Page 1

User Manual Please read the Important Notice and Warnings at the end of this document Revision 1.0

www.infineon.com page 1 of 37 2018-08-23

AN2018

-31 EVAL-M1-CTF620N3 User Manual

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design Kit

About this document

Scope and purpose

This user manual provides an overview of the evaluation board EVAL-M1-CTF620N3 including its main features,

key data, pin assignments and mechanical dimensions.

EVAL-M1-CTF620N3 is an evaluation board as part of the iMOTION™ Modular Application Design Kit. This power

board including a 3-phase CIPOS™ Tiny Intelligent Power Module (IPM) for motor drive application. In

combination with the control board equipped with the M1 20pin interface connector such as EVAL-M1-101T, it

features and demonstrates Infineon’s CIPOS™ Tiny IPM technology and Advanced Motion Control Engine (MCE

2.0) technology for permanent magnet motors drive over the full speed range.

This evaluation board EVAL-M1-CTF620N3 was developed to support customers during their first steps

designing applications with CIPOS™ Tiny IPM and running any permanent magnet motor via sensorless

sinusoidal control.

Intended audience

This user manual is intended for all technical specialists who know motor control and high power electronics

converter and this board is intended to be used under laboratory conditions.

Table of contents

About this document ....................................................................................................................... 1

Table of contents ............................................................................................................................ 1

1 Safety precautions ................................................................................................................. 3

2 Introduction .......................................................................................................................... 4

3 EVAL-M1-CTF620N3 main features ............................................................................................ 6

3.1 EVAL-M1-CTF620N3 board specifications ............................................................................................... 7

3.2 Pin assignment ........................................................................................................................................ 9

4 Getting Started with EVAL-M1-CTF620N3 ................................................................................. 11

4.1 Setting up the system............................................................................................................................ 11

4.2 iMOTION™ development tools and software ....................................................................................... 13

4.2.1 MCEWizard setup overview .............................................................................................................. 13

4.2.2 MCEDesigner setup overview .......................................................................................................... 15

5 Hardware description of EVAL-M1-CTF620N3 ............................................................................ 17

5.1 Inverter section using CIPOS™ Tiny IPM ............................................................................................... 17

5.1.1 DC bus sensing and MCEWizard configuration ............................................................................... 18

5.1.2 Motor External Current feedback configuration and calculation .................................................. 19

5.1.3 Inverter Overcurrent protection and Motor Gatekill configuration ............................................... 21

5.2 Thermistor/NTC Characteristics and protection calculation .............................................................. 22

5.2.1 CIPOS™ Internal NTC – Thermistor Characteristics ........................................................................ 22

5.2.2 Overtemperature Hardware Protection Circuit .............................................................................. 23

5.2.3 NTC shutdown value calculation and configuration ...................................................................... 24

5.3 Auxiliary power supply .......................................................................................................................... 25

Page 2

User Manual 2 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design Kit

Table of contents

5.4 Schematics for EVAL-M1-CTF620N3 ...................................................................................................... 26

5.5 PCB Layout for EVAL-M1-CTF620N3 ...................................................................................................... 28

6 Reference ............................................................................................................................. 35

Revision history............................................................................................................................. 36

Page 3

User Manual 3 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Safety precautions

1 Safety precautions

In addition to the precautions listed throughout this manual, please read and understand the following

statements regarding hazards associated with development systems.

Table 1 Precautions

Attention: The ground potential of the EVAL-M1-CTF620N3 system is biased to a negative

DC bus voltage potential. When measuring voltage waveform by oscilloscope, the scope’s

ground needs to be isolated. Failure to do so may result in personal injury or death and

equipment damage.

Attention: Only personnel familiar with the drive and associated machinery should plan

or implement the installation, start-up and subsequent maintenance of the system.

Failure to comply may result in personal injury and/or equipment damage.

Attention: The surfaces of the drive may become hot, which may cause injury.

Attention: EVAL-M1-CTF620N3 system contains parts and assemblies sensitive to

Electrostatic Discharge (ESD). Electrostatic control precautions are required when

installing, testing, servicing or repairing this assembly. Component damage may result if

ESD control procedures are not followed. If you are not familiar with electrostatic control

procedures, refer to applicable ESD protection handbooks and guidelines.

Attention: A drive, incorrectly applied or installed, can result in component damage or

reduction in product lifetime. Wiring or application errors such as under sizing the motor,

supplying an incorrect or inadequate DC supply or excessive ambient temperatures may

result in system malfunction.

Attention: Remove or connect the control board from or to the power drive. Wait three

minutes after removing power from the power drive to discharge the bus capacitors. Do

not attempt to service the drive until the bus capacitors have discharged to zero. Failure

to do so may result in personal injury or death.

Attention: EVAL-M1-CTF620N3 system is shipped with packing materials that need to be

removed prior to installation. Failure to remove all packing materials which are

unnecessary for system installation may result in overheating or abnormal operating

condition.

Page 4

User Manual 4 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Introduction

2 Introduction

The EVAL-M1-CTF620N3 evaluation power board is a part of the iMOTION™ Modular Application Design Kit for

motor drives (iMOTION™ MADK). In order to run a motor, the matching control board is required to interface

this power board.

The MADK platform is intended to use various power stages with different control boards. These boards can

easily be interfaced through the 20-pin iMOTION™ MADK M1 such as Eval-M1-101Tconnector to control board.

This board is equipped with 20-pin M1 connector and is intended for single motor control only.

This evaluation board is designed to give Easy-to-use power stage based on the Infineon's CIPOS™ Tiny

Inteligent Power Module (IPM). The board is equipped with all assembly groups for sensorless field oriented

control (FOC). It provides a single-phase AC-connector, rectifier and 3-phase output for connecting the motor.

The power stage also contains emitter shunts for current sensing and a voltage divider for DC-link voltage

measurement.

The EVAL-M1-CTF620N3 evaluation board has perfect compatibility, it is compatible with the DIP and SIP two

kind of packaging form and compatible with the different level of power CIPOS™ Tiny IPM. For example, if you

need to evaluate IM393-X6F/F, The evaluation board fully support to pin-to-pin assembly and power rating.but

if you need to evaluate IM393-S6E/F,IM393-X6F/F or IM393-L6E/F Tiny IPM, you can only do function test

evaluation and the power rating isn’t satisfied.

The EVAL-M1-CTF620N3 evaluation board is available through regular Infineon distribution partners as well as

on Infineon's website. The features of this board are described in the main features chapter of this document,

whereas the remaining paragraphs provide information to enable the customers to copy, modify and qualify

the design for production according to their own specific requirements.

Environmental conditions were considered in the design of the EVAL-M1-CTF620N3, but it is not qualified

regarding safety requirements or manufacturing and operation over the whole operating temperature range or

lifetime. The boards provided by Infineon are subject to functional testing only.

The block diagram of the EVAL-M1-CTF620N3 is depicted in Figure 1. This evaluation board includes an EMI

filter and soft power up circuit, 20 pins iMOTION™ MADK-M1 interface connector, auxiliary power supply to

provide 15V and 3.3V and the CIPOS™ Tiny IPM.

M

HVIC

20 pin iMOTION

TM

MADK-M1 connector

CIPOSTM Tiny IM393-X6F Inverter Section

Line

Neutral

15V

PWM

RFE

Itrip

PWM

VTH

GK

DCBsense

15V & 3.3V

Overcurrent and

Overtemperature

protection

Power

Supply

I_Shunt+

I_Shunt-

EMI Filter

& Soft

Power Up

Circuit

Figure 1 The Block Diagram of the EVAL-M1-CTF620N3

Page 5

User Manual 5 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Introduction

The hardware circuit regarding overtemperature and overcurrent protection is also included in this power

board. The sense connection to open emitter shunt resistor is connected to the 20 pins iMOTION™ MADK-M1

interface connector. This power board is compatible with 2 packages(DIP and SIP) of CIPOS™ Tiny IPMs that

feature Integrated Power Hybrid IC with Open Emitter pins and built-in high precision temperature monitor and

over-current protection feature, along with the short-circuit rated IGBTs and integrated under-voltage lockout

function, deliver high level of protection and fail-safe operation.

