Page 1

Industrial & Multimarket

Application Note

Version 2.0, 2011-04-14

ICL8001G / ICLS8082G

Design Guidelines

Phase-Cut-Dimmable Single-Stage LED Driver with PFC

using Quasi-Resonant Primary Power Control

Version 2.0

LED Driver ICs

Page 2

Edition 2011-04-14

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2011 Infineon Technologies AG

All Rights Reserved.

Legal Disclaimer

The information given in this document shall in no event be regarded as a guarantee of conditions or

characteristics. With respect to any examples or hints given herein, any typical values stated herein and/or any

information regarding the application ofthedevice,Infineon Technologies hereby disclaims anyand allwarranties

and liabilities of any kind, including without limitation, warranties of non-infringement of intellectual property rights

of any third party.

Information

For further information on technology, delivery terms and conditions and prices, please contact the nearest

Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements, components may contain dangerous substances. For information on the types in

question, please contact the nearest Infineon Technologies Office.

Infineon Technologies components may be used in life-support devices or systems only with the express written

approval ofInfineon Technologies, ifafailureofsuchcomponentscanreasonablybeexpectedtocausethefailure

of that life-support device or system or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Page 3

ICL8001G / ICLS8082G

Design Guidelines

Application Note 3 Version 2.0, 2011-04-14

ICL8001G / ICLS8082G Design Guidelines

werner.ludorf@infineon.com

Revision History: 2011-04-14, Version 2.0

Previous Revision:

Page Subjects (major changes since last revision)

First edition

Page 4

ICL8001G / ICLS8082G

Design Guidelines

Table of Contents

Application Note 4 Version 2.0, 2011-04-14

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Pin Configuration and Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Pin Configuration with PG-DSO-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Package PG-DSO-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Pin Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Control Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Design Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Transformer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Primary Peak Current Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Foldback Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5 Switch-on Determination for Quasi-resonant Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.6 Power Factor Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.7 VCC for Dimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Design Optimizations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Dimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 Dimming Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.2 Dimmer Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.3 Dimmer List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.4 Dimmer Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Power Stabilization for Line Voltage Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.1 Stabilization using IC Foldback Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.2 Discrete Power Stabilization Circuit for ICL8001G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Optimized Power Factor Correction Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Protection Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Output OVP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2 Output Short Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3 Input Overvoltage Protection (OVP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Explicit Questions and Answers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Control Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table of Contents

Page 5

ICL8001G / ICLS8082G

Design Guidelines

Introduction

Application Note 5 Version 2.0, 2011-04-14

1 Introduction

Objective

The objective of this application note is to describe how adimmable, highly efficient single-stage LED driver based

on the ICL8001G / ICLS8082G primary control developed by Infineon Technologies AG can be designed and how

different design targets can be considered. For this purpose, quantitative design tools for dimensioning of the

flyback transformer for QR (quasi-resonant) operation and further discrete components relevant to the power

factor correction (PFC) and dimming control functions are provided. The design process refers to a concrete

application example of a phase cut dimmable LED driver. Explicit questions and answers are treated in conclusion.

Features of ICL8001G / ICLS8082G control

• High, stable efficiency over a wide operating range

• Optimized for trailing and leading-edge dimmers

• Precise PWM for primary PFC and dimming control

• HV power cell for VCC precharging with a constant current

• Built-in digital soft start

• Foldback correction and cycle-by-cycle peak current limitation

• VCC over/undervoltage lockout

• Auto restart mode for short circuit protection

• Adjustable latch-off mode for output overvoltage protection (OVP)

Description

The ICL8001G / ICLS8082G employs a quasi-resonant (QR) operation mode and, due to the availability of

outstanding PFC performance, is optimized for off-line LED lighting applications such as dimmable LED bulbs for

incandescent lamp replacement, LED downlights and LED tubes in a power range from typically 5 W to 50 W.

Precise PWM generation enables primary control for phase cut dimming and potential for high power factors of

PF > 99 %. Depending on the power class, significantly improved driver efficiency of up to 91 % is feasible. The

product has a wide operation range of IC voltage supply and low power consumption. Multiple safety functions

ensure full system protection in failure situations. With its full feature set and simple application, the ICL8001G /

ICLS8082G represents an outstanding choice for QR flyback designs combining feature set and performance at

a minimum BOM cost.

