference)

VDD is the control supply and it provides power both

to input logic and to the output power stage. Input

logic is referenced to COM ground.

The under-voltage circuit enables the device to

operate at power on when a supply voltage of at

least a typical voltage of V

DDUV+

= 11.1V is present.

The IC shuts down all the gate drivers power

outputs, when the VDD supply voltage is below V

DDUV-

= 10.9V. This prevents the external power switches

from critically low gate voltage levels during onstate and therefore from excessive power

dissipation.

V

B(1,2,3)

and V

S(1,2,3)

(High side supplies)

VB to VS is the high side supply voltage. The high side

circuit can float with respect to COM following the

external high side power device emitter voltage.

Due to the low power consumption, the floating

driver stage is supplied by integrated bootstrap

circuit.

The under-voltage detection operates with a rising

supply threshold of typical V

BSUV+

= 11.1V and a falling

threshold of V

BSUV-

= 10.9V.

V

S(1,2,3)

provide a high robustness against negative

voltage in respect of COM. This ensures very stable

designs even under rough conditions.

V

R(1,2,3)

(Low side emitters)

The low side emitters are available for current

measurements of each phase leg. It is

recommended to keep the connection to pin COM as

short as possible in order to avoid unnecessary

inductive voltage drops.

VTH (Thermistor output)

A UL certified NTC resistor is integrated in the

module with one terminal of the chip connected to

COM and the other to VTH. When pulled up to a rail

voltage such as VDD or 3.3V by a resistor, the VTH pin

provides an analog voltage signal corresponding to

the temperature of the thermistor.

RFE (RCIN / Fault / Enable)

The RFE pin combines 3 functions in one pin: RCIN or

RC-network based programmable fault clear timer,

fault output and enable input.

The RFE pin is normally connected to an RC network

on the PCB per the schematic in Figure 5. Under

normal operating conditions, R

RCIN

pulls the RFE pin

to 3.3V, thus enabling all the functions in the IPM.

The microcontroller can pull this pin low to disable

the IPM functionality. This is is the Enable function.

Final Datashet 6 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-M6S1B / IM231-M6T2B