Evaluation boards are not subject to the same procedures as regular products regarding Returned Material

Analysis (RMA), Process Change Notification (PCN) and Product Discontinuation (PD). Evaluation boards are

intended to be used under laboratory conditions by technical specialists only.

Page 6

User Manual 6 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

EVAL-M1-CTF620N3 main features

3 EVAL-M1-CTF620N3 main features

EVAL-M1-CTF620N3 is an evaluation board for motor drive applications with 3 phase IPM. Combined in a kit

with one of the available MADK control board options, it demonstrates Infineon’s motion control IC and IPM

technology for motor drives.

Main features of CIPOS™ Tiny IPM IM393-X6F are:

• Integrated gate drivers and bootstrap function

• Temperature monitor

• Protection shutdown pin

• Low VCE(on) Trench IGBT technology

• Under voltage lockout for all channels

• Matched propagation delay for all channels

• 3.3V Schmitt-triggered input logic

• Cross-conduction prevention logic

• Isolation 2000V

RMS

min and CTI>600

• Recognized by UL(Pending)

The evaluation board characteristics are:

• Input voltage 160~265VAC

• Maximum 1200W motor power output

• Compatble with DIP and SIP

• On board EMI filter

• Current sensing with single shunt or leg shunt

• Auxiliary power supply with 15V, 3.3V

• Overcurrent protection

• Overtemperature hardware protection

• Sensing of DC-link voltage

• Thermistor output

• Fault diagnostic output

• Measurement test-points compatible to standard oscilloscope probes

• PCB is 121 mm × 120 mm and has two layers with 35μm copper each

• RoHS complaint

Page 7

User Manual 7 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

EVAL-M1-CTF620N3 main features

3.1 EVAL-M1-CTF620N3 board specifications

Table 2 depicts the important specifications of the evaluation board EVAL-M1-CTF620N3.

Table 2 EVAL-M1-CTF620N3 board specifications

Parameters

Values

Conditions

/ comments

Input

Voltage

165 - 265 V

rms

lower AC input, less motor power output

Input current

6.4A

rms

input 220 VAC, Ta=25°C, IM393

Output

Power (3phases)

1200 W

input 220VAC, f

PWM

=6 kHz, Ta=25°C,

Th=80°C(Refer to figure 2 curve)

Current per leg

6.8A

rms

input 220V

AC

, f

PWM

=6 kHz, Ta=25°C, Th=80°C

DC Bus Voltage

Maximum DC bus voltage

420 V

Minimum

DC bus voltage

120 V

Switching Frequency

Inverter switching frequency

f

PWM

20 kHz (max)

Current feedback

Inverter c

urrent sensing resistor

RS3,RS4,RS5

3

0 m

Ω

Protections

Output current trip level

1

14.7

A

peak

Configured by

changing pull up

resistor

R30. Temperature trip level

100°CFor controller board Eval

-M1-

101T

On board power supply

15 V

15 V±2

%, max

.500mA

Used for

CIPOS

™

IPM

gate driver

and LDO

3.3 V

3.3 V

±1%, max

.300mASu

pplying the 3.3V to the controller board

and

protection circuits

PCB characteristics

Material

FR4, 1.6mm

thickness, 2

layers.

35 µm copper thickness

Dimension

121mm x

120

mm

System environment

Ambient temperature

From 0 to 50°C

Non-condensing, maximum RH of 95 %

1

For iMOTION™ IC IMC1xx, there are three types of Gatekill Input Source (Refer to section 5.1.3 or control board user manual for

detail). Please note that, if select comparator for Gatakill Input Source, the external Gatakill signal will be not used. And the leg

I_Shunt will be compared by the internal comparator with the “Gatekill Comparator Reference” value set in MCEWizard only.

Page 8

User Manual 8 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

EVAL-M1-CTF620N3 main features

Figure 2 Show the relationship between Output Power and Heatsink Temperature.

Figure 2 The relationship between Output Power and Heatsink Temperature

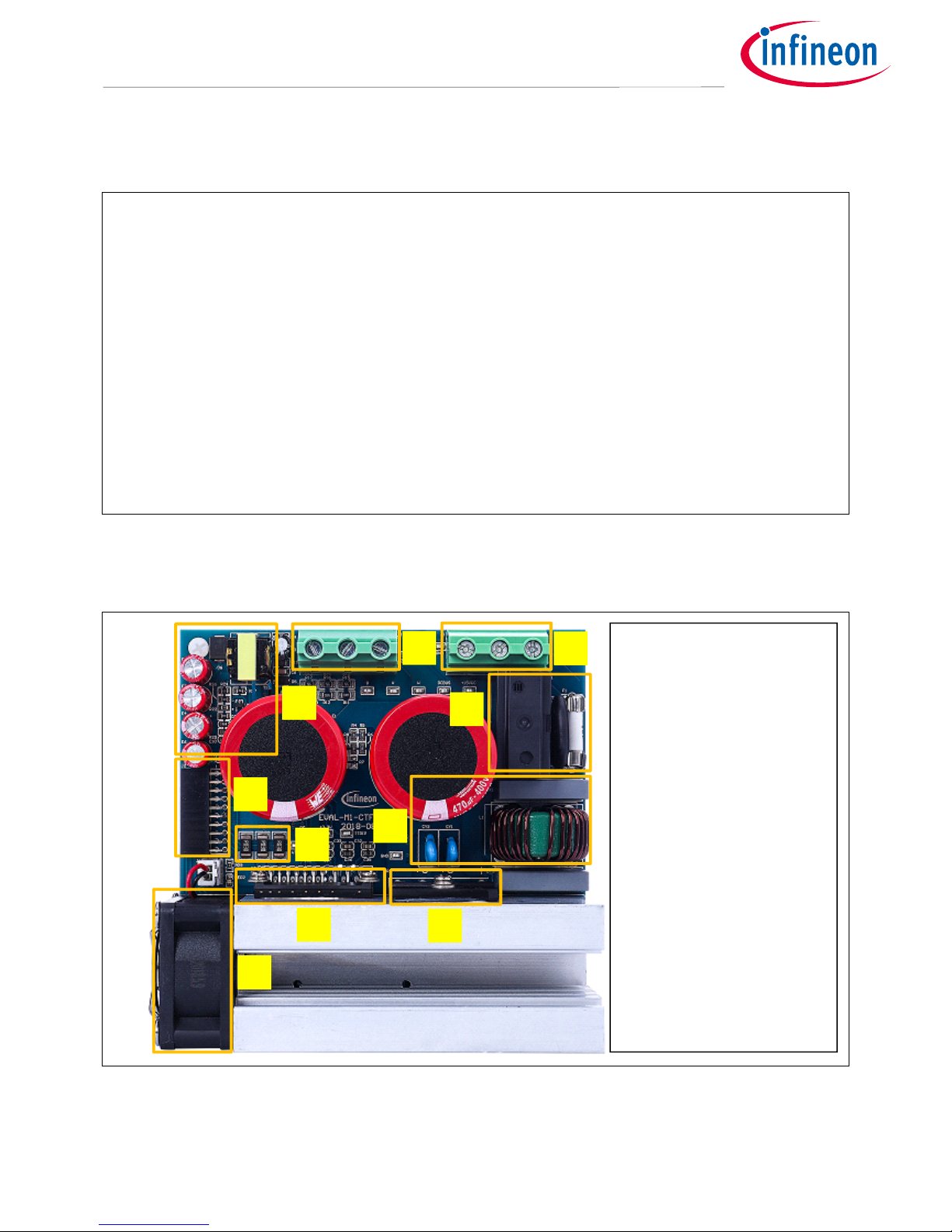

Figure 3 points out the functional groups on the top side of the EVAL-M1-CTF620N3 evaluation board.