Page 6

ICL8001G / ICLS8082G

Design Guidelines

Pin Configuration and Functionality

Application Note 6 Version 2.0, 2011-04-14

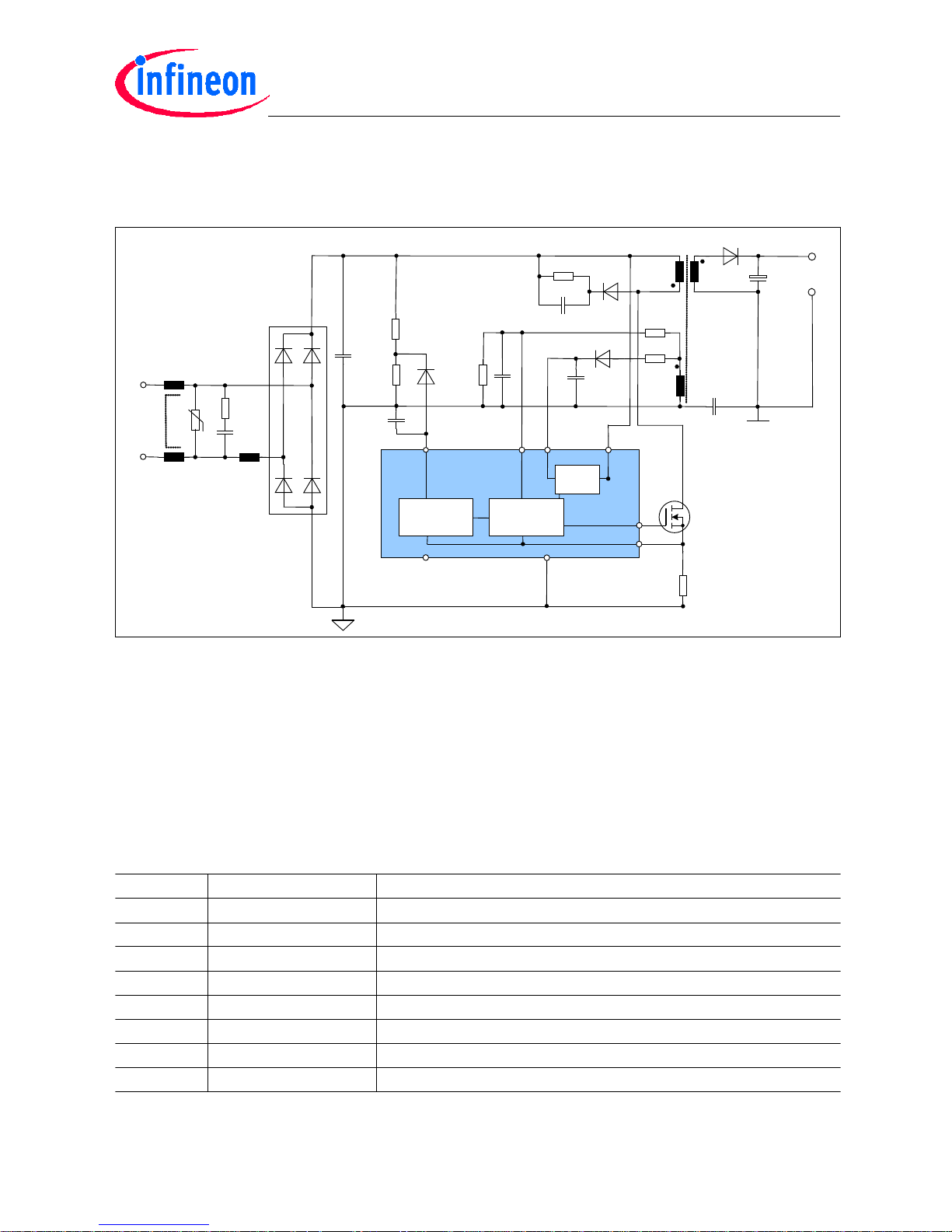

Application circuit

Figure 1 below shows the application circuit for the ICL8001G.

Figure 1 ICL8001G application circuit

2 Pin Configuration and Functionality

2.1 Pin Configuration with PG-DSO-8

Table 1 Pin Configuration for PG-DSO-8

Pin Symbol Function

1 ZCV Zero Crossing

2 VR Voltage Sense

3 CS Current Sense

4 GD Gate Drive Output

5 HV High Voltage Input

6 n.c. Not connected

7 VCC Controller Supply Voltage

8 GND Controller Ground

Cx

Cin

Rn

Cn

Dn

Cvcc

Dvcc

Rs

Do Co

L1

Rvcc

VCC

GND

T1

npnans

Rzc1

Rzc2

ZCV

ICL8001G

Vo

Vac

BR

Czc

VR

PWM-Control

Protection

GateDriver

Start-Up

Cell

Vm( Vs )

Cc

CS

Ro

Ru

NC

HV

GD

DR

Q1

CR

Rv

L2

Rc

U1

Vin

Page 7

ICL8001G / ICLS8082G

Design Guidelines

Pin Configuration and Functionality

Application Note 7 Version 2.0, 2011-04-14

2.2 Package PG-DSO-8

Figure 2 Pin Configuration of PG-DSO-8 (top view)

2.3 Pin Functionality

ZCV (Zero Crossing)

The voltage from the auxiliary winding after a time delay circuit is applied at this pin. Internally, the pin is connected

to the zero-crossing detector for switch-on determination. Additionally, the output overvoltage detection is realized

by comparing the voltage Vzc with an internal preset threshold.

VR (Voltage Sense)

The rectified input mains voltage is sensed at this pin. The signal is used to set the peak current ofthepeak-current

control and therefore enable the PFC and phase-cut dimming functionality.

CS (Current Sense)

This pin is connected to the shunt resistor for the primary current sensing, externally, and to the PWM signal

generator for switch-off determination (together with the feedback voltage), internally. Moreover, short-winding

protection is realized by monitoring the voltage Vcs during on-time of the main power switch.

GD (Gate Drive Output)

This output signal drives the external main power switch, which is a power MOSFET in most cases.

HV (High Voltage)

The HV pin is connected to the bus voltage, externally, and to the power cell, internally. The current through this

pin precharges the VCC capacitor with a constant current once the supply bus voltage is applied.

VCC (Power supply)

The VCC pin is the positive supply of the IC. The operating range is between V

VCCoff

and V

VCCOVP

.

GND (Ground)

This is the common ground of the controller.