Pin Configuration

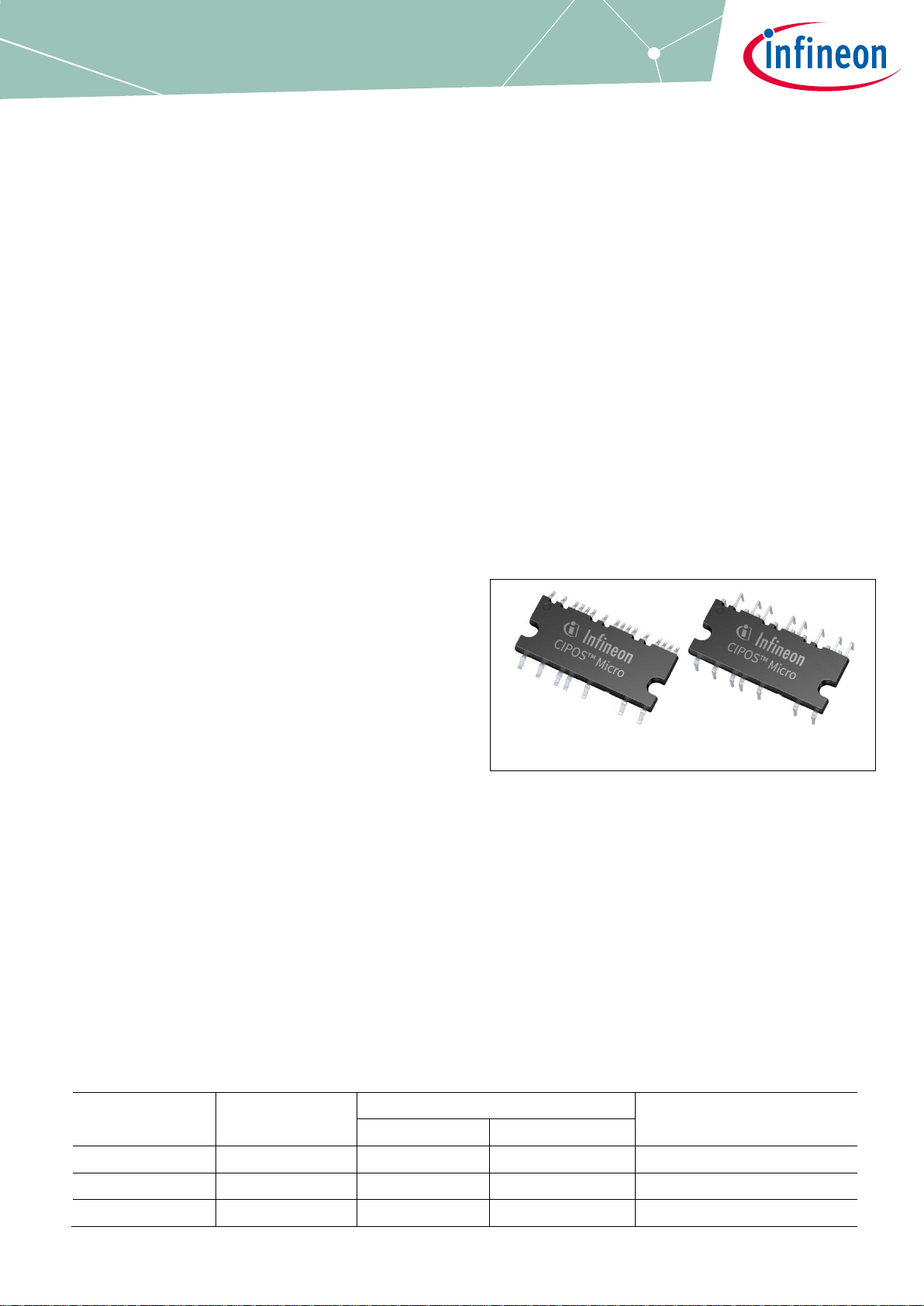

Figure 5 Typical PCB circuit connected to

the RFE pin

The Fault function allows the IPM to report a Fault

condition to the microncontroller by pulling the RFE

pin low in one of two situations. The first is an undervoltage condition on VDD and the second is when the

ITRIP pin sees a voltage rising above V

IT,TH+

.

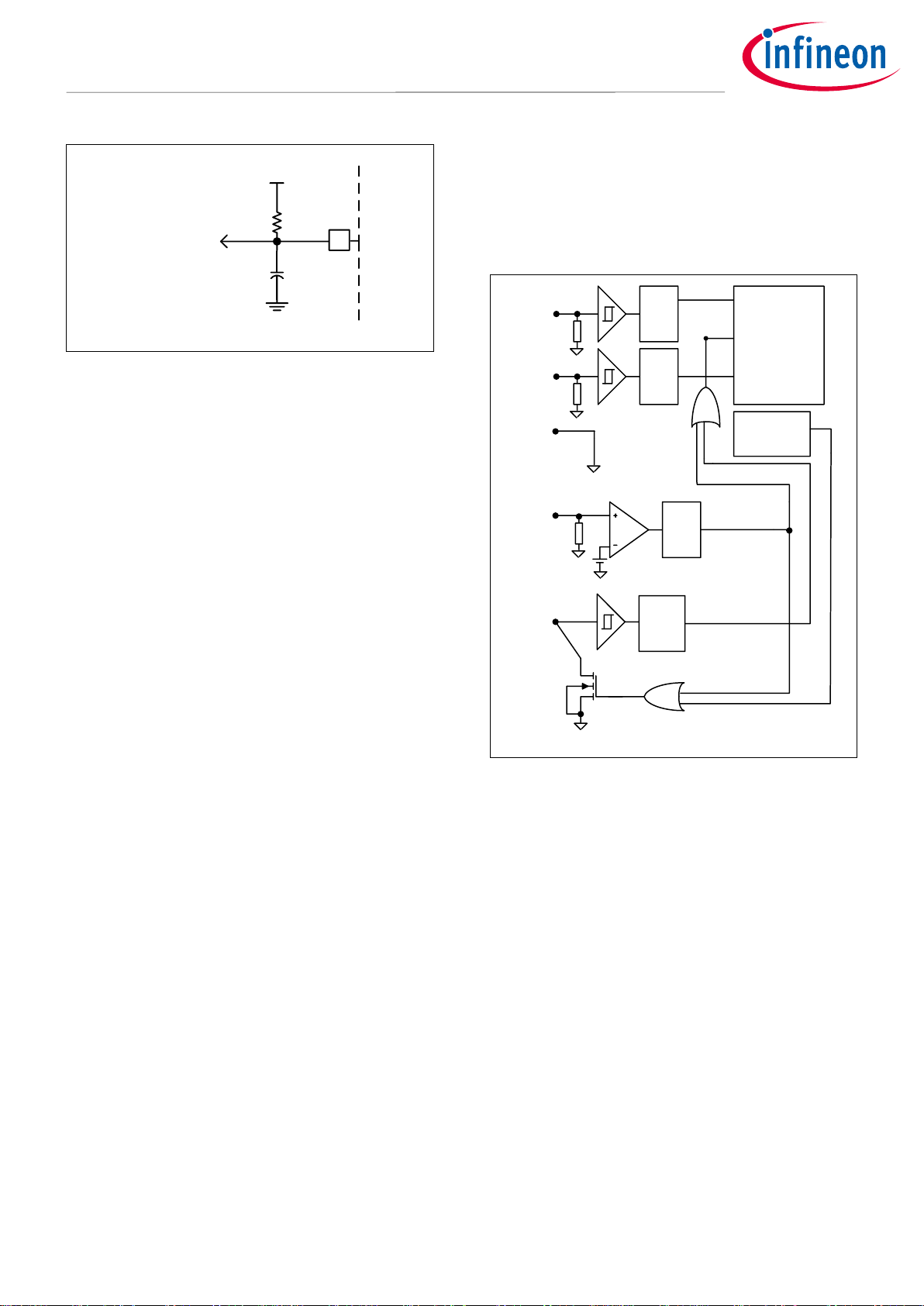

The programmable fault clear timer function

provides a means of automatically re-enabling the

module operation a preset amount of time (T

FLT-CLR

)