Figure 3 Functional groups of the EVAL-M1-CTF620N3 evaluation board’s top side

1.J1-AC

Input

connector

2. J3 - Motor phase connector

3. Relay/NTC and FUSE

4. EMI filter

5. Rectifier Bridge

6. J2 - 20 pin iMOTION™ MADKM1 interface connector for

controller board

7. Current sensing shunt

resistor RS3, RS4, RS5

8. CIPOS™ Tiny IPM U7 (SIP)

9. T1-Auxiliary power supply

transfomer

10. Fan

1

2

3

4

5

6

789

10

Page 9

User Manual 9 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

EVAL-M1-CTF620N3 main features

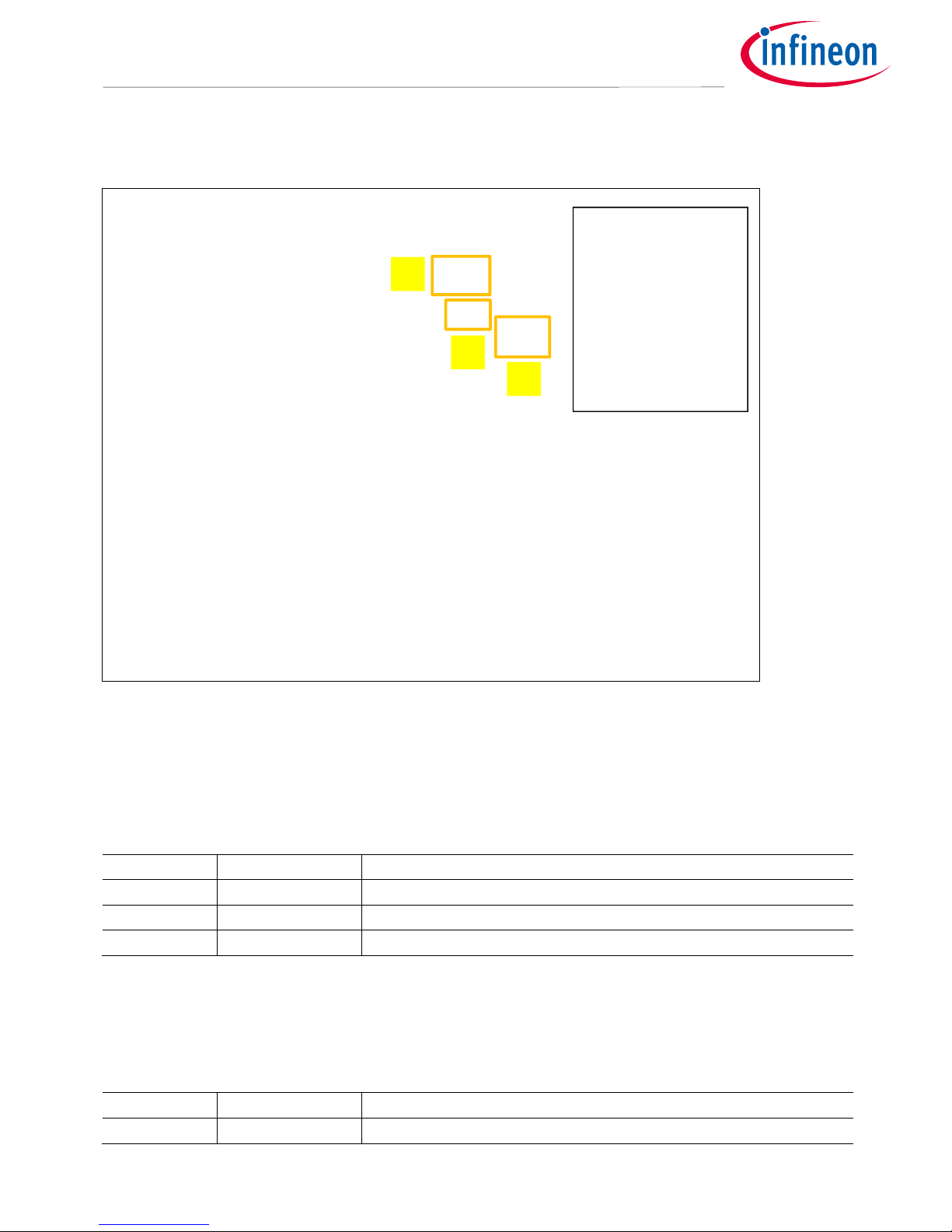

Figure 4 points out the functional groups on the bottom side of the EVAL-M1-CTF620N3 evaluation board.

Figure 4 Functional groups of the EVAL-M1-CTF620N3 evaluation board’s bottom side

3.2 Pin assignment

General information about the connectors of the EVAL-M1-CTF620N3 evaluation board is reported. Table 3

includes the details of the AC input connector J1.

Table 3 J1- AC Line connector

S. No. Pin Details

1 Line AC line input

2 Neutral AC neutral input

3 Earth Earth ground

Table 4 provides the pin assignments of the 20 pins iMOTION™ MADK-M1 interface connector J2. This connector

is the interface to the controller board.

Table 4 J2 - iMOTION™ MADK-M1 20 pin interface connector for controller board

Pin Name Pin Name Connectors

1 PWMUH 3.3 V compatible logic input for high side gate driver-Phase U

11.ICE5GR4780AG U1

12. Auxiliary power

supply Current

sensing shunt

resistor RS1, RS2

13. IFX1117MEV33H U3

12

11

13

Page 10

User Manual 10 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

EVAL-M1-CTF620N3 main features

2 GND Ground

3 PWMUL 3.3 V compatible logic input for low side gate driver-Phase U

4 GND 4 GND Ground

5 PWMVH 3.3 V compatible logic input for high side gate driver-Phase V

6 +3.3V On board 3.3 V supply

7 PWMVL 3.3 V compatible logic input for low side gate driver-Phase V

8 +3.3V On board 3.3 V supply

9 PWMWH 3.3 V compatible logic input for high side gate driver-Phase W

10 I_U Positive Current sense output

11 PWMWL 3.3 V compatible logic input for low side gate driver-Phase W

12 I_U- Negative current sense output or Ground

13 GK Gate kill signal – active low when overcurrent is detected

14 DCBSense DC bus positive voltage, scaled in 0-3.3 V range by a voltage divider

15 VTH Thermistor Output

16 I_V Positive Current sense output

17 I_V- Negative current sense output or Ground

18 I_W Positive Current sense output

19 I_W- Negative current sense output or Ground

20 VCC 15 V Power Supply

Table 5 provides the details of the motor side connector J2.

Table 5 J2 - Motor side connector

S. No. Pin Details

1 U Connected to motor phase U

2 V Connected to motor phase V

3 W Connected to motor phase W

Table 6 provides the details of the Fan connector J4.

Table 6 J4 – Fan Connector

S. No. Pin Details

1 15V Connected to 15V

2 GND Connected to Ground

Page 11

User Manual 11 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Getting Started with EVAL-M1-CTF620N3

4 Getting Started with EVAL-M1-CTF620N3

In order to run the motor system, a combination of the iMOTION™ MADK power board (EVAL-M1-CTF620N3) and

the matching MADK control board is required. The iMOTION™ Software Tools MCEDesigner and MCEWizard are

also required in order to initialy setup the system, as well as to control and fine-tune the system performance

to match users exact needs. This chapter provides more details on setting up the system and getting started

with iMOTION™ MADK development platform.

4.1 Setting up the system

After downloading and installing the iMOTION™ PC Tools (MCEWizard and MCEDesigner), following steps needs

to be executed in order to run the motor. Refer to user manul for iMOTION™ MADK control board such as (EVALM1-101T), MCEWizard and MCEDesigner documentation for more information.

Figure 5 shows the system connection using EVAL-M1-CTF620N3 and control board (used control board EVALM1-101T for example).

Figure 5 System connection example using EVAL-M1-CTF620N3 and EVAL-M1-101T

1. Connect PC-USB connector on the on-board-debugger to the PC via USB cable.

2. Connect EVAL-M1-CTF620N3’s MADK M1 20-pin interface connector (J2) to control board (see Figure 5).

3. Get the latest “IMC101T-T038 MCE Software Package” available on www.infineon.com/imotion-software

web page. (Infineon iMOTION™ control IC IMC101T-T038 is used for control board EVAL-M1-101T).

4. Connect motor phase outputs to the motor.

5. Use MCEWizard to enter the motor and evaluation board hardware parameters and click button “Export to

Designer file (.txt)” to system drive parameters file which will be used by MCEDesigner.