ZCV

VR

CS

GD

GND

VCC

NC

HV

1

2

3

4 5

6

7

8

Page 8

ICL8001G / ICLS8082G

Design Guidelines

Control Principle

Application Note 8 Version 2.0, 2011-04-14

3 Control Principle

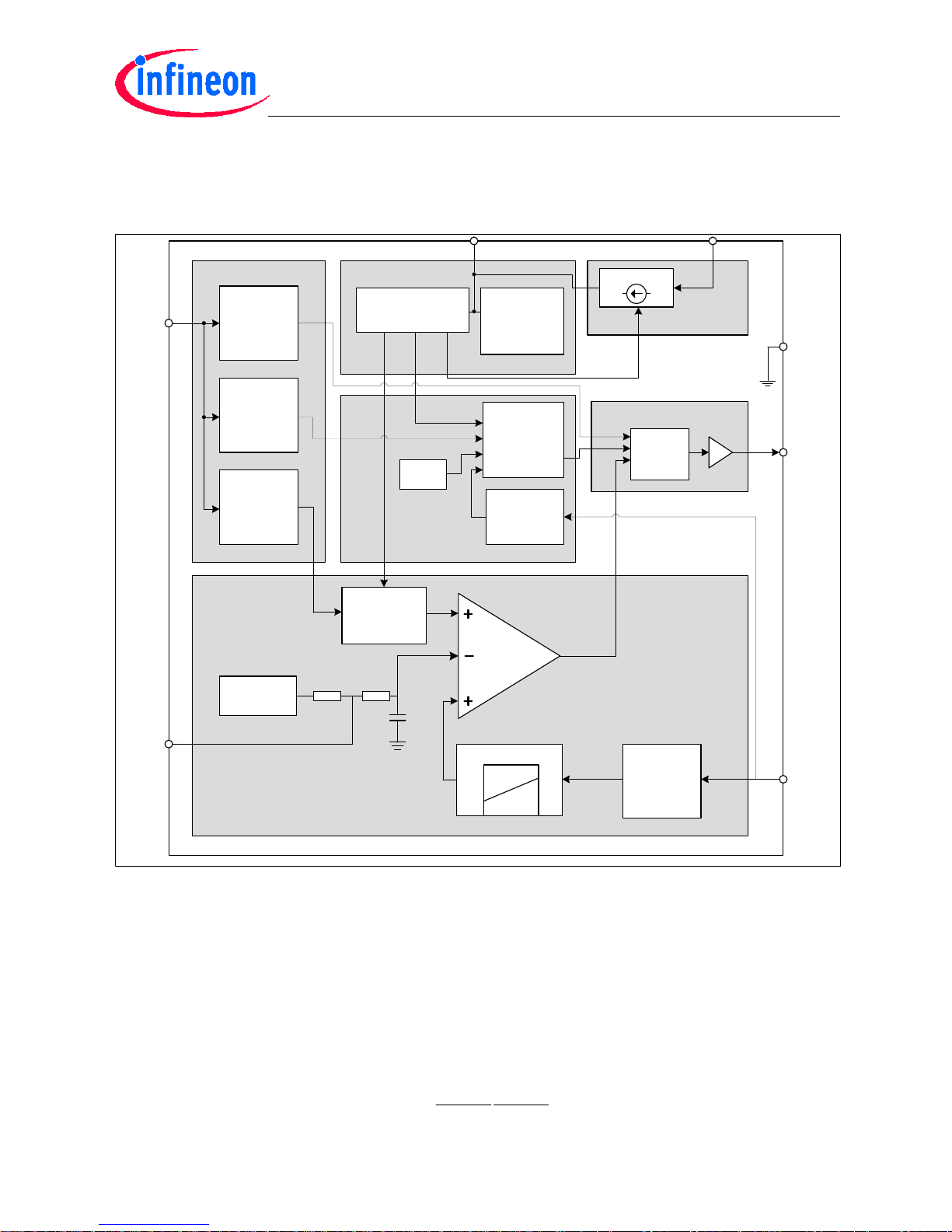

Figure 3 Block diagram of the ICL8001G

An inspection of the ICL8001G block diagram shows that the voltage measured at the shunt resistor Rs (see also

the application circuit in Figure 1), which varies according to the instant transformer primary current Ip(t),

determines the gain voltage VG as

(1)

With the PWM OPgain G

PWM

and the offset voltage ram V

PWM

VG is compared to the voltage VR, which is derived

from the input voltage divider (Ro, Ru). This means that the peak current through the power switch Q1 and the

primary inductance L varies according to the instant input voltage Vin(t) as expressed by

(2)

Depl. CoolMOS

Startup Cell

Power ManagmentZero Crossing

PWM Control

Gate Drive

Protection

HV

GND

GD

Gate

Control

Voltage

Reference

& Biasing

Over / Under-

Voltage Lockout

OTP

Restart /

Latchup

Control

VCC

CS

Leading

Edge

Blanking

VR

ZCV

Zero

Current

Detection

Over

Voltage

Protection

PM / PFC

Control

Foldback

Correction

Short

Winding

Detection

VG ( Vs )

PWM

Comparator

V

REF

V

FB

25k

2pF

PWMsPWM

VRtIpGtIpVG )())((

RsG

tVin

RuRo

Ru

tIp

PWM

)(

)(

Page 9

ICL8001G / ICLS8082G

Design Guidelines

Design Parameters

Application Note 9 Version 2.0, 2011-04-14

It can be seen in the non-dimming case that asinusoidal waveform of the primary peak current is dominant, which

defines the almost sinusoidal shape of the input current Iin(t). Beside the PFC function Equation (2) above shows

that during phase cut dimming the input current will follow the phase cut-modified input voltage, which assures the

dependence of the driver output power on the RMS input voltage V

rms

according to the law described by

Equation (24) on page 15.

