Page 1

Application Note, V1.0, July 2011

Design Guide for LLC Converter

with ICE2HS01G

Power Management & Supply

Never stop thinking.

Page 2

Edition 2011-07-06

Published by Infineon Technologies Asia Pacific,

168 Kallang Way,

349253 Singapore, Singapore

© Infineon Technologies AP 2010.

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as a guarantee

of characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement,

regarding circuits, descriptions and charts stated herein.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types

in question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express

written approval of Infineon Technologies, if a failure of such components can reasonably be expected to

cause the failure of that life-support device or system, or to affect the safety or effectiveness of that device or

system. Life support devices or systems are intended to be implanted in the human body, or to support

and/or maintain and sustain and/or protect human life. If they fail, it is reasonable to assume that the health

of the user or other persons may be endangered.

Page 3

Design Guide for LLC Converter with ICE2HS01

Revision History: 2011-07 V1.0

Previous Version: NA

Design Guide for LLC Converter with ICE2HS01G

License to Infineon Technologies Asia Pacific Pte Ltd A N - P S 0057

Liu Jianwei

Li Dong

Page 4

Page

Table of Content

Abstract ............................................................................................. 5

1

2 Design Procedure ............................................................................ 5

2.1 Target Specifications .................................................................................................................... 5

2.2 Design of Power Stage ................................................................................................................. 6

2.2.1 System specifications ...................................................................................................................... 6

2.2.2 Selection of resonant factor m ........................................................................................................ 6

2.2.3 Voltage gain .................................................................................................................................... 7

2.2.4 Transformer turns ratio .................................................................................................................... 7

2.2.5 Effective load resistance ................................................................................................................. 7

2.2.6 Resonant network ........................................................................................................................... 7

2.2.7 Transformer design ......................................................................................................................... 9

2.2.8 SR MOSFET ................................................................................................................................. 10

2.3 Design of Control Parameters and Protections ....................................................................... 10

2.3.1 Frequency setting: ......................................................................................................................... 10

2.3.2 Minimum/Maximum frequency setting: ......................................................................................... 10

2.3.3 Frequency setting for OCP: ........................................................................................................... 11

2.3.4 Dead time ...................................................................................................................................... 12

2.3.5 Softstart time, OLP blanking time and auto-restart time ............................................................... 13

2.3.6 Load pin setting ............................................................................................................................. 13

2.3.7 Current sense ................................................................................................................................ 13

2.3.8 VINS pin setting ............................................................................................................................ 15

2.3.9 Latch off function and burst mode selection ................................................................................. 15

2.4 Design of Synchronous Rectification (SR) control ................................................................. 16

2.4.1 On-time control - SRD pin and CL pin .......................................................................................... 18

2.4.2 Turn-on delay

- Vres pin ................................................................................................. 20

delayonT_

2.4.3 Advanced Turn off delay

2.4.4 A review of the control scheme ..................................................................................................... 21

2.4.5 SR Protections .............................................................................................................................. 22

2.5 Design summary ......................................................................................................................... 22

- Delay pin .............................................................................. 21

delayoffT_

3 Tips on PCB layout ........................................................................ 24

3.1 Star connection for Power stage ............................................................................................... 24

3.2 Star connection for IC ................................................................................................................. 25

Application Note 4 2011-07-06

Page 5

1 Abstract

ICE2HS01G is our 2nd generation half-bridge LLC controller designed especially for high efficiency with its

synchronous rectification (SR) control for the secondary side. With its new driving techniques, SR can be

realized for half-bridge LLC converter operated with secondary switching current in both CCM and DCM

conditions. No individual SR controller IC is needed at the secondary side.