6. Connect AC power to power input connector and power on system.

7. Open MCEDesigner and open MCEDesigner default configuration file (.irc) for IMC101T devices

(IMC101T_xx.irc) by clicking “File” menu and select “Open” in the pull down list.

AC Power

I

nput

Motor

P

hase

O

utput

s

PC-USB

C

onnector

Page 12

User Manual 12 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Getting Started with EVAL-M1-CTF620N3

8. Import system drive parameters file (generated in step 5) into MCEDesigner by clicking “File” > “Import Drive

Parameters”. Select “Update All” radio button.

9. Program the MCE Firmware and system parameters into the internal Flash memory of iMOTION™ IC by

clicking “Tools > Programmer “in the pull down menu, and then clicking on the “Program Firmware and

Parameter” radio button. See chapter MCEDesigner setup overview setion 4.2.2 for more details. If the latest

version of MCE firmware is already programmed into the IMC101T-T038 IC, then programming firmware can

be skipped by selecting “Program Parameters” radio button option. Finally click “Start” button to program

firware and parameter (or parameters only when programming firmware was skipped).

10. Start the motor by clicking the green traffic light button in the control bar.

Page 13

User Manual 13 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Getting Started with EVAL-M1-CTF620N3

4.2 iMOTION™ development tools and software

The iMOTION™ Development Tool installers for MCEDesigner and MCEWizard are available for download via

Infineon iMOTION

TM

website (http://www.infineon.com/imotion-software). All the available tools and software

variants are listed there.

On-board debugger uses the SEGGER J-Link’s driver for UART communication with IMC101T-T038. J-Link driver

will be installed during the MCEDesigner installation. In case the driver is not installed properly, please go to

SEGGER J-Link website to download and install the latest J-Link “Software and Documentation pack for

Windows”.

4.2.1 MCEWizard setup overview

After installing the MCEWizard, the shortcut for MCEWizard appears on the Windows desktop. Double click the

shortcut to open the MCEWizard and configure the parameters for evaluation boards or motor. Figure 7 shows

the “Welcome Page” for MCEWizard, where the MADK control board or power board can be selected through

the pull-down list. Infineon keeps releasing new MADK controller and power boards. Therefore, it could happen

that some of the newest power boards are not pre-configured in the MCEWizard tool and cannot be selected

through the pull-down menu. In that case, the user should select any other power board (as similar as possible)

and follow the MCEWizard setup steps by entering the parameter values which are specific to the chosen board.

Make sure both “I have modified the circuit board” and “Enable advanced question” checkmarks are selected.

Please refer to the User Manual of the corresponding power board for additional information.

After selecting the MADK control and the power board, start the MCEWizard system setup procedure by clicking

the “Next” button in the right bottom corner as shown in Figure 7.

Figure 6 Welcome Page of MCEWizard

iMOTION™ MADK system enables users to easily test different combination of control and power board with

their motors. User should be familiar with the system level parameters which are related to the motor used.

There are very limited numbers of parameters which are specific to the control board or power board hardware.

Table 7 provides the MCEWizard setup overview for hardware related parameters. Similar tables will be

Page 14

User Manual 14 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Getting Started with EVAL-M1-CTF620N3

available in each power board’s User Manual. Combination of this table and the corresponding table of the

power board provides enough information to setup the MADK-based motor drive system in shortest time.

Table 7 MCEWizard setup overview table

Page Parameter Value Comment

Welcome Page Power Board selecting MADK power board name If no, select similar

power board to modify

Options Page Motor 1 Shunt Configuration 30mΩ

Question 3 Controller Supply Voltage Refer to control board user manual

Question 19 Max DC Bus Voltage 420V

Question 23 DC Bus Sensing High Resistor 2MΩ

Question 24 DC Bus Sensing Low Resistor Refer to control board user manual 13.3kΩ by default

Question 54

NTC Temperature Shutdown

value

Calculated as the Section 5.2.3

Refer to the control

board user manual

Question 63 GateSense Low-Side Devices High is true

Question 64 GateSense High-Side Devices High is true

Question 69 Motor 1 Current Input Calculated as the Section 5.1.2

After all the MCEWizard questions are answered, the “Verify & Save Page” will be shown as in Figure 7

Figure 7 Verify and Save page for MCEWizard

Click “Calculate” button and “Export to Designer File (.txt)” button to save the parameter file which will be used

by the MCEDesigner in the next steps.

Page 15

User Manual 15 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Getting Started with EVAL-M1-CTF620N3

4.2.2 MCEDesigner setup overview

After installing MCEDesigner installer, there is a shortcut for MCEDesigner on Windows desktop. Double click

the shortcut to open MCEDesigner and then open “IMC101T_xx.irc” file as shown in Table 7.

Figure 8 MCEDesigner’s Main Display for EVAL-M1-101T

To program system drive parameters into IMC101T-T038, please click “Tools” menu and select “Programmer”

in the pull down list. The pop-up window “Program IMC controller” will show up as in Figure 9. Click on the

“Program Parameters” radio button (this is the default option), and then select the Drive System Parameter file

created using MCEWizard by clicking on “Browse”. Finally, click on the “Start” button to program the parameter

file into the IMC101T-T038 IC.

Figure 9 “Program IMC Controller” pop-up window

Page 16

User Manual 16 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Getting Started with EVAL-M1-CTF620N3

After Drive System Parameter file has been programmed into IMC102 controller, and the motor drive system is

powered, the MCEDesigner can be used to start/stop the motor, display motor current traces, change the motor

speeds, modify drive parameters and many other functions. Please refer to the MCEDesigner documentation

for more details.

Note: On-board Debugger portion of EVAL-M1-101T is galvanically isolated from the controller portion

and the attached power board. In order to program the parameters or firmware to the IMC101TT038 controller, the 3.3V DC voltage needs to be supplied to the controller portion of the EVAL-M1101T. This voltage can either be supplied by the power board (MADK power boards are designed to

supply the 3.3V to the control board through M1 connector) or by feeding the 3.3V DC voltage to the

control board through some of the available 3.3V access/test points if the power board is not

attached to the EVAL-M1-101T control board.

To program new firmware and Drive System Parameter into IMC101T-T038, please click “Tools” menu and

select “Programmer” in the pull down list. The pop-up window “Program IMC controller” will show up as in

Figure 10. Click on the “Program Firmware and Parameter” radio button, and select the Drive System

Parameter file created using MCEWizard by clicking on the “Browse” button on the row of “Program Parameter

File”, and then select the firmware file by clicking on the “Browse” button on the row of “Program Firmware

File”. Finally, click on the “Start” button to program the parameter file into the IMC101T-T038 IC.

Figure 10 Program Firmware and Parameter in “Program IMC Controller” pop-up window

All latest firmware file for different type of iMOTIONTM control ICs are available for download via Infineon

iMOTION

TM

website (http://www.infineon.com/imotion-software).

Page 17

User Manual 17 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

5 Hardware description of EVAL-M1-CTF620N3

To meet individual customer requirements and make the EVAL-M1-CTF620N3 evaluation board a basis for

development or modification, all necessary technical data like schematics, layout and components are

included in this chapter.

5.1 Inverter section using CIPOS™ Tiny IPM

The inverter section is also implemented using the CIPOS™ Tiny IPM as sketched in Figure 11. This advanced

IPM is a combination of Infineon’s newest low VCE(on) Trench IGBT technology optimized for best trade-off

between conduction and switching losses and the industry benchmark 3 phase high voltage, high speed driver

(3.3V compatible) in a fully isolated thermally enhanced package. A built-in high precision temperature monitor

and over-current protection feature, along with the short circuit rated IGBTs and integrated under-voltage

lockout function, deliver high level of protection and fail-safe operation. Using a dual in line package with full

transfer mold structure resolves isolation problems to heatsink. The three pairs of capacitors C20 and C25, C21

and C26, C22 and C27 are used as bootstrap capacitors to provide the necessary floating supply voltages V

BS3

,

V

BS2

and V

BS1

respectively.