4 Design Parameters

This chapter presents the essential design process and illustrates it in parallel with concrete values which are

considered for a sample design with the main target magnitudes VLED = 27 V, ILED = 360 mA, PF = 98 %,

η = 90 %, f < fmax = 100 kHz for the input parameters Vin = 230 V, fin = 50 Hz and Pin = VLED ILED / (η PF). The

values chosen for the 10 W/230 V LED driver demo board are close to the following calculation results.

4.1 Transformer Parameters

For QR operation, a sufficiently large reflected voltage from the secondary to the primary side present during the

flyback time tf has to be provided. After discharge of the transformer by means of the secondary winding current

the energy coupled to the reflected voltage is needed to reduce the input voltage at switch-on instantly in the VDS

valley to Vdsmin = Vin - Vr. With the selection of Vdsmin = 0 a value Vr = Vinp, where

(3)

is received according to

(4)

The ratio q = Vr / Vinp with q ≤ 1 determines the maximum input voltage Vinp to be processed with zero-voltage

switching. The winding ratio rn= np / ns is then calculated as rn= 12.

(5)

The driver operation frequency f varies over the line voltage phase and reaches its maximum values in the line

voltage phase close to the voltage peak Vinp. Consideration of a QR mode condition defines the primary

inductance L = 6.1 mH (6.3 mH chosen) based on

(6)

With the selection f = fmax, the equation for the minimum on-time

(7)

yields ton = 5.0 µs and so the minimum duty cycle becomes Dmin = 0.5 as

(8)

VinVinp 2

minVdsVinpVr

Vdo

VLED

V

r

r

n

2

2

1

2

Vr

Vinp

fPin

Vin

L

Vinf

PinL

ton12

Vin

fPinLD2

min

Page 10

ICL8001G / ICLS8082G

Design Guidelines

Design Parameters

Application Note 10 Version 2.0, 2011-04-14

Now the maximum primary peak current arising in the line phase with Vin = Vinp can be fixed as I

pmaxp

= 0.27 A

according to

(9)

Assuming a saturation inductance of Bm = 0.4 T and Ae = 20.1 mm2a minimum number of primary turns of

np ≈ 200 (np = 190 chosen) would be obtained.

(10)

The maximum magnetic permeance ALmax = 170 nH is obtained using

(11)

which determines the air gap using the k-factors in

(12)

For the often relevant E16-core, the k-factors are k1 = 42.2 and k2 = –0.701 resulting in s ≈ 0.15 mm. The

secondary number of turns is then given by

(13)

By choosing ns = 14 and the centered IC supply voltage Vccc = ( Vccmax + Vccmin )/ 2 = 19 the auxiliary winding

number will be na = 10 according to

(14)

4.2 Power Switch

The maximum voltage V

DSmax

along the drain-source path of the MOSFET arises during the line phase with Vin

= Vinp at the instant just subsequent to switching off the primary current. In this phase the high-frequency

oscillation amplitude

(15)

adds to the superposition given by the input voltage and reflected voltage to

(16)

The V

DSmax

value can be limited by either reducing the QR effect (with q) at the cost of driver efficiency or by

damping the oscillation by means of a snubber circuit. These limiting approaches can be compared in terms of

fL

Pin

I

pp2max

BmAe

IL

np

ppmax

min

2

max

np

L

AL

2

1

9

1

10max

k

k

AL

s

n

r

np

ns

Vdo

VLED

Vcc

nsna

max

Cds

Ls

IVosc

pp max

oscinpDS

VqVV )1(

max

Page 11

ICL8001G / ICLS8082G

Design Guidelines

Design Parameters

Application Note 11 Version 2.0, 2011-04-14

cost and efficiency reduction with the option of choosing MOSFETs with higher breakdown voltages. For high

efficiency it is recommended to make the adjustment V

DSmax

= 2 Vinp + Vosc < 800 V or 900 V respectively. If

necessary, a transformer design with q < 1 (meaning reduced QR operation effect) should be favored over high

snubber losses.

4.3 Primary Peak Current Control

The peak current charging the primary inductance of the transformer reaches its maximum value at the input

voltage Vinp. By choosing the maximum threshold Vcsmax = 0.75 V for the shunt voltage generated at the instant

of Vinp, the shunt resistance is Rs = 2.7 Ω based on

(17)

The upper resistor, Ro, in the input voltage divider is dimensioned in consideration of losses and PFC. For

efficiency optimization, high ohmic values are preferred. A low ohmic input voltage divider enables a maximum

power factor adjustment.