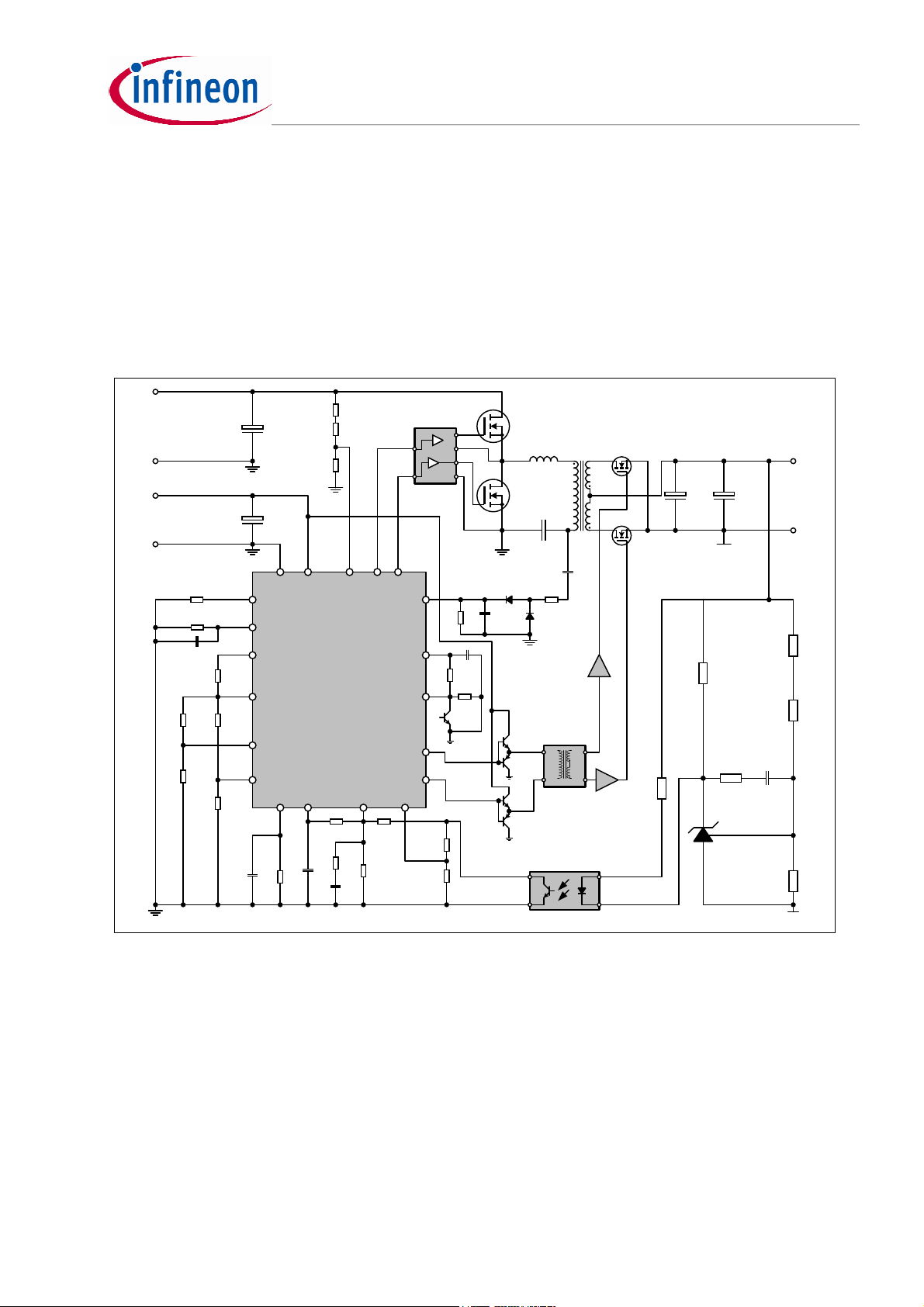

A typical application circuit of ICE2HS01G is shown in Figure 1. For best performance, it is suggested to use

half-bridge driver IC in the primary side with ICE2HS01G.

R

HV

VCC

C

BUS

INS1

R

INS2

R

INS3

HV IC

C

VCC

Q

PH

L

res

Q

PL

C

RES

Q

SH

CO1C

O2

Q

SL

V

out

C

HG LG

R

delay

R

EnA

C

EnA

R

TD

R

R

mc1

R

mc2

GND

Delay

EnA

TD

ICE2HS01G

V

ref

res1

V

mc

V

res

R

res2

C

T

C

R

T

VINSVCC

CS

CL

SRD

SHG

SLG

LOADFREQSSTimer

R

R

SS1

SS

C

SS1

OCP

R

reg

R

FMIN

R

R

CL

Q

SRD

R

FT1

R

FT2

CS2CCS2

C

CL

R

SRD

D

CS1

R

CS1

CS1

D

CS2

R

OVS1

R

IC Driver

Pulse

Trans.

Q

S1

Q

S2

R

Q

S3

Q

S4

IC Driver

OPTO

BA1

BA2

TL431

R

OVS2

C

oc

R

oc

R

OVS3

Figure 1 Typical application circuit

In this application note, the design procedure for LLC resonant converter with ICE2HS01 is presented,

together with an example of a 300W converter with 400VDC. Detailed calculation of the values of the

components around the IC is also included, together with tips on the PCB layout.

2 Design Procedure

2.1 Target Specifications

Application Note 5 2011-07-06

Page 6

The design example is based on the typical application circuit in Figure 1, where individual resonant

choke is implemented. The target specifications are summarized in Table 1.

Input voltage

Output voltage and current

Output power

Efficiency η

Resonant frequency

Hold up time

Bulk capacitor

Table 1 Target application specifications

V

in

P

T

h

C

IV ,

oo

in

f

r

out

2.2 Design of Power Stage

400VDC

12VDC, 25A

~ 300W

>96% at 100% load

>97% at 50% load

>96% at 20% load

85kHz

20ms

270uF

2.2.1 System specifications

The maximum input power can be calculated as:

P

in

Based on the required 20ms hold-up time, the minimum input voltage can be given as:

*

IV

OO

η

VV

25*12

===

96.0

2

2

_min_

nominin

C

out

W

5.312

3

TP

hin

400

2

10*270

−

10*20*5.312*2

6

−

=−=−=

V

2.337

[1]

[2]

2.2.2 Selection of resonant factor m

L

In order to achieve the highest efficiency possible, the value of resonant factor

be set as big as possible, so that the magnetizing inductance

is small, which results in low core loss and conduction loss. On the other hand, the magnetizing current

should be big enough to discharge the

ZVS to ensure safe switching and save switching loss. In this design example,

start. The ZVS of primary side MOSFET will be confirmed later with the determination of the deadtime of

switching.