Figure 11 Schematic of the 3-phase inverter section using CIPOS™ Tiny IPM on EVAL-M1-CTF620N3

+15VCC

R29

0ohm 1/8W 5%

R31

3Kohm 1/8W 5%

GND

C25

10uF 25V

1

2

3

J3

Motor Output

RS3 30mohm 3W 1%

RS5 30mohm 3W 1%

RS4

30mohm 3W 1%

R37

4.87Kohm 1/8W 1%

C29

1nF 16V

GK

VTH

ITRIP

V+

1

VS3(W)

3

VB3(W)

4

VS2(V)

6

VB2(V)

7

VS1(U)

9

VB1(U)

10

VCC

12

VTH

13

VSS/COM

14

VSS/COM

15

ITRIP

16

RFE

17

HIN1(U)

18

HIN2(V)

19

HIN3(W)

20

LIN1(U)

21

LIN2(V)

22

LIN3(W)

23

VRW

24

VRV

25

VRU

26

VRU

27

VRV

28

VRW

29

U

30

V

31

W

32

V+

33

V+

35

U6

IM393-X6E

C30

0.1uF 630V

C20

0.1uF 25V

C31

0.1uF 630V

C23

470pF 16V

GND

PWMUH

PWMUL

PWMVH

PWMVL

PWMWH

PWMWL

GK

VTH

DCBSense

C18

0.1uF 16V

C15

0.1uF 16V

C17

0.1uF 16V

+3.3V

PWMUH

PWMUL

PWMVH

PWMVL

PWMWH

PWMWL

C26

10uF 25V

C21

0.1uF 25V

C27

10uF 25V

C22

0.1uF 25V

C28C24+15VCC

GND

GND

+3.3V

GND

R36 1Kohm 1/8W 1%

C16

4700pF 16V

C14

10uF 16V

R30 10Kohm 1/8W 1%

C19

4700pF 16V

R32 1Kohm 1/8W 1%

ITRIP

R28

1Kohm 1/8W 5%

+3.3V

C13

DNI

GNDGND

GND

R33

1Kohm 1/8W 1%

ITRIP: [(3.3V * 1/ 11)+0.12+0.02] / 0.03= 14.7A peak

D8 BAT60A

D9 BAT60A

D10 BAT60A

R34 1Kohm 1/8W 1%

R35 1Kohm 1/8W 1%

I_W+

I_V+

I_U+

If single shunt config is used,

remove both RS3 and RS4,

while insert RJ1=RJ2= 0ohm

RJ1 0ohm 1/2W 1%

RJ2 0ohm 1/2W 1%

I_W+

I_V+

I_U+

I_W+ I_V+

I_V+

I_W+

I_V+

UH

UL

VH

VL

WH

WL

WL

UL

VH

UH

WH

VL

GK

VTH

VTH

U_OUT

V_OUT

W_OUT

VS1

VS2

VS3

GND

DCBUS

UH1GND

2

UL3GND

4

VH5+3.3V

6

VL7+3.3V

8

WH9I_U+

10

WL11I_U-

12

GK13DCB

14

VTH15I_V+

16

I_V-17I_W+

18

I_W-19VCC

20

J2

CON MADK 20P

LED2

GREEN

GND

GND

I_UVW-

I_UVW-

I_UVWI_UVW-

I_U+

I_U+

1

W

1

V

1

U

1

VTH

1

GK

1

ITRIP

3

1

4

5 2

U5

LM397

+15VCC

GK

ITRIP

I_U+

I_V+

I_W+

I_W+

I_V+

I_U+

1

2

J4

Fan_CON

GND

+15VCC

Page 18

User Manual 18 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

5.1.1 DC bus sensing and MCEWizard configuration

Pin 14 and pin 26 of connector J2 provide access to the DC-link voltage DCBsense. Three possible feedback

cases are associated with these pins. Figure 12 provides the DC bus sense resistor details. By default, the

resistor R7 is not mounted on EVAL-M1-CTF620N3. There must be a pull-down resistor mounted on the

corresponding controller board.

Figure 12 DC bus sense resistor on EVAL-M1-CTF620N3 evaluation board

If a pull down resistor of 13.3 kΩ referred to ground is inserted either on the EVAL-M1-CTF620N3 evaluation

board or on the control board, the DCBSense voltage results in the range of 0 to 3.3 V on the pin reflecting a DC

bus voltage range of 0 to 420 V.If a pull down resistor of 13.3 kΩ is inserted on both, EVAL-M1-CTF620N3

evaluation board and on the control card, the DCBSense results scale to 0-1.65 V. No safety issue occurs. If no

feedback is desired on the DCBSense pin, R4, R5, R6 or R8 should be removed to avoid high voltage on the

connector.

The high side resistors R4, R5, R6 and R8 for the DC bus sensing resistor divider on the controller board EVAL-

M1-CTF620N3 are 2000kΩ, and should be configured in MCEWizard as shown in Figure 13. For the low side

resistor value, please refer to the User Manual of the corresponding control board.

GND

R4

500Kohm 1/8W 1%

R5

500Kohm 1/8W 1%

R6

500Kohm 1/8W 1%

R8

500Kohm 1/8W 1%

R7

DNI

DCBsense

C3

DNI

1

DCBUS

Page 19

User Manual 19 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

Figure 13 DC bus sensing configuration in MCEWizard

5.1.2 Motor External Current feedback configuration and calculation

The current input value is product of the shunt resistance in milliohms and gain of External current sense

amplifier for EVAL-M1-101T as shown in Figure 14.

Figure 14 Current shunt feedback and sample timing for EVAL-M1-101T

The External Amplifier Gain circuit can be found in the schematics or User Manual for the control board (For

example, EVAL-M1-101T see Figure 15).

Page 20

User Manual 20 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

Figure 15 depicts IU+ current feedback sensing circuity on EVAL-M1-101T evaluation board. Please note that the

default external amplification gain is less than 1 for current sense in this evaluation board.

Figure 15 The part of Current feedback on the EVAL-M1-101T evaluation board

Based on the principle of Kirchhoff's voltage law,

≈ ≈(− ∗

)

∗

+

+ ∗ =

+

+

+

∗

=

+

=

5

6

Based on this calculation, the current input for the MADK combination of EVAL-M1-101T and EVAL-M1CTF620N3 is 25mV/A.

Please use same procedure to calculate the current input for other combinations of MADK boards and enter it

into MCEWizard as shown in Figure 16.

Figure 16

Current feedback configuration in MCEWizard for EVAL-M1-101T and EVAL-M1-CTF620N3

R7

2k, 1%

C15

220pF

IU+

R6

10k, 1%

+3.3V

R8

100R

IU

6

iMOTION

Controller

Rsh

Current shunt

resistor on power

board

V2

Ish

V1

Page 21

User Manual 21 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

5.1.3 Inverter Overcurrent protection and Motor Gatekill configuration

Figure 17 displays the overcurrent protection circuitry. The current sensing signal I_Shunt is connected to ITRIP

via through the comparator U5, and ITRIP is filtered through capacitor C23.

Figure 17 Overcurrent protection circuit on the EVAL-M1-CTF620N3 evaluation board

The typical value of ITRIP positive going threshold V

IT, TH+

is 300mV. So the inverter output peak current is about

14.7Apeak.

=

∗

33

30 + 33

+

//

+

If the motor peak current larger than the setting value I

trip

for more than ITRIP Input filter time, RFE will be

trigger low which is mean that the signal Gatekill is active. For iMOTION™ IMC1xx control IC, there are three

types of Gatekill Input Source (as shown in Figure 18). For Gatekill Input Source configured Gatekill-Pin or Both,

iMOTION™ control IC will stop the Motor when the signal GateKill is active.

But please note that, if select comparator for Gatakill Input Source, the external Gatakill signal will be not used.

And the current sensing signal I_Shunt will be compared by the internal comparator with the “Gatekill

Comparator Reference” value set in MCEWizard only.