The resistance of the lower input voltage divider resistor is expressed as

(18)

For the selection Vcsmax ≈ 0.75V and Rs = 2.7 Ω the Ru equation above helps to define (with the specification of

Ro = 560 kΩ) a resistance of Ru = 4.3 kΩ (choose Ru = 3.9 kΩ).

pp

I

Vcs

Rs

max

max

RsIGVinp

IGRsRo

Ru

ppPWM

ppPWM

max

max

Page 12

ICL8001G / ICLS8082G

Design Guidelines

Design Parameters

Application Note 12 Version 2.0, 2011-04-14

4.4 Foldback Correction

When the line input voltage increases, the comparator threshold for switching off the power switch is reached in a

shorter time and the resulting increase in operation frequency would lead to a strong increase in the LED driver

power. To limit the input voltage dependence above a certain limit Vinth, the foldback correction reduces the

threshold Vcsmax(Icz) in accordance with the current detected at the ZCD pin as expressed here:

(19)

The characteristic curve Vcsmax(Izc) implemented in the IC shows the following steps:

Figure 4 Vcsmax(lzc) characteristic curve

For the adjusted setting Vinth = Vinp and selection of the foldback operation point Vcs-max = 0.75 V / Icz = 1 mA,

using the characteristic curve the detection resistance is calculated to be Rzc1 ≈ 15 kΩ according to

(20)

From the characterisitic curve it can be seen that the Vin dependence of Vcsmax is stronger in the range of higher

threshold values. This means that if a strong impact of the foldback correction is desired, the Vcs should reach

rather high values at Vinp. For increased power constancy under input voltage voltage variations, higher values

of R4 and R19 should be chosen.

np

na

Rcz

Vin

VinIcz1)(

np

na

Icz

thVin

Rcz 1

Page 13

ICL8001G / ICLS8082G

Design Guidelines

Design Parameters

Application Note 13 Version 2.0, 2011-04-14

4.5 Switch-on Determination for Quasi-resonant Operation

For ideal quasi-resonant operation the switch-on of the power switch should occur when the transformer current

in the output circuit reaches zero and half of theoscillation period (oscillation 2 inFigure 5) definedby the leakage

inductance and the drain-source capacitance of the power switch has elapsed.

Figure 5 Determination of the switch-on instant

The delay td elapses from the instant of discharging the transformer to when the first VDS valley is reached. For

initial dimensioning of the delay circuit the relationship

(21)

can be used. For the 230 V / 10 W demo board an initial value of td ≈ 1 µs is appropriate. For output overvoltage

protection with final shutdown at Vo > 45 V it turns out to be useful to choose Rzc2 ≈ 2 kΩ. Consequently, the

capacitance of the delay circuit Czc = 580 pF (choose Czc = 470 pF) will be obtained according to

(22)

CdsLtd

2121RzcRzc

RzcRzc

tdCzc

Page 14

ICL8001G / ICLS8082G

Design Guidelines

Design Parameters

Application Note 14 Version 2.0, 2011-04-14

4.6 Power Factor Correction

The PFC function provides a sinusoidal input current waveform. For this, the setpoint at pin VR should be related

strongly to the input voltage waveform Vin(t). The internal reference voltage Vref is connected via the internal

resistor VFB to the pin VR. The voltage waveform VR(t) over the line period can be influenced in such a way that

a more trapezoidal curve is generated and the input current waveform behaves accordingly. An input voltage

divider with Ro ≈ 500 kΩ at Vac = 230 V delivers a high power factor of typically PF > 95 % and dissipates low

power for high driver efficiency. High PF values above 99 % and low total harmonic distortion of typically 10 % are

achievable at decreased power tolerances. If high power factor adjustment has priority, it is also important to select

an elevated threshold for foldback correction Vinth ≈ Vinp.

Figure 6 Power factor correction

4.7 VCC for Dimming

The dimming feature is closely coupled to the PF control as the variation of the setpoint VR(t) determines the

power flow to the QR-operated flyback. This is also true if the input voltage is shaped by means of a phase cut

dimmer, regardless of whether this is a trailing or leading edge wall dimmer. Therefore thevariation of the effective

input voltage determines thepower level supplied to theLED load at the driver output. The low frequency variation

of the input power is smoothened by means of an output capacitor Co storing enough energy to cause no visible

light flickering.

For a stable IC supply voltage at phase cut dimming more severe conditions have to be observed. Extended

temporal gaps with zero input voltage, especially at low dimming levels, are present. Also a certain decrease in

output voltage is present in the continuous dimming state of the LED. The Vcc capacitor Cvcc can be designed

using

(23)

For dimming applications the assumptions of voltage variation ∆VCCdim = 5 V, IVCC = 5 mA and Tgap

≈ 2 x 10 ms for line half-periods with phase cut dimmer malfunction, a Cvcc ≈ 20 µF would be required, while for

non-dimming application the capacitance requirement could be half of that value. For dimmable drivers with Cvcc

= 22 µF a short time of 300 ms to light can be realized due to the charging current provided by the HV start-up cell.

dim

VCC

TgapIVCC

Cvcc

Page 15

ICL8001G / ICLS8082G

Design Guidelines

Design Optimizations

Application Note 15 Version 2.0, 2011-04-14

5 Design Optimizations

5.1 Dimming

5.1.1 Dimming Principle

The LED driver input voltage at phase cut dimming with the switching instant ts will generate an effective voltage

of Vineff(ts). From the applied dimming principle it can be seen that the LED power will depend on Vineff(ts)

according to the proportionality law

(24)

where 1.5 < x < 2.0. Consequently, the light level depends on the RMS input voltage Vrms(ts) provided by the

phase cut dimmer and the dimming range is therefore given by the phase-cut limits of the wall dimmer. For the

example of a trailing edge dimmer, the following diagrams show the time dependence of the modified input voltage

V(t,ts) with the fixed parameter switching instant ts = T/4 and the RMS input voltage Vrms(ts) during a theoretical

full variation of switching instants ts for visualization of the mathematical function Vrms(ts).