C of primary side MOSFET during the transitions, to realize

ds

L is big and therefore magnetizing current

m

m

p

== is to

L

r

13=m is selected as a

LL

+

rm

L

r

Application Note 6 2011-07-06

Page 7

=

=

2.2.3 Voltage gain

It is for efficiency optimization to operate the LLC converter around the resonant frequency at nominal

input voltage, where the voltage gain

is neglected due to the implementation of individual resonant choke.

The worst case we need to consider for resonant network and transformer design is the full load

operation at minimum input voltage

M , on condition that the secondary-side leakage inductance

V . The maximum voltage gain at

1

nom

min_in

V can be calculated as:

min_in

V

nomin

_

M [3]

max

V

M

in

nom

min_

400

19.11*

===

2.337

2.2.4 Transformer turns ratio

Assuming the drain-source voltage drop of secondary-side MOSFET VV

ratio will be:

V

_

=

n [4]

nomin

)(2

+

VV

fo

M

nom

=

400

5.161*

=

)1.012(*2

+

1.0

f

, the transformer turns

2.2.5 Effective load resistance

The effective load resistance can be given as:

V

2

eff

nR

2

88

o

I

2

ππ

o

12

2

*5.16*

Ω=== 106

[5]

25

2.2.6 Resonant network

L

Q =

r

C

r

R

eff

f

Defining the normalised frequency to

the voltage gain of the converter can be written as:

2

),(

=

QFMj

)1(

−

mF

22

F = , the load factor of the LLC converter is

f is

r

−−+−

f

r

[6]

QmFjFmF

)1)(1()1(

,

Its magnitude is:

22

)),(Im()),(Re(),( QFMjQFMjQFG += [7]

The graph of voltage gain

Application Note 7 2011-07-06

G Vs F for different Q can be plotted based on [7] with Mathcad:

Page 8

=

=

=

1.5

1.413

GF0.22, ()

GF0.267, ()

GF0.3, ()

GF0.35, ()

GF0.5, ()

GF0.65, ()

GF0.8, ()

Line

Figure 2 Voltage gain G Vs normalized frequency F

Among the curves, we find that the one with

1.325

1.238

1.15

1.063

0.975

0.888

0.8

0.2 0.35 0.5 0.65 0.8 0.95 1.1 1.25 1.4

Q can achieve the required peak gainpkG , which

267.0

F

is 8% higher than

pk

From the curve, the corresponding

Having found the proper

C

r

π

L

r

rp

M for design margin, i.e.

max

28.108.1

== MG

max

F can be located where 28.1

Q, we can calculate the

1

RfQ

***2

effr

π

1

Cf

*)*2(

uHmLL

690==

ππ

rr

min

35.0

C

L

,

and

r

nF

66

===

uH

53

L as follows:

r

1

3

106*10*85*268.0*2

1

===

9232

−

10*66*)10*85*2(

G is achieved.

p

[8]

[9]

2.2.6.1 Resonant choke design

The minimum rms voltage across the resonant network is:

inrmsin

min_min__

Then the corresponding rms current flowing through the resonant choke

22

===

VVV

79.1512.337*

ππ

pk

L

can be calculated as:

r

[10]

Application Note 8 2011-07-06

Page 9

=

+

=

=

Δ

I

rmsin

max__

The peak current is

η

__

P

in

V

*

rmsin

min__

AII

49.3*2.1

==

pkrpkocp

__

300

rmsrpkr

A

06.2

===

[11]

79.151*96.0

AII

91.2*2

==

. The OCP level is set with about 20% margin:

The actual leakage inductance (

shorted is around 13uH. Therefore, the inductance for the independent resonant choke is:

If a magnetic core with specs of RM10/PC95 is selected, where

to be 0.08T to reduce core loss, the minimum turns can be given as:

N

=

min

L

=−=

leakrchoker40_

IL

⋅

__

AB

⋅

minmax

LL

L ) measured at primary side with one of the secondary side winding

leak

uHLLL

90mmA

= , and

min_

e

6

−

pkrchoker

49.3*10*40

6

−

10*90*08.0

4.19

==

2

2.2.7 Transformer design

From Figure 2, the normalized frequency

. Accordingly the actual minimum frequency

pk

min

28.1=

3

kHzfFf

3010*85*35.0*

r

1

= . According to Faraday’s law:

t

2

f

min

===

G

The voltage across the primary winding can be calculated as

period is around:

F

min

35.0

has been located to achieve maximum gain

f is:

min

)(

VVnV

. The half switching cycle

fop

B

max

is selected

[12]

+

)(

VVn

fo

f

2

min

The minimum number of turns at primary side can be found:

N

Where

Then

N

The number of turns at primary side is selected as

calculated accordingly:

Application Note 9 2011-07-06

=

min

p

min

161mmAe= with PQ3230 core. TB 62.0

N can be calculated as:

minp

=

min

p

BAN

Δ=

ep

+

)(

VVn

fo

[13]

BAf

Δ

*2

e

2

)1.012(*5.16

+

63

−

62.0*10*161*10*30*2

33

=

is selected to avoid magnetic saturation.