Figure 18 Gatekill configuration in MCEWizard for EVAL-M1-101T

R36 1Kohm 1/8W 1%

C16

4700pF 16V

C14

10uF 16V

R30 10Kohm 1/8W 1%

C19

4700pF 16V

R32 1Kohm 1/8W 1%

ITRIP

R28

1Kohm 1/8W 5%

+3.3V

C13

DNI

GNDGND

GND

R33

1Kohm 1/8W 1%

D8 BAT60A

D9 BAT60A

D10 BAT60A

R34 1Kohm 1/8W 1%

R35 1Kohm 1/8W 1%

I_W+

I_V+

I_U+

GND

I_UVW-

1

ITRIP

3

1

4

5 2

U5

LM397

+15VCC

I_W+

I_V+

I_U+

Page 22

User Manual 22 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

5.2 Thermistor/NTC Characteristics and protection calculation

This board provides Thermistor/NTC output on pin 15 of the 20 pins connector J2. Temperatures can be

calculated by resistor measurement.

5.2.1 CIPOS™ Internal NTC – Thermistor Characteristics

The thermistor characteristics for CIPOS™ Tiny IPM with build in NTC are listed as summarized in Table 8.

Table 8 CIPOS™ Internal NTC – Thermistor Characteristics

Description Condition Symbol

Value

Unit

min typ max

Resistor T

NTC

= 25°C R

NTC

44.65 47 49.35 kΩ

Resistor T

NTC

= 125°C R

NTC

1.27 1.41 1.56 kΩ

B-constant of NTC B(25/100) 3989 4050 4111 K

Temperature Range -40 - 125

℃

Page 23

User Manual 23 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

The VTH pin of CIPOS™-Modules provides direct access to the NTC, which is referenced to VSS. An external pullup resistor connected to +3.3V ensures that the resulting voltage can be directly connected to the

microcontroller.

Figure 19 Thermistor readout vs.temperature(with 4.7kohm Rext pull-down resistor)and typical

thermistor resistance values vs.temperature table

5.2.2 Overtemperature Hardware Protection Circuit

In this evaluation design kits EVAL-M1-CTF620N3 and EVAL-M1-101T, the VTH pin is directly connected to the

VTH pin for controller IC IMC101T.

Figure 20 Overtemperature protection circuit schematic for EVAL-M1-CTF620N3 and EVAL-M1-101T

VTH

1

VTH

TP10

+3.3V

R2

4.87Kohm 1/8W 1%

C9

0.01uF 16V

IM393-X6E

IMC-101T

13 VTH

NTC 7

Page 24

User Manual 24 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

5.2.3 NTC shutdown value calculation and configuration

External NTC Temperature shutdown value can be calculated as shown below and configured in MCEWizard as

shown in Figure 21. For pull-up resistor on evaluation control board, please refer to the control board’s User

Manual. For example, for EVAL-M1-101T, the pull-up resistor on the control board is 4.87kΩ. The value of

resistors R

EXT

and R

THERM

on IM393 are 4.87kΩ and 2.902kΩ (see Figure 20). The typical value of R

NTC

at 100°C is

2.902kΩ for IPM IM393 which is used in EVAL-M1-CTF620N3.

ℎ

=

@

@

+

=

ℎ

If the setting temperature is 100°C, the shutdown value should be 1.23V. If the setting temperature is 85°C, the

shutdown value should be 1.62V.

Figure 21 External temperature sense input configuration in MCEWizard

Page 25

User Manual 25 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

5.3 Auxiliary power supply

Figure 22 depicts the schematic of the auxiliary power supply for the EVAL-M1-CTF620N3 board. The circuit

includes the latest CoolSET 5 of Infineon and flyback toplogy, directly output 15V and 6V. VCC is connected to the

gate drivers inside the CIPOS™ IPM.

Figure 22 Power supply section of the EVAL-M1-CTF620N3 evaluation board

The linear voltage regulator IFX1117ME V33 generates 3.3 V from 6 V power supply VCC. The 3.3 V power supply is

used in the inverter external overcurrent comparator circuit and overtemperature hardware protection circuit.

Both VCC and 3.3 V are also present on the 20 pins iMOTION™ MADK-M1 interface connector J2 to power circuitry

on the control board.

12

3 4

SFH617A-3X007

U2

Vin Vout

GND

U3

IFX1117-ME V33

C13

ECAP 16V 100uF 8*3.5

C9

ECAP 16V 220uF 8*3.5

C14

ECAP 25V 330uF 8*3.5

C11

ECAP 25V 330uF 8*3.5

C5 ECAP 16V 100uF 5*2

C8 DNI

C10

10uF 16V

C12

1nF 16V

C16

C6

1nF 630V

68k 1/4W

R17

15M 1/4W

R13

15M 1/4W

R14

15M 1/4W

R15

4R7 1/10W

R16

R20

0ohm 1/8W 1%

48.7K 1/10W 1%

R24

R22

1.5Kohm 1/8W 1%

R19 DNI

SS3H10-E3/9AT-3A/100V

D3

BYS10-45-E3/TR3-1.5A/45V

D4

US1M-E3/61T-1A/1000V

D2

C7

2.2nF 16V

GND

GND

9.76K 1/10W 1%

R25

VCC

+3.3V

SGND

VCC

820R 1/10W 1%

R21

C15

220nF 16V

C3

1000pF 16V

SGND

+6V

Drain

6

VIN

1

Drain

7

NC

9

GATE

10

VCC

11

GND

12

Drain

5

VERR

2

FB

3

CS

4

Drain

8

U1

ICE5GR4780AG

R12

58.3Kohm 1/4W 1%

C4

0.1uF 25V

5.1R 1/4WRS1

5.1R1/4WRS2

GND

3M 1/4W

R9

3M 1/4W

R10

3M 1/4W

R11

22K 1/10WR23

+15V

SGND

1

2

3

4

5

6

7

10

9

T1

EE13-10P

DCP

ZD1

MMSZ5251B-7-F-22V 500mW

D1 DIO FRD 700mA 200V

L2

2.7uH 4A

R18

510Kohm 1/8W 1%

1

VCC

TP5

1

3.3V

TP6

U4

TL431DBZR

Page 26

User Manual 26 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

5.4 Schematics for EVAL-M1-CTF620N3

The AC linear setion schematic for EVAL-M1-CTF620N3 is provided in Figure 23.

Figure 23 AC Linear Section Schematics for EVAL-M1-CTF620N3

The Inverter setion schematic for EVAL-M1-CTF620N3 is provided in Figure 24.

Figure 24 Inverter Section Schematics for EVAL-M1-CTF620N3

CX1

0.47uF 275VAC

R1

1Mohm 1/2W 5%

1

2

4

3

L1

8121-RC-2mH 10A

BR1

BR

CX2

0.47uF 275VAC

CY1

3300pF 250VAC

CY2

3300pF 250VAC

EARTH

DCBUS

GND

GND

R4

500Kohm 1/8W 1%

R5

500Kohm 1/8W 1%

R6

500Kohm 1/8W 1%

R8

500Kohm 1/8W 1%

R7

DNI

DCBsense

RT1

NTC/5D-20

R9

100Kohm 1/2W 5%

R10

100Kohm 1/2W 5%

E2

470uF 400V 35*35

C3

DNI

EARTH

F1 10A 250V

L

N

EARTH

J1

AC input CON

LED1

RED

1

DCBUS

1 2

34

RLY1

G4A-1A-P-E-DC12-20A

Q1

FMMT493TA

D3

BAV19W

E1

470uF 400V 35*35

R2

3.3Kohm 1/8W 5%

C1

10uF 25V

C2

4.7uF 25V

R3

47ohm 1/8W 5%

D2

BAV19W

D1

BAV19W

+15VCC

GND SGND

1

GND1GND1GND

+15VCC

R29

0ohm 1/8W 5%

R31

3Kohm 1/8W 5%

GND

C25

10uF 25V

1

2

3

J3

Motor Output

RS3 30mohm 3W 1%

RS5 30mohm 3W 1%

RS4

30mohm 3W 1%

R37

4.87Kohm 1/8W 1%

C29

1nF 16V

GK

VTH

ITRIP

V+

1

VS3(W)

3

VB3(W)

4

VS2(V)

6

VB2(V)

7

VS1(U)

9

VB1(U)

10

VCC

12

VTH

13

VSS/COM

14

VSS/COM

15

ITRIP

16

RFE

17

HIN1(U)

18

HIN2(V)

19

HIN3(W)