Figure 7 Timing dependency on input voltage

Figure 8 Timing dependency on RMS input voltage

x

tsVrmstsVrmsPLED ))(())((

Page 16

ICL8001G / ICLS8082G

Design Guidelines

Design Optimizations

Application Note 16 Version 2.0, 2011-04-14

Phase cut dimming arrangement

Figure 9 Phase cut dimming arrangement

The experimental dependence PLED(Vrms) is illustrated using a 40 Weq LED bulb driver controlled with a trailing

edge phase cut dimmer.

Figure 10 Output power versus input trail edge Vrms

Effective for the application is the dependence of the LED driver power on the switching instant ts / switching angle.

The following experimental diagram obtained with an Ehmann trailing edge dimmer shows the dependence of the

switching instant ts on the driver input power (upper curve) and LED power (lower curve) respectively.

Figure 11 Relationship between switch-off instant ts and power

Phase Cut Dimmer

ICL8001G

LED Driver

LED Array

Vac

+

_

Vac

VLED

+

_

Page 17

ICL8001G / ICLS8082G

Design Guidelines

Design Optimizations

Application Note 17 Version 2.0, 2011-04-14

The lower curve corresponds closely to the lumen flux of the LED array supplied by the driver and illustrates a

continuous increase for the switching angle variation at the wall dimmer.

5.1.2 Dimmer Compatibility

The driver operation with TRIAC dimmers makes it necessary to observe the requirements regarding their holdup currents. In addition, the steep rising voltage slopes can excitate disturbing interactions with the parasitics of

the EMI filter of the driver. To dampen these interactions it is useful to implement a low-pass filter close to the EMI

filter. As placement of the filter in front of the input rectifier would decrease the EMI filter performance it is

recommendable to choose a position parallel to the input voltage divider. In the circuit diagram further below, an

R-C circuit is implemented. Dimensioning of R8 = 220 Ω and C8 = 68 nF (not integrated in the standard demo

board layout) provides stabilization for leading-edge dimmer operation. The non-dimming driver efficiency is

reduced by only typically 1 %.

Figure 12 Extended application circuit for dimming

Especially for applications with low input voltage and resulting higher input currents, shaping of the input current

waveforms has been shown to be effective in achieving dimming stability. For this, an increase in the ratio

R17 / (R17+ R19) and increasein R4 for keeping the LED power constant is suggested. The principal modification

of the modification on the different waveforms is indicated in Figure 13 below.

C1

C11

R1

C12

D5

C15

D6

R4

D21 C25

L1

R2

VCC

GND

T1

npnans

R6

R3

ZCV

ICL8001G

VLED

Vac

BR1

C18

VR

PWM-Control

Protection

GateDriver

Start-Up

Cell

ContinuousMode

DIM Control

PFC

C5

CS

R19

R17

NC

HV

GD

D7

Q1

C17

R5

L2

R7

Vin

C8

R8

5

3

1

2

6

8

Page 18

ICL8001G / ICLS8082G

Design Guidelines

Design Optimizations

Application Note 18 Version 2.0, 2011-04-14

Figure 13 Input current waveforms

For an input supply voltage of 100 V the resistors have been changed accordingly: R19 from 3.9 kΩ to 10 kΩ, R19

from 150 kΩ to 300 kΩ and R4 from 2.2 Ω to 2.7 Ω. The increased dimmer compatibility decreases the power

factor from 99 % to 86 %. This modification can be combined with dimensioning for a stronger effect of the

foldback correction. Designs with an increased VR voltage level will lead to a reduction in driver efficiency.

5.1.3 Dimmer List

Table 2 Input voltage 230 V / 10 W

Manufacturer Type/designation Power limit Dimming range

PDL Leading Edge CAT634LM 450 W 20 – 100 %

Busch Leading Edge 2200 400 W 16 – 100 %

Ehmann Leading Edge T10 300 W 3 – 100 %

Ehmann Trailing Edge T46 315 W 23 – 100 %

HPM Trailing Edge Cat400T 400 W 6 – 100 %

PDL Trailing Edge CAT624TM 450 W 10 – 100 %

Table 3 Input voltage 100 V / 10 W

Manufacturer Type/designation Power limit Dimming range

LEVITON Leading Edge decora RPI06 600 W 11 – 100 %

LEVITON Leading Edge TRIMATRON 6684 600 W 5 – 100 %

LUTRON Leading Edge SKYLARK S-600H-WH 600 W 3 – 100 %

LUTRON Leading Edge SKYLARK S-600P 600 W 4 – 100 %

LUTRON Leading Edge TOGGLER TG-600PH-IV 600 W 9 – 100 %

Page 19

ICL8001G / ICLS8082G

Design Guidelines

Design Optimizations

Application Note 19 Version 2.0, 2011-04-14

5.1.4 Dimmer Selection

With ICL8001G / ICLS8082G control the LED driver can be operated without a wall dimmer as well as using

trailing- and leading-edge dimmers. With the phase-cut dimmers applied above, a satisfying light quality and

variation in the LED lumen flux over the dimming range has been achieved. For both technologies the phase-cut

range should be sufficiently large to provide the dimming range required. The dimming range available with a

particular dimmer for incandescent lamps is directly transferred to the LED driver with ICL8001G / ICLS8082G,

but the lumen output of the LEDs at the minimum dimming position will be higher than with incandescent lamps

as they need a high amount of thermal power to enable the visible light radiation process.Particularly for operation

with 230 V input voltage, leading-edge wall dimmers with a lower rated power range – and hence lower hold-up

current requirements – should be selected in order to prevent the occurrence of repetitive TRIAC ignition.