N . The secondary side turns can be

33

min=p

Page 10

π

N

p

N

s

2.2.8 SR MOSFET

The voltage stress on the drain-source of the MOSFET is:

The RMS value of the current flowing through each MOSFET is:

_

2.3 Design of Control Parameters and Protections

2.3.1 Frequency setting:

2==

n

VVVV

fods

==

ormsd

4

2.242*)( =+=

AII

63.19

The IC internal circuit provides a regulated 2V voltage at FREQ pin. The effective resistance presented

between the FREQ pin and GND, determines the current flowing out of the FREQ pin, which in turn

defines the switching frequency.

Figure 3 shows the curve illustrating the relationship of Switching Frequency

Resistor

R connected between the FREQ pin and gound.

FREQ

FREQ Vs Effective

Figure 3

FREQ

Vs Effective Resistor

R

FREQ

2.3.2 Minimum/Maximum frequency setting:

Application Note 10 2011-07-06

Page 11

=

As discussed in section 2.2.7, the lowest switching

section, how the

Based on the definition of oscillator as in the datasheet and the external circuit around pin FREQ in

Figure 1, the minimum switching frequency will be achieved when pin SS is 2V (usually after softstart),

opto-coupler transistor is open and only

corresponding

for

R .

minF

The maximum operation frequency can possibly be seen when maximum input voltage, say 425V, is

applied, and the converter run in no load condition (

condition can be given as:

f

is actually set by the IC is explained.

min

R is connected to pin FREQ. For kHzf 30

R found from Figure 3 is 50kΩ. A standard value resistor of 51kΩ is selected

FREQ

f will be seen in full load operation at

min

minF

0

Q ), if burst mode is disabled. The gain in this

V . In this

= , the

min

min_in

V

_

nomin

max_

in

+−

max

RRR

//=

M

2

mF

2

−

mF

1

mMm

regeq

M [14]

min

V

From the gain equation, we get:

The corresponding normalized frequency

F

),(

= QM

QFG [15]

=

1

Therefore

For 180 kHz switching frequency, the corresponding equivalent resistance

according to Figure 3. Under no load normal operation, pin SS is already 2V after soft start, and collector

of opto-coupler transistor is pulled to ground, therefore

FMIN

The

R is calculated to be 8.8kΩ. A standard value resistor of 8.2kΩ is selected for the actual design.

reg

nom

−

min

400

94.01*

===

425

)1(

)1(

min

13.2

=

== .

)0(,

==

F can be found by:

max

kHzkHzFf 18085*

R at FREQ pin is 7.5kΩ

eq

2.3.3 Frequency setting for OCP:

Assuming the maximum rms current during over-current should be limited by the IC to 1.2 times the

maximum normal operation, i.e.

The corresponding impedance of the resonant network during over-current can be estimated as:

Z

During over-current, the load impedence is considered to be shorted, and thereofore the impedance of

the resonant network can be calculated as:

Application Note 11 2011-07-06

ocp

V

I

ocp

rmsinrmsocp

max___

rmsin

_

π

*2*

π

2*400

47.2*

LfjZ

rocpocp

π

===

Ω=== 73

1

Cfj

*2*

AII

47.206.2*2.12.1

[16]

π

rocp

−=+=

rocp

Lf

*2

1

Cf

*2

π

rocp

[17]

Page 12

kHzf

Solve the equation and find

R is 5kΩ according to Figure 3. According to the definition of over-current protection,

Then

Then

eq

RRR

//= ,

FMIN

R can be found as 5.6kΩ.

ocp

ocpeq

2.3.4 Dead time

The dead time selection should ensure ZVS of two primary-side MOSFET IPA60R199CP at maximum

switching frequency, where the magnetizing current to charge and discharge

magnetizing current at the end of each switching cycle can be calculated as:

ocp

250=

C is the minimum. The

ds

I

The required time to charge and discharge the

T

Then

=

min

mag

DEAD

R is around 270kΩ according to Figure 4.

TD

+

4

VC

innomds

I

mag

NVV

*)(

edsO

fL

ocpp

=

VC

22

innomds

I

mag

minmin

+

−

5.16*)1.012(

10*250*10*690*4

C is:

ds

12

−

288.0

=

36

400*10*160*2

ns

440

====

[18]

[19]

A

288.0

Figure 4

Application Note 12 2011-07-06

T Vs TDR

DEAD

Page 13

=

=

Ω

=

2.3.5 Softstart time, OLP blanking time and auto-restart time

According to the definition of the softstart of the IC in the datasheet, soft start is implemented by

sweeping the operating frequency from an initial high value until the control loop takes over. The softstart

time depends on a few components, such as the

20ms target rising time of the output voltage, the customer can start with

R , the value of

minF

and the value of

R

ocp

uFC

SS

2.2

.

C . For a

SS

The Timer pin is used to set the blanking time

RC parallel circuit,

OLP blanking time with

The restart time can be calculated as:

C andTR , are connected to this pin. Based on the definition in the datasheet, the

T

Ω= MRT1 and uFC

V

CRmsT

CRT

TTrestart

1ln(**20

TTOLP

V

TL

V

TH

TH

IR

*

BLT

T and restart time

OLP

1

T

66

−

can be calculated as:

525.0

ln(*10*10)ln(**

4

T for over load protection. The

restart

66

−

=−=−=

1ln(*10*10*100020)

ms

20301000*)

4

66

−

10*20*10

ms

240)

=−−=−−=

2.3.6 Load pin setting

One of the functions of the LOAD pin is to detect the over-load or open-loop faults. Once the voltage at this pin

is higher than 1.8V, IC will start internal and external timer and determine the entering of protection mode. The

resistor divider

bottom resistor

regulation.

overload happens. The reference voltage at frequency pin is 2V. Then the voltage at LOAD pin

V

We can find Ω= MR

pin.