20

LIN1(U)

21

LIN2(V)

22

LIN3(W)

23

VRW

24

VRV

25

VRU

26

VRU

27

VRV

28

VRW

29

U

30

V

31

W

32

V+

33

V+

35

U6

IM393-X6E

C30

0.1uF 630V

C20

0.1uF 25V

C31

0.1uF 630V

C23

470pF 16V

GND

PWMUH

PWMUL

PWMVH

PWMVL

PWMWH

PWMWL

GK

VTH

DCBSense

C18

0.1uF 16V

C15

0.1uF 16V

C17

0.1uF 16V

+3.3V

PWMUH

PWMUL

PWMVH

PWMVL

PWMWH

PWMWL

C26

10uF 25V

C21

0.1uF 25V

C27

10uF 25V

C22

0.1uF 25V

C28C24+15VCC

GND

GND

+3.3V

GND

R36 1Kohm 1/8W 1%

C16

4700pF 16V

C14

10uF 16V

R30 10Kohm 1/8W 1%

C19

4700pF 16V

R32 1Kohm 1/8W 1%

ITRIP

R28

1Kohm 1/8W 5%

+3.3V

C13

DNI

GNDGND

GND

R33

1Kohm 1/8W 1%

ITRIP: [(3.3V * 1/ 11)+0.12+0.02] / 0.03= 14.7A peak

D8 BAT60A

D9 BAT60A

D10 BAT60A

R34 1Kohm 1/8W 1%

R35 1Kohm 1/8W 1%

I_W+

I_V+

I_U+

If single shunt config is used,

remove both RS3 and RS4,

while insert RJ1=RJ2= 0ohm

RJ1 0ohm 1/2W 1%

RJ2 0ohm 1/2W 1%

I_W+

I_V+

I_U+

I_W+ I_V+

I_V+

I_W+

I_V+

UH

UL

VH

VL

WH

WL

WL

UL

VH

UH

WH

VL

GK

VTH

VTH

U_OUT

V_OUT

W_OUT

VS1

VS2

VS3

GND

DCBUS

UH1GND

2

UL3GND

4

VH5+3.3V

6

VL7+3.3V

8

WH9I_U+

10

WL11I_U-

12

GK13DCB

14

VTH15I_V+

16

I_V-17I_W+

18

I_W-19VCC

20

J2

CON MADK 20P

LED2

GREEN

GND

GND

I_UVW-

I_UVW-

I_UVWI_UVW-

I_U+

I_U+

1

W

1

V

1

U

1

VTH

1

GK

1

ITRIP

3

1

4

5 2

U5

LM397

+15VCC

GK

ITRIP

I_U+

I_V+

I_W+

I_W+

I_V+

I_U+

1

2

J4

Fan_CON

GND

+15VCC

Page 27

User Manual 27 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

The Auxiliary Power Supply setion schematic for EVAL-M1-CTF620N3 is provided in Figure 25.

Figure 25 Auxiliary Power Supply Section Schematics for EVAL-M1-CTF620N3

12

3 4

SFH617A-3X007

U2

Vin Vout

GND

U3

IFX1117-ME V33

C13

ECAP 16V 100uF 8*3.5

C9

ECAP 16V 220uF 8*3.5

C14

ECAP 25V 330uF 8*3.5

C11

ECAP 25V 330uF 8*3.5

C5 ECAP 16V 100uF 5*2

C8 DNI

C10

10uF 16V

C12

1nF 16V

C16

C6

1nF 630V

68k 1/4W

R17

15M 1/4W

R13

15M 1/4W

R14

15M 1/4W

R15

4R7 1/10W

R16

R20

0ohm 1/8W 1%

48.7K 1/10W 1%

R24

R22

1.5Kohm 1/8W 1%

R19 DNI

SS3H10-E3/9AT-3A/100V

D3

BYS10-45-E3/TR3-1.5A/45V

D4

US1M-E3/61T-1A/1000V

D2

C7

2.2nF 16V

GND

GND

9.76K 1/10W 1%

R25

VCC

+3.3V

SGND

VCC

820R 1/10W 1%

R21

C15

220nF 16V

C3

1000pF 16V

SGND

+6V

Drain

6

VIN

1

Drain

7

NC

9

GATE

10

VCC

11

GND

12

Drain

5

VERR

2

FB

3

CS

4

Drain

8

U1

ICE5GR4780AG

R12

58.3Kohm 1/4W 1%

C4

0.1uF 25V

5.1R 1/4WRS1

5.1R1/4WRS2

GND

3M 1/4W

R9

3M 1/4W

R10

3M 1/4W

R11

22K 1/10WR23

+15V

SGND

1

2

3

4

5

6

7

10

9

T1

EE13-10P

DCP

ZD1

MMSZ5251B-7-F-22V 500mW

D1 DIO FRD 700mA 200V

L2

2.7uH 4A

R18

510Kohm 1/8W 1%

1

VCC

TP5

1

3.3V

TP6

U4

TL431DBZR

Page 28

User Manual 28 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

5.5 PCB Layout for EVAL-M1-CTF620N3

The layout of this board can be used for different voltage or power classes. The PCB has two electrical layers

with 35µm copper by default and its size is 121 mm × 120 mm. The PCB board thickness is 1.6mm. Get in

contact with our technical support team to get more detailed information and the latest Gerber-files.

Figure 26 illustrates the top assembly print of the evaluation board.

Figure 26 Top assembly print of the EVAL-M1-CTF620N3 evaluation board

Figure 27 depicts the bottom assembly print of the evaluation board.

Page 29

User Manual 29 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

Figure 27 Bottom assembly print of the EVAL-M1-CTF620N3 evaluation board

Page 30

User Manual 30 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

The top layer routing of the PCB is provided in Figure 28.

Figure 28 Top layer routing of the EVAL-M1-CTF620N3

Page 31

User Manual 31 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

Figure 29 illustrates the bottom layer routing of the PCB.

Figure 29 Bottom layer routing of the EVAL-M1-CTF620N3

Page 32

User Manual 32 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

Table 9 provides the complete bill of materials for the EVAL-M1-CTF620N3.

Table 9 Bill of materials

No. Qty Part description Designator Part number Manufacturer

1 2 ECAP ALUM 470μF 400V RADIAL E1,E2

LLG2G471MELC

30

Wurth Electronics Inc.

2 1 CAP CER 470pF 16V 0805 C23 885012207031 Wurth Electronics Inc.

3 1 CAP CER 1000pF 16V 0603 C4 885012206034 Wurth Electronics Inc.

4 9 CAP CER 0.1μF 25V 0805

C5,C20,C21,C22

,C24,C32,C33,C

34,C38

885012207072 Wurth Electronics Inc.

5 1 ECAP ALUM 100μF 16V RADIAL E3 860010372006 Wurth Electronics Inc.

6 1 CAP CER 1nF 630V 1206 C6 885342208011 Wurth Electronics Inc.

7 1 CAP CER 2200pF 16V 0805 C7 885012207035 Wurth Electronics Inc.

8 1 CAP CER 4700pF 100V 1206 C8 885012208110 Wurth Electronics Inc.

9 1 ECAP ALUM 220μF 16V RADIAL E4 860080374009 Wurth Electronics Inc.

10 3 CAP CER 10μF 16V 0805 C9,C12,C14 885012107014 Wurth Electronics Inc.

11 2 ECAP ALUM 330μF 25V RADIAL E5, E7 860020474013 Wurth Electronics Inc.

12 1 CAP ALUM 100μF 16V RADIAL C13 860240374004 Wurth Electronics Inc.

13 1 CAP CER 220nF 16V 0603 C11 885012206048 Wurth Electronics Inc.

14 3 CAP CER 0.1μF 16V 0603 C15,C17,C18 885012206046 Wurth Electronics Inc.

15 2 CAP CER 4700pF 16V 0805 C16,C19 885012207037 Wurth Electronics Inc.

16 1 CAP CER 1μF 16V 0805 C27 885012207051 Wurth Electronics Inc.

17 1 CAP CER 470pF 16V 0805 C23 885012207031 Wurth Electronics Inc.