Operation with lower input voltages, such as 110 V, provides a higher input current, which in principle supports

more stable TRIAC operation.

Touch dimmers with internal IC control, which depends exclusively on a resistive load for sufficient digital IC

supply, should not be selected for LED driver control.

5.2 Power Stabilization for Line Voltage Variations

For stable lumen output and limitation of LED power during mains voltage variations it may be useful to consider

power stabilization for the LED driver design. This can be achieved by appropriate use of IC foldback correction

without additional external components.

5.2.1 Stabilization using IC Foldback Correction

Driver design can be dimensioned in such a way that PLED variation becomes smaller in the range Vin,min < Vin

< Vin,max than would be expected from the approximate quadratic power law. The effect of the foldback correction

on LED power and LED current variations can be enhanced by means of an increased R17 value with a constant

R19. This will modify the input current waveform from sinusoidal to a more rectangular curve. The LED power can

be readjusted by means of the shunt resistor R4. The effect of the foldback correction on the LED power and on

LED current variation can be further increased by additionally lowering the Vcs limit. For this second step the R6

value is decreased.

PLED is readjusted using the shunt resistor R4. The R6 value can be decreased until the latch-off threshold of the

output overvoltage detection is reached. Theprincipal experimental LED current increase for a 10 % input voltage

increase is shown in the following diagram. For input voltage drops, similar behavior is obtained for the LED

current decrease.

Page 20

ICL8001G / ICLS8082G

Design Guidelines

Design Optimizations

Application Note 20 Version 2.0, 2011-04-14

Figure 14 LED current behavior according to power factor using foldback correction

The table below shows the relevant design parameters. Consideration of EMI and driver efficiency designs with

PF > 90 % are recommended.

The LED driver should be designed for operation at the maximum voltage arising in the input voltage range.

5.2.2 Discrete Power Stabilization Circuit for ICL8001G

For especially high requirements regarding input power or LED current stability for line voltage variations, such as

∆ILED ≤ +/- 2 % at ∆Vac = +/- 10 %, and for low harmonic distortion, a solution using a discrete differential amplifier

can be proposed. Here the Vin signal is sensed by means of a voltage divider consisting of R21 and R22, and

smoothed by C21. The Zener diode D21 is used for the reference voltage. When the smoothed voltage is much

smaller than the reference voltage, the current though R23 will flow only through R24 and there is no influence on

the output power of the demo board. When the value of the smoothed voltage is near the reference voltage, part

of the current flowing through R23 will begin flowing through R25, R26 and R4 to GND to generate an additional

voltage drop. Subsequently, its waveform shows the same slope at pin CS as the rectified input voltage Vin(t).

Table 4 Design parameters for stabilization using foldback correction

R17 R19 R6 R4 Pin, rel

[%]

ILEDrel, dec

[%]

ILEDrel, inc

[%]

10k 560k 10k 3R3 4.9 3.8 4

10k 560k 6k8 3R3 6 5 5

3k9 560k 10k 2R7 12 11.6 10

Page 21

ICL8001G / ICLS8082G

Design Guidelines

Design Optimizations

Application Note 21 Version 2.0, 2011-04-14

Figure 15 Discrete power stabilization circuit

As the on-time of the power MOSFET Q1 is reduced the LED driver power is also reduced. The parameters should

be adjusted so that the smoothed voltage at the base of Q21 is equal to the reference voltage at the base of Q22

at the nominal input voltage. The maximal additional voltage drop on the CS pin should be approximately 10 % to

20 % of the original CS limit at the maximum input voltage. As the waveform of the additional voltage drop at the

CS pin has the same slope as Vin(t), the input current will not change significantly, but still enable designs with a

high power factor and low harmonic distortion. Careful optimization of the discrete stabilization circuit containing

the components stated in the BOM below when connected to the 230 V / 10 W driver delivers variations of

∆ILED ≤ + 0.3 % and ∆ILED ≤ –1.3 % at ∆Vac = +10 % and ∆Vac = –10 % respectively. There is no influence on

output short circuit and output open loop detection.

Figure 16 Bill of Materials (BOM) for power stabilization circuit

Component Value Package

Q21 BC860B (PNP) SOT23

Q22 BC860B (PNP) SOT23

C21 470nF/50V 0805

R21 2.2MΩ 0805

R22 75kΩ 0805

R23 1MΩ 0805

R24 10k 0805

R25 10k 0805

R26 1k5 0805

R27 68k 0805

D21 ZMM6V8 Minimelf

BOM of Discrete Power Stabilization Circuit for 230V / 10W

ICL8001G LED Driver Demoboard

Page 22

ICL8001G / ICLS8082G

Design Guidelines

Design Optimizations

Application Note 22 Version 2.0, 2011-04-14

5.3 Optimized Power Factor Correction Performance

Driver optimization for high power factor correction can deliver very high PF > 99 % and THD ≈ 10 %.