= [20]

LOAD

R and

R connected to GND pin should be far bigger than the

As an example, assuming

R

FT

2

RR

+

FT

1

R should be designed properly to ensure OLP is functional as required. The

1FT

2FT

FTFT

21

2FT

MR

FT22

V

82.12*

=

2.0

. A small capacitor of 1nF is usually connected to decouple noise at LOAD

, the target voltage at Load pin is 1.82V when

R , in order not to affect normal

FMIN

2.3.7 Current sense

Application Note 13 2011-07-06

Page 14

π

π

Figure 5 Current sense circuit

Assuming capacitive current divider is adopted as current sense circuit. So

C ,e. g, around 100/rC , say 470pF.

than

200Ω.

r

R is normally of a few hundred Ω for filtering purpose, say

1cs

C is chosen to be far less

1cs

We can obtain the following equation considering

C

cs

= [21]

II

ocpC

cs

1

One major design criterion for the current sense is to ensure Over-Current Protection (OCP). Accordingly,

we can also obtain:

II

RC

where 0.8V is the OCP first level.

1

+

CC

rcs

1

*

==

21

cscs

22

R

C

cs

≈

I

8.0

2

cs

1

ocp

C

r

[22]

C and

1cs

C as current divider:

r

Then we get:

−

R

cs

2

8.0

*2

C

r

*

C

I

ocp

cs

1

8.0

ππ

*

47.2*2

9

10*66

−

12

10*470

[23]

Ω===

70

Rcs2 is chosen as 68Ω.

C is selected so that the current loop speed is fast enough and the ripple on CS pin is around 20% of

2cs

490

f

nF

1

min

.

the average value.

C

2

cs

1

fR

*

min2

cs

CR is around

22*cscs

1

==≈

3

10*30*68

Application Note 14 2011-07-06

Page 15

2.3.8 VINS pin setting

The minimum operation input voltage needs to be specified for LLC resonant converter with the Vins pin.

The typical circuit of mains input voltage sense and process is shown Figure 6.

Figure 6 Mains input voltage sense

The mains input voltage is divided by

connected between VINS and Ground, an adjustable hysteresis between the on and off input voltage can

be created as

Assuming the turn-on bus voltage

typically.The

R

INSH

= k

R

INSL

A standard resistor value for

The blanking time for leaving brown-out is around 500μs and for entering brown-out is around 50μs.

Please note that the calculation above is based on typical specification values of the IC.

=

RIV *=

INSHhyshys

R and

INSH

−

VV

INoffINon

I

INS

RV

INSHth

=

−

VV

thinoff

R can be calculated as:

INSL

=

−

10*10

−

R is 24kΩ.

INSL

R and

INSH

V is 380V typically and the turn-off bus voltage

INon

320380

−

10*6*25.1

M

6

6

6

25.1320

R . With the internal current source

INSL

Ω=

Ω=

5.23

I is

hys

V is 320V

INoff

[24]

[25]

[26]

2.3.9 Latch off function and burst mode selection

Internally, the EnA pin has a pull-up current source of 100μA. By connecting a resistor outside from this

pin to ground, certain voltage level is set up on this pin. If the voltage level on this pin is pulled down

below certain level during operation, IC is latched. If the external resistor has a negative temperature

coefficient, this pin can be used to implement over- temperature protection (OTP). In this design,

selected at 1MΩ to set the pin voltage to be 2V level and no OTP is designed.

Application Note 15 2011-07-06

R is

EnA

Page 16

=

In addition to the latch-off enable function, this pin is also built for the selection of burst mode enable or

not during

LOAD pin voltage falls below 0.12V. However, if burst mode is not selected, the gate drives will not be

stopped by LOAD pin voltage.

The selection block works only after the first time IC VCC increases above UVLO. After CVCC is higher

than turn on threshod, a current source

C . After 26μs, IC will compare the voltage on EnA pin and 1.0V, if voltage on EnA pin is higher than

EnA

1.0V, the burst mode function will be enabled. As the voltage on EnA pin depends on

selecting different capacitance value, whether this IC works with burst mode can be decided.

With

Therefire burst mode will be enabled. If

mode will be disabled.

After the selection is done, the current source

IC starts to sense the EnA pin voltage latch off enable purpose. This blanking time is used to let the EnA

pin votlage be stablized to avoid mistriggering of Latch-off Enable function.

configuration before softstart. If the burst mode is enabled, the gate drives will be disabled if

1 and nFC

EnA

I , in addition to the

sele

Ω= MR

EnAseleEnA

1= , the voltage at EnA pin at the time of 26us can be calculated as:

EnA

6

−

10*26

−

RC

−

C is set to be 10n F, thus burst

EnA

I is turned off. A blanking time of 320μs is given before

66

sele

I , is turned on to charge the capacitor

EnA

R and

EnA

6

−

10*26

−

96

−

10*10

EnA

VVeeRIV

0.156.2)1(*10*10*100)1(*

>=−=−=

usVVV

26@0.126.0 <

C , by

EnA

2.4 Design of Synchronous Rectification (SR) control

Synchronous Rectification (SR) in a half-bridge LLC resonant converter is one of the key factor to achieve

high efficiency. SR control is a major benefit we offer with our new LLC controller IC ICE2HS01G.