18 1 CAP CER 1nF 16V X7R 0805 C29 885012207033 Wurth Electronics Inc.

19 9 CAP CER 10μF 25V 0805

C1,C25,C26,C27

,C28,C35,C36,C

37,C39

TMK212BBJ106

KG-T

Taiyo Yuden

20 2 CAP CER 0.1uF 630V X7R 1812 C30,C31

C4532X7R2J104

K230KA

TDK Corporation

21 2

CAP FILM 0.47μF 10% 275VAC

RADIAL

CX1,CX2

MKP275VAC474

PF

JIMSON

22 2

CAP CER 3300pF 440VAC Y5U

RADIAL

CY1, CY2 ECK-ATS332ME

Panasonic Electronic

Components

23 1 RES SMD 1MΩ 5% 1/2W 2010 R1

RC2010JR071ML

Yageo

24 1 RES SMD 3.3kΩ 5% 1/8W 0805 R2

RC0805FR073K3L

Yageo

25 1 RES SMD 47Ω 5% 1/8W 0805 R3

RC0805FR074R7L

Yageo

26 4 RES SMD 500kΩ 1% 1/8W 0805 R4,R5,R6,R8

RC0805FR07500KL

Yageo

27 2 RES SMD 100kΩ 5% 1/2W 2010 R9,R10

RC2010JR-

Yageo

Page 33

User Manual 33 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

No. Qty Part description Designator Part number Manufacturer

07100KL

28 3 RES SMD 3MΩ 5% 1/4W 1206 R11,R12,R13

RC1206JR073ML

Yageo

29 1 RES SMD 65kΩ 5% 1/4W 1206 R14

RC1206FR0765KL

Yageo

30 3 RES SMD 15MΩ 5% 1/4W 1206 R15,R16,R17

RC1206JR0715ML

Yageo

31 1 RES SMD 4.7Ω 1% 1/8W 0805 R18

RC0805FR074R7L

Yageo

32 1 RES SMD 68kΩ 5% 1/4W 1206 R19

RC1206FR0768KL

Yageo

33 1 RES SMD 510kΩ 1% 1/8W 0805 R20

RC0805FR07510KL

Yageo

34 1 RES SMD 510Ω 5% 1/4W 1206 R21

RC1206JR07510RL

Yageo

35 2 RES SMD 0 Ω 5% 1/8W 0805 R22,R29

RC0805JR070RL

Yageo

36 1 RES SMD 820Ω 1% 1/8W 0805 R23

RC0805JR07820RL

Yageo

37 1 RES SMD 1.5kΩ 1% 1/8W 0805 R24

RC0805JR071K5L

Yageo

38 1 RES SMD 22kΩ 5% 1/8W 0805 R25

RC0805JR0722KL

Yageo

39 1 RES SMD 48.7kΩ 1% 1/8W 0805 R26

RC0805FR0748K7L

Yageo

40 1 RES SMD 9.76kΩ 1% 1/8W 0805 R27

RC0805FR079K76L

Yageo

41 6 RES SMD 1kΩ 1% 1/8W 0805

R28,R32,R33,R3

4,R35,R36

RC0805FR071KL

Yageo

42 1 RES SMD 10kΩ 5% 1/8W 0805 R30

RC0805JR0710KL

Yageo

43 1 RES SMD 3kΩ 1% 1/8W 0805 R31

RC0805FR073KL

Yageo

44 1 RES SMD 4.87kΩ 1% 1/8W 0805 R37

RC0805FR074K87L

Yageo

45 2 RES SMD 5.1Ω 1% 1/4W 1206 RS1, RS2

RC1206FR075R1L

Yageo

46 3 RES SMD 0.03Ω 1% 2W 2512 wide RS3, RS4,RS5 FC4L64R030FER Ohmite

47 1 IC AUX Power PD-DSO-12 U1 ICE5GR4780AG Infineon Technologies

48 1 IC OptoCoupler U2 SFH617A-3X007 Vishay

49 1 IC REG LINEAR 3.3V 1A SOT223-4 U3

IFX1117MEV33H

TMA1

Infineon Technologies

50 1 IC TL431DBZR U4 TL431DBZR Texas Instruments

Page 34

User Manual 34 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Hardware description of EVAL-M1-CTF620N3

No. Qty Part description Designator Part number Manufacturer

51 1 IC COMPARATOR VOLT SGL SOT U5 LM397 Texas Instruments

52 1 IC CIPOS Tiny Module U6/U7 IM393-X6F/F Infineon Technologies

53 1 DIODE ZENER 22V 500mW SOD123 ZD1 MMSZ525B-7-F Wurth Electronics Inc.

54 3 DIODE FRD 100V 250mA SOD-123 D1,D2,D3 BAV19W Vishay

55 1 DIODE FRD 200V 700mA SOD-123 D4 RF071MM2STR ROHM

56 1 DIODE FRD 1000V 1A DO241AC D5 US1M-E3/61T Vishay

57 1 DIODE Schottky 100V 3A DO214AB D6 SS3H10-E3/9AT Vishay

58 1

DIODE Schottky 45V 1.5A

DO214AC

D7

BYS10-45E3/TR3

Vishay

59 3

Diode Standard 10V 3A Surface

Mount SOD323

D8, D9, D10 BAT60A Infineon Technologies

60 1 NTC thermistors for inrush RT1 NTC5D-20 Yuanlindianzi

61 1 RECT BRIDGE GPP 800V 15A GBJ BR1 GBJ1508-F Diodes Incorporated

62 1 FUSE CERAMIC 10A 250V Φ6X30 F1

RO58 /BS136210A

Zhenghao Fuse Co.

63 1 Common Choke 8108-RC L1

JWMILLER_810

8

Bourns, Inc.

64 1 FIXED 2.2uH 2.5A SMD L2 WE-PD2-S Wurth Electronics Inc.

65 1 LED RED CLEAR 0805 SMD LED1

LTSTC171KRKT

Lite-On Inc.

66 1 LED GREEN CLEAR 0805 SMD LED2 LTST-C171GKT Lite-On Inc.

67 2

CONN TERM BLOCK 3POS 9.52MM

PCB

J1, J3 1714984 Phoenix Contact

68 1

CONN RCPT .100" 20 PS DL R/A

GOLD

J2

SSW-110-02-SD-RA

Samtec Inc.

69 CONN 2P2.54 J4 XH2.54 RISYM

70 DC FAN FAN KDE2405PHBS SUNON

71 Heatsink Heatsink 100*40*40MM -

72 1 Transformer EE13-10P T1 EE13-10P -

Page 35

User Manual 35 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Reference

6 Reference

[1] Datasheet of Infineon CIPOS™ Tiny IPM IM393-X6F

[2] AN2018-02 EVAL-M1-101T User manual

[3] MCEWizard User Guide

[4] MCEDesigner User Guide

Note: All listed reference materials are available for download on Infineon’s website www.infineon.com/.

All the iMOTION MADK evaluation board’s User Manuals are available at www.infineon.com/MADK

All the CIPOS™ IPM’s Datasheets and documents are available at www.infineon.com/IPM.

Page 36

User Manual 36 of 37 Revision 1.0

2018-08-23

EVAL-M1-CTF620N3 User Manual

iMOTION™ Modular Application Design

Kit

Reference

Revision history

Document

version

Date of release Description of changes

1.0 2018-08-27 First release

Page 37

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2018-08-23

AN2018-31

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2018 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

IMPORTANT NOTICE

The information contained in this application note

is given as a hint for the implementation of the

product only and shall in no event be regarded as a

description or warranty of a certain functionality,

condition or quality of the product. Before

implementation of the product, the recipient of this

application note must verify any function and other

technical information given herein in the real

application. Infineon Technologies hereby

disclaims any and all warranties and liabilities of

any kind (including without limitation warranties of

non-infringement of intellectual property rights of

any third party) with respect to any and all

information given in this application note.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments

to evaluate the suitability of the product for the

intended application and the completeness of the

product information given in this document with

respect to such application.

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may

contain dangerous substances. For information on

the types in question please contact your nearest

Infineon Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of

the product or any consequences of the use thereof

can reasonably be expected to result in personal

injury.

Loading...

Loading...