Corresponding measurements for a 100 V / 10 W LED driver result in the timing diagrams for the setpoint voltage

VR(t) and driver input current Iin(t).

Figure 17 Optimized power factor correction

Figure 18 Bill of Materials (BOM) for 100 V / 10 W LED driver with high PF

Page 23

ICL8001G / ICLS8082G

Design Guidelines

Protection Functions

Application Note 23 Version 2.0, 2011-04-14

6 Protection Functions

The following ICL8001G / ICLS8082G protection functions are provided.

6.1 Output OVP

By means of VCC overvoltage detection it is possible to switch to Auto Restart Mode, which causes a blinking

effect of the LED. The output voltage threshold Voovp_vcc can be adjusted by means of the resistor Rvcc in the

VCC supply circuit.

A second output overvoltage threshold Voovpth can be adjusted to set Latched Off Mode using the IC threshold

Vzcovp = 3.7 V. For a decreased output OV threshold Voovpth = 35 V the Rzc2 resistance value is increased to

Rzc2 = 2.7 kΩ based on the equation

(25)

6.2 Output Short Circuit Protection

In the case of an output short circuit, the IC will switch to Auto Restart Mode by means of VCC undervoltage

detection. No special dimensioning is required for this purpose.

6.3 Input Overvoltage Protection (OVP)

Upon input overvoltage the foldback point correction becomes active and limits the LED driver input power at the

thresholds stated above.

Table 5 ICL8001G / ICLS8082G protection functions

VCC Overvoltage Auto Restart Mode

VCC Undervoltage Auto Restart Mode

Output Overvoltage Latched Off Mode

Output Short Circuit Auto Restart Mode

Short Winding Latched Off Mode

Over temperature Auto Restart Mode

vpVzconsVoovpthna

vpVzcoRzcns

Rzc12

Page 24

ICL8001G / ICLS8082G

Design Guidelines

Explicit Questions and Answers

Application Note 24 Version 2.0, 2011-04-14

7 Explicit Questions and Answers

7.1 Application

What are the main applications of ICL8001G / ICLS8082G Control?

ICL8001G / ICLS8082G is optimized for offline LED lighting like dimmable LED bulbs for incandescent lamp

replacement, LED downlights and LED tubes. The PFC function enables a power range of typically 5 W to 50 W

to be applied.

Should LED drivers for universal input voltage be designed?

Universal input designs lead to essential efficiency reduction in the LED driver and are therefore not supported by

special IC features.

Is it possible to supply different LED modules with strong variations in total forward voltages?

The LED driver requirements under strongly varyingconditions ofphase-cut dimming are tough. The VCC concept

compatible with these requirements and proposed here does not allow for strong variations in the DC output

voltage but only for limited output voltage variation. Only in this case is a constant transformer winding ratio or a

design with single transformer connecting points at the auxiliary winding sufficient.

How can driver efficiencies exceeding 90 % be realized?

Generally at higher power applications with pin ≈ 15 W, driver efficiencies > 90% can be realized using optimized

QR control with ICL8001G / ICLS8082G.

Can we disable the dimming function and use it as a constant current LED driver with a good power

factor?

TDA 4863-2 is recommended for this kind of application. For details, see the Application Note AN186.

What will happen under no-load conditions?

The application circuits based on ICL8001G / ICLS8082G are designed to work with LEDs only. Under no-load

conditions it will go to either the auto restart mode due to Vcc OVP or latched off mode due to output OVP.

7.2 Control Principle

How does ICL8001G / ICLS8082G realize dimming control and power factor correction?

Both dimming control and PFC are achieved with the input mains voltage sensing at the VR pin. This signal is used

to set the peak current of the primary winding and consequently allows both PFC and phase-cut dimming

functionality by regulating the cycle energy.

What are the effects of constant power control compared to constant current?

Under constant power control, variations in the LED forward voltage may cause certain variations in the lumen

output while, in contrast, the output remains approximately unchanged under constant LED current control.

However, the power control concept also enables the LEDs to be operated thermally under stable conditions.

Combination of output power control with power stabilization under input voltage variation as proposed above

makes it possible to optimize the heat sink design of an LED bulb or LED lighting fixture and hence minimize

system costs.

How does the ICL8001G / ICLS8082G achieve the regulation of the current through the LEDs?

ICL8001G / ICLS8082G controls the cycle energy stored in the primary inductance of the flyback transformer.

When also considering the frequency behavior, the resulting LED power depends on quite a few parameters. The

influence of input voltage variation can be reduced with the design means described above. The tolerances of the

Page 25

ICL8001G / ICLS8082G

Design Guidelines

References

Application Note 25 Version 2.0, 2011-04-14

current sense resistor R4, the voltage dividers formed by R17 and R19 as well as R6 & R3 have also to be

considered. The ICL8001G / ICLS8082G PWM parameter GPWM and offset voltage needed for low driver

tolerances possess especially high precision, as stated in the ICL8001G / ICLS8082G data sheet.

8 References

Data Sheet ICL8001G / ICLS8082G

AN EVAL-LED-ICL8001G-Bulb02 for LED Drivers 230 V / 10 W

AN EVAL-LED-ICL8082G-Bulb01 for LED Drivers 230 V / 10 W

AN186 – 40 W LED Street and Indoor Lighting Reference Design

Page 26

Published by Infineon Technologies AG

w w w . i n f i n e o n . c o m

Loading...

Loading...