Before going into details of SR control of the IC, it’s necessary to understand the ideal SR switching

mechanism for two typical working conditions, i.e. when operation frequency(

and above the resonant frequency (

gate),

V (primary low side gate),

LG

I (current flowing through secondary high side MOSFET),SLI ( current flowing through secondary low

SH

side MOSFET) and

I (current flowing through primary resonant tank).

PRI

f >

f ).Figure 7 illustrates the waveforms of

sw

r

V ( secondary high side gate),

SHG

V (secondary low side gate),

SLG

f ) is below (swf <

sw

V (primary high side

HG

f )

r

Application Note 16 2011-07-06

Page 17

Figure 7 Waveforms for LLC converter with

It can be seen from the waveforms in Figure 7 (left) that to ensure safe switching, the switch-on of the SR

MOSFET (see

while switch-off of the SR MOSFET(see

side switch(see

actual MOSFET. In this operation condition (

depends on the primary gate switching frequency.

From Figure 7 (right), the current flowing through the SR MOSFET (see

switch-off of the primary switch. To avoid the current going into negative, the SR MOSFET need to be

turn off just before the current goes to zero. In this condition, the SR MOSFET on-time is almost constant

and nearly half of the resonant period.

The control of SR in ICE2HS01G consists of four main parts: on-time control, turn-on delay, advanced

turn-off delay and protections, with the block diagram shown in Figure 8.

V ) need to be a certain time AFTER the switch-on of the primary side switch(seeLGV );

SLG

V ) needs to be certain time BEFORE the switch-off of primary

SLG

V ), in order to compensate the propagation delay of the gate signals from IC to the

LG

f >

f (left) and

sw

r

f >

f ), the SR MOSFET conduction period (on-time)

sw

r

f <

f (right)

sw

r

I ) goes to zero before the

SL

Application Note 17 2011-07-06

Page 18

Figure 8 Synchronous rectification control block diagram

2.4.1 On-time control - SRD pin and CL pin

With ICE2HS01’s control scheme, SR MOSFET ‘s turning-off depends on two conditions - turning-off of

the primary gate and the “off” instruction from SR on-time block, where the maximum on-time

preset. Whichever “off” instruction comes first will trigger the turn-off of the SR MOSFET.

As illustrated in the previous chapter, the

converter operates below resonant frequency (

and the SR gate turn-on delay

a safe value as below:

T

on

To achieve higher efficiency, a bigger

MOSFET conduction time and less body diode conduction time, which reduces conduction loss. In actual

design,

switching is guaranteed.

1

f

2

res

T can be fine-tuned by looking at the similar waveforms in Figure 7, as long as safe

max_on

delayonDEAD

_max_

T depends on the resonant frequency when LLC

max_on

f <

f ). Considering the primary side dead time

sw

r

( will be discussed later section 2.4.2), we can preset

delayonT_

usTT

31.525.032.088.5

=−−=−−< [27]

T is an advantage, because bigger on-time means longer SR

max_on

T is

max_on

T

DEAD

T with

max_on

Application Note 18 2011-07-06

Page 19

=

From Figure 9 below,

should start with a smaller SR on time for safety and then adjust it to achieve higher efficiency.

R is selected to be 66kΩ to achieve usT

SRD

31.5

on

max_

. Usually customer

Figure 9 SR on time versus SRD resistance

A simple constant on time control does not provide the best efficiency of LLC HB converter for the whole

load range. In fact, the actual resonant period of secondary current reduces when the output load

decreases or input voltage increases. The primary winding current can reflects this change. The current

sense circuit can be designed to get such information and input to CS pin. In ICE2HS01G, a function

called current level (CL) pin is implemented. During heavy load and low input voltage, the CL pin voltage

(

V ) is clamped at same voltage of SRD pin, 2V. Therefore, the SR on time in such conditions is

CL

determined by

V is reduced to be lower than 2V and extra current will be drawn from SRD pin, thereby the actual SR

CL

on time is reduced. The relationship between

R only and is equal to

SRD

T . In case of light load, with low CS voltage(CSV ), the

max_on

V and CLV is shown in Figure 10(top). The resistorCLR

CS

can be adjusted to find the suitable reducing speed of SR on time for either better reliability or better

efficiency.

calculation for the 300W design example:

We obtain the

V

cs

The corresponding

R is normally around 10 times

CL

R , which is 680kΩ in this design. Below is the detailed

SRD

V for full load condition, based on the circuit in Figure 5:

CS

12

*2

IR

rmsincs

V is clamped at 2V according to Figure 10(top) and the SR on time is

CL

C

max__2

1

cs

*

C

r

06.2*68*2

*

ππ

−

10*470

===

9

−

10*66

V

635.0

T .

max_on

Then for

V = 0.4V where CLV is exactly 2V, the corresponding load is 63% of the full load, which is

CS

around 16A output current(Figure 10, bottom).

Application Note 19 2011-07-06

Page 20

=+=

With

V < 0.4V, CLV starts to drop below 2V, extra current is drawn from SRD pin, thereby the actual

CS

SR on time is reduced with the load decreased.