after the fault condition has disappeared. Figure 6

shows the RFE-related circuit block diagram inside

the IPM.

The length of TFLT-CLR can be determined by using

the formula below.

V

RFE

(t) = 3.3V * (1 – e

-t/RC

)

T

FLT-CLR

= -R

RCIN

* C

RCIN

* ln(1-V

IN,TH+

/3.3V)

For example, if R

RCIN

is 1.2MΩ and C

RCIN

is 1nF, the T

FLT-

CLR

is about 1.7ms with V

IN,TH+

of 2.5V. It is also

important to note that C

RCIN

needs to be minimized in

order to make sure it is fully discharged in case of

over current event.

Since the ITRIP pin has a 500ns input filter, it is

appropriate to ensure that C

RCIN

will be discharged

below V

IN,TH-

by the open-drain MOSFET, after 350ns.

Therefore, the max C

RCIN

can be calculated as:

V

RFE

(t) = 3.3V * e

-t/RC

< V

IN,TH-

C

RCIN

< 500ns / ( - ln (V

IN,TH-

/ 3.3V) * R

RFE_ON

)

Consider V

IN,TH-

of 0.8V and R

RFE_ON

of 50ohm, C

RCIN

should be less than 7nF. It is also suggested to use a

R

RCIN

of between 0.5MΩ and 2MΩ.

Figure 6 RFE internal circuit structure

U/VS1, V/VS2, W/V

S3

(High side emitter and low side

collector)

These pins are motor U, V, W input pins.

V+ (Positive bus input voltage, Pin 23)

The high side IGBTs are connected to the bus

voltage. It is noted that the bus voltage should not

exceed 450V.

Input

Noise

filter

Input

Noise

filter

Deadtime &

Shoot-Through

Prevention

ITRIP

Noise

filter

HIN

LIN

COM

ITRIP

RFE

Noise

filter

VDD

Undervoltage

detection

+3.3V

R

RCIN

C

RCIN

6 RFE

IM231-L6

To Microcontroller

Final Datashet 7 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-M6S1B / IM231-M6T2B

Absolute Maximum Rating

3 Absolute Maximum Rating

3.1 Module

Table 3

Parameter

Symbol

Condition

Units

Storage temperature

T

STG

-40 ~ 150

°C

Operating case temperature

TC

-40 ~ 125

°C

Operating junction temperature

TJ

-40 ~ 150

°C

Isolation test voltage

V

ISO

1min, RMS, f = 60Hz

2000

V

3.2 Inverter

Table 4

Parameter

Symbol

Condition

Units

Max. blocking voltage

V

CES/VRRM

600

V

Output current

I

O

TC = 25°C 4 A

Peak output current

IOP

TC = 25°C, tp < 1ms

6

A

Peak power dissipation per IGBT

P

tot

TC = 25°C

8.7

W

Short circuit withstand time

T

SC

VDC = 360V, TJ = 150°C, VDD = 15V

Allowed number of short

circuits: <1000, time between

short circuits: >1s

3

μs

3.3 Control

Table 5

Parameter

Symbol

Condition

Units

Low side control supply voltage

V

DD

-0.3 ~ 20

V

Input voltage

V

IN

LIN, HIN, ITRIP, RFE

-0.3 ~ V

DD

V

High side floating supply voltage

(VB reference to VS)

V

BS

-0.3 ~ 20

V

Final Datashet 8 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-M6S1B / IM231-M6T2B

Thermal Characteristics

4 Thermal Characteristics

Table 6

Parameter

Symbol

Conditions

Min.

Typ.

Max.

Units

Junction-case thermal

resistance, all IGBTs

operating (per module)

R

TH(J-C) _M

-

2.9

3.4

°C/W

Junction-case thermal

resistance, all diodes

operating (per module)

R

TH(J-C)D_M

-

3.0

3.5

°C/W

Single IGBT thermal

resistance, junction-case

R

TH(J-C)

High side V-

phase IGBT

-

10.0

11.6

°C/W

Single diode thermal

resistance, junction-case

R

TH(J-C)D

High side V-

phase IGBT

-

11.2

13.0

°C/W

Loading...

Loading...