For filter purpose,

C is chosen to be 47nF.

CL

Figure 10 SR on time versus SRD resistance

2.4.2 Turn-on delay

When the input voltage is higher than resonant voltage, the LLC converter secondary switches are

working in CCM condition. Certain recovery time of the SR MOSFET body diode is required depending on

the current to turn-off. For better performance, the other SR MOSFET should be turn on after the

recovery phase. The turn-on delay function is built in ICE2HS01G for such purpose. When the sensed

input voltage at VINS pin is higher than the reference voltage set by Vres pin according to the resonant

voltage, SR turn-on delay is added, i.e, the SR MOSFETs are turn on 250ns after the corresponding

primary MOSFETs are turned on.

- Vres pin

delayonT_

The nominal bus voltage at resonant point is:

VVVnV

+=

The corresponding voltage at VINS pin is 1.59V. To allow the turn-on delay for input voltage above this

resonant point, we can set the voltage divider

select

operation, we can set the voltage at

and

res

res121

2

2.6

fOres

R and

Ω= kR

, and

R can be calculated to be 5.2kΩ. To disable the turn-on delay during normal

2res

V to be 1.07x1.59=1.7V. Accordingly, Ω= kR

res

Ω= kR

.

3.399)1.012(*5.16*2)(*2

R connected at VRES pin accordingly. We

1res

2res

res121

[28]

,

Application Note 20 2011-07-06

Page 21

Ω

=

2.4.3 Advanced Turn off delay

- Delay pin

delayoffT_

Advanced turn-off delay time of the SR MOSFET

, normally is determined by the propagate

delayoffT_

delay and transition time in the actual converter system. The value of

pin. For example, if the delay time required is 220ns, a

33 need to connect at Delay pin

delay

according to the curve below.

can be set by the Delay

delayoffT_

kR

Figure 11 Turn-off delay time versus Rdelay

2.4.4 A review of the control scheme

After all the SR related parameters have been set, such as maximum on-time

delay

for the two conditions when

From the waveforms on the left, the switch-on of the SR MOSFET is

, advanced turn-off delay

delayonT_

f >

sw

f and

r

, simplified typical waveforms can be drawn in Figure 12

delayoffT_

f <

f .

sw

r

after the switch-on of the

delayonT_

primary side switch; while switch-off of the SR MOSFET is in advance with

primary side switch. Under this operation condition, the SR MOSFET’s on-time changes with the primary

side MOSFET gate switching.

From the waveforms on the right, the SR MOSFET on-time is almost constant and equal to

which is independent of the primary side MOSFET turn-off.

In actual operation, the

signal comes first – the turning-off of the primary gate, or the falling edge of

f doesn’t have to be monitored. SR MOSFET will be turned off by whichever

sw

T .

max_on

T , turn-on

max_on

to the switch-off of

delayoffT_

T ,

max_on

Application Note 21 2011-07-06

Page 22

Figure 12 Waveforms for LLC converter with

f >

sw

f (left) and

r

f <

sw

f (right)

r

2.4.5 SR Protections

As the SR control in ICE2HS01G is realized with indirect method, there are some cases that the SR can

not work properly. In this cases, the SR gate drive will be disabled. Once the condition is over, IC will

restart the SR with SRSoftstart.

During softstart, the SR is disabled.When the softstart pin voltage is higher than 1.9V for 20ms, SR will be

enabled with SRSoftstart.

When LOAD pin voltage is lower than 0.2V, IC will disable the SR immediately. If LOAD pin voltage is

higher than 0.7V, IC will resume SR with SRSoftstart.

During over-current protection phase, if the softstart pin voltage is lower than 1.8V, SR will be disabled.

The SR will resume with softstart 10ms after SS pin voltage is higher than 1.9V again.

In over-current protection, if the CS pin voltage is higher than 0.9V, SR is disabled. SR will be enabled

with SRSoftstart after CS pin voltage is lower than 0.6V.

All the above four conditions are built inside the IC. If IC detects such a condition, IC will disable SR and

pull down the voltage on SRD pin to zero.

When the CS voltage suddenly drops from 0.55V to below 0.30V within 1ms, the SR gate is turned off for

1ms, after 1ms, SR operation is enabled again with SRsoftstart.

If some fault conditions are not reflected on the four conditions mentioned above but can be detected

outside with other measures, the SR can also be disabled and enabled with softstart from outside. This is

implemented on SRD pin as well. The internal SRD reference voltage has limited current source

capability. If a transistor QSRD is connected as shown in typical application circuit, the voltage on SRD

pin can be pulled to zero if this transistor is turned on, which will stop the SR. If the SRD voltage is

released and increases above 1.75V, SR is enabled with softstart.

2.5 Design summary

Figure 13 and 14 show the final schematic for the power stage and control circuit for the 300W LLC

converter.

Application Note 22 2011-07-06

Page 23

C103

2n2/Y1

TR100

PQ3230

R114

430R

R115

430R

S_L G

R123

2k2

ZD100

5V1

ZD101

5V1

SGND

R107

1R0

IC300

GNDNCVDD

INB OUT B

UCC27324_1

S_L D

12V

S_HG

OUTAINA

R108

10k

ZD102

9v1

C109

0m47/16V

C115

100p

R117

3k9

+

C116

100n

C120

NC

S_HD

S_HS

C110

0m47/16V

R118

56R

C117

10n

12V

C111

+

+

0m47/16V

S_PGND

R119

11k

R120

3k01

R125

3k6

R102

1R0

C107

0m47/16V

Q103

015N04

NC

C122

100n

R116

560

+

C119

1u

S_HG

S_L G

S_L S

12V

+

23

R103

10k

0m47/16V

C108

12V

+ C121

10u

C114 47n

R124

NC

1

IC101

TL431

Q101

015N04

+

P_VBUS

P_PGND

P_VCC

P_SGND

RT100 5R

+

C104

10u/25V

C100

270uF/450V

C105

100n/25V

+

P_VCC

P_SGND

P_SL G

P_HG

P_HS

P_VCr

P_PL G

P_PGND

C112

100n

P_SHG

P_Vre g

R109

10R

R110

10R

R100

10R

R104

10R

R111

NC

C118

1n0

R112

NC

R101

10k

R105

10k

Q104

BC546

Q105

BC557

4

3

Q100

IPA60R199CP

Q102

IPA60R199CP

Q107

BC546

Q106

BC557

C113

1u0

IC100

SFH617A-3

L100

40uH//RM10

TR101

EE13

1

2

C102

33nF/630V

33nF/630V

D100

1N4148

D101

1N4148

C106

R121

0R

R122

R106

1k0

R113

1k0

820

Figure 13 Power stage circuit of the half-bridge LLC converter

J?

CON16R

R213

1M0

C209

1u

P_VBUS

1

P_GND

2

P_VCC

3

P_LS

4

NC

5

P_LG

6

P_Vreg

7

Reg GND

8

P_HS

9

P_HG

10

NC

11

P_VCr

12

NC

13

NC

14

P_SLG

15

P_SHG

16

P_Vreg

R205

0M2

C203

820p

R214

1M0

C210

1n0

R215

2M0

C211

2.2u

R207 8k2/1%

R206 5k6/1%

C212

NC

R216

51k/1%

R202

10R

C205

100n

P_VCC

R221

R222

12k

6k2

IC200

HINVCC LIN

GND

IC-ST-L6385

EnA

SS

LOAD

FREQ

Delay

TDCSSRD

Vref

Vres VINS

P_VBUS

IC201

R223

1M5/1%

R224

1M5/1%

R203

11k

R200

10R

R201

11k

C204

100n

R208

261k

NC

R219

0R

R220

R218

33k/1%

R217

NC

Figure 14 Control circuit of the half-bridge LLC converter

GND

VCCTi mer

SHG

SLG

C201

P_HG

100n

P_HS

OUT Vboot

P_LG

LVG HVG

P_VCC

C207

R210

680k

100n

R211

154k/1%

C213

10n

C206

47nF

R228

68R

C200

100n

C208

470p/1kV

R212

200R

D201

1N4148

1N4148

C214

470n

P_VCr

D202

HG

LG

CLVmc

R225

1M5/1%

R226

1M5/1%

P_SHG

P_SLG

R209

154k/1%

R227

24k

Application Note 23 2011-07-06

Page 24

3 Tips on PCB layout

In order to avoid crosstalk on the board between power and signal path, and to keep the IC GND pin as

“clean” from noise as possible, the PCB layout must be taken care of properly. Below are some

suggestions as reference and customer can modify based on their own experience.

3.1 Star connection for Power stage

1. Connect IC VCC Ecap ground to both buck cap. ground and IC VCC ground (please refer to

the red curves in the circuit diagram below)

2. Connect driver IC input ground to IC VCC Ecap ground

3. Connect driver IC output ground to low side MOS source with short path

4. A 100nF filtering cap should be located just near IC VCC & IC GND (refer to the purple arrow)

5. The 100nF filtering cap ground should be inserted between VCC Ecap ground and IC ground

6. Connect driver IC VCC to VCC Ecap(refer to the green curve)

7. Connect driver IC high side output source to half bridge midpoint directly with short path

8. A 100nF filtering cap should be located just near driver IC VCC and IC GND(refer to the blue

arrow)

shorted

Figure 15 PCB layout tips

Application Note 24 2011-07-06

Page 25

3.2 Star connection for IC

1. Connect the following ground directly back to Vcc 100nF cap ground (please refer to the red

curves in the circuit diagram below)

• FREQ pin resistor ground

• Delay pin resistor ground

• SRD resistor ground

R

2. Connetc the following ground with

• SS cap ground

• Opto-coupler ground

3. Connect SR pulse transformer and driving circuit ground to VCC Ecap ground(refer to the yellow

curve)

4. Put 100nF ceramic cap to driver supply (refer to the blue arrow)

5. Connect all other ground using ground plane or ground track back to IC VCC 100nF cap ground

or VCC E cap ground

ground(refer to the green curves)

minF

shorted

Figure 16 PCB layout tips

Application Note 25 2011-07-06

Page 26

References

[1] Infineon Technologies: ICE2HS01 - High Performance Resonant Mode Controller for Half-bridge

LLC Resonant Converter; datasheet Ver 2.0; Infineon Technologies; Munich; Germany; May. 2010.

Application Note 26 2011-07-06

Loading...

Loading...